Page 1

ZIRCONIA SENSOR

THEORY

T4401

Issue 1

by Thomas H. Lotze

The zirconia carbon sensor is really

an oxygen sensor. The primary

mechanism for electrical current

flow in many ceramic electrolytes

is ionic conduction, in this case via

oxygen ions. T ypical construction,

basic theory, opening equations

and applications are covered.

INTRODUCTION

The purpose of this paper is to describe the typical zirconia carbon sensor in general terms, and

provide a thorough grounding in the mathematical equations governing it’s practical use.

COMMERCIAL SENSORS

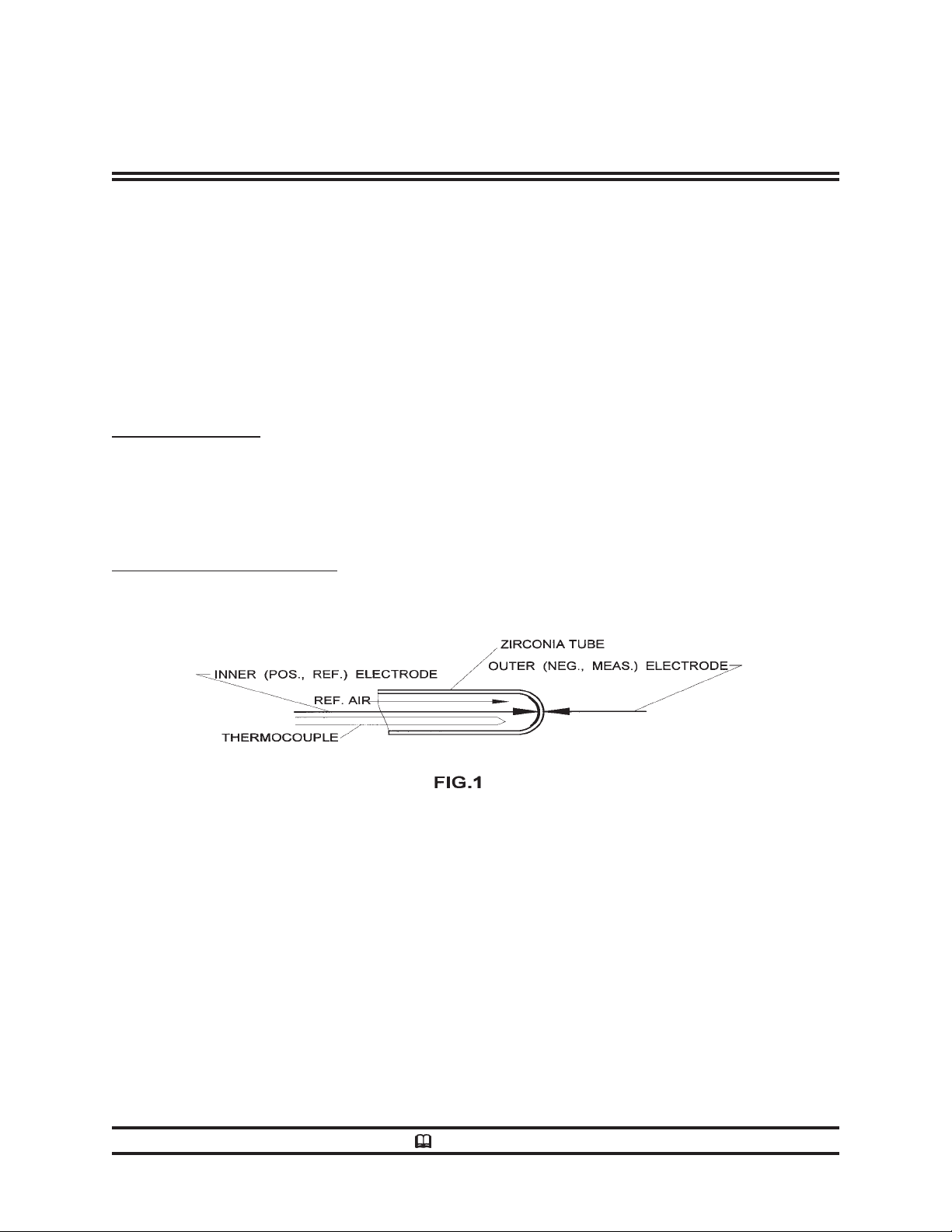

The basic elements of all commercial carbon sensors are shown in Fig. 1:

Technical Data

The tubular zirconia sensing element illustrated here is the preferred form for the SSi Gold Probe™.

Slip cast and fired at exceptionally high temperatures to provide a dense, non-porous body, this

component is not prone to develop the leakage paths that are common in probes using a cemented

zirconia plug in a tubular alumina body .

The inner, reference electrode, is spring loaded to hold it in intimate contact with the inner zirconia

surface. It consists of a specially formed extension of the lead wire that connects it to the probe

terminal block. The inner reference components are especially resistant to the normally oxidizing

reference atmosphere.

The outer, measuring electrode for most commercial probes is mechanically and electrically part of

the alloy protective sheath, and the zirconia substrate is spring loaded to make intimate contact with

this electrode. The SSi outer electrode, by virtue of premium quality, heat resistant alloy and a

proprietary surface treatment, is designed to survive the rigors of the harsh furnace atmosphere.

SUPER SYSTEMS TECHNICAL DATA SHEET

Printed in U.S.A.

SSi Super System Inc CINCINNATI, OH 45215

Page 2

T4401

Issue 1

ZIRCONIA SENSOR

THEORY

Technical Data

While probe manufacturers use a variety of materials and geometries, all properly designed sensors

will display precisely the same output when at equilibrium in a furnace atmosphere. Despite this

fact, many control instrument manufacturers will provide different algorithms for probes from

different manufacturers. This is primarily because manufacturers have derived their algorithms

using different sources for data that are not in complete agreement.

PRINCIPLES OF OPERATION

Pure zirconium oxide is a monoclinic crystalline material that transforms reversibly to a tetragonal

form at 1832°F with a large change in volume. This makes it unsuitable for normal refractory use.

If placed in solid solution, however, with 4% to 12% MgO, CaO or Y2O3, it is held in the stable

isometric (cubic) form which has no transformation in the range of heat treating atmospheres. By

virtue of the addition of these stabilizing oxides, oxygen ion vacancies are established in the crystal

lattice. The mobility of O- ions is greatly enhanced, and under certain conditions of temperature and

composition, the conductivity is entirely due to oxygen ions. This condition coincides with the

existence of the pure cubic crystalline phase, and is responsible for the oxygen sensing capability of

stabilized zirconia which will be discussed later.

A minimum quantity of the stabilizing oxides will ensure the existence of the pure cubic crystalline

phase of zirconia. When this amount is present, the zirconia is said to be fully stabilized. The

commercially available zirconia for oxygen sensors will have somewhat less than this minimum

amount, resulting in a “partially stabilized” electrolyte, having a better resistance to thermal fracture.

The zirconia in SSi sensors contains about 6 mole % (10.5 weight %) of Y2O3. The cell construction

of Fig. 1 demonstrates a characteristic typical of electrolytes having unity transference numbers for

an ionic species; there is an electromotive force displayed at it’s terminals that can be precisely

related to the corresponding molecular concentration at the two surfaces. In the case of cubic zirconia,

the cell e.m.f. is given by a form of the familiar Nernst equation,

EC=-.0275TR log10(p0/p1) millivolts (1)

where TR is the absolute temperature in degrees Rankine (= °F + 459.67), p0 and p1 are the oxygen

concentrations at the inner and outer electrodes respectively, stated in any units (usually in

atmospheres of partial pressure). Although there are applications where the oxygen present is the

only critical parameter, the heat treater is concerned with two other variables he wishes to control;

dew point and carbon potential. Fortunately, both parameters can be calculated directly from the

oxygen measurement.

SUPER SYSTEMS TECHNICAL DATA SHEET

page 2

Page 3

T4401

Issue 1

ZIRCONIA SENSOR

THEORY

Technical Data

DEW POINT This variable is utilized in control of endothermic generators that supply the basic

environment to a heat treating furnace. This environment, commonly called endo or Rx gas, is

created in the generator by combining air and a combustible such as natural gas or propane to

provide a mixture of about 20% carbon monoxide, 40% hydrogen and 40% nitrogen.

The reversible reaction that expresses the separation into oxygen and hydrogen by water is:

H2O

⇔

H2 + 1/2 O

2

By applying the principals of the law of mass action we can write an expression that accurately

describes the composition of the three components in a mixture at equilibrium:

(2)

KW = PH2 x PO

1/2

/ PH2O (3)

2

where KW is the temperature dependent equilibrium constant for this reaction and PH2, PO2 and

PH

O are the partial pressures of the corresponding materials, usually stated in atmospheres. This

2

equation dictates that a change of any of the variables causes the others to change as well in order

that equilibrium be sustained and the equation remains satisfied.The equilibrium constant is precisely

described by the following equation ( from Wagman1):

log10KW= 2.82 - 23000/T

R

(4)

The last relationship required to calculate the dew point from the measured variables is2:

log

O = 6.3979 - 4238.7/ (DP+460) (5)

10PH2

where the dewpoint, DP, is reported in degrees Fahrenheit. Combining equations (2) through (5),

we arrive at the SSi algorithm for dew point:

DP = (4238.7/(9.55731-log

+ (EC -1267.8)/0.05512TR)) - 460 (6)

10PH2

It is important to note here that there are only three specified variables in this algorithm. EC and T

are measured directly by the sensor which must include a close coupled thermocouple for precise

calculation. The third variable, PH2 may be measured by other analytical means. More commonly ,

as in the case of endothermic generators, it is assumed to be approximately 0.4 atmospheres. Because

it’ s value will vary with the control set point, the gauge pressure at the sensor, and other factors such

as peak shaving practices by the power company , it is commonly incorporated as part of a correction

factor in the control instrument. This factor is set to a value that causes the computed value of dew

point to agree with a manually measured value using a device such as the Alnor Dewpointer. The

individual correction factor is very stable. Accordingly, heat treaters find that the frequency of

manual dew point determination may be reduced significantly.

R

SUPER SYSTEMS TECHNICAL DATA SHEET

page 3

Page 4

T4401

Issue 1

ZIRCONIA SENSOR

THEORY

Technical Data

CARBON POTENTIAL The carbon potential (%C) of a heat treating atmosphere is defined as

“that value of carbon concentration achieved in a coupon of shim stock exposed to the atmosphere

until it has reached equilibrium”. The time required for this equilibration will vary with shim thickness

and furnace temperature. Table 1 illustrates the approximate effects.

Table 1 Time to equilibrium (minutes)

SHIM THICKNESS

TEMP 0.003" 0.005" 0.007"

1550 63 117 173

1600 50 91 136

1650 39 72 107

1700 32 58 86

1750 26 47 70

Corresponding to the reaction (2) for dew point calculations is the following reversible reaction

encountered in the furnace atmosphere:

CO

⇔

C +1/2 O

2

(7)

The mass action equilibrium equation for this reaction is:

1/2

/PCO (8)

2

where K

KCO = aC x PO

is the temperature dependent equilibrium constant, PO2 and PCO are the partial pressures

co

of oxygen and carbon monoxide and aC is the carbon activity-- a concentration term similar to the

partial pressure. As before, this equilibrium constant is a function of temperature (from W agman et al)1:

log10KCO = 4.5713 + 10638/T

R

(9)

Finally, the carbon activity aC has been experimentally related to %C (from Collin et al)3:

3751/T

aC= 1.07 q (10

R

)(C/(1-19.6C)) (10)

where q is a function of the alloy being treated, and is calculated as shown in Appendix A. Combining

(1), (8), (9) and (10) and rearranging, we derive the SSi algorithm relating %C to the measured

variables from the sensor:

%C = 3.792 eZ / ((324.3q / PCO) + eZ ) (11)

where Z = (EC - 820.7)/ 0.0239 T

SUPER SYSTEMS TECHNICAL DATA SHEET

R

page 4

Page 5

T4401

Issue 1

ZIRCONIA SENSOR

THEORY

Technical Data

Note that the value q/PCO is the correction factor, (or a simple function of the correction factor)

that is provided in most commercial controllers to make the calculated value of %C agree with shim

stock tests.

PRACTICAL CONSIDERATIONS

Properly maintained, the zirconia sensor provides the valuable characteristic of repeatability to the

heat treater. Periodic standardization using shim stock tests or dew point tests to establish the

appropriate correction factors will ensure repeatability , and hence product quality assurance. Although

the purist may frown at the use of such “fudge factors”, the practical considerations overwhelmingly

dictate their use. It may be found that the value of the correction factor will vary , at the extremes of

temperature and carbon potential. Appropriate values should be determined throughout the operating

region, and applied judiciously.

APPENDIX A- CALCULATION OF ALLOY FACTOR “q”

The value of q for carbon steels is close to 1.00. When alloying elements are incorporated in the

steel, it is desirable to calculate an additive factor to adjust the value of q, using the formulae in the

following table (from Neumann and Person)4:

To correct for add this value to q (= 1.00)

Silicon 0.15 %Si + 0.33 o/oSi

2

Manganese 0.0365 %Mn

Chromium -0.13 %Cr + 0.0055 %Cr

Nickel 0.03 %Ni + 0.00365 %Ni

Molybdenum -0.025 %Mo-0.01 o/oMo

Aluminum -0.03 %Al - 0.02 %Al

Copper -0.016 %Cu - 0.0014 %Cu

Vanadium -0.22 %V + 0.01 %V

2

2

2

2

2

2

REFERENCES

1. D.D. Wagman et al. J. Res. Burl Standards, 1945, 34, 143.

2. Metals Handbook 9th Ed., Vol. 4, 145.

3. R. Collin et al. J.I.S.I., Oct. 1972, 788.

4. F. Neumann and B. Person, Hart.-Techn. Mitt., 1968, 23, 296.

SUPER SYSTEMS TECHNICAL DATA SHEET

page 5

Page 6

ZIRCONIA SENSOR

THEORY

T4401

Issue 1

Technical Data

Notes

SUPER SYSTEMS TECHNICAL DATA SHEET

SSi

7205 EDINGTON DRIVE * CINCINNATI, OH 45249

SUPER SYSTEM INC.

(800) 666-4330 • (513) 772-0060 • (513) 772-9466

Loading...

Loading...