Superwinch C Series, 03000, 03001, 03003, 03002 Owner's Manual

...

VALABLE A TRAVERS LE MONDE

GARANTIE LIMITÉE. Superwinch, Inc. (le “Vendeur”) garantit à l’acheteur d’origine (“vous”) que

toutes les pièces et composants, à l’exception du câble métallique, sont sans vice de matériaux ou

de fabrication, et ce, pendant une période d’un (1) an à compter de la date d’achat prouvable.

Tout produit Superwinch défectueux sera réparé ou remplacé sans dépenses de votre part si vous

respectez ces procédures. Les garanties énoncées par les présentes sont exclusives tiennent lieu de

toutes autres garanties expresses ou implicites.

PROCÉDURE DE RECOURS À LA GARANTIE LIMITEE.

Dès découverte d’un produit Superwinch défectueux, vous devrez envoyer à Superwinch, à l’usine

ou à un Centre de réparation autorisé par l’usine, une notification écrite dudit défaut et vous

devrez envoyer par courrier ou autre service de livraison le Superwinch défectueux, port et frais

postaux payés à l’avance. Les réparations ou remplacements par le Vendeur conformément à la

présente Garantie s’effectueront normalement dans les quinze (15) jours ouvrables suivant réception du Superwinch défectueux. Le Vendeur ou ses Agents autorisés peut facturer des frais

raisonnables pour les pièces et la main d’oeuvre en cas de réparation non couverte par la présente

Garantie limitée.

LIMITATIONS ET EXCLUSIONS EN CE QUI CONCERNE LA GARANTIE ET LES REMÈDES.

La réparation et/ou le remplacement de tout Superwinch défectueux ou de tout composant d’un

tel Superwinch tel que convenu par les présentes est votre remède exclusif. Les exclusions et limitations de garanties et les limitations de REMEDES ci-dessous seront expressément applicables :

A. Garanties expresses . Le Vendeur garantit que le Superwinch est tel qu’il est décrit dans le

“Mode d’emploi Superwinch” fourni avec la présente; aucune autre garantie expresse n’est donnée en ce qui concerne le Superwinch. Si un modèle ou échantillon vous a été montRé, ledit modèle ou échantillon a été utilisé à des fins d’illustration uniquement et ne sera pas considéré une

garantie que le Superwinch sera conforme au modèle ou à l’échantillon. LE VENDEUR NE DONNE

AUCUNE GARANTIE EXPRESSE EN CE QUI CONCERNE LE CABLE MÉTALLIQUE INCORPORÉ AU PRODUIT.

B. Garantie implicite . LA GARANTIE IMPLICITE DE L’APTITUDE À LA VENTE ET TOUTE AUTRE

GARANTIE IMPLICITE S’APPLIQUERA UNIQUEMENT POUR UNE DURÉE D’UN (1) AN À COMPTER DE

LA DATE D’ACHAT PROUVABLE. LE CABLE MÉTALLIQUE EST VENDU “TEL QUEL” SANS AUTRE

GARANTIE IMPLICITE. CERTAINS ÉTATS AMÉRICAINS NE PERMETTENT PAS DE LIMITER LA DURÉE

DES GARANTIES IMPLICITES; IL EST DONC POSSIBLE QUE LA LIMITATION CI-DESSUS NE S’APPLIQUE

PAS À VOTRE CAS.

C. Dommages indirects. SUJET AUX OBLIGATIONS DE LA GARANTIE LIMITÉE DU VENDEUR

ÉNONCÉES DANS LE PRÉSENT DOCUMENT, LE VENDEUR NE SERA AUCUNEMENT RESPONSABLE DE

DOMMAGES INDIRECTS, DE QUELQUE NATURE QUE CE SOIT, NI DE DOMMAGES INDIRECTS À LA

PROPRIÉTÉ, NI DE PERTES DE PROFITS, NI DE PERTES D’UTILISATION POUVANT SURVENIR À CAUSE

D’UN DÉFAUT, D’UN MAUVAIS FONCTIONNEMENT OU D’UNE PANNE QUELCONQUE DU SUPERWINCH CI-JOINT. CERTAINS ÉTATS AMÉRICAINS NE PERMETTENT PAS D’EXCLURE OU DE LIMITER

LES DOMMAGES INDIRECTS; IL EST DONC POSSIBLE QUE LA LIMITATION CI-DESSUS NE S’APPLIQUE

PAS À VOTRE CAS.

D. Condition de la garantie. Le Vendeur ne sera pas tenu de se conformer aux obligations de

garantie fournies par les présentes si la cause du défaut, du mauvais fonctionnement ou de la

panne du Superwinch est un dommage (ne résultant pas de composants défectueux ou qui fonctionnent mal) ou une utilisation déraisonnable par vous. Le terme Utilisation déraisonnable comprend mais ne est pas limité au manquement à la maintenance, à l’installation et à l’utilisation

raisonnables et nécessaires conformément aux consignes contenues dans le Mode d’emploi

Superwinch, et à l’utilisation du Superwinch pour des charges supérieures à celle figurant dans le

Mode d’emploi pour le modèle en question. La responsabilité du Vendeur sous la présente

garantie ou pour toute perte du produit Superwinch ou dommage à celui-ci ne dépassera pas le

coût de correction des défauts du produit Superwinch ou de remplacement de celui-ci, et lors de

l’expiration de la période de garantie, toute telle responsabilité prendra fin. Les agents, distributeurs et employés du Vendeur ne sont pas autorisés à modifier la présente garantie ni à donner

d’autres garanties complémentaires obligatoires pour le Vendeur. Toute déclaration supplémentaire, qu’elle soit écrite ou orale, ne constituera donc pas une garantie et ne devra pas être considérée comme valable.

REMEDES LÉGAUX DE L’ACHETEUR. Cette garantie limitée vous donne des droits légaux spécifiques

et il est possible que vous ayez d’autres droits qui varient d’un état à l’autre aux Etats-Unis et d’un

pays à l’autre. Vous avez également des droits de garantie implicite. En cas de problème avec le

service ou la performance suivant la garantie limitée, il est possible que vous puissiez intenter une

action en justice devant la Cour des Prudhommes (“small claims court”), devant le tribunal d’état

ou devant le tribunal fédéral des Etats-Unis ou dans une autre juridiction appropriée en dehors des

Etats-Unis.

QUESTIONS. Toute question en ce qui concerne le respect des garanties énoncées dans les

présentes doit être envoyée, par écrit, à : Superwinch, Inc., Winch Drive, Putnam, CT 08260 U.S.A.

ou à Superwinch Limited, Abbey Rise, Whitchurch Road

GARANTIE LIMITÉE

OWNER’ S MANUAL

INSTALLATION • OPERATION • MAINTENANCE

SAFETY PRECAUTIONS • REPAIR PARTS

C-SERIES

12 & 24 Volt DC Electric Winch

Models 03000, 03001, 03002,

03003, 03005, 03010

READ AND UNDERSTAND THIS MANUAL

BEFORE INSTALLATION AND OPERATION

OF YOUR SUPERWINCH PRODUCT.

89-10865 Rev - 2/20/03

Superwinch, Inc. Superwinch, Ltd.

Winch Drive Abbey Rise, Whitchurch Road

Putnam, CT 06260 Tavistock, Devon PL 19 9DR

U.S.A. England

Tel. (860) 928-7787 Tel. +44 (0) 1822 614101

Fax (860) 963-0811 Fax +44 (0) 1822 615204

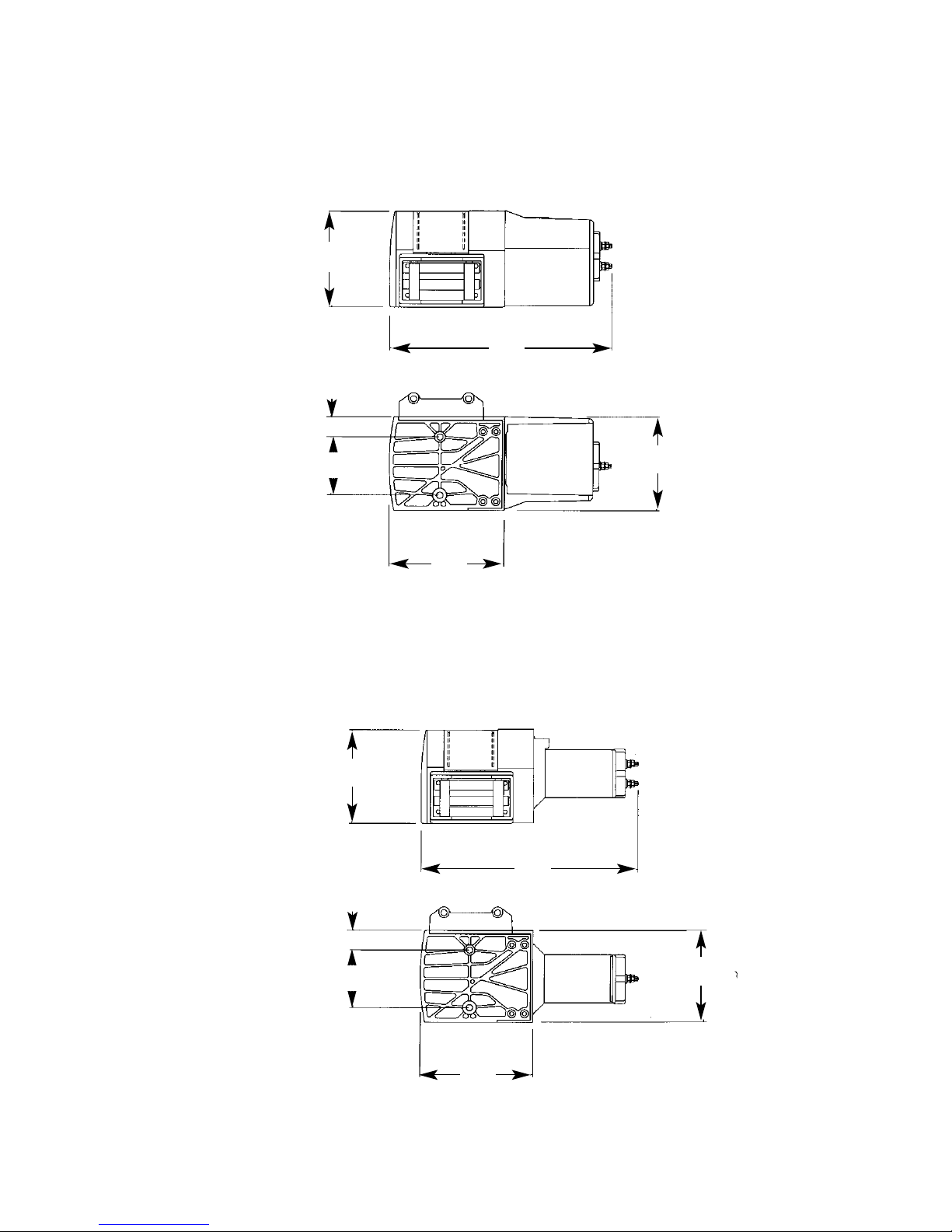

Model 03000

Model 03001

Model 03003

Models

03002

03005

03010

2

The C1000 electric winch is for intermittent duty only. Motor cool-down time

is required. Can be mounted horizontally or vertically. Winch can be

utilized in a variety of lifting operations involving machinery, trucks, boats,

farm implements, etc. Equipped with DC motor, permanently lubricated/sealed

gear box, switch with harness assembly, handsaver, and pulley block.

For additional information, consult Specifications and Performance.

DESCRIPTION

UNPACKING

Electric Motor - 1.3 peak hp (0.9

kW) 12 Volt Permanent Magnet.

Gear Ratio . . . . . . . . . . . . . . . 159:1

Braking - A wrap spring brake will

support the load when power to

the motor stops.

Remote Switch - 12’ (3.66m) Hand

held pendant switch assembly with

interlocking reverse switch and trigger.

Working Load* . 1,000 lbs (454 kg)

Safety Factor . . . . . . . . . . . . . . 5:1

(*) Based on first layer performance.

SPECIFICATIONS

This equipment must be used as recommended by the

manufacturer. Failure to follow these recommendations

could endanger your life and/or cause property damage.

Please unpack carefully and read the instructions before beginning. Inspect

carefully for any damage that may have occurred during transit. Check for

loose, missing or damaged parts.

3

Winch assembly with roller fairlead (no wire rope) 1 1 1 1

Winch assembly with roller fairlead (with wire rope) 1 1

Bolts, nuts, lockwashers 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

Flat washers 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea.

Cable ties 5 5 5 5 5 5

Owner’s Manual 1 1 1 1 1 1

Remote control switch 1 1 1 1

Without control switch 1 1

Circuit breaker assembly 1 1 1 1

Pulley block assembly 1

Handsaver 1 1 1 1 1 1

Internal solenoids 111

External solenoids 1

12 Volt Motor 1 1 1 1 1

24 Volt Motor 1

Quantity

Description 03000 03001 03002 03003 03005 03010

Load Speed Current Draw* (amps)

lbs. kg ft/min m/min 12V 24V

0 0 19.5 5.9 30 15

1000 454 14.7 4.5 80 40

(*) Based on first layer performance.

PERFORMANCE

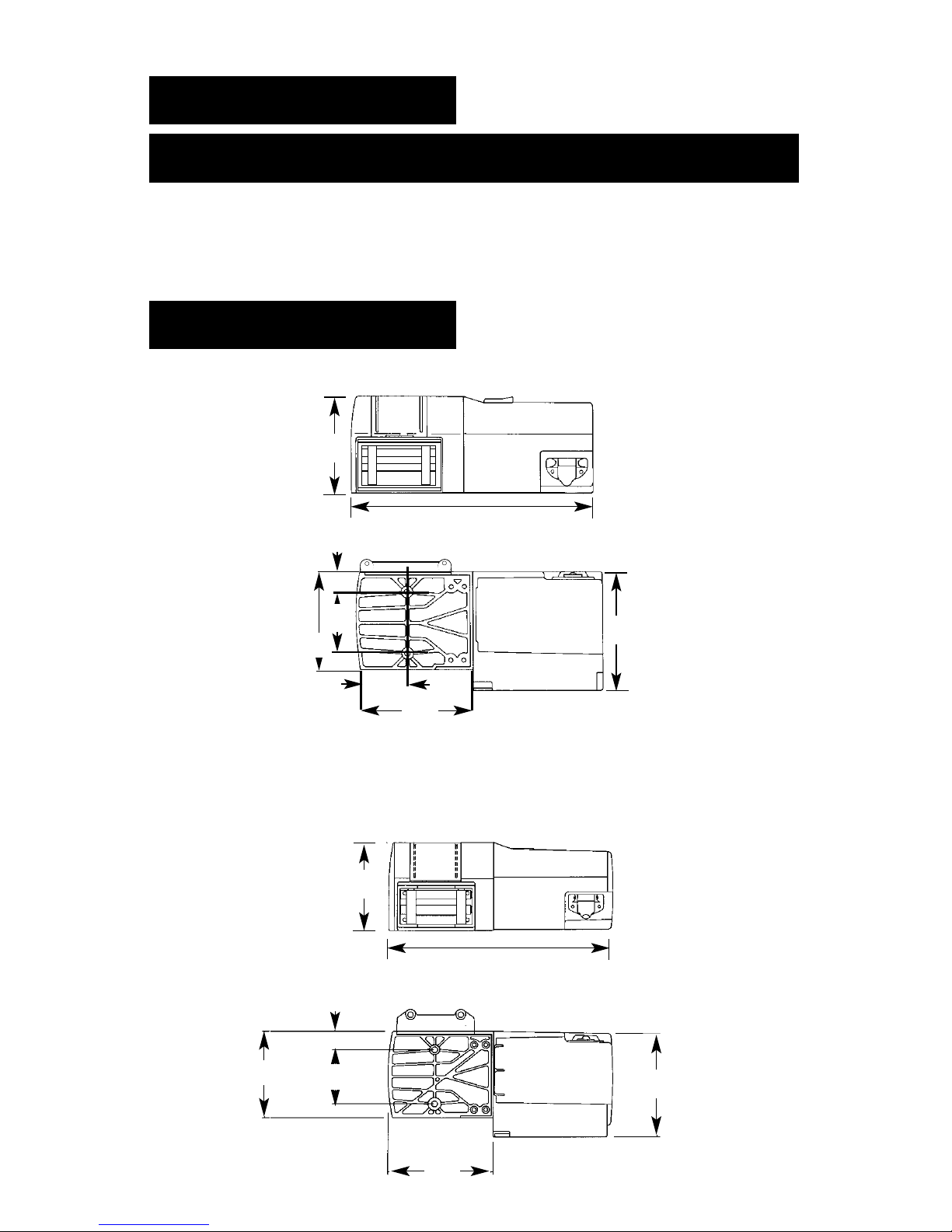

DIMENSIONS

15.1

(383)

3.1

(79)

1.24

(31.5

)

6.0

(152)

5.9

(150)

3.69

(93.7

7.1

(180)

7.2

(183)

MODELS 03002, 03005, 03010

4

MODEL 03000

6.0

(152)

15.1

(383)

7.1

(179)

3.69

(93.7)

5.9

(149)

1.25 (31.8)

7.1

(179)

NOTES:

1. All dimensions are in inches (millimeters).

2. Typical mount is to flat surface capable of handling

the loads. Bolts to be Grade 5 or better.

5

MODEL 03001

MODEL 03003

6.0

(152)

13.6

(346)

1.25 (31.8)

3.69

(93.7)

7.1

(179)

5.9

(149)

6.0

(152)

13.6

(346)

5.9

(149)

7.1

(179)

1.25 (31.8)

3.69

(93.7)

6

Do not use for

lifting, supporting, or transporting people, or over

areas where people are present.

Disconnect power before servicing.

1. READ AND SAVE ALL

INSTRUCTIONS.

2. DO NOT OVERLOAD. See

Performance information. Do not

maintain power to the winch if

the motor stalls. Overloads can

damage the winch and create

unsafe operating conditions.

3. LEARN TO USE WINCH. After

installing your winch, take the

time to practice using it so that

you are comfortable with it when

the need arises. Periodically check

the winch installation to assure

that all bolts are tight.

4. NEVER ALLOW CHILDREN OR

UNTRAINED PERSONNEL TO

OPERATE WINCH.

5. INSPECT ELECTRIC CABLE FIT-

TINGS FOR TIGHTNESS BEFORE

EACH USE.

6. REPLACE DAMAGED OR BROKEN

PARTS IMMEDIATELY WITH MANUFACTURER’S RECOMMENDED

REPLACEMENT PARTS.

Never connect

winch to

110VAC power as fatal shock

may occur.

7. USE CAUTION WHEN using

the winch. KEEP PEOPLE,

PETS, AND PROPERTY

CLEAR OF THE PATH OF THE

LOAD. DO NOT USE WINCH TO

LIFT OR MOVE PEOPLE.

8. DO NOT USE THE WINCH TO

SUPPORT AN UNATTENDED

LOAD.

9. KEEP THE ELECTRIC CABLES FROM

HEAT, OIL, AND SHARP EDGES.

Periodically inspect for damage.

10. DO NOT OPERATE THE WINCH

WHEN TIRED OR UNDER THE

INFLUENCE OF DRUGS,

ALC0HOL, OR MEDICATION.

11. NEVER INSTALL WINCH IN SUCH

A WAY THAT THE WARNING

AND INSTRUCTION LABELS ARE

OBSCURED. Someone who has

not read this manual may need

to see them to understand the

proper operation of the winch.

12. Always operate the winch with

an unobstructed view of the

winching operation.

13. CHECK FOR CORRECT DIRECTION

OF ROTATION BEFORE USING

WINCH. The winch must be

properly wired to ensure correct

direction of drum rotation.

14. REMOVE AND STORE THE

REMOTE PENDANT ASSEMBLY IN

A SAFE PLACE when not in use

to prevent unauthorized use.

15. ALWAYS UNPLUG THE

REMOTE PENDANT BEFORE

WORKING IN OR AROUND

THE ROLLER FAIRLEAD OR

WINCH DRUM (THE DANGER ZONE) to prevent the

winch from being turned on

accidentally. Use handsaver

when winding end of wire rope.

16. When lifting a load, slowly take

up the slack until it becomes

taut. Stop, recheck all winching

connections.

17. DO NOT MACHINE OR WELD

ANY PART OF THE WINCH. Such

alterations may weaken the

structural integrity of the winch,

and void your warranty.

18. Never allow shock loads to be

applied to winch.

GENERAL SAFETY

INFORMATION

LOCATION

Mount the winch to a firm base.

The structure the winch is attached

to must be capable of withstanding

a load greater than 1-1/2 times the

winch’s rated line pull.

The winch can be mounted in a

horizontal or vertical position. Do

not mount the winch where there

would be the possibility of it being

submerged in water. The winch is

weather resistant but not waterproof.

This winch MUST

be mounted

with the pull in the underwind direction. Improper mounting could damage your winch, cause the brake to

not work and void your warranty.

Step (1)

Install structural support for winch.

See "Dimensions" section for winch

dimensions.

Step (2)

Mount the winch to the mount that

you have designed.

Mounting bolts supplied are the

correct length for use with a 1/4"

(6.3mm) thick mounting plate.

Do not substi-

tute any bolt

with strength weaker than

grade 5.

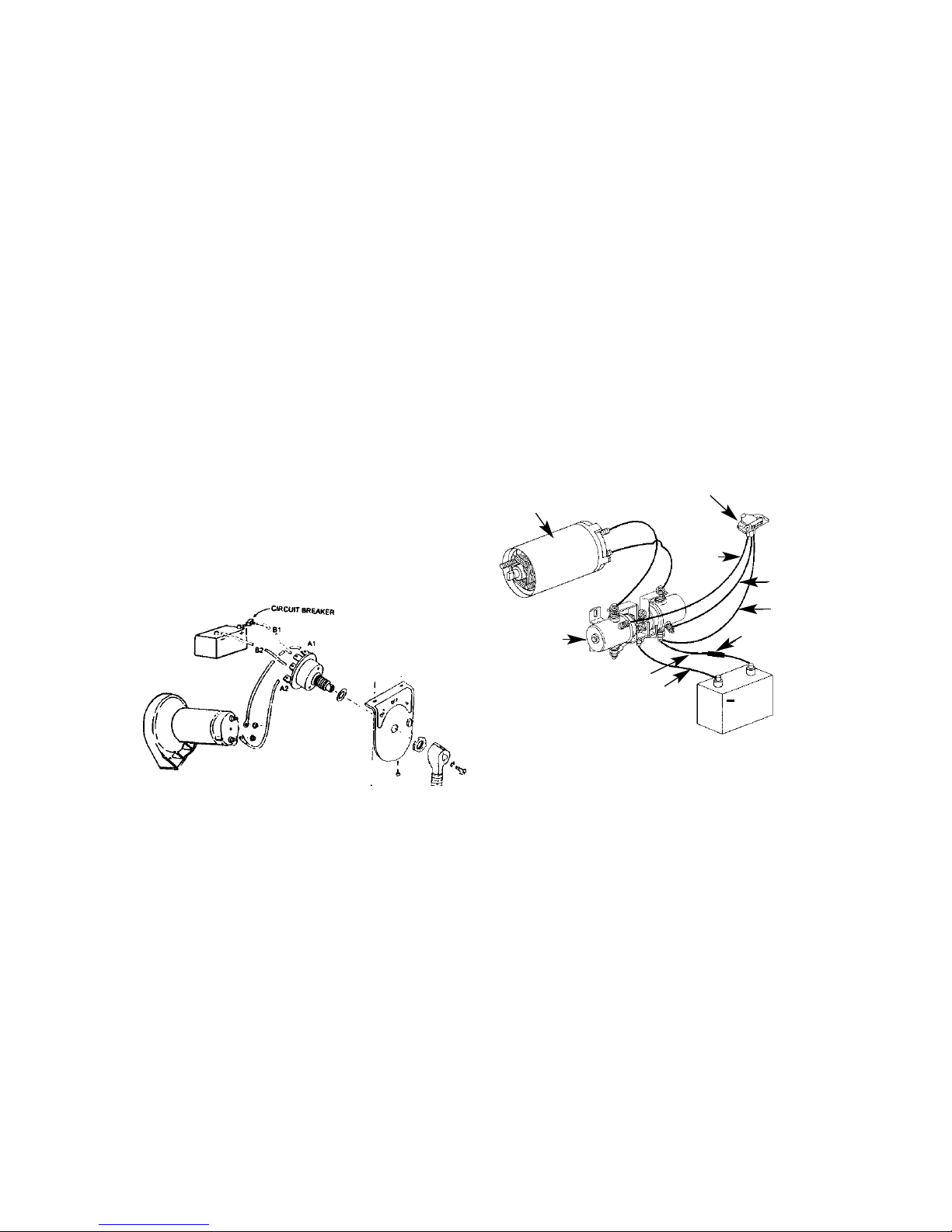

When attaching wire to the motor

terminals and solenoids (relays),

hold the inner nut when tightening

the outer nut. Do not allow the terminals to rotate. It may cause internal wire breakage or part misalignment. Be especially careful in preventing the solenoid (relay) terminals from rotating. Any rotation can

damage the solenoid (See Figure 1).

Step (3)

Disconnect the battery leads.

Batteries con-

tain gases

which are flammable and explosive.

Wear eye protection during installation and remove all metal jewelry.

Do not lean over battery while

making connections.

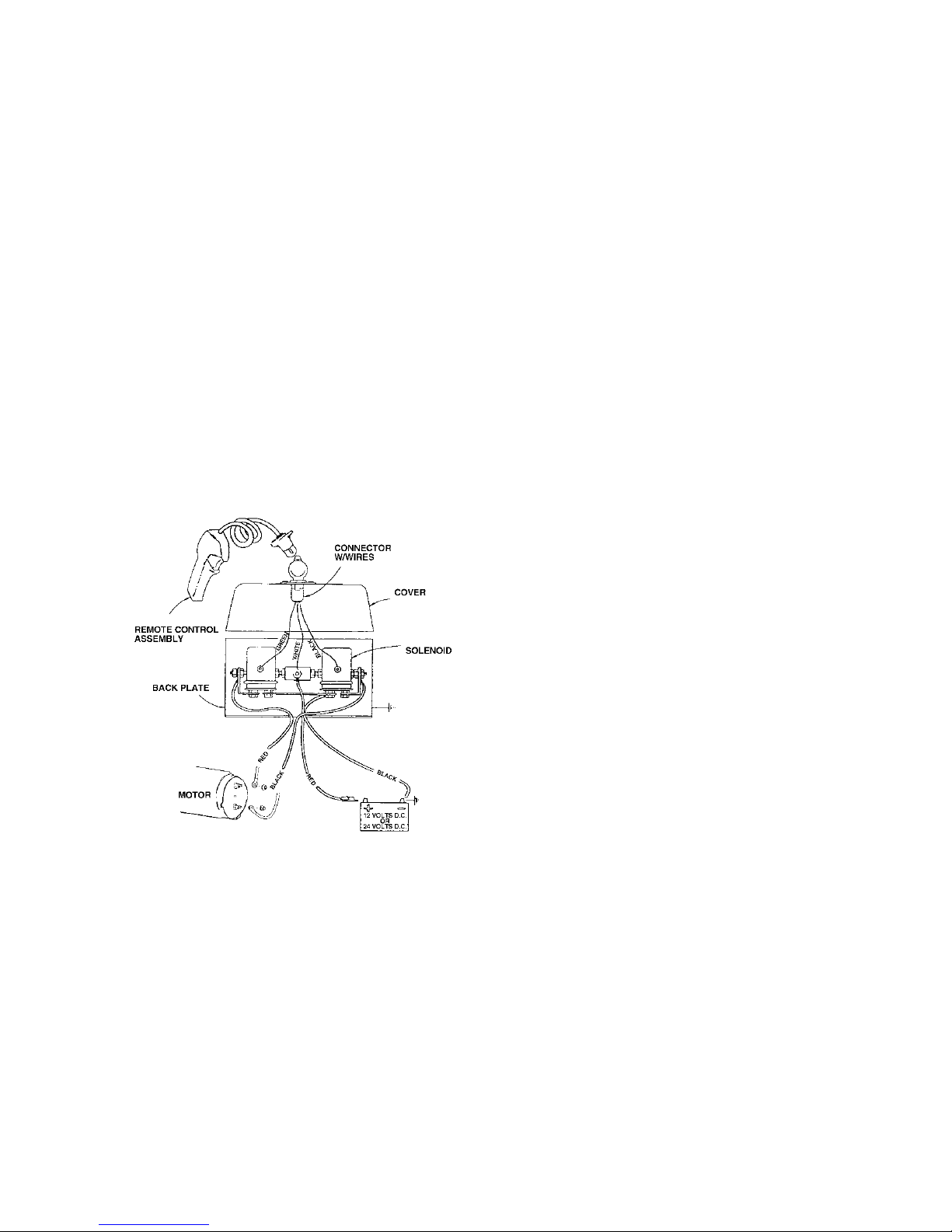

Step (4) Model 03003

Select a convenient location for

mounting the Solenoid Remote

Control Assembly. The solenoid

INSTALLATION

Figure 1

7

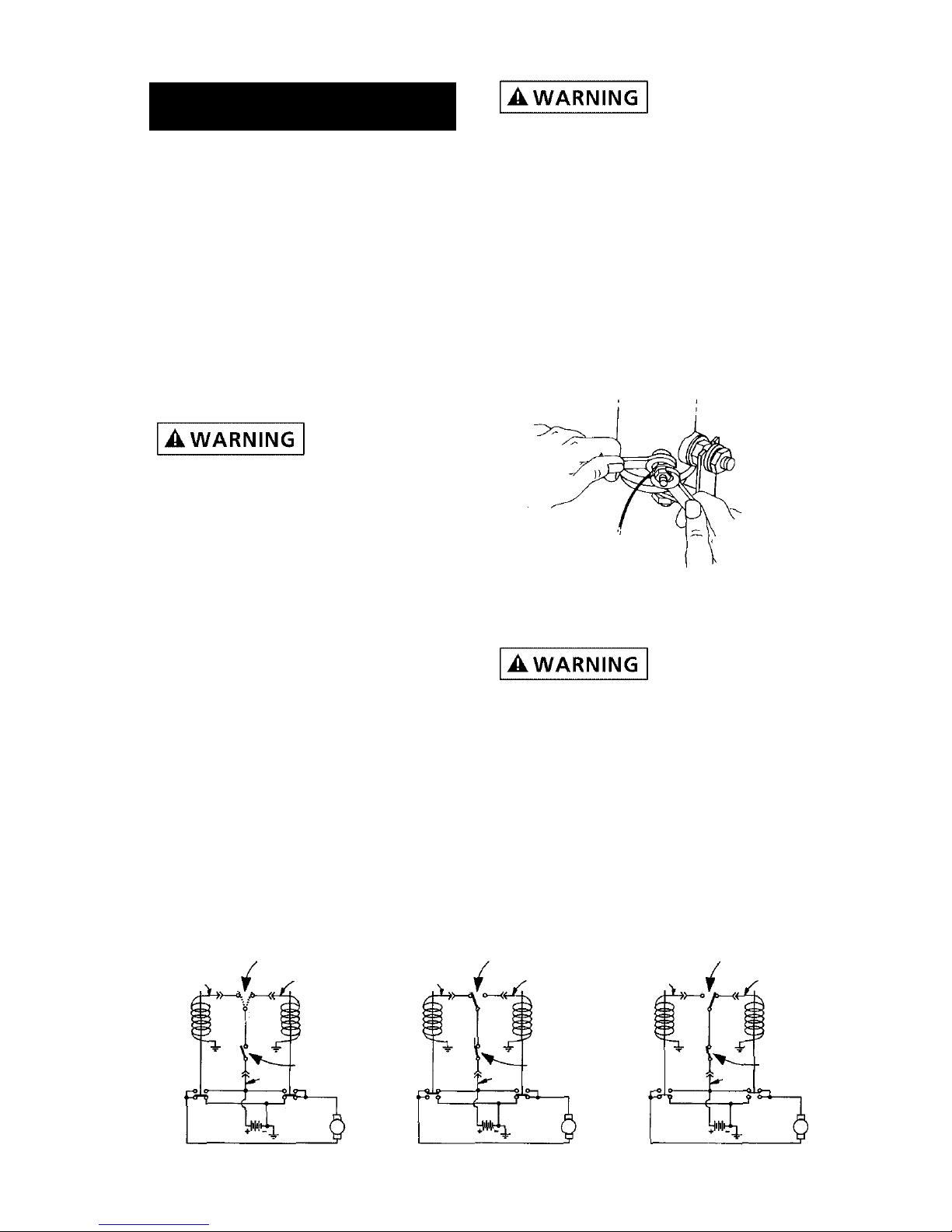

REVERSAL SWITCH

(Switch may be in

Either Position)

OFF

REVERSAL SWITCH

(Rope-In position)

WIRE ROPE IN

WIRE ROPE OUT

REVERSAL SWITCH

(Rope-Out position)

Electrical Schematic

Green

Black

4

3

1

Trigger

Switch

Load

Line

White

NC

NC

Winch

Motor

Green

Black

4

3

1

Trigger

Switch

Load

Line

White

NC

NC

Winch

Motor

Green

Black

4

3

1

Trigger

Switch

Load

Line

White

NC

NC

Winch

Motor

7

Figure 2

mounting plate must be electrically

grounded to the battery. If it is not,

the winch will not work. Preferably,

the solenoids should be mounted

vertically, with the solenoid end terminals pointing downwards.

Electrical Connection

Cut two lengths of wire, one red

and one black, to reach from the

winch to the solenoids. When routing all wires, be sure to keep them

away from all hot or moving parts.

Crimp a 1/4" ring terminal on the

end of each wire at the winch end.

Attach one wire to each motor terminal (See figure 3). Crimp a 5/16"

ring terminal at the solenoid ends

of the wires and attach to the terminals on the solenoid assembly as

shown in Figure 3.

Cut and strip two lengths of wire,

one red and one black, to reach

from the solenoids to the battery.

On the battery end of the red wire,

install a 3/16 ring terminal, and

attach to the circuit breaker. The

other end of the circuit breaker

attaches to the harness. On the

opposite end of this wire, connect a

5/16 ring terminal and attach to the

solenoid assembly (See Figure 3).

Install 5/16 ring terminals to both

ends of the black wire. Connect one

end to the solenoid assembly, and

the other end to the battery negative terminal (See Figure 3).

Connect the circuit breaker assembly bracket to the battery positive

terminal.

Plug in the remote control, and with

the directional lever in the “Rope

Out” position, momentarily depress

the trigger to check for proper rotation direction of the winch drum. If

the winch runs in the wrong direction, reverse the wires connected to

the winch motor.

Step (4) Models 03000, 03001

These winches are supplied without

controls. To design the control system for your application, you can

purchase the needed materials to

complete your system from

Superwinch, or buy them locally.

You will need a switch or a solenoid

control, a circuit breaker, hook up

wire, and wire terminals.

Switch

Select a (3) position reversing switch

with a switch action of “momentary

on”/“off”/“momentary on”.

“Momentary on” means the switch

automatically returns to OFF position when released. Minimum contact rating must be 50 amp DC carry.

Superwinch offers a (3) Position

Heavy Duty Rotary Switch Part

Number 1591. The Superwinch switch

has an internal shunt that provides

dynamic braking to further assist the

winch's brake. (See Figure 4)

Solenoids

You will need (2) 12 Volt double

pole, double through solenoids,

with a continuous current rating of

80 amps on the normally open contacts and 60 amps on the normally

closed contacts.

8

Figure 3

Superwinch offers an external solenoid pack as shown with Model

03003. (Superwinch Part Number

1515A Remote Control). It comes

with 12 foot pendant, 20 feet of 8

gauge wire, and instructions.

Circuit Breaker

We recommend using a 40 Amp

Circuit Breaker between the battery

positive terminal and the wire that

goes to the switch or solenoid pack

(See Figure 5). This can be purchased from Superwinch as Part

Number 89-32341. The circuit breaker prevents overloads to the switch

and to the winch motor.

Hookup Wire

If the total length of wire required

is less than 20 feet, use 8 gauge

wire. If the total length of wire

required exceeds 20 feet, use 6

gauge wire.

Step (4) Models 03002, 03005,

03010

Route the (2) wires to the battery.

To ensure against insulation abrasion and/or cutting, apply several

layers of electrical tape where

wiring may come in contact with

sharp metal parts. Attach the circuit

breaker assembly to the end of the

blue terminated wire. Wrap the circuit breaker assembly with electrical

tape to prevent accidental short

circuits.

Note: If you choose to locate the

winch at a greater distance than

the wires provided will permit, it

may be necessary to purchase a larger gauge wire to get the best performance from your winch. If the

total length of additional wire to be

added to the system exceeds 10 ft.

(3m), use a larger wire gauge size.

Attach the circuit breaker directly to

the battery positive terminal, and

reattach the terminal to the battery.

Connect the remaining wire to the

battery negative terminal, and connect the terminal to the battery.

(See Figure 5)

Step (5)

Pull the trigger momentarily to

check wire rope drum rotation and

direction. If the drum rotates in the

wrong direction, recheck your

wiring.

The hand-held pendant switch activates a solenoid that activates

power to the winch motor. One

solenoid is for power-in (lifting a

load) motor direction and the other

is for power-out (lowering a load)

motor direction (See Figure 6).

9

Remote

Switch

Receptacle

Solenoid

Assembly

Motor

Green

Black

Black

Blue Terminated

White

Circuit

Breaker

Figure 5

+

Figure 4

10

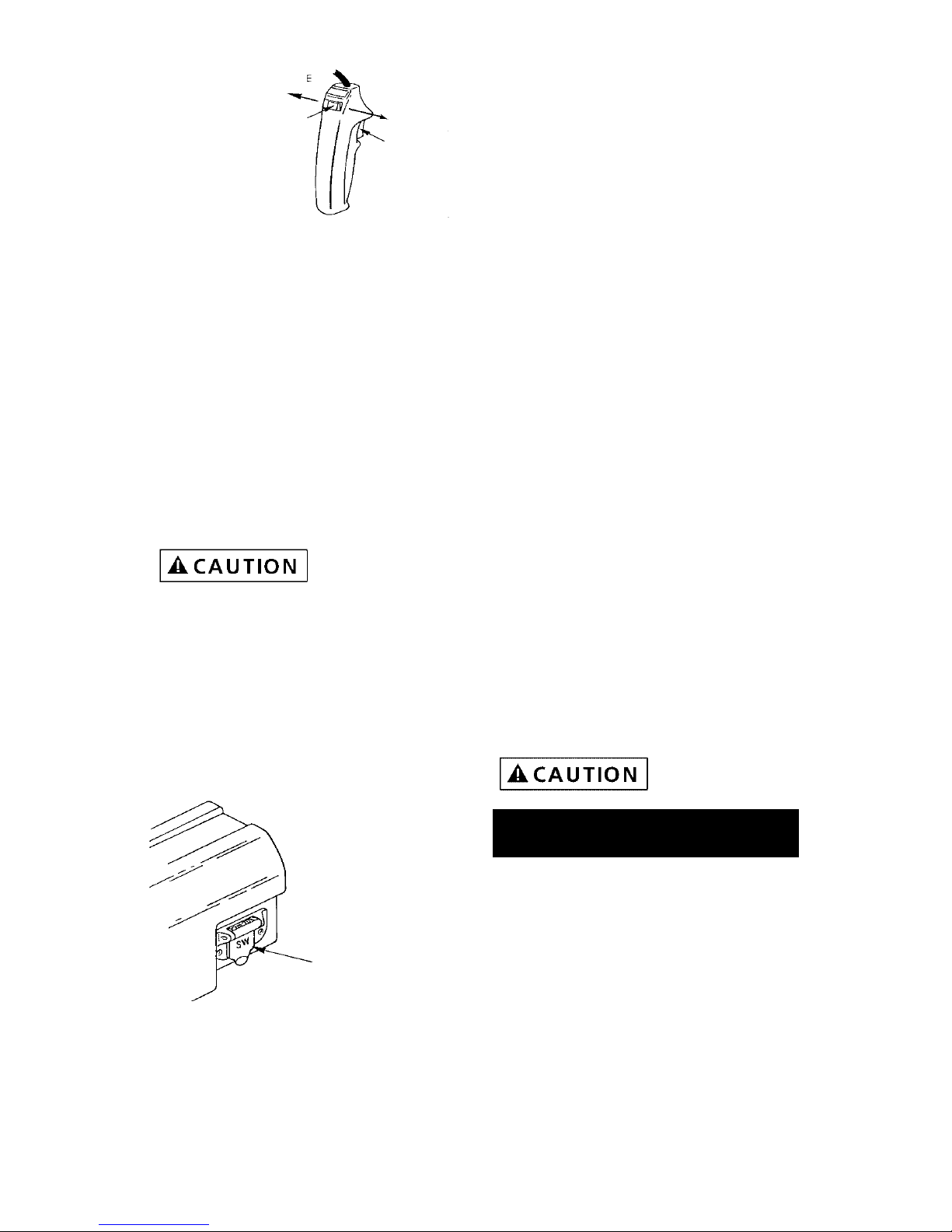

PENDANT OPERATION

The switch trigger returns to the

“OFF” position when released (See

Figure 6, Ref. A). The slide button

on the back of the switch determines the direction of the drum

rotation for lowering or lifting a

load (See Figure 6, Ref. B). The slide

is fitted with an interlock so that

the motor cannot be reversed if the

trigger is depressed. To change

direction, release the trigger, move

the slide button, and depress the

trigger again.

The switch

assembly must

be kept free of dirt and moisture to

ensure safe operation.

To connect the pendant control, lift

the dust cover on the plug receptacle (See Figure 7), and insert the

plug end of the remote switch. The

plug on the pendant control cord is

keyed and will fit into the socket

only one way.

Do not allow winch motor to overheat. The winch is for intermittent

use only. During long or heavy pulls

the motor will get hot. Allow to

cool after 2 minutes of “ON” time.

MAINTENANCE AND REPAIR

Periodically check tightness of

mounting bolts and electrical connections. Remove any dirt or corrosion that may have accumulated on

the electrical connections.

BRAKE OPERATION

Your winch has a wrap spring brake

that stops and holds loads up to

1,000 lb. (454 kg). When the winch

is powered out, as in releasing a

load, the brake is engaged and the

motor must overpower the brake

resistance to rotate the drum.

Therefore, it is normal for the

winch to operate faster in one

direction than the other. The brake

is designed for the wire rope to be

used in the underwind position

only. Drum must turn counterclockwise, looking from motor end,

when winching in.

DO NOT

OVERWIND.

Powering against the

brake will cause heat to build up in

the drum and may transfer heat to

the wire rope. DO NOT POWER OUT

FOR MORE THAN 2 MINUTES.

The drum may

get very hot.

WIRE ROPE

For safety reasons, it is important

that you use a wire rope with a

break strength of at least 5,600 lbs.

Recommended wire rope for this

winch will have a 1/4" diameter

with a 7 x 19 construction, and a

minimum break strength of 7,000

lbs. or a 7/32" diameter with 7 x 19

construction, with a minimum break

strength of 5,600 lbs.

OPERATION

Figure 6

POWER

OUT

POWER

IN

A

B

Figure 7

DUST

COVER

REPLACING THE WIRE ROPE

Replace damaged wire rope with

the manufacturer’s recommended

replacement part or a factory

approved equivalent identical in

strength, quality, lay, and stranding.

Pass the attaching end of wire rope

through the fairlead and attach it

to the drum. When inserting the

wire rope into the drum, insert it

into the correct end of the hole

provided (See Figure 8). Tighten the

set screw securely.

It is important that the wire rope be

wound tightly onto the drum.

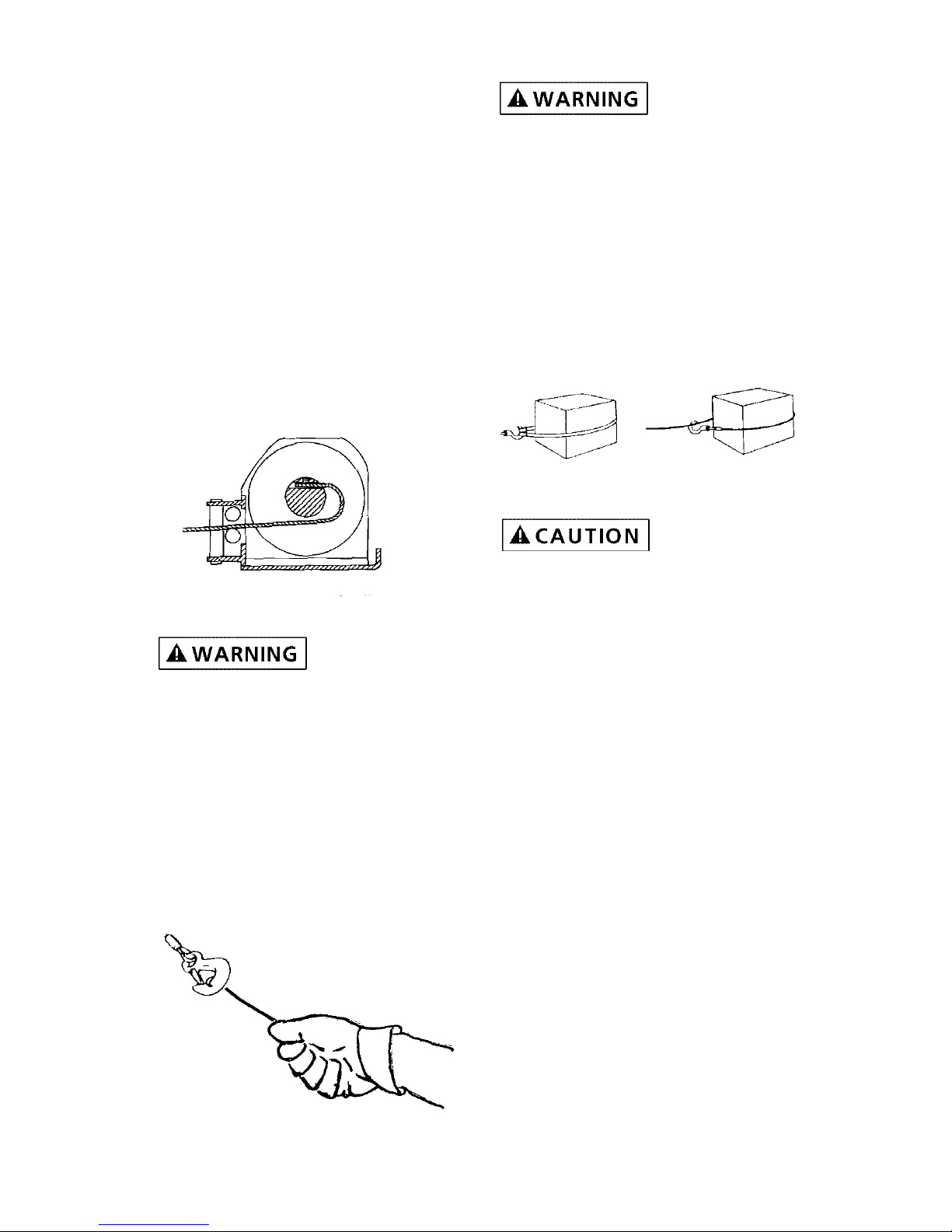

HANDLING THE WIRE ROPE

Use heavy

leather gloves

when handling wire rope. Do not

allow wire rope to slide through

hands.

1. Never winch with less than 5

turns of wire rope around winch

drum, since wire rope and fastener may not withstand the load.

ALWAYS USE HANDSAVER BAR

WHEN GUIDING HOOK FOR THE

LAST FEW FEET OF ROPE

(See Figure 9)

Keep clear of

winch wire rope

and hook when operating winch.

Never put your finger through thehook. Placing finger(s) in hook

could result in injury.

2. Never hook wire rope back onto

itself. Hooking wire rope onto

itself can damage rope. Use a

nylon sling (See Figure 10). When

using a sling, make sure that sling

is properly seated in saddle of

hook.

Avoid continu-

ous pulls from

extreme angles. This will cause wire

rope to pile up at one end of drum.

This can jam wire rope in winch

causing damage to rope or winch

itself.

3. Do not use wire rope as a ground

for welding.

4. Never touch welding electrode to

wire rope.

5. Keep wire rope tight and even on

drum.

6. Replace wire rope when frayed.

TIPS FOR EXTENDING THE LIFE OF

YOUR WINCH

1. Keep a tightly wound wire rope

drum. Do not allow the wire rope

to become loosely wound. A

loosely-wound drum allows a

wire rope under load to work its

way down into the layers of wire

rope on the drum. When this

happens, the wire rope may

become wedged within the body

of the windings, damaging the

11

Figure 10

Right

Wrong

Figure 8

Figure 9

wire rope. To prevent this problem, keep the wire rope tightly

and evenly wound on the drum

at all times. A good practice is to

rewind the wire rope under tension after each use. One way to

do this is to attach the hook to a

small load and winch that load to

rewind rope.

2. To maximize winch and wire rope

life, use pulley block to double

line heavier loads.

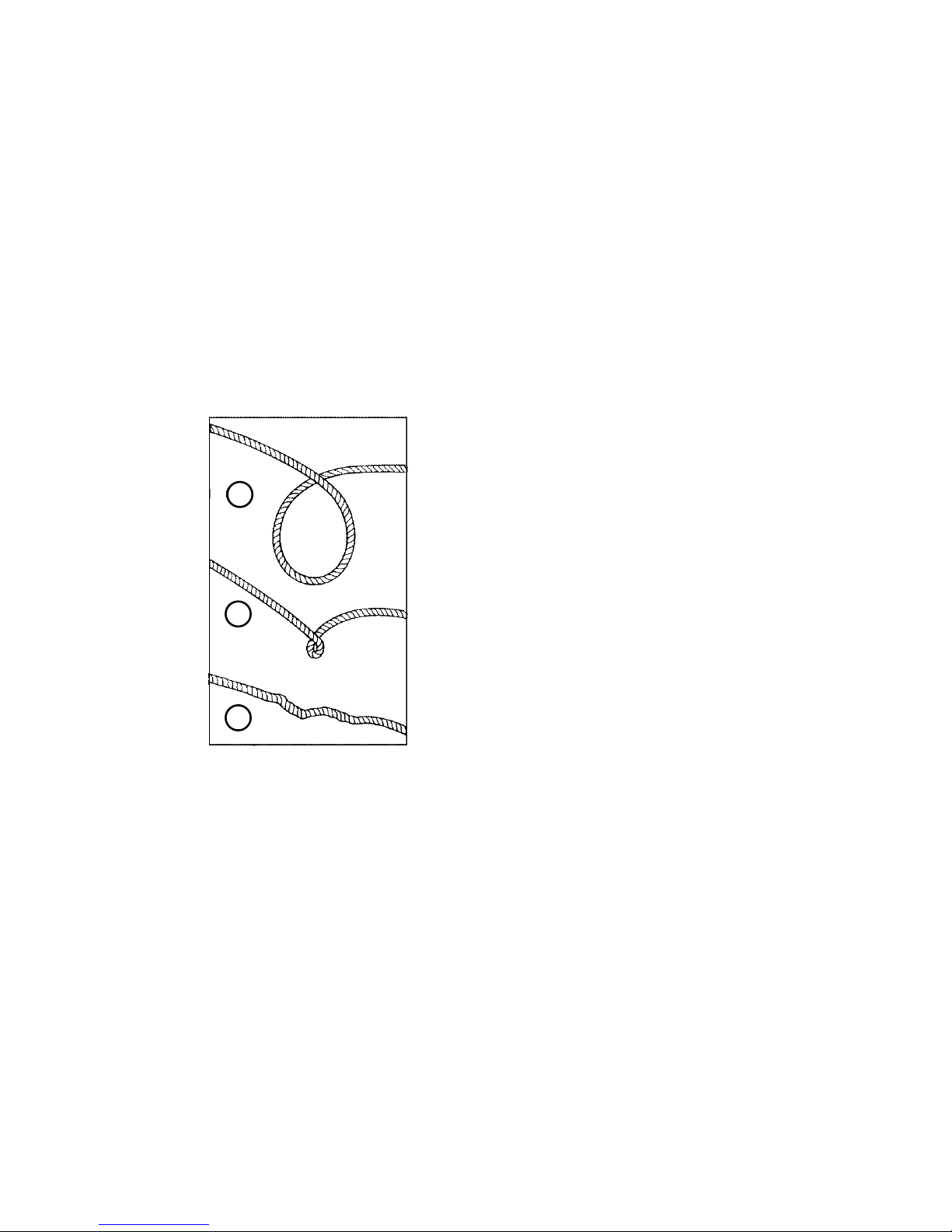

3. PREVENT KINKS BEFORE THEY

OCCUR. (See Figure 11.)

a. This is the start of a kink. At this

time, the wire rope should be

straightened.

b. The wire rope was pulled and the

loop has tightened to a kink. The

wire rope is now permanently damaged and must be replaced.

c. Kinking causes the wire strands

under the greatest tension to break

and thus reduces the load capacity

of the wire rope. The wire rope

must be replaced.

LUBRICATION

The winch is permanently lubricated. There may be grease leakage

out of winch, especially during first

few operations. This is normal and

it is not necessary to grease or oil

any internal part of winch at any

time.

Periodically lightly lubricate wire

rope with penetration oil and wipe

off excess.

Figure 11

a

b

c

12

TROUBLESHOOTING

CHART

Motor will not operate or 1. Damaged or stuck CAUTION Be prepared to

runs in one direction only solenoid disconnect power when

performing this test. If a

solenoid sticks once, it

is likely to stick again

and must be replaced

immediately

.

1. Tap solenoid to free stuck

contacts. Check by applying

voltage to the small solenoid

terminal. Be sure solenoid is

grounded back to source. A

solenoid that is not stuck will

make an audible “click” when

first energized.

2. Switch inoperative 2. Replace switch.

3. Broken wires or bad connection 3. Check for poor connections.

CAUTION Always use 2

wrenches (See Figure 1).

4. Damaged motor 4 Replace or repair motor.

5. Solenoids not grounded 5. Check the ground path

between battery negative and

solenoid base.

Winch will not shut off Solenoid stuck “ON” If a solenoid sticks on, reverse

direction and hold trigger switch

until the power lead can be disconnected. A safety disconnect

switch is available as an accessory.

Motor runs extremely hot 1. Long period of operation 1. Allow to cool.

2. Damaged motor 2. Replace or repair motor.

3. Damaged brake 3. Replace or repair brake.

Motor runs but with insufficient 1. Weak battery 1. Recharge or replace battery.

power or line speed Check charging system.

2. Battery to winch wire

extended with same size wire 2. Use larger diameter wire.

3. Poor battery connection 3. Check battery terminals for

corrosion. Clean as required.

4. Poor ground 4. Check and clean connections.

5. Damaged brake 5. Repair or replace brake.

Winch runs backward 1. Motor wires reversed 1. Recheck wiring.

2. Solenoids wired incorrectly 2. Recheck wiring.

Will not hold load 1. Excessive load 1. Reduce load or double line.

2. Worn or damaged brake 2. Repair or replace brake.

Symptom Possible Cause(s) Corrective Action

13

14

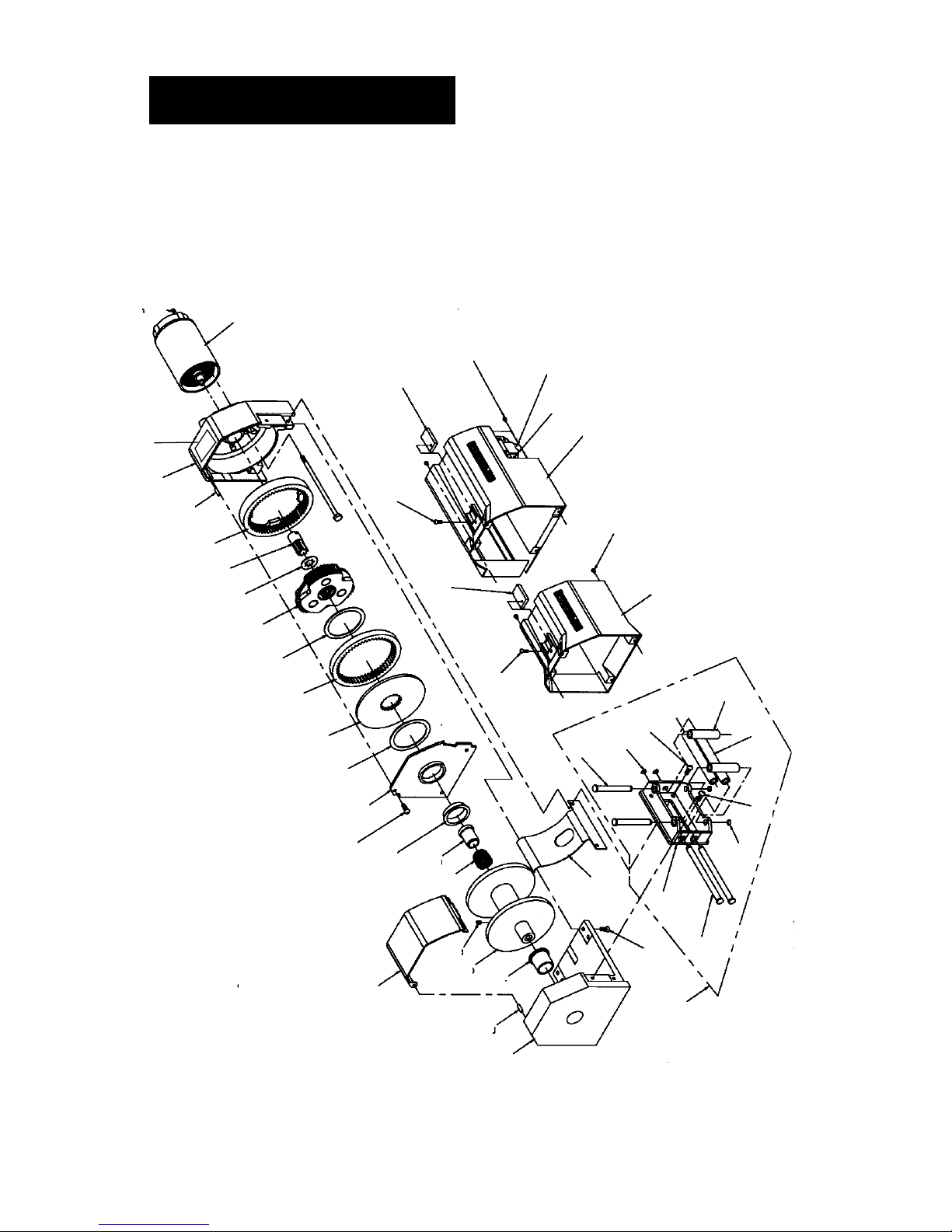

REPLACEMENT

PARTS

1

2

3

4

5

6

7

8

9

29

10

11

12

13

11

14

15

16

17

19

37

34

37

25

26

30

27

28

29

26

23

24

21

22

20

34

33

36

32

33

31

37&38

2

18

Safety

65

15

1 Base 89-52021 1

2 Groove pin 89-23303-01 2

3 Cable guard 89-32268 1

4 Main bearing 89-22268 1

5 Drum 89-40152 1

6 M6 x 1 x 8mm Set PT screw 90-23164-12 2

7 Brake spring 89-22342 1

8 Brake adapter 89-22287 1

9 Drum bearing 89-22269 1

10 Drum support 89-40092 1

11 Thrust washer 90-12574 2

12 Drive plate 89-32263 1

13 Rotating ring gear 89-32265 1

14 Planetary carrier assembly 89-22141 1

15 Wear washer 89-22271 1

16 Sun gear 89-32253 1

17 Stationary Ring Gear 89-32266 1

18 Housing Assembly 89-40157 1

19 12V Motor (03000, 03001, 03002, 03003, 03005) 90-33256 1

24V Motor (03010) 89-32386 1

20 Cable Tension Plate 89-32295 1

21 Screw, FCHSS M6 x 1 x 16 87-22291-02 4

22 Roller Fairlead Shaft (Includes 22-27) 1

23 Roller Fairlead Shaft (Long) 89-22334-02 2

24 Roller Fairlead Frame 89-40113 1

25 Roller Fairlead Shaft (Short) 89-22334-01 2

26 3/8 Retaining Ring 90-23029-08 4

27 5/8 x 2.352 Roller 90-12568-04 2

28 5/8 x 4.735 Roller 90-12568-06 2

29 M6 x 1 x 13mm BHDCS Screw 89-22290-01 2

30 M6 x 1 x 16mm BHDCS Screw 89-22290-02 5

31 Motor Cover Assembly (03000) 89-40131 1

(includes logo, 34 & 37)

32 Motor Cover Assembly (03002, 03005, 03010) 89-40131-03 1

(Includes logo, 34 & 37)

33 M4 x 0.7 x 6mm (03000, 03002, 03005, 03010) 89-22292-01 4

34 Filler Block (03000, 03002, 03005, 03010) 89-12032 1

36 SKT Half Connector (03002, 03005, 03010) 90-22115 1

37 8-32 Pan Head Screw (03000) 90-23032-03 1

8-32 Pan Head Screw (03002, 03005, 03010) 90-23032-03 3

38 8-32 Hex Flange Nut (03002, 03005, 03010) 90-23149-06 2

NS Handsaver Bar 89-32300 1

NS 1/4 x 25’ Wire Rope Assembly (03005) 1577B 1

NS 1/4 x 50’ Wire Rope Assembly (03010) 1577A 1

NS Pulley Block with Hook (03005) 2207 1

NS Mounting Hardware Package 90-22877 1

NS Terminal Package (03003) 90-22885 1

NS 12V Circuit Breaker Assembly (03002, 03003, 03005)87-22873-11 1

NS 24V Circuit Breaker Assembly (03010) 90-22873-01 1

(NS) Not Shown

Reference

Number Description Part Number Qty

REPLACEMENT

PARTS LIST

REPLACEMENT

PARTS

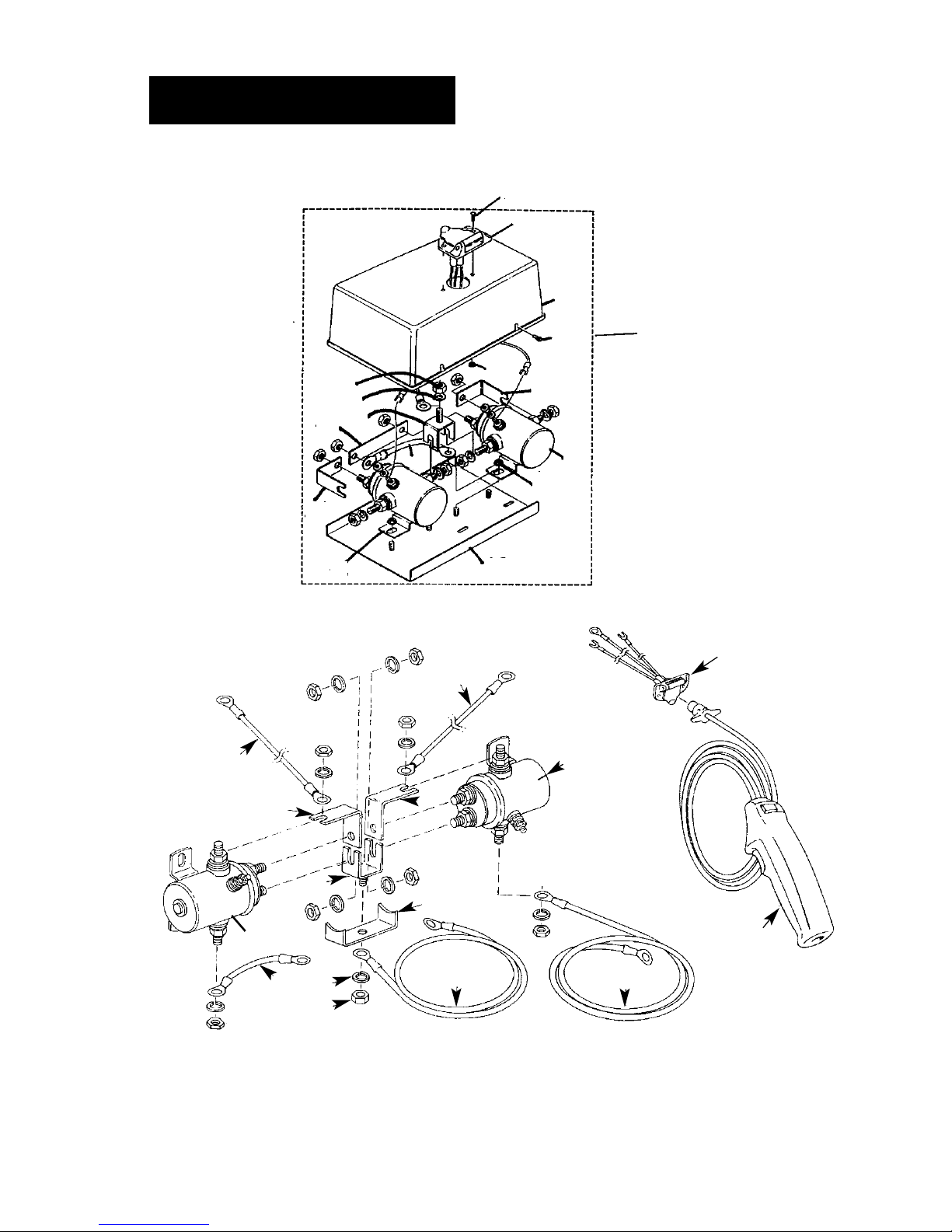

55

56

54

42

51

50

49

48

47

54

46

67

36

64

53

46

16

37

36

59

60

38

50

51

53

57

54

46

61

62

46

54

63

58

REPLACEMENT

PARTS LIST

46 12V Solenoid (03002, 03003, 03005) 90-20329 2

24V Solenoid (03010) 90-20331 2

47 6 GA x 5’ Leadwire Assembly (Pos) (03002, 03010) 90-23292-20 1

6 GA x 20’ Leadwire Assembly (Pos) (03005) 89-23292-27 1

48 6 GA x 5’ Leadwire Assembly (Neg) (03002, 03010) 90-20187-06 1

6 GA x 10’ Leadwire Assembly (Neg) (03005) 89-23292-26 1

49 Ground Strap (03002, 03005, 03010) 89-22356 1

50 5/16 Lockwasher (03002, 03003, 03005, 03010) 92-23057-03 1

51 5/16-18 Hex Nut (03002, 03003, 03005, 03010) 92-23034-04 1

52 6 GA x 3 1/2” Leadwire Assembly 90-23292-06 1

(03002, 03005, 03010)

53 Buss Bar 2 Assembly (03002, 03003, 03005, 03010) 92-10200 1

54 Buss Bar 1 (03002, 03005, 03010) 92-20126 2

55 8 GA x 9 3/8” Leadwire Assembly (Red) (03005) 89-23292-21 1

8 GA 9 3/8” Leadwire Assembly (03002, 03010) 90-20187-08 1

56 8 GA x 6” Leadwire Assembly (Black) (03005) 89-23306-02 1

6 GA x 6” Leadwire Assembly (03002, 03010) 89-23292-19 1

57 Buss Bar 3 (03003) 92-20128 1

58 6 GA x 2 3/4” Leadwire Assembly (03003) 90-20187-07 1

59 8-32 x 1/4 HW Taptite Screw (03003) 90-22247 1

60 8-32 x 1/4 HW Taptite Screw (03003) 90-23039-03 4

61 10-32 Flange Hex Nut (03003) 90-23149-01 4

62 Solenoid Pack Back Plate (03003) 90-32070 1

63 12V Remote Solenoid Pack (03003) 90-32139

(Includes 35, 36, 37, 46, 49, 52, 54, 60, 65, 66, 67, 68

64 Remote Control Assembly 90-22117 1

(03002, 03003, 03005, 03010)

65 Safety Label, 3/4” icon, 3 x 2 89-20330 1

Reference

Number Description Part Number Qty

17

Loading...

Loading...