Page 1

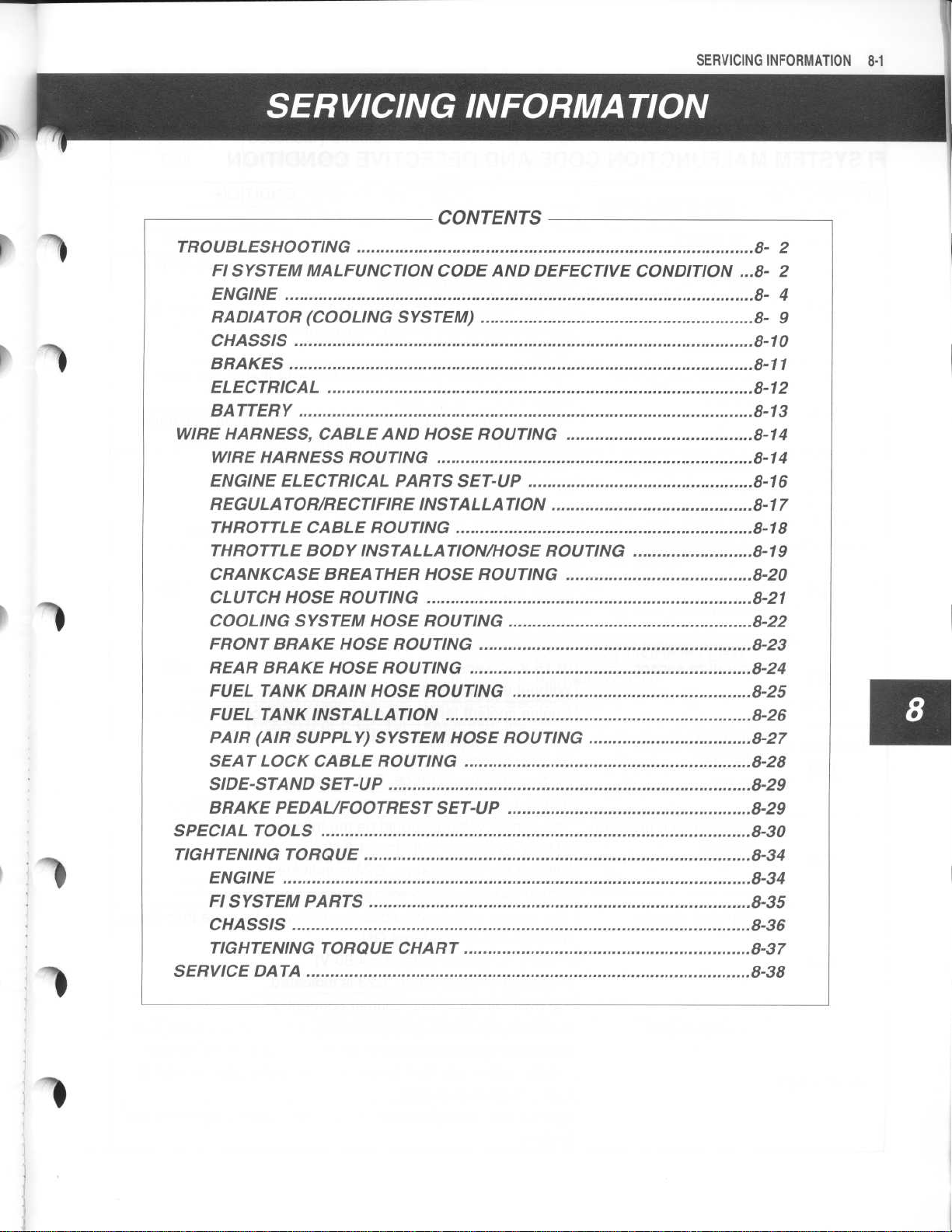

CONTENTS

SERVICING INFORMATION

8- 1

TROUBLESHOOTING~~

Fl SYSTEM MALFUNCTION CODE AND DEFECTIVE CONDITION

ENGINE

RADIATOR (COOLING SYSTEM)

CHASSIS

BRAKES

ELECTRICAL

BATTERY

WIRE HARNESS, CABLE AND HOSE ROUTING

WIRE HARNESS ROUTING

ENGINE ELECTRICAL PARTS SET-UP

REGULATOR/RECTIFIRE INSTALLATION

THROTTLE CABLE ROUTING

THROTTLE BODY INSTALLATION/HOSE ROUTING

CRANKCASE BREATHER HOSE ROUTING

CLUTCH HOSE ROUTING

COOLING SYSTEM HOSE ROUTING

FRONT BRAKE HOSE ROUTING

REAR BRAKE HOSE ROUTING

FUEL TANK DRAIN HOSE ROUTING

FUEL TANK INSTALLATION

PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING

SEAT LOCK CABLE ROUTING

SIDE-STAND SET-UP

BRAKE PEDAL/FOOTREST SET-UP

SPECIAL TOOLS

TIGHTENING TORQUE

ENGINE

Fl SYSTEM PARTS

CHASSIS

TIGHTENING TORQUE CHART

SERVICE DATA

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

8- 2

. .

.8- 2

8- 4

8- 9

8-10

8-11

8-12

8-13

8-14

8-14

8-16

8-17

8-18

~

8-19

8-20

8-21

8-22

8-23

8-24

8-25

8-26

8-27

8-28

8-29

8-29

8-30

8-34

8-34

8-35

8-36

8-37

8-38

8

Page 2

8-2SERVICING INFORMATION

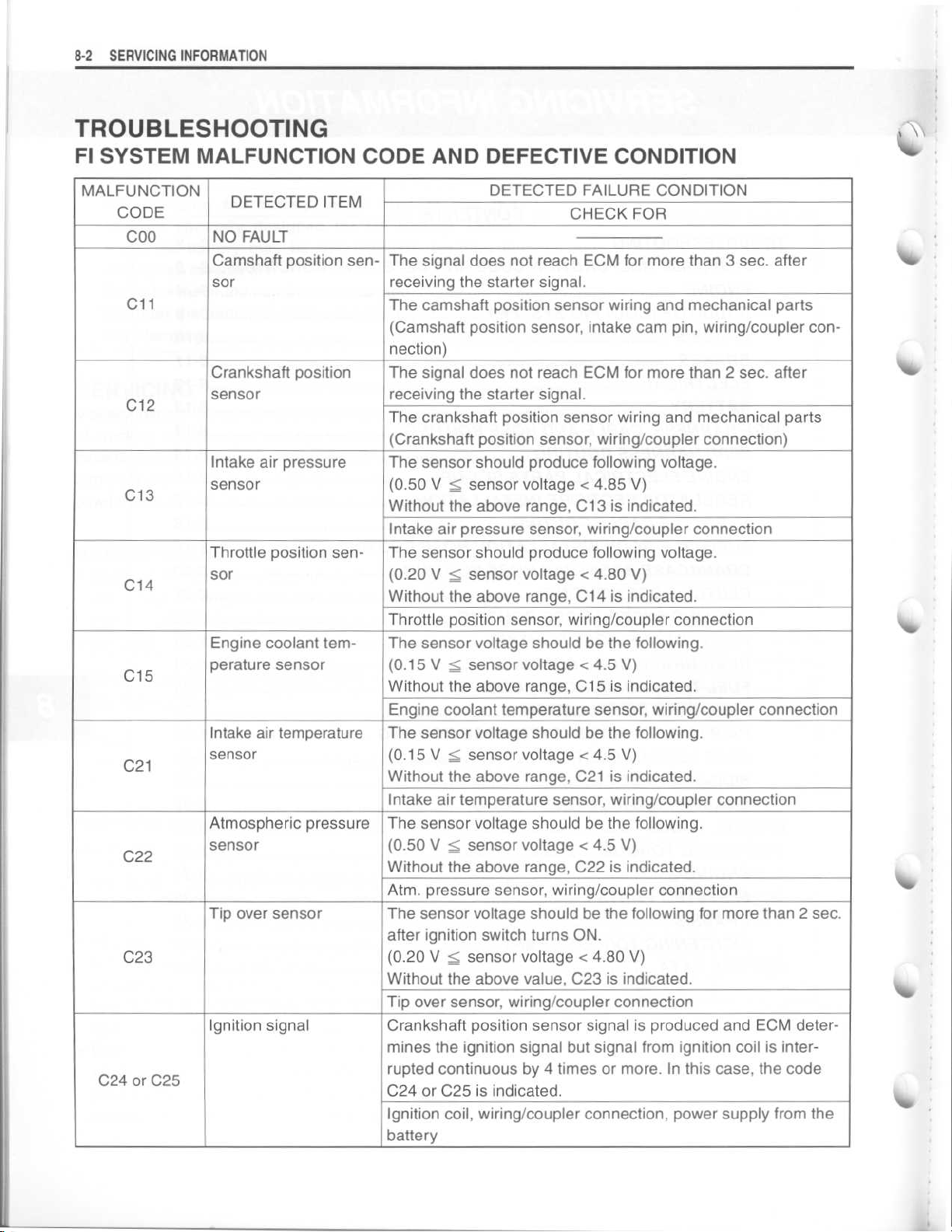

TROUBLESHOOTING

FI SYSTEM MALFUNCTION CODE AND DEFECTIVE CONDITION

MALFUNCTION

CODE

COO

C11

C12

C13

C14

C15

C21

C22

C23

C24 or C25

DETECTED ITEM

NO FAULT

Camshaft position sensor

Crankshaft position

sensor

Intake air pressure

sensor

Throttle position sensor

Engine coolant temperature sensor

Intake air temperature

sensor

Atmospheric pressure

sensor

Tip over sensor

Ignition signal

The signal does not reach ECM for more than 3 sec

receiving the starter signal

The camshaft position sensor wiring and mechanical parts

(Camshaft position sensor, intake cam pin, wiring/coupler connection)

The signal does not reach ECM for more than 2 sec

receiving the starter signal

The crankshaft position sensor wiring and mechanical parts

(Crankshaft position sensor, wiring/coupler connection)

The sensor should produce following voltage

(0

Without the above range, C13 is indicated

Intake air pressure sensor, wiring/coupler connection

The sensor should produce following voltage

(0

Without the above range, C14 is indicated

Throttle position sensor, wiring/coupler connection

The sensor voltage should be the following

(0

Without the above range, C15 is indicated

Engine coolant temperature sensor, wiring/coupler connection

The sensor voltage should be the following

(0

Without the above range, C21 is indicated

Intake air temperature sensor, wiring/coupler connection

The sensor voltage should be the following

(0

Without the above range, C22 is indicated

Atm

The sensor voltage should be the following for more than 2 sec

after ignition switch turns ON

(0

Without the above value, C23 is indicated

Tip over sensor, wiring/coupler connection

Crankshaft position sensor signal is produced and ECM deter-

mines the ignition signal but signal from ignition coil is interrupted continuous by 4 times or more

C24 or C25 is indicated

Ignition coil, wiring/coupler connection, power supply from the

battery

DETECTED FAILURE CONDITION

CHECK FOR

. after

.

. after

.

.

.50 V < sensor voltage < 4

.20 V < sensor voltage < 4

.15 V <_ sensor voltage < 4

.15 V < sensor voltage < 4

.50 V < sensor voltage < 4

. pressure sensor, wiring/coupler connection

.20 V < sensor voltage < 4

.85 V)

.

.

.80 V)

.

.

.5 V)

.

.

.5 V)

.

.

.5 V)

.

.

.80 V)

.

. In this case, the code

.

.

Page 3

SERVICING INFORMATION 8

.3

C28

C29

C31

C32 or C33

C41

C42

C44

C49

Secondary throttle

valve actuator

cated

STVA lead wire/coupler, STVA

Secondary throttle

valve position sensor

The sensor should produce following voltage

(0

Without the above range, C29 is indicated

Secondary throttle position sensor, wiring/coupler connection

Gear position signal

Gear position signal voltage should be higher than the following

for more than 2 seconds

(Gear position switch voltage >_ 0

Without the above value, C31 is indicated

Gear position sensor, wiring/coupler connection, gearshift cam,

etc

Fuel injector

Crankshaft position sensor signal is produced and ECM determines the injection signal but fuel injection signal is interrupted

continuous by 4 times or more

C33 is indicated

Injector, wiring/coupler connection, power supply to the injector

Fuel pump relay

No voltage is applied to fuel pump although fuel pump relay is

turned ON, or voltage is applied to fuel pump although fuel

pump relay is turned OFF

Fuel pump relay, connecting lead, power source to fuel pump

relay

Ignition switch

Ignition switch signal is not input in the ECM

Ignition switch, lead wire/coupler

Heated oxygen sensor

(HO2S) [For E-02, 19]

During 02 feedback control, 02 sensor voltage is higher or

lower than the specification

No signal is detected during engine operation or no electrical

power is supplied from the battery

HO2S lead wire/coupler connection

Battery voltage supply to the HO2S

PAIR control solenoid

valve (PAIR valve)

When no operating voltage is supplied from the ECM, C49 is

indicated

PAIR

No operating voltage is supplied from the ECM, C28 is indi-

. STVA can not operate

.

.

.10 V < sensor voltage < 4

.90 V)

.

.

.6 V)

.

.

. In this case, the code C32 or

.

.

.

.

.

. PAIR valve can not operate

valve

lead wire/coupler

.

Page 4

8-4SERVICING INFORMATION

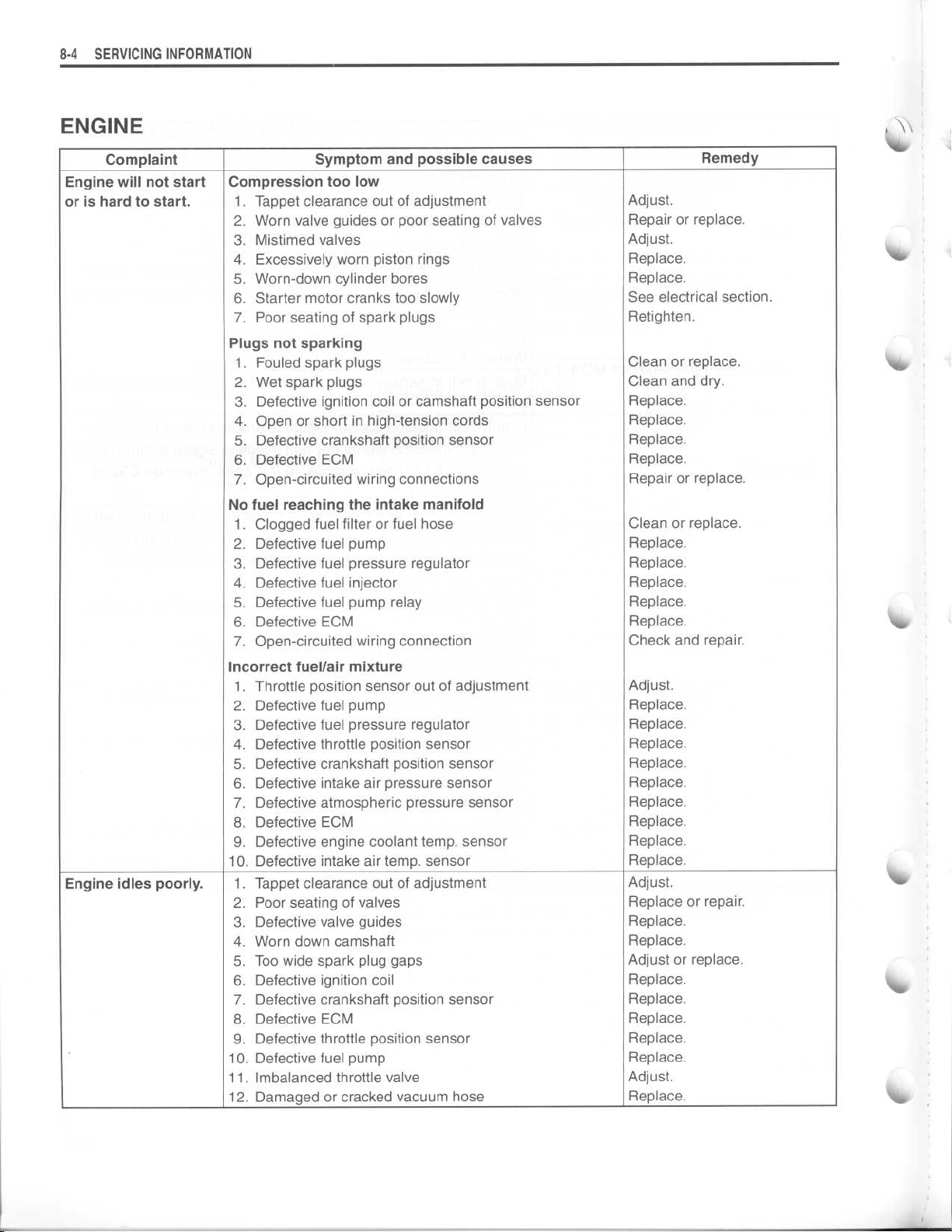

ENGINE

Complaint

Engine will not start

or is hard to start

Engine idles poorly.1

.

Symptom and possible causes

Compression too low

1

. Tappet clearance out of adjustment

2

. Worn valve guides or poor seating of valves

3

. Mistimed valves

4

. Excessively worn piston rings

5

. Worn-down cylinder bores

6

. Starter motor cranks too slowly

7

. Poor seating of spark plugs

Plugs not sparking

1

. Fouled spark plugs

2

. Wet spark plugs

. Defective ignition coil or camshaft position sensor

3

4

. Open or short in high-tension cords

. Defective crankshaft position sensor

5

6

. Defective ECM

7

. Open-circuited wiring connections

No fuel reaching the intake manifold

1

. Clogged fuel filter or fuel hose

2

. Defective fuel pump

. Defective fuel pressure regulator

3

4

. Defective fuel injector

. Defective fuel pump relay

5

6

. Defective ECM

7

. Open-circuited wiring connection

Incorrect fuel/air mixture

1

. Throttle position sensor out of adjustment

2

. Defective fuel pump

3

. Defective fuel pressure regulator

4 . Defective throttle position sensor

5

. Defective crankshaft position sensor

6

. Defective intake air pressure sensor

7

. Defective atmospheric pressure sensor

8

. Defective ECM

. Defective engine coolant temp

9

10

. Defective intake air temp

. Tappet clearance out of adjustment

2

. Poor seating of valves

3

. Defective valve guides

4

. Worn down camshaft

5

. Too wide spark plug gaps

. Defective ignition coil

6

7

. Defective crankshaft position sensor

. Defective ECM

8

9 . Defective throttle position sensor

10

. Defective fuel pump

11

. Imbalanced throttle valve

12

. Damaged or cracked vacuum hose

. sensor

. sensor

Adjust

Repair or replace

Adjust

Replace

Replace

See electrical section

Retighten

Clean or replace

Clean and dry

Replace

Replace

Replace

Replace

Repair or replace

Clean or replace

Replace

Replace

Replace

Replace

Replace

Check and repair

Adjust

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Replace or repair

Replace

Replace

Adjust or replace

Replace

Replace

Replace

Replace

Replace

Adjust

Replace

Remedy

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page 5

SERVICING INFORMATION

8-5

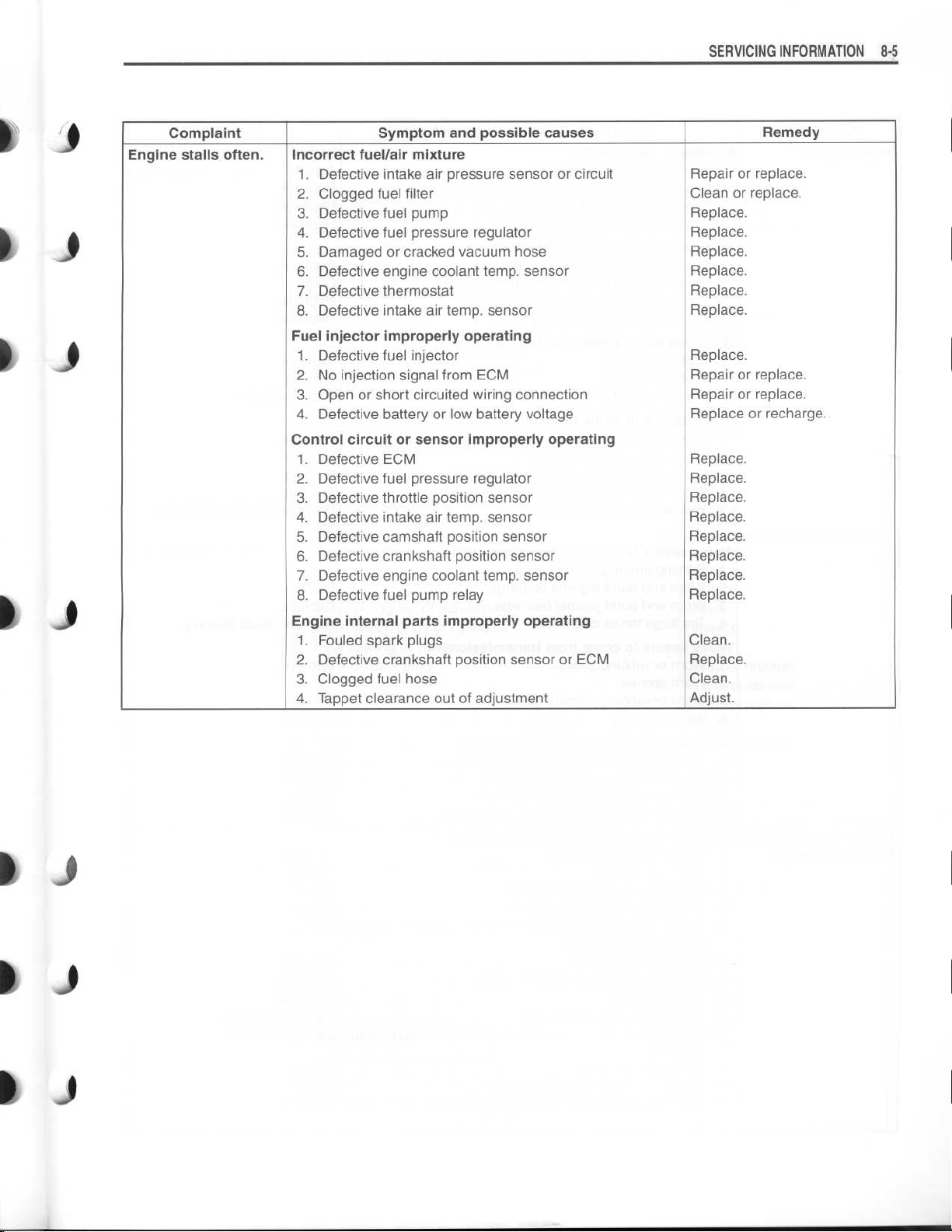

Complaint Symptom and possible causes

Engine stalls often.Incorrect fuel/air mixture

1

. Defective intake air pressure sensor or circuit

2

. Clogged fuel filter

3

. Defective fuel pump

4

. Defective fuel pressure regulator

5

. Damaged or cracked vacuum hose

6

. Defective engine coolant temp

7

. Defective thermostat

8

. Defective intake air temp . sensor

Fuel injector improperly operating

1

. Defective fuel injector

2

. No injection signal from ECM

3

. Open or short circuited wiring connection

4

. Defective battery or low battery voltage

Control circuit or sensor improperly operating

1

. Defective ECM

2

. Defective fuel pressure regulator

3

. Defective throttle position sensor

4

. Defective intake air temp . sensor

5

. Defective camshaft position sensor

6

. Defective crankshaft position sensor

7

. Defective engine coolant temp

8

. Defective fuel pump relay

Engine internal parts improperly operating

1

. Fouled spark plugs

2

. Defective crankshaft position sensor or ECM

3

. Clogged fuel hose

4

. Tappet clearance out of adjustment

. sensor

. sensor

Remedy

Repair or replace

Clean or replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Repair or replace

Repair or replace

Replace or recharge

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Clean

Replace

Clean

Adjust

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page 6

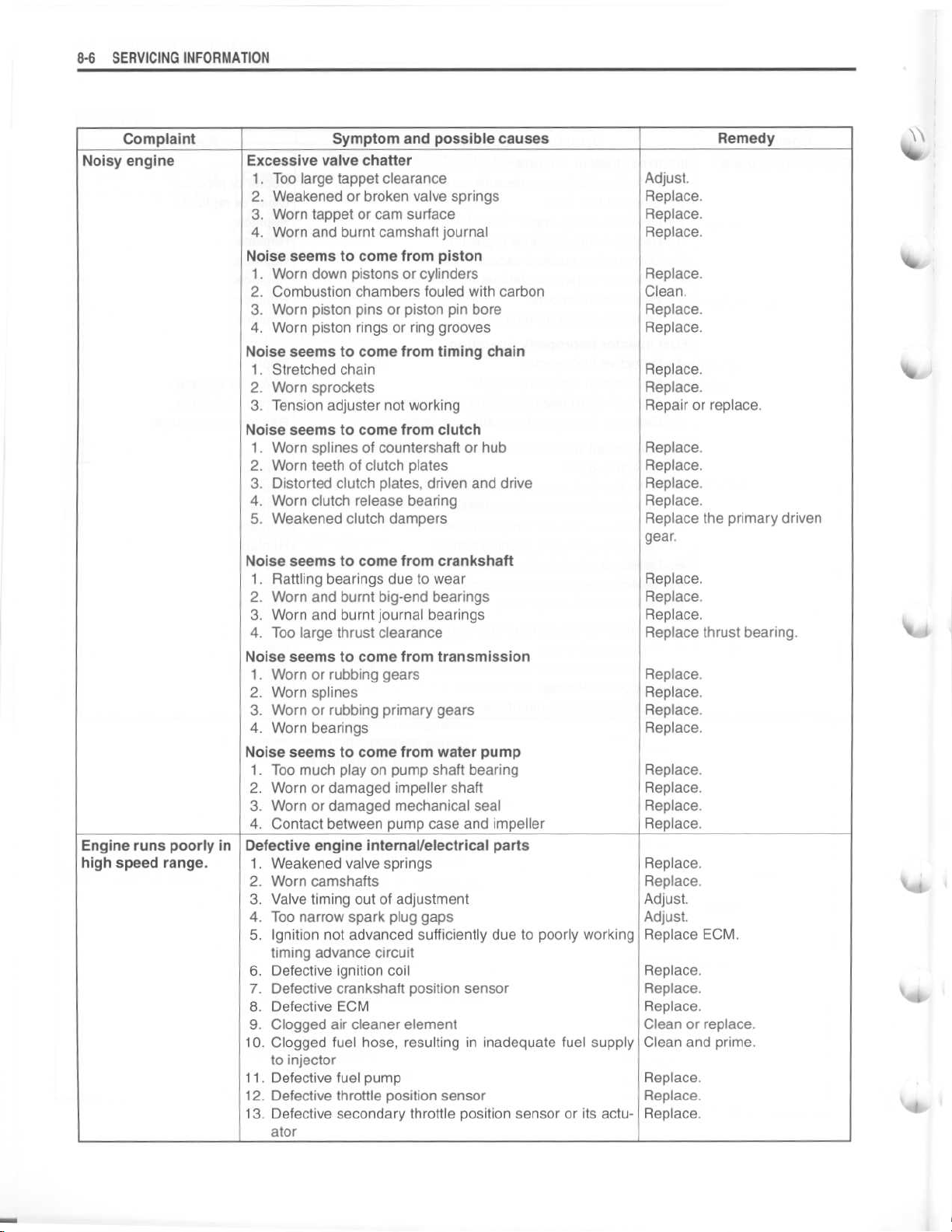

8-6SERVICING INFORMATION

Complaint

Noisy engine

Noise seems to come from transmission

Noise seems to come from water pump

Engine runs poorly in

high speed range

Defective engine internal/electrical parts

.

10

11

12

13

Symptom and possible causes

Excessive valve chatter

1

. Too large tappet clearance

2

. Weakened or broken valve springs

3

. Worn tappet or cam surface

4

. Worn and burnt camshaft journal

Noise seems to come from piston

1

. Worn down pistons or cylinders

2

. Combustion chambers fouled with carbon

3

. Worn piston pins or piston pin bore

4

. Worn piston rings or ring grooves

Noise seems to come from timing chain

1

. Stretched chain

2

. Worn sprockets

3

. Tension adjuster not working

Noise seems to come from clutch

1

. Worn splines of countershaft or hub

2

. Worn teeth of clutch plates

3 . Distorted clutch plates, driven and drive

4

. Worn clutch release bearing

. Weakened clutch dampers

5

Noise seems to come from crankshaft

1

. Rattling bearings due to wear

2

. Worn and burnt big-end bearings

. Worn and burnt journal bearings

3

4

. Too large thrust clearance

1

. Worn or rubbing gears

2

. Worn splines

3

. Worn or rubbing primary gears

4

. Worn bearings

1

. Too much play on pump shaft bearing

2

. Worn or damaged impeller shaft

3

. Worn or damaged mechanical seal

4

. Contact between pump case and impeller

1

. Weakened valve springs

2

. Worn camshafts

3

. Valve timing out of adjustment

4

. Too narrow spark plug gaps

5

. Ignition not advanced sufficiently due to poorly working

timing advance circuit

6

. Defective ignition coil

7

. Defective crankshaft position sensor

8

. Defective ECM

9

. Clogged air cleaner element

. Clogged fuel hose, resulting in inadequate fuel supply

to injector

. Defective fuel pump

. Defective throttle position sensor

. Defective secondary throttle position sensor or its actu-

ato r

Adjust

.

Replace

Replace

Replace

Replace

Clean

Replace

Replace

Replace

Replace

Repair or replace

Replace

Replace

Replace

Replace

Replace the primary driven

gear

Replace

Replace

Replace

Replace thrust bearing

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace ECM

Replace

Replace

Replace

Clean or replace

Clean and prime

Replace

Replace

Replace

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Remedy

.

.

.

.

.

!I

W

i

I

Page 7

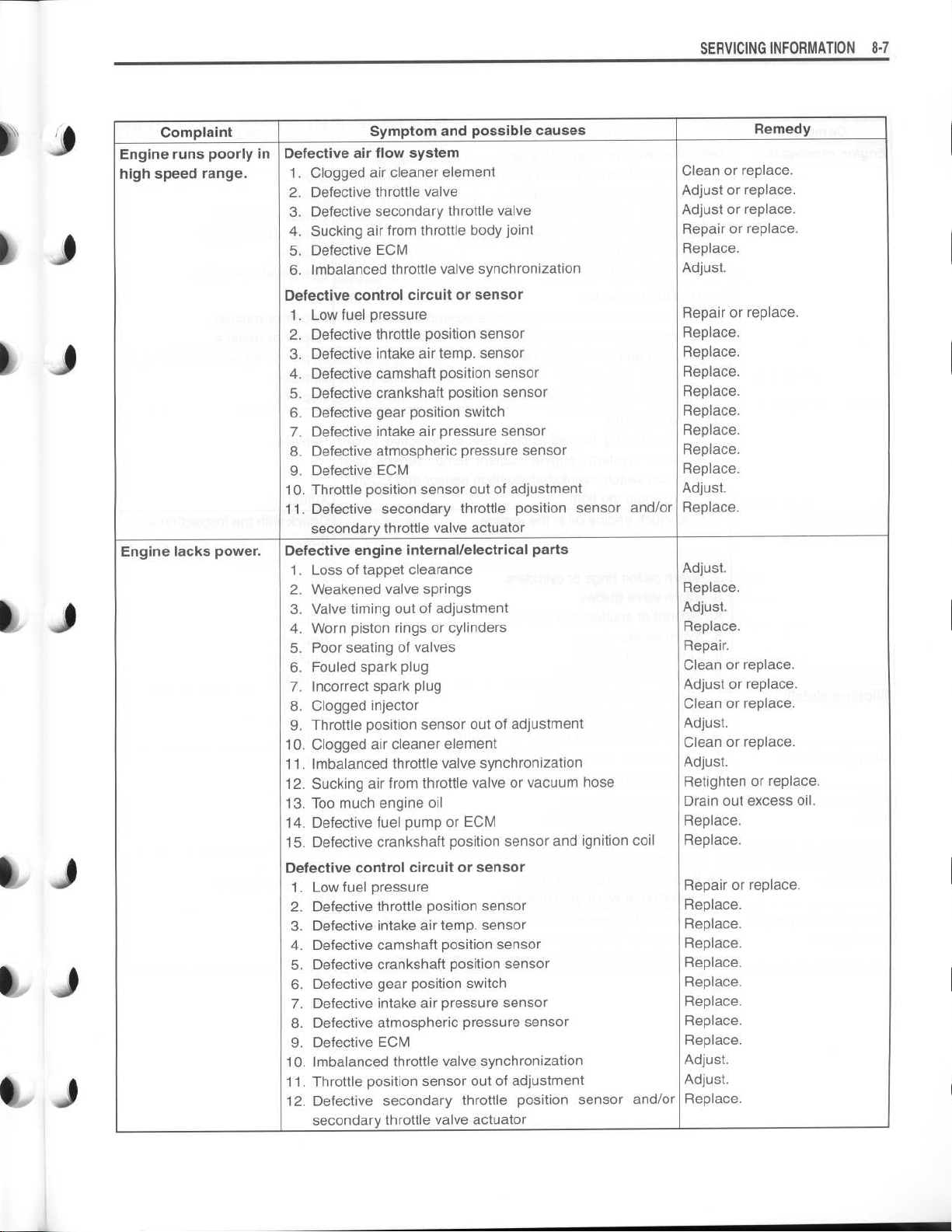

SERVICING INFORMATION 8-7

k I

1 J

1 J

Complaint

Engine runs poorly in

high speed range

Engine lacks power

Defective air flow system

.

.

Symptom and possible causes

1

. Clogged air cleaner element

. Defective throttle valve

2

3

. Defective secondary throttle valve

. Sucking air from throttle body joint

4

5

. Defective ECM

. Imbalanced throttle valve synchronization

6

Defective control circuit or sensor

. Low fuel pressure

1

2 . Defective throttle position sensor

. Defective intake air temp

3

4

. Defective camshaft position sensor

5

. Defective crankshaft position sensor

. Defective gear position switch

6

7

. Defective intake air pressure sensor

. Defective atmospheric pressure sensor

8

9

. Defective ECM

10

. Throttle position sensor out of adjustment

11

. Defective secondary throttle position sensor and/or

secondary throttle valve actuator

Defective engine internal/electrical parts

. Loss of tappet clearance

1

2

. Weakened valve springs

. Valve timing out of adjustment

3

4

. Worn piston rings or cylinders

. Poor seating of valves

5

6

. Fouled spark plug

7

. Incorrect spark plug

8

. Clogged injector

. Throttle position sensor out of adjustment

9

. Clogged air cleaner element

10

11

. Imbalanced throttle valve synchronization

12

. Sucking air from throttle valve or vacuum hose

. Too much engine oil

13

14

. Defective fuel pump or ECM

. Defective crankshaft position sensor and ignition coil

15

Defective control circuit or sensor

. Low fuel pressure

1

2

. Defective throttle position sensor

. Defective intake air temp

3

4

. Defective camshaft position sensor

. Defective crankshaft position sensor

5

6

. Defective gear position switch

7

. Defective intake air pressure sensor

. Defective atmospheric pressure sensor

8

. Defective ECM

9

. Imbalanced throttle valve synchronization

10

. Throttle position sensor out of adjustment

11

. Defective secondary throttle position sensor and/or

12

secondary throttle valve actuator

. sensor

. sensor

Clean or replace

Adjust or replace

Adjust or replace

Repair or replace

Replace

Adjust

.

Repair or replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

.

Replace

Adjust

.

Replace

Adjust

.

Replace

Repair

Clean or replace

Adjust or replace

Clean or replace

Adjust

.

Clean or replace

Adjust

.

Retighten or replace

Drain out excess oil

Replace

Replace

Repair or replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Remedy

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page 8

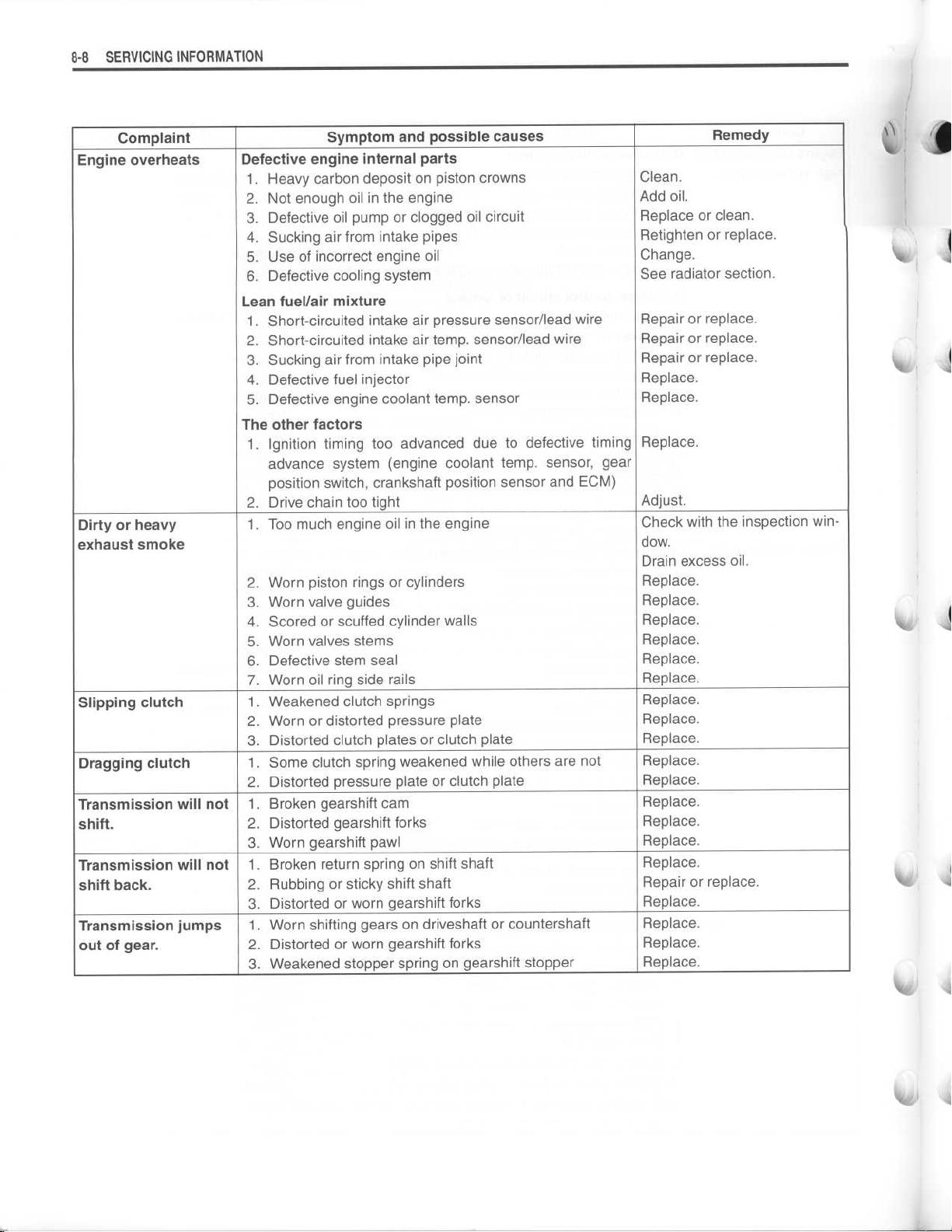

SERVICING INFORMATION

8

-8

Complaint

Engine overheats

Dirty or heavy

exhaust smoke

Slipping clutch

Dragging clutch

Transmission will not

shift

.

Transmission will not

shift back

Transmission jumps

out of gear

.

.

Defective engine internal parts

Lean fuel/air mixture

The other factors

Symptom and possible causes

1

. Heavy carbon deposit on piston crowns

. Not enough oil in the engine

2

3

. Defective oil pump or clogged oil circuit

. Sucking air from intake pipes

4

5

. Use of incorrect engine oil

. Defective cooling system

6

. Short-circuited intake air pressure sensor/lead wire

1

2

. Short-circuited intake air temp

. Sucking air from intake pipe joint

3

4

. Defective fuel injector

5

. Defective engine coolant temp

. Ignition timing too advanced due to defective timing

1

advance system (engine coolant temp

position switch, crankshaft position sensor and ECM)

2

. Drive chain too tight

1

. Too much engine oil in the engine

2

. Worn piston rings or cylinders

3

. Worn valve guides

. Scored or scuffed cylinder walls

4

. Worn valves stems

5

6

. Defective stem seal

7

. Worn oil ring side rails

1

. Weakened clutch springs

. Worn or distorted pressure plate

2

3

. Distorted clutch plates or clutch plate

1

. Some clutch spring weakened while others are not

2

. Distorted pressure plate or clutch plate

1

. Broken gearshift cam

. Distorted gearshift forks

2

3

. Worn gearshift pawl

. Broken return spring on shift shaft

1

. Rubbing or sticky shift shaft

2

3

. Distorted or worn gearshift forks

. Worn shifting gears on driveshaft or countershaft

1

2

. Distorted or worn gearshift forks

. Weakened stopper spring on gearshift stopper

3

. sensor/lead wire

. sensor

. sensor, gear

Clean

Add oil

Replace or clean

Retighten or replace

Change

See radiator section

Repair or replace

Repair or replace

Repair or replace

Replace

Replace

Replace

Adjust

Check with the inspection window

.

Drain excess oil

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Repair or replace

Replace

Replace

Replace

Replace

Remedy

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

I

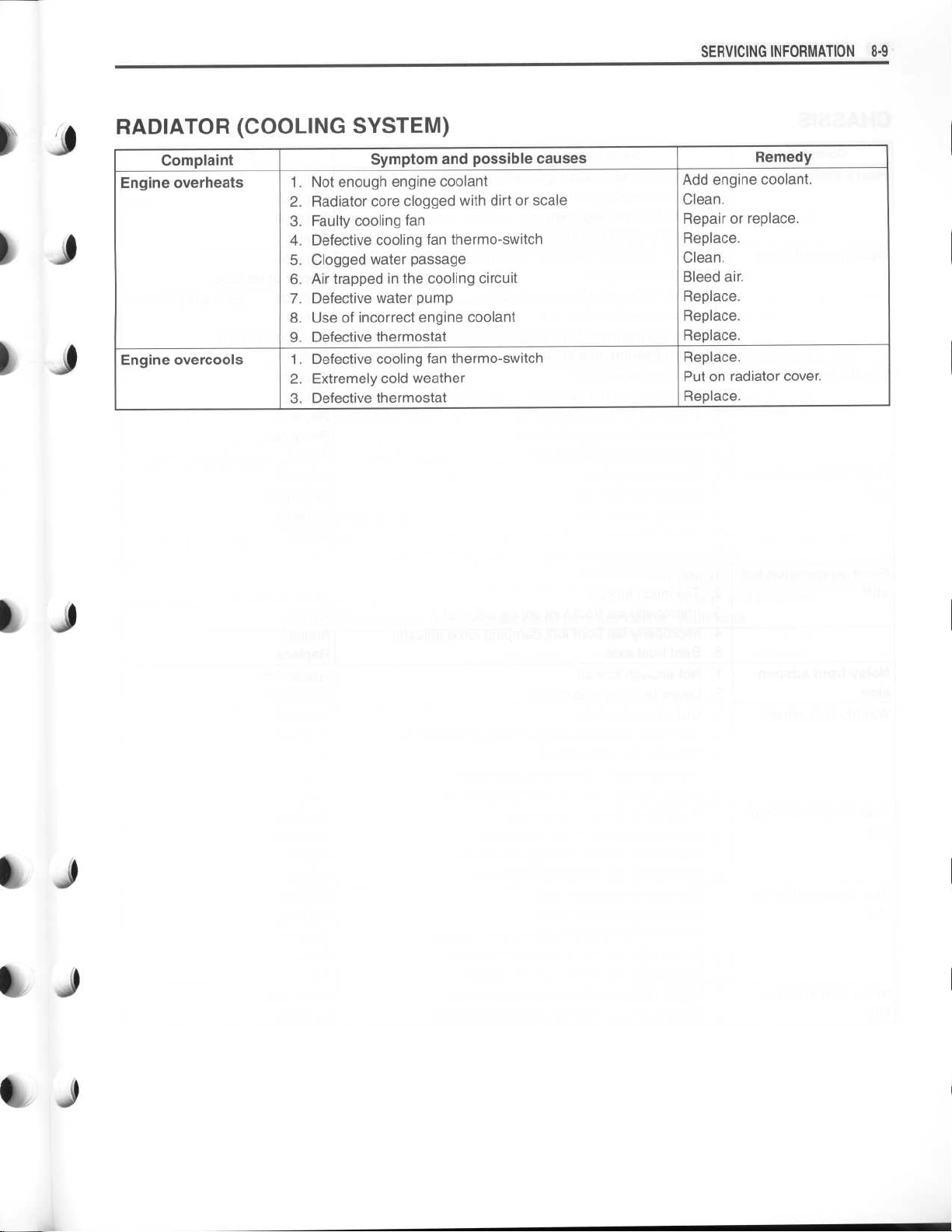

Page 9

~

~

~

~

~

1 Y

SERVICING INFORMATION

~

Y

RADIATOR (COOLING SYSTEM)

Complaint Complaint

Engine overheats

Engine

Engine overcools

Engine

Symptom and possible causes

.

1

. Not enough engine coolant

2

. Radiator core clogged with dirt or scale

. Radiator

2

3

. Faulty cooling fan

3

.

.

4

. Defective cooling fan 5

. Clogged water passage

5

.

. Air cooling circuit

6

. Air trapped in the cooling circuit

6

. Defective water pump

7

7

.

8

. Use of incorrect engine coolant

8

.

9

. Defective thermostat

9

.

.

1.Defective cooling

. Extremely cold weather

2

3

. Defective thermostat

cooling

Defective

clogged with dirt or scale

passage

engine coolant

cooling fan thermo-switch

possible causes

coolant

fan thermo-switch

RemedyRemedy

Add engine coolant

Add engine coolant

Clean

.

Clean

.

Repair or replace

Replace

Clean

Clean

Bleed air

Bleed air

Replace

Replace

Replace

Replace

Replace

Put on radiator cover

Replace

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

8 .9

Page 10

8-10

SERVICING

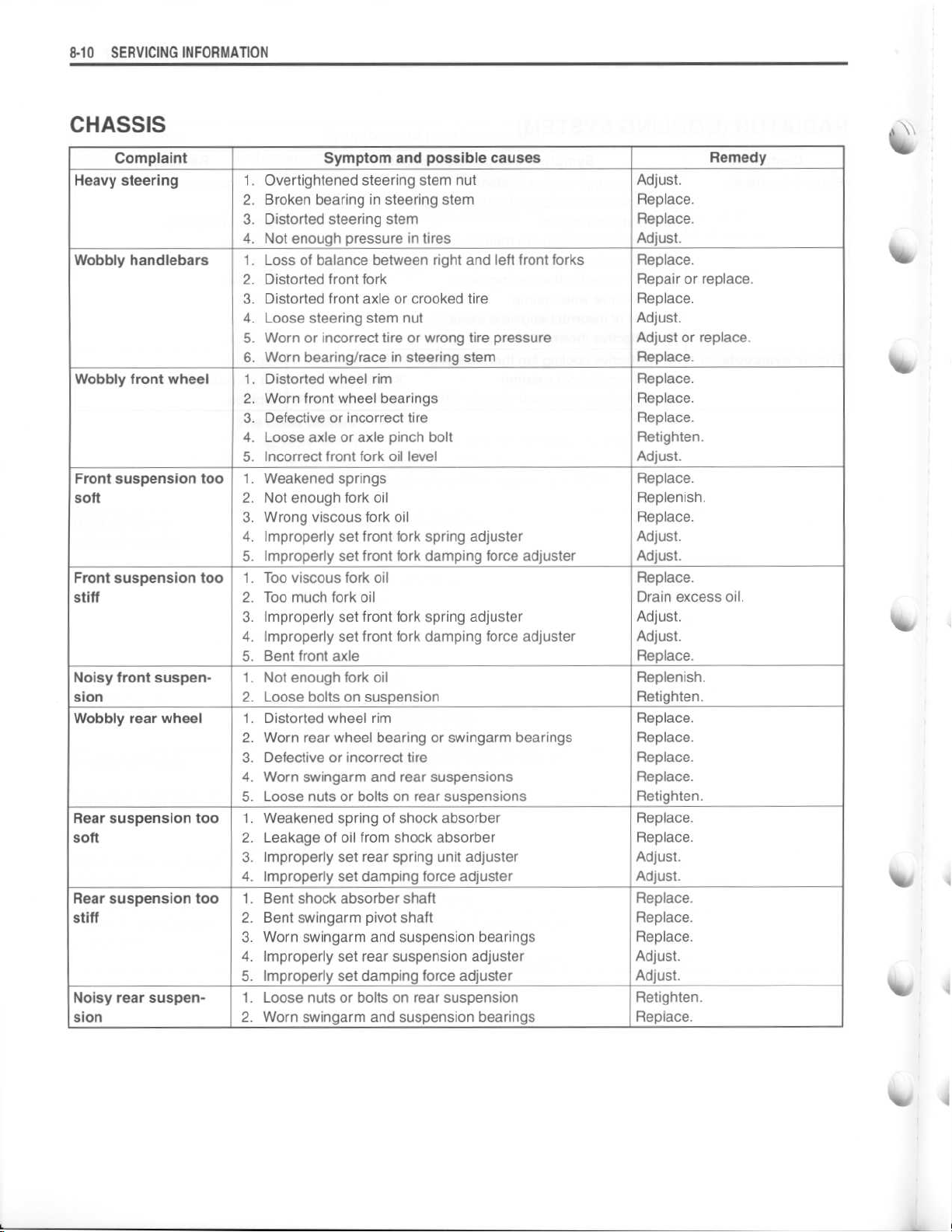

CHASSIS

INFORMATION

Complaint

Heavy steering

Wobbly handlebars

Wobbly front wheel1. Distorted wheel rim

Front suspension too

soft

Front suspension too

stiff

Noisy front suspension

Wobbly rear wheel

Rear suspension too

soft

Rear suspension too

stiff

Noisy rear suspension

1

. Overtightened steering stem nut

. Broken bearing in steering stem

2

3

. Distorted steering stem

4

. Not enough pressure in tires

1

. Loss of balance between right and left front forks

2

. Distorted front fork

3

. Distorted front axle or crooked tire

4

. Loose steering stem nut

. Worn or incorrect tire or wrong tire pressure

5

6

. Worn bearing/race in steering stem

2

. Worn front wheel bearings

3

. Defective or incorrect tire

4

. Loose axle or axle pinch bolt

5

. Incorrect front fork oil level

1

. Weakened springs

2

. Not enough fork oil

3

. Wrong viscous fork oil

4

. Improperly set front fork spring adjuster

. Improperly set front fork damping force adjuster

5

1

. Too viscous fork oil

2

. Too much fork oil

3

. Improperly set front fork spring adjuster

4

. Improperly set front fork damping force adjuster

5

. Bent front axle

1

. Not enough fork oil

2

. Loose bolts on suspension

1

. Distorted wheel rim

2

. Worn rear wheel bearing or swingarm bearings

3

. Defective or incorrect tire

4

. Worn swingarm and rear suspensions

5

. Loose nuts or bolts on rear suspensions

1

. Weakened spring of shock absorber

2

. Leakage of oil from shock absorber

3

. Improperly set rear spring unit adjuster

4

. Improperly set damping force adjuster

1

. Bent shock absorber shaft

2

. Bent swingarm pivot shaft

3

. Worn swingarm and suspension bearings

4

. Improperly set rear suspension adjuster

. Improperly set damping force adjuster

5

1

. Loose nuts or bolts on rear suspension

2

. Worn swingarm and suspension bearings

Symptom and possible causes

Remedy

Adjust

.

Replace

Replace

Adjust

Replace

Repair or replace

Replace

Adjust

Adjust or replace

Replace

Replace

Replace

Replace

Retighten

Adjust

Replace

Replenish

Replace

Adjust

Adjust

Replace

Drain excess oil

Adjust

Adjust

Replace

Replenish

Retighten

Replace

Replace

Replace

Replace

Retighten

Replace

Replace

Adjust

Adjust

Replace

Replace

Replace

Adjust

Adjust

Retighten

Replace

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

V&

%r

Page 11

~

a

,

a

Si

Si

•

i

J

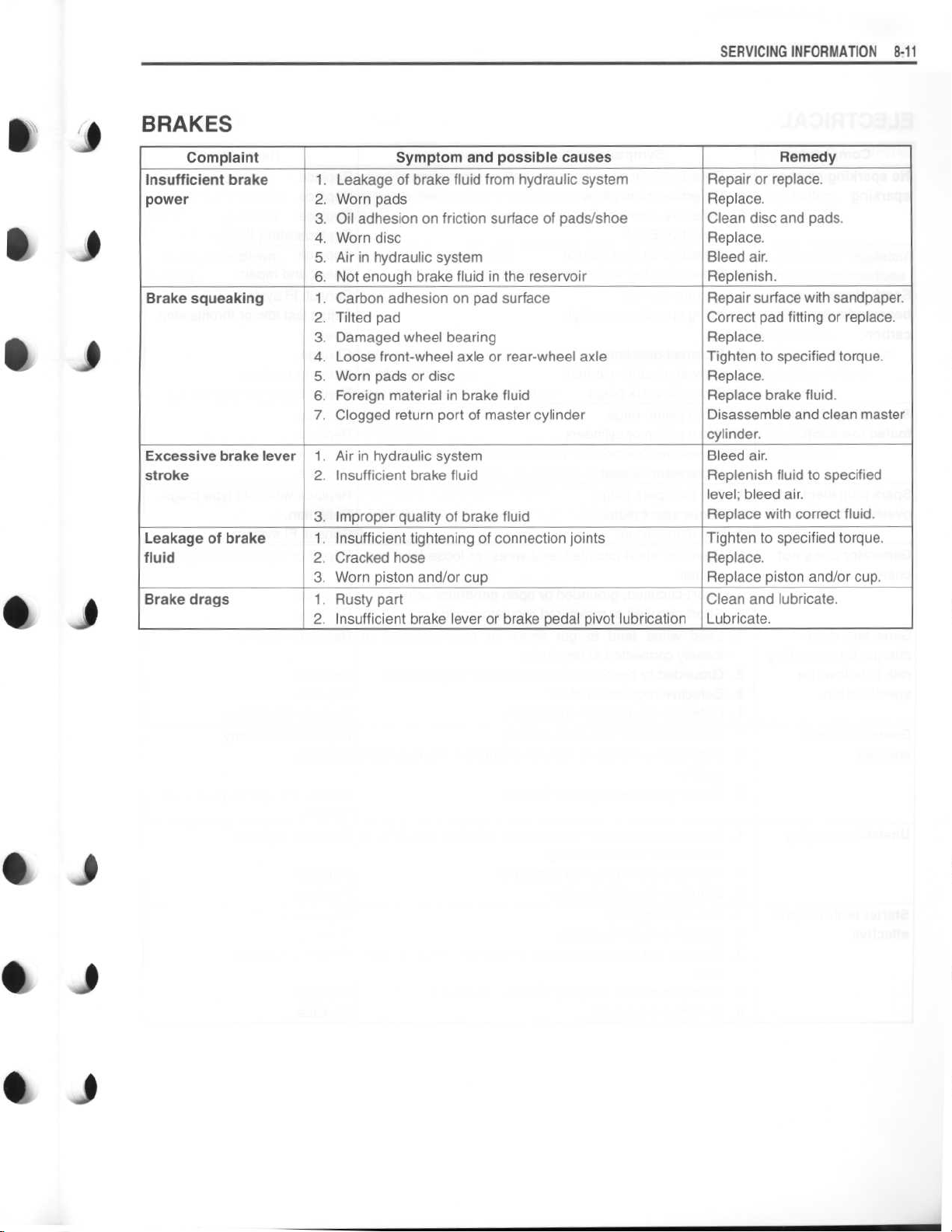

Complaint

Insufficient brake

power

Brake squeaking

Excessive brake lever

stroke

Leakage of brake

fluid

Brake drags

SERVICING INFORMATION

Symptom and possible causes

1

. Leakage of brake fluid from hydraulic system

2

. Worn pads

3

. Oil adhesion on friction surface of pads/shoe

4

. Worn disc

. Air in hydraulic system

5

6

. Not enough brake fluid in the reservoir

1

. Carbon adhesion on pad surface

2

. Tilted pad

3

. Damaged wheel bearing

4

. Loose front-wheel axle or rear-wheel axle

5

. Worn pads or disc

6 . Foreign material in brake fluid

7

. Clogged return port of master cylinder

1

. Air in hydraulic system

2

. Insufficient brake fluid

. Improper quality of brake fluid

3

1

. Insufficient tightening of connection joints

2

. Cracked hose

3

. Worn piston and/or cup

1

. Rusty part

2

. Insufficient brake lever or brake pedal pivot lubrication

Repair or replace

Replace

Clean disc and pads

Replace

Bleed air

Replenish

Repair surface with sandpaper

Correct pad fitting or replace

Replace

Tighten to specified torque

Replace

Replace brake fluid

Disassemble and clean master

cylinder

Bleed air

Replenish fluid to specified

level

Replace with correct fluid

Tighten to specified torque

Replace

Replace piston and/or cup

Clean and lubricate

Lubricate

Remedy

.

.

.

.

.

.

.

.

; bleed air

.

.

8-11

.

.

.

.

.

.

.

.

.

.

.

Si

0 1

Ii

Page 12

8

-12 SERVICING

INFORMATION

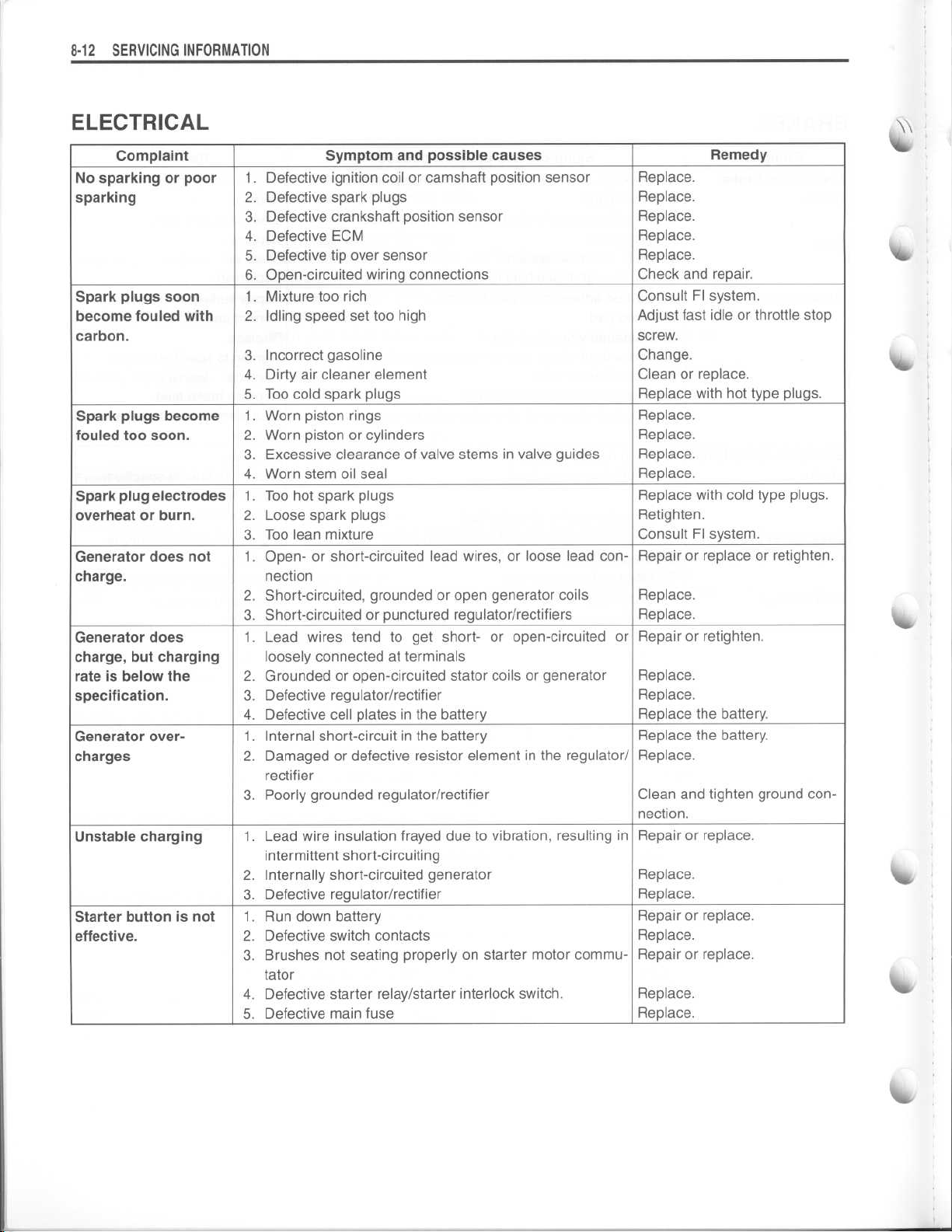

ELECTRICAL

Complaint Symptom and possible causes

1

No sparking or poor

sparking

Spark plugs soon

become fouled with

carbon

Spark plugs become

fouled too soon

Spark plug electrodes

overheat or burn

Generator does not

charge

Generator does

charge, but charging

rate is below the

specification

Generator overcharges

Unstable charging

Starter button is not

effective

.

.

.

.

.

.

. Defective ignition coil or camshaft position sensor

2

. Defective spark plugs

. Defective crankshaft position sensor

3

4

. Defective ECM

. Defective tip over sensor

5

6

. Open-circuited wiring connections

1

. Mixture too rich

2

. Idling speed set too high

. Incorrect gasoline

3

4

. Dirty air cleaner element

5

. Too cold spark plugs

1

. Worn piston rings

2

. Worn piston or cylinders

3

. Excessive clearance of valve stems in valve guides

4

. Worn stem oil seal

1

. Too hot spark plugs

2

. Loose spark plugs

3

. Too lean mixture

1

. Open- or short-circuited lead wires, or loose lead con-

nection

2

. Short-circuited, grounded or open generator coils

. Short-circuited or punctured regulator/rectifiers

3

. Lead wires tend to get short- or open-circuited or

1

loosely connected at terminals

. Grounded or open-circuited stator coils or generator

2

3

. Defective regulator/rectifier

4

. Defective cell plates in the battery

1

. Internal short-circuit in the battery

2

. Damaged or defective resistor element in the regulator/

rectifier

3

. Poorly grounded regulator/rectifier

. Lead wire insulation frayed due to vibration, resulting in

1

intermittent short-circuiting

2 . Internally short-circuited generator

3

. Defective regulator/rectifier

1

. Run down battery

2

. Defective switch contacts

. Brushes not seating properly on starter motor commu-

3

tator

4

. Defective starter relay/starter interlock switch

5

. Defective main fuse

\\

Remedy

Replace

Replace

Replace

Replace

Replace

Check and repair

Consult FI system

Adjust fast idle or throttle stop

screw

Change

Clean or replace

Replace with hot type plugs

Replace

Replace

Replace

Replace

Replace with cold type plugs

Retighten

Consult FI system

Repair or replace or retighten

Replace

Replace

Repair or retighten

Replace

Replace

Replace the battery

Replace the battery

Replace

Clean and tighten ground connection

Repair or replace

Replace

Replace

Repair or replace

Replace

Repair or replace

.

Replace

Replace

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Page 13

I P

P

BATTERY

Complaint

1

"Sulfation", acidic

white powdery substance or spots on

surfaces of cell plates

Battery runs down

quickly

Battery "sulfation"1. Incorrect charging rate

.

. Cracked battery case

. Battery has been left in a run-down condition for a long

2

time

1

. Trouble in charging system

2

. Cell plates have lost much of their active material as a

result of overcharging

. Internal short-circuit in the battery

3

4

. Too low battery voltage

. Too old battery

5

(When not in use battery should be checked at least

once a month to avoid sulfation

. The battery was left unused in a cold climate for too

2

long

Symptom and possible causes

.

.

.

.)

SERVICING INFORMATION 8-12

Remedy

Replace the battery

Replace the battery

Check the generator, regulator/

rectifier and circuit connections

and make necessary adjustments to obtain specified

charging operation

Replace the battery, and correct the charging system

Replace the battery

Recharge the battery fully

Replace the battery

Replace the battery

Replace the battery if badly

sulfated

.

.

.

.

.

.

.

.

.

1 l

J

1 1

Page 14

8-14

SERVICING INFORMATION

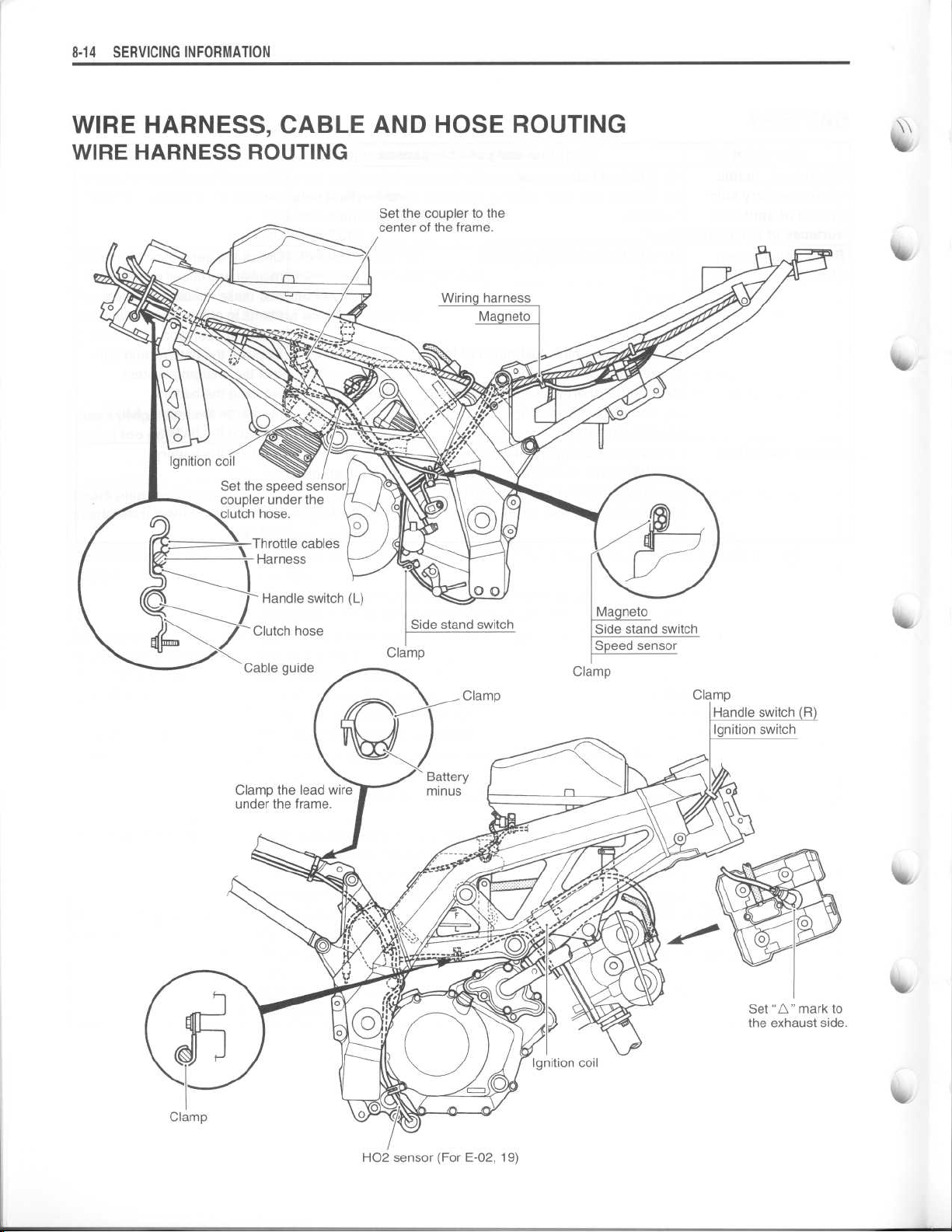

WIRE HARNESS, CABLE AND HOSE ROUTING

WIRE HARNESS ROUTING

Set the coupler to the

Ignition coil

Set the speed sensor

coupler under the

clutch hose

center of the frame

.

.

Handle switch (L)

/ Clutch hose

Cable guide

Clamp

Clamp

Set "A" mark to

the exhaust side

.

Clamp

H02 sensor (For E-02, 19)

Page 15

~

Horn

Set the connector and harness

between the frame and

the reservoir tank

.

SERVICING INFORMATION

Clamp the harness without contacting

to the bracket

.

Clamp

Harness

Rear

turn signal

Licence

lamp

8-15

light

(L)

Taping clamp

Taping clamp

Set

"s"

the exhaust side

mark to

.

Set the coupler inside of

the triangle area between

Set the high tension cord

backward as much as possible

without contacting to the fuel tank

Head lamp

the frame and fender

.

.

Page 16

SERVICING INFORMATION

8-16

ENGINE ELECTRICAL PARTS SET-UP

Apply bond to the groove

of the grommet

.

0

#2 Cylinder

I

Apply bond to the groove

of the grommet

.

10 N

.m

.0 kgf-m, 7

(1

Forward

.3 lb-ft)

Page 17

SERVICING INFORMATION8.17

1

1 1

I )

1

•

REGULATOR/RECTIFIRE INSTALLATION

0

I

l

't

Page 18

8-18

SERVICING INFORMATION

THROTTLE CABLE ROUTING

Throttle cable (pull)

Throttle cable (return)

Harness

Handle switch (L)

Throttle cable guide (pull)

Throttle cable guide (return)

Page 19

~

~

THROTTLE BODY INSTALLATION/HOSE ROUTING

I

1 J

SERVICING INFORMATION 8-19

1 J

1

Water temperature sensor

18 N

•m

(1

.8 kgf-m, 13 lb-ft)

\\

Forward

15-25°

VIEW OF TOP

(Throttle body clamp position)

25°

Air cleaner side

(A

1 l

down side

:

OA

: The ends of the clamp face

©

.

The clamp bolt head faces

. . .

. . .

Air temperature sensor

18 N

•m

(1

.8 kgf-m, 13 lb-ft)

Page 20

8-20

SERVICING INFORMATION

CRANKCASE BREATHER HOSE ROUTING

The clamp bolt head faces

OA

:

©

: The ends of the clamp face

© right side

Breather hose

. .

.

. . .

.

Page 21

S

.Y

Y

y

CLUTCH HOSE ROUTING

VIEW A

After the clutch cable hose union touching to the stopper,

tighten the union bolt

SERVICING INFORMATION 8-21

.

Si

1 l

Clamp the clutch hose firmly

.

Pass through the clutch hose

outside of the guide

SECT C

Clamp the clutch hose firmly

.

l

A-

.

d

l

0

After the clutch hose union

touching to the stopper,

)

tighten the union bolt

.

Page 22

~

8-22

SERVICING INFORMATION

COOLING SYSTEM HOSE ROUTING

Pass through the reservoir hose

right side of the breather hose and

high tension cord

.

(O

bottom side

.

© right side

© front side

Pass through

the reservoir

hose notch of

heat shield

.

.

:

The ends of the clamp face..

OA

©

: The clamp bolt head faces

.

Press fitting position of bearing

surface of clutch cover

.

© up side

. . .

.

.

4

-

u

'~

Tighten the clamp bolt to the

0

specified torque

2 N -m (0

.

.2 kg-m, 1

.5 lb-ft)

side

OA u

side

.

p

.

Page 23

~

W

O

w

w w

After the brake hose union

touching to the stopper,

tighten the union bolt

.

After the brake hose unions

touching to the stopper,

tighten the union bolt

.

After positioning the clamp

with the stopper,

tighten the clamp bolt

Insert the clamp /

to the hole of the

front fender fully

After the brake hose union touching

to the stopper, tighten the union bolt

.

.

.

Page 24

Be careful not to contact the seat rail and

reservoir tank, when installing

The white paint faces outside

.

.

Face the clamp ends backward

After the brake hose union touching

to the stopper, tighten the union bolt

.

.

After the brake hose union touching

to the stopper, tighten the union bolt

.

Page 25

SERVICING INFORMATION

8-25

k

j

s

FUEL TANK DRAIN HOSE ROUTING

Si

41 1

1

1

6

Page 26

8-

2 6

SERVICING INFORMATION

FUEL TANK INSTALLATION

Page 27

~

PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING

k

~7

I

k j

1 1

Matching mark

(White)

SERVICING INFORMATION

8-27

0 p

1 1

Si

-

~m

o

i

Matching mark

(Yellow)

ME

.

10 N

.m 1

.0 kgf-m, 7

A

.0 lb-ft)

r„(©7

w

1

PAIR read valve

Page 28

SERVICING INFORMATION

8-28

SEAT LOCK CABLE ROUTING

Seat lock cable

Page 29

1 1

1 1

SIDE-STAND SET-UP

0

40 N

(4

.0 kgf-m, 29

.m

SERVICING INFORMATION

.0 Ib-ft)

8-29

j

1 1

comi(comal

0

100 N

.m

(10 .0 kgf-m, 72

BRAKE PEDAVFOOTREST SET-UP

.5 Ib-ft)

C

I

[950N

.m

.0 kgf-m, 36

(5

.0 Ib-ft)

I )

ii )

0

1

a

Page 30

8-30

SERVICING INFORMATION

SPECIAL TOOLS

09900-00410

Hexagon wrench set

09900-06107

Snap ring pliers

09900-06108

Snap ring pliers

09900-09004

Impact driver set

I

kAo

09900-18740

Hexagon wrench

(24 mm)

r

1

1111110

!s

09900-20101 or

09900-20102 Micrometer Micrometer Micrometer

Vernier calipers

I

09900-20607 09900-20803

Dial gauge

(1/100 mm, 10 mm)

q

U®

i~

Orr,

-

9

9~

o

2i

09900-q

09900-22302

Plastigauge

3.r2

0

1

09900-20202 09900-20204 09900-20205

(25-50 mm)

®r

r,

09900-20701

Magnetic stand

09900-22403

Small bore gauge

(18 -

35 mm)

(75-100 mm)

~

09900-20806 09900-20805 09900-21304

Thickness gauge

09900-25008 09900-25009 09913-10750

Multi circuit tester

set

(0-25 mm)

Tire depth gaugeV-block (100 mm)

Needle pointed

probe set

~

\

~'

taq

09900-20602

Dial gauge

(1/1 000 mm, 1 mm)

l

ot

.

1Cir

Compression gauge

adapter

09913-13121

Carburetor balancer

set

09913-50121

Oil seal remover

09913-60210

Journal bearing

remover/installer set

09913-60230 09913-60240

Journal bearing Journal bearing

remover/installer

ro

holder

Page 31

I P

k P

k j

4Ir

09913-70210

Bearing installer set

~

09915-40610

Oil

\

filter wrench

09915-64512

Compression gauge

SERVICING INFORMATION8-3

09915-72410

Oil pressure gauge

attachment

09915-74511

Oil pressure

1

gauge

I

e

09915-74521

Oil pressure gauge

hose

09916-14910

Valve spring com-

pressor attachment

09916-34550

Valve guide reamer

(5

.5 mm)

09915-74532

Oil pressure gauge

adaptor

09916-21111

Valve

seat cutter set

09916-34580

Valve guide reamer

(10

.8 mm)

09915-77331

Meter (for high pres-

sure)

09916-24480

Solid pilot

(N-140-5

09916-44910

Valve guide

remover/installer

.5)

09916-10911

Valve lapper set

Valve seat cutter

head

See page 3-42

09916-53340

Attachment

09916-14510

Valve spring com-

pressor

09916-34542

.

Reamer handle

09916-84511

Tweezers

09917-47010

Vacuum pump

gauge

;P

0

09920-13120

Crankcase separating tool

09920-53740

Clutch sleeve hub

holder

09921-20240

Bearing remover set

i

09923-73210

Bearing remover

Page 32

8-32

SERVICING INFORMATION

i

09923-74511

Bearing puller

Final drive gear

bearing installer/

remover

001

~09924-74570

09924-84510

Bearing installer set

09924-84521

Bearing installer set

~g4

09925-18011

Steering bearing

installer

09930-10121

Spark plug wrench

set

09930-30450

Rotor remover bolt

09940-14911

Steering stem nut

wrench

09930-11920

Torx bit JT40H

09930-44541

Rotor holder

®

09940-14940

Swingarm pivot

thrust adjuster

socket wrench

09930-11940

Bit holder

09930-73110

Startertorque

holder

09940-14960

Steering nut wrench

socket

limiter

± i

09930-11950

09930-11960

Torx wrench

09930-73120

Starter

socket

torque limiter

O

09940-14990

Engine mounting

thrust adjuster

socket wrench

09930-30102

Sliding shaft

09930-82720

Mode selection

switch

F

09940-30250

Front fork assem-

bling tool

All

-

09940-40211

Fuel pressure gauge

adapter

IPlI

_

09940-40220

Fuel pressure gauge

hose attachment

09940-52841

Front fork inner rod

holder

~,

"

P

AR

09940-52861

Front fork oil seal

installer

09940-92720

Spring scale

Page 33

SERVICING INFORMATION 8-

3 3

1

•

1 f

1 0

0 9941-34513

Steering race

installer

NOTE

: When ordering a special tool, please confirm whether it is available or not

09943-74111

Fork oil level gauge

.

4 j

0 )

k

)

Page 34

~

~

~

~

~

~

~

~

~

~

~

8-34 SERVICING INFORMATION

TIGHTENING TORQUE

ENGINE

ITEM N-m

Cylinder head cover bolt

Spark plug

Camshaft journal holder bolt

Cam chain tension adjuster bolt

Cam chain tension adjuster mounting bolt

Cam drive idle gear/sprocket shaft

Cam chain tensioner mounting bolt

Cylinder head nut

Cylinder head bolt

PAIR read valve cover bolt

Cylinder nut

Water drain bolt

Clutch sleeve hub nut

Clutch spring set bolt

Clutch spring support bolt

Cam drive idle gear/sprocket nut

Primary drive gear nut

Generator cover plug

Valve timing inspection plug

Generator rotor bolt

Starter clutch bolt

Generator stator set bolt

Generator stator clamp bolt

Crankshaft position sensor set bolt

Gear position sensor mounting bolt

Gearshift cam stopper bolt

Gearshift cam stopper plate bolt

Gearshift arm stopper bolt

Oil pressure switch

Crankcase bolt

Generator cover bolt

Clutch cover bolt

Gearshift cover bolt

Water pump case bolt

Oil gallery plug

[M

[M

[M

[M

[M

[M

[M

[M

[M

[M

[M

[M

[M

[M

[F]

[R]

: 8]

: 6]

: 10]

: 6]

: 6]

: 6]

: 6]

: 8]

: 6]

: 6]

: 6]

: 6]

: 16]

: 8]

14

11

10

23

7 0

10

40

10

25

10

47

10

10

10

5

.5

95

10

23

70

115

15

23

140

25

12

6

.5

6

.5

6

.5

10

10

23

14

11

26

11

11

11

10

35

18

kgf-m

1

.4

1 .1

1

.0

2

.3

.7

1

.0

4

.0

1

.0

2

.5

1

.0

4

.7

1

.0

1

.0

1

.0

0

.55

9

.5

1

.0

2

.3

7

.0

11

.5

1

.5

2

.3

14

.0

2

.5

1

.2

0

.65

0

.65

0

.65

1

.0

1

.0

2

.3

1

.4

1

.1

2

.6

1

.1

1

.1

1

.1

1

.0

3

.5

1

.8

lb-ft

10

8

.0

7

.0

16

5

.0

7

.0

29

7

.0

18

7

.0

34

7

.0

7

.0

7

.0

4

.0

68

7

.0

16

50

83

11 .0

16

101

18

8

.5

4

.7

4

.7

4

.7

7

.0

7

.0

16

10

8

.0

19

8

.0

8

.0

8

.0

7

.3

25

.5

13

.0

.0

.5

.0

.0

.0

.5

.5

.5

.0

.5

.0

.0

.5

.0

.0

Page 35

~

ITEM N

Oil drain plug

Piston cooling oil nozzle screw

Oil pump mounting bolt

Conrod bearing cap bolt

Muffler mounting bolt and exhaust pipe bolt

Muffler mounting nut

Oil cooler mounting bolt

Oil cooler hose union bolt

Engine sprocket nut

Engine mounting pinch bolt

Engine mounting bolt/nut

Engine mounting thrust adjuster

Engine mounting thrust adjuster lock nut

Cooling fan thermo-switch

(Initial)

(Final)

[M

: 12]

[M

: 10]

•m

23

8 0

10

35

After tightening to

a turn (90°)

.

23

25

10

23

115

23

93

55

12

45

17

kgf-m

the above torque,

SERVICING INFORMATION 8-

Ib-ft

2

1

3

2

2

1

2

11

2

9

5

1

4

1

.3

.8

.0

.5

.3

.5

.0

.3

.5

.3

.3

.5

.2

.5

.7

16

.5

6

.0

7

.0

25

.5

tighten 1/4 of

16

.5

18

7

.3

16

83

16

67

40

8

.5

32

12

.0

.5

.0

.5

.6

.0

.5

.5

3

5

FI SYSTEM PARTS

ITEM

ECTS

TATS

CMPS mounting bolt

H02 sensor (For E-02, 19)

Fuel delivery pipe mounting screw

Fuel pump mounting bolt

Throttle body connecting bolt

Actuator motor cover nut

TPS mounting screw

STPS mounting screw

N•m

18

18

10

47

.5

5 0

10

5 0

2 0

3

.5

2 0

kgf-m

1

.8

1

.8

1

.0

4

.75

.5

1

.0

.5

.2

0

.35

.2

I b-ft

13

.0

13

.0

7

.3

34

.3

3

.7

7

.3

3

.7

1

.5

2

.5

1

.5

Page 36

~

8-36

SERVICING INFORMATION

CHASSIS

ITEM

Steering stem head nut

Steering stem lock nut

Front fork upper clamp bolt

Front fork lower clamp bolt

Front fork cap bolt

Front fork inner rod lock nut

Front fork damper rod bolt

Front axle

Front axle pinch bolt

Handlebar clamp bolt

Front brake master cylinder mounting bolt

Front brake caliper mounting bolt

Front brake caliper housing bolt

Front brake pad mounting pin

Brake hose union bolt

Clutch master cylinder mounting bolt

Clutch hose union bolt

Air bleeder valve (Clutch)

Air bleeder valve (Front)

Air bleeder valve (Rear)

Front brake disc bolt

Rear brake caliper mounting bolt

Rear brake caliper sliding pin

Rear brake master cylinder mounting bolt

Rear brake master cylinder rod lock nut

Rear brake pad mounting pin

Rear brake pad mounting pin plug

Front footrest bracket mounting bolt

Front footrest bolt

Swingarm pivot shaft

Swingarm pivot nut

Swingarm pivot shaft lock nut

Rear shock absorber mounting nut (Upper and lower)

Cushion lever mounting nut (Front)

Cushion rod mounting nut (Upper and lower)

Rear brake disc bolt

Rear axle nut

Rear sprocket nut

Seat rail bolt

Steering damper bolt

Steering damper nut

Steering stem nut

(For E-03, 28, 33)

(For the others)

N -m

90

80

23

23

23

15

23

100

23

23

10

26

23

16

23

10

23

5

.4

7

.5

6 0

23

23

27

10

18

18

2

.5

23

39

15

100

90

50

78

78

35

100

120

60

55

23

23

45

kgf-m

9

.0

8

.0

2

.3

2

.3

2

.3

1

.5 11 .5

2

.3

10

.0

2

.3

2

.3

1

.0

2

.6

2

.3

1

.6 11 .5

2

.3

1

.0

2

.3

0

.54

0

.75

.6

2

.3

2

.3

2

.7

1

.0

1

.8

1

.8

0

.25

2

.3

3

.9

1

.5

10

.0

9

.0

5

.0

7

.8

7

.8

3

.5

10

.0

12

.0

6

.0

5

.5

2

.3

2

.3

4

.5

I

b-ft

65

58

16

16

16

16

72

16

16

7

19

16

16

7

16

4

5

4

16

16

20

7

13

13

1

16

28

11

70

65

36

56

56

25

72

87

43

40

16

16

32

.0

.0

.5

.5

.5

.5

.5

.5

.5

.0

.0

.5

.5

.0

.5

.0

.5

.4

.5

.5

.5

.0

.0

.0

.8

.5

.0

.0

.0

.0

.0

.5

.5

.5

.5

.0

.5

.0

.5

.5

.5

Page 37

TIGHTENING TORQUE CHART

For other bolts and nuts listed previously, refer to this chart

:

SERVICING INFORMATION 8-

7

3

1 f

1 0

Bolt Diameter

®

(mm)

4

5 3 0

6 5

8 13

10

12

14

16

18

OA

Conventional bolt

Conventional or "4" marked bolt

N

•m

1

.5

.5

29

45

65

105

160

kgf-m

0

.15

.3

0

.55

1

.3 9

2

.9

4

.5

6

.5

10

.5

16

.0

lb-ft

1

.0

2

.0

4

.0

.5

21

.0

32

.5

47

.0

76

.0

115

.5

ORION

"4" marked bolt

"7" marked bolt

N

•m

2

.3

4

.5

10

23

50 5

85

135

210

240

kgf-m

0

.23

0

.45

1

.0

2

.3

.0

8

.5

13

.5

21

.0

24

.0

"7" marked bolt

lb-ft

1

.5

3

.0

7

.0

16

.5

36

.0

61

.5

97

.5

152

.0

173

.5

1 0

0

1 0

I

P

Page 38

8-38 SERVICING INFORMATION

SERVICE DATA

VALVE + GUIDE

ITEM

Valve diam

Tappet clearance (when cold)

Valve guide to valve stem clearance

Valve guide I .D

Valve stem O.D.

Valve stem deflection

Valve stem runout

Valve head thickness

Valve seat width

Valve head radial runout

Valve spring free length

Valve spring tension

.

.

EX

EX

IN

EX

IN

. & EX

IN

EX

IN

. & EX

IN

. & EX

IN

. & EX

IN

. & EX

IN

. & EX

IN

. & EX

IN

. & EX

IN

IN

116

Unit

: mm (in)

STANDARD

36

(1

.42)

.

.

.

.

.

.

.

.

.

.

.

.

.

(20.1- 23

(0

(0

(0

(0

(0

at length 35

33

(1

.30)

0

.10-0

(0

.004 -0.008)

0

.20-0

(0

.008 -0.012)

0

.010 -0.046

.0004-0

0

.030 - 0

.0012-0

5

.500 -5.512

.2165 -0.2170)

5

.475-5

.2156-0

5

.455 - 5

.2148 -0.2154)

0

(0

.035

197-227 N

.1 kgf, 44

.20

.30

.0018)

.066

.0026)

.490

.2161)

.470

.9-1

.1

- 0

.043)

.3 -51.0 Ibs)

.6 mm (1

.40 in)

LIMIT

0

.35

(0

.014)

0

.05

(0

.002)

0

.5

(0 .02)

0

.03

(0

.001)

41

.2

(1

.62)

CAMSHAFT + CYLINDER HEAD

ITEM

Cam height

Camshaft journal oil clearance

Camshaft journal holder I

Camshaft journal O.D.

Camshaft runout

.D

.

IN

EX

IN

. & EX

IN

. & EX

IN

. & EX

IN

. & EX

.

.

.

.

.

STANDARD

37

.78 -

(1

.487-1

36

.38 - 36 .42

(1

.432 -1.434)

0

.019 - 0

(0

.0007 - 0

22

.012-22

(0

.8666 -0.8671)

21

.972

(0

.8650 -0.8659)

37

.053

.0021)

- 21

.82

.489)

.025

.993

Unit

: mm (in)

LIMIT

37

.48

(1

.476)

36

.08

(1

.420)

0

.150

(0

.0059)

0

.10

(0

.004)

Page 39

~

SERVICING INFORMATION 8-39

ITEM

Cam drive idle gear/sprocket

thrust clearance

Cylinder head distortion

ITEM

Compression pressure

(Automatic de-comp

Compression pressure difference

Piston to cylinder clearance

Cylinder bore

Piston diam

Cylinder distortion

Piston ring free end gap

Piston ring end gap

Piston ring to groove clearance

Piston ring groove width

Piston ring thickness

Piston pin bore I.D.

Piston pin O.D.

.

. actuated)

STANDARD

0

(0

STANDARD

1k000gf-

(10

- 14 gf/cm2,

0

(0

.0006 - 0

98

(3

.8583 -3.8589)

97

(3

.8575 - 3 .8581)

Measure at 10 mm (0

1st

2nd

1 st

2nd

1 st

2nd

1 st

2nd

Oil

1 st

2nd

22

.002-22

(0

.8662-0

21

.993-22

(0

.8658-0

.15-0

.006 -

.015

.000-98

.980-97

.29

.011)

0

_

1 400 kPa

142-199 psi)

-

- 0

.025

.0010)

.015

.995

.4 in) from the skirt end

Approx

Approx

(0

(0

(0

(0

. 8

.8 (0

.35)

. 10 .1 (0

0

.15-0

(0

.006 -0.014)

0

.30-0

(0

.012

0

.93-0

.0366 -0.0374)

1

.55-1

.0610-0

1

.01 -1

.0398-0

2

.51 -2

.0988 - 0

.86-0

0

.034

(0

.38-1

1

(0

.054-0

0

.97-0

(0

.038 -0.039)

- 0

- 0

.008

.8665)

.000

.8661)

.35

.45

.018)

.95

.57

.0618)

.03

.0406)

.53

.0996)

.91

.036)

.40

.055)

.99

.40)

LIMIT

0

.05

(0

.002)

Unit

: mm (in)

LIMIT

800 kPa

(8 kgf/cm2,

114 psi)

200 kPa

(2 kgf/cm2,

28 psi)

0

.12

(0

.0047)

Nicks or

Scratches

97

.880

(3

.

.8535)

0

.05

(0

.002)

7

.0

(0

.28)

8

.1

(0

.32)

0

.7

(0 .03)

0

.7

(0

.03)

0

.18

(0

.0071)

0

.15

(0

.0059)

-

_

22

.030

(0

.8673)

21 .980

(0

.8654)

Page 40

8-40

SERVICING INFORMATION

CONROD + CRANKSHAFT

ITEM

Conrod small end I.D.

Conrod big end side clearance

Con rod big end width

Crank pin width

Conrod big end oil clearance

Crank pin O.D.

Crankshaft journal oil clearance

Crankshaft journal O.D.

Crankshaft runout

OIL PUMP

ITEM

Oil pressure (at 60 °C, 140 °F)

STANDARD

22

.010-22

(0

.8665 - 0

0

.17-0

(0

.007 -0.013)

21

.95-22

(0

.864-0

44

.17-44

(1

.739 - 1

0

.040

(0

.0016 - 0

44

.976-45

(1

.7707

0

.002-0

(0

.0008 - 0

47

.985-48

(1

.8892 - 1

STANDARD LIMIT

Above 350 kPa (3

Below 650 kPa (6

at 3 000 r/min

.018

.8668)

.32

.00

.866)

.22

.741)

- 0

.064

.0025)

.000

- 1

.7717)

.029

.0011)

.000

.8898)

.5 kgf/cm2, 50 psi)

.5 kgf/cm2,

92 psi)

Unit

LIMIT

22

(0

.8677)

0

(0

0.080

(0

.0031)

0.080

(0

.0031)

0

(0

.002)

.040

.50

.020)

_

.05

: mm (in)

CLUTCH

ITEM

Drive plate thickness

Drive plate claw width

Driven plate distortion

Clutch spring free length

Clutch master cylinder bore

Clutch master cylinder piston

diam

.

Clutch release cylinder bore

Clutch release cylinder piston

diam

.

Clutch fluid type

No

No

. 2 and 3

No

No

. 2 and 3

. 1

. 1

STANDARD

2

.92-3

(0

.115 - 0

3

.72-3

(0

.146 - 0

13

.85-13

(0

.545 - 0

13

.90

.547 -

(0

_

28

.1

(1

.11)

14

.000-14

(0

.5512-0

13

.957-13

(0

.5495 - 0

35

.700-35

(1

.4055 - 1 .4079)

35

.650-35

(1

.4035 - 1

.5528)

.5505)

.4045)

DOT 4

-14.00

0

.043

.984

.762

.675

.08

.121)

.88

.153)

.96

.550)

.551)

Unit

LIMIT

2

.103)

(0

3

(0

.135)

13

.514)

(0

13

(0

.516)

0

(0

.004)

26

(1

_

_

_

.62

.42

.05

.10

.10

.05)

: mm (in)

.7

Page 41

THERMOSTAT + RADIATOR + FAN + COOLANT

ITEM

Thermostat valve opening temperature

Thermostat valve lift

Radiator cap valve opening

pressure

Cooling fan thermo-switch operating temperature

Engine coolant temperature

sensor resistance

Engine coolant type

Engine coolant

OFF -* ON

-*

ON

20 °C

(68 °F)

40 °C

(104 °F)

60 °C

(140 °F)

80 °C

(176 °F)

Use an anti-freeze/coolant compatible with aluminum

radiator, mixed with distilled water only, at the ratio of

50

:50

Reservoir

tank side

Engine

side

Over 8

OFF

.

.0 mm (0

110 kPa (1

STANDARD

86.5- 89

(188-193 °F)

.31 in) at 100 °C (212 °F)

.1 kgf/cm

Approx

Approx

Approx

Approx

Approx

Approx

Approx

.3/0

(0

Approx

(2

.1/1

SERVICING INFORMATION 8-

.5 °C

2

, 15

.6 psi)

. 105 °C (221 (IF)

. 100 °C (212 °F)

. 2

.45 kQ

. 1

.15 kQ

. 0

.58 kQ

. 0

.32 kQ

. 250 ml

.2 US/Imp qt)

. 1 950 ml

.7 US/Imp qt)

LIMIT

-

-

-

-

-

4

1

DRIVE TRAIN

ITEM

Primary reduction ratio

Final reduction ratio

Gear ratio

Shift fork to groove clearance

Shift fork groove width

Shift fork thickness

Drive chain

Drive chain slack

Gearshift lever height

Low

2nd

3rd

4th

5th

Top

20-link

Type

Links

length

STANDARD

1

.838 (57/31)

.352 (40/17)

2

2

.666 (32/12)

1

.933 (29/15)

1

.500 (27/18)

1

.227 (27/22)

1

.086 (25/23)

1

.000 (24/24)

0 .1 -0

(0

.004 -

5

.197 -0.201)

(0

4

(0

.189-0

108 links, ENDLESS

(0

.3

.012)

0

.0-5

.1

.8-4

.9

.193)

RK530SMOZ1

20-30

.2)

.8-1

65

(2

.56)

Unit

: mm (in) Except ratio

LIMIT

0

.50

(0

.020)

_

-

319

.4

(12

.6)

Page 42

8-42 SERVICING INFORMATION

INJECTOR + FUEL PUMP + FUEL PRESSURE REGURATOR

ITEM

Injector resistance

Fuel pump discharge amount

for 10 seconds at 300 kPa (3

Fuel pressure regulator operating set pressure

168 ml and more (5

Approx

SPECIFICATION

11

-

13 L2 at 20 °C (68 °F)

.7/5

.9 US/Imp oz)

.0 kgf/cm2,

. 300 kPa (3

.0 kgf/cm2,

43 psi)

43 psi)

FI-SENSORS

NOTE

ITEM

CMP sensor peak voltage

CKP sensor resistance

CKP sensor peak voltage

IAP sensor input voltage

IAP sensor output voltage

TP sensor input voltage

TP sensor resistance

TP sensor output voltage

ECT sensor input voltage

ECT sensor resistance

IAT sensor input voltage

IAT sensor resistance

AP sensor input voltage

AP sensor output voltage

TO sensor resistance

TO sensor voltage

GP switch voltage

Injector voltage

Ignition coil primary peak volt-

age

STP sensor input voltage

STP sensor resistance Closed

STP sensor output voltage

STV actuator resistance

Heated oxygen sensor output

voltage

Heated oxygen sensor resis-

tance

PAIR solenoid valve resistance

Closed

Opened

Closed

Opened

Approx

Opened

Closed

Opened

SPECIFICATION

3 .7 V and more

130-240 S2

5 .0 V and more (When cranking)

4.5-5.5 V

Approx

Approx

Approx 2

0

.6 V and more (From 1st to top)

200 V and more (When cranking)

Approx

Approx

0

0

.6 V and more at 3 000 r/min

4 -

20-24 Q at 20 °C (68 °F)

. 2

.5 V at idle speed

4.5-5.5 V

Approx

Approx

Approx

Approx

4.5-5.5 V

. 2

.45 kQ at 20 °C (68 °F)

4.5- 5

.45 kQ at 20 °C (68 °F)

4

.5

- 5

. 4

.0 V at 100 kPa (760 mmHg)

19.1-19.7 kQ

1

.4 V and less

Battery voltage

4.5-5.5 V

Approx

Approx

. 0

.58 V at input voltage is 5

. 4

.38 V at input voltage is 5

7 -

.4 V and less at idle speed

5 Q at 23 °C (73

.5 V

.5 V

14 Q

. 1

.12 k4

. 4

.26 kQ

. 1

.12 V

. 4

.26 V

.58 kQ

. 0

. 4

.38 kQ

.4 °F)

NOTE

.0 V

.0 V

Except for USA

Except for USA

Except for USA

Page 43

SERVICING INFORMATION 8-

4

3

ID No

ITEM

.

16G0 (For E-02, 19), 16G1 (For E-33),

SPECIFICATION

16G2 (For E-03, 24, 28, E-19 UD/UF)

Bore size

Fast idle r/min

Idle r/min

1 900 -

1 200 ± 100 r/min/Warmed engine

2 500 r/min at 25 °C (77 °F)

Throttle cable play

ITEM

Firing order

Spark plug

Type

SPECIFICATION

1

.2

NGK

DENSO

Gap

(0

Spark performance Over 8(0.3)

Crankshaft position sensor

resistance

Ignition coil resistance

Primary

130-240 S2

2.8-4.2 S2

Secondary

Crankshaft position sensor peak

voltage

Ignition coil primary peak volt-

age

Generator coil resistance

Generator Max

. output

Generator no-load voltage

(When engine is cold)

Regulated voltage

Starter relay resistance

Battery

Type

designation

Capacity

Fuse size

Headlight

HI

LO

Fuel

Ignition

Turn signal

Fan motor

Approx

75 V and more (AC) at 5 000 r/min

5

.0 V and more

200 V and more When cranking

0.2-0.7 Q

. 400 W at 5 000 r/min

14.0-15.5 V at 5 000 r/min

3 -

6 Q

FTX 14-BS

12 V 43

.2 kC (12 Ah)/10 HR

15 A

15 A

10A

15 A

10A

15 A

Main 30 A

52 mm

2.0-4.0 mm

(0

.08-0

.16 in)

: CR8EK

: U24ETR

0

.6-0

.7

.024 -0.028)

at 1 atm

.

24-36 kQ

Unit : mm (in)

NOTE

BI

- G

tap -Otap

OO

S+

tap-Plug cap

When cranking

Y - Y

Page 44

8-44 SERVICING INFORMATION

WATTAGE

ITEM

Headlight

Position light

Brake light/Taillight

Turn signal light

Speedometer/Tachometer light

Turn signal indicator light

High beam indicator light

Neutral indicator light

Fuel indicator light

Coolant temperature/oil pressure/F1 indicator light

License light

HI

LO

BRAKE + WHEEL

ITEM

Rear brake pedal height

Brake disc thickness

Brake disc runout

(Front & Rear)

Master cylinder bore

Master cylinder piston diam

Brake caliper cylinder bore

Brake caliper piston

.

diam

Brake fluid type

.

Leading

Trailing

Leading

Trailing

Front

Rear

Front

Rear

Front

Rear

Front

Rear

Front

Rear

SPECIFICATION

STANDARD

55-65

(2

.17

- 2

(0

.197 ± 0

(0.97

_

15

.870-15 .913

(0

.6248

14

.000-14 .043

(0

.5512-0

15

.827-15 .854

(0

.6231-0

13

.957-13 .984

(0

.5495-0

30

.230-30

(1

.1902-1

33

.960-34

(1

.3370-1

38

.180-38

(1

.5031-1

30

.167-30

(1

.1876-1

33

.901-33

(1

.3346-1

38

.115-38

(1

.5005-1

DOT 4

60 x 2

55 x 2

5 x 2

LED

21x4

LED

LED

LED

LED

LED

LED

5

.56)

5

.0 ± 0

.2

.008)

± 0

.2

7 ± 0 .008)

- 0

.6265)

.5529)

.6242)

.5506)

.1921)

.3389)

.5051)

.1890)

.3360)

.5019)

.280

.010

.230

.200

.934

.148

: mm (in)

Unit

LIMIT

_

4

.5

.18)

(0

4

.5

(0

.18)

0

.30

.012)

(0

_

_

_

Unit

: W

Page 45

SERVICING INFORMATION 8-

4 5

ITEM

Wheel rim runout

(Front & Rear)

Wheel axle runout

Wheel rim size

Tire size

Tire type

Tire tread depth

Axial

Radial

Front

Rear

Front

Rear

Front

Rear

Front

Rear

Front

Rear

SUSPENSION

ITEM

Front fork stroke

Front fork spring free length

Front fork oil level

(without spring, inner tube fully

compressed)

Front fork spring adjuster

Front fork damping force

adjuster

Rear shock absorber spring preset length

Rear shock absorber damping

force adjuster

Rear wheel travel

Swingarm pivot shaft runout

Rebound

Compres-

sion

Rebound

Compres-

sion

STANDARD

-

17 x MT 3 .50, 17M/C x MT 3

17 x MT 5 .50, 17M/C x MT 5

120/70 ZR17M/C (58W), tubeless

180/55 ZR17M/C (73W), tubeless

MICHELIN

MICHELIN

STANDARD

6th groove from top

1 turn out from stiffest position

1 turn out from stiffest position

3/4 turn out from stiffest position

2-1/4 turns out from stiffest position

: PILOT SPORT E

: PILOT SPORT L

120

(4 .72)

296

.3

(11

.7)

162

(6

.4)

199

.5

(7 .85)

129

(5 .08)

.50

.50

LIMIT

2

(0

2

(0

0

(0

.010)

0

(0

.010)

-

1

(0

2

(0

Unit

LIMIT

290

(11

0

(0

.0

.08)

.0

.08)

.25

.25

.6

.06)

.0

.08)

: mm (in)

-

.4)

-

-

-

_

.3

.01)

TIRE PRESSURE

COLD INFLATION

TIRE PRESSURE

FRONT

REAR

kPa

250

250

SOLO

RIDING

kgf/cm

2

.50

2

.50

DUAL

2

psi

36

36

kPa

250

290

RIDING

kgf/cm

2

.50

2

.90

2

psi

36

42

Page 46

8-46 SERVICING INFORMATION

FUEL + OIL

ITEM

Fuel type

Fuel tank

Engine oil type

Engine oil capacity

Front fork oil type

Front fork oil capacity (each leg)

Use only unleaded gasoline of at least 87 pump

octane (R/2 + M/2) or 91 octane or higher rated by the

research method

Tertiary Butyl Ether), less than 10 % ethanol, or less

than 5 % methanol with appropriate cosolvents and

corrosion inhibitor is permissible

Gasoline used should be graded 91 octane or higher

An unleaded gasoline is recommended

Change

Filter change

Overhaul

SUZUKI FORK OIL L01 or an equivalent fork oil

SPECIFICATION

. Gasoline containing MTBE (Methyl

.

.

16 L (4

17 L (4

SAE 1OW-40, API SF or SG

(16

.69/17

.5 US/Imp gal)

.2/3

.7 US/Imp gal)

.5/3

2 700 ml

(2

.9/2

.4 US/Imp qt)

2 900 ml

(3 .1/2

.6 US/Imp qt)

3 300 ml

.9 US/Imp qt)

(3 .5/2

494 ml

.39 US/Imp oz)

NOTE

E-03, 28, 33

.

The others

The others

E-33

Loading...

Loading...