Page 1

THE CHARLESTON SERIES

Vent Free Universal Firebox

model numbers VFBC32 VFBC36 VFBC42

Homeowner’s Installation

and Operating Manual

Carefully review the instructions supplied

FOR USE ONLY WITH A LISTED

GAS-FIRED UNVENTED

DECORATIVE ROOM HEATER

NOT TO EXCEED 40,000 BTU/H.

DO NOT BUILD A WOOD FIRE

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life

with decorative type unvented room heater

for the minimum fireplace size requirements

DO NOT INSTALL AN APPLIANCE IN THIS

FIREBOX UNLESS THIS FIREBOX MEETS

THE MINIMUM DIMENSIONS REQUIRED FOR

THE INSTALLATION

Installer:

Leave this manual with the appliance.

Consumer:

Retain this manual for future reference.

Page 2

Congratulations!

INSTALLER/CONSUMER

SAFETY INFORMATION

Read and save these instructions.

This book contains your installation instructions and should be kept in a safe place. For you to realize

all the advantages and use of the reliable service that has been engineered into your Sure Heat

Manufacturing fireplace, you must carefully follow all of the instructions contained in this book regarding

installation and operation of the fireplace.

These instructions should be read carefully in their entirety before beginning installation of

the fireplace.

It is suggested that you wear work gloves and safety glasses to protect your hands and eyes when

installing your fireplace. NOTE: Authorities having jurisdiction (i.e. building inspectors, fire marshals, etc.)

should be consulted before installation to determine the need to obtain a permit.

These fireboxes are approved as universal fireboxes and can be paired with any ANSI Z21.11.2

approved vent free gas log set. The vent free log manufacturer’s instructions, including their

required dimensional clearances for firebox size, must be followed.

Refer to the manual that is packed with the log set for operating instructions.

General Installation Information

In planning the installation for the appliance it is necessary to determine where the unit is to be installed

and whether optional accessories are desired. Gas supply piping should also be planned. The following

steps represent the normal sequence of installation. Each installation is unique, however, and might

require a different sequence.

1. Position firebox prior to framing or into prepared framing.

2. Plumb gas line. (Gas connections should only be performed by an experienced,

licensed/certified tradesman).

3. Install vent-free gas log heater per the instructions provided with the vent-free gas log heater.

4. Complete finish wall material, surround and optional hearth extension to your individual taste.

Table of Contents

Safety Information

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Hearth Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fireplace Framing Dimensions

Installation Instructions

Locating the Fireplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Drafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installing the Firebox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Finishing the Fireplace

Hearth Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Install Optional Outside Air Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Blower Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Replacement Parts

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

3

7-14

8

15

Page 3

Safety Information

MPORTANT

I

Read these instructions carefully before installing or trying to

operate a vent-free gas heater in this firebox.

• Any change to this heater or its

controls can be dangerous.

• Improper installation or use of the heater can

cause serious injury or death from fire, burns,

explosion or carbon monoxide poisoning.

• Do NOT allow fans to blow directly into the

fireplace. Avoid any drafts that alter burner

flame patterns.

1. Due to high temperatures, the appliance should be located out of

fic and away from furniture and draperies.

traf

2. Children and adults should be alerted to the hazard of high

surface temperature and should stay away to avoid burns or

clothing ignition.

3. Young children should be carefully supervised when they are in

the same room with the appliance.

4. Do not place clothing or other flammable material on or near

the appliance.

5. Any safety screen or guard removed for servicing an appliance

must be replaced prior to operating the heater.

6. Installation and repair should be done by a qualified

service person.

7. To prevent malfunction and/or sooting, an unvented gas heater

should be cleaned before use at least annually by a

professional service person. More frequent cleaning may be

required due to excessive lint from carpeting, bedding material,

etc. It is imperative that control compartments, burners and

circulating air passages be kept clean.

CARBON

8.

9. The installation must conform with local codes or, in the absence

This unit complies with

10.

11. Do not install heater in a bathroom or bedroom.

12. Correct installation of the logs, proper location of the heater, and

13. Avoid any drafts that alter burner flame patterns. Do not allow

MONOXIDE POISONING:

monoxide poisoning are similar to the flu with headaches,

dizziness and/or nausea. If you have these signs, obtain fresh

air immediately. Have the heater serviced as it may not be

operating properly.

of local codes, with the

Z223.1/NFPA54.

enclosures for gas-fired unvented decorative room heaters.

annual cleaning are necessary to avoid potential problems with

sooting. Sooting, resulting from improper installation or

operation, can settle on surfaces outside the fireplace. See log

placement instructions for proper installation.

fans to blow directly into fireplace. Do not place a blower inside

burn area of firebox. Ceiling fans may create drafts that alter

burner flame patterns. Sooting and improper burning will occur

National Fuel Gas Code, ANSI

ANSI

Early signs of carbon

Z21.91.2001 ventless firebox

14. Candles, incense oil lamps, etc. produce

combustion byproducts including soot. Vent-free appliances will

not filter or clean soot produced these types of products. In

addition, the smoke and/or aromatics (scents) may be reburnt

in the vent-free appliance which can produce odors. It is

recommended to minimize the use of candles, incense, etc.

while the vent-free appliance is in operation.

15. An unvented gas-fired heater uses air (oxygen) from the room in

which it is installed. Provisions for adequate combustion and

ventilation air must be provided. See installation guidelines.

16. Keep room area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

17. Unvented gas heaters are a supplemental zone heater. They are

not intended to be a primary heating appliance.

18. Unvented gas heaters emit moisture into the living area. In most

homes of average construction, this does not pose a problem.

In houses of extremely tight construction, additional mechanical

ventilation is recommended.

19. During manufacturing, fabricating and shipping, various

components of this appliance are treated with certain oils, films

or bonding agents. These chemicals are not harmful but may

produce annoying smoke and smells as they are burned off

during the initial operation of the appliance, possibly causing

headaches, or eye or lung irritation. This is a normal and

temporary occurrence.

The initial break-in operation should last two to three hours with

the burner at the highest setting. Provide maximum ventilation

by opening windows or doors to allow odors to dissipate. Any

odors remaining after this initial break-in period will be slight

and will disappear with continual use.

20. Input ratings are shown in BTU per hour and are for elevations

up to 2,000 feet. For elevations above 2,000 feet, input ratings

should be reduced 4% for each 1,000 feet above sea level.

Refer to the National Fuel Gas Code.

21. The appliance and its appliance main gas valve must be

disconnected from the gas supply piping systems during any

pressure testing of that system at test pressures in excess of

1/2 psig (3.5kPa).

22. The appliance must be isolated from the gas supply piping

system by closing its equipment shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

23. Do not use this room heater if any part has been under water.

Immediately call a qualified service technician to inspect the

room heater and to replace any part of the control system and

any gas control which has been under water

24. Never burn solid fuels in a fireplace where an unvented room

heater is installed.

25. Always have a fireplace screen in place when the appliance is in

operation, and unless other provisions for combustion air are

provided, the screen shall have an opening(s) for induction of

combustion air

26. Do not fill spaces around the firebox with insulation or other

materials. These spaces must be maintained to prevent the

firebox from coming in contact with combustible materials.

.

.

.

3

Page 4

Product Features

o not attempt to burn solid wood fuels, vented gas log sets, or any other combustible in this

D

unvented firebox. Also, do not install a vent-free gas log set in this firebox if the minimum

clearance and height requirements of the log set are too large for the firebox.

You have purchased a vent-free firebox. This installation manual will enable you to obtain a safe, efficient

and dependable installation of your vent-free firebox system.

Do not alter or modify the firebox or its components under any circumstances. Any modifications or alteration

of the firebox system, including but not limited to the firebox and accessories, may void the warranty, listings and

approvals of this system, and could result in an unsafe and potentially dangerous installation.

Before You Start

Carefully inspect the contents for shipping damage. If any parts are missing or damaged, immediately inform

the dealer from whom you purchased the appliance. Do not attempt to install any art of the appliance unless you

have all the parts in good condition.

Make Sure That You Have Received All Parts

Check your packing list to verify that all listed parts have been received. You should have the following:

1. Vent-Free Gas Firebox 3. Installation and Operating Manual

2. Canopy 4. Five (5) sheet metal screws for canopy.

What You Will Need For Installation

Tools

• Phillips screwdriver • Square

• Hammer • Saw and/or sabersaw

• Tee Joint • Electric drill and bits

• Level

• Measuring T

• Pliers • Pipe sealant approved

Notice:

Illustrations shown in this manual reflect "typical" installations with nominal dimensions and are for design

and framing reference only. Actual installations may vary due to individual design preferences. However,

always maintain minimum clearances to combustible materials and do not violate any specific installation

requirements.

ape •

• Pipe wrench

Piping complying with

local codes

for use with propane/L.P.G.

(resistant to sulfer compounds)

Building Supplies

• Framing materials

• Wall finishing materials

• Caulking material

(non-combustible)

Fireplace surround materials

•

(non-combustible)

4

Page 5

Specifications

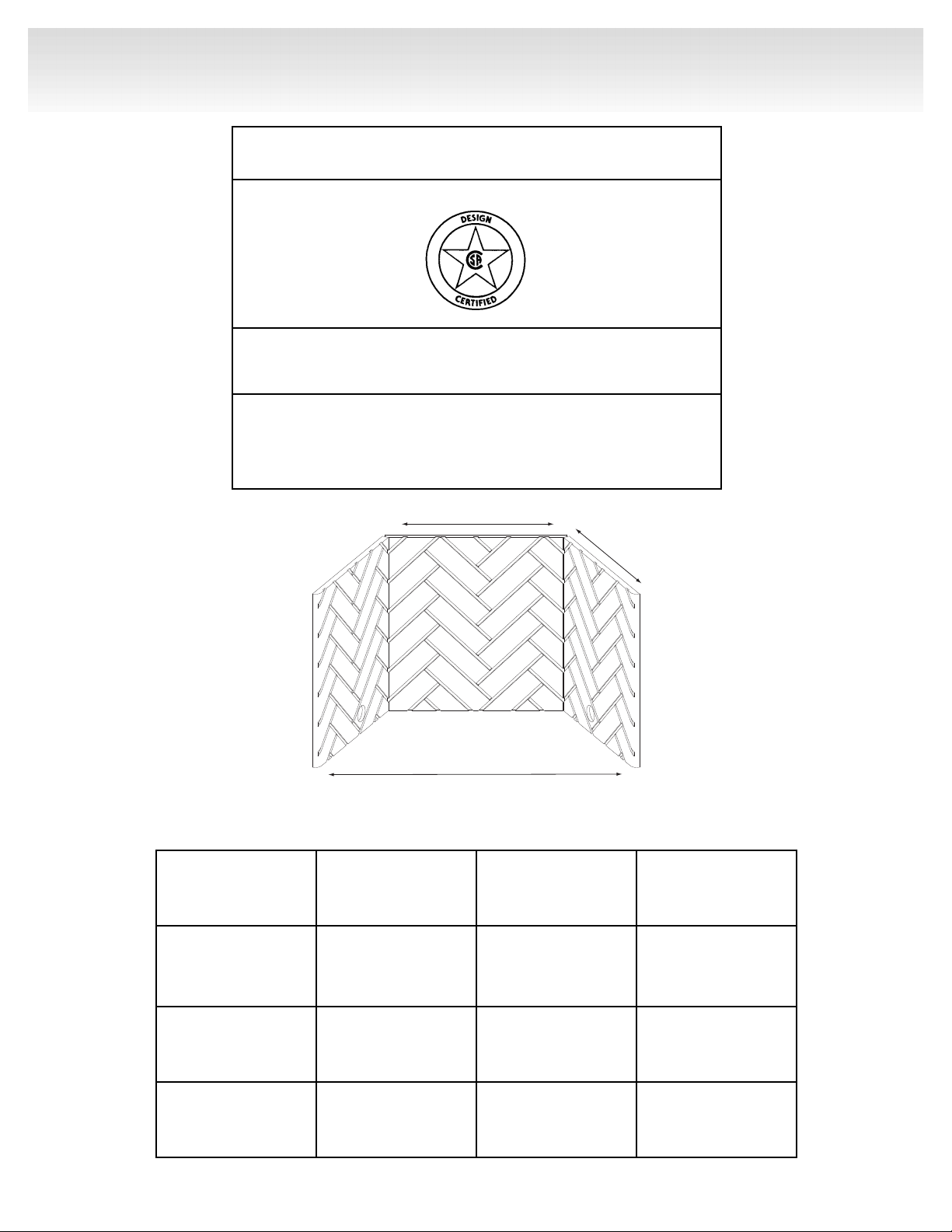

A

B

C

VFBC 32, VFBC 36, VFBC 42

Certified To

Design Certified

Certified To IAS 2-97 Ventless Firebox Enclosures For

Gas Fired Decorative Type Unvented Room Heaters

For use with

Any ANSI Z21.11.2

Unvented Room Heaters

Fig. 1: Firebox

Internal

Dimensions

Hearth Dimensions

MODEL

Front Width

(Brick to Brick)

A

Back Width

(Back to Brick)

B

Hearth

Depth

C

VFBC32

VFBC36

VFBC42

26"

(660 mm)

30"

(762 mm)

36"

(915 mm)

5

16"

(406 mm)

20"

(507 mm)

26"

(660 mm)

17"

(432mm)

17"

(432mm)

17"

(432mm)

Page 6

Framing Specifications

A

C

B

D

F

E

K

L

H

J

G

P

M

N

P

Fig. 2

VFBC 32 VFBC 36 VFBC 42

A 31.75" 35.75 41.75"

B 23" 23" 23"

C 35" 39" 45"

D 8.5" 8.5" 8.5"

E 38" 38" 38"

F 40.15" 40.15" 40.15"

G 10.3" 10.3" 10.3"

H 19" 19" 19"

J 10.5" 10.5" 10.5"

K 22" 26" 32"

L 20.3" 20.3" 20.3"

M 60" 64" 70"

N 30.5" 32.5" 35.75"

P 42.5" 45.5" 49.75"

6

Page 7

Installation and Instructions

Wall

Full Room Projection

Flush

Partial

Room

Projection

Corner

Room Divider

Locating the Fireplace

Figure 3 shows some of the many ways your

fireplace may be installed. Consider the traffic pattern

in your room and the location of doors and windows.

oving air from ceiling fans, open doors and hot air

M

grills may cause the flames to soot. If a disturbance is

found that affects the flames, it must be eliminated by

turning off the ceiling fan, closing the door or closing or

moving the hot register. A corner location may be best

where space is limited.

Your fireplace weighs no more than some of your

fine furniture. If the fireplace is located near a load

bearing wall, additional supports to the foundation will

not be necessary.

HEAVY FACINGS SUCH AS BRICK, STONE,

ETC., MAY REQUIRE ADDITIONAL FOUNDATION

SUPPORT. ALTHOUGH THIS UNIT MAY BE

INSTALLED ON COMBUSTIBLE SURFACES, IT

MUST NOT BE INSTALLED ON CARPET OR VINYL.

Gas Line Installation

Plumbing connection should only be

performed by a qualified, licensed plumber. Main

gas supply must be off when plumbing gas line to

fireplace or performing service

supply propane/L.P.G. from the tank must be

internally tinned.

OTE: When connecting propane/L.P.G. vent-free

N

room heaters, you must use pipe sealant resistant to

propane/L.P.G.

IMPORTANT: Hold heater regulator with a wrench

to prevent movement when connecting to inlet piping.

Check Gas Type: The gas supply must be he

same as stated on the heater's rating plate. If the gas

supply is different, DO NOT INSTALL THE HEATER.

Contact our dealer for the correct model.

Connecting directly to an unregulated

propane/L.P.G. tank can cause an explosion.

After completing connection, test all gas joints from

the gas meter to the gas heater regulator for leaks.

Using water soap and water solution or a gas sniffer.

DO NOT USE AN OPEN FLAME.

Do not connect directly to natural gas

1/2 PSI or 2 PSI systems. Always make sure natural

gas pressure is regulated 10.5 w.c. (maximum

before operating unit).

Consult all local codes. All gas piping must be

installed to comply with local codes, or in the absence

of local codes, with the latest edition of the national

Fuel Gas Coe ANSI Z223.1/NFPA54.

The 1⁄2" gas line may enter either from the left side

or the right side of the firebox. Gas access holes are

provided on both sides of the firebox.

Install a

the firebox. Outside the firebox, the gas line connects

to a gas shut-off valve recessed flush into the wall or

The valve should be controlled by a removable

.

floor

valve key for safety.

An

and plugged

installed upstream of the heater.

A sediment trap may be upstream of the heater

to prevent moisture and contaminants from passing

through trap to the heater controls and burners.

Failure to do so could prevent the heater from

operating reliably

An external regulator must be used on all

propane/L.P.G. heaters, in addition to the regulator

fitted to the heater

to 13" w.c. (maximum).

1

⁄2" gas line through the hole provided in

ANSI approved manual shut-of

1

⁄8" NPT

pressure tapping point must be

. Consult applicable codes.

, to reduce the supply tank pressure

Any copper tubing used to

f valve, union

Fig. 3: Locating the Fireplace

7

Page 8

Installation and Instructions

A

B

Mantel

Guard

Mantel

Fireplace

Opening

A heat reducing mantel guard is shipped with

Drafts

Do not locate the fireplace in high traffic areas or

areas exposed to high drafts and winds. Locate the

ireplace away from furniture and draperies.

f

Fireplace Clearances

The fireplace may be placed directly on a

combustible floor, against a combustible wall at

marked clearances or on a raised wooden platform.

If the fireplace is to be installed on a raised

wooden platform, the platform must be a continuous

level surface. The fireplace must be secured in place

so it cannot shift positions. The nailing flanges on the

sides of the firebox make securing it to the framing

easy. They were designed to allow the installation of

wallboard or plywood flush with the face of the fireplace.

Only the header (Fig. 2, page 6) may rest on the

standoffs on top of the firebox.

b)

the fireplace. Use of this mantel guard is

required in order to reduce mantel heights as

shown in figure 5. When the mantel guard is

installed, a combustible mantel piece may

roject 2" from the wall at 6" above the

p

fireplace opening. A 6" mantel projection at 13"

above the fireplace opening and a 10" projection at 22" above the opening. (Fig 4 and 6)

c) If the fireplace has no mantelpiece, then the

heat resistant material must extend upwards a

distance of at least 9" from the fireplace

opening. (Fig. 4)

When the fireplace is installed over carpeting,

vinyl, tile or any combustible material other than wood

flooring, it must be installed on a metal or wood panel

extending its full width and depth. Alternatively, the

carpeting, vinyl, tile, etc., may be removed from

beneath the fireplace before installing.

COMBUSTIBLE MATERIALS MUST NOT BE

INSTALLED OVER OR TOUCH ANY BLACK PAINTED

SURFACE.

Clearances

To ensure a safe installation the following

instructions must be carefully observed.

1.

Sidewall Clearances: Clearances from the side of

the fireplace opening to any combustible wall

should not be less that 9".

2. Ceiling Clearances: The ceiling height should

not be less than 42" from the top of the

fireplace opening.

Mantel Clearances:

3.

a) Noncombustible materials used in this

installation such as slate, marble, tile, etc.

must comply with local ,state ,national codes

and manufactures specifications. Do not install

a combustible material behind sheet metal.

Failure to use noncombustible materials above

the opening as specified in these instructions

may cause damage to the materials used and

create a fire hazard.

Fig. 4

8

Page 9

Installation and Instructions

B

DETAIL B

To install the required mantel guard you will need a

lathead screwdriver. The mantel guard has seven

f

holes along the top edge. Loosen seven screws in the

upper channel (top front edge) of the firebox. Line up

slots in mantel guard with holes in the upper channel

of the firebox. The mantel guard will fit tightly in the

top front edge of the fireplace opening. Once guard is

secure tighten all screws.

The required firebox canopy

(mantel guard) supplied with this unit from Sure

Heat (the manufacturer) must not be modified or

replaced with a canopy (mantel guard) that/which

may be provide by the manufacture or supplier of

the decorative room heater.

1) Floor Clearances: No clearance is required if the

appliance is installed per these instructions.

Clearance to Combustible Mantel with Mantel

Guard in place.

Mantel Depth

(A)

2" 4" 6" 8" 10"

Installing the Firebox

Installation must conform with local

codes, or in the absence of local codes,

with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54.

This list of specific instructions will help you

make certain that every installation operation is done

correctly. Complete the installation steps in the

sequence shown.

LOCAL BUILDING CODES SHOULD BE

CONSUL

PARTICULAR REQUIREMENTS CONCERNING THE

INSTALLATION OF FACTORY BUILT FIREPLACES.

consideration the factors previously outlined in the

Locating the Fireplace section of this manual.

Step 1: Framing the Firebox

TED IN ALL CASES AS TO THE

Select the location for the fireplace by taking into

The width of the framed openings must be 37" for

32" models, 41" for 36" models or 47" for 42"

models. (Fig. 2, page 6)

The entire fireplace can be elevated above the

floor to achieve a raised hearth effect. This can be

done by adding a small platform to achieve the

desired height.

Clearance

Fireplace

Opening (B)

Fig. 5 Chart

Fig. 6

6.5" 10" 13" 17" 22"

Step 2: Install the Firebox

Install the firebox into the framed opening by

setting it directly in front of the opening and

sliding it into the proper position.

Step 3: Level the Firebox

Check the level of the firebox on the top edge of

the fireplace face. Shim if necessary

.

9

Page 10

Installation and Instructions

DETAIL C

C

Stand

Off

Caulking or Sealant

Noncombustible

Insulation

Finishing Material

Top View

Side View

Caulking or Sealant

Noncombustible Material

Finishing Material

Insulation

Stud

tep 4: Secure the Firebox

S

Four (4) nailing flanges are supplied with the

fireplace to level the box and secure firmly in

place; Bend the nailing flanges from the sides of

the fireplace as shown in Figure 7.

Note: The nailing flanges have two (2) sets of

holes to allow for adjustment for 1⁄2" or 1" offset of

the face of the unit. When installing the nailing

flanges, choose the set of holes on the nailing

flange that fit with your application.

Note: This firebox employs spacers, stand offs and

nailing flanges to inhibit contact of parts of the firebox with combustible construction .

do not alter the spacers or divert

from their intended use or notch the framing in

any manner.

Step 5: Gas Piping and Connection

The gas piping must be installed in accordance

with local codes or, in the absence of local codes,

in accordance with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, latest edition.

Piping should be tested for leaks prior to final wall

installation. Test for leaks, using a soap and water

solution or any acceptable solution or mechanical

gas leak detector, after completing the connection.

DO NOT USE OPEN FLAME.

tep 6: Optional Procedure for

S

Cold Climate Installations

The insulation and sealing of the enclosure around

the fireplace is very important in cold climates. If

the enclosure is insulated and sealed properly, you

can avoid future cold air problems. The time taken

to install the firebox correctly is well worthwhile.

The following steps are to stop potential cold air

problems. (Do not use Kraft Faced insulation paper faced)

Insulation of the Fireplace Enclosure

When in a chase or an outside wall, the fireplace

enclosure should be insulated like any other wall of

your home. Insulation should be installed on the

outside wall(s) and the wall about the fireplace.

(Do not use Kraft Faced insulation - paper faced.)

Insulate to Seal Under the Fireplace

Insulating under the fireplace is beneficial for

installations on a concrete slab in cold weather

climates. The fireplace should be placed on insulating

board. It is important that a hard, rigid surface be

maintained, so do not use fiberglass insulation for

this purpose.

WHEN INSTALLING A FIREPLACE

IN AN INSULATED ENCLOSURE, BE SURE TO

MAINTAIN ALL MARKED AIR SPACES. DO NOT

USE KRAFT (PAPER FACED) INSULATION .

Fig. 7

Seal Seams

Sealing the seams of the fireplace is beneficial for

installations in cold weather climates where the outer

wall meets the bottom pan and the front face.

seal between the fireplace and finishing materials.

Use high temperature caulk. Refer to Figure 8 for

details of sealing spaces between the fireplace and

finishing materials.

10

Also

Fig. 8

Page 11

Installation and Instructions

Combustible Platform

Combustibles Allowed

(no carpet or vinyl)

Surround

1/2”

Seal with Non-Combustible Material

Hearth Brick

Hearth

Extension

Finishing the Fireplace

There are a wide variety of finishing materials

available for your fireplace from formal wall treatments

with marble and mantles to rustic wood paneling, stone

r brick.

o

IT IS IMPORTANT THAT THE BLACK FACE OF

THE FIREPLACE NOT BE COVERED WITH ANY

TYPE OF COMBUSTIBLE MATERIAL.

Noncombustible facing materials such as marble,

brick or ceramic tile may overlap the black face of the

fireplace up to the opening on either side of the

fireplace. Seal all joints between the black fireplace

face and the wall covering with a heat-resistant

material such as rock wool insulation or mortar. Be

sure to use high temperature adhesive or mortar when

anchoring brick, stone or tile to the face of the

fireplace. Check to see whether man-made brick and

stone are made of noncombustible materials before

using them on the face of the fireplace. Some of these

products contain combustible materials. Combustible

wall coverings such as paneling or wallboard may not

overlap the black face of the fireplace. The space

between the wall covering and the fireplace should be

sealed with a heat-resistant material such as rock wool

insulation or mortar.

NOTE: An “L” shaped steel lintel must be installed

across the top of the firebox opening where facing

materials such as brick or stone are used on the face

of the firebox. It acts as a support/firestop. It should be

attached to the face of the fireplace with screws and

sealed to the fireplace with a heat-resistant sealer.

Hearth Extension

An optional hearth extension may be used, but is

not required for these fireboxes.

A raised hearth extension may be used as shown

in Figure 9.

Install Optional Outside Air Kit

The VAK1 Outside Air Kit can be installed to bring

combustion air to the heated room air. The air drawn

into the heated room air from outside the home or

unheated area helps relieve the pressure in the home.

The duct termination should be located so it is

exposed to an out-of-doors opening of at least 100

square inches. If the duct termination must be located

in a crawl space or basement, be sure the termination

area has 100 square inches of ventilation opening to

outside air.

The duct termination must be located so it does

not compete for air flow with exhaust fans, gas vent

hoods or other air consuming devices or appliances. It

must not be obstructed by rafters, insulation materials

or other obstructions. The less restrictive the air

supply, the better the outside air kits will perform.

It is good practice to protect your hands and

eyes during installation by wearing work gloves and

safety glasses.

Do not install termination into a garage

or other area that could contain flammable liquids

or fumes, into a confined attic space or non

ventilated soffit .

These vent free fireplaces are not to be

used with any TYPE or MODEL of glass doors.

Fireplace screens must be in

the closed position across the entire hearth

opening prior to the operation of the decorative

room heater.

NOTE: Information on provisions for adequate

combustion and ventilation air are located in the

unvented room heaters installation instructions.

Fig. 9

11

Page 12

Installation and Instructions

A

DETAIL A

Ceiling

Duct

Duct

Termination

40ʼ Max

Duct Run

Soffit Termination

Exterior Wall Termination

Exterior Wall

40ʼ Max. Duct Run

Duct

Duct Te rmination

Rain Cap

Installation Instructions

etermine the location of the fireplace as

D

described in the fireplace installation manual. Then

plan the location of the duct termination and the route

of the duct run between the fireplace and the

duct termination.

Duct run must be limited to a maximum distance

of 40' (12.2m) from the fireplace pipe collar to duct

termination. This will provide the least restriction to air

flow. No more than four (4) 90º elbows can be used.

Duct run may be horizontal, vertical, inclined or any

combination of these. (Fig. 10) You are now ready to

install the Outside Air Kit.

Soffit Termination

40' Max

uct Run

D

1. Remove the screws retaining the outside air

coverplate, if provided. (Located on the left side of

front open units, on backside of multi-sided units.)

Discard coverplate. (Fig. 11)

2. Secure the inlet collar assembly to the outer casing

with four screws (screws not provided).

3. Slide the duct over the collar and attach the duct to

the collar using the plastic tie straps or three (3)

screws (screws not provided). Continue attaching

the ducting together using three (3) screws at each

joint until you have installed sufficient duct to arrive

at your duct termination locations.

4. At the termination end, install the duct termination.

This should be installed from the outside of the

home. Cut a hole in the desired location

approximately 4" in diameter, caulk around the

hole, and slide the termination through the opening

from outside the home.

The termination/rain cap

should be caulked around its perimeter to assure

a tight seal. The rain cap opening should be

positioned downward.

The Outside Air Kit is now installed and ready

for use.

xterior Wall Termination

E

Exterior Wall

Rain Cap

Duct Termination

Fig. 10

40' Max. Duct Run

Duct

Fig. 11

12

Page 13

Installation and Instructions

M

FIREBOX ENCLOSURE

INSTALLER CONNECT TO

110 VAC HOUSE WIRING

PER APPLICABLE

LOCAL CODES

BLOWER MOTOR ACCESSORY

SPST BLOWER SWITCH

STEEL HANDI-BOX

W/SINGLE GANG

RECEPTACLE

VFBC WIRING DIAGRAM - ALL SIZES

Electrical Junction Box

Wiring should be connected at a customer

provided junction box, outside the firebox, prior to the

installation of the blower kit.

Electrical Services

If an electrical supply of 120V is being roughed in

to the fireplace junction box to provide for future

installation of the optional blower kit, the wiring should

be connected to the junction box.

NOTE: All electrical connections (Fig. 12) are to

be made in accordance with CSA Standard C22.1

Canadian Electrical Code part 1 or with the National

Electrical Code, ANSI/NFPA 70 (latest edition) and/or

in accordance with local codes.

Install Optional Blower/Fan Kit – BL102

NOTE: A FEW BASIC SAFETY RULES BEFORE

YOU START:

1. Make sure you have and are using/wearing proper

personal safety devices such as but not limited to

gloves, safety eye glasses/eye protection .

2. Check to ensure that electrical service has been

provided to the junction box located in the bottom

chamber of the firebox.

3. Check local building codes before installation of the

firebox and blower kit.

All wiring must be installed and/or inspected as

4.

necessary to comply with the local authority

having jurisdiction.

5. The circuit breaker controlling the power supply to

the pre-wired junction box in the appliance must be

in the off position before beginning installation of

the blower .

6. The appliance, when installed, must be electrically

grounded in accordance with local codes or – in

the absence of local codes – with the National

Electrical Code, ANSI/NFPA 70 or the Canadian

Electrical Code, CSA C22.1

Fig. 12

13

Page 14

Installation and Instructions

Blower outlet duct lines up with cut outs.

Remove cover

to install fan.

Read all the installation instructions for

the appliance before beginning the installation of

the blower kit – BL102.

BL102 Blower Installation

Step 1.

Carefully unpack the blower assembly and

completely familiarize yourself with the parts. Care

should be taken not to damage the fan blades.

NOTE: If you are uncertain or unclear with

any instruction or parts, stop and immediately

contact the seller or manufacturer listed on

these instructions for further explanation

and/or direction.

Step 2.

Locate the blower access cutout found at the rear

center of the hearth pan (floor). Next, remove

cover and prepare the blower by removing the

tape backing from the velcro on the blower

housing. Place blower assembly against the

back cutout with the blower outlet duct pointing

towards the rear/back of the unit. Then, press

firmly to attach the tape to the bottom of the

fireplace. (Fig. 13)

Fig. 13

Step 3.

Locate the junction box cutout found on the right

side of the hearth pan. Rout the power cord under

the hearth pan and plug it into the receptacle outlet

found in the junction box. (Fig. 14)

Step 4.

Turn power back on and test the blower operation.

Step 5.

Replace blower cutout cover to original location

and position on the hearth pan.

Fig. 14

14

Page 15

Parts and Servicing

12 3

6

4

5

7 is not pictured

1 Firebrick Left 23321101 23361101 23421101

2 Firebrick Middle 23321201 23361201 23421201

3 Firebrick Right 23361301 23361301 23361301

4 Screen Mesh Wire 20323001 20363001 20423001

5 Mantel Guard 23321401 23361401 23421401

6 Screen Mesh 22322001 22362001 22422001

7 Outside Air Kit 20005001 20005001 20005001

Contact Sure Heat Manufacturing for questions

concerning prices and policies covering replacement

parts. Parts may be ordered through your Sureheat

distributor or dealer.

ou will need the correct name, part number

Y

and model number of the appliance when ordering

replacement parts.

Should you need additional information beyond

what your dealer can furnish, contact:

VFBC32 VFBC36 VFBC42

Servicing

Repair and replacement work should only be done

by a qualified service person.

Always shut off the gas supply and make sure

the appliance is cool before beginning any

service operation.

Always check for gas leaks after servicing.

Sure Heat Manufacturing

3130 Moon Station Road

Kennesaw, GA 30144

(800) 229-5647

www.sureheat.com

15

Page 16

LIMITED LIFETIME WARRANTY

Limited Warranty shall apply to the original purchaser at the original installation point only

The following components are warranted for life to the original owner, subject of proof of purchase: Firebox, Combustion

Changer, Heat Exchanger.

General Warranty: This Limited Lifetime Warranty will be void if the appliance is not installed by a qualified installer in

accordance with the installation instructions. The Limited Lifetime Warranty will also be void if the appliance is not

operated and maintained according to the operating instructions supplied with the appliance, and does not extend to (1)

firebox assembly damage by accident, neglect, misuse, abuse, alteration, negligence of others, including the installation

thereof by unqualified installers, (2) the costs of removal, reinstallation or transportation of defective parts on the

appliance, or (3) incidental or consequential damage. All service work must be performed by an authorized

service representative.

This warranty is expressly in lieu of other warranties, express or implied, including the warranty of the merchantability of

fitness for the purpose and of all other obligations or liabilities. Sure Heat Mfg. Co. does not assume for it any otter

obligations or liabilities in connection with the sale or use of the appliance. In states that do not allow limitation on how

long an implied warranty lasts, or do not allow exclusion of indirect damage, those limitations of exclusions may not apply

to you. You may also have the additional rights not covered in this Limited Lifetime Warranty.

Sure Heat Mfg. Co. reserves the right to investigate any and all claims against the Limited Lifetime Warranty and decide

upon method of settlement.

All costs for removal and reinstallation are the expressed responsibility of the purchaser.

For repair or replacement of a defective part or parts, contact our customer service department at 1-800-229-5647. You

will be asked to provide valid warranty registration, proof of purchase and model number.

Purchased From: ______________________________________________Date: __________________________

Size: o VFBC32 o VFBC36 o VFBC42

Name ______________________________________Date: ____________Phone ( ) __________________

Address ____________________________________________________________________________________

City ________________________________________State ____________Zip __________________________

E-mail ______________________________________________________________________________________

If you have other questions, please contact Customer Service Hotline

(800) 229-5647

RMH-130-0CD1011

11/09/2005

16

Loading...

Loading...