Page 1

SURE HEAT

Installation and Operating Instructions for

NATURAL & L.P. GAS

VENT FREE REMOTE CONTROLLED SYSTEM

Model: SCVFR18L, SCVFR18N, SCVFR24L, SCVFR24N, VFMO24N

DANGER:

FAILURE TO FOLLOW THESE INSTRUCTIONS CAREFULLY AND WITHOUT ERROR, OR FAILURE TO

HEED ANY AND ALL WARNINGS IN THESE INSTRUCTIONS CAN RESULT IN AN EXPLOSION, FIRE OR

THE PRODUCTION OF CARBON MONOXIDE GAS WHICH CAN CAUSE PROPERTY DAMAGE, BODILY

INJURY OR DEATH.

Sure Heat

Manufacturing

1861 West Oak Parkway

Marietta, GA 30062

Tel: (770) 422-8008

Fax: (770) 424-3842

NOTE: THIS UNIT CANNOT BE CONVERTED TO DIFFERENT GAS TYPES.

WARNING: If the information in this manual is not followed exactly, a re or explosion

may result causing property damage, personal injury or loss of life.

- Do not store or use gasoline or other ammable vapors or liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance

• Do not touch any electrical switch.

• Do not touch any telephone in your building.

• Immediately call your gas supplier from a neighbor’s telephone.

• Follow the gas suppliers instructions.

• If you cannot reach your gas supplier, call the re department.

- Installation and service must be performed by a qualied installer, service agency or the

gas supplier.

This is an unvented gas-red heater. It uses air (oxygen) from the room in which it is

installed. Provisions for adequate combustion and ventilation air must be provided.

THIS APPLIANCE MAY BE INSTALLED IN AN AFTERMARKET MANUFACTURED (MOBILE) HOME, WHERE NOT PROHIBITED

BY STATE OR LOCAL CODES. INSTALL ONLY IN A SOLID-FUEL BURNING FIREPLACE OR APPROVED VENTLESS FIREBOX

ENCLOSURE (MANUFACTURED UNVENTED FIREPLACE) AS SPECIFIED BY THESE INSTRUCTIONS.

* AFTERMARKET: COMPLETION OF SALE, NOT FOR PURPOSE OF RESALE, FROM THE MANUFACTURER.

THIS APPLIANCE IS ONLY FOR USE WITH THE TYPE OF GAS INDICATED ON THE RATING LABEL ATTACHED TO THE

APPLIANCE. THIS APPLIANCE IS NOT CONVERTIBLE FOR USE WITH OTHER GASES. THIS UNIT IS CONSTRUCTED IN

ACCORDANCE WITH ANSI Z21.11.2B-2004.

Page 2

IMPORTANT INFORMATION

This appliance is designed as an unvented room heater when installed in a non-combustible replace with the

ue damper closed.

This appliance may be used as a heating appliance only if unvented heating appliances are permitted by local

state and city codes. If unvented heaters are not permitted, then the replace vent damper must be locked at

the minimum vent area required by local codes, or in the absence of local codes, by the latest edition of the

National Fuel Gas Code (ANSI Z223.1 or latest edition).

This installation manual contains valuable safety instructions and installation procedures that should be

understood before installation of the unit. The owner of this appliance should keep this instruction manual to

refer to in the future. It is the installer’s responsibility to instruct the owner of this unit in the proper use and

maintenance of this appliance.

DANGER: THIS APPLIANCE, AS ANY GAS-FIRED APPLIANCE, CAN PRODUCE POISONOUS CARBON

MONOXIDE ALONG WITH OTHER COMBUSTION PRODUCTS. CARBON MONOXIDE, IN STRONG

CONCENTRATIONS, CAN CAUSE SICKNESS, SERIOUS PERSONAL INJURY AND DEATH.

GASEOUS FUELS ARE HIGHLY EXPLOSIVE IN CERTAIN CONCENTRATIONS AND ARE VERY

FLAMMABLE. ANY GAS LEAKS IN THE PLUMBING SUPPLYING GAS TO THIS APPLIANCE CAN LEAD

TO FIRE OR EXPLOSION.

WHEN PROPERLY INSTALLED, USED AND MAINTAINED, THIS APPLIANCE SHOULD NOT PRODUCE

CARBON MONOXIDE IN DANGEROUS QUANTITIES. HOWEVER, SINCE CARBON MONOXIDE CAN BE

DEADLY POISONOUS, THE INSTALLER AND ALL USERS OF THIS APPLIANCE SHOULD READ AND

FOLLOW THESE INSTRUCTIONS CAREFULLY.

FIREPLACE SIzING GUIDE AND BTU INFORMATION

BTU Information

Opening Front Rear Fireplace Natural Gas L.P. Gas

Set Size Height Width Width Depth Max. Min. Max. Min.

18” 18” 22” 18” 12” 34,000 22,000 34,000 22,000

24” 18” 28” 20” 15” 40,000 22,000 40,000 22,000

Sufcient space must be provided around this appliance to provide air for combustion and ventilation. Any

alterations to this unit or its controls may be hazardous.

Do not install this heater in bedrooms or bathrooms, or campers.

These instructions should be studied carefully before the installation and operation of this unit.

The installation must conform with local codes or, in the absence of local codes, with the National Fuel gas

Code ANSI Z223.1, latest edition.

The installation and repair of this unit should be conducted by a licensed or qualied service person.

WARNING: This appliance is only for installation in a solid fuel burning replace made

of non-combustible materials or approved ventless rebox enclosure.

This appliance must be kept clear from combustible materials, gasoline or other ammable vapors and liquids.

Solid fuels should not be burned in a replace where an unvented room heater is installed.

Keep burner and control compartment clean. See Installation and Operating Instructions accompanying heater.

Due to high temperatures, the appliance should be located out of trafc and away from furniture and draperies.

Children should be supervised when they are in the same room with the appliance.

All people should be notied of the high surface temperatures of the system to avoid burns or clothing ignition.

This system should be inspected upon installation and annually by a professional service person. It is

necessary to keep controls, burner and air passageways clear of any debris.

Do not place any combustible material on or around the appliance.

Page 2

Page 3

IMPORTANT INFORMATION

Do not use this appliance if any part has been submerged under water. Immediately call a qualied service

technician to inspect the appliance and to replace any part of the control system and any gas control which has

been under water.

This heater shall not be installed in a conned space unless provisions are provided for adequate combustion

and ventilation air. The National Fuel Gas Code denes a conned space as a space whose volume is less

than 50 cubic feet per 1,000 BTU per hour (4.8m3 per kw) of the aggregate input rating of all appliances

installed in that space and an unconned space as a space whose volume is not less that 50 cubic feet per

1,000 BTU per hour (4.8m3 per kw) of the aggregate input rating of all appliances installed in that space.

Rooms communicating directly with the space in which the appliances are installed, through openings not

furnished with doors, are considered a part of the unconned space

WARNING: If the area in which the heater may be operated is smaller than that dened as an

unconned space provide adequate combustion and ventilation air by one of the methods

described in the National Fuel Gas Code, ANSI z223.1, 1992, Section 5.3

This appliance is equipped with an ODS (oxygen depletion sensor) pilot light safety system that turns off the

appliance if enough fresh air is not available. Additional ventilation is obtained by opening a door to another

room or opening a window.

Always ensure that there is proper ventilation from the area the system is operating in.

Any outside air ducts and/or ash dumps in the replace shall be permanently closed at time of

appliance installation.

This appliance must be used with glass doors in the OPEN position.

A replace screen with an opening for combustion air must be in place when the appliance is operating, unless

other provisions for combustion air are provided.

IMPORTANT: During the manufacturing process this appliance is treated with certain coloring agents. These

agents are not harmful, but may produce annoying smoke and smell as they are burned off. This

is a temporary occurrence that ceases after 4 to 6 hours of use. During the “burning off” period,

provide ventilation by opening windows, doors and the chimney ue to allow odors to dissipate.

Any remaining odors will burn off with continued use.

UNPACKING

Unpack the appliance carefully and inspect for missing parts or damages that may have occurred during

shipping. If any part of the appliance is missing or damaged, please notify Sure Heat Manufacturing at (800)

229-8647. An incomplete or damaged appliance may be hazardous.

DO NOT INSTALL A DAMAGED OR INCOMPLETE APPLIANCE.

FIREPLACE PREPARATION

The replace needs to be properly prepared before installing this replace unit.

1. Turn off gas supply to the replace.

2. Clean chimney and replace oor of any combustible material to limit the smell from the system.

WARNING: Before installing in a solid fuel burning replace, the chimney ue and rebox must be

cleaned of soot, creosote, ashes and loose paint by a qualied chimney cleaner.

Page 3

Page 4

GAS PIPING AND GAS PRESSURE REQUIREMENTS

Check the type of gas that is supplied to your replace. Use only the gas type indicated on the heater’s rating

plate. If the gas listed on the plate is not your type of gas supply, DO NOT INSTALL THE SYSTEM. Contact

your dealer for the proper model.

All gas piping must be installed to comply with local and national fuel gas codes. Do not use exible hose

unless it is allowed by local codes. Compounds used on threaded joints of gas piping musts be resistant to the

action of LP gas.

The gas supply line to the replace should not be less than 1/2” inside dimension.

The gas supply must be of sufcient size to provide a minimum natural gas pressure of 7 inches water column

for natural gas or 11 inches for L.P. gas. The maximum inlet gas pressure to the appliance must not exceed

10 inches for natural gas and 13 inches for L.P. gas. If this appliance is to be supplied with L.P. gas the tank

or bottle supplying the gas must have a regulator that reduces gas pressure between 11 and 13 inches water

column.

Include a manual shutoff valve and union in the line so the appliance may be disconnected for servicing.

Provide a 1/8” NPT plugged tapping for pressure gauge connection between shutoff valve and the appliance.

Test for leaks using soap and water solution after completing the connection. DO NOT USE OPEN FLAME!

WARNING: The appliance and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of

1/2 psig (3.5 kPa). The appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2 psig. Pressures in excess of 1/2

psig will cause damage to the unit.

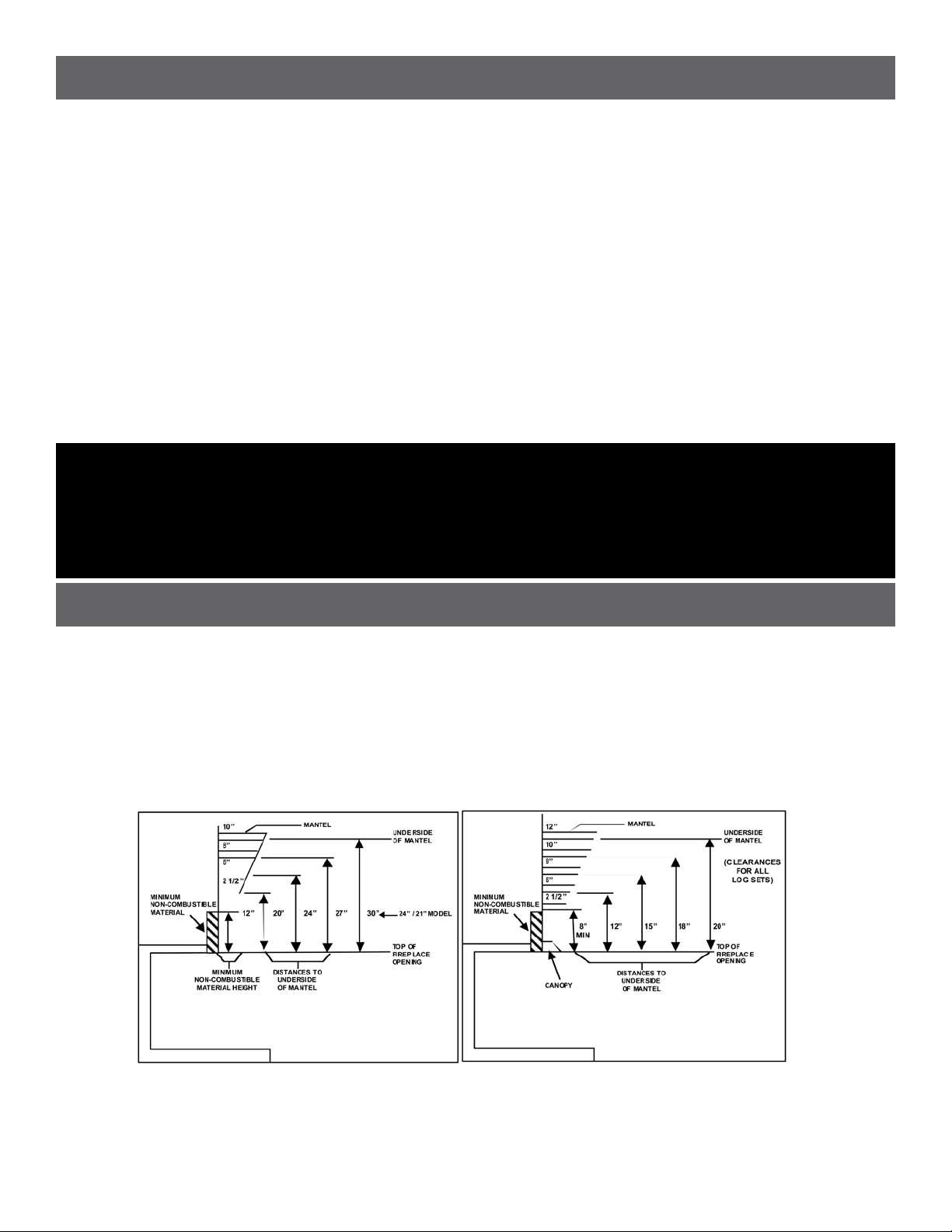

FIREPLACE CLEARANCES

To guarantee safe installation into a noncombustible replace, certain space requirements must be fullled.

1. The clearance from the side of the unit to any combustible wall should not be less than 15 1/2 inches.

2. The clearance from the ceiling to the top of the replace opening should not be less than 42 inches.

3. The minimum clearance to combustible items in front of the heat is 36 inches.

4. For any replace in which this unit is installed, there are certain mantel clearance requirements that

must be met.

Minimum Mantel Clearance Minimum Mantel Clearance with Canopy

You must have non-combustible material(s) above the replace opening. Non-combustible materials (such as

slate, marble, tile, etc.) must be at least 1/2 inch thick. Some decorative replace surrounds (cultured marble)

may get discolored from the heat produced by the system. With sheet metal, you must have non-combustible

material behind it. If non-combustible material is less than 8” you must install replace canopy

(Model AMG-100).

Page 4

Page 5

BURNER SYSTEM LOCATION

The Burner system should be located towards the back and centred in the combustion chamber of the

replace. The burner system should be centred from left to right, with about an inch of space on either side.

CONNECTING GAS SUPPLY TO BURNER PAN AND LOG GRATE PLACEMENT

1. Place burner system in proper location.

2. Attach brass 3/8” to 1/2” gas inlet tting to the 1/2” gas supply stub.

3. Carefully bend the ared tubing as needed to make the connection between the burner assembly and the

gas inlet tting.

4. Next attach the ared tubing to the burner assembly rst, then to the gas inlet tting.

- Avoid kinking the ared tubing while bending. If tubing must be cut, use a tube cutter. Flare the cut end of

the tube with a aring tube.

5. Be certain all connections are tight and use pipe compound on all male threads to seal joints.

NOTE: The pipe compound must be resistant to the action of L.P. Gas. Test all connections with a soapy

water solution with gas supply turned on. If bubbles appear on any connection, re-tighten and reset. Once it

is determined there are no leaks whatsoever, turn off gas supply and move to next assembly step.

Flared

Tubing

Gas Supply

Stub

Gas Inlet

Fitting

Page 5

Page 6

LOG PLACEMENT

1. The largest log is placed in the front part of the grate with the notches facing upwards (see Figure 1 and

Figure 2).

NOTE: The front log should be as far to the front of the grate as possible.

2. The second largest log (Log with Burner Notch) is to be placed on the second tier of the grate (See Figure 1

and Figure 2).

3. The back log is to be placed on the back tier. (See Figure 1 and Figure 2).

4. Place the top logs as shown in Figure 2 and Figure 3. Incorrect log placement can lead to the production

of harmful carbon monoxide while the unit is in operation. Be sure that the logs are correctly placed in the

notches provided for them. There should be no direct impingement of ames on any of the logs.

WARNING: Failure to position the parts specically approved with this

heater may result in property damage or personal injury.

MODELS: SCVFR18LP, SCVFR18NG,

SCVFR24LP, SCVFR24NG

Place back main log on back of burner frame.

Back Main Log

Place middle main log on back of burner frame.

Middle Main Log

Place front main log in front of burner system.

MODEL:

VFM0L24

Place back main log on back of burner frame.

Back Main Log

Place middle main log in position. Make sure the

log notch is placed over the burner.

Middle Main Log

Place front main log in front of burner system.

Log Notch

Front Main Log

Top Logs

Cover Logs

Arrange remaining top logs. Then place the cover

logs in front of control valve and remote sensor.

Top Logs

Three (3) Top Logs

Three (3) Cover Logs

Arrange remaining 3 top logs. Then place the 3 cover

logs in front of control valve and remote sensor.

Front Main Log

DECORATIVE STONE

The decorative stone from the bag provided should be spread on the bottom tray of the grate. (SeeFigure 3) The stone

should not be placed on or near the burner. Contact with the burner can cause the production of carbon monoxide.

Page 6

Page 7

FINAL CHECKPOINTS BEFORE OPERATION

1. Before setting the logs in place, turn the gas on and check each joint in the gas line with a soap and water

solution for leaks. Bubbles indicate leaks. Repair any leaks and recheck before proceeding.

DANGER: DO NOT USE OPEN FLAME TO TEST FOR LEAKS!

2. I t is most convenient to light the pilot and check the operation of the burner without the logs in place. After

the nal check of the gas supply is complete and the corrections are made, go to the “Lighting Operation”

section of this manual.

3. After the pilot ame is established, turn the control knob to the “ON” position. The burner should ignite within

four (4) seconds. If the burner does not ignite within four (4) seconds, turn valve to “OFF” position.

4. With the pilot and burner in operation, check each connection with soap and water solution again for leaks. If

any leaks are found, turn gas supply off and correct them immediately.

5. After the gas connections are secure, turn control knob to “OFF” position. Allow system to cool down.

6. Set the front log, the longest log, in position centred side to side on the front part of the grate with the thin

at surface of the log on the grate.

7. Set the middle log, the second longest log, in position centred side to side on the middle supporting brackets

with the thin at surface of the log on the grate.

8. Set the back log, the third longest log, in position centred side to side on the back supporting brackets with

the thin at surface of the log on the grate. The top log should be positioned according to the notches left

available by the bottom logs. See Figure 2 and 3 on page 5 for top log placement.

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a re or explosion may

result causing property damage, personal injury or loss of life.

A. This appliance is equipped with an ignition device (piezo) which lights the pilot automatically. If the Piezo

fails to light the pilot,turn to “Match Lighting” Instructions on Page 8.

PIEzO

B. BEFORE LIGHTING the unit, smell around the appliance area for gas. Be sure to smell next to the oor

because some gas is heavier than air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any telephone in your building.

• Immediately call your gas supplier from a neighbor’s telephone.

• Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

• Installation and service must be performed by a qualied installer, service agency or the gas supplier.

C. Use only your hand to push in or turn the pilot control knob. Never use tools. If the knob will not push in or

turn by hand, do not try to repair. call a qualied service technician.

WARNING: THE USE OF FORCE OR ATTEMPTED REPAIR MAY RESULT IN A FIRE OR EXPLOSION.

D. Do not use this appliance if any part has been under water. Immediately call a qualied service technician

to inspect the appliance and replace any part of the control system and any gas control which has been

under water.

Page 7

Page 8

TECHNICAL DATA

REMOTE CONTROL

Supply voltage:

4.5V (three 1.5 V “AAA” batteries)

Ambient temperature ratings:

0 - 60°C (32 - 140°F)

Radio frequency:

315 MHz

RECEIVER:

Supply voltage:

6.0V (four 1.5 V “AA” batteries)

Ambient temperature ratings:

0 - 60°C (32 - 140°F)

Radio frequency:

315 MHz

REMOTE CONTROL

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES.

OPERATION IS SUBJECT TO THE FOLLOWING

TWO CONDITIONS:

(1) This device may not cause harmful interference, AND

(2) This device must accept any interference received, including

interference that may cause undesired operation.

Changes or modications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

WARNING: The transmitter and the receiver are radio frequency

appliances. If the receiver is mounted inside metallic cases,severe

loss of performances (reduction of the range of working) may result.

ATTENTION!

- Turn “OFF” main gas supply of the appliance during installation or

maintenance of the receiver.

- Place the receiver’s 3 position slider switch in the “OFF” position during

installation or maintenance.

- Turn “OFF” main gas supply of the appliance prior to removing or

reinserting the batteries in the receiver.

ON/OFF

Key

Side

Slider

COMMUNICATION BETWEEN THE

REMOTE CONTROL AND THE RECEIVER

To program the transmitter to the receiver,

move the three positions slider of the

receiver in the REMOTE position and

depress the ON/OFF key of the transmitter.

The System has got an automatic learning

mode that allows the receiver to mate with

a new transmitter in the event that the

transmitter must be replaced. As soon as the

receiver receives the rst correct command

from any remote control it captures the new

address and then “beeps” 3 times to conrm

the synchronization and command execution.

Transmission

light

INSTALLING BATTERIES

Child safety

function ON

CHILD SAFETY LOCK-OUT FEATURE

With this function it is possible to deactivate the remote control key.

If the batteries of the Receiver are low, the

appliance can be switched on manually by

moving the 3 position slider switch on the

Child safety

function OFF

BACKUP FUNCTION

Receiver to the ON position.

-

-

+ +

Install four (4) “AA”

batteries into the

remote receiver

box as shown on

the left.

Page 8

Install three (3)

-

-

+

“AAA” batteries

into the remote

control as shown

on the left.

Page 9

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information label found on the unit.

2. Make sure the switch (Not the pilot control knob) is turned to “OFF”. (See Figure 4)

3. Turn off all electrical power to the unit.

4. Push in pilot control knob slightly and turn clockwise to “OFF”.

5. Wait ve (5) minutes to clear out any gas. Then smell for gas, including near the oor.

• If you smell gas: STOP! Follow B on the safety Information label.

• If you don’t smell gas continue on to the next step.

6. The pilot is located by the main burner.

7. Push in the pilot control knob slightly and turn counter-clockwise to “PILOT”.

8. Hold the pilot control knob in and push the piezo button (located on the left side of the unit) until the pilot ame appears.

9. Continue holding the pilot control knob for up to one (1) minute before releasing. The knob will

pop back out upon release. Pilot should remain lit. If it goes out repeat steps 5 through 8.

• If knob does not pop out when released, stop and immediately call your service technician.

• If the pilot will not stay lit after several tries, turn the gas control knob to “OFF” and call your service technician.

10. Push in the pilot control knob and turn counter-clockwise to “ON”.

11. It will take 2 - 3 minutes for thermocouple to heat up and ame to appear.

12. This valve is equipped with a HI/LO feature. Set unit to desired ame height. The valve is also equipped with a safety

lockout feature that will prevent the relighting of the pilot after it is extinguished. You must wait one (1) minute for valve

to reset itself before relighting the pilot.

13. Then move switch to “REMOTE”. You will then be able to switch the unit “ON” or “OFF” using the remote.

14. To operate unit with remote:

a. Make sure switch is turned to “REMOTE”

b. Make sure pilot control knob is switched to “ON”

c. Press button once to turn unit “ON”. You will hear a soft beep than the ame will appear.

d. To turn the unit “OFF”. Press the button on the remote once after ve (5) seconds the ame

will disappear and the unit will turn off (NOTE: the pilot light will remain on).

HI/LO

Setting

Make sure switch

is turned to “OFF”

when lighting; and

“REMOTE” to use

the remote.

Pilot

control

knob

MATCH LIGHTING INSTRUCTIONS

If the pilot cannot be ignited with the piezo, it can be manually lit with a match. Follow steps 2 through 8. Push

the pilot control knob in fully and hold it in. Immediately light the pilot with a match. Continue to hold the pilot

control knob in for about one (1) minute. After one (1) minute, release the knob and it will pop back out. The

pilot should remain lit. If it goes out, repeat steps 2 through 8.

• If the control knob does not pop out when released, STOP and immediately call your service

technician or gas supplier.

• If the pilot will not stay lit after several tries, turn the pilot control knob clockwise to “OFF” and

call your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Turn the switch to “OFF”.

2. Push in the pilot control slightly and turn clockwise to “OFF”. DO NOT FORCE.

Page 9

Page 10

MAINTENANCE OF THE SYSTEM

- Under normal use, this unit will require only limited cleaning.

- To clean the unit, rst turn the pilot control knob to “OFF” and allow the system to cool down.

- The logs and grate can get very hot. Handle only when the system is cool.

- Keep the control valve, logs and burner area clean by vacuuming or brushing at least twice a year.

- Visually inspect the pilot. Dust or blow away any dust or lint that has accumulated.

- Sufcient space must be provided around this appliance to provide air for combustion and ventilation. Keep the front of

the appliance clear of all obstacles and materials.

- Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any

other appliance.

- During the manufacturing process this appliance is treated with certain coloring agents. These agents are not harmful,

but may produce an annoying smell and smoke as they are burned off. This is a temporary occurrence that ceases

after two (2) to three (3) hours of use.

- There is a small hole (about the size of a pen tip) through the shaft of the pilot light. This is located about 1 inch from

the mouth (it runs horizontally through the shaft). Take a small brush (old toothbrush, etc.) and brush that hole and the

surrounding area really well. Use a vacuum hose to clean any soot around the pilot area. This cleans out the oxygen

depletion sensor. If there is any debris (soot, dust, spider webs, etc.) in this area, it will not sense enough oxygen to run

the unit. This should be done a at least once a year as

standard maintenance.

- Clean the pilot opening with a toothbrush.

- If your unit shuts down, and the above does not work, please do the following:

a. Locate your thermocouple (follow the copper line to the back of the control box). It is connected with a 3/16” nut.

b. Disconnect and clean with a dry paper towel. Reconnect and tighten nger tight, then 1/4 turn with

a wrench.

FOR FURTHER ASSISTANCE PLEASE CONTACT OUR

CUSTOMER SERVICE DEPARTMENT AT 1-800-229-5647

FINAL CHECKS

Things TO Do:

• Use only the type of gas for which your system is designed. The type of gas the system is equipped for is stated

on the rating plate.

• Install appliance and all gas piping according to local codes.

• Disconnect or isolate the system during line pressure testing.

• Make sure 1/2” gas line is run to the replace to ensure sufcient gas volume to the appliance.

• Install the system only in a replace suitable for burning solid fuel.

• Use pipe sealant on threaded joints of gas piping that is resistant to the action of LP gas.

• Install a manual shutoff valve, union and 1/8” NPT plugged pressure tap ahead of controls.

• Use mild soap and water solution when checking for leaks.

• Keep the area around the appliance clear and free of combustible materials, gasoline and any ammable or

explosive material.

• Follow the lighting and operation procedures given in this manual.

• Periodically inspect the pilot and burner ame.

• Clean the appliance as described in this manual.

• Keep the logs properly positioned.

Things NOT To Do:

• Do NOT modify or alter this appliance in any way.

• Do NOT use this appliance with any gas other than that for which it is equipped.

• Do NOT install this appliance in any area where gasoline or any ammable material is used or stored.

• Do NOT use open ame to check for leaks.

• Do NOT operate this system with glass doors in the CLOSED position.

• Do NOT block or restrict any grilles of a factory built replace in which the appliance is installed.

• Do NOT burn solid fuels in a replace where this appliance is installed.

Page 10

Page 11

TROUBLESHOOTING

Problem Cause Corrective Action

• No Pilot ignition - pilot valve not on - turn valve to “PILOT” and depress,

keep match near pilot burner until ignition.

- gas line not clear - inspect supply lines for tube kinks or obstructions.

- air in gas line - turn valve to “PILOT” and depress,

keep match near pilot burner until ignition.

- allow air to purge through the line,

may take up to (5) minutes.

- no gas supply to replace - check to see if the replace is hooked

to the gas supply.

- no L.P. gas - ll tank

- main shutoff valve closed - turn valve on

• Inadequate ame - valve partially closed - open valve fully

- gas line obstruction - inspect burner for tube kinks or obstructions.

• Unit shuts off - thermocouple is overheating - reposition logs to keep main burner

ame off the thermocouple assembly.

- ODS needs to be cleaned - Please see the maintenance section

on how to properly clean the ODS.

• Unit ON/OFF issues - unit will not turn “ON” - After the pilot has been lit make sure

to wait 2-3 minutes for ame to appear.

- make sure to only press button on

remote ONCE and wait for soft beep

and the ame will appear.

- unit will not turn “OFF” - make sure to only press the button on

remote ONCE, wait for soft beep, after

5 seconds the ame will go out and

the unit will be “OFF” but the pilot light

will still be “ON”.

- if you want to completely turn “OFF”

the unit make sure to turn the pilot

control knob to “OFF” and the remote

sensor switch to “OFF”.

• Remote control - low battery detection - when the transmitter/receiver

transmitter/receiver (transmitter/receiver) batteries are low, depressing the

ON/OFF key the light intensity of

the LED is weak to alert of a low

battery condition before losing

battery power at all. As soon as the

depleted batteries are replaced, the

transmitter/ receiver will restart its

normal operation.

Page 11

Page 12

WARRANTY

Warranty shall apply to the original purchaser at the original installation point only.

All logs are guaranteed for three years against manufacturer’s defects.

The burner assembly system is guaranteed for a period of (3) years from the date of purchase and will be

replaced for freight costs only.

Pilot, valves and thermocouples are guaranteed for a period of one (1) year under the original

manufacturers warranty.

General Warranty: This warranty does not apply in the case of improper installation, neglect, accident,

misuse or as a result of modications of the original product.

All costs for removal and re-installation are the expressed responsibility of the purchaser.

For repair, replacement, or service to defective part(s)please contact our Customer Service Hotline, number

below. Thereafter with valid warranty registration and proof of purchase, call the Customer Service Hotline for

authorization to ship defective part prepaid and insured in original carton to Sure Heat Manufacturing,

1861 West Oak Parkway, Marietta, GA 30062. Goods returned improperly packaged are the sole responsibility

of purchaser.

It is agreed that any repair or replacement is the exclusive remedy from Sure Heat Manufacturing. In no case

shall Sure Heat be liable for any consequential damage or breach of this or any other warranty expressed or

implied whatsoever. This limitation as to consequential damages shall not apply in states where prohibited.

Purchased From:____________________________________________ Date:_________________

Size: 18” Model:

24” Model:

Name:_________________________________________________ Phone: (____)_____________________

Address:________________________________________________________________________________

City:___________________________________________ State: _____ Zip: __________________________

Please photocopy and return to Sure Heat within 14 days of purchase.

If you have other questions, please contact our

Customer Service Hotline (800) 229-5647.

Page 12

RMH-130-00533

08/08

Loading...

Loading...