Super System GOLD PROBE Installation Manual

Copyright 2005 Release A 07/01/2005

GOLD PROBE

INSTRUCTION MANUAL

M4501

SSiSUPER SYSTEMS INC.

7205 Edington Drive • Cincinnati, Ohio 45249 1-513-772-0060 • 1-800-666-4330 •

FAX 1-513-772-9466

GOLD PROBE MANUAL

Table Of Contents

♦ Introduction .................. |

1 |

♦ Specifications ............... |

1 |

♦ Characteristics .............. |

2 |

♦ Operating Theory .......... |

3 |

♦ Installation .................... |

4 |

♦ Maintenance .................. |

5 |

♦ Troubleshooting ............ |

7 |

♦ Control Systems ............ |

8 |

♦ Warranty ..................... |

10 |

GOLD PROBE MANUAL

INTRODUCTION

Thank you for selecting the Gold Probe™ for your atmosphere control application.

The Gold Probe™ represents “state of the art” in carbon sensor technology. It has been designed for use in carbon control systems as applied to both carbon control in atmosphere furnaces and dew point in endothermic generators.

The Gold Probe™, with its unique measuring electrode construction, is the product of a team of design and application engineers, each with over twenty years of atmosphere control experience. The SSi engineering team has long recognized that the sensor is the most critical component in the atmosphere control system and has traditionally been the weakest link. Now, reliability, repeatability and accuracy are assured with the inclusion of the Gold Probe™ in your control system.

SPECIFICATIONS

♦Useful %C Range- .01 to 1.6%

♦Temperature Range1200°F to 2000°F (649°C to 1093°C)

♦Stabilitywithin +/- 1 mVDC

♦Impedanceless than 10 kohms @ 1700°F (927°C)

♦Useful output- 0 to 1250 mVDC

♦Length21 1/2", 25 3/4", 35" (546mm, 654mm, 889mm)

♦Weight- 3.7, 4.0, 5.8 lbs

♦Insertion14.3", 18.6”, 20”or 27.8" (363mm, 472mm, 508mm,or 706mm)

♦Mounting- 1" (25.4mm) NPT

♦Sheath dia.- 0.84" (1/2" pipe) (21mm, 13mm pipe)

1

GOLD PROBE MANUAL

CHARACTERISTICS

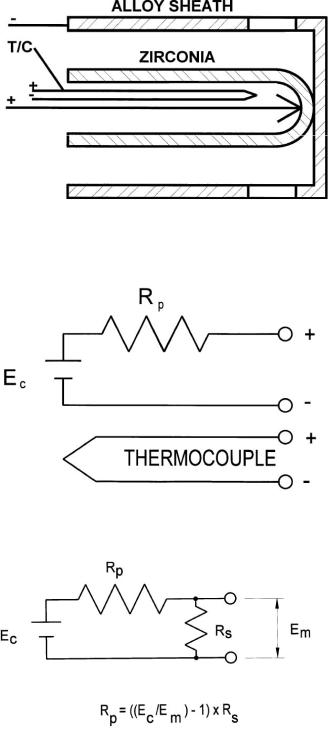

The typical zirconia carbon sensor consists of a closed end tube with the sensing portion at the tip. The entire tube may be zirconia or there may be a slug of zirconia cemented in the tip. Fig.1 illustrates the Gold Probe™ design with details omitted for clarity. The tip of the tube is spring loaded into contact with the sheath, which also serves as the outer electrode. The inner electrode is spring loaded into contact with the inner zirconia surface. A thermocouple is positioned close to the inner electrode surface and reference air bathes the sensing surface.

To the instrument technician, the probe looks like a battery (see Fig.2.) It displays a voltage, Ec, from

which the carbon potential can be calculated. The probe thermocouple is shown next to the sensing electrode.

The value of the internal resistance can be measured, as shown in Fig. 3, by putting a shunt resistor across the probe, measuring the resultant voltage, Em and carrying out the simple calculation

shown.

FIG. 1

FIG. 2

FIG. 3

2

BASIC OPERATING THEORY

Carbon potential of a conventional furnace atmosphere is defined as the %C achieved in a coupon of carbon steel shim stock equilibrated in the furnace atmosphere. Unfortunately, equilibration time is long, so it is impossible to continuously control the atmosphere on the basis of shim stock measurements. A zirconia sensor, however, can be used to measure and control the carbon potential precisely, and on a continuous basis.

Strictly speaking, the zirconia probe is not sensing carbon at all. It is an oxygen sensor with a mVDC output described by Equation (1).

Fortunately, an empirical (experimental) relationship exists between oxygen concentration and carbon potential, and this relationship has been used in carbon control instruments since the early ‘70’s. The equation used by most control manufacturers today is illustrated by Equation (2), which states that there are only three variables affecting the measured millivoltage. Because the actual equation used is somewhat complex, it is not reproduced here. A full description of probe theory will be found in SSi technical bulletin T4401 (Zirconia Sensor Theory).

All competitive probes will invariably agree within one or two millivolts when exposed to the same atmosphere under equilibrium conditions. Differences in values listed by probe vendors relate to differences in manufacturers’ source data, but the true value of the zirconia probe is its repeatability.

GOLD PROBE MANUAL

ZIRCONIA O2 RESPONSE

Ec = 0.0276TR log (Pf /Pa) millivolts |

(1) |

Zr PROBE ALGORITHM |

|

%C= ( EC , %CO, TR) mVDC |

(2) |

Where:  means ‘is a function of’ %C is the carbon potential

means ‘is a function of’ %C is the carbon potential

%CO is carbon monoxide percentage TR is the absolute temperature in degrees

Rankine (deg. F + 460).

and EC is the probe output in millivolts.

3

GOLD PROBE MANUAL

INSTALLATION

If your new probe is to be installed in an existing probe entry, be advised that your warranty requires that the probe should extend no more than 4" (101mm) into the furnace chamber. This is because, at operating temperatures, the sheath can sag enough to cause breakage of the zirconiasensing element.

For new installations, an entry fitting must be provided at the furnace wall to permit the probe to extend from 2" to 4" (51mm to 101mm) into the furnace chamber. Listed here are several conditions that should be considered when choosing a location for the entry fitting. Most of these conditions allow for some compromise, and represent, at best, recommendations.

A variety of fittings have been used to provide the 1" (25.4mm) NPT entry. The simplest is the 1 1/2" (38mm) coupling, as shown in Fig. 4.

The furnace is prepared by drilling a 1 1/2" (38mm) diameter hole through the wall and the insulation. The hole must be at right angles to the wall to avoid interference with probe insertion. The fitting is then welded or screwed to the wall to provide a gas-tight entry.

Your Gold Probe™ has been shipped with an o- ring compression fitting which allows you to adjust the insertion. Manual tightening of the cap is adequate for side mounting. A wrench should be used for vertical mounting to assure probe will not move. When installing in a hot furnace, insert the first four inches directly, then at a rate of 2" (51mm) per minute in order to avoid thermal shock fracture.

NOTE:

Your Gold Probe™ has been thoroughly tested in our controlled atmosphere furnace. Therefore, the sheath shows evidence of thermal discoloration.

ENTRY FITTING LOCATION

♦In top third of work zone......

♦Close to control thermocouple......

♦Distant from radiant tubes......

♦Away from carrier gas entry......

♦Clear of work baskets......

WARNING

Zirconia is thermal shock sensitive. Insert into hot furnace no faster than 2" (51mm) per minute (after first 4 inches or 101 millimeters).

4

Loading...

Loading...