Page 1

SECTION 14

www.zukioffroad.com

TRANSFER GEAR BOX

CONTENTS

14-l.

14-2.

14-3.

14-4.

14-5.

14-6.

14-7.

14-8.

14-9.

14-10.

GENERAL DESCRIPTION

SELECTIVE FLOWS OF TRANSFER DRIVE

GEAR RATIO DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

TRANSFER SERVICES NOT REQUIRING

TRANSFER REMOVAL . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . 14-5

REMOVAL .............................................

DISASSEMBLY

INSPECTION OF COMPONENTS

REASSEMBLY

MAINTENANCE SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-22 12

TIGHTENING TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-23

..........................................

.........................................

................................. 14-2

..................

...........................

14-3

14-6

14-8

14-12

14-14

14-1

Page 2

14-1. GENERAL DESCRIPTION

The transfer gear box is an auxiliary transmission for on-off control of two-speed drive transmitted to

both front and rear axles concurrently and provides additional speed reductions, HIGH and LOW, for any

selection of main transmission gears.

The functions of this auxiliary transmission are mainly two-selection between four-wheel drive (front and

rear axles) and two-wheel drive (rear axle) and between HIGH and LOW for four-wheel drive. Three

propeller shafts are associated with the gear box.

These functions are accomplished by means of four shafts arranged in three-axis configuration and two

sliding clutches. The selection is effected by actuating these clutches from a single control lever located

beside the driver’s seat. The gear box is mounted on a chassis frame.

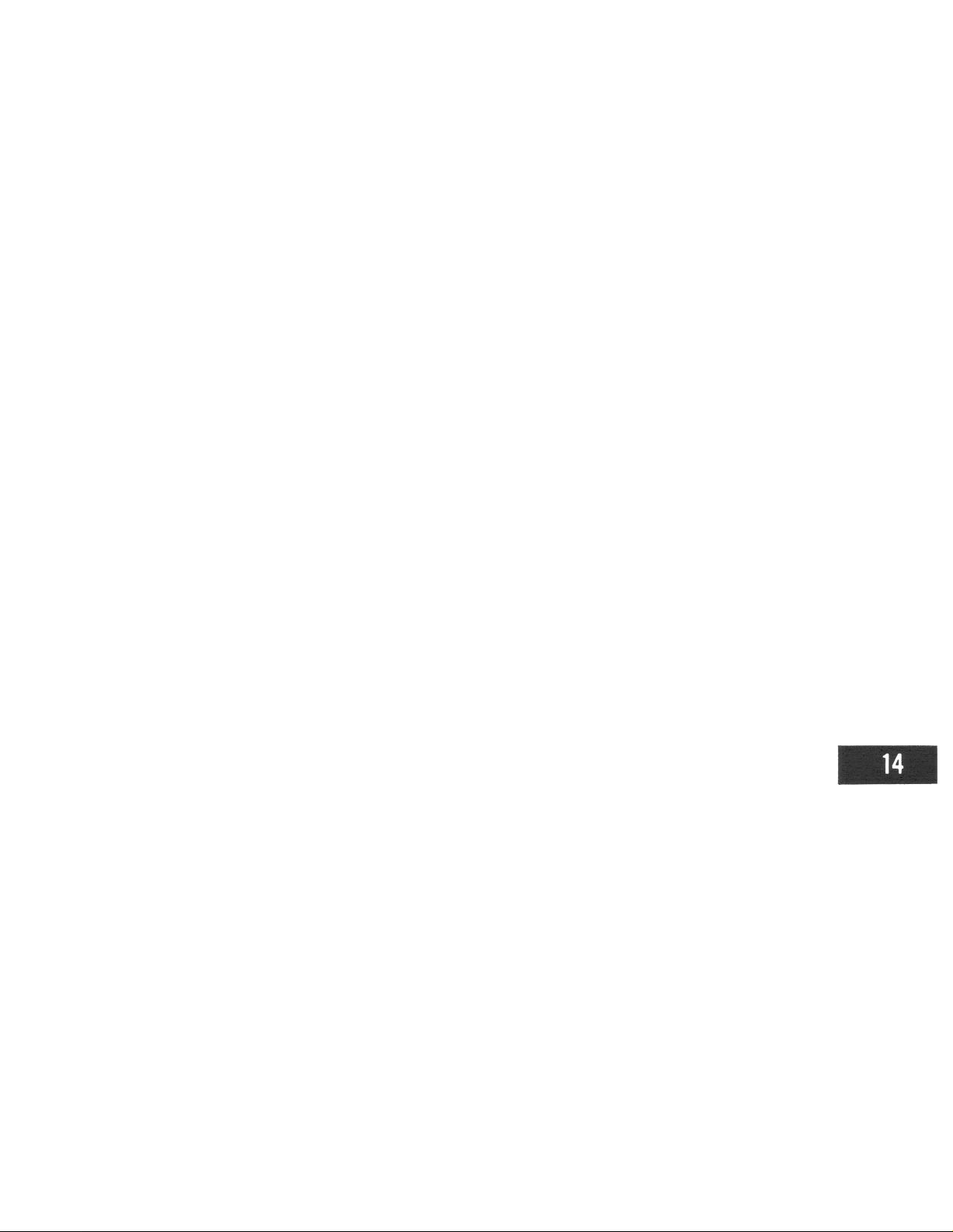

1.

Flange

Oil seal

2.

3. Circlip

Bearing

4.

5. Nut

Input shaft

6.

7. Bearing

Counter shaft lock plate

8.

9. O-ring

Counter shaft

10.

Bearing

11.

12.

Spacer

Thrust washer

13.

14. Counter gear

Flange

15.

16.

Oil seal

17. Circlip

18.

Bearing

Output front shaft

19.

Bearing

20.

21. Circlip

Sleeve

22.

Hub

23.

24.

Bearing

Thrust washer

25.

Bearing

26.

Output high gear

27.

Sleeve

28.

Output rear shaft

29.

Output low gear

30.

31.

Bearing

Speedometer drive gear

32.

Bearing

33.

Retainer

34.

Oil seal

35.

Speedometer driven gear

36.

Speedometer gear case

37.

Oil seal

38.

Shim

39.

Flange

40.

Washer

41.

Fig.

14- 1

Fig. 14-1

14-2

Page 3

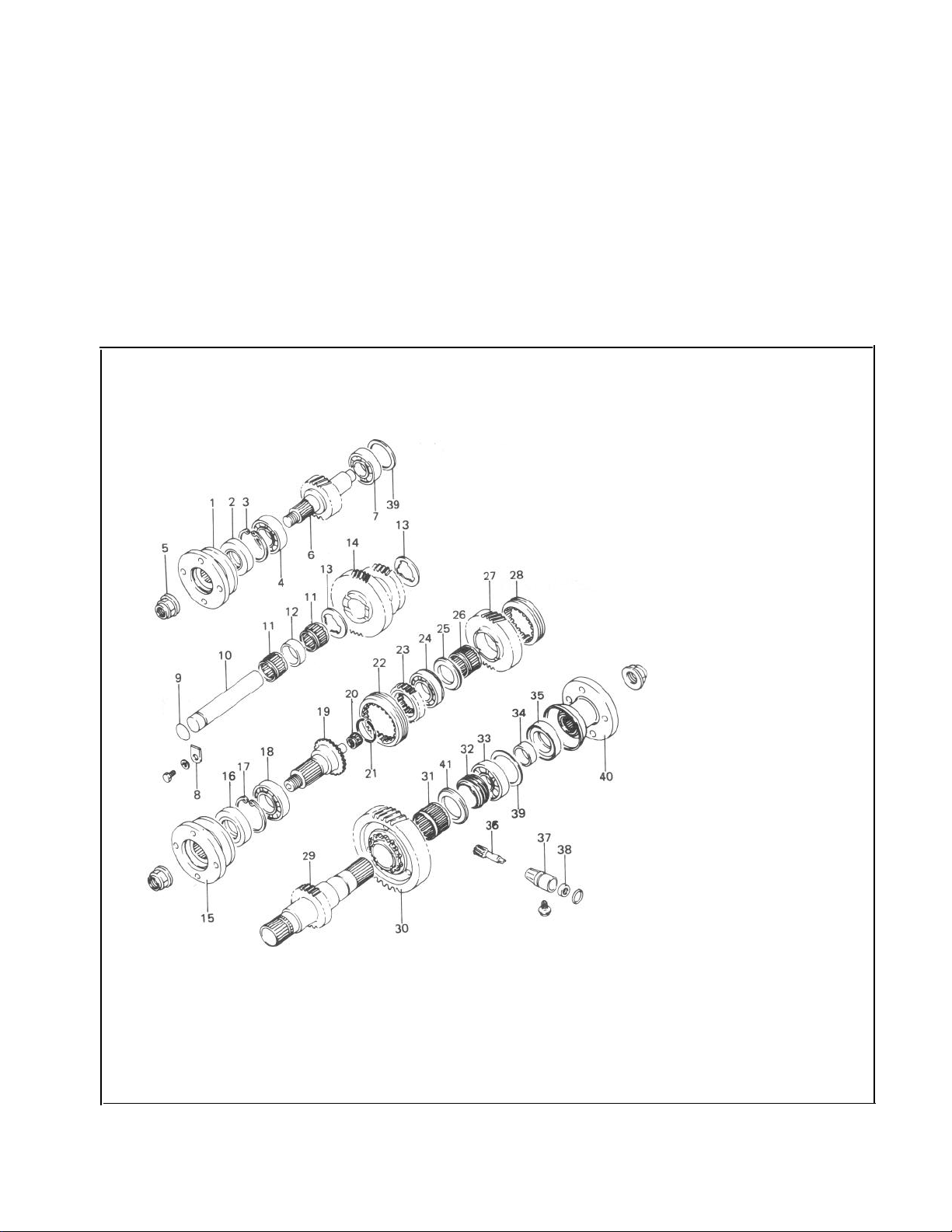

14-2. SELECTIVE FLOWS OF TRANSFER DRIVE

2-Wheel Drive (Rear-Wheel Drive)

Rear shifter fork pushes rear clutch sleeve into

“high” gear, thus coupling the gear to output

rear shaft.

Drive flows from input shaft to output rear shaft

through big gear, “high” gear and rear clutch.

Gear shift control lever position

a-wheel drive

(Rear wheel drive)

tra”SmiSSion

Fig. 14-2

4-Wheel Drive HIGH (All-Wheel Drive on HIGH)

Under the conditions of rear-wheel drive,

described above, front shifter fork pushes the

sleeve of front clutch onto the toothed clutch

ring, thus coupling output rear shaft to output

front shaft. Front shaft and rear

together on HIGH.

Gear shift control lever position

4-wheel

drive HIGH

shaft run

To front wheel

From

.

transm’ss’on

e

Fig. 14-3

14-3

Page 4

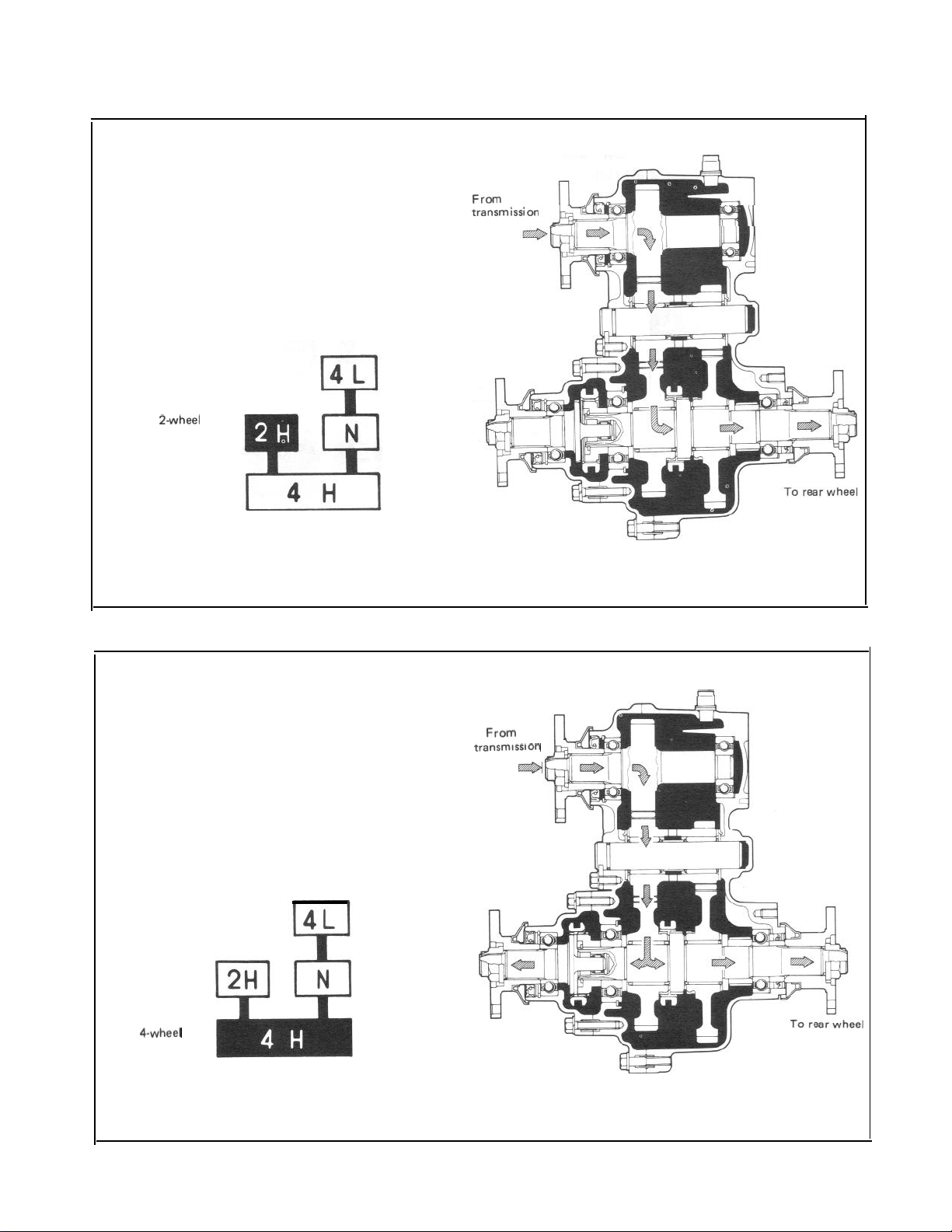

4-Wheel Drive LOW (All-Wheel Drive on LOW)

Front shifterforkactuates front clutch to couple

rear shaft to front shaft; and rear shifter fork

actuates rear clutch to couple “low” gear to rear

shaft. Front shaft and rear shaft run together on

LOW.

Gear shift control lever position

4-wheel

drive LOW

2H

From

5l

Fig. 14-4

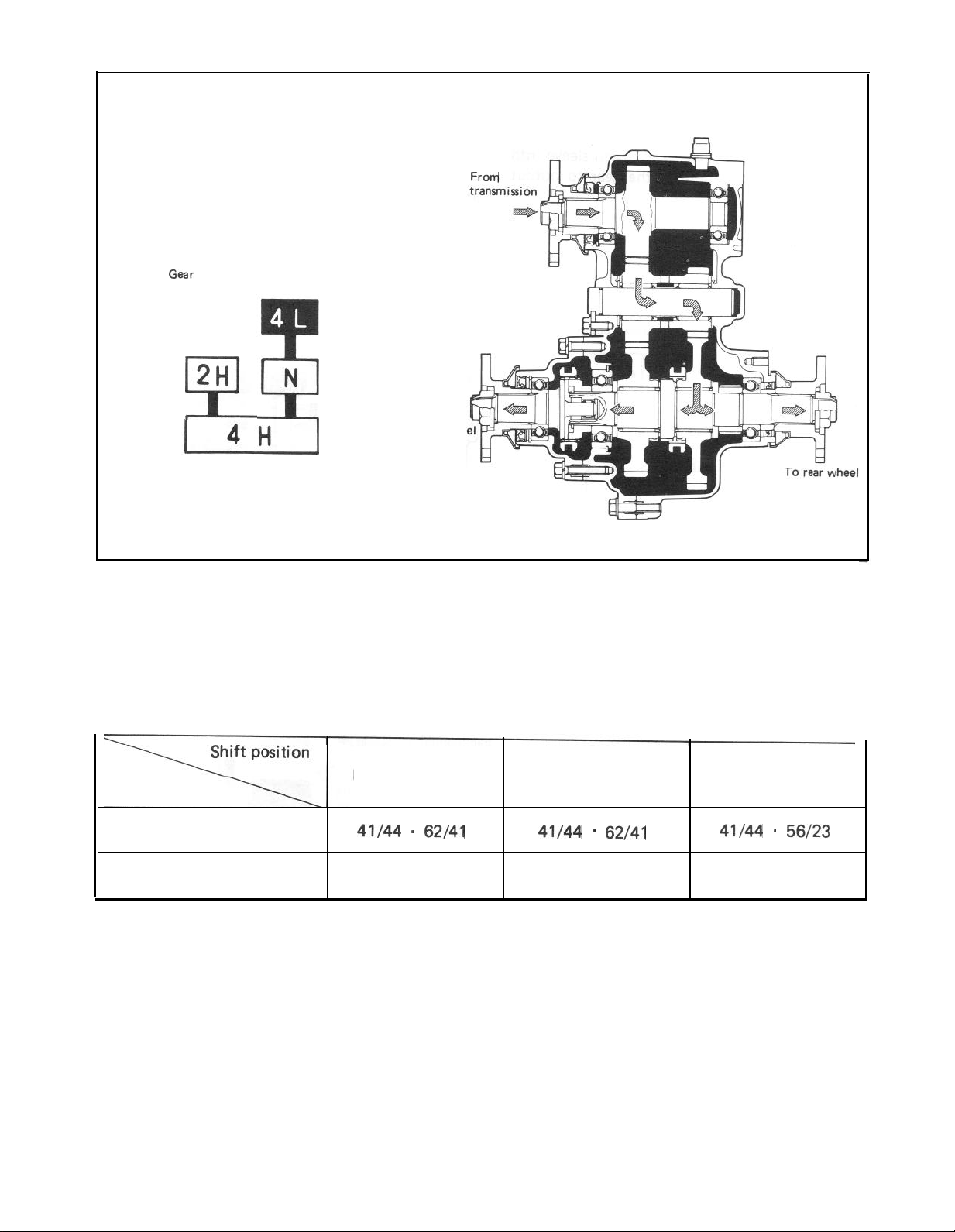

14-3. GEAR RATIO DATA

Gear

To front whe

Rear-wheel drive

41/44 -

62/41

All-wheel drive high

41/44

-

62/41

All-wheel drive low

41/44 - 56/23

14-4

Reduction

1.409

1.409

2.268

Page 5

14-4. TRANSFER SERVICES NOT REQUIRING TRANSFER REMOVAL

Following parts or components do not require transfer removal to receive services (replacement, inspec-

tion) :

Part or Component

1. Universal-joint yoke flanges

2. Front drive shift shaft fork

3. Transfer output front shaft oil seal

4. Transfer output front shaft bearing

5. Transfer output front shaft

6. Transfer front case

7. Front drive clutch hub

8. Front drive clutch sleeve

9. Transfer input shaft oil seal

10. 4WD indicator light switch

11. Speedometer driven gear

12. Gear shift control lever

13. Gear shift control boot No. 1, No. 2

14. Gear shift control lever spring seat

.

Nature of Service

Replacement or inspection

Replacement or inspection

I

Replacement or inspection

Replacement

Replacement

Replacement

Replacement or inspection

Replacement or inspection

Replacement

Replacement or inspection

Replacement or inspection

Replacement or inspection

Replacement

Replacement or inspection

14-5

Page 6

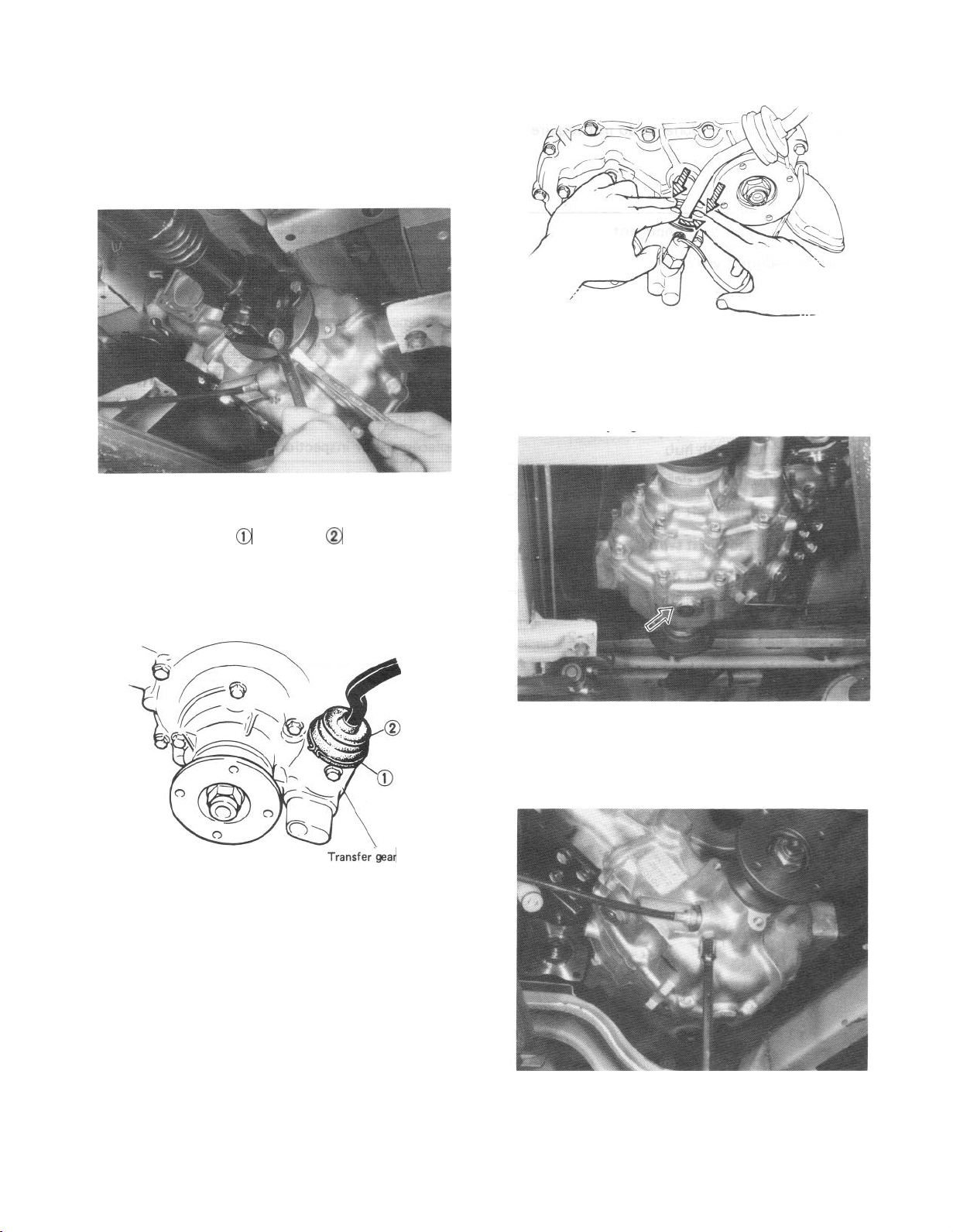

14-5. REMOVAL

1) Lift up car and remove securing bolts from

each universal-joint flange connection to

sever 3 propeller shafts from transfer gear

box.

Fig. 14-5

2) Remove clamp @ and boot @ from transfer

gear box.

Fig. 14-7

4) Drain out oil from gear box by loosening

its drain

plug.

Transfer‘gear case

Fig. 14-6

3) Twist control lever guide counterclockwise

while pushing it down; this will permit lever

to be removed from gear box.

14-6

Fig. 14-8

Fig.

14-8

5) Disconnect speedometer drive cable from

transfer gear box.

Fig. 14-9

Page 7

6) Disconnect 4WD switch lead wire at coupler.

7) Remove 3 mounting nuts securing gear box

to

chassis, and take down gear box.

Fig. 14-11

14-7

Page 8

14-6. DISASSEMBLY

Universal-Joint Yoke Flanges

There are 3 flanges to be removed: one from

input shaft and other from output front and rear

shafts. Lock flange so that it will not turn, and

loosen and remove nut holding flange to the

shaft. Draw off flange.

Fig. 14-12 @ Special tool (09930401131

Fig. 14-16

Remove bolts securing transfer front case,

and

take off case.

Speedometer Driven Gear

Loosen speedometer driven gear case bolt

and remove speedometer driven gear case with

gear.

Fig. 14-15

Transfer Front Case

Remove the indicator light switch from front

case.

NOTE:

Use care not to lose switch ball. This ball is

larger than interlock ball and locating balls.

Fig. 14-17

By tapping output front shaft with a plastic

hammer,

front case.

Fig. 14-18

remove output front shaft from

14-8

Page 9

After removing oil seal, remove circlip and drive

bearing out of front case by using bearing

installer (special tool).

Bearing installer 0 : (09913-76010)

Fig. 14-19

Transfer Center Case

Remove bolts fastening center case and rear

case together.

Do not

loosen bolt @ at

this

point.

Fig. 14-21

Fig. 14-20

By tapping rear case and output rear shaft with.

a plastic hammer, separate center and rear case.

Fig. 14-22

Given below are procedures for disassembling

component parts of center case as separted from

rear case.

1) Loosen gear shift locating spring plug and

take out spring and locating ball.

Fig. 14-23

14-9

Page 10

2) Using spring pin remover (special tool), drive

2 spring pins out of front drive shift shaft

@

and reduction shift shaft

Spring pin remover

@

0.

:

(09922-85811).

Fig. 14-26

Fig. 14-24

3) Remove forks and shift shafts.

NOTE:

At this time, locating ball and spring will jump

out of hole, use care not to lose them.

5) Pull out counter gear,

Remove counter shaft

loosening counter shaft

bearings and spacer.

from center case by

lock plate bolt.

Fig. 14-27

6) Remove input shaft from center case by

hammering thick part of case or input

shaft center with a plastic hammer.

Fig. 14-25

4) Hammer output rear shaft with a plastic

hammer to drive it out of center

case.

14-10

Fig. 14-28

Page 11

7) Remove output shaft rear bearing and

retainer together by using bearing puller.

After removing bearing, speedometer drive

gear, thrust washer, output low gear and

needle roller bearing can be removed.

Fig. 14-29

8) Remove front drive clutch hub circlip and

pull clutch hub off shaft by using bearing

puller and puller attachment (special tool A).

(A)

09926-5801 0

Fig. 14-31

10) When input shaft is removed or center case

and rear case are separated, input shaft

bearings may come off. In such a case,

bearings can be removed from shaft by using

bearing puller.

NOTE:

Use care to prevent damage to needle roller

bearing in output rear shaft when removing

clutch hub.

/

(A)

099263801 0

Fig. 14-30

9) Remove front bearing by using bearing

puller and puller attachment (special tool

A).

NOTE:

Use care to prevent damage to needle roller

bearing in output rear shaft while bearing is

being removed.

**

i

ta

“+

Fig. 14-32

14-11

Page 12

11) When input shaft is removed, front bearing

may be left in case. In this case, after removing oil seal and circlip, bearing can be taken

out of case by using bearing installer (special

tool).

Bearing installer @ : (09913-75810)

Fig. 14-33

Transfer Rear Case

1) When center case and rear case are separated,

input shaft may be left in rear case. In this

case, remove input shaft from rear case by

hammering thick part of case with a plastic

hammer.

14-7. INSPECTION OF COMPONENTS

Gear Teeth

Inspect gear teeth 0, internal teeth of rear

clutch sleeve @ and clutch teeth of gear 3. for

wear, cracking, chipping and other

malcondition. Replace gear or sleeve as necessary.

Fig. 14-35

Fig. 14-34

14-12

Fig. 14-36

Locating Spring

Check each shifter fork shaft locating spring for

strength by measuring its free length. If length is

noted to be less than service limit, replace it.

Free length of

locating spring

Page 13

Fig. 14-37

Bearings

Check each bearing by spinning its outer race by

hand to “feel” smoothness of rotation. Replace

bearing if noted to exhibit sticking, resistance

or abnormal noise when spun or rotated by

hand.

Fig. 14-38

Fig. 14-39 Output high gear

Fig. 14-40 Output low gear

Gear Shift Shafts

Check each part as indicated in below figures for

uneven wear. Replace defective parts.

Side Clearance of Gears

With gear, bearing and thrust washer installed

on shaft, check for side clearances of gears.

If clearance exceeds service limit, replace thrust

washer.

Side clearance

I

of gear

output

gears

low gear

high gear

Standard

0.175 (0.007 -

0.325mm

0.012in)

Service limit

0.7mm

(0.027in)

I

Fig. 14-41

14-13

Page 14

4WD Gear Shift Lever

Check lower end of gear shift lever where gear

shift fork shaft contacts @ for wear and any

kind of damage. Worn or damaged shift lever

must be replaced with new one.

Fig. 14-42

14-8. REASSEMBLY

NOTE:

l All parts to be used in reassembly must be

perfectly clean.

l Oil or grease sliding and rubbing surfaces of

transfer components just before using them

in reassembly with gear oil and SUZUKI

SUPER GREASE A (99000-25010).

l

Oil seals, “0” rings, gaskets and similar sealing

members must be in perfect condition. For

these members, use replacement parts in

stock.

l Tightening torque is specified for important

-

fasteners

other components. Use torque wrenches and

constantly refer to specified data given in

P. 14-23.

Input Shaft

Press-fit bearings onto both sides of input shaft

by using bearing installer (special tool).

Bearing installer (A) :

mainly bolts - of transfer and

(09913-84510)

Fig. 14-43

(A)

14-14

Page 15

Output Rear Shaft

Install following parts onto shaft in such order

and directions as prescribed in the figure.

6 9

1. Circlip

2. Hub

3.

Bearing

4.

Bearing

outer ring

5. Thrust washer

6. Output

7. Bearing (long)

8. Output rear shaft

high gear

9.

Sleeve

10. Bearing (short)

11. Outputlowgaar

12.

Thrust washer

13. Speed meter drive gear

14. Bearing

15. Retainer

2) Fit circlip @ securely into groove in shaft.

Fig. 14-46

3) After installing sleeve, bearing (short), low

gear and thrust washer, press-fit speedometer

drive gear by using bearing installer (special

tool).

Bearing installer (A) : (09913-84510)

(A)

Fig. 14-44

1) After installing bearing (long), high gear and

thrust washer, press-fit bearing 1. and then

hub @ by using bearing installer (special

tool).

Bearing installer (A) : (0991384510)

Fig. 14-45

Fig. 14-47

4) Press-fit bearing @ and the retainer @ by

using bearing installer (special tool).

Bearing installer (A) : (0991384510)

Fig. 14-48

14-15

Page 16

Shim Adjustment of Input and Output Shafts

Clearance in thrust direction of both input and

output shafts is adjusted by putting shims

between input shaft rear bearing and rear case

for input shaft and between output shaft rear

bearing and rear case for output shaft.

As thrust clearance is specified as follows

determine shim thickness to meet specification

according to the following procedures.

Thrust clearance

specification

0.05 - 0.15 mm

(0.002 - 0.006 in.)

[Input shaft]

1) Take measurement “A” of rear case as shown

in figure below by using depth gauge,

2) Take measurement

“6”

of center case with

bearing circlip installed.

3) Take measurement

“C” (between bearing

inner races) of input shaft with bearings

installed, by using micrometer.

NOTE:

l

Before measuring, make sure that each

bearing

is free from abnormal noise or resistance by

spinning its outer race.

l Each measurement in above steps 1) to 3)

must be taken accurately in careful manner,

If shim thickness is determined based on

rough measurement, clearance of each shaft in

thrust direction will not satisfy specification.

And improper clearance may cause oil leakage,

broken bearing and abnormal noise.

l Take the same measurement at 3 to 4 diffe-

rent positions and use their mean.

1.1.

14-48-14-48-

Fig.Fig.

Fig. 14-48-1

Center caseCenter case

2.2.

Rear caseRear case

3.3.

Input shaftInput shaft

4. Output shaft4. Output shaft

11

Bearing circlipBearing circlip

5.5.

GasketGasket

6.6.

Gasket thicknessGasket thickness

7.7.

(0.3

mm or 0.012 in)

(0.3

mm or 0.012 in)

4) Using measurements obtained in steps 1) to 3)

and equation described below, calculate shim

thickness which is necessary for proper

thrust clearance.

Thrust clearance = (“A” + “B” + Gasket

thickness) - “C”

As the above equation holds for thrust

clearance and gasket thickness is specified as

0.3 mm and thrust clearance as 0.05 to 0.15

mm, shim thickness is calculated by the

following equation.

Shim thickness = (“A” + “B” + 0.3 )

-

(“C” + 0.05 - 0.15)

14-16

[Example]

Supposing A, B and C are as follows;

A = 81.35 mm (3.203 in.)

B = 35.70 mm (1.405 in.)

C = 117.05 mm (4.608 in.)

Shim thickness = (81.35 + 35.70 + 0.3)

6

(117.05 + 0.05 N 0.15)

=

117.35- 117.10~

-

117.20

= 0.25 - 0.15

In this case, use of 0.15 to 0.25 mm (0.006 to

0.009 in) thick shim(s) will ensure specified

thrust clearance which is 0.05 to 0.15 mm

(0.002 to 0.006 in). Therefore 2 pieces of

0.1 mm (0.004 in) thick shim should be

selected in available shims below to satisfy

thickness.

Page 17

5) When shim thickness is determined, select

proper shim(s) from among the following

shims and use it (them) between input shaft

rear bearing and rear case when matching

center case and rear case.

Available shim 0.1,

size (thickness)

(0.004,0.012,0.020

0.3,0.5

mm

in.)

[Output shaft]

Just as with input shaft, take measurements of

“A’ “, “B’ ” and “C’ ” as indicated in Fig.

14-48-1, calculate shim thickness and install

proper shim(s) between output shaft rear bearing

and rear case when matching center case and

rear case.

I

Fig. 14-48-2

fig.

14-48-2

1. Shim for input shaft

2. Shim for output shaft

14-17

Page 18

Rear Case

1) Install oil seal in rear case and apply grease

to oil seal lip.

Fig. 14-49

2) Install counter shaft thrust washer to rear

case, bringing its face without depressions

against case and fit its bent portion securely

into groove in case.

Center Case

1) Install input shaft front bearing circlip and

oil seal in center case.

Snap ring pliers @ : (09900~6108)

Fig. 14-51

2) Install input shaft to center case.

NOTE:

Apply ample amount of grease to both surfaces

of washer so as to lubricate sliding surfaces and

prevent washer from moving out of place or

slipping off.

Fig.

14-50

Fig. 14-50

Fig. 14-52

Fig.

14-52

3) After greasing 0 ring on counter shaft,

insert shaft into center case and secure

shaft with lock plate and bolt.

14-18

Fig. 14-53

Fig.

14-53

Page 19

4) Install the counter shaft thrust washer to

center case. For installation, apply ample

amount of grease to both faces of the washer

so as to lubricate sliding surfaces and prevent

it from moving out of place or slipping off

and bring its face without depressions against

center case, and fit its bent portion into

groove in case securely.

Fig. 14-54

Fig.

14-54

Fig. 14-56

Fig. 14-56

7) When installing front drive shift shaft and

reduction shift shaft in center case, install

spring 0, ball 0, shaft 0, ball @, shaft

0,

ball 8, spring 0 and plug 8. in that

order.

5) Install needle roller bearings, spacer and

counter gear on counter shaft.

Fig. 14-55

Fig. 14-55

6) Install output shaft assembly to center case.

d 18-3ON.m

Fig. 14-57

Fig. 14-57

8) Fit forks on shift shafts and lock them

with spring pins. Forks should be fitted in

correct direction

according to below figure.

(1.8 - 3.0 kg-m

(13.5 - 21.5

lb-ft)

1

Fig. 14-58

Fig. 14-58

14-19

14-19

Page 20

Center and Rear Cases

1) Check center case (or rear case) to ensure

that it is provided with 2 dowel pins

0.

Fig. 14-59

2) Put gasket on center case. Bring rear case

and center case into match and apply

uniform force gradually all around rear case

with a plastic hammer. Tighten center case

securing bolts to specified torque.

Fig. 14-61

NOTE:

l

Matching must be made carefully so as not to

move countershaft thrust washers out of place.

l

Be sure to install shims determined in previ-

ous item

Output Shafts”

“Shim Adjustment of Input and

between input shaft rear

bearing and rear case and between output

shaft rear bearing and rear case.

Fig. 14-60

Fig. 14-62

3) Apply grease to output front shaft rear

bearing.

Fig. 14-63

14-20

Page 21

Front Case

1) Install bearing, circlip and oil seal to front

case. Apply grease to oil seal lip and install

output front shaft using bearing installer

(special tool).

Bearing installer (A) : (09913-76010)

Fig. 14-64

2) Put gasket on center case.

3) Check front case to ensure that it is provided

with 2 dowel pins.

Fig. 14-66

5) When installing speedometer driven gear

and its gear case in rear case, apply grease to

0 ring and oil seal lip, and align bolt holes

in rear case and driven gear case.

Fig. 14-65

4) Install front case to center case.

Fig. 14-67

6) Install 4WD ball and switch. Then clamp

switch lead wire properly.

/

Fig. 14-68

1.6 - 2.3 kgm

(12.0 - 16.5

lb-h)

14-21

Page 22

7) Install propeller shaft flanges and tighten

nuts to specified torque and

talk

the nuts.

8) Upon completion of entire assembly work,

install transfer in chassis body in reverse

sequence of removal. Pour gear oil into

transfer gear box.

Refer to information given in next oil and

oil capacity for oil to be used and specified

amount.

NOTE:

When installing oil filler and drain plugs to

transfer case, apply sealant (SUZUKI BOND

No.1215, 99000-31110) to thread part of plug.

14-9. MAINTENANCE SERVICES

Oil Level

Oil level must be checked with car held in

horizontal position in both front to rear and side

to side directions.

Oil level plug and oil filler plug are one and the

same as shown in figure.

If oil flows out of filler plug hole or if oil level is

found up to hole when plug is removed, amount

of oil is appropriate. Replenish oil if noted as

insufficient.

Oil and Oil Capacity

Whenever car is lifted up for any service including oil change,

transfer gear box for oil leakage. Correct defects,

if any, and change or refill oil.

make sure to check around

Transfer oil capacity

Transfer oil Gear oil SAE

specification

0.8 litre

75W-80

(1.7/l .4

8OW-90,

or

75W-90

US/Imp. pt)

It is highly recommended to use SAE

gear oil.

For viscosity chart, refer to P. 1-20.

@ : Oil drain plug

Fig. 14-70

@ : Oil filler & level plug

75W-90

14-22

Page 23

14-10. TIGHTENING TORQUE

Fastening parts

Front case bolt

Center case bolt

Counter shaft lock

Counter shaft lock

plate bolt

Universal

Universal joint

joint flange

flange nut

Transfer mounting

bracket bolt

Transfer mounting nut

Cross joint bolt & nut

Oil filler and drain

plug

14-23

Loading...

Loading...