Suzuki AN400 SERVICE MANUAL

FOREWORD

This manual contains an introductory description on

the SUZUKI AN400 and procedures for its inspection/service and overhaul of its main components.

Other information considered as generally known is

not included.

Read the GENERAL INFORMATION section to

familiarize yourself with the motorcycle and its maintenance. Use this section as well as other sections

to use as a guide for proper inspection and service.

This manual will help you know the motorcycle better so that you can assure your customers of fast

and reliable service.

GROUP INDEX

GENERAL INFORMATION

PERIODIC MAINTENANCE

ENGINE

1

2

3

* This manual has been prepared on the basis

of the latest specifications at the time of publication. If modifications have been made since

then, differences may exist between the content of this manual and the actual motorcycle.

* Illustrations in this manual are used to show

the basic principles of operation and work

procedures. They may not represent the

actual motorcycle exactly in detail.

* This manual is written for persons who have

enough knowledge, skills and tools, including

special tools, for servicing SUZUKI motorcycles. If you do not have the proper knowledge

and tools, ask your authorized SUZUKI

motorcycle dealer to help you.

!

Inexperienced mechanics or mechanics

without the proper tools and equipment

may not be able to properly perform the

services described in this manual.

Improper repair may result in injury to the

mechanic and may render the motorcycle

unsafe for the rider and passenger.

FI SYSTEM

FUEL SYSTEM AND THROTTLE

BODY

COOLING AND LUBRICATION

SYSTEM

CHASSIS

ELECTRICAL SYSTEM

SERVICING INFORMATION

EMISSION CONTROL

INFORMATION

4

5

6

7

8

9

10

© COPYRIGHT SUZUKI MOTOR CORPORATION 2002

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE LOOKING FOR:

1. The text of this manual is divided into sections.

2. The section titles are listed in the GROUP INDEX.

3. Holding the manual as shown at the right will allow you to find

the first page of the section easily.

4. The contents are listed on the first page of each section to

help you find the item and page you need.

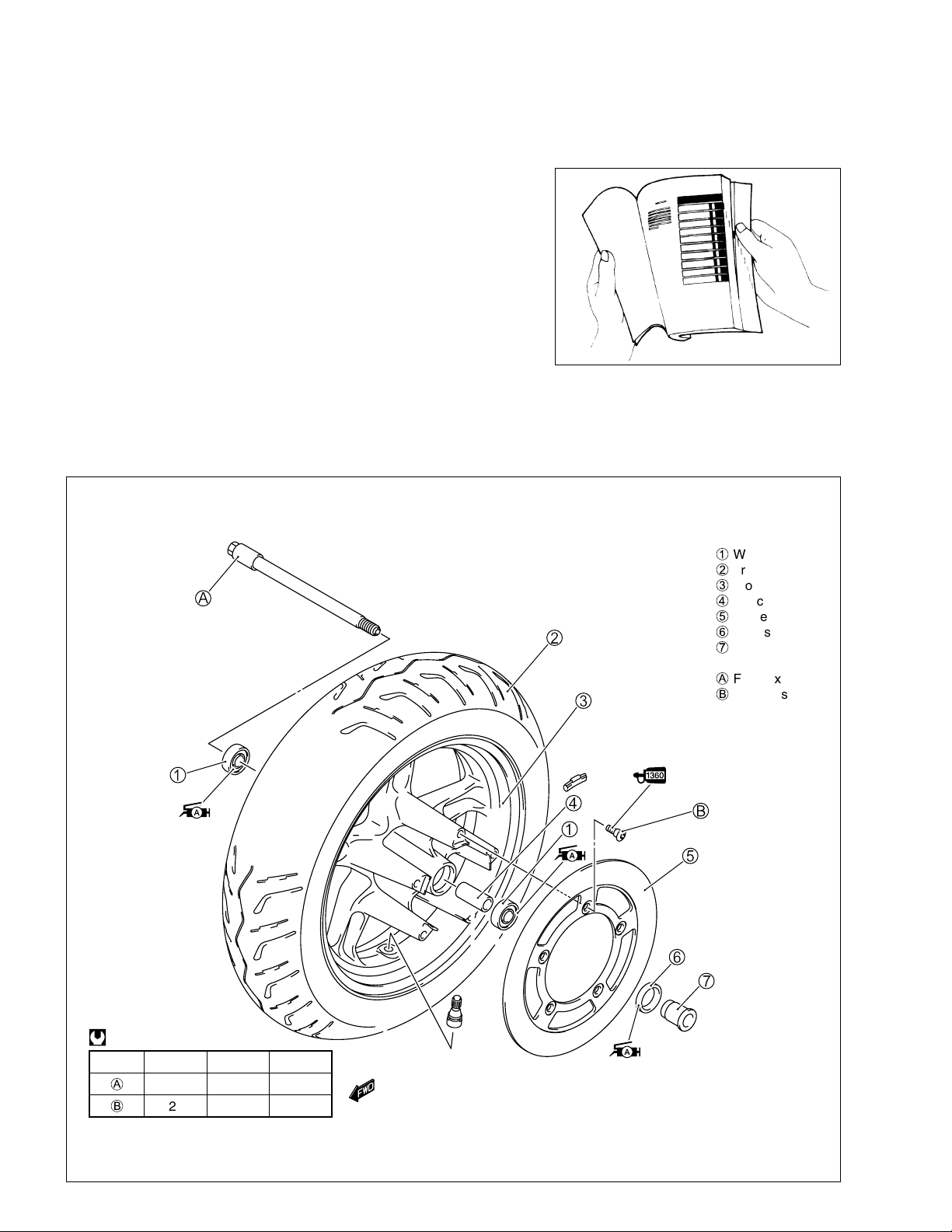

COMPONENT PARTS AND WORK TO BE DONE

Under the name of each system or unit, is its exploded view. Work instructions and other service information

such as the tightening torque, lubricating points and locking agent points, are provided.

Example: Front wheel

1

Wheel bearing

2

Front tire

3

Front wheel

4

Spacer

5

Brake disc

6

Dust seal

7

Spacer

ITEM N·m kgf-mIb-ft

A

B

65 6.5 47.0

23 2.3 16.5

A

Front axle

B

Brake disc bolt

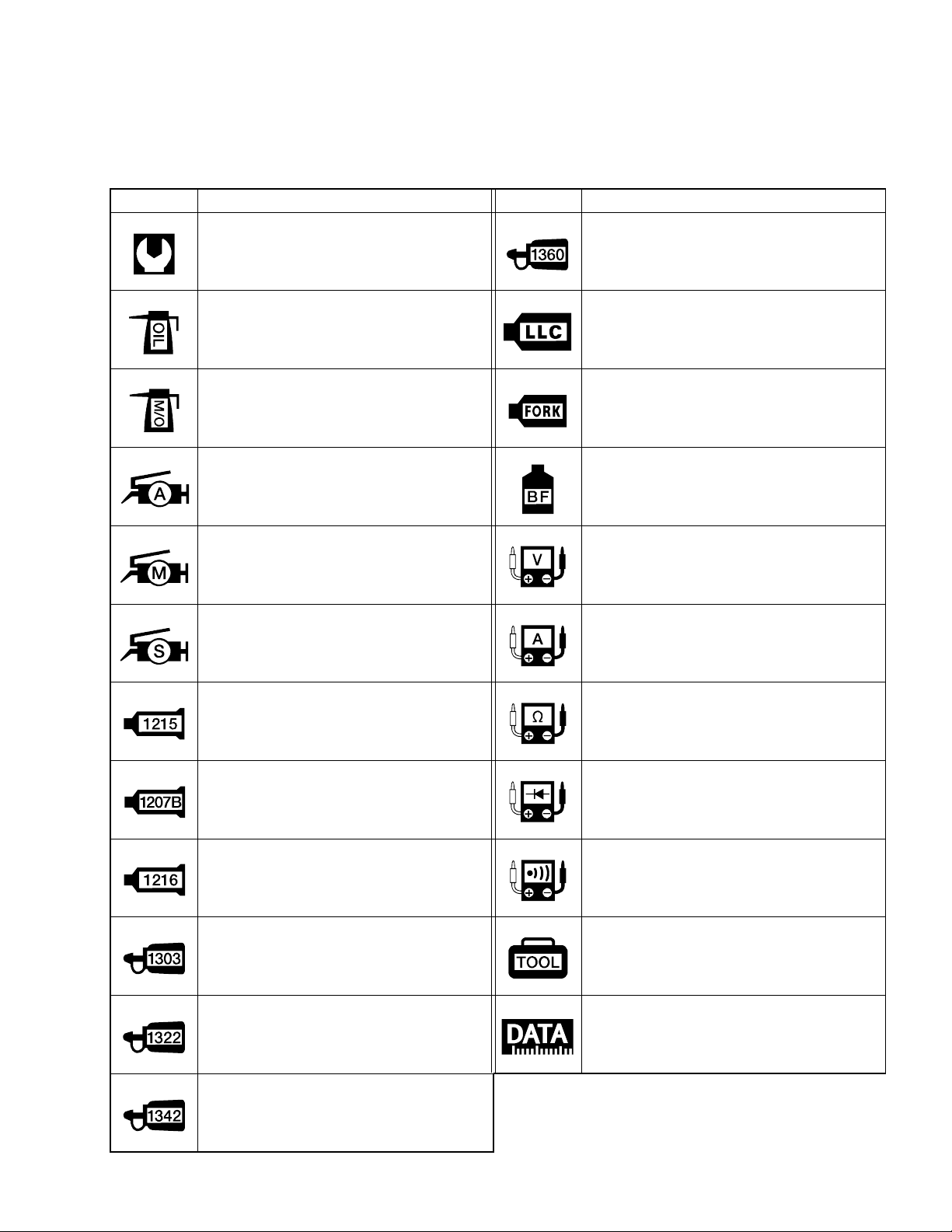

SYMBOL

Listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table.

SYMBOL DEFINITION SYMBOL DEFINITION

Torque control required.

Data beside it indicates specified

torque.

Apply oil. Use engine oil unless otherwise specified.

Apply molybdenum oil solution.

(Mixture of engine oil and SUZUKI

MOLY PASTE in a ratio of 1:1)

Apply SUZUKI SUPER GREASE “A”.

99000-25010 (Others)

99000-25030 (USA)

Apply SUZUKI MOLY PASTE.

99000-25140

Apply SUZUKI SILICONE GREASE.

99000-25100

Apply THREAD LOCK SUPER “1360”.

99000-32130

Use engine coolant.

99000-99032-11X

Use fork oil.

99000-99044-10G

Apply or use brake fluid.

Measure in voltage range.

Measure in current range.

Apply SUZUKI BOND “1215”.

99000-31110 (Except USA)

Apply SUZUKI BOND “1207B”.

99104-31140 (USA)

Apply SUZUKI BOND “1216”.

99000-31230

Apply THREAD LOCK SUPER “1303”.

99000-32030

Apply THREAD LOCK SUPER “1322”.

99000-32110 (Except USA)

Apply THREAD LOCK “1342”.

99000-32050 (USA)

Measure in resistance range.

Measure in diode test range.

Measure in continuity test range.

Use special tool.

Indication of service data.

ABBREVIATIONS USED IN THIS MANUAL

A

ABDC : After Bottom Dead Center

AC : Alternating Current

ACL : Air Cleaner, Air Cleaner Box

API : American Petroleum Institute

ATDC : After Top Dead Center

ATM Pressure: Atmospheric Pressure

A/F : Air Fuel Mixture

B

BBDC : Before Bottom Dead Center

BTDC : Before Top Dead Center

B+ : Battery Positive Voltage

C

CKP Sensor : Crankshaft Position Sensor

(CKPS)

CKT : Circuit

CLP Switch : Clutch Lever Position Switch

(Clutch Switch)

CO : Carbon Monoxide

CPU : Central Processing Unit

E

ECM : Engine Control Module

Engine Control Unit (ECU)

(FI Control Unit)

ECT Sensor : Engine Coolant Temperature

Sensor (ECTS), Water Temp.

Sensor (WTS)

EVAP : Evaporative Emission

EVAP Canister: Evaporative Emission

Canister (Canister)

F

FI : Fuel Injection, Fuel Injector

FP : Fuel Pump

FPR : Fuel Pressure Regulator

FP Relay : Fuel Pump Relay

FTPC Valve : Fuel Tank Pressure Control Valve

G

GEN : Generator

GND : Ground

GP Switch : Gear Position Switch

D

DC : Direct Current

DMC : Dealer Mode Coupler

DOHC : Double Over Head Camshaft

DRL : Daytime Running Light

H

HC : Hydrocarbons

I

IAC Valve : Idle Air Control Valve

IAP Sensor : Intake Air Pressure Sensor (IAPS)

IAT Sensor : Intake Air Temperature Sensor

(IATS)

IG : Ignition

L

LCD : Liquid Crystal Display

LED : Light Emitting Diode

(Malfunction Indicator Lamp)

LH : Left Hand

M

MAL-Code : Malfunction Code

(Diagnostic Code)

Max : Maximum

MIL : Malfunction Indicator Lamp

(LED)

Min : Minimum

N

NOX : Nitrogen Oxides

O

OHC : Over Head Camshaft

OLS : Oil Level Switch

OPS : Oil Pressure Switch

P

PCV : Positive Crankcase

Ventilation (Crankcase Breather)

R

RH : Right Hand

ROM : Read Only Memory

S

SAE : Society of Automotive Engineers

T

TO Sensor : Tip Over Sensor (TOS)

TP Sensor : Throttle Position Sensor (TPS)

GENERAL INFORMATION 1-1

GENERAL INFORMATION

CONTENTS

WARNING/CAUTION/NOTE......................................................................... 1- 2

GENERAL PRECAUTIONS .......................................................................... 1- 2

1

SUZUKI AN400 (

SERIAL NUMBER LOCATION ..................................................................... 1- 4

FUEL, OIL AND ENGINE COOLANT RECOMMENDATION....................... 1- 4

FUEL (FOR USA AND CANADA) ..........................................................1- 4

FUEL (FOR OTHER COUNTRIES) ........................................................ 1- 4

ENGINE OIL AND TRANSMISSION OIL (FOR USA)............................1- 5

ENGINE OIL AND TRANSMISSION OIL

(FOR OTHER COUNTRIES)................................................................... 1- 5

FINAL GEAR OIL ...................................................................................1- 5

BRAKE FLUID ........................................................................................1- 5

FRONT FORK OIL.................................................................................. 1- 5

ENGINE COOLANT ................................................................................ 1- 5

WATER FOR MIXING.............................................................................1- 5

ANTI-FREEZE/ENGINE COOLANT .......................................................1- 5

LIQUID AMOUNT OF WATER/ENGINE COOLANT..............................1- 6

BREAK-IN PROCEDURES........................................................................... 1- 7

INFORMATION LABELS .............................................................................. 1- 8

SPECIFICATIONS......................................................................................... 1- 9

DIMENSIONS AND DRY MASS.............................................................1- 9

ENGINE................................................................................................... 1- 9

DRIVE TRAIN ......................................................................................... 1- 9

CHASSIS ................................................................................................ 1- 9

ELECTRICAL.......................................................................................... 1-10

CAPACITIES........................................................................................... 1-10

03-MODEL)....................................................................... 1- 4

’

COUNTRY AND AREA CODES ................................................................... 1-11

1-2 GENERAL INFORMATION

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the symbol

and the words WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by these signal words.

!

Indicates a potential hazard that could result in death or injury.

"

Indicates a potential hazard that could result in motorcycle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

Please note, however, that the warnings and cautions contained in this manual cannot possibly cover all

potential hazards relating to the servicing, or lack of servicing, of the motorcycle. In addition to the WARNINGS and CAUTIONS stated, you must use good judgement and basic mechanical safety principles. If you

are unsure about how to perform a particular service operation, ask a more experienced mechanic for

advice.

GENERAL PRECAUTIONS

!

* Proper service and repair procedures are important for the safety of the service mechanic and

the safety and reliability of the motorcycle.

* When 2 or more persons work together, pay attention to the safety of each other.

* When it is necessary to run the engine indoors, make sure that exhaust gas in forced out-

doors.

* When working with toxic or flammable materials, make sure that the area you work in is well-

ventilated and that you follow all of the material manufacturer’s instructions.

* Never use gasoline as a cleaning solvent.

* To avoid getting burned, do not touch the engine, engine oil, radiator and exhaust system

until they have cooled.

* After servicing the fuel, oil, water, exhaust or brake systems, check all lines and fittings

related to the system for leaks.

GENERAL INFORMATION 1-3

"

* If parts replacement is necessary, replace the parts with Suzuki Genuine Parts or their equiva-

lent.

* When removing parts that are to be reused, keep them arranged in an orderly manner so that

they may be reinstalled in the proper order and orientation.

* Be sure to use special tools when instructed.

* Make sure that all parts used in reassembly are clean. Lubricate them when specified.

* Use the specified lubricant, bond, or sealant.

* When removing the battery, disconnect the negative cable first and then the positive cable.

* When reconnecting the battery, connect the positive cable first and then the negative cable,

and replace the terminal cover on the positive terminal.

* When performing service to electrical parts, if the service procedures not require use of bat-

tery power, disconnect the negative cable the battery.

* When tightening the cylinder head and case bolts and nuts, tighten the larger sizes first.

Always tighten the bolts and nuts diagonally from the inside toward outside and to the speci-

fied tightening torque.

* Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, self-locking

nuts, cotter pins, circlips and certain other parts as specified, be sure to replace them with

new ones. Also, before installing these new parts, be sure to remove any left over material

from the mating surfaces.

* Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger

than required to slip the circlip over the shaft. After installing a circlip, always ensure that it is

completely seated in its groove and securely fitted.

* Use a torque wrench to tighten fasteners to the specified torque. Wipe off grease and oil if a

thread is smeared with them.

* After reassembling, check parts for tightness and proper operation.

* To protect the environment, do not unlawfully dispose of used motor oil, engine coolant and

other fluids: batteries, and tires.

* To protect Earth’s natural resources, properly dispose of used motorcycle and parts.

1-4 GENERAL INFORMATION

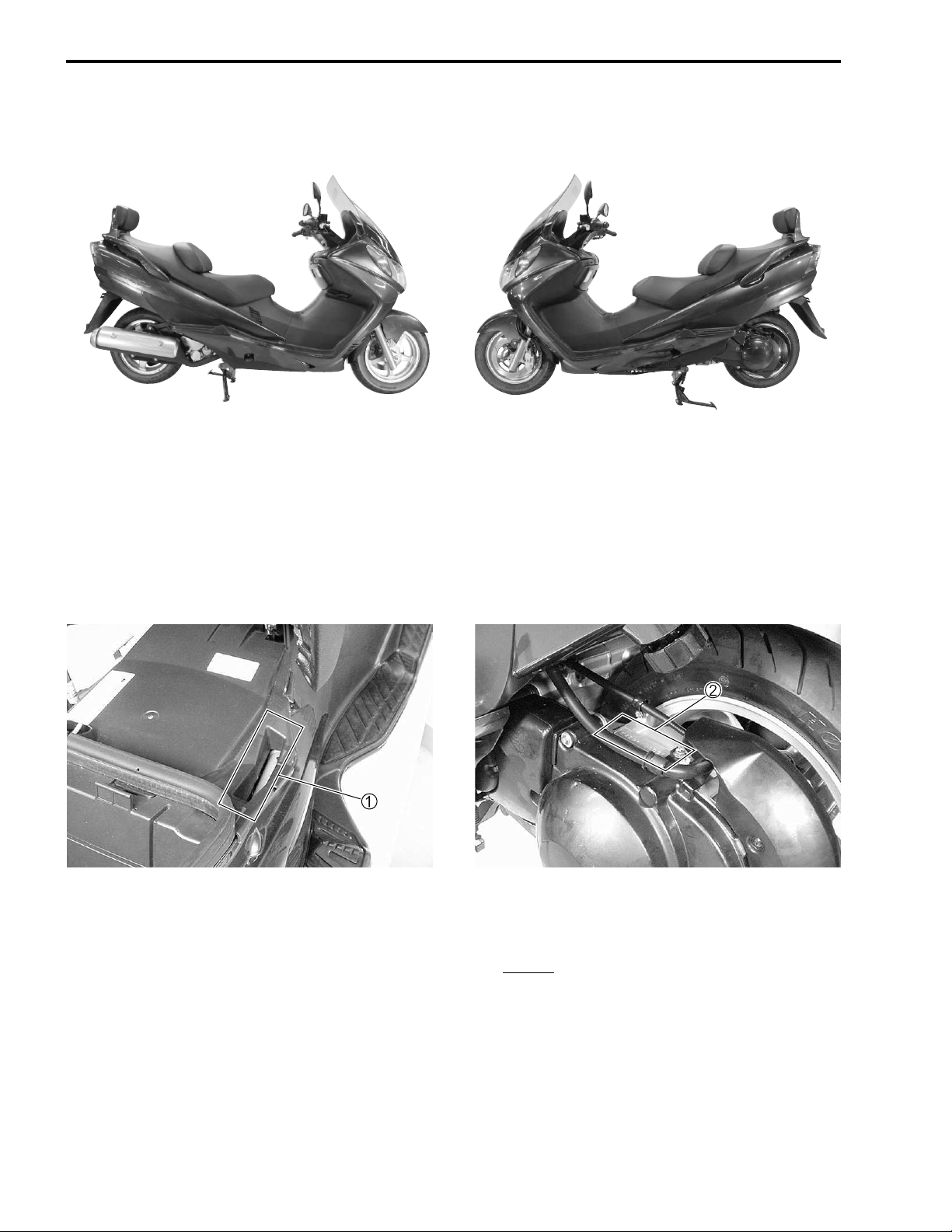

SUZUKI AN400 (’03-MODEL)

RIGHT SIDE LEFT SIDE

• Difference between photographs and actual motorcycles depends on the markets.

SERIAL NUMBER LOCATION

The frame serial number or V.I.N. (Vehicle Identification Number)

frame tube. The engine serial number

required especially for registering the machine and ordering spare parts.

2 is located on the left side of the crankcase. These numbers are

1 is stamped on the right side of the

FUEL, OIL AND ENGINE COOLANT RECOMMENDATION

FUEL (FOR USA AND CANADA)

Use only unleaded gasoline of at least 87 pump octane ( ) or 91 octane or higher rated by the

research method.

Gasoline containing MTBE (Methyl Tertiary Butyl Ether), less than 10% ethanol, or less than 5% methanol

with appropriate cosolvents and corrosion inhibitor is permissible.

FUEL (FOR OTHER COUNTRIES)

Gasoline used should be graded 91 octane (Research Method) or higher. Unleaded gasoline is recommended.

R + M

2

GENERAL INFORMATION 1-5

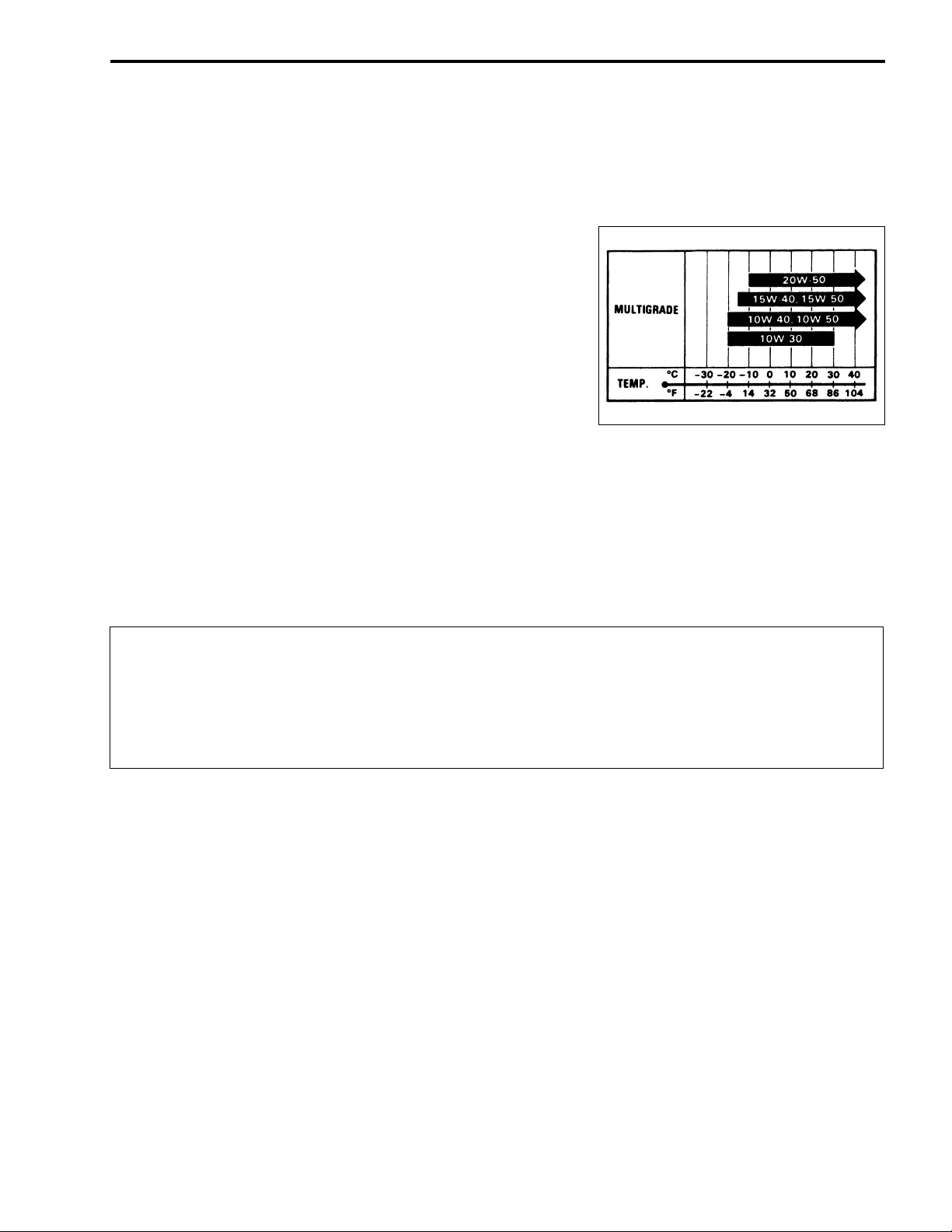

ENGINE OIL AND TRANSMISSION OIL (FOR USA)

SUZUKI recommends the use of SUZUKI PERFORMANCE 4 MOTOR OIL or an oil which is rated SF or SG

under the API (American Pertoleum Institute) service classification. The recommended viscosity is SAE

10W-40. If an SAE 10W-40 oil is not available, select and alternative according to the following chart.

ENGINE OIL AND TRANSMISSION OIL (FOR

OTHER COUNTRIES)

Use a premium quality 4-stroke motor oil to ensure longer service life of your motorcycle. Use only oils which are rated SF or

SG under the API service classification. The recommended viscosity is SAE 10W-40. If an SAE 10W-40 motor oil is not available, select an alternative according to the right chart.

FINAL GEAR OIL

Use hypoid gear oil that meets the API service classification GL-5 and is rated SAE #90. Use a hypoid gear

oil with a rating of SAE #80 if the motorcycle is operated where the ambient temperature is below 0 °C

(32 °F).

BRAKE FLUID

Specification and classification: DOT 4

!

Since the brake system of this motorcycle is filled with a glycol-based brake fluid by the manufacturer, do not use or mix different types of fluid such as silicone-based and petroleum-based

fluid for refilling the system, otherwise serious damage will result.

Do not use any brake fluid taken from old or used or unsealed containers.

Never re-use brake fluid left over from a previous servicing, which has been stored for a long

period.

FRONT FORK OIL

Use fork oil #10 or an equivalent fork oil.

ENGINE COOLANT

Use an anti-freeze/engine coolant compatible with an aluminum radiator, mixed with distilled water only.

WATER FOR MIXING

Use distilled water only. Water other than distilled water can corrode and clog the aluminum radiator.

ANTI-FREEZE/ENGINE COOLANT

The engine coolant perform as a corrosion and rust inhibitor as well as anti-freeze. Therefore, the engine

coolant should be used at all times even though the atmospheric temperature in your area does not go down

to freezing point.

Suzuki recommends the use of SUZUKI COOLANT anti-freeze/engine coolant. If this is not available, use

an equivalent which is compatible with an aluminum radiator.

1-6 GENERAL INFORMATION

LIQUID AMOUNT OF WATER/ENGINE COOLANT

Solution capacity (total): Approx. 1 300 ml (1.4/1.1 US/Imp qt)

For engine coolant mixture information, refer to cooling system section, page 6-3.

"

Mixing of anti-freeze/engine coolant should be limited to 60%. Mixing beyond it would reduce

its efficiency. If the anti-freeze/engine coolant mixing ratio is below 50%, rust inhabiting performance is greatly reduced. Be sure to mix it above 50% even though the atmospheric temperature does not go down to the freezing point.

GENERAL INFORMATION 1-7

BREAK-IN PROCEDURES

During manufacture only the best possible materials are used and all machined parts are finished to a very

high standard but it is still necessary to allow the moving parts to “BREAK-IN” before subjecting the engine

to maximum stresses. The future performance and reliability of the engine depends on the care and restraint

exercised during its early life. The general rules are as follows.

• Keep to these break-in engine speed limits:

Initial 800 km: Below 4 000 r/min

Up to 1 600 km: Below 6 000 r/min

• Upon reaching an odometer reading of 1600 km you can subject the motorcycle to full throttle operation.

1-8 GENERAL INFORMATION

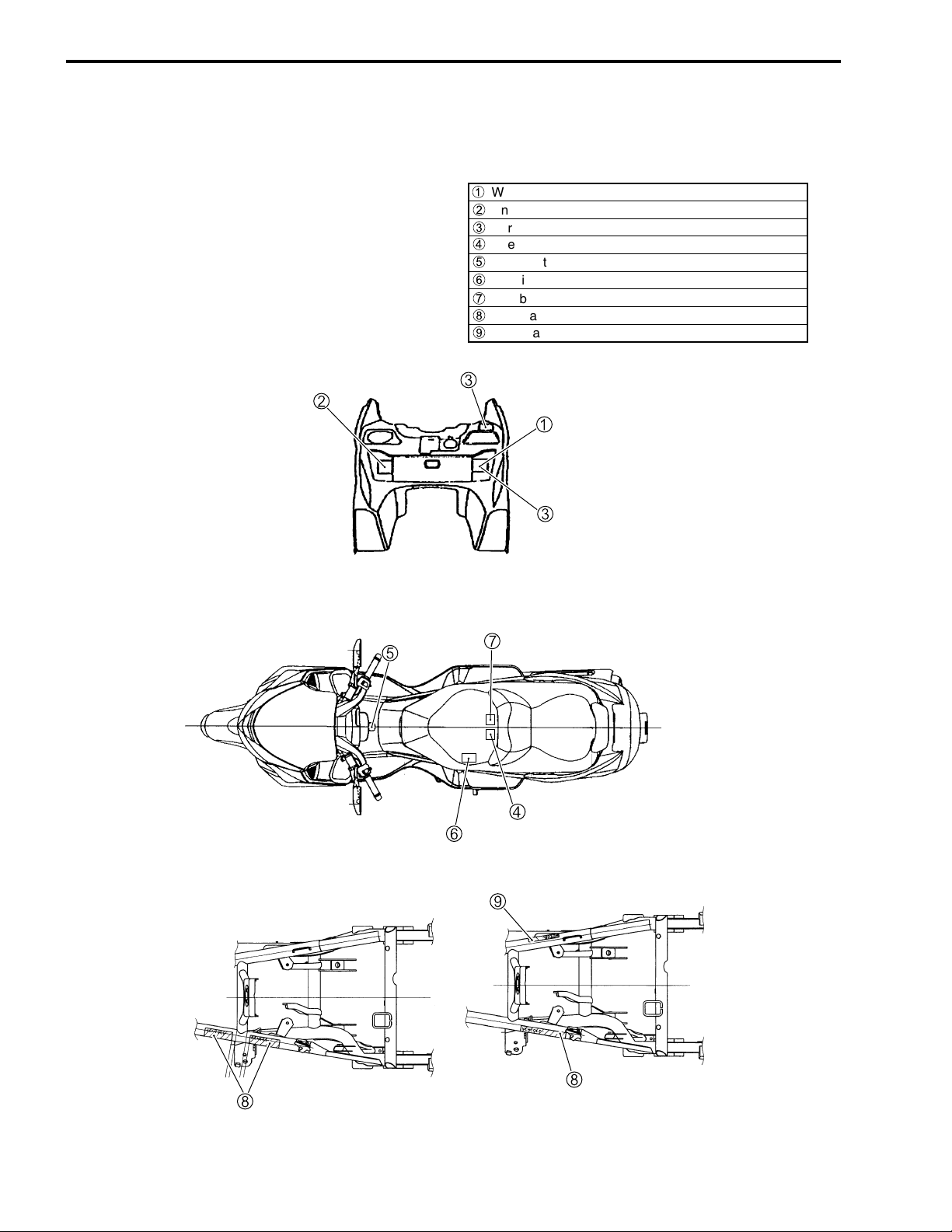

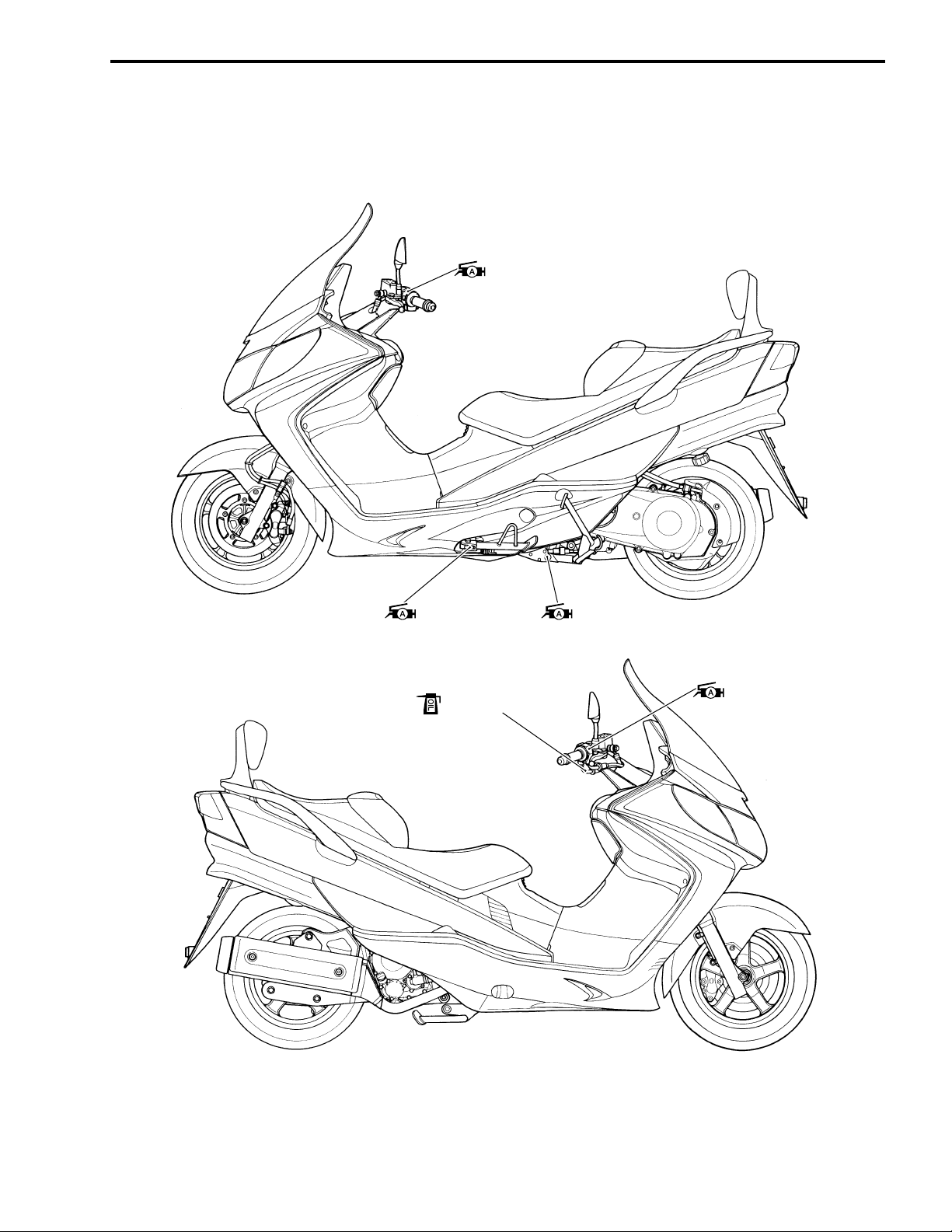

INFORMATION LABELS

1

Warning safety label

2

Engine starting label

3

Screen warning label

4

Tire pressure label

5

Fuel caution label (For E-02)

6

Loading capacity label

7

ID label

8

Information label (For E-03, 28, 33)

9

Noise label (For E-03, 33)

Front box

Stick the label on the frame tube.

Stick the label on the front trunk box cover.

Stick the label on the trunk box cover.

E-28

E-03, 33

GENERAL INFORMATION 1-9

SPECIFICATIONS

DIMENSIONS AND DRY MASS

Overall length .......................................................................... 2 260 mm (89.0 in)

Overall width ........................................................................... 760 mm (29.9 in)

Overall height .......................................................................... 1 375 mm (54.1 in)

Wheelbase .............................................................................. 1 590 mm (62.6 in)

Ground clearance.................................................................... 125 mm (4.9 in)

Seat height .............................................................................. 695 mm (27.4 in)

Dry mass ................................................................................. 184 kg (405 lbs)

ENGINE

Type ........................................................................................ 4-stroke, liquid-cooled, OHC

Number of cylinders ................................................................ 1

Bore......................................................................................... 83.0 mm (3.268 in)

Stroke ...................................................................................... 71.2 mm (2.803 in)

Piston displacement ................................................................ 385 cm³ (23.5 cu.in)

Compression ratio ................................................................... 10.2 : 1

Fuel system............................................................................. Fuel injection

Air cleaner ............................................................................... Polyurethane foam element

Starter system ......................................................................... Electric

Lubrication system .................................................................. Wet sump

Idle speed................................................................................ 1 400 ± 100 r/min

DRIVE TRAIN

Clutch ...................................................................................... Dry shoe,automatic,centrifugal type

Gearshift pattern ..................................................................... Automatic

Final reduction ratio................................................................. 6.168 (31/14 × 39/14)

Gear ratio ................................................................................ 2.203 – 0.854 (variable change)

Drive system ........................................................................... V-belt drive

CHASSIS

Front suspension..................................................................... Telescopic,coil spring,oil damped

Rear suspension ..................................................................... Link type,coil spring,oil damped

Front fork stroke ...................................................................... 100 mm (3.9 in)

Rear wheel travel .................................................................... 100 mm (3.9 in)

Caster...................................................................................... 27°

Trail ......................................................................................... 106 mm (4.2 in)

Steering angle ......................................................................... 40° (right and left)

Turning radius ......................................................................... 2.8 m (9.2 ft)

Front brake.............................................................................. Disc brake

Rear brake .............................................................................. Disc brake

Front tire size .......................................................................... 110/90-13 M/C 55P,tubeless

Rear tire size ........................................................................... 130/70-13 M/C 63P,tubeless

1-10 GENERAL INFORMATION

ELECTRICAL

Ignition type............................................................................. Electronic ignition (Transistorized)

Ignition timing.......................................................................... 10 ° B.T.D.C.at 1 400 r/min

Spark plug............................................................................... NGK CR7E or DENSO U22ESR-N

Battery..................................................................................... 12 V 28.8 kC (8 Ah)/10 HR

Generator ................................................................................ Three-phase A.C.generator

Main fuse ................................................................................ 30 A

Fuse ........................................................................................ 10/15/10/10/10/10 A

Headlight................................................................................. 12 V 35/35 W

Position/parking light ............................................................... 12 V 5 W (For…E-02,19, 54)

Brake light/Taillight.................................................................. 12 V 21/5 W × 2

License plate light ................................................................... 12 V 5 W

Trunk light ............................................................................... 12 V 5 W

Turn signal light....................................................................... 12 V 21 W

Speedometer/Tachometer light............................................... 12 V 1.7 W

Coolant temperature gauge light............................................. 12 V 1.7 W

Fuel level gauge light .............................................................. 12 V 1.7 W

Turn signal indicator light ........................................................ 12 V 1.7 W × 2

High beam indicator light ........................................................ 12 V 1.7 W

Brake-lock indicator light......................................................... 12 V 1.7 W

Oil change indicator light......................................................... 12 V 1.7 W

Fuel injection warning light...................................................... 12 V 1.7 W

CAPACITIES

Fuel tank, including reserve .................................................... 13.0 L (3.4/2.9 US/lmp gal)

Engine oil, oil change............................................................... 1 900 ml (2.0/1.7 US/Imp qt)

with filter change .................................................... 2 000 ml (2.1/1.8 US/lmp qt)

overhaul ................................................................. 2 300 ml (2.4/2.0 US/lmp qt)

Final gear oil,oil change.......................................................... 190 ml (6.4/6.7 US/lmp oz)

overhaul ............................................................ 200 ml (6.8/7.0 US/lmp oz)

Front fork oil (each leg) ........................................................... 284 ml (9.6/10.0 US/lmp oz)

Coolant.................................................................................... 1.3 L (1.4/1.1 US/lmp qt)

These specifications are subject to change without notice.

COUNTRY AND AREA CODES

The following codes stand for the applicable country (-ies) and area (-s).

CODE COUNTRY or AREA

E-02

E-03

E-19

E-28

E-33

E-54

U.K.

U.S.A. (Except for California)

EU

Canada

California (U.S.A.)

Israel

GENERAL INFORMATION 1-11

PERIODIC MAINTENANCE 2-1

PERIODIC MAINTENANCE

CONTENTS

PERIODIC MAINTENANCE SCHEDULE ..................................................... 2- 2

PERIODIC MAINTENANCE CHART...................................................... 2- 2

LUBRICATION POINTS ......................................................................... 2- 3

MAINTENANCE AND TUNE-UP PROCEDURES ........................................ 2- 4

AIR CLEANER........................................................................................ 2- 4

EXHAUST PIPE BOLT AND MUFFLER BOLT .....................................2- 5

VALVE CLEARANCE............................................................................. 2- 5

SPARK PLUG......................................................................................... 2- 7

FUEL LINE.............................................................................................. 2- 8

ENGINE OIL AND OIL FILTER .............................................................. 2- 8

FINAL GEAR OIL ...................................................................................2-10

IDLE SPEED ........................................................................................... 2-11

THROTTLE CABLE PLAY ..................................................................... 2-12

COOLING FAN FILTER.......................................................................... 2-13

COOLING SYSTEM................................................................................2-13

DRIVE V-BELT INSPECTION ................................................................ 2-15

PAIR(AIR SUPPLY)SYSTEM ................................................................. 2-15

BRAKE SYSTEM.................................................................................... 2-16

STEERING ..............................................................................................2-20

FRONT FORK......................................................................................... 2-21

REAR SUSPENSION.............................................................................. 2-21

TIRE ........................................................................................................ 2-22

CHASSIS BOLT AND NUT ....................................................................2-23

COMPRESSION PRESSURE CHECK ......................................................... 2-25

2

COMPRESSION TEST PROCEDURE ................................................... 2-25

OIL PRESSURE CHECK .............................................................................. 2-26

OIL PRESSURE TEST PROCEDURE ................................................... 2-26

AUTOMATIC CLUTCH INSPECTION........................................................... 2-27

1.INITIAL ENGAGEMENT INSPECTION ............................................... 2-27

2.CLUTCH “LOCK-UP” INSPECTION................................................... 2-27

BRAKE-LOCK............................................................................................... 2-28

INSPECTION ..........................................................................................2-28

ADJUSTMENT........................................................................................ 2-28

2-2 PERIODIC MAINTENANCE

PERIODIC MAINTENANCE SCHEDULE

The chart below lists the recommended intervals for all the required periodic service work necessary to keep

the motorcycle operating at peak performance and economy. Mileages are expressed in terms of kilometers, miles and time for your convenience.

NOTE:

More frequent servicing may be performed on motorcycles that are used under severe conditions.

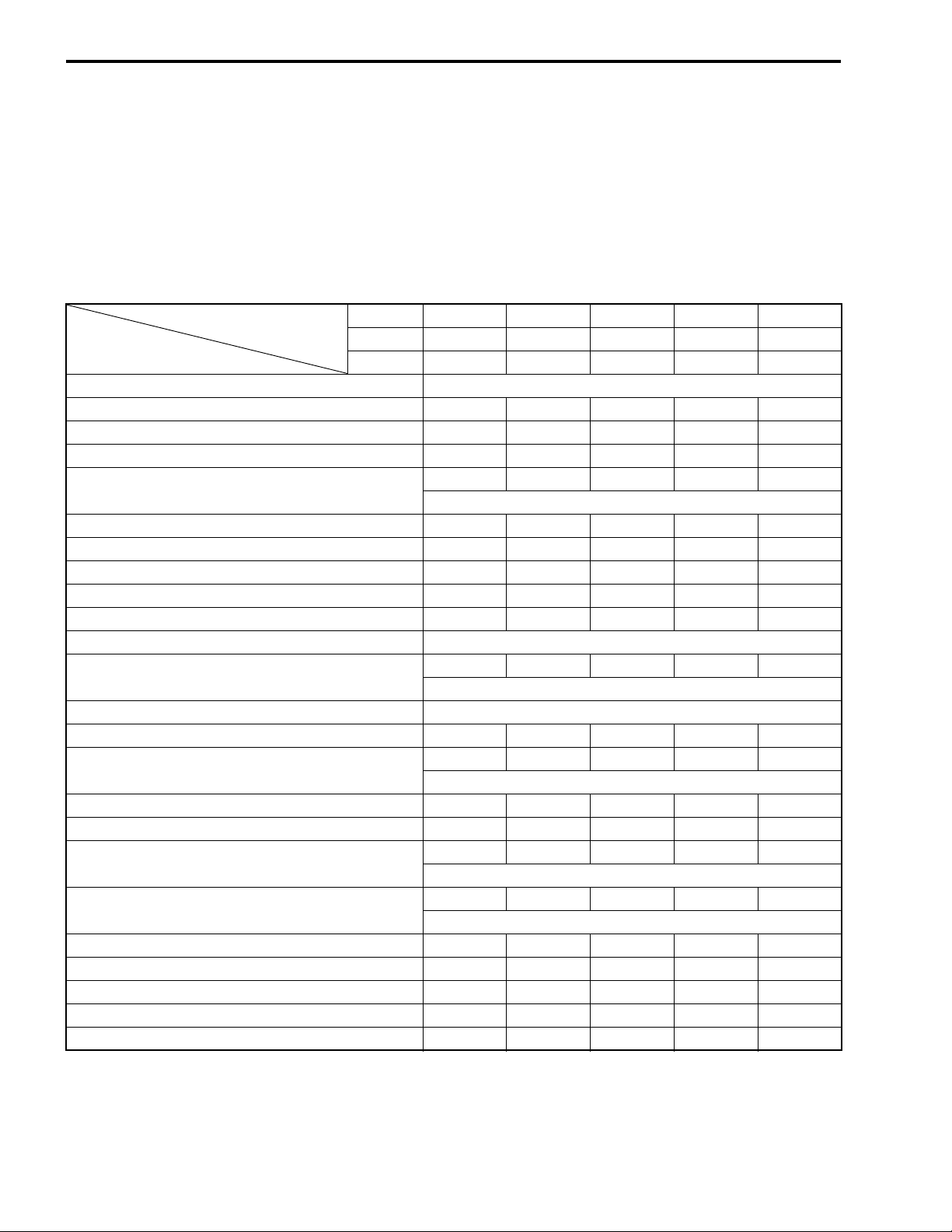

PERIODIC MAINTENANCE CHART

Interval miles 600 4 000 7 500 11 000 14 500

km 1 000 6 000 12 000 18 000 24 000

Item months 1 6 12 18 24

Air cleaner element Clean every 3 000 km (1 800 miles)

Exhaust pipe bolts and muffler bolts T T T T T

Valve clearance I I I I I

Spark plug ---- I R I R

Fuel line

Engine oil R R R R R

E n gi ne oi l fi lte r R ---- ---- R ---Fi na l g ear oi l ---- ---- R ---- R

Idle speed IIIII

Throttle cable play I I I I I

Cooling fan filter Clean every 3 000 km (1 800 miles)

Radiator hose

Engine coolant Replace every 2 years

D r iv e V- bel t ---- ---- I ---- R

Evaporative emission control system

E-33 (California) model only

PAIR (air supply) system ---- ---- I ---- I

Brake IIIII

Brake hose

Brake fluid

S te er in g I ---- I ---- I

Fro nt f o r k ---- ---- I ---- I

R e a r su sp e ns io n ---- ---- I ---- I

Tire IIIII

Chassis bolts and nuts T T T T T

----IIII

Replace every 4 years

----IIII

Replace every 4 years

---- ---- I ---- I

Replace vapor hose every 4 years

----IIII

Replace every 4 years

----IIII

Replace every 2 years

NOTE:

I=Inspect and clean, adjust, replace or lubricate as necessary;

R=Replace; T=Tighten

PERIODIC MAINTENANCE 2-3

LUBRICATION POINTS

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle.

Major lubrication points are indicated below.

Combination brake

lever folder

Side-stand pivot

and spring hook

Throttle cables

Center stand pivot

and spring hook

Front brake

lever holder

NOTE:

* Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or grime.

* Lubricate exposed parts which are subject to rust, with a rust preventative spray whenever the motorcycle

has been operated under wet or rainy conditions.

2-4 PERIODIC MAINTENANCE

MAINTENANCE AND TUNE-UP PROCEDURES

• This section describes the servicing procedures for each item

of the Periodic Maintenance requirements.

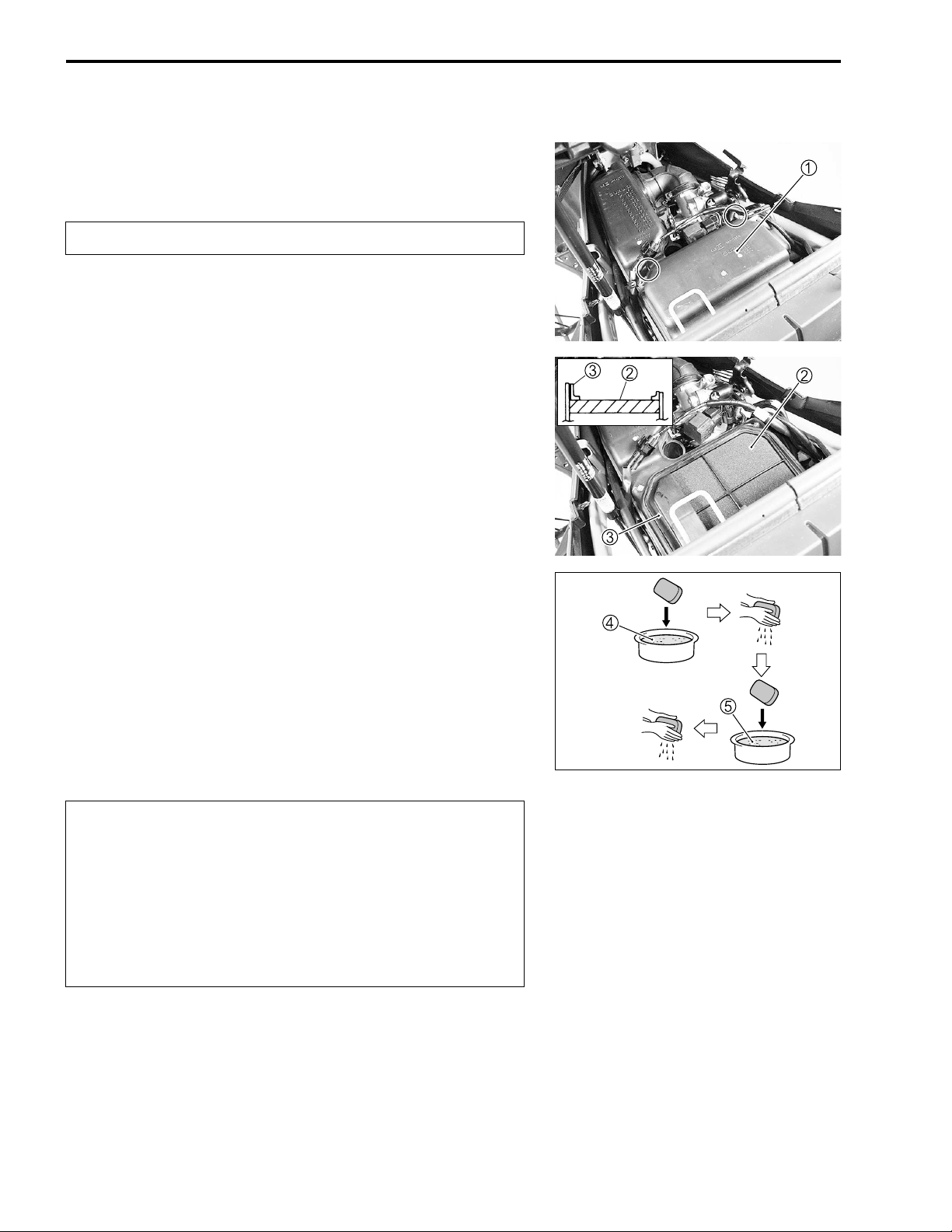

AIR CLEANER

Clean every 3 000 km (1 800 miles).

• Remove the front trunk box cover. (!7-16)

• Remove the air cleaner cover

1.

• Remove the air cleaner element

NOTE:

* When installing the air cleaner element, the letter mark on the

element should be positioned outside.

* When installing the air cleaner element retainer

side

A of the retainer flange should be positioned forward.

• Fill a washing pan of a proper size with a non-flammable

cleaning solvent

vent and wash it.

• Gently squeeze the element to remove the excess solvent: do

not twist or wring the element or it will develop tears.

• Immerse the element in motor oil

excess oil. The element should be wet but not dripping.

• Reinstall the cleaned or new air cleaner element in the

reverse order of removal.

"

* Inspect the air cleaner element for tears. A torn ele-

ment must be replaced.

* If driving under dusty conditions, clean the air

cleaner element more frequently. The surest way to

accelerate engine wear is to use the engine without

the element or to use a torn element. Make sure that

the air cleaner is in good condition at all times. Life

of the engine depends largely on this component!

4. Immerse the element in the cleaning sol-

2.

3, the long

5 and squeeze out the

PERIODIC MAINTENANCE 2-5

EXHAUST PIPE BOLT AND MUFFLER BOLT

Tighten initially at 1 000 km (600 miles, 1 months) and

every 6 000 km (4 000 miles, 6 months) thereafter.

• Remove the under cover. (!7-14)

• Tighten the exhaust pipe bolts

and muffler mounting nut

torque wrench.

# Exhaust pipe bolt: 23 N·m (2.3 kgf-m, 16.5 lb-ft)

Exhaust pipe joint nut: 30 N·m (3.0 kgf-m, 21.5 lb-ft)

Muffler mounting nut: 23 N·m (2.3 kgf-m, 16.5 lb-ft)

1, exhaust pipe joint nuts 2

3 to the specified torque with a

VALVE CLEARANCE

Inspect initially at 1 000 km (600 miles, 1 months) and

every 6 000 km (4 000 miles, 6 months) thereafter.

• Remove the trunk box. (!7-18)

• Remove the air cleaner box and throttle body. (!5-14)

• Remove the cooling fan cover. (!3-11)

• Remove the cooling fan filter. (!3-11)

• Remove the cylinder head cover

1.

2-6 PERIODIC MAINTENANCE

• The valve clearance specification is different for intake and

exhaust valves. Valve clearance adjustment must be checked

and adjusted, 1) at the time of periodic inspection, 2) when

the valve mechanism is serviced, and 3) when the camshaft is

disturbed by removing it for servicing.

$ Valve clearance (When cold):

Standard: IN.: 0.08 – 0.13 mm (0.003 – 0.005 in)

EX.: 0.17 – 0.22 mm (0.007 – 0.009 in)

NOTE:

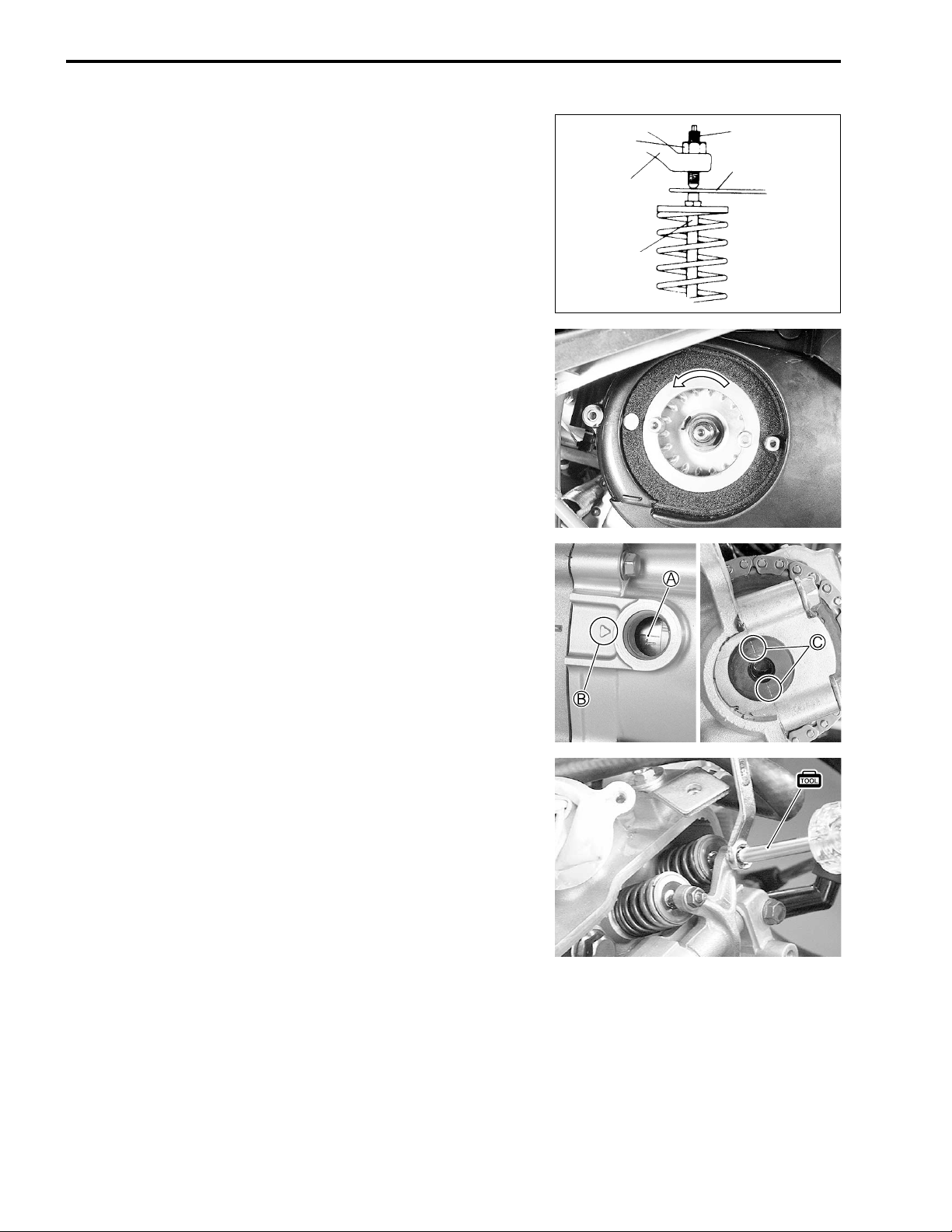

* The piston must be at (TDC) on the compression stroke in

order to check the valve clearance or to adjust valve clear-

ance.

* The clearance specification is for COLD state.

* To turn the crankshaft for clearance checking, and rotate in

the normal running direction. The spark plug should be

removed.

• Turn crankshaft to bring the “TDC” line

index mark

• Check that the engrave line

B on the generator stator case.

C locates parallel with the mating

A on the rotor to the

face between the cylinder head cover when viewed from the

side.

Lock nut

Rocker arm

Valve stem

Tappet screw

Thickness gauge

• Insert a thickness gauge between the valve stem end and the

adjusting screw on the rocker arm.

• If the clearance is out of specification, bring it into the specified range.

% 09900-20806: Thickness gauge

09917-14920: Valve clearance adjusting driver

PERIODIC MAINTENANCE 2-7

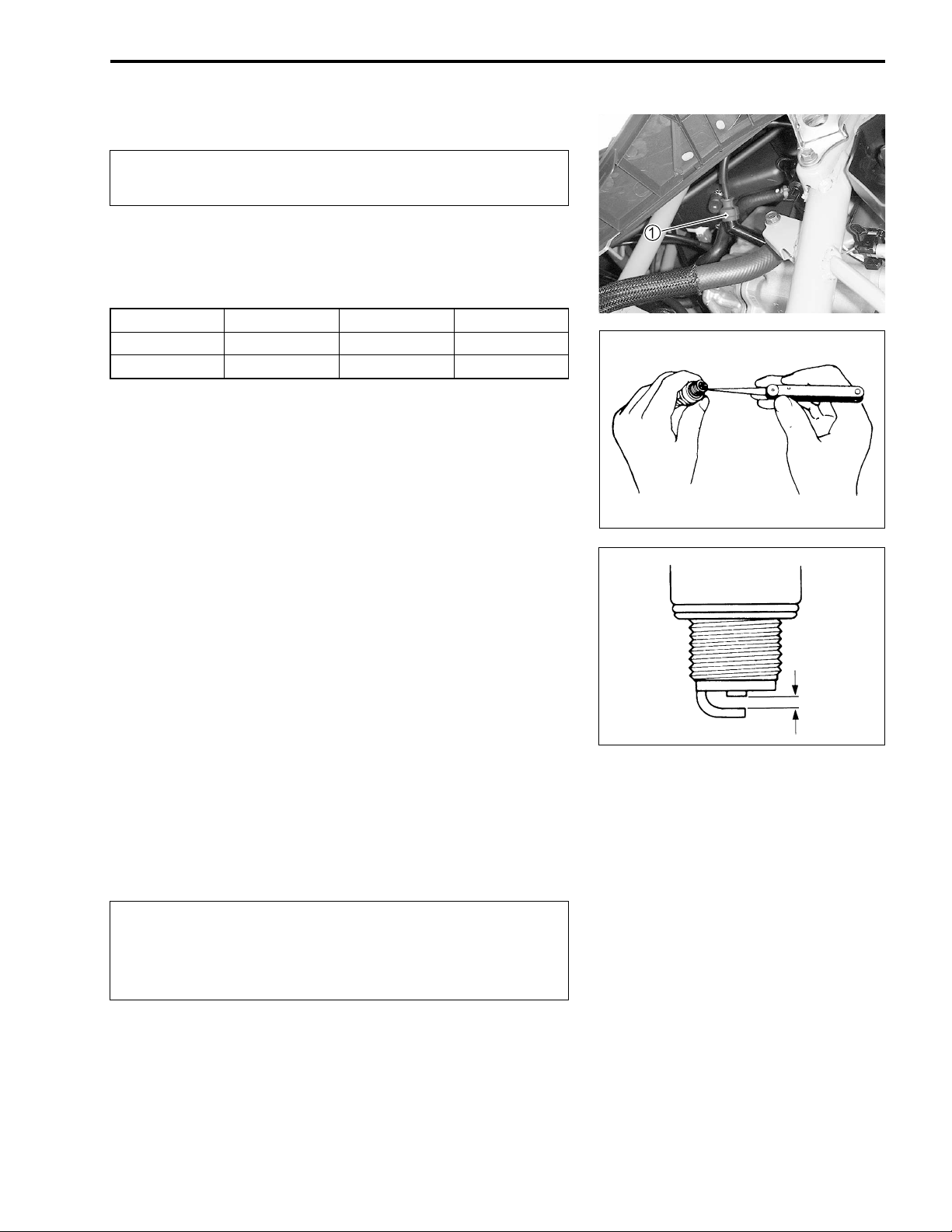

SPARK PLUG

Inspect at 6 000 km (4 000 miles, 6 months) and replace every 12 000 km (7 000 miles, 12 months) thereafter.

REMOVAL

• Remove the left side leg shield. (!7-15)

• Disconnect the spark plug cap

% 09930-10121: Spark plug socket wrench set

Hot type Standerd Cold type

NGK CR6E CR7E CR8E

ND U20ESR-N U22ESR-N U24ESR-N

CARBON DEPOSIT

• Inspect to see the carbon deposit on the plug.

• If the carbon is deposited, remove it with a spark plug cleaner

machine or carefully using a tool with a pointed end.

1 and remove the spark plug.

SPARK PLUG GAP

• Measure the plug gap with a thickness gauge if it is correct. If

not, adjust it to the following gap.

$

Spark plug gap: Standard: 0.7 – 0.8 mm (0.028 – 0.031 in)

% 09900-20803: Thickness gauge

ELECTRODE’S CONDITION

• Inspect to see the worn or burnt condition of the electrodes. If

it is extremely worn or burnt, replace the plug. And also

replace the plug if it has a broken insulator, damaged thread,

etc.

"

Confirm the thread size and reach when replacing the

plug. If the reach is too short, carbon will be deposited

on the screw portion of the plug hole and engine damage may result.

2-8 PERIODIC MAINTENANCE

REMOUNTING

"

Before using a spark plug wrench, carefeuuly turn the

spark plug by finger into the threads of the cylinder

head to prevent damage the aluminum threads.

• Install the spark plug to the cylinder head by finger tight, and

then tighten it to the specified torque.

# Spark plug: 11 N·m (1.1 kgf-m, 8.0 lb-ft)

FUEL LINE

Inspect initially at 6 000 km (4 000 miles, 6 months).

Replace every 4 years.

• Inspect the fuel hose

defects are found, the fuel hose must be replaced.

1 for damage and fuel leakage. If any

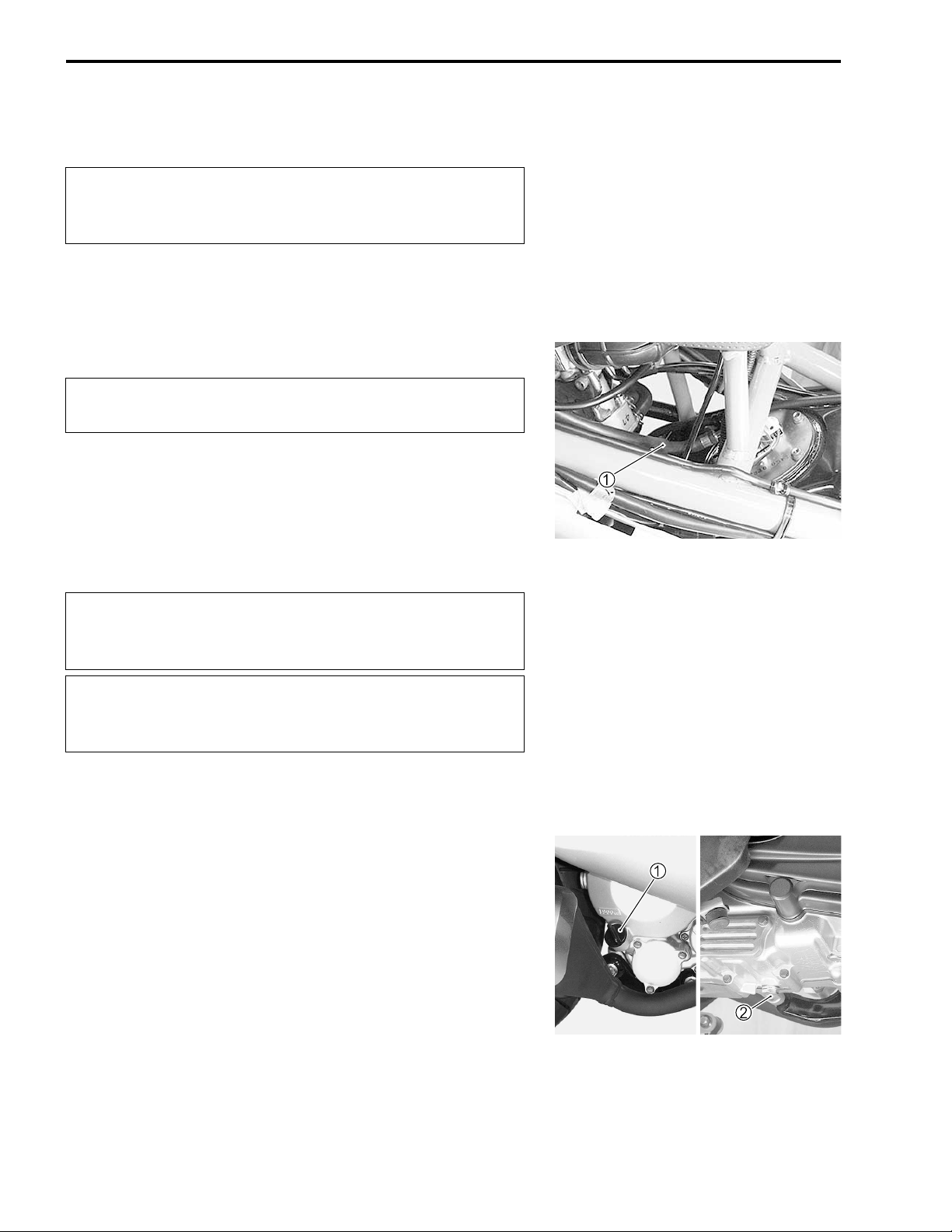

ENGINE OIL AND OIL FILTER

(ENGINE OIL)

Replace initially at 1 000 km (600 miles, 1 months) and

every 6 000 km (4 000 miles, 6 months) thereafter.

(OIL FILTER)

Replace initially at 1 000 km (600 miles, 1 months) and

every 18 000 km (11 000 miles, 18 months) threafter.

• Oil should be changed while the engine is warm. Oil filter

replacement at the above intervals, should be done together

with the engine oil change.

ENGINE OIL REPLACEMENT

• Keep the motorcycle upright with the center stand.

• Place an oil pan below the engine, and drain the oil by remov-

ing the filler cap

1 and oil drain plug 2.

PERIODIC MAINTENANCE 2-9

• Fit the oil drain plug

3 securely, and pour fresh oil through

the oil filler. The engine will hold about 2 000 ml of oil. Use an

API classification of SF or SG oil with SAE 10W-40 viscosity.

# Oil drain plug: 23 N·m (2.3 kgf-m, 16.5 lb-ft)

• Install the filler cap.

• Place the motorcycle on the center stand.

• Start up the engine and allow it to run for several minutes at

idling speed.

• Turn off the engine and wait about one minute, then check the

oil level by removing the filler cap

4. If the level is below mark

“L”, add oil to “F” level.

If the level is above mark “F”, drain oil to “F” level.

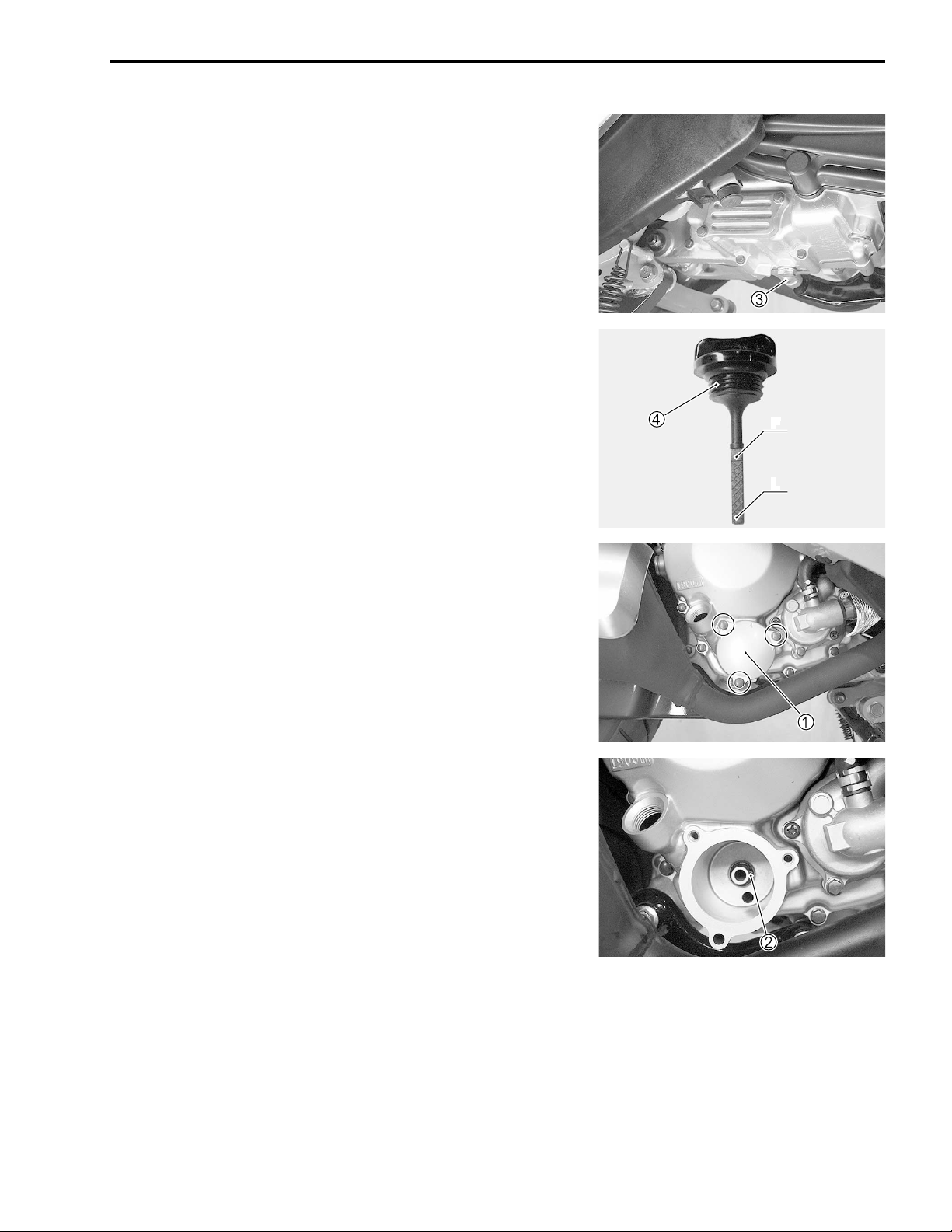

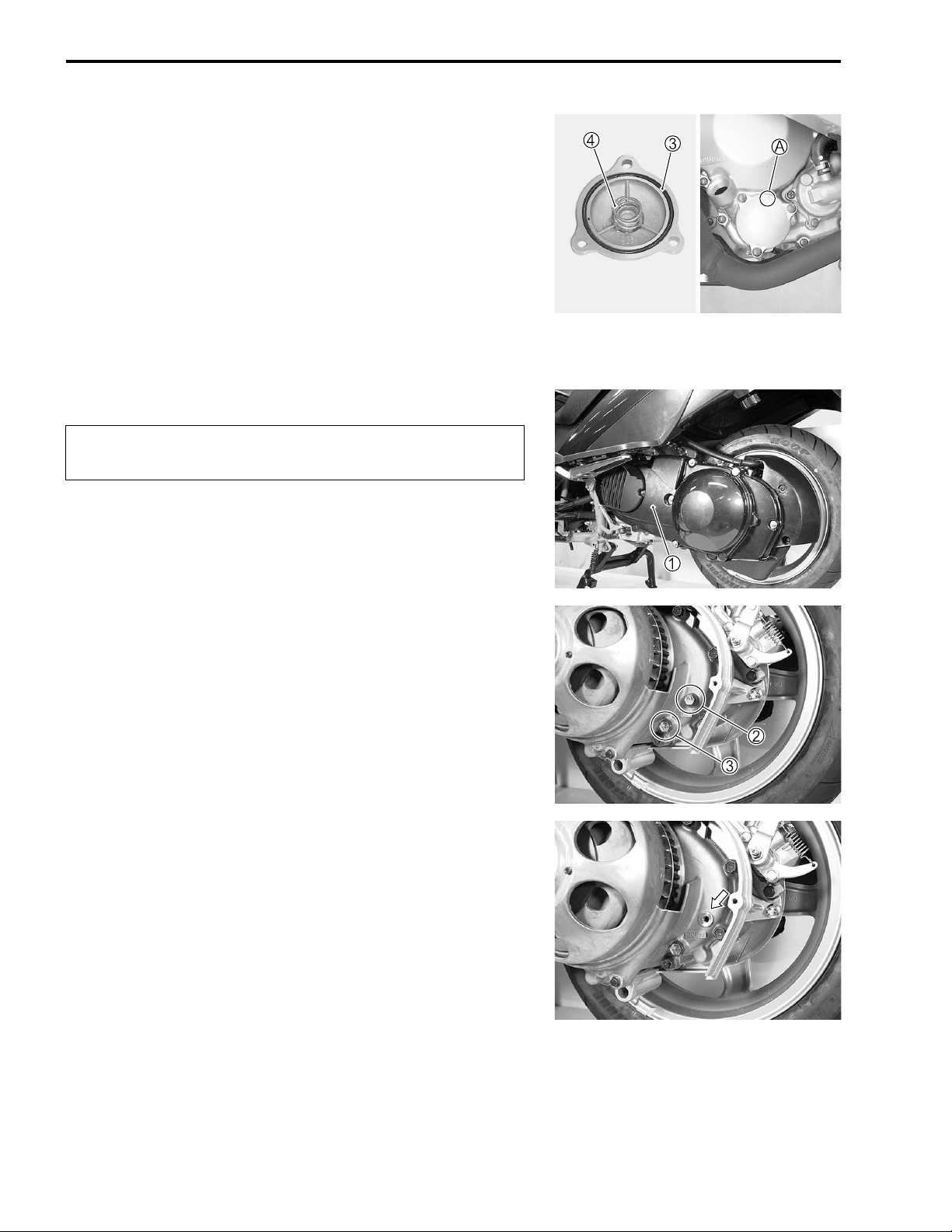

OIL FILTER REPLACEMENT

• Drain engine oil in the same manner of engine oil replacement

procedure.

• Remove the oil filter cap

1.

• Remove the oil filter.

F

L

• Install the new O-ring

2 and new oil filter.

2-10 PERIODIC MAINTENANCE

• Install the new O-ring

NOTE:

* Before installing the oil filter cap, apply engine oil lightly to the

new O-ring

* The triangle mark

topward.

# Oil filter cap bolt: 10 N·m (1.0 kgf-m, 7.0 lb-ft)

$ Engine oil capacity

Oil change: Approx.1 900 ml (64.22/66.90 US/lmp oz)

Filter change: Approx.2 000 ml (67.60/70.42 US/lmp oz)

Overhaul engine: Approx.2 300 ml (77.74/80.98 US/lmp oz)

3.

3 and spring 4 to the oil filter cap.

A on the oil filter cap should be positioned

FINAL GEAR OIL

Replace every 12 000 km (7 500 miles, 12 months) thereafter.

TRANSMISSION OIL REPLACEMEMT

• Keep the motorcycle upright with the center stand.

• Remove the left side leg shield. (!7-15)

• Remove the clutch cover

• Place an oil pan below the mission case.

1. (!3-16)

• Remove the oil level plug

level is below the level hole, add oil until oil flows from the

level hole.

& Oil viscosity and classification

• Tighten the oil level plug

# Oil level plug: 12 N·m (1.2 kgf-m, 8.5 lb-ft)

NOTE:

If oil is dirty with sludge or used for a long period, drain the oil by

removing the oil drain plug

level hole.

# Oil drain plug: 12 N·m (1.2 kgf-m, 8.5 lb-ft)

$ NECESSARY AMOUNT OF FINAL GEAR OIL

Oil change: Approx.190 ml (6.42/6.69 US/lmp oz)

Overhaul: Approx.200 ml (6.76/7.04 US/lmp oz)

2 and inspect the oil level. If the

:SAE 10 W-40 with SF or SG

2 to the specified torque.

3 and pour fresh oil through the oil

PERIODIC MAINTENANCE 2-11

IDLE SPEED

Inspect initially at 1 000 km (600 miles, 1 months) and

every 6 000 km (4 000 miles, 6 months) thereafter.

NOTE:

Make this adjustment when the engine is hot.

• Remove the front trunk box cover. (!7-16)

• Remove the left side leg shield. (!7-15)

• Connect an electric tachometer.

• Start up the engine and set its speed at anywhere between

1400 and 1600 r/min by turning idle adjust screw

$ Engine idle speed: Standard : 1400 ± 100 r/min

% 09900-26006: Tachometer

1.

2-12 PERIODIC MAINTENANCE

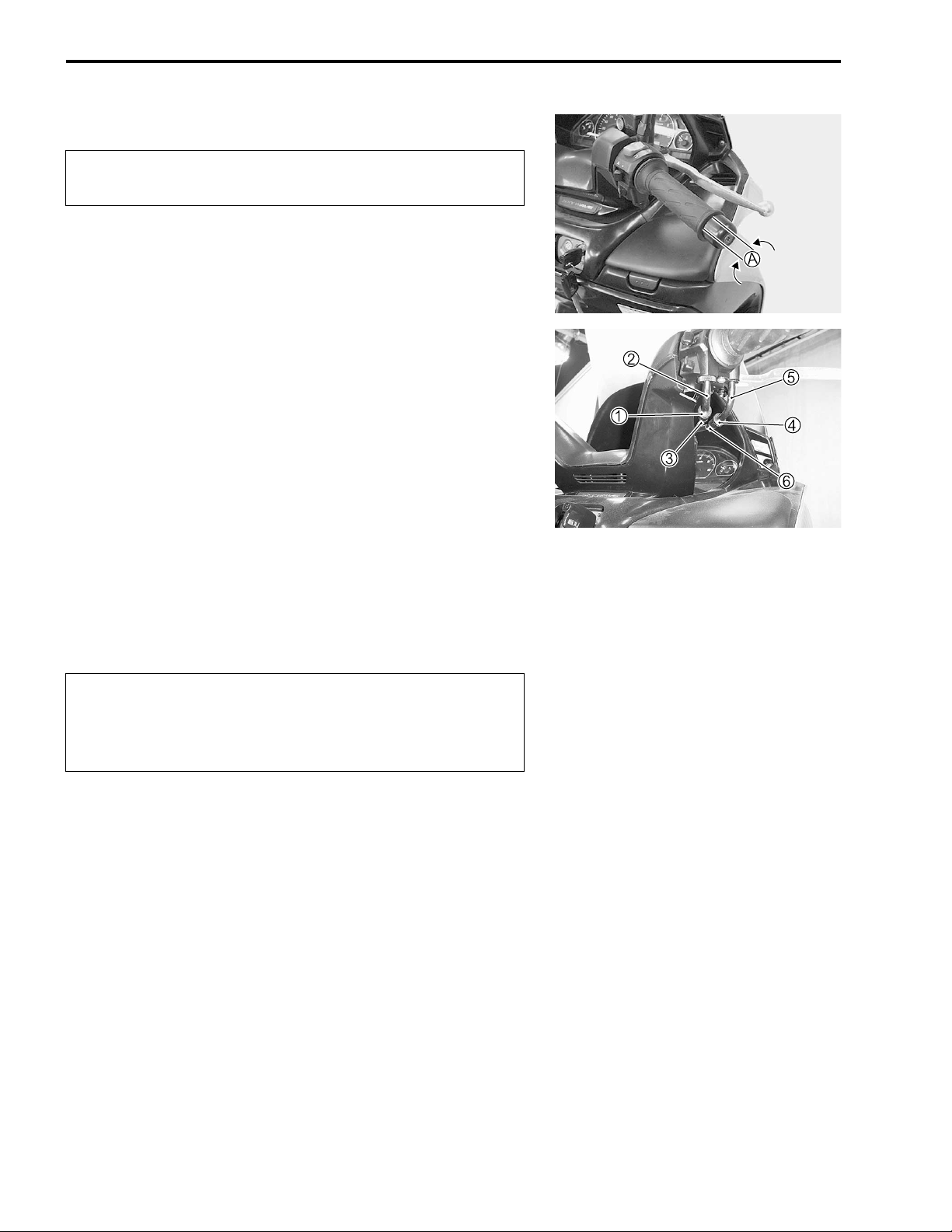

THROTTLE CABLE PLAY

Inspect initially at 1 000 km (600 miles, 1 months) and

every 6 000 km (4 000 miles, 6 months) thereafter.

Adjust the throttle cable play

First step:

• Loosen the lock nut

turn in the adjuster

Second step:

• Loosen the lock nut

• Turn the adjuster

should be 2.0 – 4.0 mm (0.08 – 0.16 in) at the throttle grip.

• Tighten the lock nut

Third step:

• While holding the throttle grip at the fully closed position,

slowly turn out the adjuster

to feel resistance.

• Tighten the lock nut

$ Throttle cable play

'

3 fully into the threads.

6 in or out until the throttle cable play A

A with the following three steps.

1 of the throttle returning cable 2 and

4 of the throttle pulling cable 5.

4 while holding the adjuster 6.

3 of the throttle returning cable 2

1 while holding the adjuster 3.

A: 2.0 – 4.0 mm (0.08 – 0.16 in)

After the adjustment is completed, check that handlebar movement does not raise the engine idle speed

and that the throttle grip returns smoothly and automatically.

PERIODIC MAINTENANCE 2-13

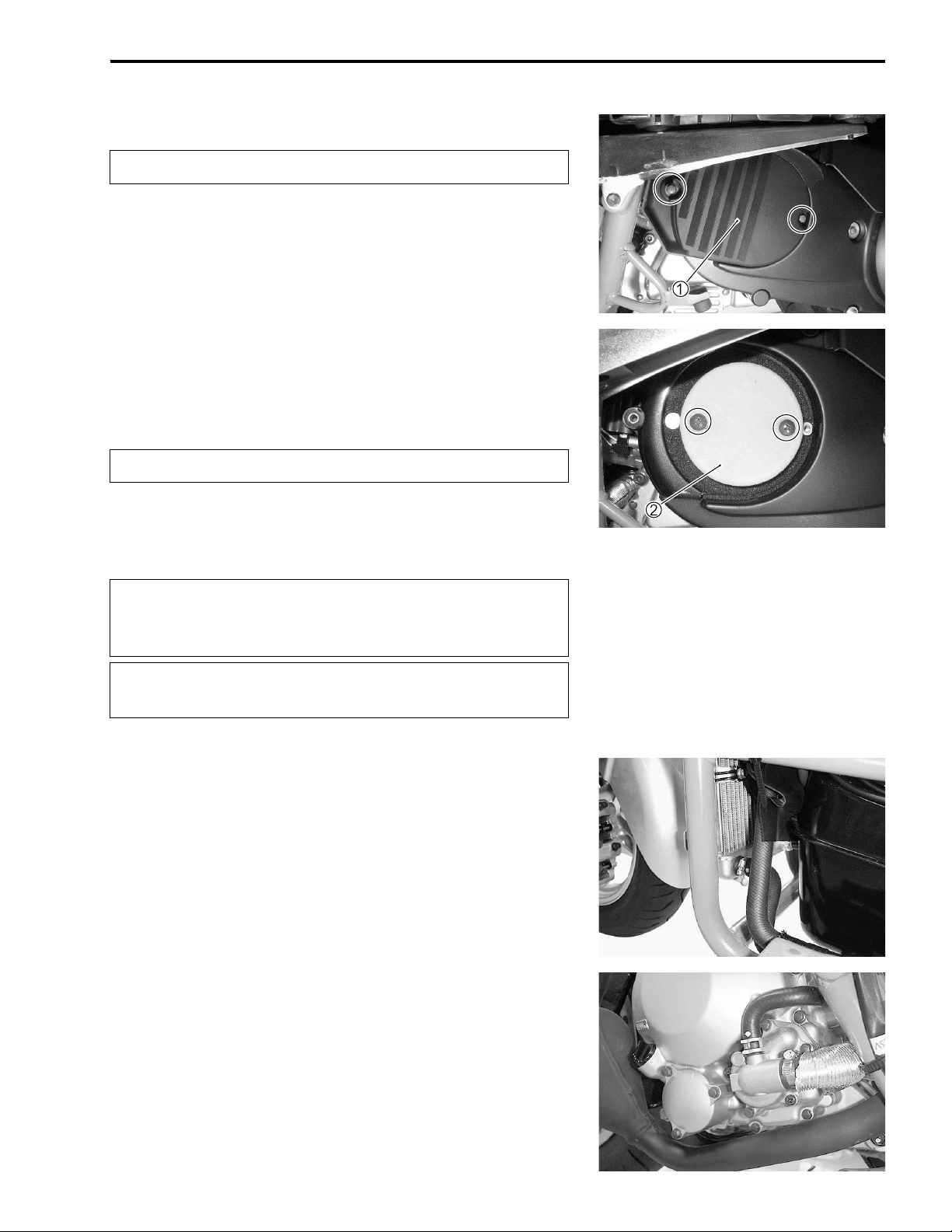

COOLING FAN FILTER

Clean every 3 000 km (1 800 miles).

• Remove the left side leg shield. (!7-15)

• Remove the cooling fan cover

1.

• Remove the cooling fan filter

• Clean the fan filter.

• Reinstall the cleaned or new filter in the reverse order of

removal.

"

Do not apply oil or water to the fan filter.

2.

COOLING SYSTEM

(RADIATOR HOSE)

Inspect every 6 000 km (4 000 miles, 6 months).

Replace radiator hoses every 4 years.

(ENGINE COOLANT)

Replace engine coolant every 2 years.

RADIATOR HOSES

Check to see the radiator hoses for crack, damage or engine

coolant leakage.

If any defects are found, replace the radiator hoses with new

ones.

Loading...

Loading...