Page 1

EMISSION CONTROL INFORMATION

EMISSION CONTROL INFORMATION

CONTENTS

9-1

01

0

0

EMISSION CONTROL SYSTEMS

FUEL INJECTION SYSTEM

CRANKCASE EMISSION CONTROL SYSTEM

EXHAUST EMISSION CONTROL

NOISE EMISSION CONTROL SYSTEM

EVAPORATIVE EMISSION CONTROL SYSTEM (FOR E-33)

PAIR (AIR SUPPLY) SYSTEM INSPECTION

HOSES

PAIR REED VALVE

PAIR CONTROL SOLENOID VALVE

PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING

HEATED

EVAPORATIVE EMISSION CONTROL SYSTEM INSPECTION

(FOR E-33)

HOSES

EVAP CANISTER

TANK PRESSURE CONTROL VALVE

EVAP CANISTER HOSE ROUTING (FOR E-33)

~

OXGEN

~

~

~

SENSOR (HO2S) INSPECTION (FOR E-02,19)

~

~

~

~

SYSTEM (PAIR SYSTEM)

~

~

~

~

~

~

9- 2

2

99- 3

~

~

~

9- 4

9- 5

9- 5

9- 6

9- 6

9- 6

9- 6

9- 8

9- 9

9-10

9-10

9-10

9-10

9-11

0

It

9

Page 2

9-2

EMISSION CONTROL INFORMATION

EMISSION CONTROL SYSTEMS

FUEL INJECTION SYSTEM

SV1000S motorcycles are equipped with a fuel injection system for emission level control

This fuel injection system is precision designed, manufactured and adjusted to comply with the applicable

emission limits

.

.

~%~~~

~

BEFORE-PRESSURIZED

FUEL

PRESSURIZED FUEL

RELIEVED FUEL

I'

Ift

Page 3

~

0

0

9

EMISSION CONTROL INFORMATION 9-3

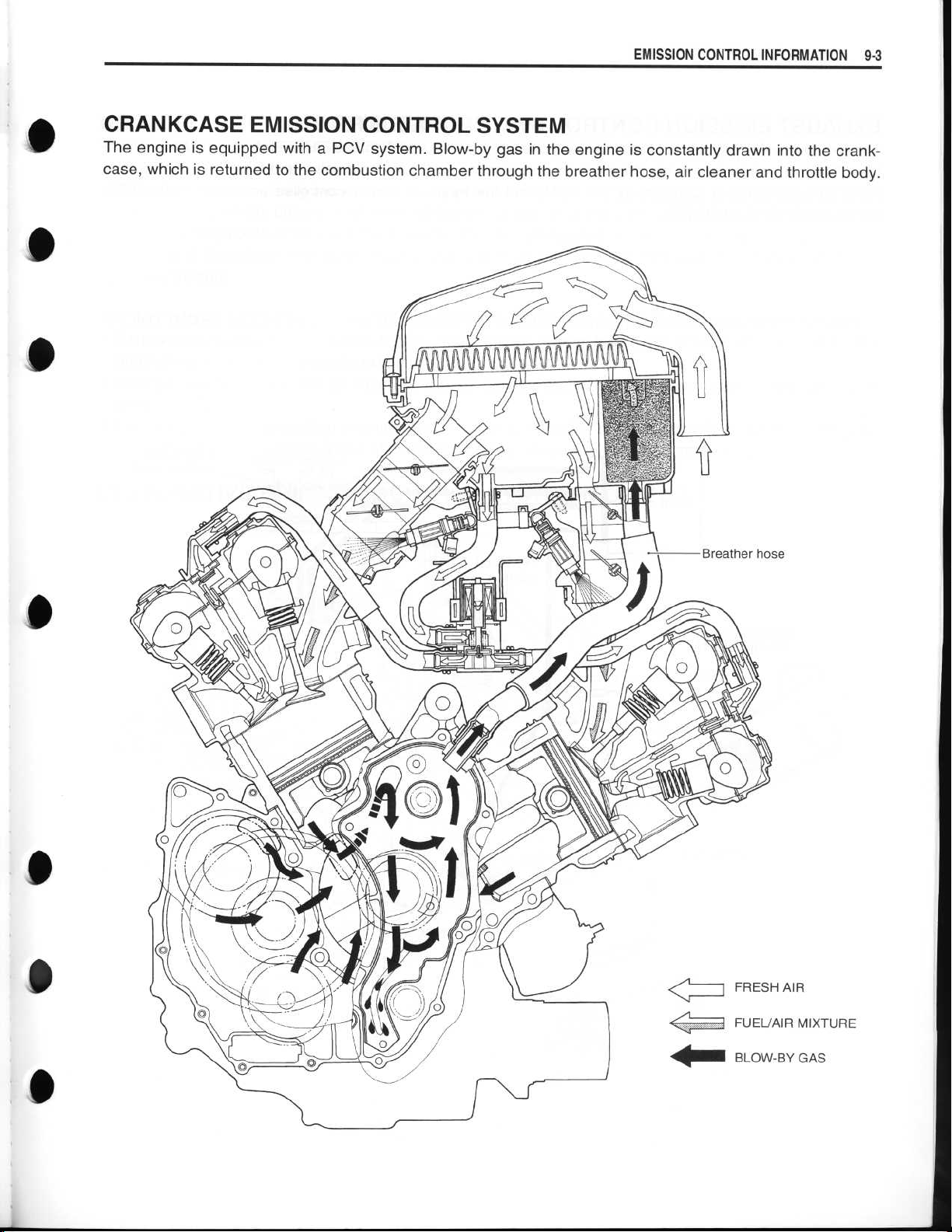

CRANKCASE EMISSION CONTROL SYSTEM

The engine is equipped with a PCV system

case, which is returned to the combustion chamber through the breather hose, air cleaner and throttle body

. Blow-by gas in the engine is constantly drawn into the crank-

.

0

0

0

C

411111110

FRESH AIR

FUEL/AIR MIXTURE

BLOW-BY GAS

Page 4

9-4 EMISSION CONTROL INFORMATION

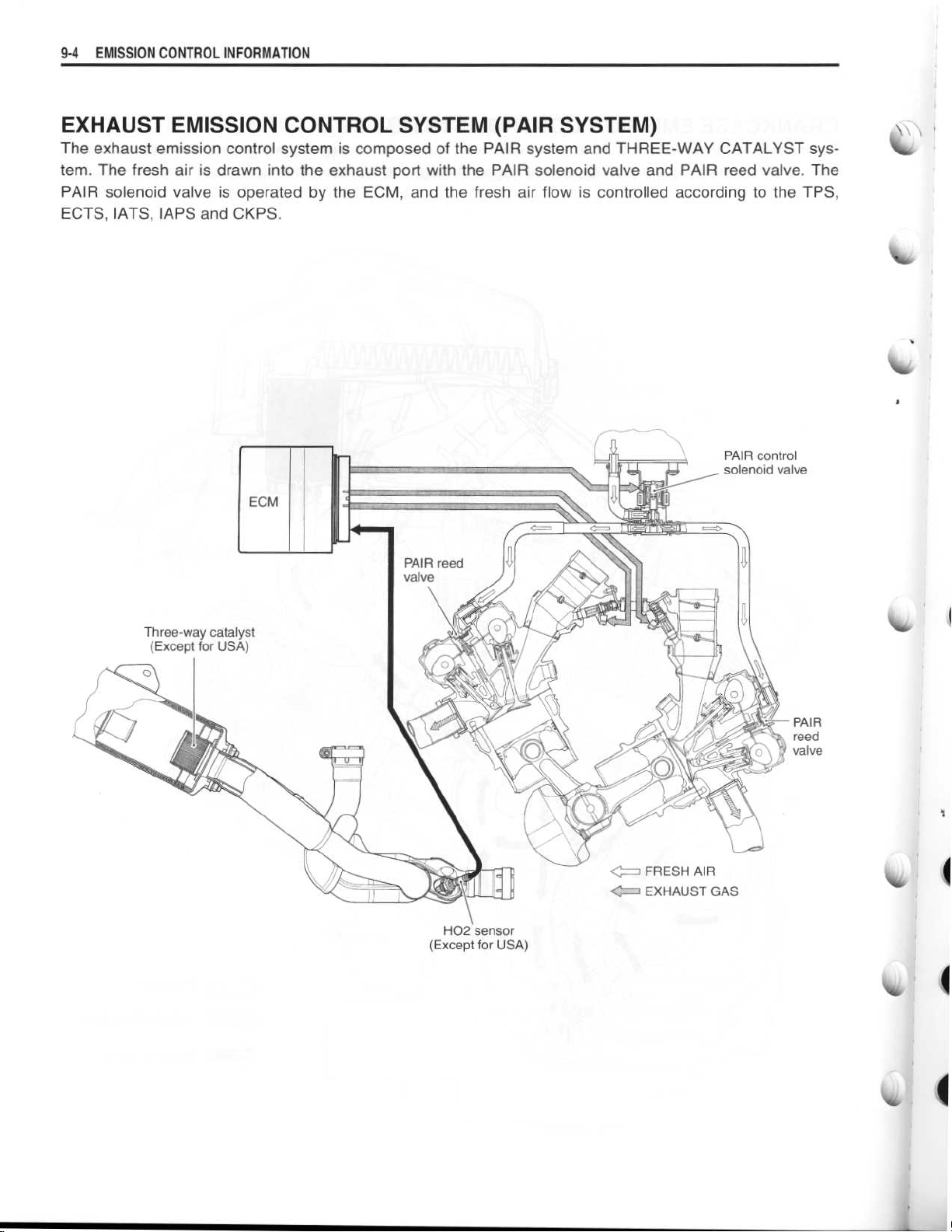

EXHAUST EMISSION CONTROL SYSTEM (PAIR SYSTEM)

The exhaust emission control system is composed of the PAIR system and THREE-WAY CATALYST sys-

tem

. The fresh air is drawn into the exhaust port with the PAIR solenoid valve and PAIR reed valve

PAIR solenoid valve is operated by the ECM, and the fresh air flow is controlled according to the TPS,

ECTS, IATS, ZAPS and CKPS

.

. The

H02 sensor

(Except for USA)

I

Page 5

~

~

~

EMISSION CONTROL INFORMATION 9-5

NOISE EMISSION CONTROL SYSTEM

0

0

TAMPERING WITH THE NOISE CONTROL SYSTEM PROHIBITED

acts or the causing thereof

1

. The removal or rendering inoperative by any person, other than for purposes of maintenance, repair or

replacement, of any device or element of design incorporated into any new vehicle for the purpose of

noise control prior to its sale or delivery to the ultimate purchaser or while it is in use, or

2

. The use of the vehicle after such device or element of design has been removed or rendered inoperative

by any person

.

:

: Federal law prohibits the following

0

0

AMONG THOSE ACTS PRESUMED TO CONSTITUTE TAMPERING ARE THE ACTS LISTED BELOW

Removing or puncturing the muffler, baffles, header pipes, screen type spark arrester (if equipped) or any

•

other component which conducts exhaust gases

•

Removing or puncturing the air cleaner case, air cleaner cover, baffles or any other component which

conducts intake air

•

Replacing the exhaust system or muffler with a system or muffler not marked with the same model spe-

cific code as the code listed on the Motorcycle Noise Emission Control Information label

.

.

.

:

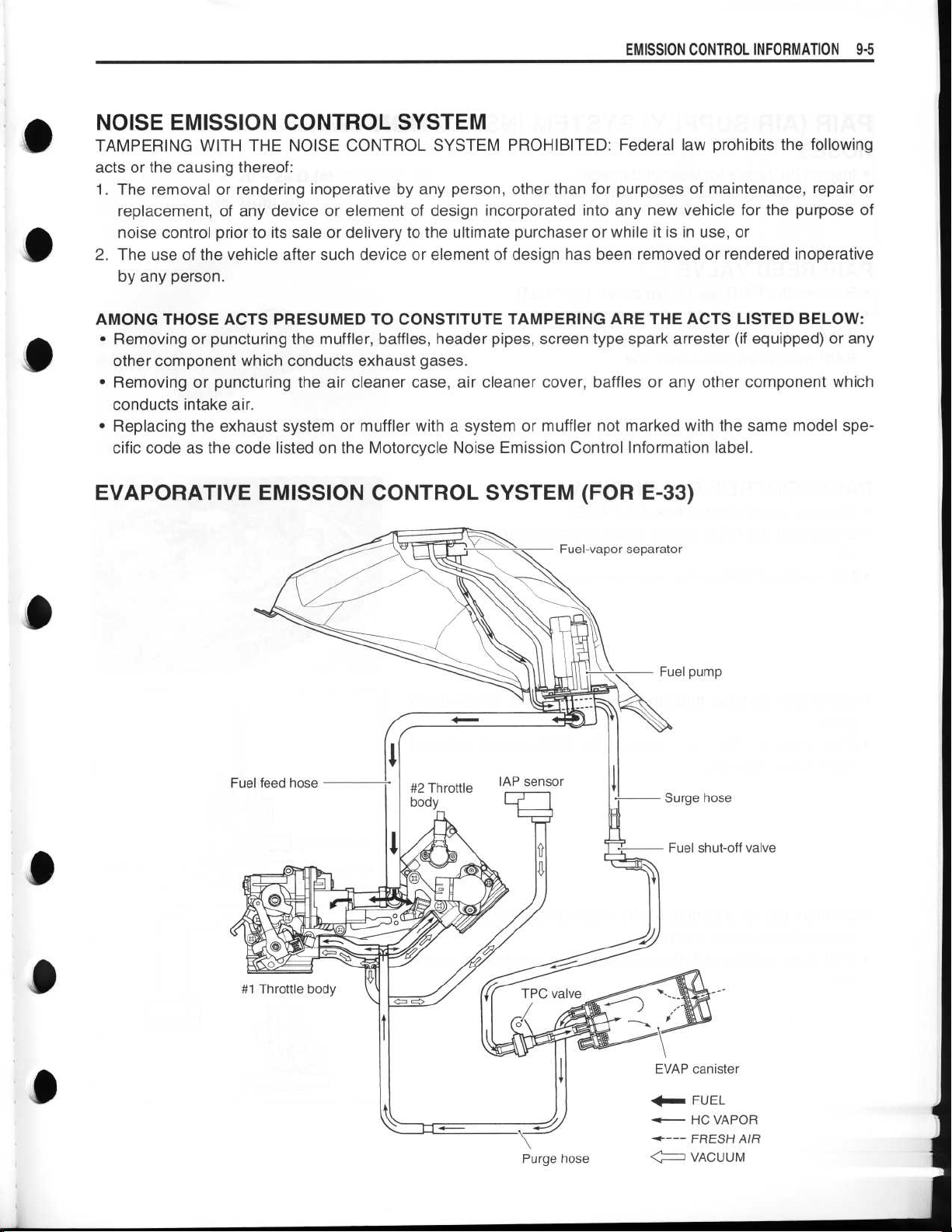

EVAPORATIVE EMISSION CONTROL SYSTEM (FOR E-33)

0

#1 Throttle body

EVAP canister

FUEL

1~

<- HC VAPOR

----

FRESH AIR

< f

VACUUM

Page 6

~

~

~

~

~

~

~

~

~

~

~

~

9-6 EMISSION CONTROL INFORMATION

PAIR (AIR SUPPLY) SYSTEM INSPECTION

HOSES

•

Inspect the hoses for wear or damage

•

Inspect that the hoses are securely connected

PAIR REED VALVE

•

Remove the PAIR reed valve cover

•

Inspect the reed valve for the carbon deposit

If the carbon deposit is found in the reed valve, replace the

•

PAIR reed valve with a new one

.

.

. (=3-34)

.

.

PAIR CONTROL SOLENOID VALVE

Remove the air cleaner box

•

Disconnect the PAIR control solenoid valve lead wire coupler

•

10

.

Remove the PAIR control solenoid valve

•

Check that air flows through the air inlet port to the air outlet

•

ports

.

If air does not flow out, replace the PAIR control solenoid

•

valve with a new one

•

Connect the 12 V battery to the PAIR control solenoid valve

terminals and check the air flow

•

If air does not flow out, the solenoid valve is in normal condition

.

.(f-74-75)

(Z

.

.

.

No

I

Page 7

~

EMISSION CONTROL INFORMATION 9-7

•

Check the resistance between the terminals of the PAIR con-

9

trol solenoid valve

.

0

0

0

Resistance

09900-25008

~gy Tester knob indication

If the resistance is not within the standard range, replace the

PAIR control solenoid valve with a new one

: 20-24 S (at 20 °C/68 °F)

: Multi circuit tester set

: Resistance (S2)

.

0

Page 8

~

9-8EMISSION

CONTROL INFORMATION

PAIR (AIR SUPPLY) SYSTEM HOSE ROUTING

Matching mark

(White)

I II

11

.Mm

4V

'

10 N•m1

0

MI

Matching mark

(Yellow)

.0 kgf-m, 7

.0 lb-ft)

1

%

4

4

4

PAIR read valve

qu

4

Page 9

~

~

~

0

0

EMISSION CONTROL INFORMATION 9-9

H EATED OXGEN SENSOR (HO2S) INSPECTION (FOR E-02, 19)

•

Disconnect the H02 sensor lead wire coupler

•

Inspect the H02 sensor and its circuit referring to flow table of

the malfunction code (C44)

.

. (=4-61)

J

I

•

Check the resistance between the terminals of the H02 sensor

.

Resistance

.

.

09900-25008

Tester knob indication

0

If the resistance is not within the standard range, replace the

H02 sensor with a new one

NOTE

:

* Temperature of the sensor affects resistance value largely

* Make sure that the sensor heater is at correct temperature

A WARNING

Do not remove the H02 sensor while it is hot

CAUTION

Be careful not to expose it to excessive shock

Do not use an impact wrench while removing or

installing the H02 sensor unit

Be careful not to twist or damage the sensor lead wire

: 4-5 S2 (at 23 °C/73

: Multi circuit tester set

: Resistance (0)

.

.4 °F)

.

.

.

.

.

.

0

0

0

Page 10

~

~

~

~

9-10

EMISSION CONTROL INFORMATION

EVAPORATIVE EMISSION CONTROL SYSTEM INSPECTION

(FOR E-33)

•

Remove the air cleaner box.((-

HOSES

Inspect the hoses for wear or damage

Make sure that the hoses are securely connected

EVAP CANISTER

Inspect the canister for damage to the body

TANK PRESSURE CONTROL VALVE

Inspect the tank pressure contorol valve body for damage

Inspect the tank pressure control valve operation in the following

procedure

.

r4-75)

.

VA

.

.

Vol,'

.

I

0

•

Remove the tank pressure control valve

•

When air pressure is applied to the tank pressure control

valve from the side

control valve

•

When air pressure is applied to the tank pressure control

valve from the side ©, air should not flow through the purge

valve

.

•

If the tank pressure control valve operates otherwise, it must

be replaced

A WARNING

Gasoline and gasoline vapor is toxic

of fuel remains in the tank pressure control valve

when checking it

Do not swallow the fuel when blowing the tank pres-

sure control valve

NOTE

:

When connecting the tank pressure control valve to the hose,

the side © should face toward the fuel shut-off valve side, and

the side AO should face toward the canister side

.

.

air should flow out through the purge

OO

,

.

.

.

. A small amount

.

1

% 4

1

4,

Page 11

EMISSION CONTROL INFORMATION

9-11

•

EVAP CANISTER HOSE ROUTING (FOR E-33)

EVAP canister

Fuel shut-off valve

Clamp ends should face top side

Clamp ends should face outside

Tank pressure~~~

control valve

.

i

.

Page 12

~

~

~

WIRING DIAGRAM

FI SYSTEM WIRING DIAGRAM

0

0

0

is

ECM

© BATT

©FP

41 TOS

33 AT

a

+B

18 CLT

® IG1

© IG2

©VM

36 THW

© SOL

05 FI #1

Fl #2

21 STA

© MO+

©MO-

14 THA

10 VCC

19 TPS

34 E2

® STPS

© H02 (OXH)

24 H02 (OX)

(2

G+

31 GP

© N+

30 N-

3s TS

16 PM

© PA

® TACO

© TECH

40 NT

•

•

•

IGNITION COIL 30 A

IG2

-R/W

- Y/B

-Br/W

O/R

-

O/G

-

B/Y

-B

-W/BI-

-Y/R

-B/BI

-Br

-Gr/W

-

Gr/B

-

Y/G

-

B/R

-

R/B

-

Dg

--R

-P/W

-B/Br

-y-

-

W/B

-

W/G

-

Y/W

-

G/BI

- G

-W/R

-G/B

-G/Y

-

-

-

-B/W-

-B/W-

-B/W

MODE SELECTION SWITCH

Br/B

B/G

BI

-

IG1

15A

MAIN

SWITCH

10A

6'`p

10A

TIP OVER SENSOR

0

L

ATMOSPHERIC

PRESSURE

SENSOR

NEUTRAL

LAMP

SI

RE

FUE

4)

SPEEDOMETER

INTAKE AIR CONTROL VALVE

PRESSURE

SENSOR

PAIR SOLENOID

SIDESTAND

SWITCH

Page 13

~

~

~

RELA

RELAY

I

ENGINE STOP

Y

SWITCH

FUEL PUMP RELAY

GEAR CLUTCH

END

POSITION LEVER

ITCH SWITCH

POSITION

SWITCH

HO2SENSOR

(Except for USA)

FUEL INJECTOR

Fl

STPS SECONDARY THROTTLE POSITION SENSOR

ECTS ENGINE COOLANT TEMP SENSOR

TPS

THROTTLE POSITION SENSOR

TATS

INTAKE AIR TEMP SENSOR

CMPS

CAMSHAFT POSITION SENSOR

CKPS

CRANKSHAFT POSITION SENSOR

STVA SECONDARY THROTTLE VALVE ACTUATOR

10

Page 14

~

~

~

~

~

~

~

~

~

WIRING DIAGRAM

E-03, 24, 28, 33

R:TURN SIGNAL INDICATOR LIGHT (R)

L:TURN SIGNAL INDICATOR LIGHT (L)

B

: HI-BEAM INDICATOR LIGHT

N:NEUTRAL INDICATOR LIGHT

F:FUEL WARNNING LIGHT

O

: OIL PRESSURE, FI INDICATOR LIGHT

POSITION LIGHT (R)

B

Br-,1-Br

Bnv~env

FRONT TURN SIGNAL LIGHT (R)

Lg

Lg

B/W

B/W

HEADLIGHT (R)

HEADLIGHT (L)

FRONT TURN SIGNAL LIGHT (L)

a

POSITION LIGHT (L)

B

-/W~13111W

B/W

B/W

B/W

Y

W

Y

W

BB/W

,

B/W

Lg

W -

Br

Y -

B -

HANDLEBAR

HAZARD ENGINE

N

vi'

SPEEDOMETER

m m

~mm0

OmOammm~

-

-

Lg

Y

-

BIW

- W

-

IIL'

B

IGNITION SWITCH

~onom

mMMO

mu∎∎//

MESON

SWITCH SWITCH

m

~~ooo3>

Ell

SWITCH

STOP

STARTER FRONT BRAKE

SWITCH SWITCH

ICoT mCl

J

(R)

IL

PORE,'

swIT

m

m

m

03

u

mjJmom3mmm

J

~

HORN

IIIIIIIIII

O

O//

i~~ //

HORN

BUTTON TURN SIGNAL LIGHT

mCN

El

~C01-

0-11

SWITCH

HANDLEBAR SWITCH (L)

PASSING DIMM

SWITCH

DIMMER

SWITCH

OCR

LEVER

POSITION

SWITCH

o'o

mm

B/R

CTid//

FAN MOTOR FAN

SWITCH

m

0

00

MOTOR

mam

STP

SENSOR

I

ACTUATOR

MOTOR

mm¢m

mmi/j

m¢¢m

m i

¢

~y

#2 #1

INJECTOR

m` mm5oL~~

O

IAP

SENSOR

R(

Ofm

CENSO

R

mm`

mm

ECT

SENS(

Page 15

~

~

~

~

~

~

~

~

~

~

IRE

FUEL

PUMP

¢gym

:~i2

REAR BRAKE

SWITCH

MEN

M//

mm

of

FUEL PUMP

RELAY

ffm

m0=>

SENSOR

m

mm

AP

SENSOR

0

m ¢

~IIIIIII

mm

~m~m

;mm0O

IIIillllllllll

m

~¢m~~>o~B?z5

¢

m>m

Oc~mmam>3

ECM

IIIIIIIIIIIIIIIIIIII

C3B~>mms?Oam¢m`>LmQ~¢m~~¢>

mi3m>r

>ommmmm3

mmm

(

III II

m~mr~¢Z

mmmmmm

~~

¢ ¢

0 3

10

¢~

Cm

m¢m

GEAR

POSITION

SWITCH

Br

B/W

REAR TURN SIG NAL LIGHT (R)

Lg

B/W

Br

B/W

B

REAR TURN SIGN

O

mm

0OO

>

R-1

FUSE BOX

m

om

F

1

. HEAD HI 15 A

2

. HEAD LO 15 A

3

. FUEL

4

. IGNITION 15 A

5

. SIGNAL

6

. FAN~15A

10 A

10A

PAIR

SORENOID

SENSOR

m

SPEEDOMETER

SENSOR

¢

0

SIDE STAND

SWITCH

GENERATOR

-RECTIFIER

RECTIFIER

STARTER 1

MOTOR

Z- S2 Q~ q~

m

>mm

: MAIN 30 A

STARTER

RELAY

BATTERY

LIC ENSE LIGHT

B

B

B

B/W

10

BRAKE LIG HTITAILLIGHT

Gr

0

B/W

W/BW/B

B

I

ji

B/W

AL LIGHT (L)

V-

Page 16

0

Prepared by

SUZUKI MOTOR CORPORATION

0

0

February, 2003

Part No

. 99500-39250-03E

Printed in Japan

476

Page 17

SUZUKI MOTOR CORPORATION

Printed in Japan ~TK

;

K3

Loading...

Loading...