Page 1

ELECTRICAL SYSTEM

CONTENTS

ELECTRICAL SYSTEM

7-1

CAUTIONS IN SERVICING

COUPLER

CLAMP

FUSE

SEMI-CONDUCTOR EQUIPPED PART

BATTERY

CONNECTING THE BATTERY

WIRING PROCEDURE

USING THE MULTI CIRCUIT TESTER

LOCATION OF ELECTRICAL COMPONENTS

CHARGING SYSTEM

TROUBLE SHOOTING

INSPECTION

STARTER SYSTEM AND SIDE-STAND/IGNITION INTERLOCK

SYSTEM

TROUBLE SHOOTING

STARTER MOTOR REMOVAL AND DISASSEMBLY

STARTER MOTOR INSPECTION

STARTER MOTOR REASSEMBLY

STARTER RELAY INSPECTION

SIDE-STAND/IGNITION INTERLOCK SYSTEM PARTS

INSPECTION

IGNITION SYSTEM

TROUBLESHOOTING

INSPECTION

COMBINATION METER

REMOVAL

PARTS NAME

OPERATING PROCEDURE

ENGINE COOLANT TEMPERATURE METER AND INDICATOR

LAMPS

RELAYS

~

HEADLIGHT AND POSITION LIGHT

BRAKE LIGHT/TAILLIGHT, TURN SIGNAL LIGHT AND

LICENCE PLATE LIGHT

TURN SIGNAL/SIDE-STAND RELAY

STARTER RELAY

FUEL PUMP RELA Y

SWITCHES

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

7- 3

7- 3

7- 3

7- 3

7- 3

7- 4

7- 4

7- 4

7- 4

7- 5

7- 7

7- 7

7- 9

7-12

7-12

7-13

7-14

7-15

7-16

7-17

7-20

7-20

7-22

7-25

7-25

7-26

7-26

~

7-28

7-31

7-31

7-32

7-33

7-33

7-33

7--33

7-34

7

Page 2

7-2

ELECTRICAL

SYSTEM

ELECTRICAL SYSTEM

CONTENTS

BATTERY

SPECIFICATIONS

INITIAL CHARGING

SERVICING

RECHARGING OPERATION

~

~

7-36

~

~

~

7-36

7-36

7-37

7-38

Page 3

~

~

~

~

~

~

~

~

~

~

~

~

CAUTIONS IN SERVICING

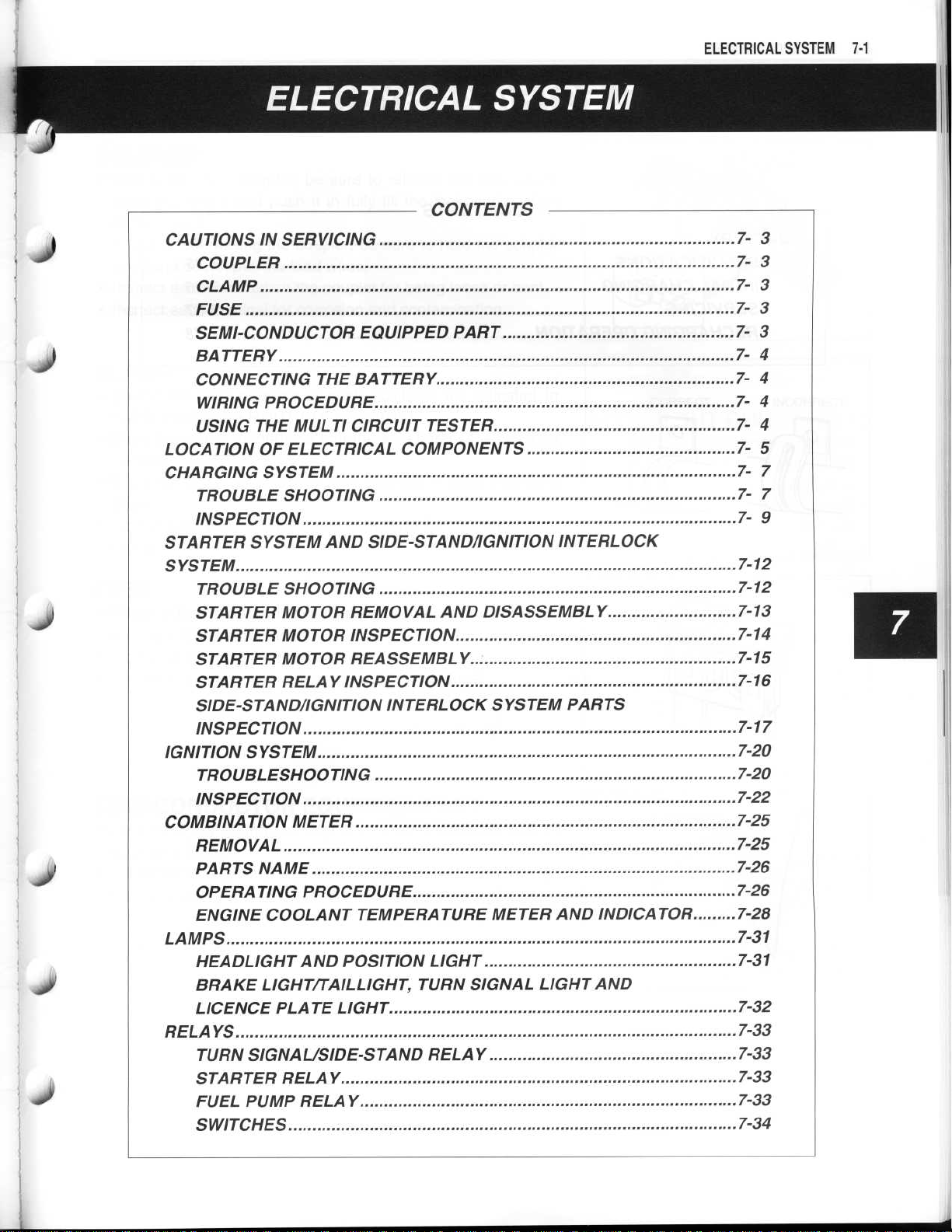

COUPLER

•

With a lock type coupler, be sure to release the lock before

disconnecting it and push it in fully till the lock works when

connecting it

•

When disconnecting the coupler, be sure to hold the coupler

itself and do not pull the lead wires

•

Inspect each terminal on the coupler for being loose or bent

•

Inspect each terminal for corrosion and contamination

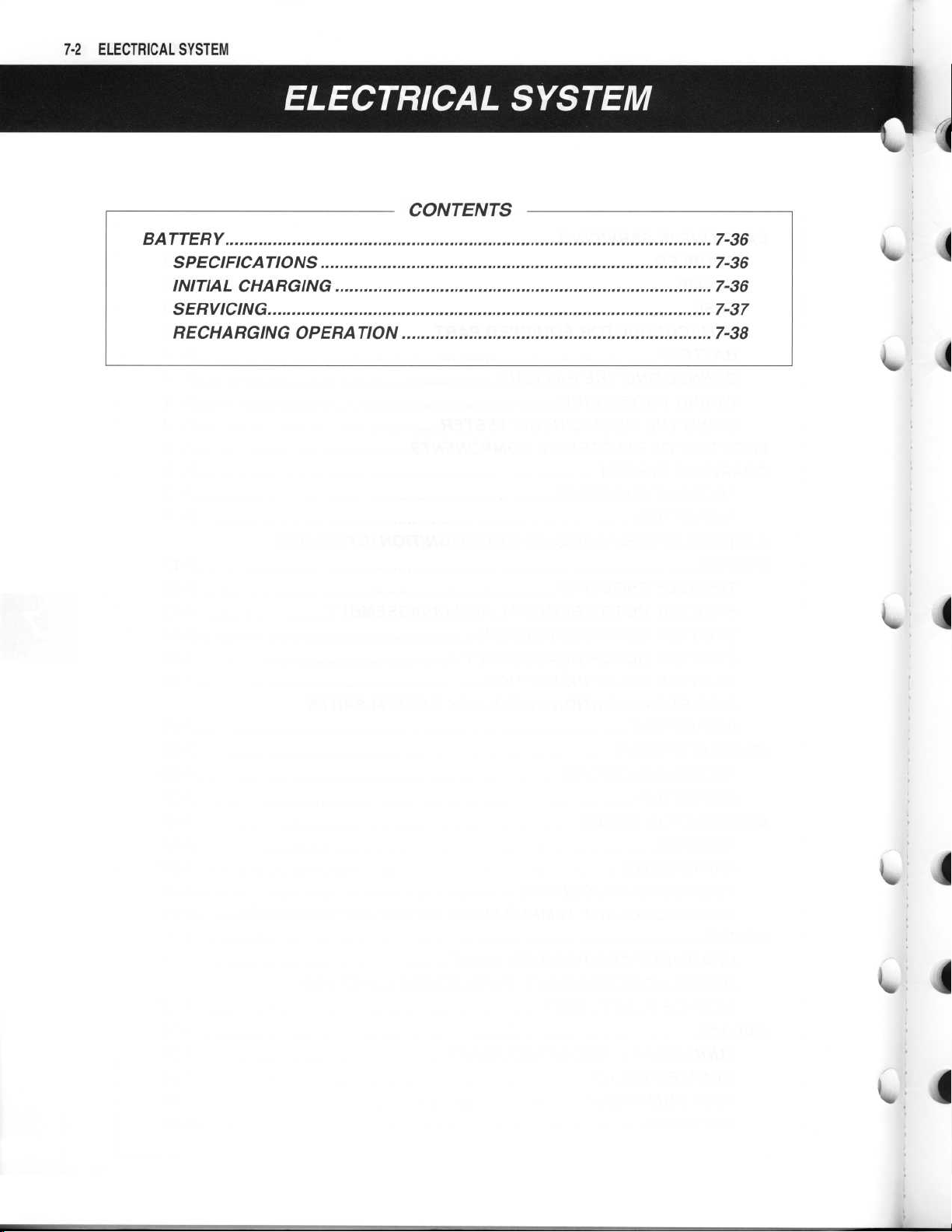

CLAMP

•

Clamp the wire harness at such positions as indicated in

"WIRE HARNESS ROUTING"

•

Bend the clamp properly so that the wire harness is clamped

securely

•

In clamping the wire harness, use care not to allow it to hang

down

.

•

Do not use wire or any other substitute for the band type

clamp

.

.

.

.

.

.

-

78-14)

(C"

.

ELECTRICAL SYSTEM 7-

3

FUSE

•

When a fuse blows, always investigate the cause, correct it

and then replace the fuse

•

Do not use a fuse of a different capacity

•

Do not use wire or any other substitute for the fuse

.

.

.

SEMI-CONDUCTOR EQUIPPED PART

•

Be careful not to drop the part with a semi-conductor built in

such as a ECM

•

When inspecting this part, follow inspection instruction strictly

Neglecting proper procedure may cause damage to this part

.

.

.

Page 4

~

~

~

~

~

~

~

~

~

~

7-4 ELECTRICAL SYSTEM

BATTERY

•

The MF battery used in this motorcycle does not require maintenance (e.g.,

replenishment)

•

During normal charging, no hydrogen gas is produced

ever, if the battery is overcharged, hydrogen gas may be produced

. Therefore, be sure there are no fire or spark sources

(e.g., short circuit) nearby when charging the battery

•

Be sure to recharge the battery in a well-ventilated and open

area

.

•

Note that the charging system for the MF battery is different

from that of a conventional battery

battery with a conventional battery

electrolyte level inspection, distilled water

.

. How-

.

. Do not replace the MF

.

CONNECTING THE BATTERY

•

When disconnecting terminals from the battery for disassem-

bly or servicing, be sure to disconnect the

wire, first

•

When connecting the battery lead wires, be sure to connect

theOObattery lead wire first

•

If the terminal is corroded, remove the battery, pour warm

water over it and clean it with a wire brush

•

After connecting the battery, apply a light coat of grease to the

battery terminals

•

Install the cover over the

.

.

.

.

battery terminal

O

battery lead

O

.

WIRING PROCEDURE

•

Properly route the wire harness according to the "WIRE HARNESS ROUTING" section

. (CJ8-14)

USING THE MULTI CIRCUIT TESTER

•

Properly use the multi circuit testerOand

Improper use can cause damage to the motorcycle and

tester

.

•

If the voltage and current values are not known, begin mea-

suring in the highest range

•

When measuring the resistance, make sure that no voltage is

applied

•

After using the tester, be sure to turn the switch to the OFF

position

CAUTION

Before using the multi circuit tester, read its instruc-

tion manual

. If voltage is applied, the tester will be damaged

.

.

.

e

probes

.

.

Page 5

~

~

~

~

ELECTRICAL SYSTEM 7-5

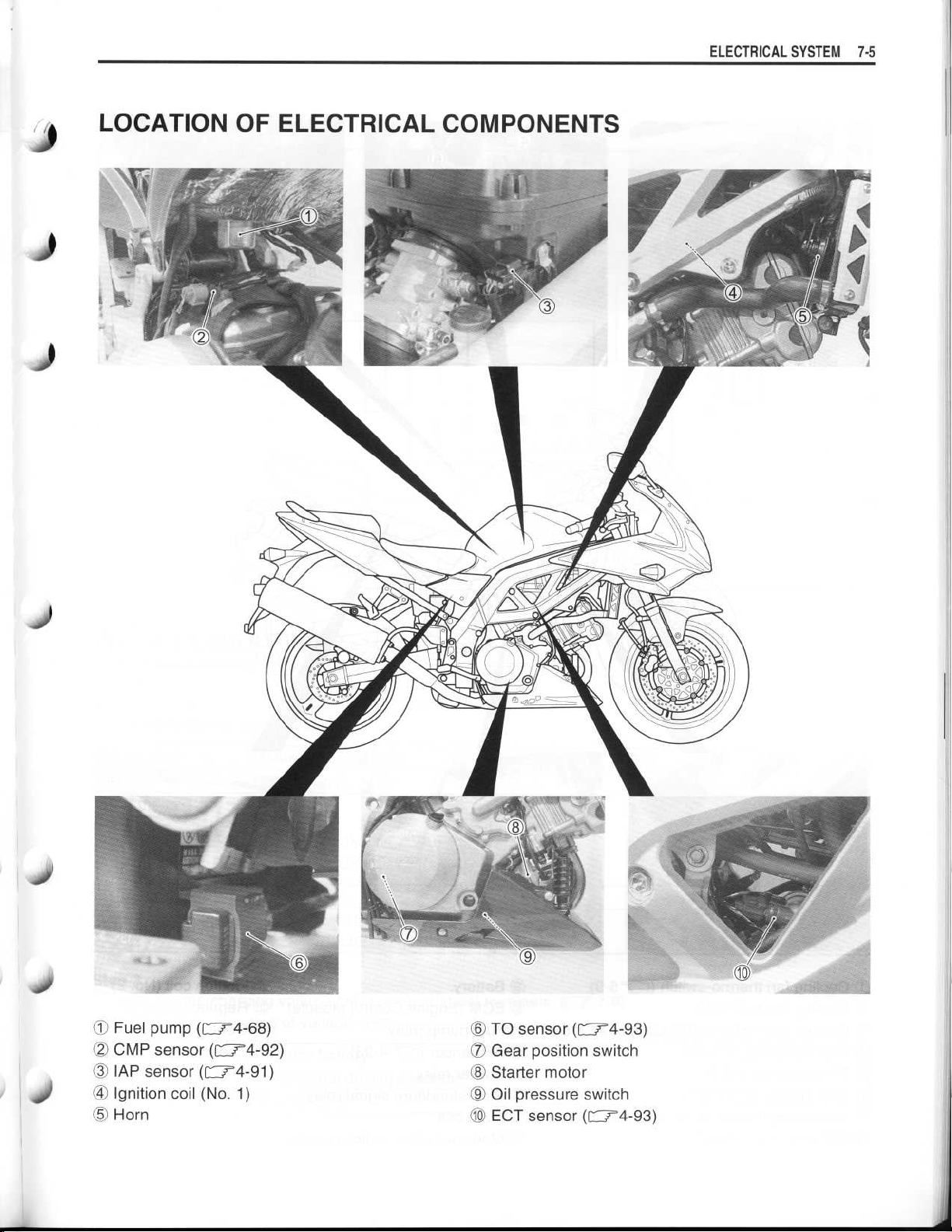

LOCATION OF ELECTRICAL COMPONENTS

~ 40

•

Fuel pump (C14-68)

02 CMP sensor (C'4-92)

~3 IAP sensor (=4-91)

Ignition coil (No

•

05 Horn

. 1)

® TO sensor (=4-93)

07 Gear position switch

Starter motor

•

Oil pressure switch

•

1o ECT sensor(f-

4-93)

4-93)

Page 6

~

~

~

~

~

~

~

~

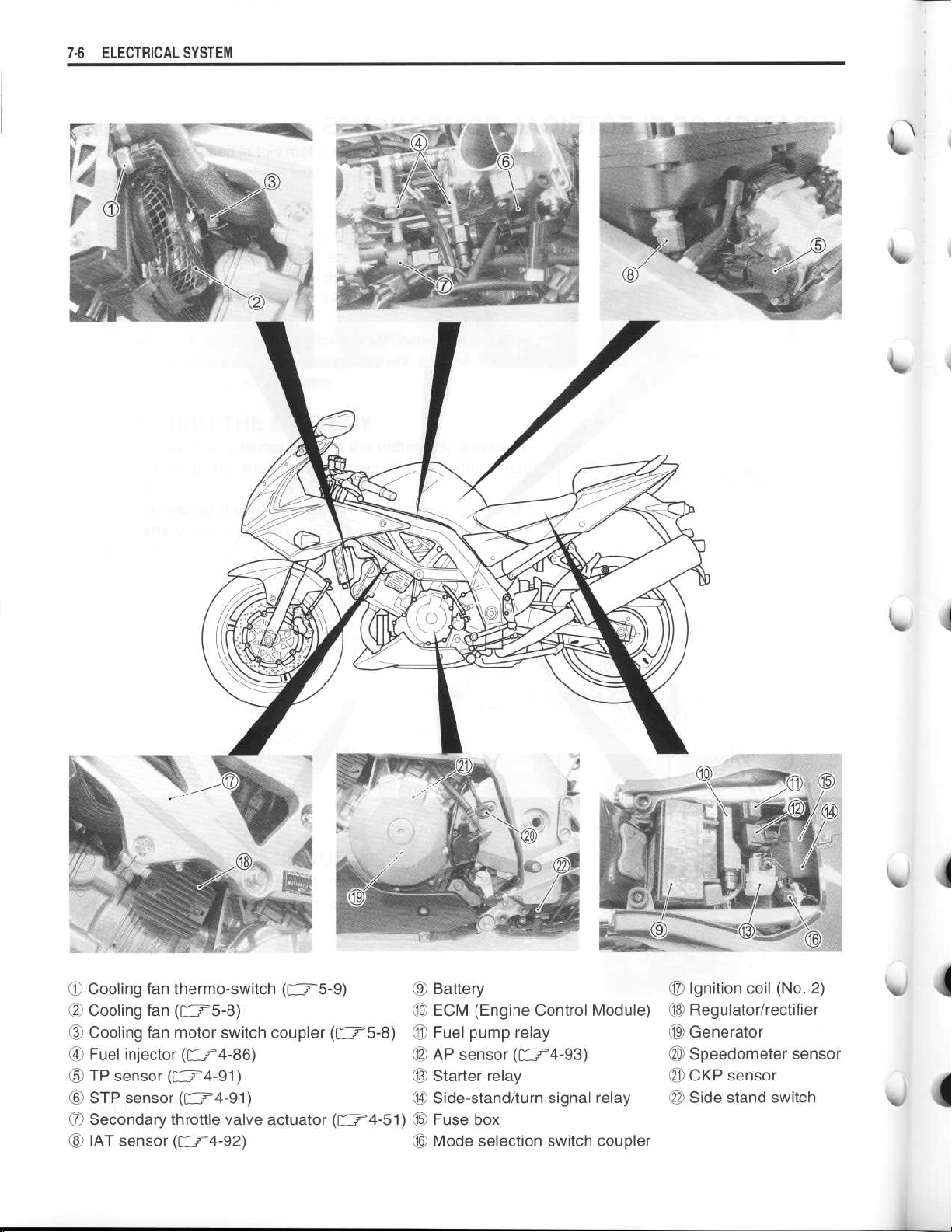

7-6 ELECTRICAL SYSTEM

90 Cooling fan thermo-switch

Cooling fan

•

Cooling fan motor switch coupler (=5-8)

•

•

Fuel injector

~5 TP sensor (=4-91)

STP sensor

•

Secondary throttle valve actuator (=4-51)

•

IAT sensor

•

(r

-

75-8)

(r

--

74-86)

(f"74-91)

(r

--

74-92)

(

F-75-9)

O

10 ECM (Engine Control Module)

5-8)

0

13 Starter relay

14 Side-stand/turn signal relay

4-51) 15 Fuse box

16 Mode selection switch coupler

Battery

11 Fuel pump relay

AP sensor (=4-93)

4-93)

17 Ignition coil (No

18 Regulator/rectifier

19 Generator

20 Speedometer sensor

21 CKP sensor

22 Side stand switch

. 2)

Page 7

~

~

~

~

~

~

~

~

~

~

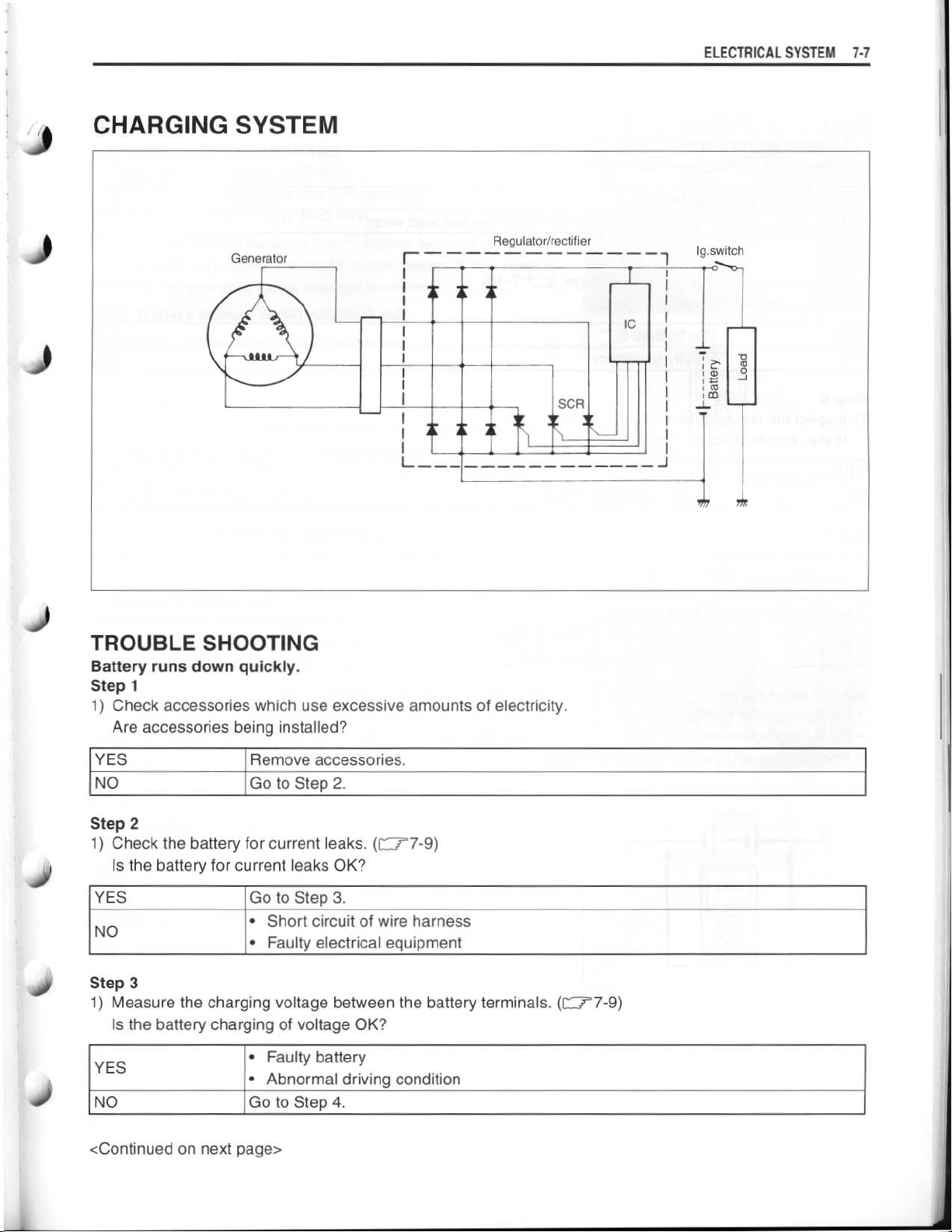

j CHARGING SYSTEM

ELECTRICAL SYSTEM 7-7

4)

4)

Regulator/rectifier

Generator

I

TROUBLE SHOOTING

Battery runs down quickly

.

I

I

I

I

I

I

I

.,

~

SCR

I

I

is

Step 1

1) Check accessories which use excessive amounts of electricity

.

Are accessories being installed?

Ig

l

.switch

I N

m

a

m

0

J

40

YES

NO

Remove accessories

Go to Step 2

.

.

Step 2

1) Check the battery for current leaks

. (=7-9)

Is the battery for current leaks OK?

YES

NO

Go to Step 3

Short circuit of wire harness

•

•

Faulty electrical equipment

.

Step 3

1) Measure the charging voltage between the battery terminals

. (11r7-9)

Is the battery charging of voltage OK?

Faulty battery

YES

NO

•

•

Abnormal driving condition

Go to Step 4

.

<Continued on next page>

Page 8

~

~

~

~

~

~

7-8 ELECTRICAL SYSTEM

Step 4

1) Measure the resistance of the generator coil

Is the resistance of generator coil OK?

. (=7-1 0)

YES

NO

Step 5

1) Measure the generator no-load voltage

Is the generator no-load voltage OK?

YES

NO

Step 6

1) Inspect the regulator/rectifier

Is the regulator/rectifier OK?

YES

NO

Step 7

1) Inspect the wirings

Are the wirings OK?

YES

NO

Go to Step 5

Faulty

Go to Step 6

Faulty

Go to Step 7

Faulty regulator/rectifier

.

Faulty battery

Short circuit of wire harness

•

•

Poor contact of couplers

.

generator

.

generator

.(I"

77-11)

.

coilordisconnected

. (C_r7-10)

lead~^.iros

Battery overcharge

•

Faulty regulator/rectifier

•

Faulty battery

•

Poor contact of generator lead wire coupler

Page 9

~

~

~

~

~

ELECTRICAL SYSTEM

INSPECTION

j

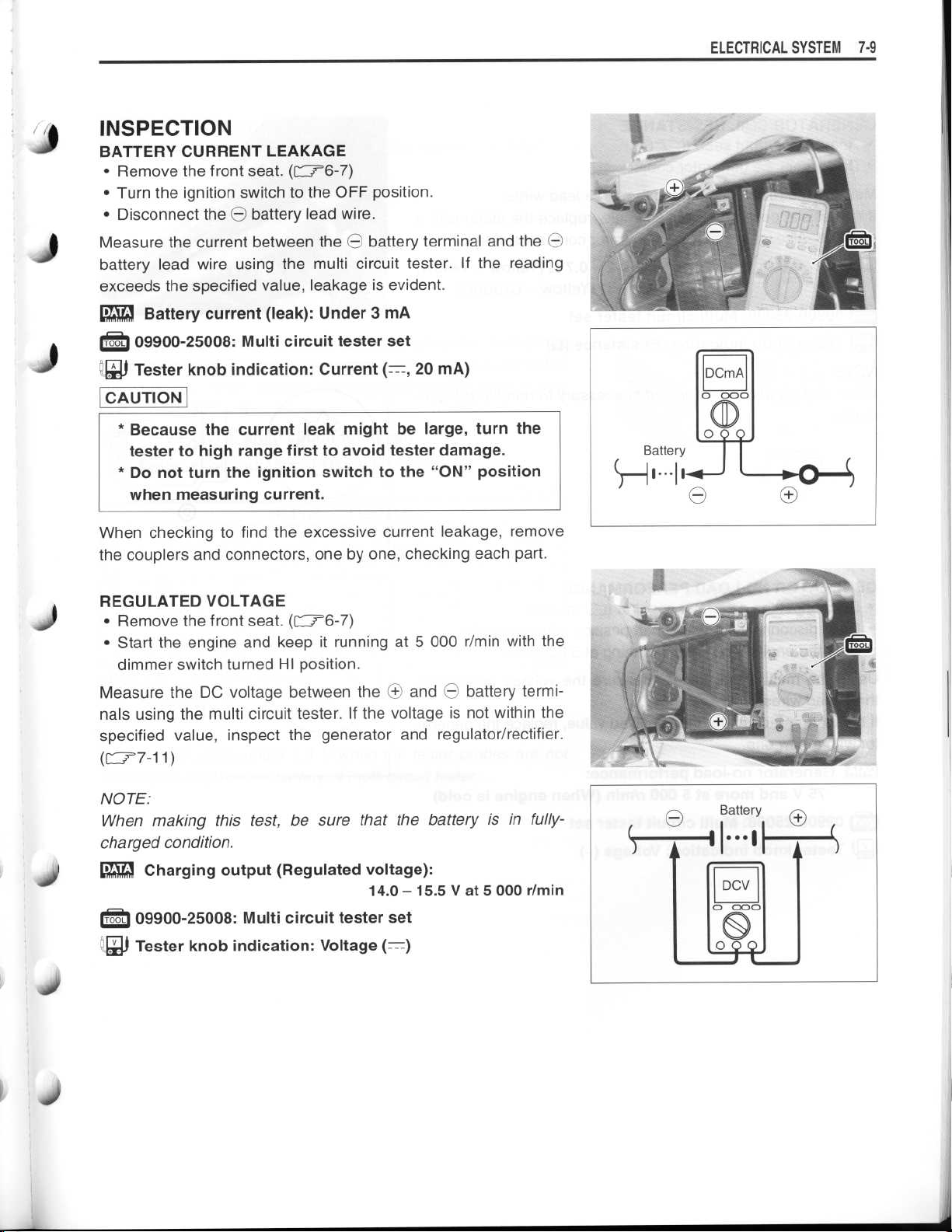

BATTERY CURRENT LEAKAGE

Remove the front seat

•

•

Turn the ignition switch to the OFF position

•

Disconnect theObattery lead wire

Measure the current between the

battery lead wire using the multi circuit tester

exceeds the specified value, leakage is evident

Battery current (leak)

09900-25008

~j Tester knob indication

CAUTION

* Because the current leak might be large, turn the

tester to high range first to avoid tester damage

* Do not turn the ignition switch to the "ON" position

when measuring current

: Multi circuit tester set

. (=6-7)

: Under 3 mA

: Current

.

.

.

battery terminal and the

O

. If the reading

.

20 mA)

(-,

O

.

7-9

When checking to find the excessive current leakage, remove

the couplers and connectors, one by one, checking each part

REGULATED VOLTAGE

Remove the front seat.(r'6-7)

•

Start the engine and keep it running at 5 000 r/min with the

•

dimmer switch turned HI position

Measure the DC voltage between the

nals using the multi circuit tester

specified value, inspect the generator and regulator/rectifier

(r--r7-1

NOTE

When

charged condition

.

1)

:

making

Charging output (Regulated voltage)

.

09900-25008

Tester knob indication

this

test,besure

.

: Multi circuit tester set

.

and

O

. If the voltage is not within the

that

the

14.0- 15

: Voltage

(-)

battery termi-

O

battery is in fully-

:

.5 V at 5 000 r/m i n

.

.

Page 10

~

~

~

~

~

7

.10 ELECTRICAL SYSTEM

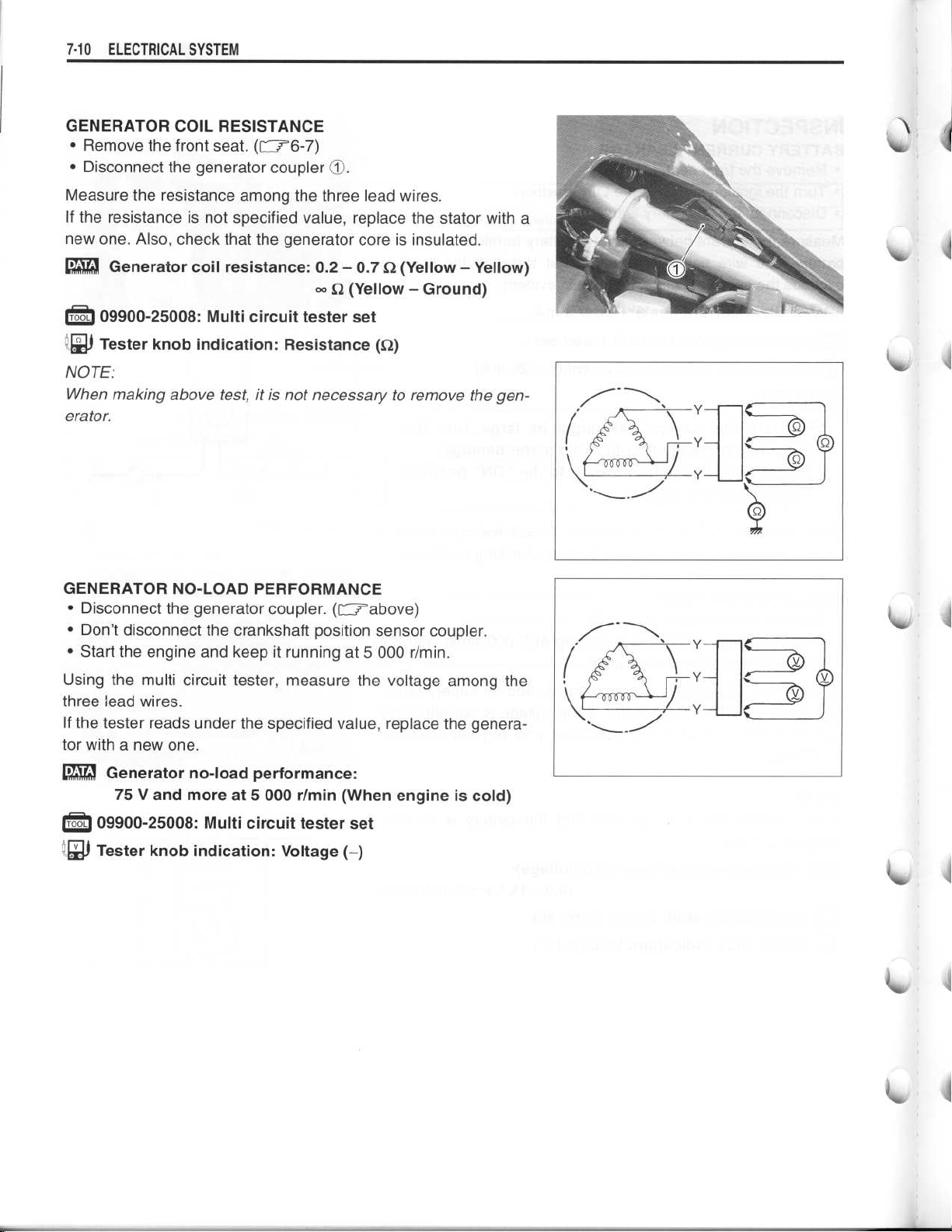

GENERATOR COIL RESISTANCE

•

Remove the front seat

•

Disconnect the generator coupler

Measure the resistance among the three lead wires

If the resistance is not specified value, replace the stator with a

new one

['~Generator coil resistance

. Also, check that the generator core is insulated

. (F-

76-7)

: 0.2- 0

D

.

.

(Yellow-Yellow)

.7 S2

-

S (Yellow-Ground)

.

09900-25008

Tester knob indication

ZJ

NOTE

:

When making above test, it is not necessary to remove the generator

.

GENERATOR NO-LOAD PERFORMANCE

•

Disconnect the generator coupler

•

Don't disconnect the crankshaft position sensor coupler

•

Start the engine and keep it running at 5 000 r/min

Using the multi circuit tester, measure the voltage among the

three lead wires

If the tester reads under the specified value, replace the generator with a new one

: Multi circuit tester set

: Resistance (S2)

. (Crabove)

.

.

.

.

A

A

A

Generator no-load performance

75 V and more at 5 000 r/min (When engine is cold)

09900-25008

Tester knob indication

: Multi circuit tester set

: Voltage

:

(-)

Page 11

~

~

I

4)

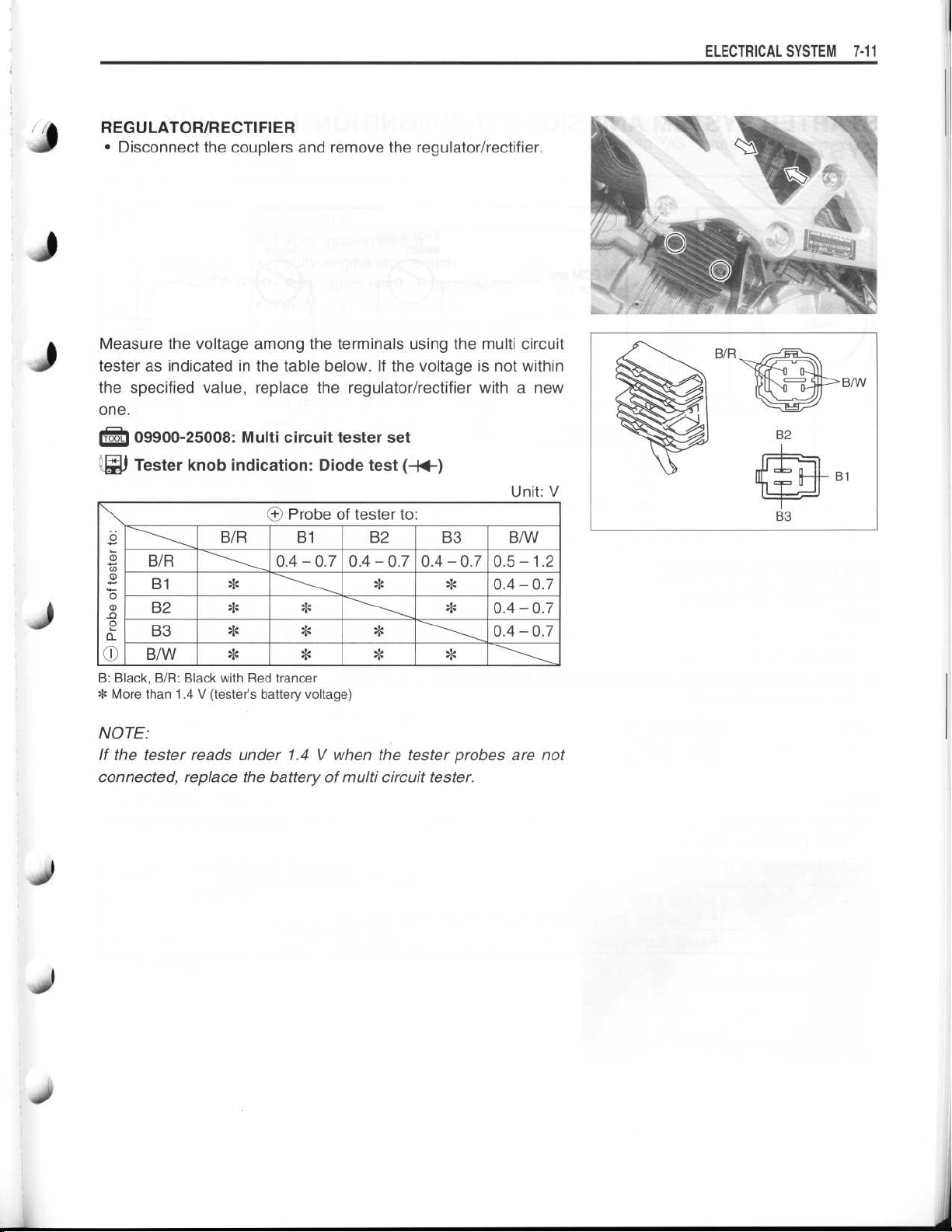

REGULATOR/RECTIFIER

•

Disconnect the couplers and remove the regulator/rectifier

Measure the voltage among the terminals using the multi circuit

tester as indicated in the table below

the specified value, replace the regulator/rectifier with a new

one

.

09900-25008

~$

Tester knob indication

g

~'

B/R

131

0

B2

B3

a

B/W

OI

B

: Black, B/R

* More than 1

: Black with Red trancer

.4 V (tester's battery voltage)

: Multi circuit tester set

: Diode test

Probe of tester to

O

B/R

*

*

131

0.4-0.70.4-0.70.4-0.70.5-1

*

. If the voltage is not within

(-W)

:

B2 B3

*

*

*

.

Unit

: V

B/W

.2

0

.4-0

.7

0

.4-0

.7

0.4-0.7

ELECTRICAL SYSTEM

7-11

NOTE

:

If the tester reads under 1

connected, replace the battery of multi circuit tester

.4 V when the tester probes are not

.

Page 12

~

~

~

7-12 ELECTRICAL SYSTEM

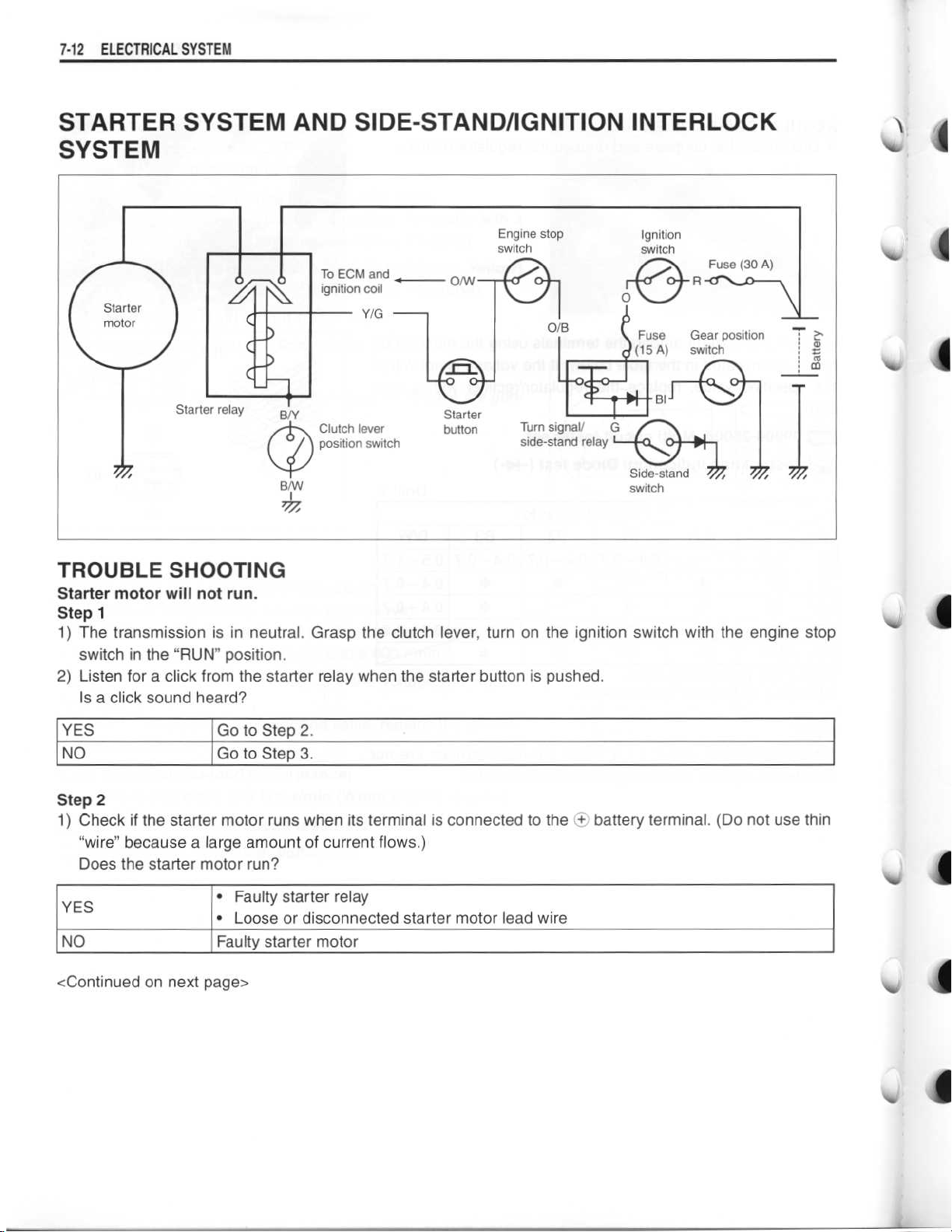

STARTER SYSTEM AND SIDE-STAND/IGNITION INTERLOCK

SYSTEM

Engine stop

switch

0

Starter

motor

Starter relay

To ECM and

0

ignition coil

B/Y

Clutch lever

position switch

B/W

I

Y/G

Starter

button

W

TROUBLE SHOOTING

Starter motor will not run

Step 1

1) The transmission is in neutral

switch in the "RUN" position

2) Listen for a click from the starter relay when the starter button is pushed

Is a click sound heard?

.

. Grasp the clutch lever, turn on the

ignition switch with the engine stop

.

Ignition

switch

Fuse (30 A)

.

ro

m

A

rr

In

J

YES

NO

Step 2

1) Check if the starter motor runs when its terminal is connected to the

"wire" because a large amount of current flows

Go to Step 2

Go to Step 3

.

.

.)

battery terminal

O

. (Do not use thin

Does the starter motor run?

Faulty starter relay

YES

NO

•

•

Loose or disconnected starter motor lead wire

Faulty starter motor

<Continued on next page>

Page 13

~

~

~

~

~

~

~

~

~

~

~

~

~

Step 3

1) Measure the starter relay voltage at the starter

starter button is pushed

Is the voltage OK?

YES

NO

Step 4

1) Check the starter relay.(F-t

Is the starter relay OK?

.

Go to Step 4

•

Faulty ignition switch

•

Faulty engine stop switch

•

Faulty clutch lever position switch

Faulty gear position switch

•

•

Faulty turn signal/side-stand relay

•

Faulty starter button

•

Poor contact of connector

•

Open circuit in wire harness

.

7-1 6)

relay connectors (between Y/GO+and B/YO)when the

ELECTRICAL SYSTEM7-1

3

YES

NO

NOTE

:

Poor contact of the starter relay

Faulty starter relay

The starter motor runs when the transmission is in neutral with the side-stand up or down, but does not run

when the transmission is in any position other than neutral with the side-stand down

2) Check the side-stand switch

Is the side-stand switch OK?

YES

NO

Engine does not turn though the starter motor runs

•

Faulty starter torque limiter (=3-64)

Open circuit in wire harness

•

•

Poor contact of connector

Faulty side-stand switch

. (CIT7-17)

.

.

STARTER MOTOR REMOVAL AND

DISASSEMBLY

•

Remove the under cowling

•

Disconnect the starter motor lead wire

starter motor

.

. (=6-5)

6-5)

90 and remove the

Page 14

~

~

~

~

7-14 ELECTRICAL SYSTEM

•

Disassemble the starter motor as shown in the illustration

.

0-ring

T

Housing

02

©3

Armature

Washer

•

0-ring

O5

Starter motor case

•

07 Starter brush holder assembly

0-ring

•

STARTER MOTOR INSPECTION

CARBON BRUSH

Inspect the brushes for abnormal wear, cracks, or smoothness

in the brush holder

If any damages are found, replace the brush assembly with a

new one

.

.

i

V

COMMUTATOR

Inspect the commutator for discoloration, abnormal wear or

undercut

If abnormal wear is found, replace the armature with a new one

OA

.

.

If the commutator surface is discolored, polish it with #400 sand

paper and wipe it using a clean dry cloth

.

If there is no undercut, scrape out the insulator 10 with a saw

blade

.

ARMATURE COIL INSPECTION

Check for continuity between each segment, and between each

segment and the armature shaft using the multi circuit tester

.

If there is no continuity between the segments or there is continuity between the segments and shaft, replace the armature

with a new one

09900-25008

i E

Tester knob indication

0

e

.

: Multi circuit tester set

: Continuity test

(

•I

)))

Page 15

~

~

~

~

~

ELECTRICAL SYSTEM 7-15

OIL SEAL INSPECTION

Check the oil seal lip for damage or leakage

If any damage is found, replace the housing end

.

.

J

STARTER MOTOR REASSEMBLY

l

Reassemble the starter motor in the reverse order of disassem-

bly

. Pay attention to the following points

•

Apply SUSUKI SUPER GREASE to the lip of the oil seal

:

.

99000-25030

99000-25010

•

Apply a small quantity of SUZUKI MOLY PASTE to the armature shaft

Apply a small quantity of THREAD LOCK to the starter motor

•

housing bolts

•

Apply SUZUKI SUPER GREASE to the O-ring

.

99000-25140

99000-32050

99000-25030

99000-25010

: SUZUKI SUPER GREASE "A" (USA)

: SUZUKI SUPER GREASE "A" (Others)

: SUZUKI MOLY PASTE

.

: THREAD LOCK "1342"

.

: SUZUKI SUPER GREASE "A" (USA)

: SUZUKI SUPER GREASE "A" (Others)

Tighten the starter motor lead wire nut to the specified torque

•

: 5 N

.m (0

Starter motor lead wire nut

19

.5 kgf-m, 3

.7 Ib-ft)

.

Page 16

~

~

~

~

~

~

7-16 ELECTRICAL SYSTEM

STARTER RELAY INSPECTION

•

Remove the front seat.(F--r6-7)

•

Disconnect theObattery lead wire from the battery

•

Disconnect the starter relay coupler 1O

•

Remove the starter relay cover 02

.

.

.

•

Disconnect the starter motor lead wire

wire ®

•

Remove the starter relay 05

Apply 12 V to ® and © terminals and check for continuity

between the positive and negative terminals using the multi circuit tester

relay is OK

CAUTION

Do not apply a battery voltage to the starter relay for

more than five seconds, since the relay coil may overheat and damaged

.

.

. If the starter relay clicks and continuity is found, the

.

09900-25008

Tester knob indication

: Multi circuit tester set

: Continuity test (

.

and battery lead

(s

•~

l))

Measure the relay coil resistance between the terminals using

the multi circuit tester

value, replace the starter relay with a new one

Starter relay resistance

. .

09900-25008

~y Tester knob indication

. If the resistance is not within the specified

.

: 3 - 6

: Multi circuit tester set

: Resistance (SZ)

SZ

Page 17

~

~

~

~

J

SIDE-STAND/IGNITION INTERLOCK

SYSTEM PARTS INSPECTION

Check the interlock system for proper operation

system does not operate properly, check each component for

damage or abnormalities

the component with a new one

SIDE-STAND SWITCH

•

Lift and support the fuel tank

•

Disconnect the side-stand switch coupler and measure the

voltage between Green and Black/Yellow lead wires

09900-25008

P71

i

Tester knob indication

ON

(Side-stand up)

OFF

(Side-stand down)

: Multi circuit tester set

. If any abnormality is found, replace

.

.

(

F-74-65)

: Diode test (-~W)

Green

(O+

Probe)

0 .4

-

1

.4 V and more

(Tester's battery voltage)

. If the interlock

.

Black/Yellow

Probe)

(O

0

.6 V

ELECTRICAL SYSTEM 7-

1

7

NOTE

:

If the tester reads under 1

connected, replace its battery

GEAR POSITION SWITCH

•

Lift and support the fuel tank

•

Disconnect the gear position switch coupler and check the

continuity between Blue and Black with the transmission in

"NEUTRAL"

ON (Neutral)

OFF (Expect neutral)

CAUTION

When disconnecting and connecting the gear position

switch coupler, make sure to turn OFF the ignition

switch, or electronic parts may get damaged

.

.4 V when the tester probes are not

.

.

(r

-

74-65)

Blue

0

Black

0

.

Down

Page 18

~

~

~

~

7-18

ELECTRICAL SYSTEM

•

Connect the gear position switch coupler to the wiring harness

.

•

Turn the ignition switch to "ON" position and side-stand to

upright position

Measure the voltage between Pink and Black lead wires using

the multi circuit tester when shifting the gearshift lever from low

to top

.

.

Gear position switch voltage

(* Low to top gear position)

(*

Except neutral position)

09900-25008

09900-25009

1

711

Tester knob indication

TURN SIGNAL/SIDE-STAND RELAY

The turn signal/side-stand relay is composed of the turn signal

relay, and the side-stand relay and diode

•

Remove the front seat

•

Remove the turn signal/side-stand relay

SIDE-STAND RELAY INSPECTION

First check the insulation betweenOandOterminals with the

tester

. Then apply 12 V to terminalsODand ©

©) and check the continuity betweenODand

continuity, replace the turn signal/side-stand relay with a new

one

.

.

.

09900-25008

: Multi circuit tester set

: Needle pointed probe set

: Voltage

. (=6-7)

6-7)

: Multi circuit tester set

.6 V and more

: 0

(Pink-Black)

(--)

.

.

(

O+

toOandOto

(e

.

If there is no

Tester knob indication

e

0

: Continuity test

(•))))

Page 19

~

~

ELECTRICAL SYSTEM 7-

DIODE INSPECTION

J

~

Measure the voltage between the terminals using the multi cir-

cuit tester

0

0

0

0

0-

go

NOTE

If the multi circuit tester reads under 1

probes are not connected, replace its battery

. Refer to the following table

Probe of tester to

©, ©

~

0

©, ©

0

.4-0

.6

09900-25008

Tester knob indication

:

: Multi circuit tester set

: Diode test

.

Unit

:

OO

More than 1

(Tester's battery

voltage)

(-W)

.4 V when the tester

.

.4 V

: V

iii

© OO

1 9

Page 20

~

~

7-20

ELECTRICAL SYSTEM

IGNITION SYSTEM

Engine stop switch

0

CKP

sensor

I

I

1 0

I

Cam position

sensor

ECM

Power

source

circuit

0

Wave form

arrangement

circuit

Wave form

arrangement

circuit

Throttle

position

sensor

CPU

Engine

coolant temp

sensor

.

Gear

position

switch

Ignition

coil

0

t 0

a

00

0

°

o

'ta

Spark plug

#1

#2

m m

Side-

b

standstand

relay

Fuse

Ignition

switch

Fuse

Battery

V

NOTE

:

The fuel cut-off circuit is incorporated in this ECM in order to prevent over-running of engine

speed reaches 10 600 r/min, this circuit cuts off fuel at the fuel injector

.

. When engine

CAUTION

Under no load, the engine can run over 10 600 r/min, even if the fuel cut-off circuit is effective,

and it may cause engine damage

time

.

. Do not run the engine without load over 10 600 r/min at any-

TROUBLESHOOTING

NOTE

:

Check that the transmission is in neutral and the engine stop switch is in the "RUN" position

lever

. Check that the fuse is not blown and the battery is fully-charged before diagnosing

No spark or poor spark

Step 1

1) Check the ignition system couplers for poor connections

.

Is there connection in the ignition switch couplers?

YES

NO

Go to Step 2

.

Poor connection of couplers

. Pull the clutch

.

<Continued on next page>

Page 21

~

~

~

~

~

~

~

~

ELECTRICAL SYSTEM 7-21

Step 2

1) Measure the battery voltage between input lead wires (O/W and B/W) at the ECM with the ignition switch

in the "ON" position

Is the voltage OK?

.

YES

NO

Step 3

1) Measure the ignition coil primary peak voltage

NOTE

:

This inspection method is applicable only with the multi circuit tester and the peak volt adaptor

Is the peak voltage OK?

YES

NO

Step 4

1) Inspect the spark plugs

Are the spark plugs OK?

YES

NO

Go to Step 3

•

Faulty ignition switch

Faulty turn signal/side-stand relay

•

•

Faulty engine stop switch

•

Broken wire harness or poor connection of related circuit couplers

Go to Step 4

Go to Step 5

. (=2-6)

Poor connection of the spark plug cap

•

•

Go to Step 5

Faulty spark plug

.

.

.

2-6)

.

(-s)

.(f"

77-22)

.

(-s)

Step 5

1) Inspect the ignition coils

Are the ignition coils OK?

YES

NO

Step 6

1) Measure the crankshaft position sensor peak voltage and its resistance

NOTE

:

The crankshaft position

peak volt adaptor

Are the peak voltage and its resistance OK?

YES

NO

.

. (E177-23)

Go to Step 6

Faulty ignition coil

sensor

Faulty ECM

•

•

Poor connection of ignition couplers

Faulty crankshaft position sensor

.

(-s)

peak voltage inspection is applicable only with the mufti circuit tester and

.

Page 22

~

~

~

~

~

~

~

~

~

~

7-22

ELECTRICAL SYSTEM

INSPECTION

IGNITION COIL PRIMARY PEAK VOLTAGE

•

Lift and support the fuel tank.(l1_,,--4-65)

•

Disconnect both of the spark plug caps.(f'72-6)

•

Connect new spark plugs to each spark plug cap and ground

them

.

NOTE

:

Make sure that all couplers and spark plugs are connected properly and the battery used is in fully-charged condition

CAUTION

Avoid grounding the spark plugs and suppling the

electrical shock to the cylinder head cover (magnesium parts) in order to prevent the magnesium material from damage

.

.

Measure the No

in the following procedure

Connect the multi circuit tester with peak voltage adaptor as

•

follows

No

.

. 1 ignition coil

. 1 and No

:OOProbe

•

No

. 2 ignition coil

:OOProbe

•

NOTE

:

Do not disconnect the ignition coil primary wire coupler

. .

09900-25008

CAUTION

Before using the multi circuit tester and peak volt

adaptor, be sure to refer to the appropriate instruction

manual

•

Shift the transmission into neutral

•

Allow the engine to crank for a few seconds, and then measure the ignition coil primary peak voltage

.

: Multi circuit tester set

. 2 ignition coils primary peak voltage

.

: Black terminal

Probe

: Ground

: White/Blue terminal

Probe

: Ground

.

.

.

r

In

•

Repeat the above procedure a few times and measure the

highest ignition coil primary peak voltage

Ignition coil primary peak voltage

Tester knob indication

WARNING

A

While testing, do not touch the tester probes and

spark plugs to prevent receiving an electric shock

•

If the peak voltage is lower than the specified values, inspect

the ignition coil.(F---r7-23)

: Voltage

.

: 200 V and more

(--)

.

Page 23

~

~(~

~

~

~

ELECTRICAL SYSTEM 7-23

IGNITION COIL RESISTANCE

•

J

Disconnect the spark plug caps

Measure the ignition coil resistance in both the primary and sec-

ondary windings

range, replace the ignition coil with a new one

. If the resistance is not within the standard

.

.

1

Ignition coil resistance

Primary

Secondary

09900-25008

Tester knob indication : Resistance

CKP SENSOR PEAK VOLTAGE

•

Remove the front seat

•

Disconnect the ECM coupler

NOTE

:

Make sure that all of the couplers are connected properly and

the battery used is in fully-charged condition

: 2.8-4.2 S2

: 24 -

: Multi circuit tester set

((O

terminal -Sterminal)

36 kL2 (Plug cap

. (116-7)

.

-Oterminal)

(4)

.

Measure the CKP sensor peak voltage in the following procedures

.

•

Connect the multi circuit tester with peak volt adaptor as fol-

lows

.

O

Probe

: Green/Blue lead wire

Probe

9

. .

09900-25008

CAUTION

Before using the multi circuit tester and peak volt

adaptor, be sure to refer to the appropriate instruction

manual

: Green lead wire

: Multi circuit tester set

.

Page 24

~

~

~

~

~

~

~

~

7-

2 4

ELECTRICAL SYSTEM

•

Shift the transmission into neutral

•

Allow the engine to crank for a few seconds, and then measure the CKP sensor peak voltage

•

Repeat the above procedure a few times and measure the

highest peak voltage

[

CKP sensor peak voltage

I

rPli

Tester knob indication

If the peak voltage is lower than the specified values, check the

peak voltage at the CKP sensor lead wire coupler

•

Disconnect the CKP sensor lead wire coupler and connect the

multi circuit tester with the peak volt adaptor

•

Probe

: Green lead wire

Probe

•

•

Measure the CKP sensor peak voltage at the CKP sensor

lead wire coupler in the same manner as on the ECM coupler

: Blue lead wire

.

: Voltage

.

.

: 5

.0 V and more

(-)

(Z

.

.

.

CKP sensor peak voltage

Tester knob indication

~,~

If the peak voltage on the CKP sensor lead wire coupler is OK

but on the ECM coupler is out of specification, the wire harness

must be replaced

the CKP sensor must be replaced and re-checked

CKP SENSOR RESISTANCE

Measure the resistance between the lead wires and ground

the resistance is not specified value, the CKP sensor must be

replaced

.

CKP sensor resistance

09900-25008

Tester knob indication

. If both peak voltages are out of specification,

: Multi circuit tester set

: 5

.0 V and more

: Voltage

: 130 -

W Q (Green -

: Resistance (S2)

(-)

240 Q (Green-Blue)

Ground)

.

. If

Page 25

~

~

~

~

COMBINATION METER

ELECTRICAL SYSTEM

J)

Conbination meter cover

Conbination meter unit

(2

7- 2

5

REMOVAL

•

Remove the body cowling

•

Remove the meter panel mounting bolts and disconnect the

meter coupler 1T

CAUTION

•

When disconnecting and connecting the combination meter coupler, make sure to turn OFF the ignition switch, or electronic parts may get damaged

•

Do not attempt to disassemble the combination

meter unit

.

.

.

(r

--

r6-6)

.

Page 26

~

~

~

~

~

~

~

7-26

ELECTRICAL SYSTEM

PARTS NAME

10 Turn signal indicator light

(2

Neutral indicator light

(3 Indicator light (Oil, Temp

•

SELECT button

•

Clock

Coolant temperature/Fl display

•

(7

Odo/Trip meter display

•

ADJUST button

~9 Fuel indicator light

1o High beam indicator light

., FI)

OPERATING PROCEDURE

INITIAL DISPLAY

When the ignition switch is turned to ON, the indicator light

andOcome on, then ©9 goes out two seconds later

NOTE

:

If the

power supply is cut (e, g, when the battery is replaced)

* The speedometer, tripmeter and clock are displayed after the

initial display appears

* Since the clock resets to

.

"1

:00",

it will need to be readjusted

CHANGE THE DISPLAY MODE

With each press of the SELECT button, the display changes

between odometer, tripmeter A and tripmeter B as shown

WARNING

A

Odometer

-n

Tripmeter A~~ Tripmeter

To avoid riding with only one hand, do not operate the

buttons while riding

.

ODOMETER

•

Displays the total distance travelled

.

:

.

.

B1-

1

TRIPMETER

•

Displays the distance travelled since the tripmeter was last

reset

NOTE

:

The tripmeters A and B can be used independently

Hold down the ADJUST button for two seconds to reset the

•

tripmeter

.

.

Page 27

~

~

CLOCK

•

Displays the time (hours and minutes) on a 12-hour clock

•

Setting the time

10 Push the SELECT and ADJUST buttons simultaneously until

the hour display starts blinking

02 Adjust the hour display by pushing the ADJUST button

NOTE

:

.

.

When the ADJUST button is kept depressed for more than two

seconds, the display progresses continuously

03 Push the SELECT button

changed

.

. The setting that is blinking can be

.

ELECTRICAL SYSTEM 7-

ADJ

2 7

® Adjust the minute display by pushing the ADJUST button

($ Push the SELECT button to finish setting time

.

.

TACHOMETER

•

The tachometer pointer operates one time as shown below to

reset tachometer pointer, when connecting the

tachometer coupler

i

.

battery or

Page 28

~

~

~

~

7-28 ELECTRICAL SYSTEM

ENGINE COOLANT TEMPERATURE METER

AND INDICATOR

•

Disconnect the engine coolant temperature sensor coupler

CAUTION

When connecting and disconnecting the engine coolant temp

OFF the ignition switch, or electronic parts may get

damaged

•

Connect the variable resistor

•

Turn the ignition switch "ON"

•

Check the LCD and LED operations when the resistance is

adjusted to the specified values

. sensor lead wire coupler, make sure to turn

.

between the terminals

OO

.

.

.

.

Engine

coolant

temp

.

Variable resister

sensor

Resistance

AO

Over 2

(Jumper wire)

If either one or all indications are abnormal, replace the combi-

nation meter with a new one

NOTE

If the engine stop switch is turned OFF while the ignition switch

is ON, the LCD displays "CHEC"

This condition implies that combination meter receives no signal

from the ECM

In that case, they are restored to ordinary indication by turning

the engine stop switch RUN

.45 kS

Approx

0

.811 kS2

Approx

0

.1 kS2

0c

:

LED © LCD ©

OFF

.

OFF

.

ON

ON

.

---

"50"

"120"-"139"

"HI"

.

. But it is not malfunction

.

LCD

0

-

Flicker

Flicker

Water

temperature

Under 19 °C

Approx

120-139

Over 140 °C

50 °C

.

.

0

C

Page 29

~

~

~

~

1

FUEL LEVEL INDICATOR SWITCH INSPECTION

. (=4-69)

•

Remove the fuel pump assembly

•

Connect 12 V battery and test bulb (12 V, 3

level indicator switch as shown in the right illustrations

bulb should come on after several seconds if the switch is in

good condition

.

4-69)

.4 W) to the fuel

. The

ELECTRICAL SYSTEM 7-

29

•

When the switch is immersed in water under the above condition, the bulb should go out

unit with a new one

FUEL LEVEL INDICATOR LIGHT INSPECTION

If the fuel level indicator light does not function properly, check

the fuel level indicator switch and its lead wire/coupler

If the fuel level indicator switch and its lead wire/coupler are all

right, replace the combination meter with a new one

OIL PRESSURE INDICATOR

NOTE

:

Before inspecting the oil pressure switch, check the engine oil

level.(rr2-15)

.

. If the bulb remains it, replace the

.

.

•

Remove the under cowling

•

Disconnect the oil pressure switch lead wire from the oil pres-

sure switch

•

Turn the ignition switch "ON" position

.

.(C7-6-5)

.

Page 30

~

~

~

7

.30 ELECTRICAL SYSTEM

Check if the oil pressure indicator will light, when grounding the

lead wire

replace the meter with a new one after checking the connection

of couplers

SPEEDOMETER

If the speedometer, odometer or trip meter does not function

properly, inspect the speedometer sensor and connection of

coupler 1)

right, replace the meter with a new one

. If the oil pressure indicator does not function properly,

.

. If the speedometer sensor and connection are all

.

SPEEDOMETER SENSOR

•

Disconnect speedometer sensor coupler

•

Remove the speedometer sensor (2 by removing its mounting

bolt

.

•

Connect 12 V battery, 10 kQ resistor and the multi circuit

tester as shown in the right illustration

B/R

: Black with Red tracer

B/W

: Black with White tracer

B

: Black

:

.

09900-25008

Tester knob indication

•

Under above condition, if a suitable screwdriver touching the

pick-up surface of the speedometer sensor is moved, the

tester reading voltage changes (0 V

the tester reading voltage does not change, replace the

speedometer sensor with a new one

NOTE

:

The highest voltage reading in this test will be the same as that

of battery voltage

: Multi circuit tester set

: Voltage

.

.

.

(=)

- 12 V or 12 V -

.

0 V)

. If

Page 31

~

~

~

~

LAMPS

HEADLIGHT AND POSITION LIGHT

ELECTRICAL SYSTEM7-3

10

Head light

12 V 60/55 W x 2

(2 Position light

12 V 5 W x 2

1

l

BULB REPLACEMENT

Headlight

•

Remove the headlight coupler and boot

•

Unhook the holder spring 9I and replace the headlight bulb

Position light

•

Open the lids

•

Remove the position light couplers 10

. (L & R)

.

. (L & R)

.

CAUTION

If you touch the bulb with your bare hands, clean the

bulb with a cloth moistened with alcohol or soapy

water to prevent premature bulb failure

.

Page 32

~

~

7-32

ELECTRICAL

HEADLIGHT BEAM ADJUSTMENT

Adjust the headlight beam, both vertical and horizontal

•

Turn the adjuster

NOTE

:

To adjust the headlight beam, adjust the beam horizontally first,

then adjust the vertically

•

Turn the bolt © for the vertical adjustment

SYSTEM

for the horizontal adjustment

OA

.

.

.

.

BRAKE LIGHT/TAILLIGHT, TURN SIGNAL LIGHT AND LICENCE PLATE

LIGHT

Page 33

RELAYS

TURN SIGNAL/SIDE-STAND RELAY

The turn signal/side-stand relay is composed of the turn signal

relay, side-stand relay and diode

INSPECTION

Before removing the turn signal/side-stand relay, check the

operation of the turn signal light

If the turn signal light does not illuminate, inspect the bulb, turn

signal switch and circuit connection

If the bulb, turn signal switch and circuit connection are OK, the

turn signal relay may be faulty

side-stand relay with a new one

NOTE

:

* Make sure that the battery is fully charged

* Refer to page 7-17 for the side-stand relay and diode inspec-

tion

.

.

.

.

; therefore, replace the turn signal/

.

.

ELECTRICAL SYSTEM 7-33

T)

SIDE-STAND RELAY

TURN

SIGNAL

RELAY

4)

STARTER RELAY

r -

77-1

6

FUEL PUMP RELAY

17'4-69

Page 34

~

~

~

~

~

7-34

ELECTRICAL SYSTEM

SWITCHES

IGNITION SWITCH REMOVAL

•

Lift and support the fuel tank

•

Remove the air cleaner box.(F

•

Disconnect the ignition switch coupler

•

Remove the body cowling.(

•

Remove the ignition switch mounting bolts with the special

tools

.

. (=4-65)

74-75)

--

r -

76-6)

.

09930-11920

09930-11940

CAUTION

When reusing the ignition switch bolt, clean thread and

apply THREAD LOCK

99000-32050

: Torx bit JT40H

: Bit holder

.

: THREAD LOCK "1342"

Page 35

~

~

ELECTRICAL SYSTEM 7.3 5

J

J

Inspect each switch for continuity with the multi circuit tester

tive switch assemblies with new ones

09900-25008

IGNITION

Position

ON

P

DIMMER SWITCH

Position

HI (=D)

LO (D)

TURN SIGNAL SWITCH

Position

L

PUSH

R

PASSING LIGHT SWITCH

Position

PUSH

ENGINE STOP SWICH

Position

OFF (>Z)

RUN (0)

STARTER BUTTON

Position

PUSH

HORN BUTTON

Position

PUSH

SWITCH

Color

Color

Color

Color

Color

Color

Color

: Multi circuit tester set

R

W

0 0

Lg

0

0

y

0 0

Lbl

0 0

0

0 Y

O/B

0

O/W

0

13/131

0

ON

.

Br

0

B

O/W

Y/G

B/W

. If any abnormality is found, replace the respec-

HAZARD

Color

Position

ON

OFF

FRONT BRAKE SWITCH

Color

Position

OFF

ON

REAR BRAKE SWITCH

Color

Position

OFF

ON

CLUTCH LEVER POSITION SWITCH

Color

Position

OFF

ON

OIL PRESSURE SWITCH

Color

Position

ON (engine

is stopped)

OFF (engine

is running)

NOTE

:

Before inspecting the oil pressure switch, check the

engine oil level

WIRE COLOR

B~:

Black

Br

: Brown

LbI

: Light blue

Lg

: Light green

0

:

Orange

R

:

Red

Y~:

Yellow

W

: White

Lg

0

B/R

O/G

B/Y

G/Y Ground

. (C72-15)

Lbl

0

0 0

W/B

0

O O

B/BI

: Black with Blue tracer

B/W

: Black with White tracer

B/Y

: Black with Yellow tracer

B/R

: Black with Red tracer

G/Y

: Green with Yellow tracer

O/B

: Orange with Black tracer

O/G

: Orange with Green tracer

O/W

: Orange with White tracer

ON

:Orange with Yellow tracer

W/B

: White with Black tracer

Y/G

: Yellow with Green tracer

B

0

B/BI

0

B/Y

Page 36

~

~

~

~

~

~

~

~

~

7-36

ELECTRICAL SYSTEM

BATTERY

SPECIFICATIONS

Type designation

Capacity

Anode plates

•

Separator (fiberglass plate)

•

Cathode plates

•

Upper cover breather

•

12 V, 43

FTX14-BS

.2 kC (12 Ah)/10 HR

© Stopper

Filter

•

Terminal

•

•

Safety valve

INITIAL CHARGING

FILLING ELECTROLYTE

•

Remove the aluminum tape 10 sealing the battery electrolyte

filler holes 02

•

Remove the caps

.

(T

.

NOTE

:

* After filling the electrolyte completely, use the removed caps

O3 as the sealed caps of battery filler holes

* Do not remove or pierce the sealed areas ® of the electrolyte

container

•

Insert the nozzles of the electrolyte container ($ into the bat-

tery's electrolyte filler holes, holding the container firmly so

that it does not fall

fluid to spill

.

. Take precaution not to allow any of the

.

.

IN

V

Page 37

~

~

~

ELECTRICAL SYSTEM7-37

•

Make sure air bubbles © are coming up each electrolyte con-

tainer, and leave in this position for about more than 20 min-

0

O

oV

0

0

J

°

0

L)

U

O

o

Vo

0

U

O

O

°

o

I

0

H,

I

U

0

O

o

0

U

G

V

0

Go

G

oU

0

0G

~`

1

utes

.

NOTE

:

If on air bubbles are coming up from a filler port, tap the bottom

of the electrolyte container two or three times

Never remove the container from the battery

•

After confirming that the electrolyte has entered the battery

completely, remove the electrolyte containers from the bat-

tery

. Wait for about more than 20 minutes

.

.

.

l

•

Insert the caps O7 into the filler holes, pressing in firmly so that

the top of the caps do not protrude above the upper surface of

the battery's top cover

CAUTION

•

Never use anything except the specified battery

•

Once install the caps to the battery

the caps

•

Do not tap the caps with a hammer when installing

them

.

.

.

.

; do not remove

Page 38

~

~

~

~

~

~

~

~

7-

ELECTRICAL SYSTEM

3

8

•

For initial charging, use the charger specially designed for MF

battery

CAUTION

•

•

•

.

For charging the battery, make sure to use the

charger specially designed for MF battery

wise, the battery may be overcharged resulting in

shortened service life

Do not remove the cap during charging

Position the battery with the cap facing upward during charging

.

.

. Other-

.

SERVICING

Visually inspect the surface of the battery container

of cracking or electrolyte leakage from the sides of the battery

have occurred, replace the battery with a new one

terminals are found to be coated with rust or an acidic white

powdery substance, clean the battery terminals with sandpaper

. If any signs

. If the battery

.

RECHARGING OPERATION

•

Measure the battery voltage using the multi circuit tester

the voltage reading

battery with a battery charger

CAUTION

When recharging the battery, remove the battery from

the motorcycle

NOTE

:

While recharging, do not remove the caps on the top of the bat-

tery

.

Recharging time

CAUTION

Be careful not to permit the charging current to

exceed 6 A at any time

•

After recharging, wait at least 30 minutes and then measure

the battery voltage using the multi circuit tester

voltage is less than 12

battery voltage is still less than 12

replace the battery with a new one

•

When a battery is left unused for a long time, its voltage

needs to be regularly measured

used for more than one month (especially during the winter

season), measure the battery voltage at least once a month

is less

.

: 1

.4 A for 5 to 10 hours or 6 A for 1 hour

than the

.

.

.5 V, recharge the battery again

12 V

.5 V after recharging,

.

. When the motorcycle is not

recharge the

(DC),

. If the battery

. If

. If the

.

Charging period

(V)

18

17

16

15

14 13

12

0 10

Stop charging

20

30 40 50

Time

60

(Minutes)

Loading...

Loading...