Page 1

EN

SUUNTO

COMBOS AND

MECHANICAL INSTRUMENTS

USER’S GUIDE

• Combo Consoles

• Console Compasses CB-71 and CB-71/DS

• Depth Gauge SM-16

• Pressure Gauge SM-26 and SM-36

Page 2

Page 3

General Instructions

Suunto diving instruments are constructed of high quality materials and are designed for normal

recreational use. The product should provide many years of reliable service if the user observes

the necessary precautions in the following directions.

SUUNTO Combo Consoles

Introduction

The Suunto combo consoles allows you to create a personal combo according to your own

specifi c needs. Analogue gauges, dive computers and compasses fi t together like building

blocks, giving the possibility to add as many instruments as you like.

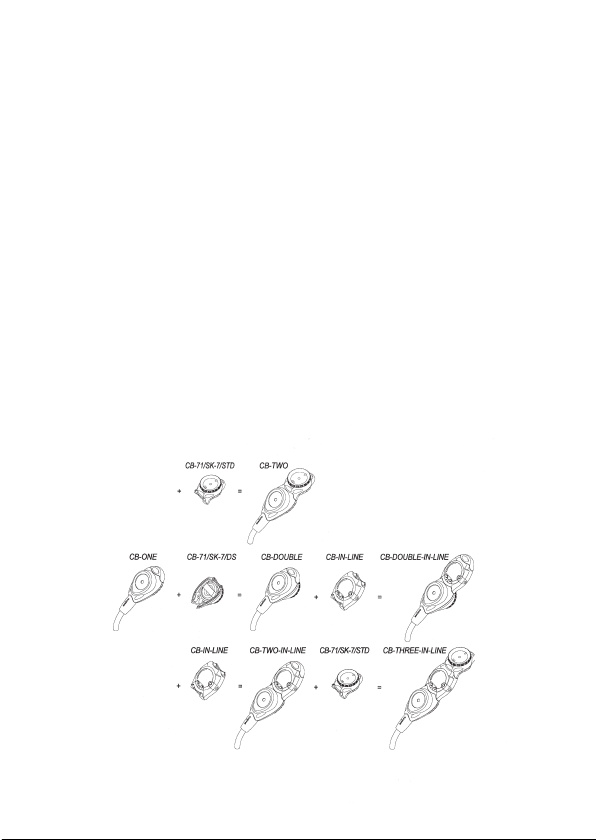

The Suunto Combo modules and instruments can be combined in an almost infi nite amount of

combinations, and allow you to change or upgrade your combo confi guration. The new combos

consist of four main modules: the pressure gauge module, the instrument module and two different compass modules.

The pressure gauge module is designed for the Suunto pressure gauges and it can also be

used with the new Suunto Quick Release (QR). The instrument module can be fi tted with

Suunto dive computers or with the newly designed Suunto analog depth gauges. Depending on the user’s choice, an SK-7 compass module can either be fi tted on the back side of

the pressure gauge module or on top of the pressure gauge or instrument module. The basic

combinations are displayed below:

3

Page 4

Assembling the Combo Modules

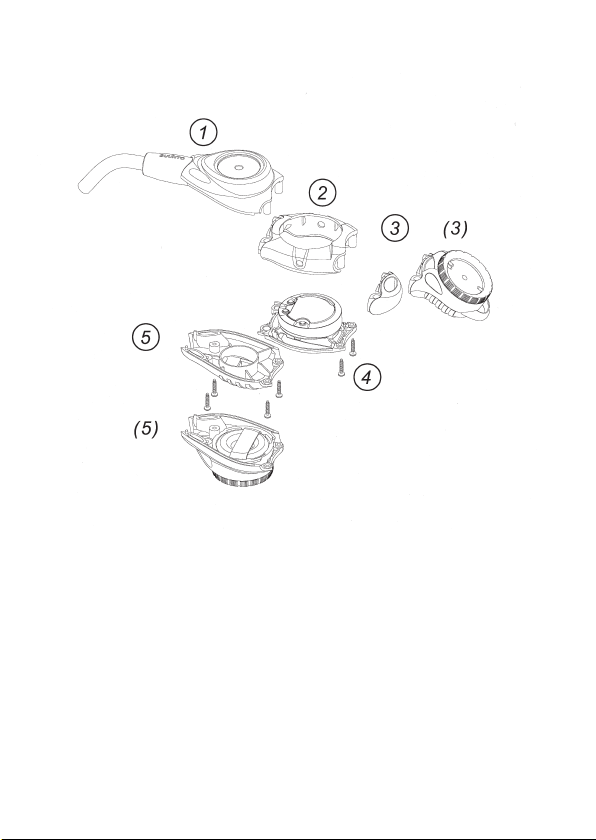

The Combo modules are to be assembled in the order described by the illustration below:

1. CB-One module front cover with SM-26/36 pressure gauge in place

(see section CB-ONE Module assembly)

2. CB-In line module front cover

3. CB-end piece or CB-71 compass (optional)

4. CB-In line module back cover with instrument

5. CB-One module back cover or CB-71/DS compass (optional)

4

Page 5

CB-ONE Module Assembly

The CB-ONE Module is designed to fi t the Suunto SM-26/36 analog pressure gauges.

Before assembling the CB-ONE module the hose cover needs to be fi tted on the pressure

hose. The hose cover ensures that the SM-26/36 pressure gauge fi ts properly on the CB-ONE

module.

If the Suunto Quick Release is used, the hose cover is not to be used

(See section CB-ONE module assembly using the SUUNTO Quick Release).

After attaching the hose cover the pressure hose and gauge are assembled on the

CB-ONE front cover according to the picture.

After the pressure gauge is in place the CB-ONE back cover

(or alternatively the CB-71/SK-7/DS compass) is attached with four screws.

5

Page 6

CB-ONE Module Assembly when using the SUUNTO Quick Release

If the SUUNTO Quick Release (QR) is used the hose cover should be attached on the high

pressure hose below the female end of the QR. The male part is attached to the pressure

gauge which is then fi tted onto the CB-ONE front cover according to the picture below.

CB-IN-LINE Module Assembly

The CB-IN-LINE module fi ts the Suunto Vyper, Gekko, Solution, Favor/Fusion, Octopus II and

Companion dive computers or the SM-16 round depth gauge.

The Vyper locks in place on the IN-LINE module back cover. For the other instruments there

are lugs on the back cover aiding the orientation.

The Solution, Favor and Companion can be fi tted with display shield V5615. The display

shield is attached after the console has been assembled by bending the console so that

the shield fi ts between the computer and the console cover. The Vyper is delivered with a

pre-attached display shield (V5875).

6

Page 7

SUUNTO Console Compasses CB-71/SK-7/STD and CB-71/SK-7/DS

The high-quality, liquid-fi lled Suunto diving compasses are durable, reliable and easy to use.

The CB-71/SK-7 is available in two versions: the CB-71/SK-7/STD for attachment on top of

the combo modules or the Cobra dive computer, and the CB-71/SK-7/DS for attachment on

the back side of the CB-ONE module.

Compass use for divers

General instructions

Usually a compass must be held precisely in a horizontal position, otherwise the needle will

sting. The SK-7 compass may however be inclined about ±30 degrees.

Sighting a compass bearing

Hold the compass so that the compass is in a horizontal position and the direction line points

away from you. Turn with the compass until the direction line points at your destination, then

turn the direction ring until the magnetic North needle is aligned between the slit marks. The

front end of the direction line on the SK-7 shows your compass bearing, and as long as the

North needle is aligned between the slit marks, the direction points toward your destination.

The SK-7 compasses also have a side reading window, which also enables you to take a

bearing by directing the compass towards the destination and by reading the compass bearing from the side window. This bearing can be memorized by turning the direction ring to that

bearing.

Setting a given bearing or direction

The scale division on the SK-7 is 360 degrees clockwise from 0 degrees at North. Turn the

direction ring until the front end of the direction line is at the desired direction. Turn the compass until the needle falls between the slit marks. The direction line now points in the desired

direction.

Magnetic declination

Maps and marine charts are drawn in correlation to the geographic poles, while the magnetic

compass needle is subject to magnetic declination which varies according to the location.

General orientation on the diving site

Before diving, check the main compass bearings at the dive site, paying special attention to

memorizing the direction of the shoreline and bearings of landmarks that may be of importance.

Natural aids to underwater navigation

• The underwater extension of the shore’s inclination tells the diver if he is following the

shoreline. Be careful however as underwater ridges may lead you astray.

Surface occasionally to check your position.

• The dip and stratifi cation of rocks on the shore can often be followed over large areas

under water

• Sand ripples usually form long lines parallel to the shore

• The direction of currents should be noted by their effect on algae or drifting particles.

Use the compass to check the bearing of the current

7

Page 8

• In shallow water, the sun’s direction can be seen from shadows on the bottom, or by looking

towards the surface

• Swimming in a straight line along the bottom is greatly facilitated if you can line up three

distinctive objects in your line of vision. As you reach the fi rst one, line up a new one farther

away, so that you again have three points determining your course. This way you can counteract the effects of side current.

Compass Balancing

The horizontal and vertical components of earth’s magnetic fi eld vary considerably in different

locations. For this reason Suunto compasses are balanced for 5 different zones. If the compass

is used in an adjacent balancing zone the compass needle will tilt only slightly. However, the

farther the compass is used from it’s intended zone, the more the needle will tilt. In extreme

situations the needle might stick. For this reason it is very important to know in which country

the compass will be used.

Compass zone map

1

2

3

SUUNTO Mechanical Gauges

Suunto depth gauge SM-16

Models available: 45 m, 70 m, 150 ft, 230 ft

Suunto pressure gauge SM-26

Models available: 200bar

Suunto pressure gauge SM-36

Models available: 300bar and 4000psi

4

8

5

Page 9

Before usage

Depth gauge:

Before diving, check the position of the depth indicating pointer. Atmospheric conditions

(altitude, temperature) may cause the point to not indicate zero. If this is the case, turn the adjusting screw located at the right side of the gauge to align the pointer to zero. The adjustment

is to be made at the temperature of usage. Repeated unnecessary adjustments may cause

excessive wear to the seals and eventual leakage.

CAUTION!

Do not attempt to adjust the water entry port located at the left side of gauge. Tampering

with the port can cause damage to internal components. Do not pressure test gauge in air.

Always immerse the gauge in water while pressure testing it.

Pressure gauge:

The hose has an end fi tting with 7/16” 20 UNF-thread. If your regulator has a different thread

size in the high pressure (HP-output) port, ask your dealer for the correct adapter. Always

inspect the o-ring at the male thread to be sure it is clean and undamaged before connecting it

to the regulator.

Always turn your air supply on slowly. Always turn the pressure gauge dial face away from your

face when turning on the air supply.

Do not overtighten the hose at the gauge, the fi tting is pressure proof even when tightened with

fi ngers.

Service

Avoid subjecting the gauges to excessive shock loads such as those that might occur from

being dropped or hit against an immovable object. Do not subject the gauges to pressures

beyond their maximum range. Temperature extremes can be damaging. In general, the gauges

should not be exposed to temperatures to which you would not expose yourself.

After use:

Rinse the gauges or the console with fresh water and store them out of direct sunlight, in a dry

place at room temperature.

CAUTION!

Do not attempt to clean the gauges with anything other than water. Use of cleaning agents

or compressed air can cause permanent damage. The introduction of any probe into the

water entry port of the depth gauge or the pressure relief valve opening of the pressure

gauge can also damage internal components.

Before prolonged storage the instruments should be removed from the console, rinsed with

fresh water and stored separately.

9

Page 10

CAUTION!

Do not attempt to disassemble the gauges. Special tools and training are required to

perform the adequate service.

The instruments must be serviced by an authorized dealer every second year or after 200 dives

(whichever comes fi rst).

Operating and Storage Temperatures

SM-16 Operating temperature 0° C to 40° C [32° F to 104° F]

Storage temperature -20° C to 50° C [-4° F to 122° F]

SM-26 and SM-36 Operating and storage temperature 0° C to 40° C [32° F to 104° F]

Technical Specifi cations

The Suunto depth gauge SM-16 complies with the prEN 13319 standard.

The tolerances for depth gauges are:

At 3m +0.8 / -0.4 m

At 6m +0.8 / -0.4 m

At 9m ±0.8 m

At 15m +1/ -1.2 m

At 30m +1/ -1.2 m

At 45m +1/ -1.5 m

At 60m +1 / -1.5 m

The SM-26 and SM-36 pressure gauges comply with the EN 250 standard.

The tolerances for pressure gauges, measured at decreasing pressure are:

At 40 bar ± 5 bar

At 100 bar ± 10 bar

At 200 bar ± 10 bar

At 300 bar ± 10 bar

10

Page 11

COPYRIGHT

This publication and its contents are proprietary to Suunto Oy.

Suunto, Wristop Computer, Suunto Combo, Replacing Luck and their logos are registered

or unregistered trademarks of Suunto Oy. All rights reserved.

While we have taken great care to ensure that information contained

in this documentation is both comprehensive and accurate,

no warranty of accuracy is expressed or implied.

Its content is subject to change at any time without notice.

Printed in Finland 09.2006 / Esa Print Oy / 161188

Page 12

www.suunto.com

Made in Finland

© Suunto Oy 11 / 2005, 09 / 2006

Loading...

Loading...