Page 1

Fl SYSTEM

CONTENTS

Fl SYSTEM

4-1

PRECAUTIONS IN SERVICING~~

Fl SYSTEM TECHNICAL FEATURES

FI SYSTEM PARTS LOCATION

FI SYSTEM WIRING DIAGRAM

SELF-DIAGNOSIS FUNCTION

FAIL-SAFE FUNCTION

Fl SYSTEM TROUBLESHOOTING

CONNECTOR/COUPLER

FUSE

~

~

~

~

~

. . . .

. . . . . . . . ..... . . . . . . . . . ..... . . . . . . . . . . .

. . . . .

~

~

~

~

~

~

. .~. . . . . .

.....

. . . . .

.

ECM/VARIOUS SENSORS

ELECTRICAL CIRCUIT INSPECTION PROCEDURE

USING TESTERS

INJECTION TIME (INJECTION VOLUME)

COMPENSATION OF INJECTION TIME (VOLUME)

INJECTION STOP CONTROL

FUEL DELIVERY SYSTEM

FUEL PUMP

FUEL PRESSURE REGULATOR

FUEL INJECTOR

FUEL PUMP CONTROL SYSTEM

ECM (FI CONTROL UNIT)

INJECTION TIMING

SENSORS

USER MODE

DEALER MODE

TPS ADJUSTMENT ----

CUSTOMER COMPLAINT ANALYSIS

SELF-DIAGNOSTIC PROCEDURES

SELF-DIAGNOSIS RESET PROCEDURE

MALFUNCTION CODE AND DEFECTIVE CONDITION

"C11"CMP SENSOR CIRCUIT MALFUNCTION

"C12" CKP SENSOR CIRCUIT MALFUNCTION

"C13" IAP SENSOR CIRCUIT MALFUNCTION

"C14" TP SENSOR CIRCUIT MALFUNCTION

"C15" ECT SENSOR CIRCUIT MALFUNCTION

"C21

"C22" AP SENSOR CIRCUIT MALFUNCTION

"C23" TO SENSOR CIRCUIT MALFUNCTION

"C24" or "C25" IGINTION SYSTEM MALFUNCTION

"C28" STV ACTUATOR CIRCUIT MALFUNCTION

"C29" STP SENSOR CIRCUIT MALFUNCTION

"C31 "

"C32" or "C33" FUEL INJECTOR CIRCUIT MALFUNCTION

"C41

"C42" IG SWITCH CIRCUIT MALFUNCTION

"C44" H02 SENSOR (HO2S) CIRCUIT MALFUNCTION

(FOR E-02,19)

"C49" PAIR CONTROL SOLENOID VALVE

~

"

IA T SENSOR CIRCUIT MALFUNCTION

GEAR POSITION (GP) SWITCH CIRCUIT MALFUNCTION

" FP RELAY CIRCUIT MALFUNCTION

~

~

~

. . .

. . . ..... . . . .

~

~

~

~.. . . . . . . . . .

. . . . . . .

~

~

~

~

~

. . . . . . .

4- 3

4- 3

. . . . . . . . . . .

. . . . .

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

. . . . . . . .

~

~

~

. . . . ....~

. . .....4- 4

4- 4

4- 6

4- 9

4-10

4-10

4-11

4-11

4-12

4-13

4-14

4-14

4-15

4-16

4-16

4-17

4-21

4-23

4-24

4-24

4-25

4-26

4-27

4-28

4-28

4-30

4-30

4-31

4-33

4-35

4-37

4-40

4-42

4-44

4-46

4-49

4-51

4-51

4-53

4-57

4-58

4-60

4-60

. .

.4-61

4-63

4

Page 2

4-2Fl SYSEM

Fl SYSTEM

CONTENTS

FUEL SYSTEM

FUEL TANK LIFT-UP

FUEL TANK REMOVAL

FUEL TANK INSTALLATION

FUEL PRESSURE INSPECTION

FUEL PUMP INSPECTION

FUEL PUMP RELAY INSPECTION

FUEL PUMP AND FUEL FILTER REMOVAL

FUEL MESH FILTER INSPECTION AND CLEANING

FUEL PUMP CASE BUSHING INSPECTION

FUEL PUMP AND FUEL MESH FILTER INSTALLATION

THROTTLE BODY AND STV ACTUATOR

CONSTRUCTION

AIR CLEANER AND THROTTLE BODY REMOVAL

THROTTLE BODY DISASSEMBLY

THROTTLE BODY CLEANING

THROTTLE BODY INSPECTION

THROTTLE BODY REASSEMBLY

THROTTLE BODY INSTALLATION

STP SENSOR ADJUSTMENT

FUEL INJECTOR INSPECTION

FUEL INJECTOR REMOVAL

FUEL INJECTOR INSTALLATION

FAST IDLE INSPECTION

FAST IDLE ADJUSTMENT

THROTTLE VALVE SYNCHRONIZATION

THROTTLE CABLE ADJUSTMENT

SENSOR

~

lAP SENSOR INSPECTION

IAP SENSOR REMOVAL/INSTALLATION

TP SENSOR INSPECTION

STP SENSOR INSPECTION

STP SENSOR REMOVAL/INSTA LLA TION

CKP SENSOR INSPECTION

CKP SENSOR REMO VAUINSTALLA TION

CMP SENSOR INSPECTION

CMP SENSOR REMOVAL/INSTALLATION

IAT SENSOR INSPECTION

IAT SENSOR REMOVAL/INSTALLATION

ECT SENSOR INSPECTION

ECT SENSOR REMOVAL/INSTALLATION

AP SENSOR INSPECTION

AP SENSOR REMOVAL/INSTALLATION

TO SENSOR INSPECTION

TO SENSOR REMOVAL/INSTALLATION

HO2 SENSOR INSPECTION (FOR E-02,19)

H02 SENSOR REMOVAL/INSTALLATION (FOR E-02,19)

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

TP

~

SENSOR ADJUSTMENT~4-85

~

~

~

~

~

~

~

~

~

~

TP SENSOR REMOVAL/INSTALLATION~4-91

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

4-92

~

4-65

4-65

4-65

4-66

4-67

4-68

4-69

4-69

~

~

~

~

4-71

4-71

4-71

4-74

4-74

4-75

4-77

4-80

4-80

4-81

4-84

4-85

4-86

4-86

4-86

4-87

4-87

4-88

4-90

4-91

4-91

4-91

4-91

4-91

4-91

4-92

4-92

4-92

4-92

4-92

4-93

4-93

4-93

4-93

4-93

4-93

4-93

4-94

Page 3

~

~

~

~

PRECAUTIONS IN SERVICING

When handling the FI component parts or servicing the FI system, observe the following points for the safety of the system

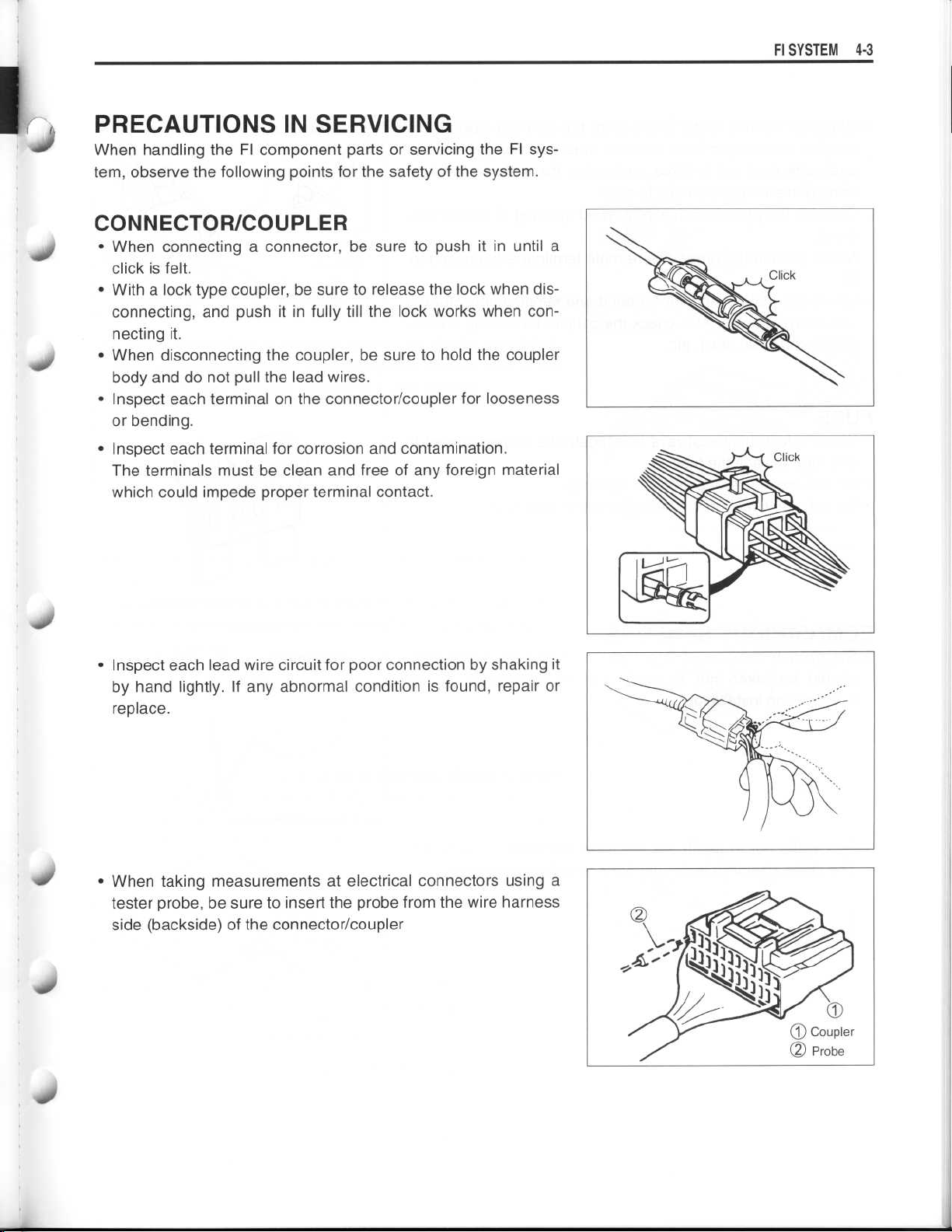

CONNECTOR/COUPLER

•

When connecting a connector, be sure to push it in until a

click is felt

•

With a lock type coupler, be sure to release the lock when disconnecting, and push it in fully till the lock works when connecting it

•

When disconnecting the coupler, be sure to hold the coupler

body and do not pull the lead wires

•

Inspect each terminal on the connector/coupler for looseness

or bending

•

Inspect each terminal for corrosion and contamination

The terminals must be clean and free of any foreign material

which could impede proper terminal contact

.

.

.

.

.

.

.

FI SYSTEM 4-

3

•

Inspect each lead wire circuit for poor connection by shaking it

by hand lightly . If any abnormal condition is found, repair or

replace

•

When taking measurements at electrical connectors using a

tester probe, be sure to insert the probe from the wire harness

side (backside) of the connector/coupler

.

Page 4

~

~

~

~

4

-4 Fl SYSTEM

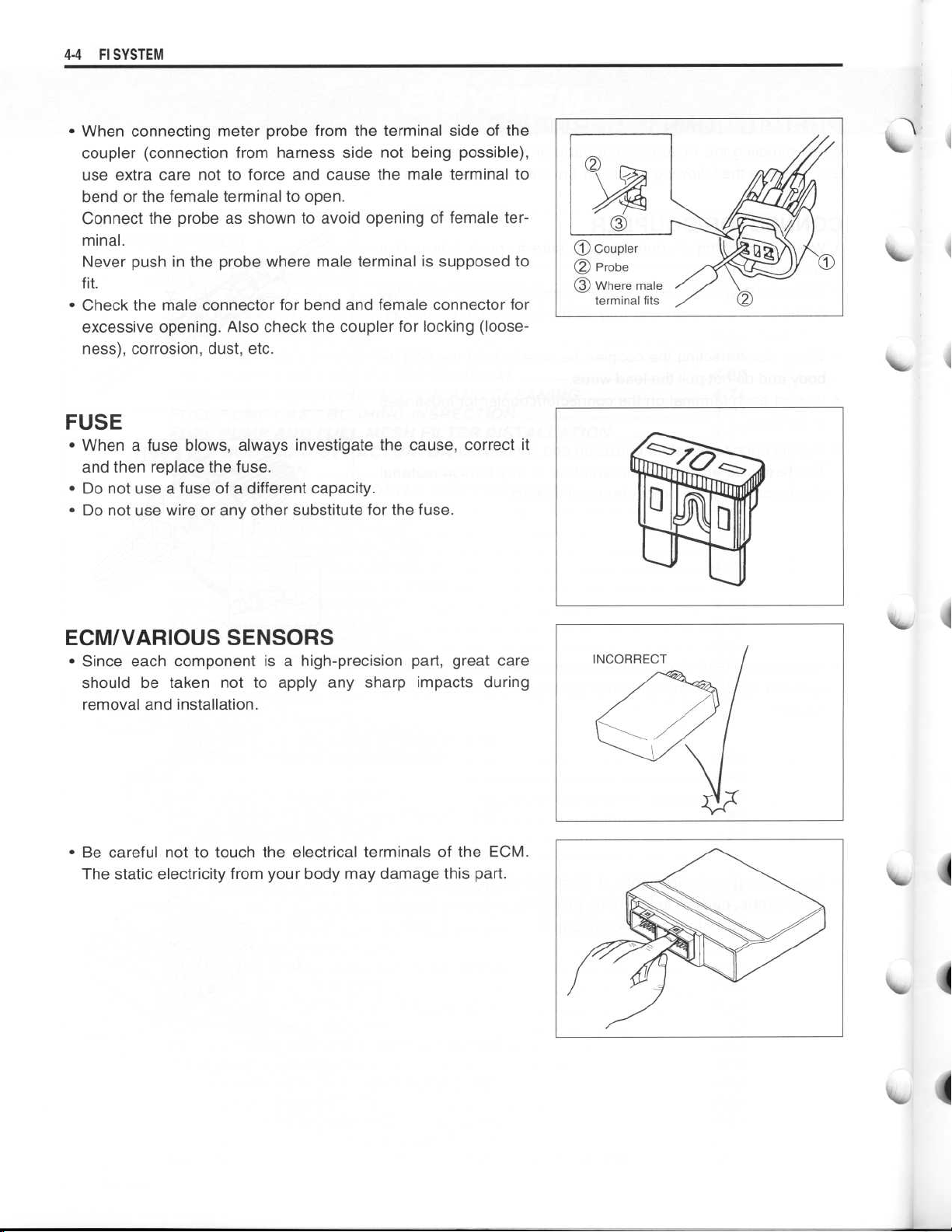

•

When connecting meter probe from the terminal side of the

coupler (connection from harness side not being possible),

use extra care not to force and cause the male terminal to

bend or the female terminal to open

Connect the probe as shown to avoid opening of female ter-

minal

.

Never push in the probe where male terminal is supposed to

.

fit

Check the male connector for bend and female connector for

•

excessive opening

ness), corrosion, dust, etc

. Also check the coupler for locking (loose-

.

.

FUSE

When a fuse blows, always investigate the cause, correct it

•

and then replace the fuse

Do not use a fuse of a different capacity

•

•

Do not use wire or any other substitute for the fuse

.

.

.

ECM/VARIOUS SENSORS

Since each component is a high-precision part, great care

•

should be taken not to apply any sharp impacts during

removal and installation

Be careful not to touch the electrical terminals of the ECM

•

The static electricity from your body may damage this part

.

.

.

I"

Page 5

~

FI SYSTEM4-5

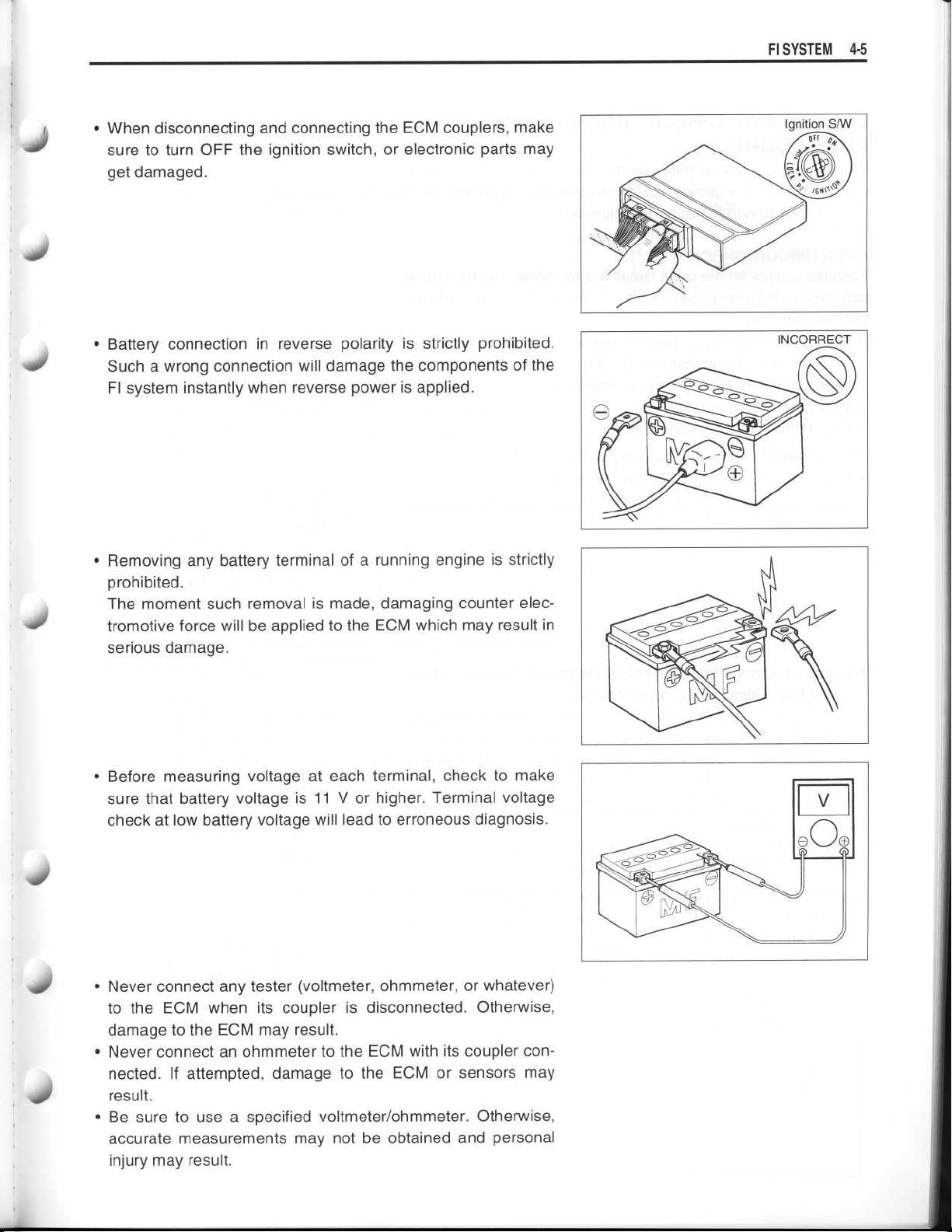

•

When disconnecting and connecting the ECM couplers, make

sure to turn OFF the ignition switch, or electronic parts may

get damaged

.

Battery connection in reverse polarity is strictly prohibited

•

Such a wrong connection will damage the components of the

FI system instantly when reverse power is applied

•

Removing any battery terminal of a running engine is strictly

prohibited

The moment such removal is made, damaging counter electromotive force will be applied to the ECM which may result in

serious damage

Before measuring voltage at each terminal, check to make

•

sure that battery voltage is 11 V or higher

check at low battery voltage will lead to erroneous diagnosis

.

.

. Terminal voltage

.

.

.

4

Never connect any tester (voltmeter, ohmmeter, or whatever)

•

to the ECM when its coupler is disconnected

damage to the ECM may result

Never connect an ohmmeter to the ECM with its coupler con-

•

nected

result

•

Be sure to use a specified voltmeter/ohmmeter

accurate measurements may not be obtained and personal

injury may result

. If attempted, damage to the ECM or sensors may

.

.

.

. Otherwise,

. Otherwise,

Page 6

~

~

~

~

~

~

~

4

-6 FI SYSTEM

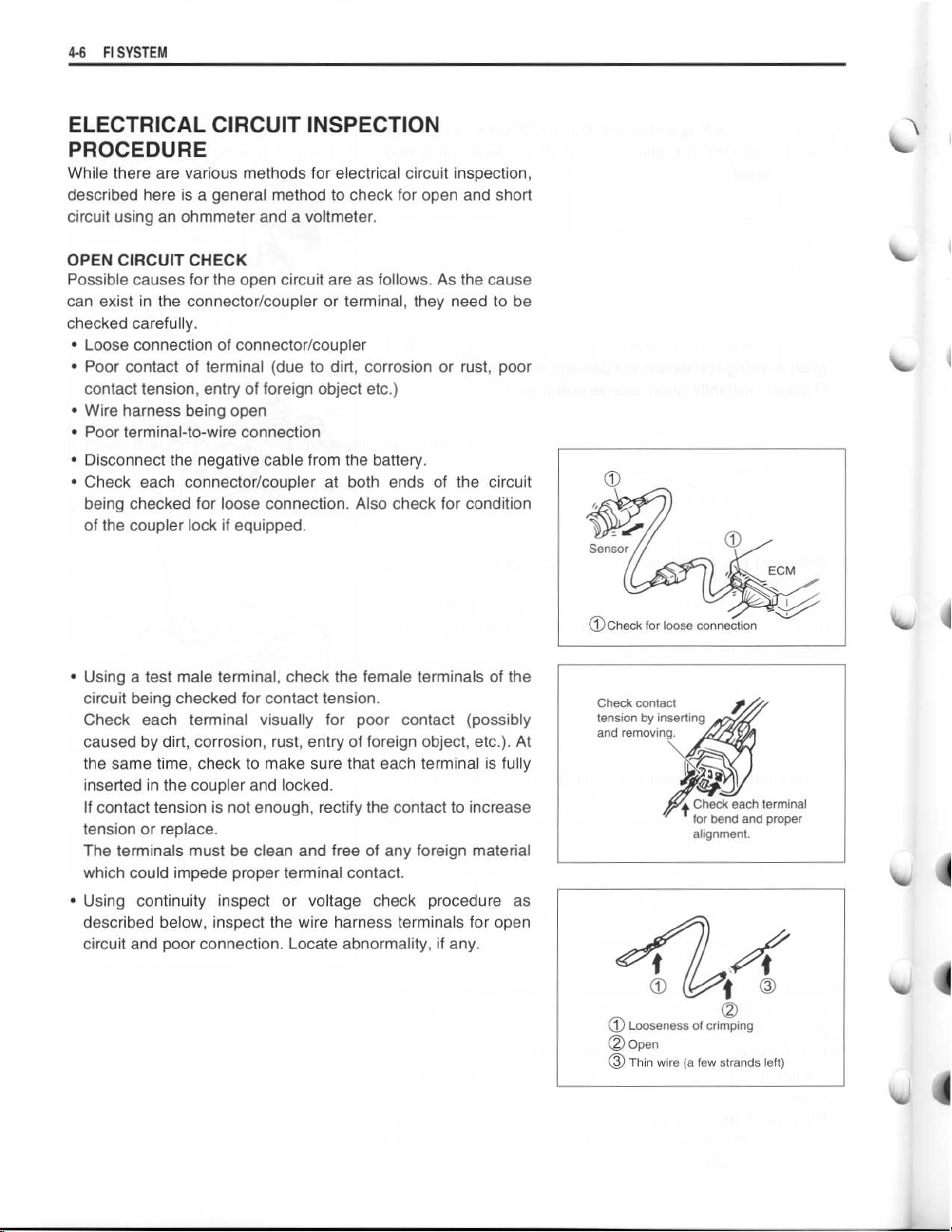

ELECTRICAL CIRCUIT INSPECTION

PROCEDURE

While there are various methods for electrical circuit inspection,

described here is a general method to check for open and short

circuit using an ohmmeter and a voltmeter

OPEN CIRCUIT CHECK

Possible causes for the open circuit are as follows

can exist in the connector/coupler or terminal, they need to be

checked carefully

•

Loose connection of connector/coupler

•

Poor contact of terminal (due to dirt, corrosion or rust, poor

contact tension, entry of foreign object etc

•

Wire harness being open

•

Poor terminal-to-wire connection

.

.

. As the cause

.)

•

Disconnect the negative cable from the battery

•

Check each connector/coupler at both ends of the circuit

being checked for loose connection

of the coupler lock if equipped

Using a test male terminal, check the female terminals of the

•

circuit being checked for contact tension

Check each terminal visually for poor contact (possibly

caused by dirt, corrosion, rust, entry of foreign object, etc

the same time, check to make sure that each terminal is fully

inserted in the coupler and locked

If contact tension is not enough, rectify the contact to increase

tension or replace

The terminals must be clean and free of any foreign material

which could impede proper terminal contact

Using continuity inspect or voltage check procedure as

•

described below, inspect the wire harness terminals for open

circuit and poor connection

.

. Locate abnormality, if any

. Also check for condition

.

.

.

.

.)

. At

.

.

Check contact

tension by inserting

and removing

.

441

t

Check each terminal

for bend and proper

alignment

.

Page 7

~

~

~

~

~

~

~

~

~

FI SYSTEM 4-7

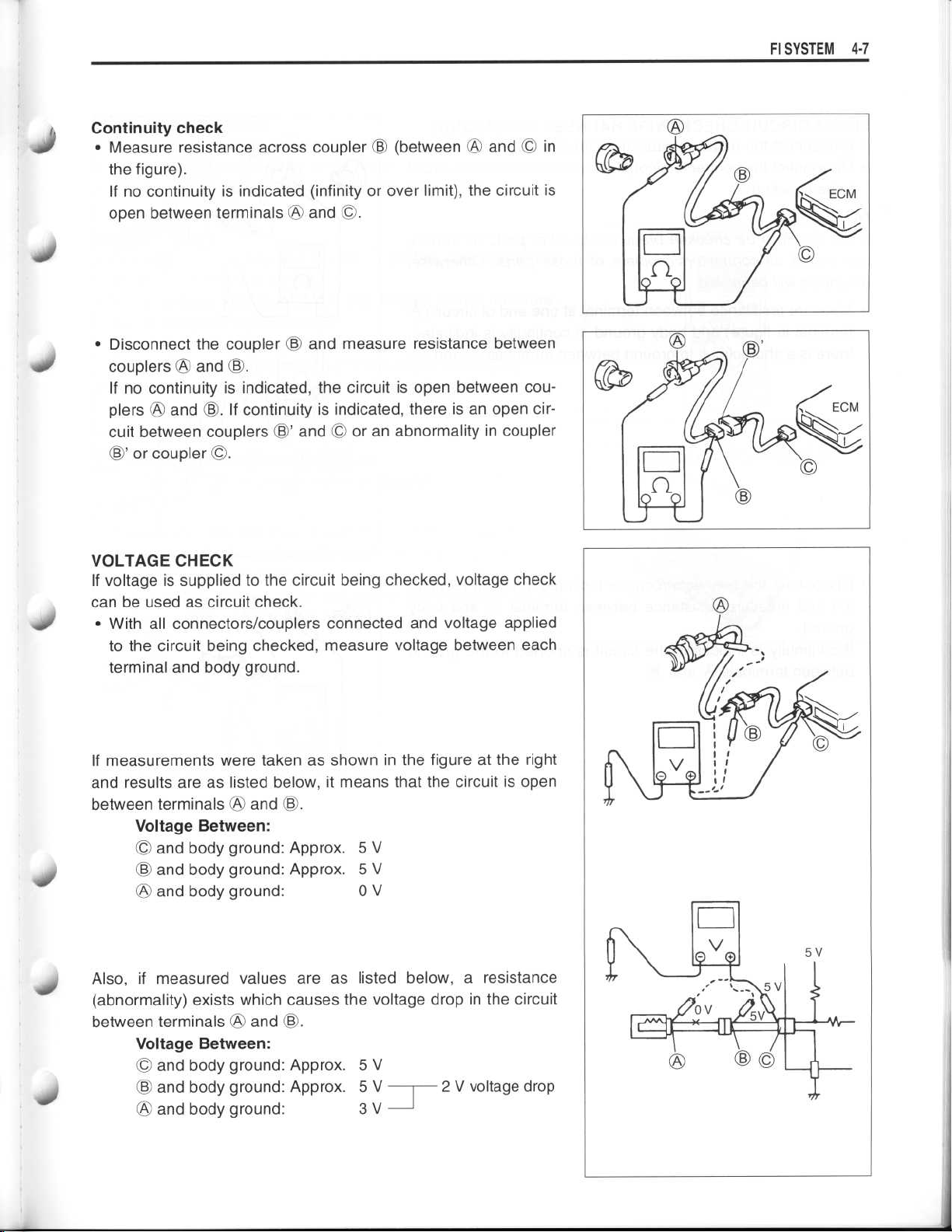

Continuity check

•

.-

S

Measure resistance across coupler © (between

the figure)

If no continuity is indicated (infinity or over limit), the circuit is

open between terminalsWOand ©

Disconnect the coupler © and measure resistance between

•

couplersWOand ©

If no continuity is indicated, the circuit is open between couplersWOand ©

cuit between couplers ©' and © or an abnormality in coupler

©' or coupler ©

.

.

.

. If continuity is indicated, there is an open cir-

.

and © in

WO

,,ill/

40

10

VOLTAGE CHECK

If voltage is supplied to the circuit being checked, voltage check

can be used as circuit check

•

With all connectors/couplers connected and voltage applied

to the circuit being checked, measure voltage between each

terminal and body ground

If measurements were taken as shown in the figure at the right

and results are as listed below, it means that the circuit is open

between terminals

Voltage Between

•

and body ground

•

and body ground

and body ground

•

Also, if measured values are as listed below, a resistance

(abnormality) exists which causes the voltage drop in the circuit

between terminalsWOand ©

Voltage Between

and body ground

•

•

and body ground

and body ground

•

WO

and ©

.

.

.

:

: Approx

: Approx

:

.

:

: Approx

: Approx

:

. 5 V

. 5 V

0 V

. 5 V

. 5 V

3 V

2 V voltage drop

Page 8

~

~

4-8 FI

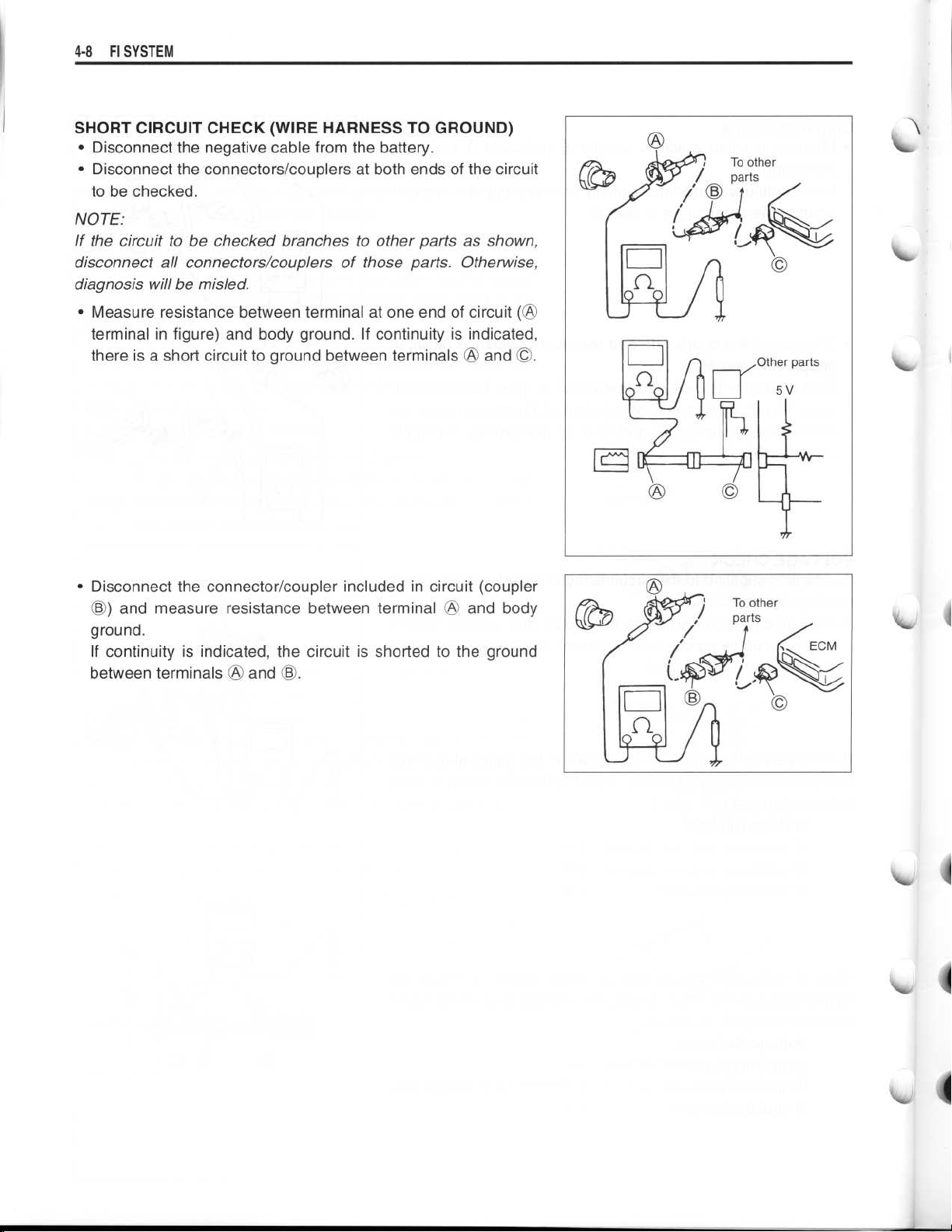

SHORT CIRCUIT CHECK (WIRE HARNESS TO GROUND)

NOTE

If the circuit to be checked branches to other parts as shown,

disconnect all connectors/couplers of those parts

diagnosis will be misled

SYSTEM

•

Disconnect the negative cable from the battery

•

Disconnect the connectors/couplers at both ends of the circuit

to be checked

:

•

Measure resistance between terminal at one end of circuit

terminal in figure) and body ground

there is a short circuit to ground between terminals

.

.

. If continuity is indicated,

.

. Otherwise,

and ©

OA

(A

.

•

Disconnect the connector/coupler included in circuit (coupler

©) and measure resistance between terminalOOand body

ground

If continuity is indicated, the circuit is shorted to the ground

between terminalsOand ©

.

.

Page 9

~

~

~

~

~

~

~

~

Fl SYSTEM 4-9

USING TESTERS

•

Use the Suzuki multi-circuit tester (09900-25008)

•

Use well-charged batteries in the tester

•

Be sure to set the tester to the correct testing range

Using the tester

•

Incorrectly connecting the (+ andOprobes may cause the

inside of the tester to burnout

•

If the voltage and current are not known, make measurements using the highest range

•

When measuring the resistance with the multi-circuit tester,

will be shown as 10

•

Check that no voltage is applied before making the measurement

. If voltage is applied, the tester may be damaged

•

After using the tester, turn the power off

.00 MS2 and "1" flashes in the display

.

.

.

.

.

.

.

.

40

40

Irs

09900-25008

09900-25009

NOTE

:

•

When connecting the multi-circuit tester, use a needle pointed

probe set to the back side of the lead wire coupler and connect

the probes of tester to them

* Use a needle pointed probe set to prevent the rubber of the

waterproof coupler from damage

: Multi-circuit tester

: Needle pointed probe set

.

.

q0

Page 10

~

4-10 FI SYSTEM

FI SYSTEM TECHNICAL FEATURES

INJECTION TIME (INJECTION VOLUME)

The factors to determine the injection time include the basic fuel injection time which is calculated on the

basis of the intake air pressure, engine speed and throttle opening angle, and various compensations

These compensations are determined according to the signals from various sensors that detect the engine

and driving conditions

.

.

-

Intake Air Pressure

Sensor (IAP Sensor)

~

Crankshaft Position

Sensor (CKP Sensor)

Throttle Position

Sensor (TP Sensor)

Various

Sensors

Injectors

Intake air pressure

signal

Engine speed

signal

Throttle opening

signal

Various signals

Injection signal

~

ECM

Basic

fuel

injection

time

Compensation

Ultimate

fuel

injection

time

- -

-t

44

Page 11

FI SYSTEM 4

.11

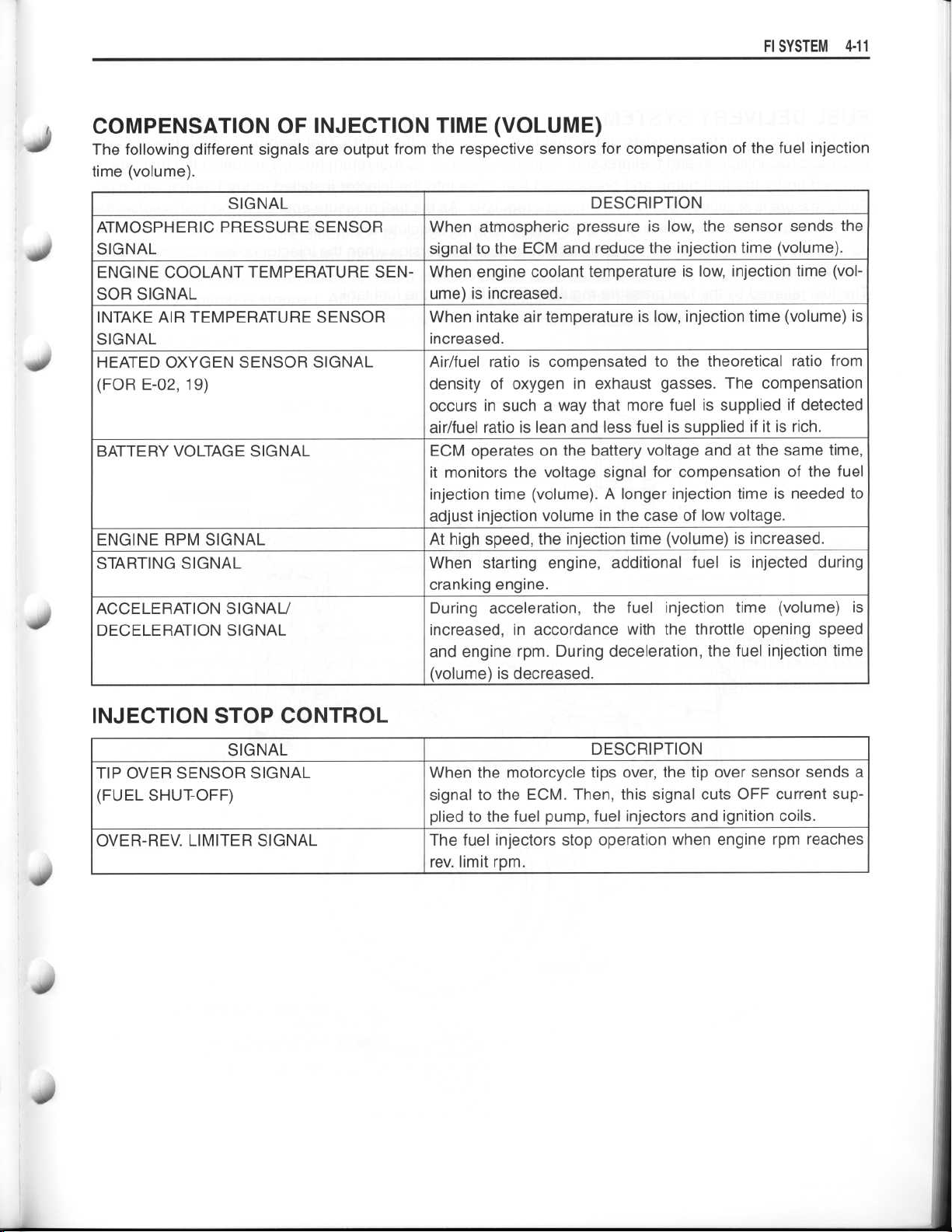

COMPENSATION OF INJECTION TIME (VOLUME)

The following different signals are output from the respective sensors for compensation of the fuel injection

time (volume)

.

S

S

SIGNAL

ATMOSPHERIC PRESSURE SENSOR

SIGNAL

ENGINE COOLANT TEMPERATURE SEW

SOR SIGNAL

INTAKE AIR TEMPERATURE SENSOR

SIGNAL

HEATED OXYGEN SENSOR SIGNAL

(FOR E-02,19)

BATTERY VOLTAGE SIGNAL

ENGINE RPM SIGNAL

STARTING SIGNAL

ACCELERATION SIGNAL/

DECELERATION SIGNAL

DESCRIPTION

When atmospheric pressure is low, the sensor sends the

signal to the ECM and reduce the injection time (volume)

When engine coolant temperature is low, injection time (volume) is increased

When intake air temperature is low, injection time (volume) is

increased

Air/fuel ratio is compensated to the theoretical ratio from

density of oxygen in exhaust gasses

occurs in such a way that more fuel is supplied if detected

air/fuel ratio is lean and less fuel is supplied if it is rich

ECM operates on the battery voltage and at the same time,

it monitors the voltage signal for compensation of the fuel

injection time (volume)

adjust injection volume in the case of low voltage

At high speed, the injection time (volume) is increased

When starting engine, additional fuel is injected during

cranking engine

During acceleration, the fuel injection time (volume) is

increased, in accordance with the throttle opening speed

and engine rpm

(volume) is decreased

.

.

. The compensation

. A longer injection time is needed to

.

.

. During deceleration, the fuel injection time

.

.

.

.

INJECTION STOP CONTROL

SIGNAL

TIP OVER SENSOR SIGNAL

(FUEL SHUT-OFF)

OVER-REV

. LIMITER SIGNAL

DESCRIPTION

When the motorcycle tips over, the tip over sensor sends a

signal to the ECM

plied to the fuel pump, fuel injectors and ignition coils

The fuel injectors stop operation when engine rpm reaches

. limit rpm

rev

. Then, this signal cuts OFF current sup-

.

.

Page 12

4

-12 Fl SYSTEM

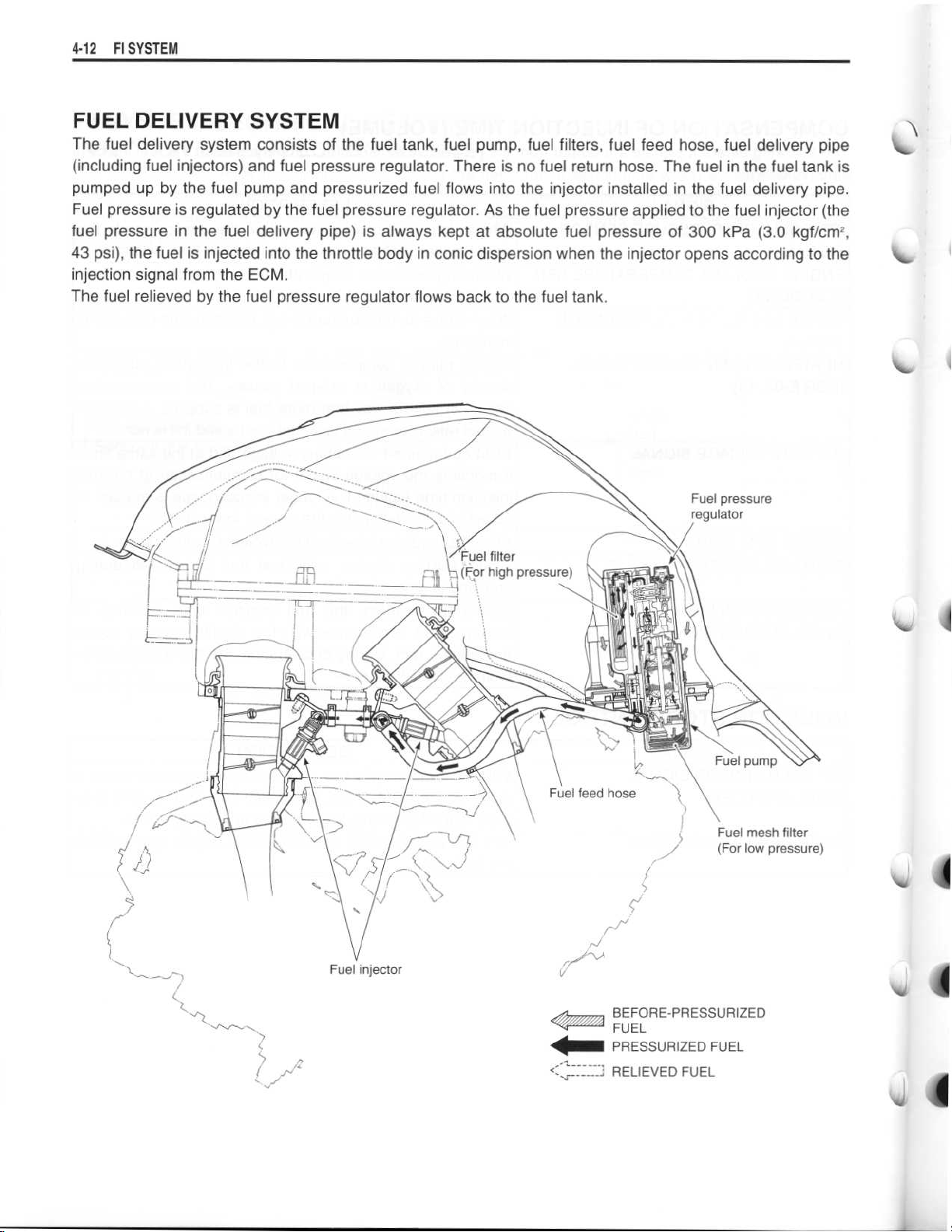

FUEL DELIVERY SYSTEM

The fuel delivery system consists of the fuel tank, fuel pump, fuel filters, fuel feed hose, fuel delivery pipe

(including fuel injectors) and fuel pressure regulator . There is no fuel return hose

pumped up by the fuel pump and pressurized fuel flows into the injector installed in the fuel delivery pipe

Fuel pressure is regulated by the fuel pressure regulator

. As the fuel pressure applied to the fuel injector (the

fuel pressure in the fuel delivery pipe) is always kept at absolute fuel pressure of 300 kPa (3

43 psi), the fuel is injected into the throttle body in conic dispersion when the injector opens according to the

injection signal from the ECM

The fuel relieved by the fuel pressure regulator flows back to the fuel tank

.

.

. The fuel in the fuel tank is

.

.0 kgf/cm2,

Fuel pressure

regulator

Fuel injector

BEFORE-PRESSURIZED

FUEL

PRESSURIZED FUEL

__~RELIEVED FUEL

Page 13

~

Fl SYSTEM 4

.13

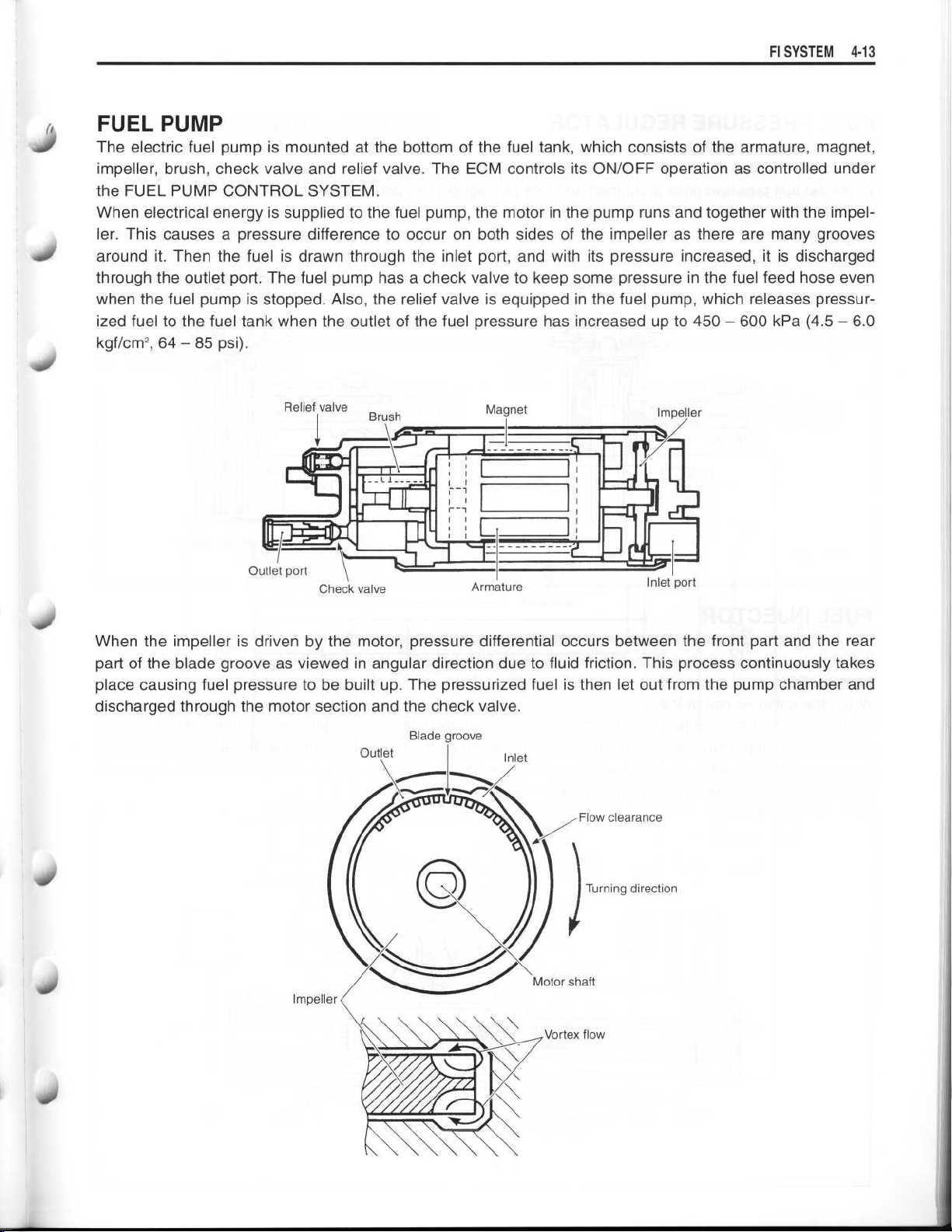

FUEL PUMP

The electric fuel pump is mounted at the bottom of the fuel tank, which consists of the armature, magnet,

impeller, brush, check valve and relief valve

the FUEL PUMP CONTROL SYSTEM

When electrical energy is supplied to the fuel pump, the motor in the pump runs and together with the impeller

. This causes a pressure difference to occur on both sides of the impeller as there are many grooves

around it

through the outlet port

when the fuel pump is stopped

. Then the fuel is drawn through the inlet port, and with its pressure increased, it is discharged

. The fuel pump has a check valve to keep some pressure in the fuel feed hose even

. Also, the relief valve is equipped in the fuel pump, which releases pressurized fuel to the fuel tank when the outlet of the fuel pressure has increased up to 450

kgf/cm2,

64

- 85 psi)

.

Relief valve

'∎

Brush

. The ECM controls its ON/OFF operation as controlled under

.

-

600 kPa (4.5-6.0

Magnet

I

Impeller

S

1

-71-

W1101

Check valve

When the impeller is driven by the motor, pressure differential occurs between the front part and the rear

part of the blade groove as viewed in angular direction due to fluid friction

place causing fuel pressure to be built up

discharged through the motor section and the check valve

. The pressurized fuel is then let out from the pump chamber and

Blade groove

Outlet

L_

Armature

Inlet

Inlet port

. This process continuously takes

.

40

Page 14

~

4-14 FI SYSTEM

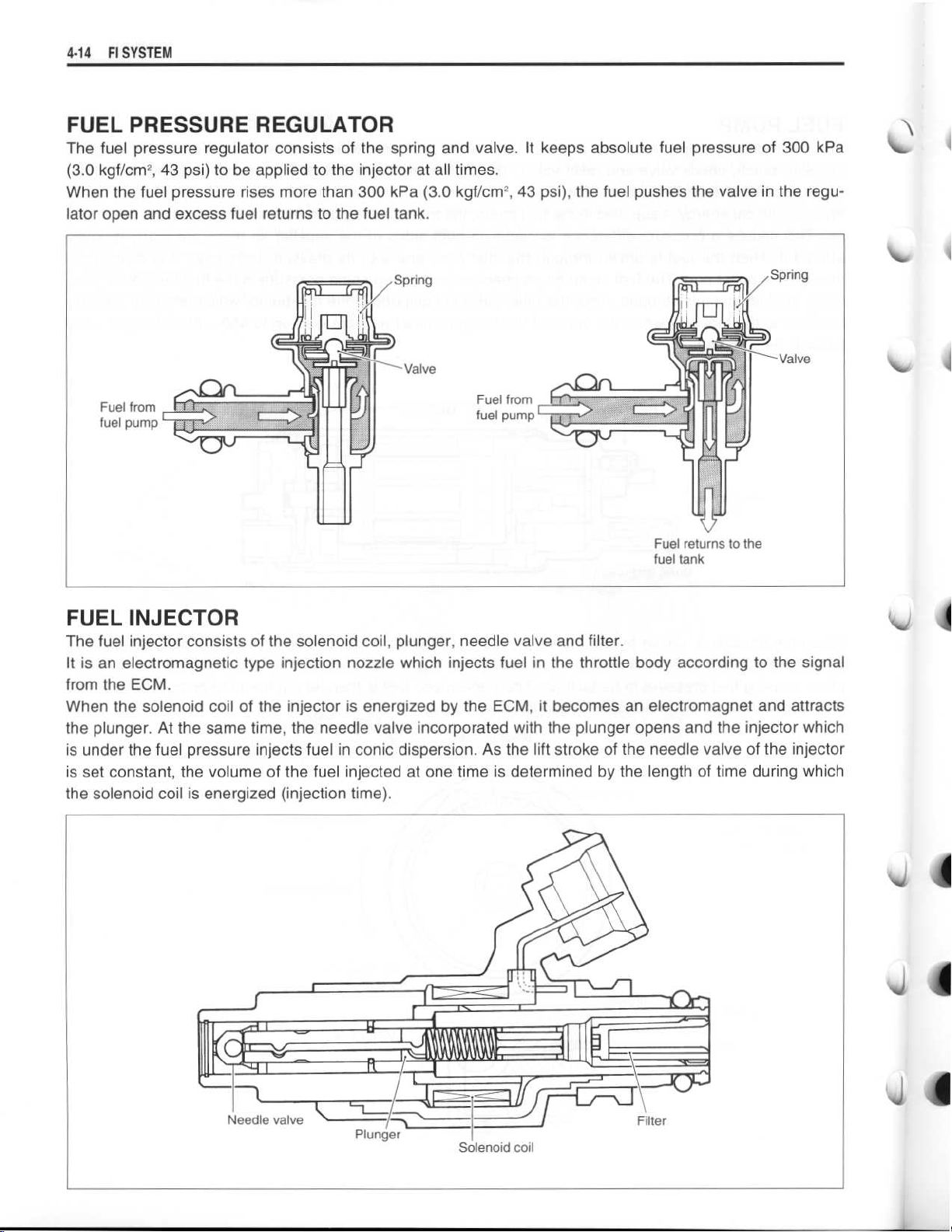

FUEL PRESSURE REGULATOR

The fuel pressure regulator consists of the spring and valve

(3

.0 kgf/cm2, 43 psi) to be applied to the injector at all times

When the fuel pressure rises more than 300 kPa (3

lator open and excess fuel returns to the fuel tank

.0 kgf/cm2,

.

. It keeps absolute fuel pressure of 300 kPa

.

43 psi), the fuel pushes the valve in the regu-

FUEL INJECTOR

The fuel injector consists of the solenoid coil, plunger, needle valve and filter

It is an electromagnetic type injection nozzle which injects fuel in the throttle body according to the signal

from the ECM

.

When the solenoid coil of the injector is energized by the ECM, it becomes an electromagnet and attracts

the plunger

is under the fuel pressure injects fuel in conic dispersion

. At the same time, the needle valve incorporated with the plunger opens and the injector which

. As the lift stroke of the needle valve of the injector

is set constant, the volume of the fuel injected at one time is determined by the length of time during which

the solenoid coil is energized (injection time)

.

.

u

10,

IV

1~

~

Needle valve

~

Plunger

1111110-

Filter

Solenoid coil

Page 15

~

~

~

~

~

Fl SYSTEM4-15

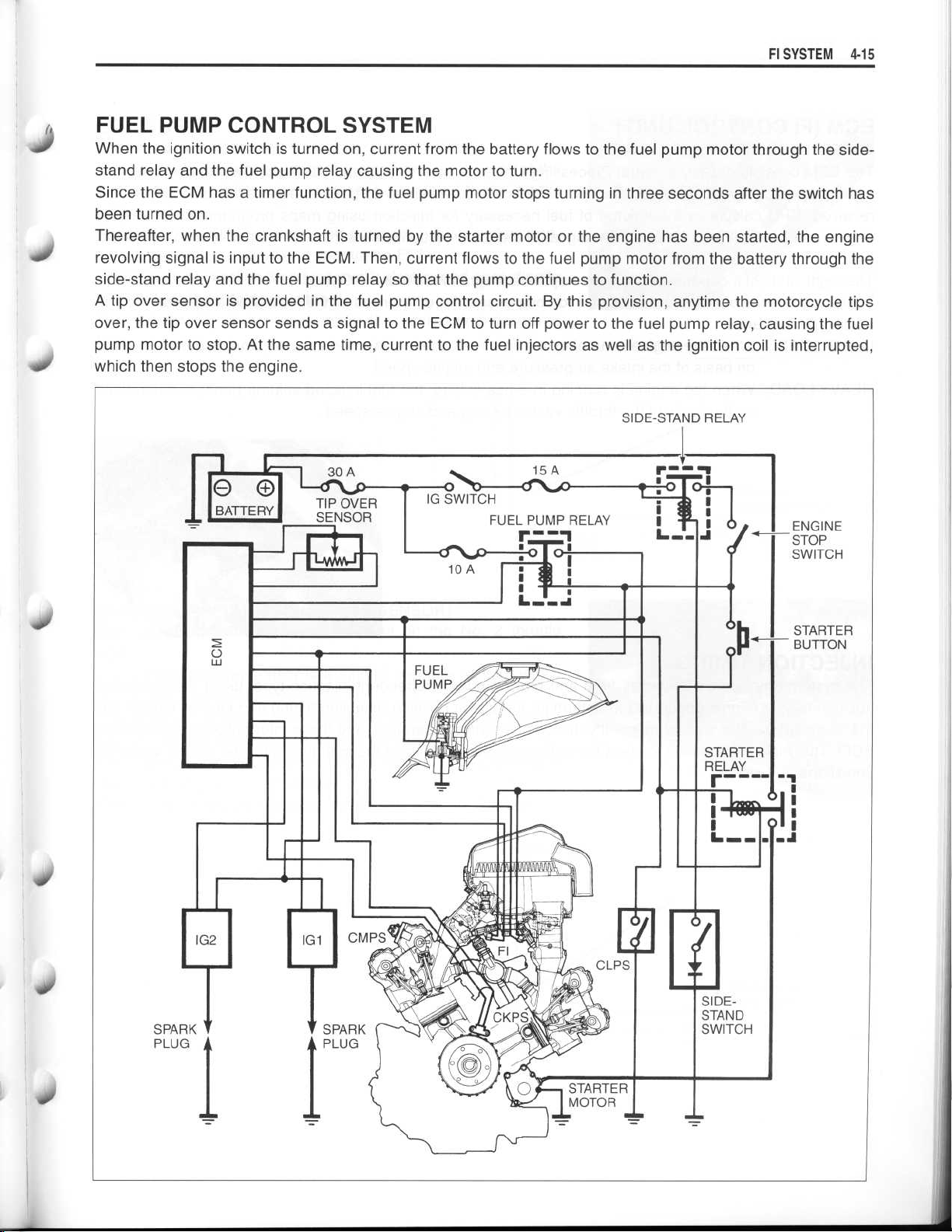

FUEL PUMP CONTROL SYSTEM

When the ignition switch is turned on, current from the battery flows to the fuel pump motor through the sidestand relay and the fuel pump relay causing the motor to turn

Since the ECM has a timer function, the fuel pump motor stops turning in three seconds after the switch has

been turned on

.

Thereafter, when the crankshaft is turned by the starter motor or the engine has been started, the engine

revolving signal is input to the ECM

. Then, current flows to the fuel pump motor from the battery through the

side-stand relay and the fuel pump relay so that the pump continues to function

A tip over sensor is provided in the fuel pump control circuit . By this provision, anytime the motorcycle tips

over, the tip over sensor sends a signal to the ECM to turn off power to the fuel pump relay, causing the fuel

pump motor to stop

which then stops the engine

. At the same time, current to the fuel injectors as well as the ignition coil is interrupted,

.

.

.

SIDE-STAND RELAY

O O

BATTERY

30A

TIP OVER

SENSOR

15A

IG SWITCH

FUEL PUMP RELAY

to

Page 16

4-16 FI SYSTEM

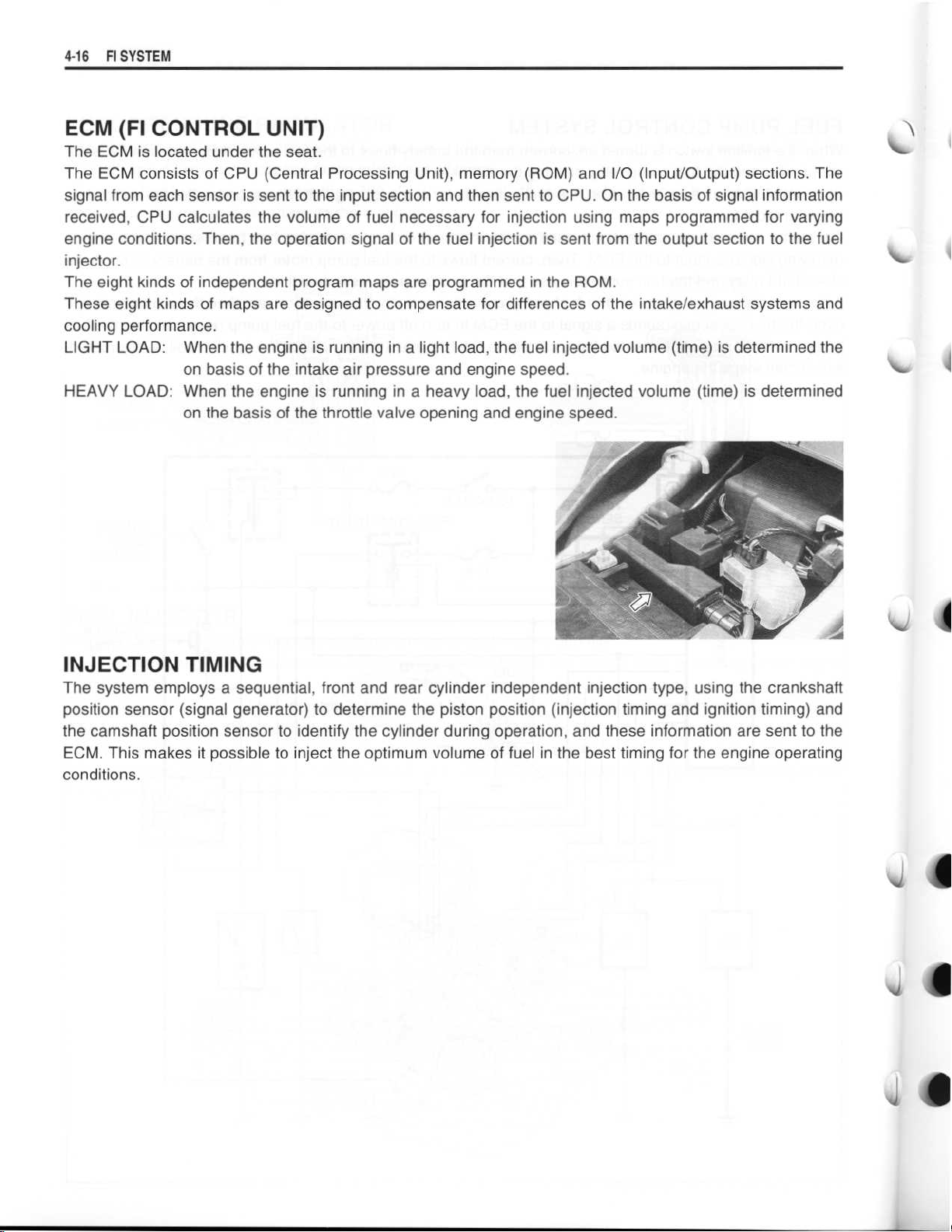

ECM (FI CONTROL UNIT)

The ECM is located under the seat

The ECM consists of CPU (Central Processing Unit), memory (ROM) and I/O (Input/Output) sections

signal from each sensor is sent to the input section and then sent to CPU

received, CPU calculates the volume of fuel necessary for injection using maps programmed for varying

engine conditions

injector

The eight kinds of independent program maps are programmed in the ROM

These eight kinds of maps are designed to compensate for differences of the intake/exhaust systems and

cooling performance

LIGHT LOAD:When the engine is running in a light load, the fuel injected volume (time) is determined the

HEAVY LOAD

.

. Then, the operation signal of the fuel injection is sent from the output section to the fuel

.

on basis of the intake air pressure and engine speed

: When the engine is running in a heavy load, the fuel injected volume (time) is determined

on the basis of the throttle valve opening and engine speed

.

. The

. On the basis of signal information

.

.

.

INJECTION TIMING

The system employs a sequential, front and rear cylinder independent injection type, using the crankshaft

position sensor (signal generator) to determine the piston position (injection timing and ignition timing) and

the camshaft position sensor to identify the cylinder during operation, and these information are sent to the

ECM

. This makes it possible to inject the optimum volume of fuel in the best timing for the engine operating

conditions

.

J

is

Page 17

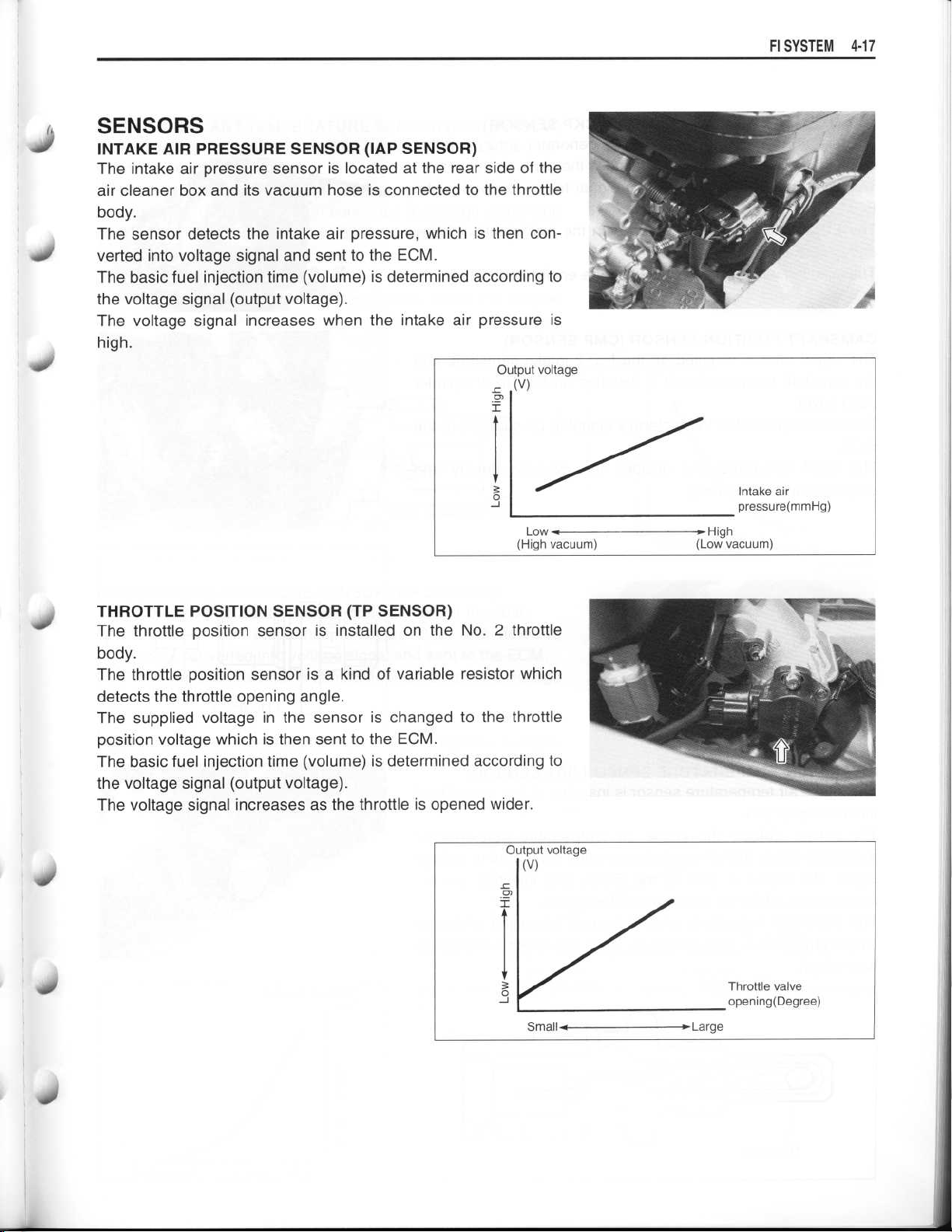

SENSORS

INTAKE AIR PRESSURE SENSOR (IAP SENSOR)

The intake air pressure sensor is located at the rear side of the

air cleaner box and its vacuum hose is connected to the throttle

body

.

The sensor detects the intake air pressure, which is then converted into voltage signal and sent to the ECM

The basic fuel injection time (volume) is determined according to

the voltage signal (output voltage)

The voltage signal increases when the intake air pressure is

high

.

.

.

FI SYSTEM 4-17

THROTTLE POSITION SENSOR (TP SENSOR)

The throttle position sensor is installed on the No

body

.

The throttle position sensor is a kind of variable resistor which

detects the throttle opening angle

The supplied voltage in the sensor is changed to the throttle

position voltage which is then sent to the ECM

The basic fuel injection time (volume) is determined according to

the voltage signal (output voltage)

The voltage signal increases as the throttle is opened wider

.

.

.

. 2 throttle

.

Page 18

4-18

FI SYSTEM

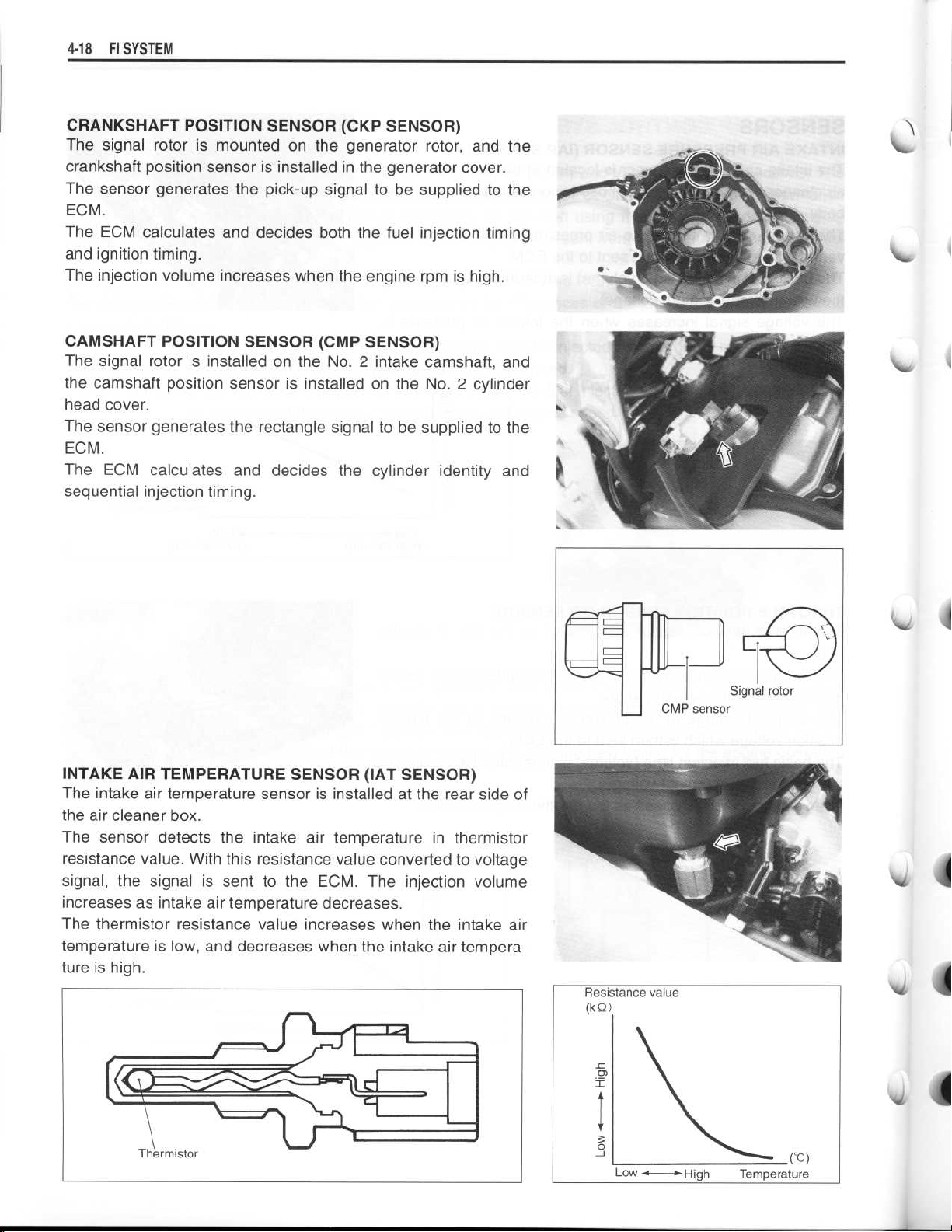

CRANKSHAFT POSITION SENSOR (CKP SENSOR)

The signal rotor is mounted on the generator rotor, and the

crankshaft position sensor is installed in the generator cover

.

The sensor generates the pick-up signal to be supplied to the

ECM

.

The ECM calculates and decides both the fuel injection timing

and ignition timing

The injection volume increases when the engine rpm is high

.

.

CAMSHAFT POSITION SENSOR (CMP SENSOR)

The signal rotor is installed on the No

the camshaft position sensor is installed on the No

head cover

.

. 2 intake camshaft, and

. 2 cylinder

The sensor generates the rectangle signal to be supplied to the

ECM

.

The ECM calculates and decides the cylinder identity and

sequential injection timing

.

CMP sensor

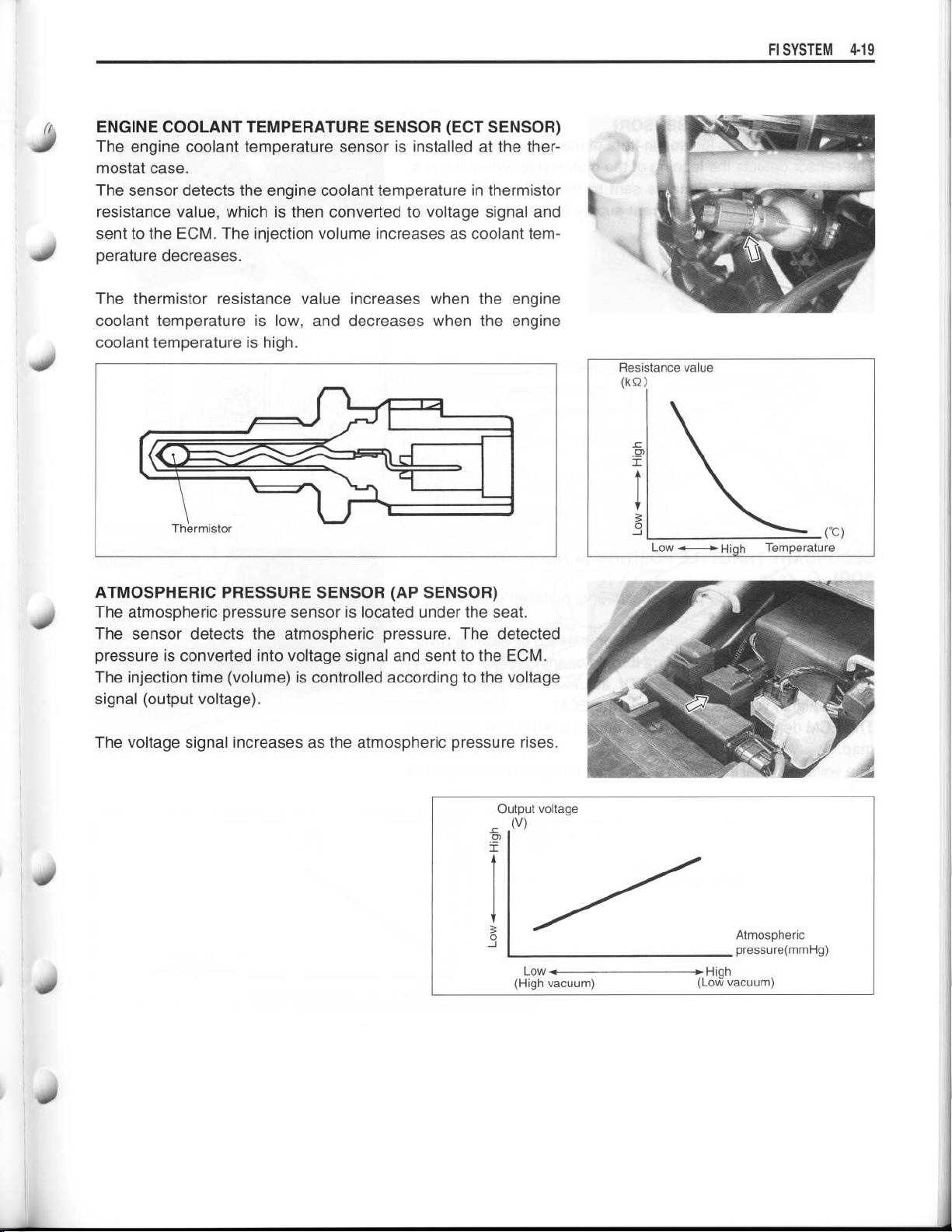

INTAKE AIR TEMPERATURE SENSOR (IAT SENSOR)

The intake air temperature sensor is installed at the rear side of

the air cleaner box

.

The sensor detects the intake air temperature in thermistor

resistance value

signal, the signal is sent to the ECM

increases as intake air temperature decreases

. With this resistance value converted to voltage

. The injection volume

.

The thermistor resistance value increases when the intake air

temperature is low, and decreases when the intake air tempera-

ture is high

.

10

~

1

Signal rotor

Thermistor

Page 19

FI SYSTEM 4-19

(I

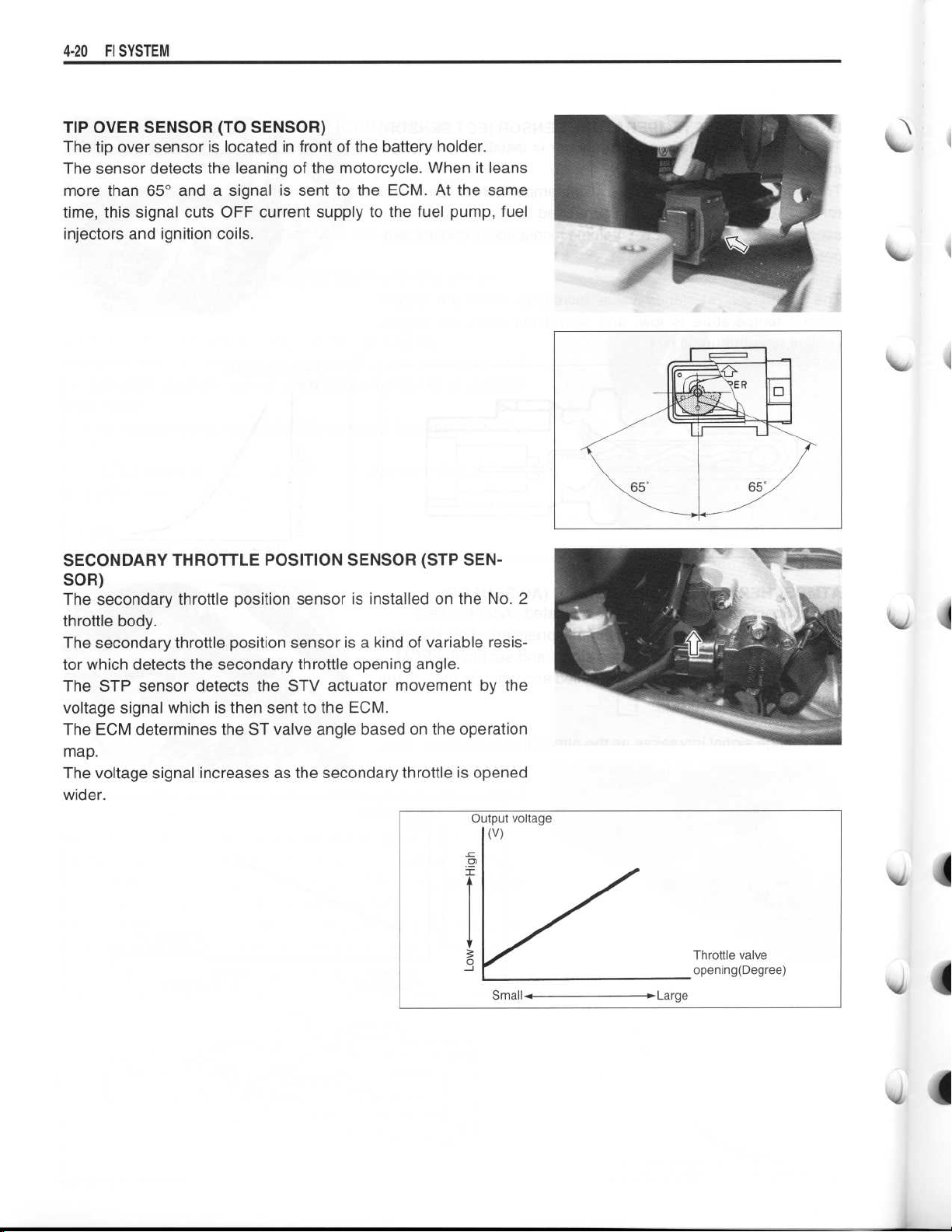

ENGINE COOLANT TEMPERATURE SENSOR (ECT SENSOR)

The engine coolant temperature sensor is installed at the ther-

mostat case

.

The sensor detects the engine coolant temperature in thermistor

resistance value, which is then converted to voltage signal and

sent to the ECM

perature decreases

. The injection volume increases as coolant tem-

.

The thermistor resistance value increases when the engine

coolant temperature is low, and decreases when the engine

coolant temperature is high

Thermistor

.

10

ATMOSPHERIC PRESSURE SENSOR (AP SENSOR)

The atmospheric pressure sensor is located under the seat

The sensor detects the atmospheric pressure

. The detected

pressure is converted into voltage signal and sent to the ECM

.

.

The injection time (volume) is controlled according to the voltage

signal (output voltage)

The voltage signal increases as the atmospheric pressure rises

.

.

Page 20

4-20 Fl

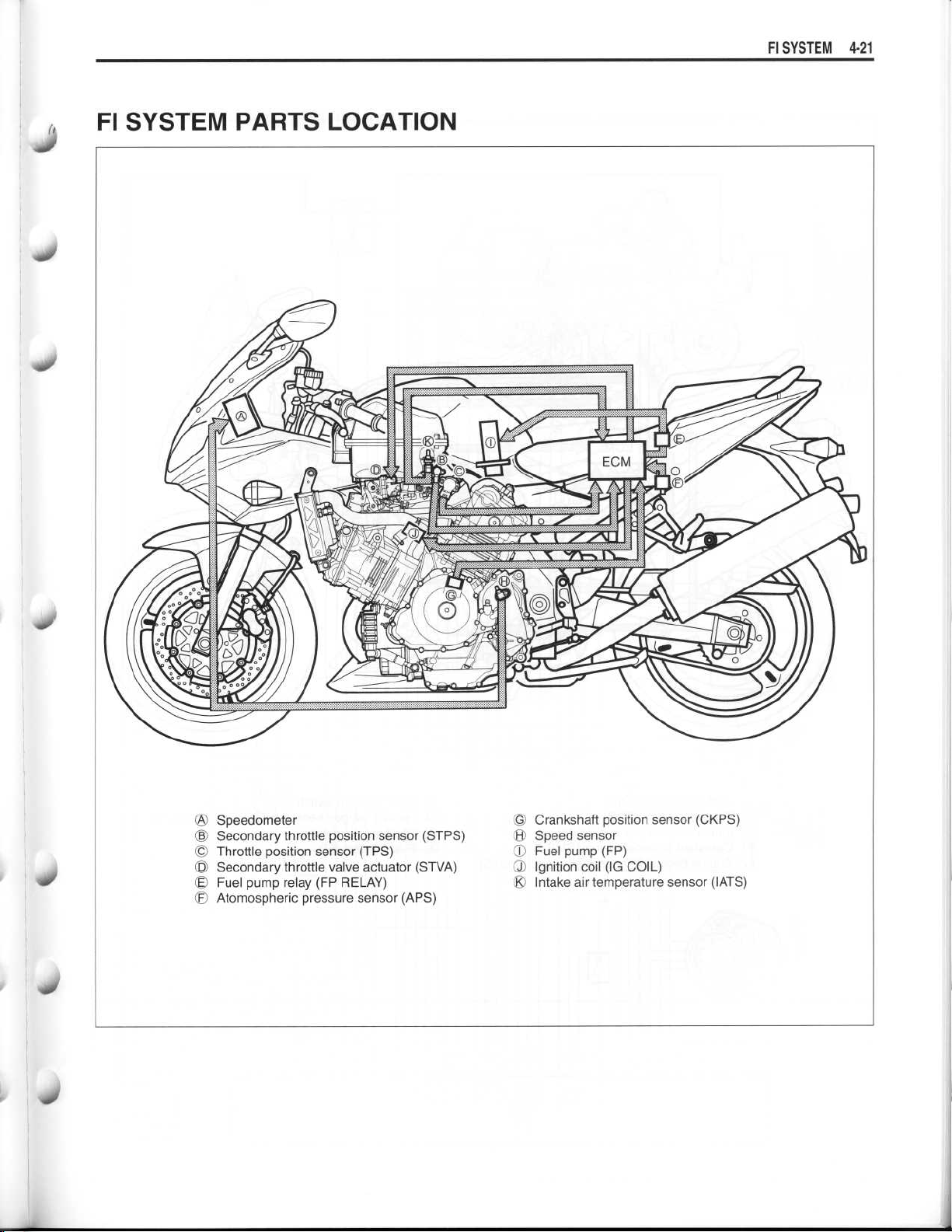

TIP OVER SENSOR (TO SENSOR)

The tip over sensor is located in front of the battery holder

The sensor detects the leaning of the motorcycle

more than 65° and a signal is sent to the ECM . At the same

time, this signal cuts OFF current supply to the fuel pump, fuel

injectors and ignition coils

SYSTEM

.

. When it leans

.

NNW

SECONDARY THROTTLE POSITION SENSOR (STP SENSOR)

The secondary throttle position sensor is installed on the No

throttle body

The secondary throttle position sensor is a kind of variable resistor which detects the secondary throttle opening angle

The STP sensor detects the STV actuator movement by the

voltage signal which is then sent to the ECM

The ECM determines the ST valve angle based on the operation

map

.

The voltage signal increases as the secondary throttle is opened

wider

.

.

.

.

. 2

4

Page 21

FI SYSTEM 4-

2

1

0

.r

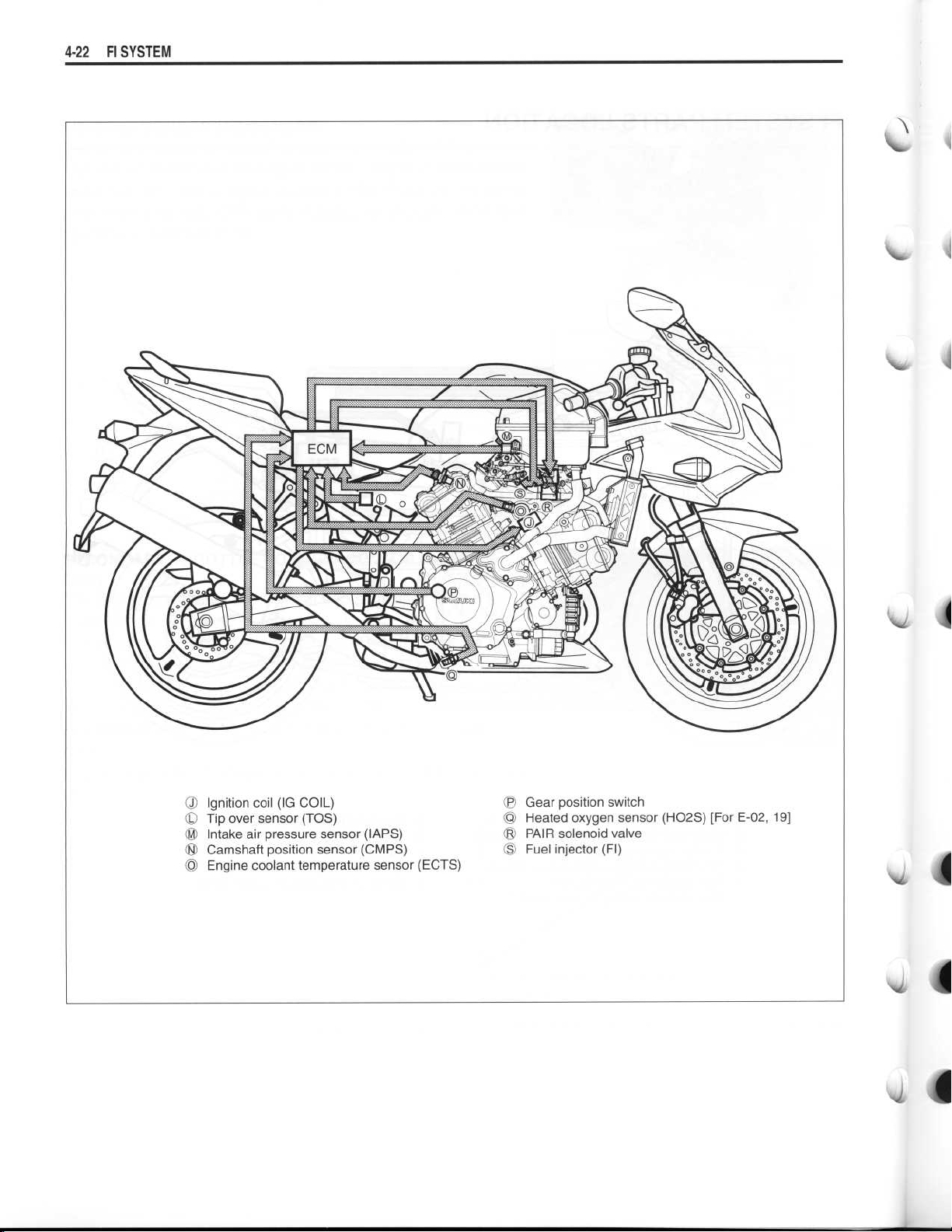

FI SYSTEM PARTS LOCATION

Speedometer

OA

©

Secondary throttle position sensor (STPS)®Speed sensor

Throttle position sensor (TPS)

©

Secondary throttle valve actuator (STVA)©Ignition coil (IG COIL)

©

©OFFuel pump relay (FP RELAY)

Atmospheric pressure sensor (APS)

©

Crankshaft position sensor (CKPS)

Fuel pump (FP)

O

®

Intake air temperature sensor (IATS)

Page 22

~

~

~

~

~

4-22

FI SYSTEM

Ignition coil (IG COIL)

•

•

Tip over sensor (TOS)

Intake air pressure sensor (ZAPS)

•

•

Camshaft position sensor (CMPS)

•

Engine coolant temperature sensor (ECTS)

® Gear position switch

® Heated oxygen sensor (HO2S) [For E-02, 19]

® PAIR solenoid valve

Fuel injector (FI)

OO

Page 23

~

~

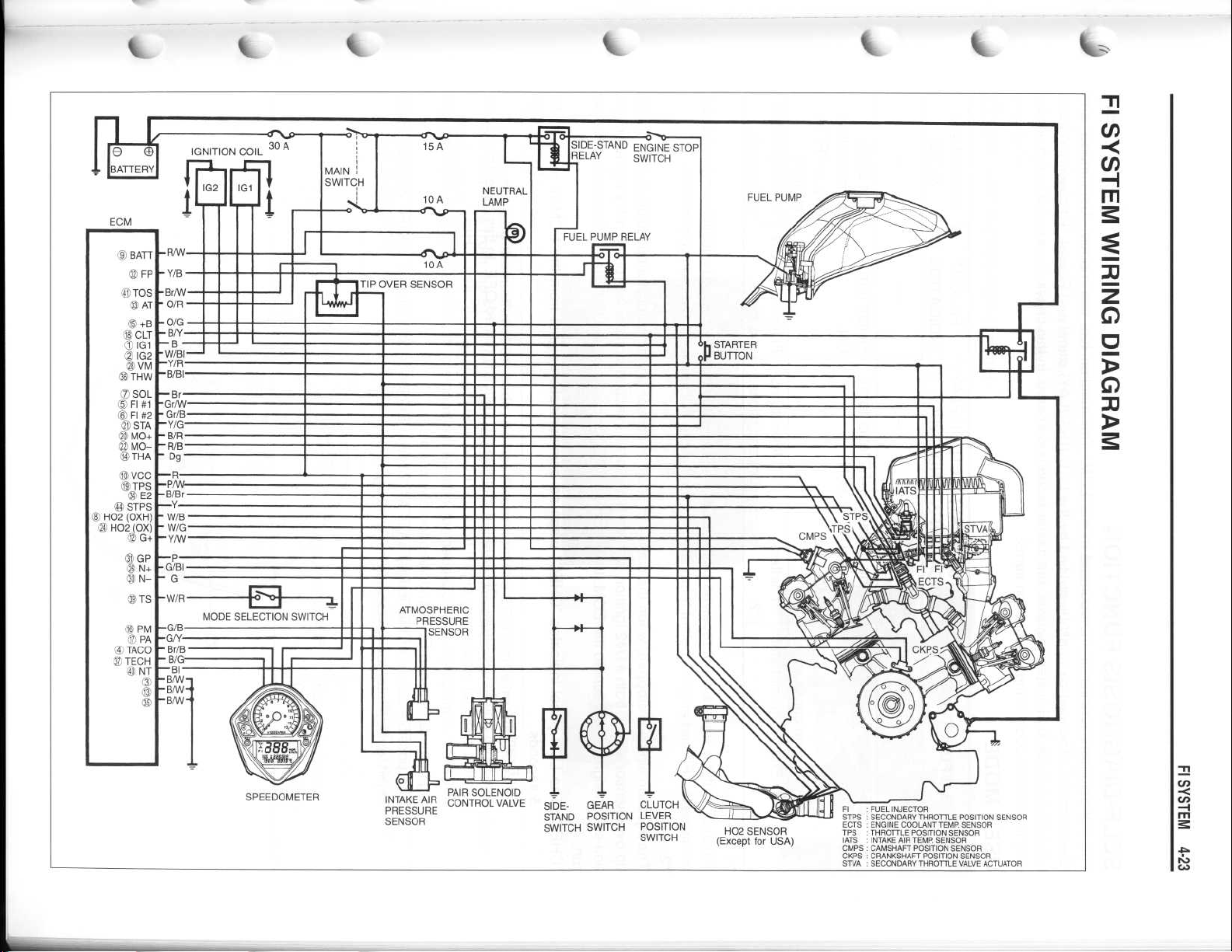

SIDE-STAND ENGINE STOP

_RELAY

SWITCH

ECM

4-

C

H02 (OXH)

C

H02 (OX)

4

© TECH

BATT

OO

2

,

FP

TOS

© AT

'f$ +B

CLT

G1

1

0

G2

VM

THW

SOL

5 FI #1

CFI#2

© STA

3

MO+

© MO-

94 THA

VCC

v TPS

E2

STPS

G+

GP

N+

N-

T S

1e` PM

,It PA

TACO

4© NT

C

C13

©

-

Br

-Gr/W

- Gr/B

-

Y/G

-

B/R

-

R/B

Dg

-R

-P/W

-B/Br

-Y

-

W/B

- W/G

-

Y/W

MODE SELECTION SWITCH

1

IG1

1

10A

TIP OVER SENSOR

ATMOSPHERIC

PRESSURE

SENSOR

NEUTRAL

LAMP

FUEL PUMP RELAY

IL

O

h

STARTER

Y BUTTON

FUEL PUMP

CMPS

TPS

STPS

7

FI

FI

ECTS

.

y

SPEEDOMETER

0

INTAKE AIR

INTAKE

PRESSURE

SENSOR

PAIR SOLENOID

CONTROL VALVE

GEAR

SIDE-

POSITION LEVER

STAND

SWITCH SWITCH

CLUTCH

POSITION

SWITCH

H02SENSOR

(Except for USA)

FI~FUEL INJECTOR

STPS SECONDARY THROTTLE POSITION SENSOR

ECTS ENGINE COOLANT TEMP

TPS

THROTTLE POSITION SENSOR

IATS

INTAKE AIR TEMP SENSOR

CMPS CAMSHAFT POSITION SENSOR

CKPS CRANKSHAFT POSITION SENSOR

STVA

SECONDARY THROTTLE VALVE ACTUATOR

. SENSOR

Page 24

4-24 FI SYSTEM

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function is incorporated in the ECM

"Dealer mode"

. The user can only be notified by the LCD (DISPLAY) panel and FI light

tion of the individual FI system devices, the dealer mode is prepared

sary to read the code of the malfunction items

USER MODE

.

. The function has two modes, "User mode" and

. In this check, the special tool is neces-

. To check the func-

MALFUNCTION

"NO"

"YES"

LCD (DISPLAY)

INDICATION

Engine coolant

temp

.

Engine coolant

temp

. and "Fl"

letters

Engine can start

*

.

1

Engine can not start."Fl" letters*2"Fl" letter turns

*

1

When one of the signals is not received by the ECM, the fail-safe circuit works and injection is not stopped

In this case, "Fl" and engine coolant temp

. are indicated in the LCD panel and motorcycle can run

LCD (DISPLAY)

DA

INDICATION ©

"Fl" letter turns

ON

.

ON and blinks

FI LIGHT

INDICATION

FI light turns

ON

.

FI light turns ON

.

and blinks

.

INDICATION

CC

;

MODE

Each 2 sec

.

Engine coolant

temp

. or "Fl" is

indicated

.

"Fl" is indicated

continuously

.

.

.

*2

The injection signal is stopped, when the camshaft position sensor signal, crankshaft position sensor signal,

tip over sensor signal, both #1/#2 ignition signals, both #1/#2 injection signals, fuel pump relay signal or ignition switch signal is not sent to the ECM

.

run

"CHEC"

: The LCD panel indicates "CHEC" when no communication signal from the ECM is received for

5 seconds

For Example

.

:

The ignition switch is turned ON, and the engine stop switch is turned OFF

ometer does not receive any signal from the ECM, and the panel indicates "CHEC"

If "CHEC" is indicated, the LCD does not indicate the trouble code

ing harness between ECM and speedometer couplers

The possible cause of this indication is as follows

stand/ignition inter-lock system is not working

. In this case, "Fl" is indicated in the LCD panel

. Motorcycle does not

. In this case, the speed-

.

. It is necessary to check the wir-

.

; Engine stop switch is in OFF position

. Ignition fuse is burnt

.

. Side-

N

Page 25

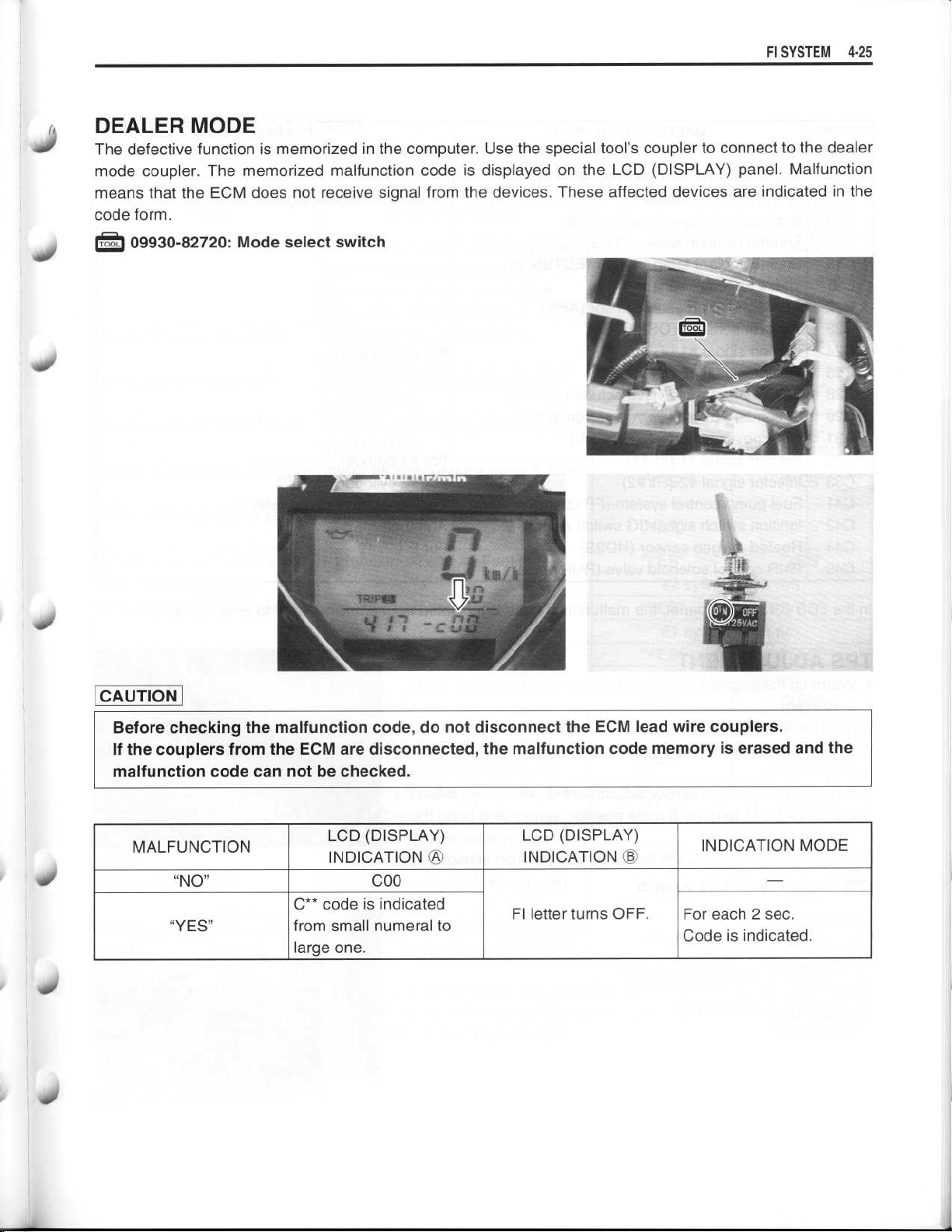

DEALER MODE

The defective function is memorized in the computer

mode coupler

means that the ECM does not receive signal from the devices

code form

.

•

09930-82720

. The memorized malfunction code is displayed on the LCD (DISPLAY) panel

.

: Mode select switch

. Use the special tool's coupler to connect to the dealer

. These affected devices are indicated in the

FI SYSTEM4-25

. Malfunction

40

CAUTION

Before checking the malfunction code, do not disconnect the ECM lead wire couplers

If the couplers from the ECM are disconnected, the malfunction code memory is erased and the

malfunction code can not be checked

MALFUNCTION

"NO"

"YES"

LCD (DISPLAY)

INDICATION

C** code is indicated

from small numeral to

large one

.

C00

.

LCD (DISPLAY)

INDICATION

FI letter turns OFF.For each 2 sec

INDICATION MODE

Code is indicated

.

-

.

.

Page 26

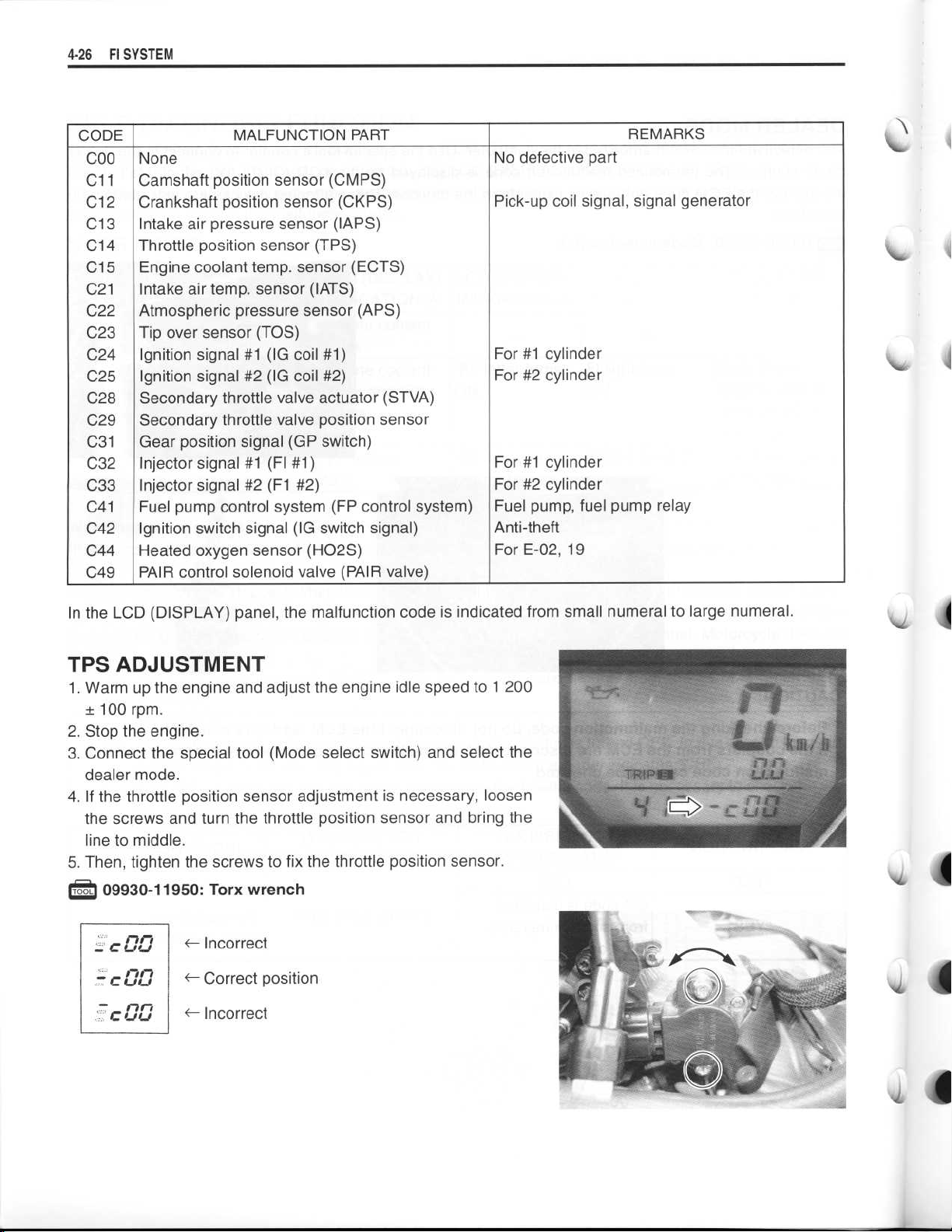

4-26 FI SYSTEM

CODE

COO

C11

C12

C13

C14

C15

C21

C22

C23

C24

C25

C28

C29

C31

C32

C33

C41

C42

C44

C49

MALFUNCTION PART

None

No defective part

Camshaft position sensor (CMPS)

Crankshaft position sensor (CKPS)

Pick-up coil signal, signal generator

Intake air pressure sensor (ZAPS)

Throttle position sensor (TPS)

Engine coolant temp

Intake air temp

. sensor (ECTS)

. sensor (IATS)

Atmospheric pressure sensor (APS)

Tip over sensor (TOS)

Ignition signal #1 (IG coil #1)

Ignition signal #2 (IG coil #2)

For #1 cylinder

For #2 cylinder

Secondary throttle valve actuator (STVA)

Secondary throttle valve position sensor

Gear position signal (GP switch)

Injector signal #1 (FI #1)

Injector signal #2 (F1 #2)

Fuel pump control system (FP control system)

Ignition switch signal (IG switch signal)

Heated oxygen sensor (HO2S)

For #1 cylinder

For #2 cylinder

Fuel pump, fuel pump relay

Anti-theft

For E-02, 19

PAIR control solenoid valve (PAIR valve)

REMARKS

In the LCD (DISPLAY) panel, the malfunction code is indicated from small numeral to large numeral

.

TPS ADJUSTMENT

. Warm up the engine and adjust the engine idle speed to 1 200

1

± 100 rpm

. Stop the engine

2

. Connect the special tool (Mode select switch) and select the

3

dealer mode

. If the throttle position sensor adjustment is necessary, loosen

4

the screws and turn the throttle position sensor and bring the

line to middle

. Then, tighten the screws to fix the throttle position sensor

5

.

.

09930-11950

C L/

C

r_ %i(J

U %

J

.

.

.

.

: Torx wrench

-

Incorrect

Correct position

-

~- Incorrect

.

Page 27

40

FI SYSTEM 4-

2 7

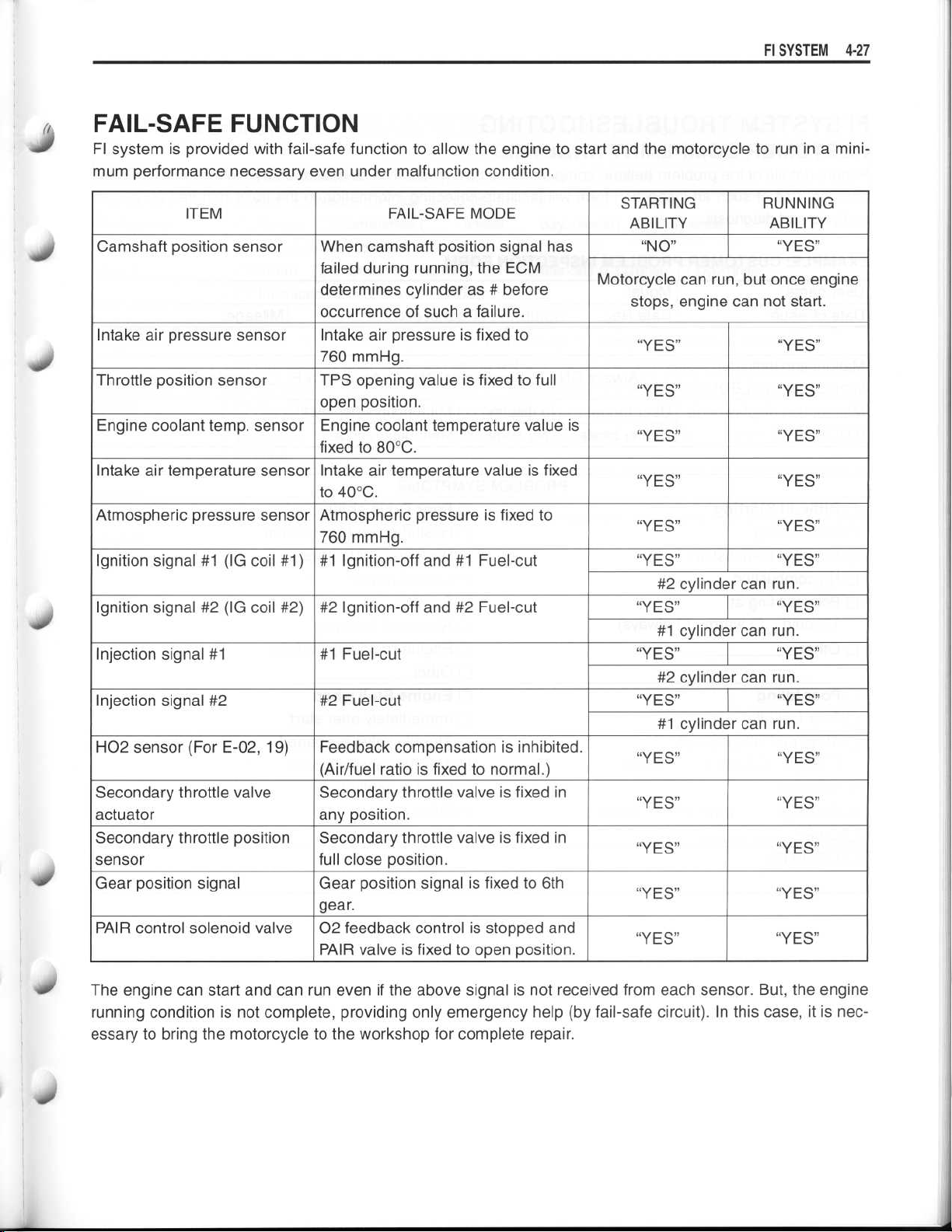

FAIL-SAFE FUNCTION

FI system is provided with fail-safe function to allow the engine to start and the motorcycle to run in a mini-

mum performance necessary even under malfunction condition

.

ITEM

Camshaft position sensor

Intake air pressure sensor

Throttle position sensor

Engine coolant temp

Intake air temperature sensor

Atmospheric pressure sensor

Ignition signal #1 (IG coil #1)

Ignition signal #2 (IG coil #2)

Injection signal #1

Injection signal #2

H02 sensor (For E-02, 19) Feedback compensation is inhibited

Secondary throttle valve

actuator

Secondary throttle position

sensor

Gear position signal

PAIR control solenoid valve

. sensor

When camshaft position signal has

failed during running, the ECM

determines cylinder as # before

occurrence of such a failure

Intake air pressure is fixed to

760 mmHg

TPS opening value is fixed to full

open position

Engine coolant temperature value is

fixed to 80°C

Intake air temperature value is fixed

to 40°C

Atmospheric pressure is fixed to

760 mmHg

#1 Ignition-off and #1 Fuel-cut

#2 Ignition-off and #2 Fuel-cut

#1 Fuel-cut

#2 Fuel-cut

(Air/fuel ratio is fixed to normal

Secondary throttle valve is fixed in

any position

Secondary throttle valve is fixed in

full close position

Gear position signal is fixed to 6th

gear

02 feedback control is stopped and

PAIR valve is fixed to open position

FAIL-SAFE MODE

Motorcycle can run,

.

.

.

.

.

.

.

.)

.

.

.

.

STARTING

ABILITY

"NO"

stops, engine

"YES" "YES"

"YES"

"YES"

"YES"

"YES" "YES"

"YES" "YES"

#2 cylinder

"YES" "YES"

#1 cylinder

"YES" "YES"

#2 cylinder

"YES" "YES"

#1 cylinder

"YES" "YES"

"YES" "YES"

"YES" "YES"

"YES"

"YES" "YES"

RUNNING

ABILITY

"YES"

but once engine

can not start

"YES"

"YES"

"YES"

can run

can run

can run

can run

"YES"

.

.

.

.

.

10

The engine can start and can run even if the above signal is not received from each sensor

running condition is not complete, providing only emergency help (by fail-safe circuit)

essary to bring the motorcycle to the workshop for complete repair

.

. But, the engine

. In this case, it is nec-

Page 28

~

~

~

~

~

4-

2 8

FI SYSTEM

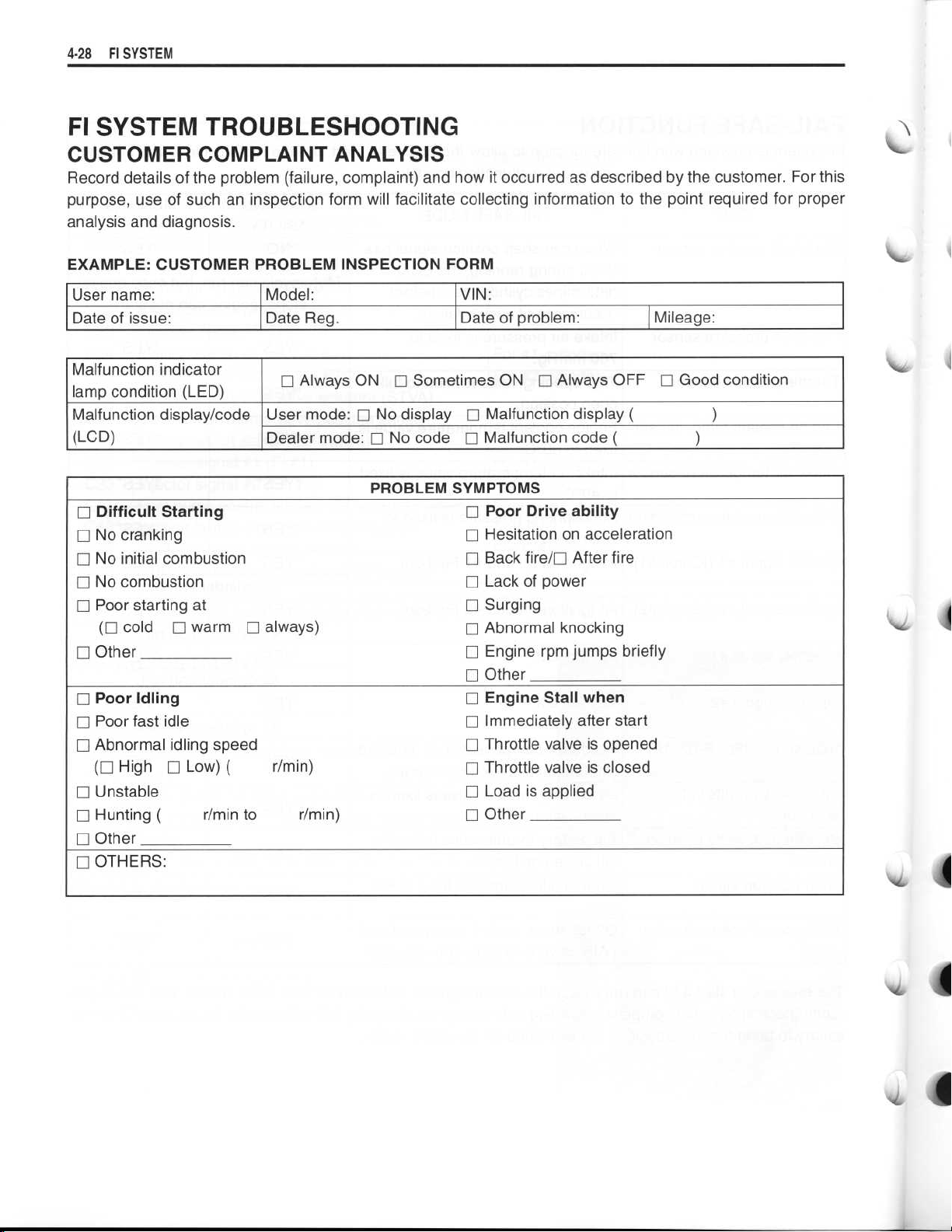

FI SYSTEM TROUBLESHOOTING

CUSTOMER COMPLAINT ANALYSIS

.

Record details of the problem (failure, complaint) and how it occurred as described by the customer

purpose, use of such an inspection form will facilitate collecting information to the point

analysis and diagnosis

.

required for proper

For this

EXAMPLE

User name

Date of issue

Malfunction indicator

lamp condition (LED)

Malfunction display/code

(LCD)

Difficult Starting

∎

0 No cranking

∎ No initial combustion

] No combustion

Poor starting at

]

(I] cold

I] Other

Poor Idling

]

∎ Poor fast idle

∎ Abnormal idling speed

(∎ High

Unstable

]

∎ Hunting

Other

]

OTHERS

]

: CUSTOMER PROBLEM INSPECTION FORM

:

.

∎ warm ∎ always)

Low)

El

(

:

(

r/min to~r/min)

Model

:

Date Reg

•

User mode

Dealer mode

r/min)

.

Always ON ∎ Sometimes ON

No display ∎ Malfunction display

: El

: ∎ No code]Malfunction code

PROBLEM SYMPTOMS

VIN

:

Date of problem

Poor Drive ability

]

∎ Hesitation on acceleration

Back fire/∎ After fire

El

∎ Lack of power

∎ Surging

Abnormal knocking

]

∎ Engine rpm jumps briefly

∎ Other

Engine Stall when

]

∎ Immediately after start

∎ Throttle valve is opened

] Throttle valve is closed

∎ Load is applied

Other

]

:

∎ Always OFF ∎ Good condition

Mileage

(

(

:

)

)

Page 29

~

~

~

~

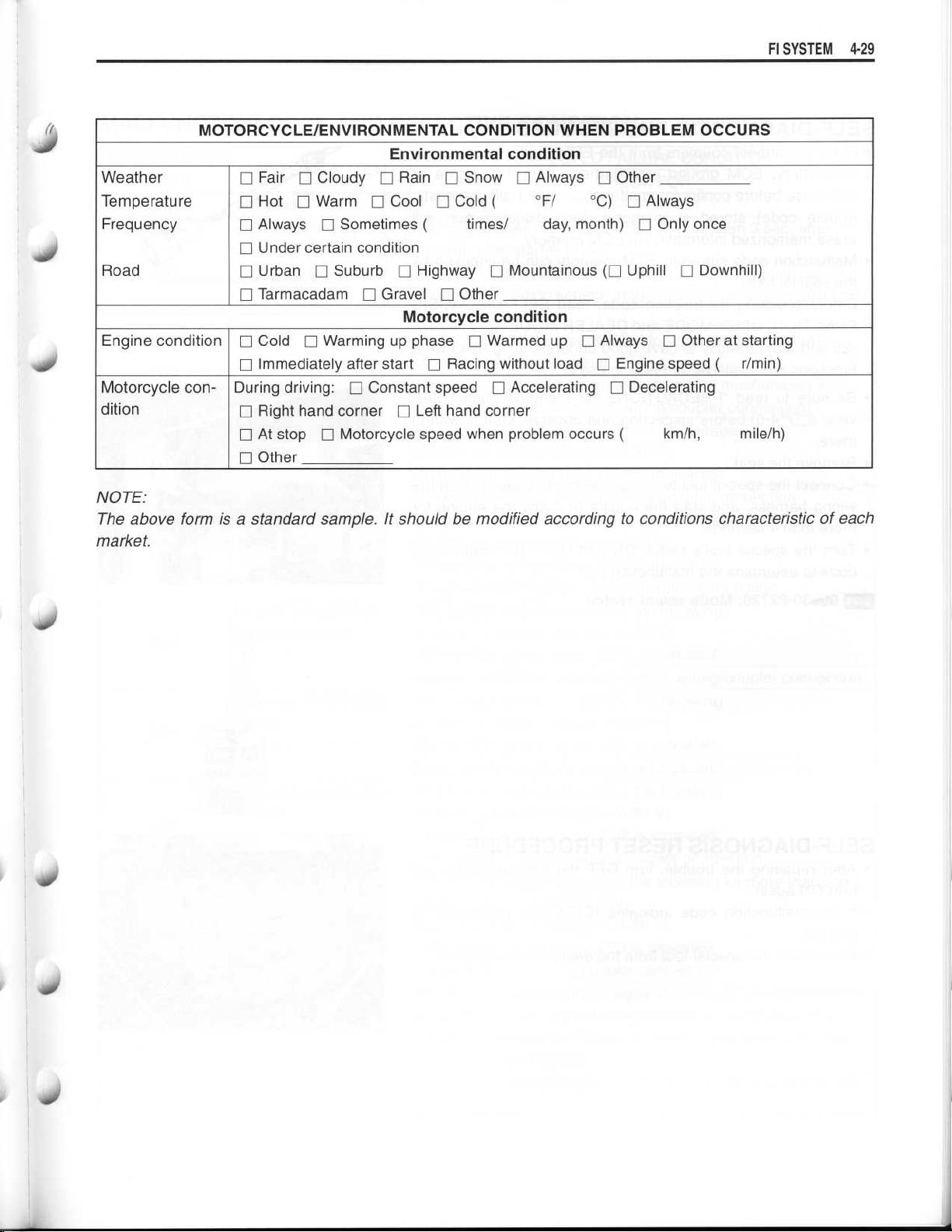

Fl SYSTEM4-29

MOTORCYCLE/ENVIRONMENTAL CONDITION WHEN PROBLEM OCCURS

Environmental condition

Weather

Temperature

Frequency

Road

Engine conditionElCold

Motorcycle condition

∎ Fair 0 Cloudy 0 Rain El Snow ∎ Always ∎ Other

0 Hot

∎ Always

∎ Under certain condition

El

El

∎ Immediately after startElRacing without load ∎ Engine speed(r/min)

During driving

∎ Right hand cornerElLeft hand corner

∎ At stop

LI

El Warm El

El

Urban

Tarmacadam

Other

El

Warming up phase ∎ Warmed up ∎ Always

El

El Motorcycle speed when problem occurs (~km/h,

Cool ∎ Cold

Sometimes(

Suburb

: ∎ Constant speed ∎ Accelerating

El Highway El Mountainous (LI Uphill El

Gravel ∎ Other

El

Motorcycle condition

times/

(

°F/~°C)

day, month) ∎ Only once

Always

El

El

Decelerating

El

Downhill)

Other at starting

mile/h)

NOTE

:

The above form is a standard sample

market

.

. It should be modified according to conditions characteristic of each

Page 30

~

~

~

~

~

~

~

~

4-30 FI SYSTEM

SELF-DIAGNOSTIC PROCEDURES

•

Don't disconnect couplers from the ECM, battery cable from

the battery, ECM ground wire harness from the engine or

main fuse before confirming malfunction code (self-diagnostic

trouble code) stored in memory

erase memorized information in ECM memory

•

Malfunction code stored in ECM memory can be checked by

the special tool

•

Before checking malfunction code, read SELF-DIAGNOSIS

FUNCTION "USER MODE and DEALER MODE" (r r4-24,

-25 and -26) carefully to have good understanding as to what

functions are available and how to use it

•

Be sure to read "PRECAUTIONS for Electrical Circuit Service" (r r4-6) before inspection and observe what is written

there

.

•

Remove the seat

•

Connect the special tool to the dealer mode coupler ®A at the

wiring harness, and start the engine or crank the engine for

more than 4 seconds

•

Turn the special tool's switch ON and check the malfunction

code to determine the malfunction part

.

.

.

. Such disconnection will

.

.

.

09930-82720

SELF-DIAGNOSIS RESET PROCEDURE

•

After repairing the trouble, turn OFF the ignition switch and

turn ON again

•

If the malfunction code indicates (COO), the malfunction is

cleared

•

Disconnect the special tool from the dealer mode coupler

.

: Mode select switch

.

.

Page 31

MALFUNCTION CODE AND DEFECTIVE CONDITION

Fl SYSTEM 4-31

40

S

MALFUNCTION

CODE

C00

C11

C12

C13

C14

C15

C21

C22

C23

C24 or C25

DETECTED ITEM

NO FAULT

Camshaft position sen-

sor

Crankshaft position

sensor

Intake air pressure

sensor

Throttle position sensor

Engine coolant tem-

perature sensor

Intake air temperature

sensor

Atmospheric pressure

sensor

Tip over sensor

Ignition signal

The signal does not reach ECM for more than 3 sec

receiving the starter signal

The camshaft position sensor wiring and mechanical parts

(Camshaft position sensor, intake cam pin, wiring/coupler connection)

The signal does not reach ECM for more than 2 sec

receiving the starter signal

The crankshaft position sensor wiring and mechanical parts

(Crankshaft position sensor, wiring/coupler connection)

The sensor should produce following voltage

(0

Without the above range, C13 is indicated

Intake air pressure sensor, wiring/coupler connection

The sensor should produce following voltage

(0

Without the above range, C14 is indicated

Throttle position sensor, wiring/coupler connection

The sensor voltage should be the following

(0

Without the above range, C15 is indicated

Engine coolant temperature sensor, wiring/coupler connection

The sensor voltage should be the following

(0

Without the above range, C21 is indicated

Intake air temperature sensor, wiring/coupler connection

The sensor voltage should be the following

(0

Without the above range, C22 is indicated

Atm

The sensor voltage should be the following for more than 2 sec

after ignition switch turns ON

(0

Without the above value, C23 is indicated

Tip over sensor, wiring/coupler connection

Crankshaft position sensor signal is produced and ECM deter-

mines the ignition signal but signal from ignition coil is interrupted continuous by 4 times or more

C24 or C25 is indicated

Ignition coil, wiring/coupler connection, power supply from the

battery

DETECTED FAILURE CONDITION

CHECK FOR

. after

.

. after

.

.

.50 V < sensor voltage < 4

.20 V <_ sensor voltage < 4

.15 V < sensor voltage < 4

.15 V <_ sensor voltage < 4

.50 V <_ sensor voltage < 4

. pressure sensor, wiring/coupler connection

.20 V < sensor voltage < 4

.85 V)

.

.

.80 V)

.

.

.85 V)

.

.

.85 V)

.

.

.85 V)

.

.

.80 V)

.

. In this case, the code

.

.

Page 32

4-32 FI SYSTEM

C28

C29

C31

C32 or C33

C41

C42

C44

C49

Secondary throttle

valve actuator

No operating voltage is supplied from the ECM, C28 is indi-

cated

STVA lead wire/coupler, STVA

Secondary throttle

valve position sensor

The sensor should produce following voltage

(0

Without the above range, C29 is indicated

Secondary throttle position sensor, wiring/coupler connection

Gear position signal

Gear position signal voltage should be higher than the following

for more than 2 seconds

(Gear position switch voltage > 0

Without the above value, C31 is indicated

Gear position sensor, wiring/coupler connection, gearshift cam,

etc

Fuel injector

Crankshaft position sensor signal is produced and ECM determines the injection signal but fuel injection signal is interrupted

continuous by 4 times or more

C33 is indicated

Injector, wiring/coupler connection, power supply to the injector

Fuel pump relay

No voltage is applied to fuel pump although fuel pump relay is

turned ON, or voltage is applied to fuel pump although fuel

pump relay is turned OFF

Fuel pump relay, connecting lead, power source to fuel pump

relay

Ignition switch

Ignition switch signal is not input in the ECM

Ignition switch, lead wire/coupler

Heated oxygen sensor

(HO2S) [For E-02, 19]

During 02 feedback control, 02 sensor voltage is higher or

lower than the specification

No signal is detected during engine operation or no electrical

power is supplied from the battery

H02S lead wire/coupler connection

Battery voltage supply to the HO2S

PAIR control solenoid

valve (PAIR valve)

When no operating voltage is supplied from the ECM, C49 is

indicated

PAIR valve lead wire/coupler

. STVA can not operate

.10 V 5 sensor voltage < 4

.

.90 V)

.

.

. In this case, the code C32 or

.

.

.

. PAIR valve can not operate

.

.

.6 V)

.

.

.

114

Page 33

~

~

.00

Fl SYSTEM 4-

3 3

"C11" CMP SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION POSSIBLE CAUSE

The CMP sensor signal does not reach ECM for•Metal particles or foreign materiel being attached

more than 3 seconds after receiving the starter signal

INSPECTION

Step 1

1) Lift and support the fuel tank with its prop stay

2) Turn the ignition switch OFF

3) Check the CMP sensor coupler for loose or poor contacts

If OK, then measure the CMP sensor peak voltage

.

. (=4-65)

on the CMP sensor and rotor tip

•

CMP sensor circuit open or short

•

CMP sensor malfunction

•

ECM malfunction

.

.

+0

4) Insert the needle pointed probes to the CMP sensor coupler

and crank the engine a few seconds or start the engine, and

measure the peak voltage

[

CMP sensor peak voltage

09900-25008

09900-25009

~tzj Tester knob indication : Voltage (_)

Is the peak voltage OK?

YES

NO

: Multi circuit tester

: Needle pointed probe set

Go to step 2

Replace the CMP sensor with a new one, if the

rotor is OK

.

: 3

.7 V and more

Y/W

((

.

.

-OB/W)

Page 34

~

~

~

~

~

~

~

4-34 FI SYSTEM

Step 2

1) Remove the CMP sensor

.

2

2) If the metal particles or foreign material is attached on the

CMP sensor and rotor tip, signal not flow correctly to the

ECM

. Clean the CMP sensor and rotor tip with a spray type

carburetor cleaner and blow dry with compressed air and also

change the engine oil if necessary

.

Is the cleaning OK?

•

Y/W or B/W wire open or shorted to ground, or

YES

NO

poor 12 or 13 connection

If wire and connection are OK, intermittent trou-

•

ble or faulty ECM

•

Recheck each terminal and wire harness for

.

open circuit and poor connection

•

Loose or poor contacts on the CMP sensor coupler or ECM coupler

•

Replace the CMP sensor with a new one

.

(E-

;-4-23)

. (=4-6)

4-6)

Irl

0 0 0 0 0 0 0 0 0 0 0

0000000000000000000000

.

.

1213

0 0

0 0 0 0 0 0 0 0 0

ECM coupler

~\

Page 35

~

~

FI SYSTEM 4-35

do

40

rI

"C12" CKP SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION

•

No CKP sensor signal for more than 2 seconds after

receiving the starter signal

INSPECTION

Step 1

(r

1) Remove the seat

screw

.

2) Turn the ignition switch OFF

3) Check the CKP sensor coupler for loose or poor contacts

If OK, then measure the CKP sensor resistance

4) Disconnect the CKP sensor coupler and measure the resistance

.

CKP sensor resistance

[

,

5) If OK, then check the continuity between each terminal and

ground

[

.

CKP sensor continuity

r6-3) and left seat tail cover mounting

.

: 130-240 S2

(Blue-Green)

:WQ (Infinity)

(Blue-Ground)

(Green-Ground)

Metal particles or foreign materiel being attached

on the CKP sensor and rotor tip

•

CKP sensor circuit open or short

•

CKP sensor malfunction

•

ECM malfunction

.

.

POSSIBLE CAUSE

(

;round

. .

09900-25008

R J Tester knob indication

Are the resistance and continuity OK?

YES

NO

: Multi circuit tester set

: Resistance (S2)

Go to step 2

Replace the CKP sensor with a new one

.

.

Page 36

~

~

~

~

~

4-36 FI SYSTEM

Step 2

1) Disconnect the CKP sensor coupler

.

2) Crank the engine a few seconds with the starter motor, and

measure the CKP sensor peak voltage at the coupler

CKP sensor peak voltage

: 5

.0 V and more

(0+

Blue -OGreen)

3) Repeat the above test procedure a few times and measure

the highest peak voltage

.

4) If OK, then measure the CKP sensor peak voltage at the ECM

terminals

. .

09900-25008

. (N+/N- or

(SAX)

: Multi circuit tester set

.

0000000000000000000000

000

.000500000000000000

26~30

~

ECM coupler

V

Tester knob indication

: Voltage (---)

Is the peak voltage OK?

•

Green or G/BI wire open or shorted to ground,

or poor 26 or 30 connection

If wire and connection are OK, intermittent trou-

YES

•

ble or faulty ECM

•

Recheck each terminal and wire harness for

open circuit and poor connection

•

Loose or poor contacts on the CKP sensor cou-

NO

pler or ECM coupler

•

Replace the CKP sensor with a new one

.

(L_?--4-23)

.

.

(r

--

74-6)

.

.

Page 37

~

~

FI SYSTEM 4-37

"C13" IAP SENSOR CIRCUIT MALFUNCTION

d

40

40

DETECTED CONDITION

IAP sensor voltage low or high

(0

.50 V < Sensor voltage < 4

(without the above range)

NOTE

:

Note that atmospheric pressure varies depending on

weather conditions as well as altitude

Take that into consideration when inspecting volt-

age

.

INSPECTION

Step 1

1) Lift and support the fuel tank with its prop stay

2) Turn the ignition switch OFF

3) Check the IAP sensor coupler for loose or poor contacts

If OK, then measure the IAP sensor input voltage

.85 V)

.

.

.

([7'4-65)

Clogged vacuum passage between throttle body

•

and IAP sensor

Air being drawn from vacuum passage between

•

throttle body and IAP sensor

IAP sensor circuit open or shorted to ground

•

•

IAP sensor malfunction

ECM malfunction

•

.

.

POSSIBLE CAUSE

4) Disconnect the IAP sensor coupler

5) Turn the ignition switch ON

6) Measure the voltage at the Red wire and ground

7) If OK, then measure the voltage at the Red wire and B/Br

wire

.

IAP sensor input voltage

~ •

09900-25008

(Eli Tester knob indication

Is the voltage OK?

YES

NO

: Multi circuit tester set

Go to Step 2

•

Loose or poor contacts on the ECM coupler

Open or short circuit in the Red wire or B/Br

•

wire

.

.

: Voltage

.

.

: 4.5-5.5 V

(O+

Red -OGround)

(O+

Red -OB/Br)

(-)

.

.

B/Br

Page 38

~

~10~

~

~

~

~

~

~

4- 38FI SYSTEM

Step 2

1) Connect the IAP sensor coupler

2) Insert the needle pointed probes to the lead wire coupler

3) Start the engine at idle speed

.

.

.

4) Measure the IAP sensor output voltage at the wire side coupler (between G/B and B/Br wires)

(

IAP sensor output voltage

.

.

09900-25008

09900-25009

Tester knob indication

: Multi circuit tester set

: Needle pointed probe set

: Voltage

.

: Approx

G/B -OB/Br)

(O

(--)

. 2

.5 V at idle speed

4

YES

NO

Go to Step 3

•

Check the vacuum hose for crack or damage

•

Open or short circuit in the G/B wire

•

Replace the IAP sensor with a new one

.

.

.

.

Step 3

1) Remove the IAP sensor.(1

r4-91)

2) Connect the vacuum pump gauge to the vacuum port of the

IAP sensor

3) Arrange 3 new 1

age is 4

minal and

4) Check the voltage between Vout and ground

.

.5 V batteries in series (check that total volt-

.5

- 5

.0 V) and connectOterminal to the ground ter-

terminal to the Vcc terminal

O+

.

. Also, check if

voltage reduces when vacuum is applied up to 400 mmHg by

using vacuum pump gauge

. .

09917-47010

09900-25008

Tester knob indication

Zi

: Vacuum pump gauge

: Multi circuit tester set

Is the voltage OK?

. (r-

74-39)

: Voltage (--)

6

0000000000000000000000

00000000000

`~

~

16

.0000000000

34

~

1%

1

YES

NO

Red, G/B or B/Br wire open or shorted to

•

ground, or poor 10,16 or 34 connection

(r

-

7-4-23)

If wire and connection are OK, intermittent trou-

•

ble or faulty ECM

•

Recheck each terminal and wire harness for

.

.

open circuit and poor connection . (C r4-6)

If check result is not satisfactory, replace the IAP

sensor with a new one

.

ECM coupler

10

Page 39

Fl SYSTEM 4-39

S

MW

Output voltage (Vcc voltage 4.5-5.0 V, ambient temp

30

°C, 68-86 °F)

ALTITUDE

(Reference)

(ft)

0

2000

2001

1 1

5 000

5 001

8 000

8 001

10 000 3 048

(m)

0

610 707

611

1 524

1 525

1

2 438

2 439

1

ATMOSPHERIC

PRESSURE

(mmHg)

760

707

634

634

567

567

526

kPa

100

1

94

94

85

85

1

76

76

70

. 20

OUTPUT

VOLTAGE

(V)

3

.4-4

3

.0-3

2

.6-3

2

.4-3

-

.0

.7

.4

.1

Page 40

~

~

~

4-

4 0

FI SYSTEM

"C14" TP SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION

Output voltage low or high

(0

.20 V < Sensor voltage < 4

.80 V)

(without the above range)

•

TP sensor maladjusted

•

TP sensor circuit open or short

•

TP sensor malfunction

•

ECM malfunction

POSSIBLE CAUSE

INSPECTION

Step 1

1) Lift and support the fuel tank with its prop stay

2) Turn the ignition switch OFF

.

3) Check the TP sensor coupler for loose or poor contacts

If OK, then measure the TP sensor input voltage

4) Disconnect the TP sensor coupler

5) Turn the ignition switch ON

.

.

6) Measure the voltage at the Red wire and ground

. (=4-65)

.

.

.

7) If OK, then measure the voltage at the Red wire and B/Br

wire

.

L

TP sensor input voltage

. .

09900-25008

: Multi circuit tester set

: 4.5-5.5 V

Red -OGround)

(O

(O+

Red

-OB/Br)

~g Tester knob indication

: Voltage

Is the voltage OK?

YES

NO

Go to Step 2

•

Loose or poor contacts on the ECM coupler

•

Open or short circuit in the Red wire or B/Br

wire

.

.

(--)

.

Page 41

~

~

~

~

~

~

~

~

FI SYSTEM 4-41

(i

Step 2

1) Turn the ignition switch OFF

2) Disconnect the TP sensor coupler

.

.

3) Check the continuity between P/W wire and ground

L

TP sensor continuity

: -

0 (Infinity)

(P/W - Ground)

4) If OK, then measure the TP sensor resistance at the coupler

.ilk'`~(between P/W and B/Br wires)

.

5) Turn the throttle grip and measure the resistance

[

TP sensor resistance

Throttle valve is closed

Throttle valve is opened

09900-25008

~J

Tester knob indication

: Multi circuit tester set

: Approx

: Approx

: Resistance (S2)

Are the resistance and continuity OK?

YES

NO

Go to Step 3

Reset the TP sensor position correctly

•

•

Replace the TP sensor with a new one

.

.12 kS2

. 1

. 4

.26 kS2

.

.

.

.

or

Step 3

1) Connect the TP sensor coupler

2) Insert the needle pointed probes to the lead wire coupler

3) Turn the ignition switch ON

.

.

.

4) Measure the TP sensor output voltage at the coupler

(between *+ P/W andOB/Br) by turning the throttle grip

.

TP sensor output voltage

Throttle valve is closed

Throttle valve is opened

09900-25008

09900-25009

: Multi circuit tester set

: Needle pointed probe set

.~Tester knob indication

: Approx

: Approx

: Voltage

. 1

. 4

(- -)

.12 V

.26 V

Is the voltage OK?

000000000x00000000

0000000000000000000000

"1'-,

~

YES

• Red, P/W or B/Br wire open or shorted to

ground, or poor 10,19 or 34 connection

4-23)

(=4-23)

•

If wire and connection are OK, intermittent trouble or faulty ECM

•

Recheck each terminal and wire harness for

.

open circuit and poor connection

.

(L'4-6)

.

If check result is not satisfactory, replace the TP

NO

sensor with a new one

.

10

34

ECM coupler

is

.000

Page 42

~

~

~

~

~

4-42

FI SYSTEM

"C15" ECT SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION

Output voltage low or high

.15 V < Sensor voltage < 4

(0

.85 V)

(without the above range)

ECT sensor circuit open or short

•

ECT sensor malfunction

•

ECM malfunction

•

POSSIBLE CAUSE

INSPECTION

Step 1

1) Turn the ignition switch OFF

2) Check the ECT sensor coupler for loose or poor contacts

.

.

If OK, then measure the ECT sensor voltage at the wire side

coupler

3) Disconnect the coupler and turn the ignition switch ON

4) Measure the voltage between B/BI wire terminal and ground

.

.

.

5) If OK, then measure the voltage between B/BI wire terminal

and B/Br wire terminal

ECT sensor voltage

09900-25008

Tester knob indication

.

: 4 .5

- 5

.5 V

(O+

B/Bl -OGround)

BIB I

(O+

-OBIB r)

: Multi circuit tester set

: Voltage (-)

Is the voltage OK?

YES

NO

Go to Step 2

•

Loose or poor contacts on the ECM coupler

Open or short circuit in the B/BI wire or B/Br

•

wire

.

.

.

Page 43

~

~

~

~

~

.

.d

Step 2

1) Turn the ignition switch OFF

2) Measure the ECT sensor resistance

[

ECT sensor resistance

.

:

Approx

.

. 2

.45 kSZ at 20 °C (68 °F)

(Terminal-Terminal)

09900-25008

~gy Tester knob indication

Refer to page 5-10 for details

: Multi circuit tester set

: Resistance (S2)

.

Is the resistance OK?

•

B/BI or B/Br wire open or shorted to ground, or

YES

poor 34 or 36 connection

If wire and connection are OK, intermittent trou-

•

ble or faulty ECM

•

Recheck each terminal and wire harness for

.

. (F-74-23)

open circuit and poor connection

NO

Replace the ECT sensor with a new one

.(r-7-

4-6)

.

0000000000000000000000

00000000000

~

.0•0000000o

34 36

ECM coupler

~

Fl SYSTEM 4-

4 3

Engine Coolant Temp

20 °C (68 °F)

40 °C (104 °F)

80 °C (176 °F)

100 °C (212 °F)

Resistance

Approx

Approx

Approx

Approx

. 0

. 2

.45 kQ

. 1

.15 kQ

. 0

.318 kS2

.1836 kS2

Page 44

~

~

~

~

~

4-44

FI SYSTEM

"C21" IAT SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION

Output voltage low or high

(0

.15 V <_ Sensor voltage < 4

(without the above range)

INSPECTION

Step 1

1) Lift and support the fuel tank with its prop stay

2) Turn the ignition switch OFF

3) Check the IAT sensor coupler for loose or poor contacts

If OK, then measure the IAT sensor voltage at the wire side

coupler

4) Disconnect the coupler and turn the ignition switch ON

5) Measure the voltage between Dg wire terminal and ground

6) If OK, then measure the voltage between Dg wire terminal

and B/Br wire terminal

.

IAT sensor voltage

.85 V)

.

.

: 4.5- 5

(O

(~+

.5 V

Dg -OGround)

Dg -0B/Br)

.

(r

•

IAT sensor circuit open or short

•

IAT sensor malfunction

•

ECM malfunction

--

74-65)

.

.

.

POSSIBLE CAUSE

09900-25008

Tester knob indication

~J

Is the voltage OK?

YES

NO

: Multi circuit tester set

Go to Step 2

Loose or poor contacts on the ECM coupler

•

•

Open or short circuit in the Dg wire or B/Br wire

: Voltage (--)

.

.

.

Page 45

~

~

~

FI SYSTEM 4-45

Step 2

1) Turn the ignition switch OFF

2) Measure the IAT sensor resistance

.

.

IAT sensor resistance

. .

09900-25008

: Multi circuit tester set

Tester knob indication

Is the resistance OK?

•

Dg or B/Br wire open or shorted to ground, or

poor 14 or 34 connection

If wire and connection are OK, intermittent trou-

YES

•

ble or faulty ECM

•

Recheck each terminal and wire harness for

open circuit and poor connection

NO

Replace the IAT sensor with a new one

Intake Air Temp

20 °C (68 °F)

40 °C (104 °F)

80 °C (176 °F)

100 °C (212 °F)

: Approx

(Terminal -

. 2

.45 kL2 at 20 °C (68 °F)

Terminal)

: Resistance (S2)

. (=4-23)

.

. (C r4-6)

Resistance

Approx

Approx

Approx

Approx

. 2

. 1

. 0

.322 kQ

. 0

.189 kQ2

.

.45 kQ

.14 kS2

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0000000000050000000000

ECM coupler

14

34

:

NOTE

IAT sensor resistance measurement method is the same way as

that of the ECT sensor

. Refer to page 5-10 for details

.

Page 46

~

~

4

.46 FI SYSTEM

"C22" AP SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION

AP sensor voltage low or high

(0

.50 V < Sensor voltage < 4

(without the above range)

NOTE

:

Note that atmospheric pressure varies depending on

weather conditions as well as altitude

Take that into consideration when inspecting volt-

age

.

INSPECTION

Step 1

1) Remove the seat.([7'6-7)

2) Turn the ignition switch OFF

3) Check the AP sensor coupler for loose or poor contacts

If OK, then measure the AP sensor input voltage

4) Disconnect the AP sensor coupler

5) Turn the ignition switch ON

6) Measure the voltage at the Red wire and ground

7) If OK, then measure the voltage at the Red wire and B/Br

wire

.

.85 V)

.

.

.

.

•

Clogged air passage with dust

•

AP sensor circuit open or shorted to ground

•

AP sensor malfunction

•

ECM malfunction

.

.

.

POSSIBLE CAUSE

IN

('~,~AP sensor input voltage

: 4 .5

(O

(O+

09900-25008

Tester knob indication

Is the voltage OK?

YES

NO

: Multi circuit tester set

: Voltage (---)

Go to Step 2

•

Loose or poor contacts on the ECM coupler

•

Open or short circuit in the Red wire or B/Br

wire

.

.

- 5

.5 V

Red

-OGround)

Red

-OB/Br)

1

.

B/Br

Page 47

~

~

~

~

~

~

~

~

~

FI SYSTEM 4-47

~(

Step 2

1) Connect the AP sensor coupler

2) Insert the needle pointed probes to the lead wire coupler

Turn the ignition switch ON

.

.

.

3) Measure the AP sensor output voltage at the wire side coupler (between G/Y and B/Br wires)

(

AP sensor output voltage

Approx

(E

G/Y

09900-25008

09900-25009

)g Tester knob indication

YES

NO

: Multi circuit tester set

: Needle pointed probe set

: Voltage

Go to Step 3

•

Check the air passage for clogging

Open or short circuit in the G/Y wire

•

•

Replace the AP sensor with a new one

.

.

:

. 4

.0 V (760 mmHg, 100 kPa)

-OB/Br)

(--)

.

.

.

Step 3

1) Remove the AP sensor

.

2) Connect the vacuum pump gauge to the air passage port of

the AP sensor

3) Arrange 3 new 1

age is 4.5- 5

minal andO+terminal to the Vcc terminal

4) Check the voltage between Vout and ground

.

.5 V batteries in series (check that total volt-

.0 V) and connectOterminal to the ground ter-

.

. Also, check if

voltage reduces when vacuum is applied up to 400 mmHg by

using vacuum pump gauge

. .

09917-47010

09900-25008

: Vacuum pump gauge

: Multi circuit tester set

. (=4-48)

rvli

Tester knob indication

itv

~

Is the voltage OK?

•

Red, G/Y or B/Br wire open or shorted to

ground, or poor 10,17 or 34 connection

: Voltage

(-)

000000000

000000000 0*0000 00000

.

10

.000000500000

34

ECM coupler

17

~

(C r4-23)

YES

If wire and connection are OK, intermittent trou-

•

ble or faulty ECM

•

Recheck each terminal and wire harness for

open circuit and poor connection

.

. (E7'4-6)

If check result is not satisfactory, replace the AP

NO

sensor with a new one

.

Page 48

FI

4-48

Output voltage (Vcc voltage 4

30 °C, 68-86 °F)

SYSTEM

.5-5

.0 V, ambient temp

. 20

-

ALTITUDE

(Reference)

(ft)

0 0

2000

2001

5 000

5 001

1

8 000

8 001

10 000

(m)

610

611

1

1 524

1 525

2 438

2 439

1

3 048

ATMOSPHERIC

PRESSURE

(mmHg)

760 100

707

707

1

634

634

567

567

526

kPa

94

94

85

85

76

76

70

OUTPUT

VOLTAGE

(V)

3

.4-4

3

.0-3

2

.6-3

.4-3

2

.0

.7

.4

.1

Page 49

~

~

~

~

FI SYSTEM 4-49

(r

"C23" TO SENSOR CIRCUIT MALFUNCTION

DETECTED CONDITION

Output voltage low or high

(0

.20 V < Sensor voltage < 4

(without the above range)

INSPECTION

Step 1

1) Remove the frame cover

2) Turn the ignition switch OFF

3) Check the TO sensor coupler for loose or poor contacts

If OK, then measure the TO sensor resistance

4) Disconnect the TO sensor coupler

5) Measure the resistance between Red wire and B/Br wire terminals

[

~p Tester knob indication

.

TO sensor resistance

09900-25008

Is the resistance OK?

: Multi circuit tester set

.80 V)

. (Clr6-7)

.

.

.1 -19

: 19

(Red -

: Resistance (S2)

.7 kS2

B/Br)

.

TO sensor circuit open or short

•

TO sensor malfunction

•

•

ECM malfunction

.

POSSIBLE CAUSE

1

YES

NO

Go to Step 2

Replace the TO sensor with a new one

.

.

S

Page 50

~

~

~

~

~

~

~

~

4-50 FI SYSTEM

Step 2

1) Connect the TO sensor coupler

2) Insert the needle pointed probes to the lead wire coupler