Page 1

•

S V 10005

SERVICE MANUAL

I

1 99500-39250-03E 0

II II II II

Page 2

IMPORTANT

All street-legal Suzuki motorcycles with

displacementof50

Environmental Protection agency emission regulations

These regulations set specific standards for exhaust

emission output levels as well as particular servicing

requirements

required to properly inspect and service SV1000S in

accordance with all EPA regulations

recommended that the chapter on Emission Control,

Periodic Servicing and Fl SYSTEM be thoroughly

reviewed before any type of service work is performed

Further information concerning the EPA emission

regulations and U.S. Suzuki's emission control program

can be found in the U.S. SUZUKI EMISSION CONTROL

PROGRAM MANUAUSERVICE BULLETIN

. This manual includes specific information

cc

or greater are subject

. It is strongly

.

engine

to

.

.

0

f

1

0

1

40

Of

of

Page 3

FOREWORD

This manual contains an introductory

the SUZUKI SV1000S and procedures for its

inspection/service and overhaul of its main compo-

nents

.

Other information considered as generally known is

not included

Read the GENERAL INFORMATION section to

familiarize yourself with the motorcycle and its maintenance

to use as a guide for proper inspection and service

This manual will help you know the motorcycle bet-

ter so that you can assure your customers of fast

and reliable service

.

. Use this section as well as other sections

.

description

on

GENERAL INFORMATION

PERIODIC MAINTENANCE

.

ENGINE

FI SYSTEM

* This manual has been prepared on the basis

of the latest specifications at the time of publication

. If modifications have been made since

then, differences may exist between the content of this manual and the actual motorcycle

* Illustrations in this manual are used to show

the basic principles of operation and work

procedures

actual motorcycle exactly in detail

* This manual is written for persons who have

enough knowledge, skills and tools, including

special tools, for servicing SUZUKI motorcy-

cles

. If you do not have the proper knowledge

and tools, ask your authorized SUZUKI

motorcycle dealer to help you

. They may not represent the

.

.

.

COOLING AND LUBRICATION

SYSTEM

CHASSIS

ELECTRICAL SYSTEM

SERVICING INFORMATION

GROUP /NDE

4

E

WARNING

A

Inexperienced

without the proper tools

may

not

be

services described in this manual

Improper repair may result in injury to the

mechanic and may render the motorcycle

unsafe for the rider and passenger

mechanics

able

to

properly

or

and

mechanics

equipment

perform

.

.

SUZUKI MOTOR CORPORATION

© COPYRIGHT SUZUKI MOTOR CORPORATION 2003

the

EMISSION CONTROL

INFORMATION

WIRING DIAGRAM

Page 4

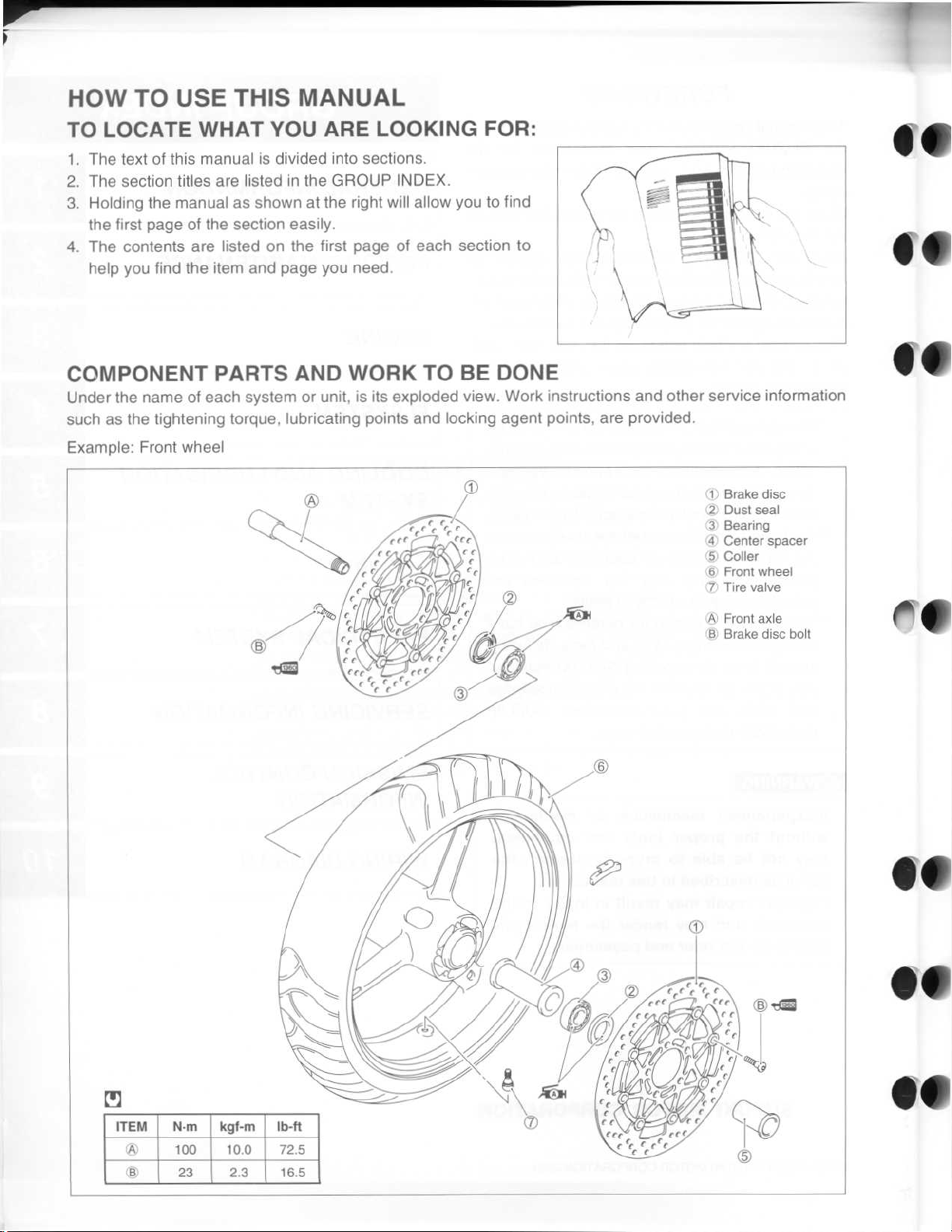

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE LOOKING FOR

1.The text of this manual is divided into sections

2

. The section titles are listed in the GROUP INDEX

. Holding the manual as shown at the right will allow you to find

3

the first page of the section easily

4

. The contents are listed on the first page of each section to

help you find the item and page you need

.

.

.

.

:

COMPONENT PARTS AND WORK TO BE DONE

Under the name of each system or unit, is its exploded view

such as the tightening torque, lubricating points and locking agent points, are provided

Example

: Front wheel

. Work instructions and other service information

.

1~ Brake disc

•

Dust seal

(3 Bearing

Center spacer

•

•

Coller

•

Front wheel

•

Tire valve

44P

•

4

•

•

Front axle

•

Brake disc bolt

T

•

0

ITEM

CA)

N

100

23

.m

kgf-m

10

.0

2

.3

lb-ft

72

.5

165

of

Page 5

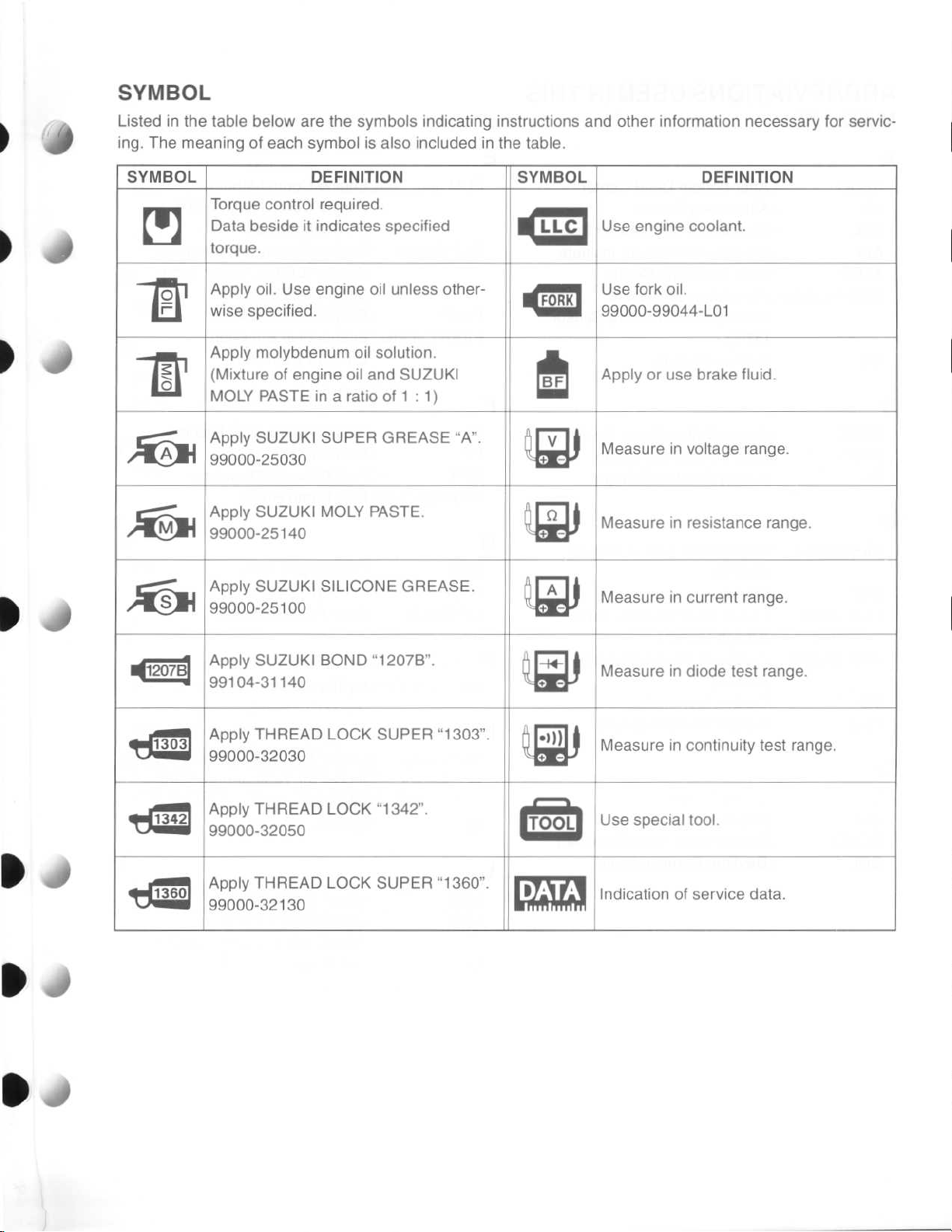

SYMBOL

Listed in the table below are the symbols indicating instructions and other information necessary for servicing

. The meaning of each symbol is also included in the table

.

SYMBOL

0

r

0

©

DEFINITION

Torque control required

Data beside it indicates specified

torque

.

Apply oil

wise specified

Apply molybdenum oil solution

(Mixture of engine oil and SUZUKI

MOLY PASTE in a ratio of 1:1)

Apply SUZUKI SUPER GREASE

99000-25030

Apply SUZUKI MOLY PASTE

99000-25140

Apply SUZUKI SILICONE GREASE

99000-25100

. Use engine oil unless other-

.

.

.

"A"

.

.

.

SYMBOL

LLC

FORK

BF

Lo

a

~©

a

Lo

o

DEFINITION

Use engine coolant

Use fork oil

99000-99044-LO1

Apply or use brake fluid

Measure in voltage range

Measure in resistance range

Measure in current range

.

.

.

.

.

.

1207B

1303

V

1342

1360

Apply SUZUKI BOND "1207B"

99104-31 140

Apply THREAD LOCK SUPER "1303"

99000-32030

Apply THREAD LOCK "1342"

99000-32050

Apply THREAD LOCK SUPER "1360"

99000-32130

.

.

.

.

L o

0

j

1

))

L

o a

TOOL

DATA

Measure in diode test range

Measure in continuity test range

Use special tool

Indication of service data

.

.

.

.

Page 6

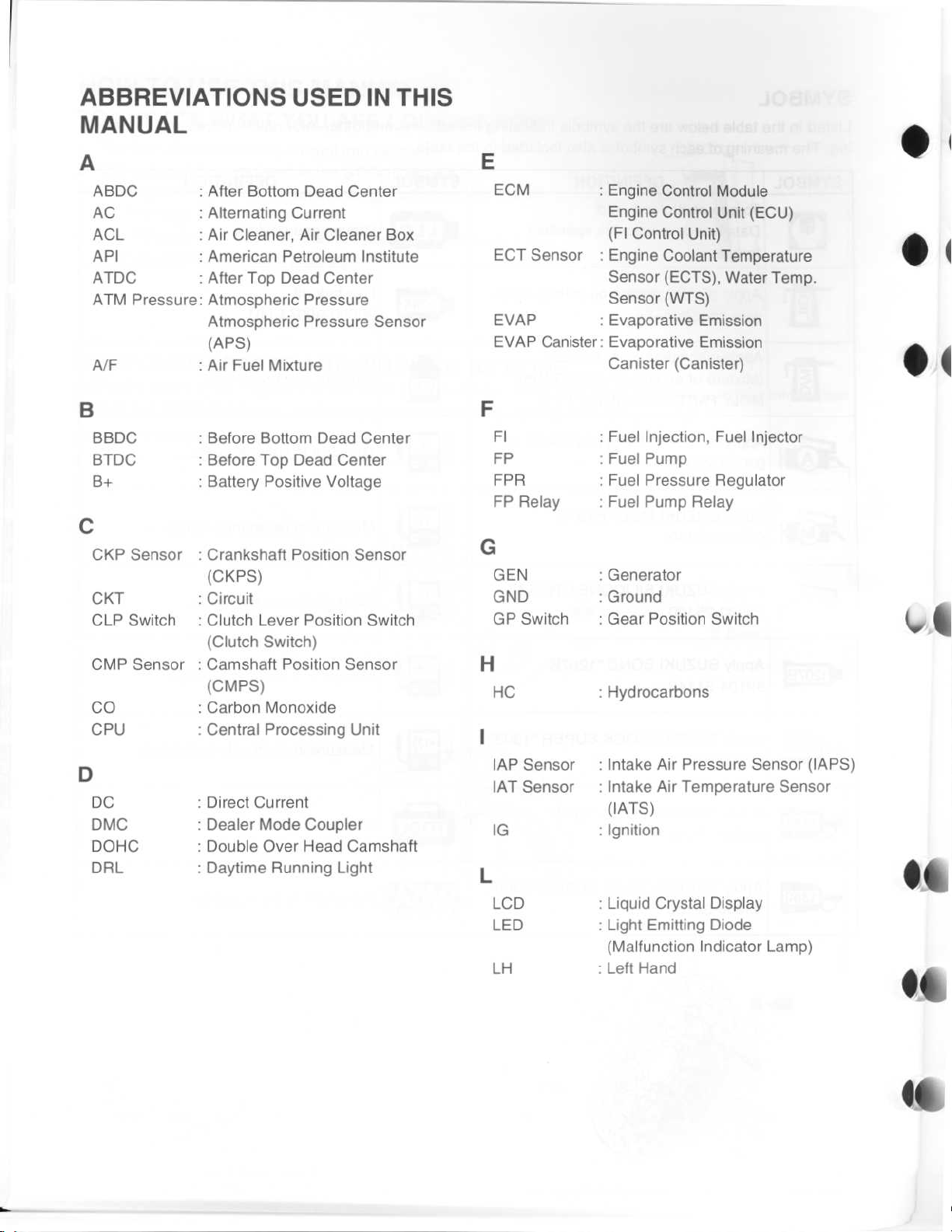

ABBREVIATIONS USED IN THIS

MANUAL

I

A

ABDC

AC

ACL

API

ATDC

ATM Pressure

A/F

: After Bottom Dead Center

: Alternating Current

:

Air Cleaner, Air Cleaner Box

: American Petroleum Institute

: After Top Dead Center

: Atmospheric Pressure

Atmospheric Pressure Sensor

(APS)

: Air Fuel Mixture

E

ECM

ECT Sensor:Engine Coolant Temperature

EVAP

EVAP Canister

:

Engine Control Module

Engine Control Unit (ECU)

(FI Control Unit)

Sensor (ECTS), Water Temp

Sensor (WTS)

:

Evaporative Emission

: Evaporative Emission

Canister (Canister)

.

0

I

1

B

BBDC

BTDC

B+

C

CKP Sensor:Crankshaft Position Sensor

CKT

CLP Switch

CMP Sensor

CO

CPU

D

DC

DMC

DOHC

DRL

:

Before Bottom Dead Center

:

Before Top Dead Center

: Battery Positive Voltage

(CKPS)

: Circuit

: Clutch Lever Position Switch

(Clutch Switch)

: Camshaft Position Sensor

(CMPS)

:

Carbon Monoxide

:

Central Processing Unit

: Direct Current

:

Dealer Mode Coupler

Double Over Head Camshaft

:

:

Daytime Running Light

F

FI

FP

FPR

FP Relay

G

GEN

GND

GP Switch:

H

HC

IAP Sensor:

IAT Sensor:Intake Air Temperature Sensor

IG

L

LCD

LED

LH

:

Fuel Injection, Fuel Injector

:

Fuel Pump

: Fuel Pressure Regulator

: Fuel Pump Relay

:

Generator

:

Ground

Gear Position Switch

Hydrocarbons

:

Intake Air Pressure Sensor (ZAPS)

(IATS)

: Ignition

:

Liquid Crystal Display

:

Light Emitting Diode

(Malfunction Indicator Lamp)

:

Left Hand

of,

4 6

Page 7

•

0

O

M

MAL-Code

Max

MIL

Min

N

NOx

Malfunction Code

(Diagnostic Code)

Maximum

Malfunction Indicator Lamp

(LED)

Minimum

Nitrogen Oxides

s1

i

0

OHC

OPS

P

PCV

R

RH

ROM

S

SAE

STC System

STP Sensor

ST Valve

STV Actuator

Over Head Camshaft

Oil Pressure Switch

Positive Crankcase

Ventilation (Crankcase Breather)

Right Hand

Read Only Memory

Society of Automotive Engineers

Secondary Throttle Control

System (STCS)

Secondary Throttle Position

Sensor (STPS)

Secondary Throttle Valve (STV)

Secondary Throttle Valve Actuator

(STVA)

•

i

I

T

TO Sensor

TP Sensor

V

VD

Tip Over Sensor (TOS)

Throttle Position Sensor (TPS)

Vacuum Damper

Page 8

SAE-TO-FORMER SUZUKI TERM

This table lists SAE (Society of Automotive Engineers) J1930 terms and abbreviations which may be used in

1

i

this manual in compliance with SAE recommendations, as well as their former SUZUKI names

.

t

FULL TERM ABBREVIATION

A

Air

Cleaner

B

Barometric

Battery

C

Camshaft

Crankshaft

D

Data

Diagnostic Test

Diagnostic

E

Positive

Position

Link

Connector

Trouble

Pressure

Position

SAE TERM

FORMER SUZUKI TERM

1

Voltage

Sensor

Sensor

Mode

Code

ACL

BARO

B+

CMP

CKP

DLC

DTM

DTC

Sensor

Sensor

Air

Cleaner,

Barometric

Pressure

Battery

Camshaft

Crankshaft

Crank

Dealer

Diagnostic

(APS,APSensor)

Voltage,

Position

Angle

Mode

Air

Cleaner Box

Pressure,

+B

Sensor

Position

Code,

Sensor (CKPS),

Coupler

Malfunction

Atmospheric

(CMPS)

Code

4

Electronic

Engine

Engine

Engine

Engine

Evaporative

Evaporative

Purge

F

Fan

Fuel

Fuel

G

Generator

Ignition

Control

Coolant

Coolant

Speed

Valve

Control

Level

Sensor

Pump

Module

Level

Temperature

Emission

Emission

Canister

El

ECM

ECL

ECT

RPM

EVAP

EVAP

Purge

FC

FP

GEN

Canister

Valve

Engine

Fl

Coolant

Coolant

perature

Water

Engine

Evaporative

Purge

Fuel

Fuel

Generator

Control

Control

Unit,

Level

Temperature,

Temperature

Speed (RPM)

(Canister)

Valve

Level

Sensor,

Pump

(FP)

Module

Engine

Emission

(SP

Valve)

Fuel

(ECM)

Control

Engine

Level

Unit

(ECU)

Coolant

Gauge

Tem-

1

•

06

46

Ground

GND

Ground

(GND,

GRD)

Page 9

•

FULL TERM ABBREVIATION

H

Heated Oxygen Sensor

I

Idle Speed Control

Ignition Control

Ignition Control Module

Intake Air Temperature

I

M

Malfunction Indicator Lamp

Manifold Absolute Pressure

Mass Air Flow

0

On-Board Diagnostic

SAE TERM

HO2S

ISC

IC

ICM

IAT

MIL

MAP

MAF

OBD

FORMER SUZUKI TERM

Heated Oxgen Sensor (HO2S), 02 Sensor

Electronic Spark Advance (ESA)

Intake Air Temperature (IAT), Air Tempera-

ture

LED Lamp

Malfunction Indicator Lamp (MIL)

Intake Air Pressure, Intake Vacuum

Air Flow

Self-Diagnosis Function

Diagnostic

Open Loop

P

Programmable Read Only Memory

Pulsed Secondary Air Injection

R

Random Access Memory

Read Only Memory

S

Secondary Air Injection

Secondary Throttle Control System

Secondary Throttle Valve

Secondary Throttle Valve Actuator

T

Throttle Body

Throttle Body Fuel Injection

OL

PROM

PAIR

RAM

ROM ROM

AIR

STCS

STV

STVA

TB

TBI

Pulse Air Control (PAIR)

STC System (STCS)

ST Valve (STV)

STV Actuator (STVA)

Throttle Body (TB)

Throttle Body Fuel Injection (TBI)

Throttle Position Sensor

V

Voltage Regulator

Volume Air Flow

TP Sensor

VR

VAF

TP Sensor (TPS)

Voltage Regulator

Air Flow

Page 10

GENERAL INFORMATION

.

CONTENTS

GENERAL

INFORMATION

1-1

1

WARNING/CAUTION/NOTE

GENERAL PRECAUTIONS

SUZUKI SV1000SK3 ('03-MODEL)

SERIAL NUMBER LOCATION

FUEL, OIL AND ENGINE COOLANT RECOMMENDATION

FUEL (FOR USA AND CANADA)

FUEL (FOR OTHER COUNTRIES)

ENGINE OIL

BRAKE FLUID

FRONT FORK OIL

ENGINE COOLANT

WATER FOR MIXING

ANTI-FREEZE/ENGINE COOLANT

LIQUID AMOUNT OF WATER/ENGINE COOLANT

BREAK-IN PROCEDURES

CYLINDER IDENTIFICATION

INFORMATION LABELS

SPECIFICATIONS

COUNTRY AND AREA CODES

1- 2

2

11- 4

1- 4

1- 4

1- 4

1- 4

1- 5

1- 5

1- 5

1- 5

1- 5

1- 5

1- 5

1- 6

1- 6

1- 7

1- 8

1-10

6-

6-

4)

r

)

Page 11

1- 2

GENERAL INFORMATION

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully

and the words WARNING, CAUTION and NOTE have special meanings

sages highlighted by these signal words

A

WARNING

Indicates a potential hazard that could result in death or injury

CAUTION

Indicates a potential hazard that could result in motorcycle damage

NOTE

:

Indicates special information to make maintenance easier or instructions clearer

Please note, however, that the warnings and cautions contained in this manual cannot possibly cover all

potential hazards relating to the servicing, or lack of servicing, of the motorcycle

INGS and CAUTIONS stated, you must use good judgement and basic mechanical safety principles

are unsure about how to perform a particular service operation, ask a more experienced mechanic for

advice

.

.

. To emphasize special information, the symbol

. Pay special attention to the mes-

.

.

.

. In addition to the WARN-

. If you

GENERAL PRECAUTIONS

WARNING

A

•

Proper service and repair procedures are important for the safety of the service mechanic and

the safety and reliability of the motorcycle

•

When 2 or more persons work together, pay attention to the safety of each other

•

When it is necessary to run the engine indoors, make sure that exhaust gas is forced outdoors

.

•

When working with toxic or flammable materials, make sure that the area you work in is wellventilated and that you follow all of the material manufacturer's instructions

•

Never use gasoline as a cleaning solvent

•

To avoid getting burned, do not touch the engine, engine oil, radiator and exhaust system

until they have cooled

•

After servicing the fuel, oil, water, exhaust or brake systems, check all lines and fittings

related to the system for leaks

.

.

.

.

.

.

Page 12

1 40

4

1

GENERAL INFORMATION 1-3

CAUTION

•

If parts replacement is necessary, replace the parts with Suzuki Genuine Parts or their equivalent

.

•

When removing parts that are to be reused, keep them arranged in an orderly manner so that

they may be reinstalled in the proper order and orientation

•

Be sure to use special tools when instructed

•

Make sure that all parts used in reassembly are clean

•

Use the specified lubricant, bond or sealant

•

When removing the battery, disconnect the negative cable first and then the positive cable

•

When reconnecting the battery, connect the positive cable first and then the negative cable,

and replace the terminal cover on the positive terminal

•

When performing service to electrical parts, if the service procedures not require use of bat-

tery power, disconnect the negative cable the battery

•

When tightening the cylinder head and case bolts and nuts, tighten the larger sizes first

Always tighten the bolts and nuts diagonally from the inside toward outside and to the specified tightening torque

•

Whenever you remove oil seals, gaskets, packing, 0-rings, locking washers, self-locking

nuts, cotter pins, circlips and certain other parts as specified, be sure to replace them with

new ones

from the mating surfaces

•

Never reuse a circlip

than required to slip the circlip over the shaft

completely seated in its groove and securely fitted

•

Use a torque wrench to tighten fasteners to the specified torque

thread is smeared with them

•

After reassembling, check parts for tightness and proper operation

. Also, before installing these new parts, be sure to remove any left over material

.

.

. When installing a new circlip, take care not to expand the end gap larger

.

.

.

. After installing a circlip, always ensure that it is

.

.

. Lubricate them when specified

.

.

. Wipe off grease and oil if a

.

.

.

.

0 I

0

•

To protect the environment, do not unlawfully dispose of used motor oil, engine coolant and

other fluids

•

To protect Earth's natural resources, properly dispose of used motorcycle and parts

0

: batteries and tires

.

.

Page 13

1

-4 GENERAL INFORMATION

SUZUKI SV1000SK3 ('03-MODEL)

4

41

RIGHT SIDE

Difference between illustrations and actual motorcycles depends on the markets

.

LEFT SIDE

SERIAL NUMBER LOCATION

The frame serial number or V.I.N

steering head pipe . The engine serial number2is located on the right side of the crankcase

bers are required especially for registering the machine and ordering spare parts

. (Vehicle Identification Number)

1O is stamped on the right side of the

. These num-

.

01

FUEL, OIL AND ENGINE COOLANT RECOMMENDATION

FUEL (FOR USA AND CANADA)

Use only unleaded gasoline of at least 87 pump octane (R/2 + M/2) or 91

research method

Gasoline containing MTBE (Methyl Tertiary Butyl Ether), less than 10% ethanol,

with appropriate cosolvents and corrosion inhibitor is permissible

.

.

FUEL (FOR OTHER COUNTRIES)

Gasoline used should be graded 91 octane (Research Method) or higher

mended

.

octane or higher rated by the

or less than 5% methanol

.

Unleaded gasoline is recom-

ko

Page 14

GENERAL INFORMATION 1-5

ENGINE OIL

SUZUKI

MOTOR OIL or an oil which is rated SF or SG under the API

(American Petroleum Institute) service classification

ommended viscosity is SAE 1 OW-40

available, select an altematice according to the right chart

recommends the use of SUZUKI PERFORMANCE 4

. The rec-

. If an SAE 1 OW-40 oil is not

.

MUITIGRADE

°C

TEMP

-30 -20

.

0

°F

-22 -4

20W-50

15W-40, 15W 50

1OW 40

. 10W 50

10W 30

-10 0 10 20 30

11 +1t+I 1

14 32 50 68 86

104

40

BRAKE FLUID

Specification and classification

A WARNING

Since the brake system of this motorcycle is filled with a glycol-based brake fluid by the manufacturer, do not use or mix different types of fluid such as silicone-based and petroleum-based

fluid for refilling the system, otherwise serious damage will result

Do not use any brake fluid taken from old or used or unsealed containers

Never re-use brake fluid left over from a previous servicing, which has been stored for a long

period

.

: DOT 4

.

.

FRONT FORK OIL

Use fork oil L01 or an equivalent fork oil

.

ENGINE COOLANT

Use an anti-freeze/engine coolant compatible with an aluminum radiator, mixed with distilled water only

.

WATER FOR MIXING

Use distilled water only

. Water other than distilled water can corrode and clog the aluminum radiator

.

ANTI-FREEZE/ENGINE COOLANT

The engine coolant perform as a corrosion and rust inhibitor as well as anti-freeze

coolant should be used at all times even though the atmospheric temperature in your area does not go down

to freezing point

.

Suzuki recommends the use of SUZUKI COOLANT anti-freeze/engine coolant

an equivalent which is compatible with an aluminum radiator

.

. Therefore, the engine

. If this is not available, use

LIQUID AMOUNT OF WATER/ENGINE COOLANT

Solution capacity (total)

For engine coolant mixture information, refer to cooling system section, page 5-3

: 2 200 ml (2

.3/1

.9 US/Imp qt)

.

CAUTION

Mixing of anti-freeze/engine coolant should be limited to 60%

its efficiency

mance is greatly reduced

ture does not go down to the freezing point

. If the anti-freeze/engine coolant mixing ratio is below 50%, rust inhabiting perfor-

. Be sure to mix it above 50% even though the atmospheric tempera-

.

. Mixing beyond it would reduce

Page 15

1- 6

GENERAL INFORMATION

BREAK-IN PROCEDURES

6

4

$6

41

1

6

During manufacture only the best possible materials are used and all machined parts are finished to a very

high standard but it is still necessary to allow the moving parts to "BREAK-IN" before subjecting the engine

to maximum stresses

exercised during its early life

•

Keep to these break-in engine speed limits

Initial

Up to 1 600 km (1 000 miles)

Over

•

Upon reaching an odometer reading of 1 600 km (1 000 miles) you can subject the motorcycle to full throt-

tle operation

800 km(500 miles)

1 600 km (1 000 miles)

. The future performance and reliability of the engine depends on the care and restraint

. The general rules are as follows

:

: Below 6 000 r/min

: Below 9 000 r/min

: Below 12 500 r/min

. However, do not exceed 12 500 r/min at any time

:

.

CYLINDER IDENTIFICATION

The two cylinders of this engine are identified as No

viewed by the rider on the seat)

.

. 1 and No

. 2 cylinder, as counted from front to rear (as

l1

(a

Page 16

INFORMATION LABELS

GENERAL INFORMATION 1-7

V

dP

1O Noise label

O2 Information label

03 Vacuum hose routing label

Fuel caution label

(4)

($ Manual caution label

© Frame caution label

O7 Warning screen label

® Warning steering label

Tire air pressure label

O

C0) Warning safety label

11 ICES Canada label

ID plate

13 E19 ID label

14 Safety plate

A

: Attached

SV1000S

A For E-03, 24, 33

A For E-03, 28, 33

A For E-33

A For E-02, 24

A For E-03, 33

A

A For E-28 (LH, RH)

Other (RH)

A

A A

A

A For E-28

A For E-03, 28, 33

A For E-03, 28, 33

SV1000SD

A A

A

A A

A A

A A

SV1000SF

A

A

A

(7

French

Page 17

GENERAL INFORMATION

1- 8

SPECIFICATIONS

DIMENSIONS AND DRY MASS

Overall length

Overall width

Overall height

Wheelbase

Ground clearance

Seat height

Dry mass

ENGINE

Type

Number of cylinders

Bore

Stroke

Displacement

Compression ratio

Fuel system

Air cleaner

Starter system

Lubrication system

Idle speed

2 130 mm (83

745 mm (29

1 170 mm (46

1 430 mm (56

150 mm(5

810 mm (31

189 kg (416 Ibs)

190 kg (418 Ibs)E-33

4-stroke, liquid-cooled, DOHC, 90° degree V-twin

2

.0 mm (3

98

66 .0 mm (2

996 cm3(60

11.3: 1

Fuel injection

Non-woven fabric element

Electric

Wet sump

1 200 ± 100 r/min

.9 in)

.3 in)

.1 in)

.3 in)

.9 in)

.9 in)

.858 in)

.598 in)

.8 cu

. in)

t1

$4

l1

DRIVE TRAIN

Clutch

Transmission

Gearshift pattern

Primary reduction ratio

Gear ratios, Low

Final reduction ratio

Drive chain

2nd

3rd

4th

5th

Top

Wet multi-plate type

6-speed constant mesh

1-down, 5-up

1

.838 (57/31)

2

.666 (32/12)

1

.933 (29/15)

1

.500 (27/18)

1

.227 (27/22)

1

.086 (25/23)

1

.000 (24/24)

2

.352 (40/17)

RK530 SMOZ1, 108 links

•

$

•

t

40

Page 18

CHASSIS

Front suspension

Rear suspension

Front suspension stroke

Rear wheel travel

Caster

Trail

Steering angle

Turning radius

Front brake

Rear brake

Front tire size

Rear tire size

Telescopic, coil spring, oil damped

Link type, coil spring, oil damped

120 mm (4

129 mm (5

24

.5°

98 mm (3

30° (right & left)

3

.2 m (10

Disc brake, twin

Disc brake

120/70 ZR17M/C (58W), tubeless

180/55 ZR1 7M/C (73W), tubeless

ELECTRICAL

Ignition type

Ignition timing

Spark plug

Battery

Generator

Main fuse

Fuse

Headlight

Position light

License plate light

Turn signal light

Brake light/Taillight

Speedometer/Tachometer light

Fuel level indicator light

Turn signal indicator light

Neutral indicator light

High beam indicator light

Oil pressure/Coolant temperature/Fuel injection

warning light

Electronic ignition (Transistorized)

5° B

. T

. D

NGK

: CR8EK or DENSO

12 V 43

Three-phase A.C. Generator

30 A

15/15/10/15/15/10 A

12 V 60/55 W x 2

12 V 5 Wx2

12 V 5 W

12V21 W x 4

LED

LED

LED

LED

LED

LED

LED

.2 kC (12 Ah)/10 HR

GENERAL INFORMATION 1-9

.72 in)

.08 in)

.9 in)

.50 ft)

. C at 1 200 r/min

: U24ETR

0

.l

CAPACITIES

Fuel tank

Engine oil, oil change

Front fork oil (each leg)

Coolant

These specifications are subject to change without notice

with filter change

overhaul

16 L (4

17 L (4

2 700 ml (2

2 900 ml (3

3 300 ml (3

2

.2/3

.5 US/Imp gal)

.7 US/Imp gal)For the others

.5/3

.9/2

.1/2

.5/2

494 ml (16

.2 L (2

.3/1

.9 US/Imp qt)

.

.4 US/Imp qt)

.6 US/Imp qt)

.9 US/Imp qt)

.39 US/Imp oz)

.69/17

For E-33

Page 19

1-10 GENERAL INFORMATION

COUNTRY AND AREA CODES

The following codes stand for the applicable country(-ies) and area(-s)

CODE

E-02

E-03

E-19

E-24

E-28

E-33

U

. K

U

. S . A

EU

Australia

Canada

California (U

COUNTRY or AREA

.

. (Except for California)

. S . A

.)

.

Loading...

Loading...