Suzuki 86W41, 990C0-86B40 User Manual

Description: Part Number:

Synchronizer 990C0-86B40/86W41

Contents

Applications: Installation Time:

NOTE: Weight:

Suzuki Marine Boats

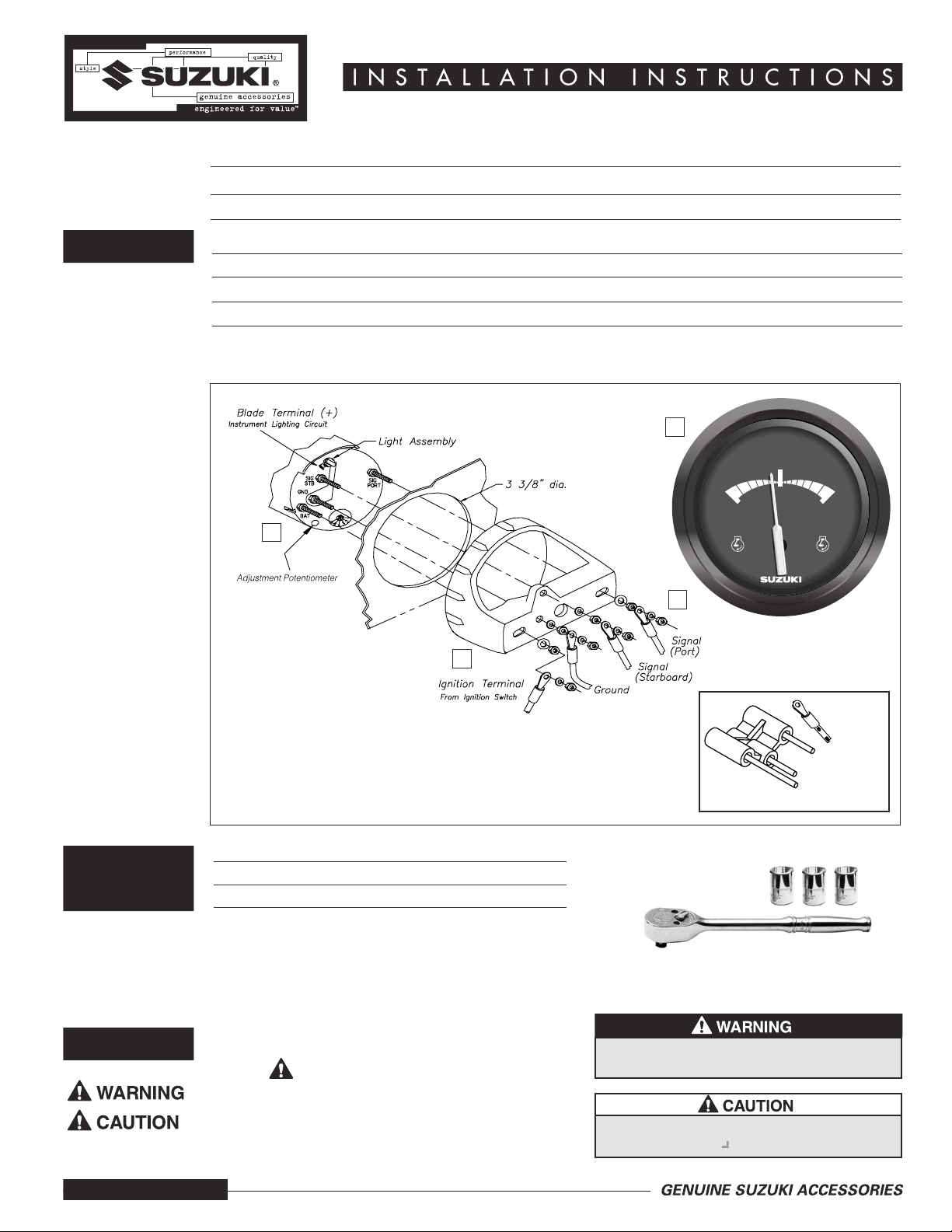

Mounts in standard 3 3/8" hole.

1

1 lbs

HRS

Ref. Part Number Description QTY

1. 990C0-86B40/86W41

BC0146

2. Mounting Bracket 1

Synchronizer 1

3. Mounting Hardware 1

.

T

C

M

A

D

,

E

E

L

I

N

L

I

U

V

.

S

S

A

.

SYNC

A

.

7

5

0

0

-

9

0

-

2

5

A

STB

D

SLOW

C

N

U

PORT

OW

SL

.

P

R

O

C

A

I

R

A

F

1

1

3

Tools

Required

Important

NOTE

IS0207B ECR5609 8/2005

2

Ref.

Tools Description

1. 3/8" Nut Driver

2. Suzuki Terminal Kit 09900-28701

Please read this manual and follow its instructions

carefully. To emphasize special information, the

symbol and the words WARNING, CAUTION

and NOTE have special meanings. Pay special

attention to the messages highlighted by these signal words:

NOTE: Indicates special information to make

maintenance easier or instructions clear.

If so equipped

YELL

RED

OW

YELL

BLACK

GRAY

Indicates potential hazard that could

result in death or injury.

Indicates potential hazard that could

result in vehicle damage.

OW/

Disconnect battery during installation.

Tighten nuts on backclamp only slightly more than you can tighten with your fingers.

Six inch-pounds of torque is sufficient. Over tightening may result in damage to the

instrument and may void your warranty.

Gasket cement or other adhesive is not required to secure tubing to fittings.

Description

Installation

The dual engine synchronizer is designed to indicate

engine synchronization extremely accurately

speeds of the two engines are compared to each

other. Engine synchronization may be difficult at idle

speeds. For proper operation, both engines must be

of the same type, have the same number of cylinders,

and have similar ignitions. Malfunctioning ignition

systems or high speed "point bounce" will result in

inability to sync properly.

when the

1. Location: The synchronizer should be located at

least 18" from a magnetic compass. Some

interference (erratic operation)

synchronizer during radio transmissions. This will

neither damage nor degrade it's performance.

2.

Be certain to use stranded, insulated wire not

lighter than 18AWG that is approved for marine use. It

is recommended that insulated wire terminals,

preferably ring type, be used on all connections to the

gauge, except the light which requires a 1/4" female

blade terminal.

may be noticed on the

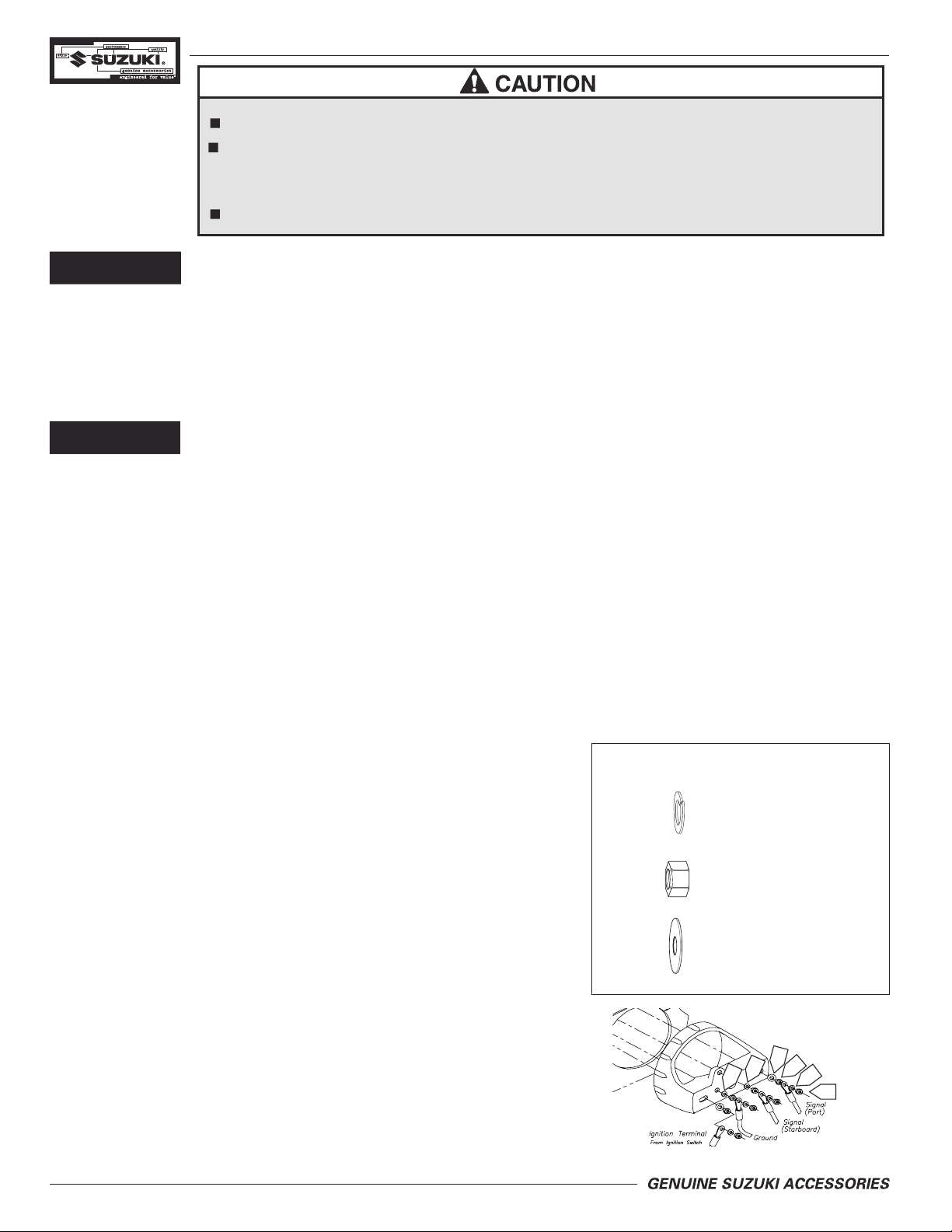

3. Cut a 3-3/8" dia hole in the dash and mount the

gauge with backclamp supplied.

4. Using a small screwdriver, SLIGHTLY depress

and turn the selector switch on the back of the

synchronizer to the correct position to match the

engine application. (See label on the side of the

synchronizer.) Depressing the switch too hard may

cause damage to gauge! Be sure the selector switch

has locked into the detent at the correct position by

slightly rotating the switch

screwdriver.

back and forth with the

5. If this gauge kit has been supplied with a three

prong connector, slide the connector over the three

instrument studs. Be sure the gray, yellow, and black

bullets are connected to the gray, yellow, and black

wires of the main engine harness.

the yellow wire of the main engine harness.

8. Connect yellow/ red extension lead st ud

connector to the PORT signal (SIG)

the synchronizer.

9.

Connect the black extension lead stud

connector to the negative (-) post of the synchronizer

and plug the bullet end into the

engine harness.

post terminal of

black wire of the main

10. Connect the GREEN/ORANGE extension

lead to the blade terminal adjacent to the twist-out

light assembly to the positive “+” side of the

instrument lighting circuit and the bullet end to the

boat lighting circuit. No separate ground is required

for the lighting. Reconnect the battery.

11.

at the factory, and should never need adjustment.

However, If

the Calibration section at the end of this manual.

12.

socket assembly one-eighth turn counterclockwise

until it pops out. Bulb pulls straight out of socket

assembly. It is a GE No.194 instrument lamp.

Calibration: This gauge has been calibrated

you are experiencing problems refer to

NOTE: To change the light bulb, twist tan

Mounting Hardware Kit

A

B

C

x 6

x

x 2

6

6.

Connect the gray extension lead stud connector

to the positive (+) post of the synchronizer and plug the

bullet end into the gray wire of the main engine

harness.

7. Connect the yellow extension lead stud

connector to the STARBOARD signal (SIG) post

terminal of the synchronizer and plug the bullet into

C

A

A

B

A

B

Loading...

Loading...