Page 1

Copyright 2005

GOLD PROBE

Release A

07/01/2005

INSTRUCTION MANUAL

M4501

SSiSUPER SYSTEMS INC.

7205 Edington Drive • Cincinnati, Ohio 45249 1-513-772-0060 • 1-800-666-4330 •

FAX 1-513-772-9466

Page 2

GOLD PROBE MANUAL

Table Of Contents

♦ Introduction .................. 1

♦ Specifications ............... 1

♦ Characteristics .............. 2

♦ Operating Theory .......... 3

♦ Installation .................... 4

♦ Maintenance .................. 5

♦ Troubleshooting ............ 7

♦ Control Systems ............ 8

♦ Warranty ..................... 10

Page 3

GOLD PROBE MANUAL

INTRODUCTION

Thank you for selecting the Gold Probe™ for your atmosphere control application.

The Gold Probe™ represents “state of the art” in carbon sensor technology. It has been

designed for use in carbon control systems as applied to both carbon control in

atmosphere furnaces and dew point in endothermic generators.

The Gold Probe™, with its unique measuring electrode construction, is the product of a

team of design and application engineers, each with over twenty years of atmosphere

control experience. The SSi engineering team has long recognized that the sensor is the

most critical component in the atmosphere control system and has traditionally been the

weakest link. Now, reliability, repeatability and accuracy are assured with the inclusion

of the Gold Probe™ in your control system.

SPECIFICATIONS

♦ Useful %C Range- .01 to 1.6%

♦ Temperature Range- 1200°F to 2000°F

(649°C to 1093°C)

♦ Stability- within +/- 1 mVDC

♦ Impedance- less than 10 kohms @ 1700°F

(927°C)

♦ Useful output- 0 to 1250 mVDC

♦ Length- 21 1/2", 25 3/4", 35"

(546mm, 654mm, 889mm)

♦ Weight- 3.7, 4.0, 5.8 lbs

♦ Insertion- 14.3", 18.6”, 20”or 27.8"

(363mm, 472mm, 508mm,or

706mm)

♦ Mounting- 1" (25.4mm) NPT

♦ Sheath dia.- 0.84" (1/2" pipe)

(21mm, 13mm pipe)

1

Page 4

GOLD PROBE MANUAL

CHARACTERISTICS

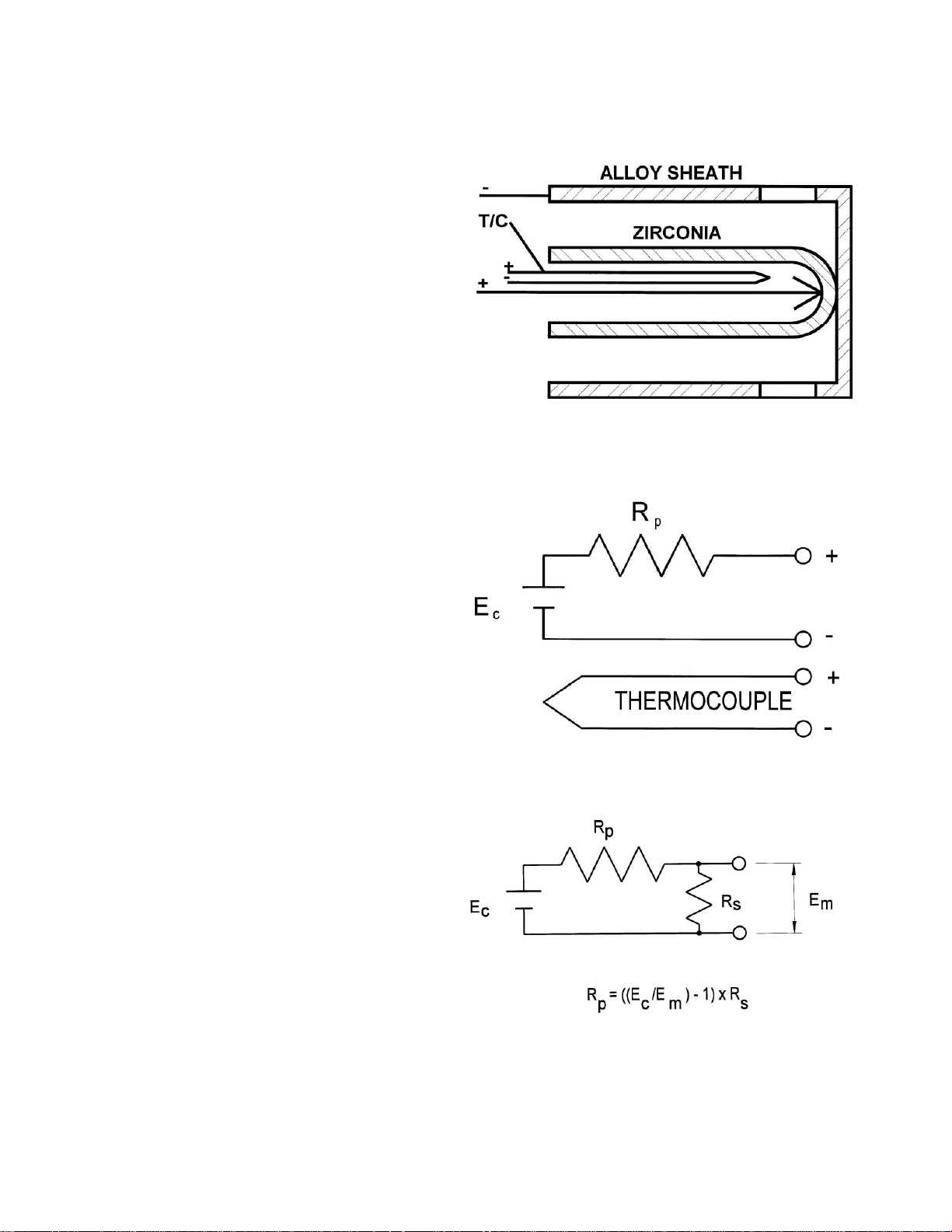

The typical zirconia carbon sensor consists of a

closed end tube with the sensing portion at the tip.

The entire tube may be zirconia or there may be a

slug of zirconia cemented in the tip. Fig.1

illustrates the Gold Probe™ design with details

omitted for clarity. The tip of the tube is spring

loaded into contact with the sheath, which also

serves as the outer electrode. The inner electrode

is spring loaded into contact with the inner

zirconia surface. A thermocouple is positioned

close to the inner electrode surface and reference

air bathes the sensing surface.

FIG. 1

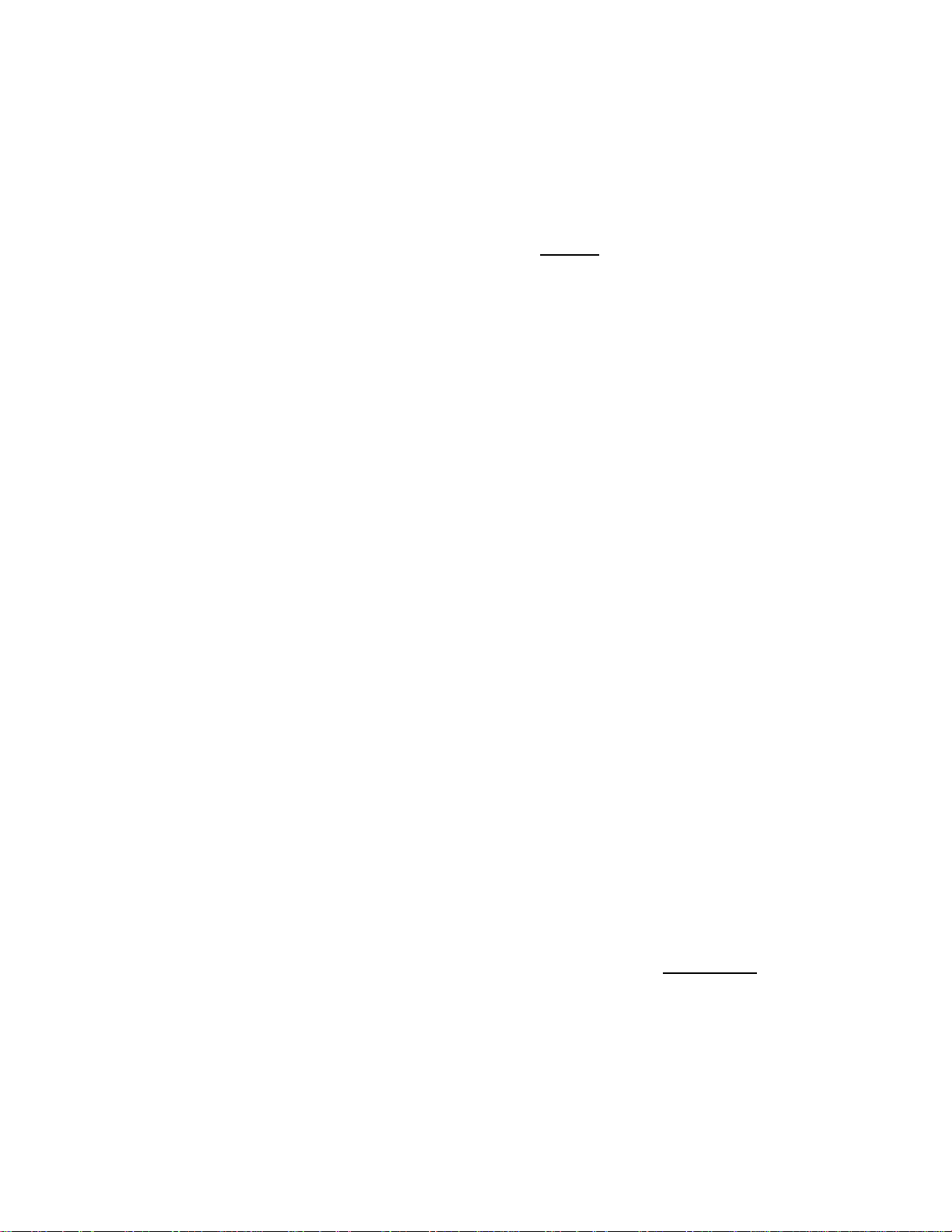

To the instrument technician, the probe looks like

a battery (see Fig.2.) It displays a voltage, Ec, from

which the carbon potential can be calculated. The

probe thermocouple is shown next to the sensing

electrode.

The value of the internal resistance can be

measured, as shown in Fig. 3, by putting a shunt

resistor across the probe, measuring the resultant

voltage, Em and carrying out the simple calculation

shown.

FIG. 2

FIG. 3

2

Page 5

BASIC OPERATING THEORY

Carbon potential of a conventional furnace

atmosphere is defined as the %C achieved in a

coupon of carbon steel shim stock equilibrated in

the furnace atmosphere. Unfortunately,

equilibration time is long, so it is impossible to

continuously control the atmosphere on the basis

of shim stock measurements. A zirconia sensor,

however, can be used to measure and control the

carbon potential precisely, and on a continuous

basis.

Strictly speaking, the zirconia probe is not

sensing carbon at all. It is an oxygen sensor with

a mVDC output described by Equation (1).

Fortunately, an empirical (experimental)

relationship exists between oxygen concentration

and carbon potential, and this relationship has

been used in carbon control instruments since the

early ‘70’s. The equation used by most control

manufacturers today is illustrated by Equation

(2), which states that there are only three

variables affecting the measured millivoltage.

Because the actual equation used is somewhat

complex, it is not reproduced here. A full

description of probe theory will be found in SSi

technical bulletin T4401 (Zirconia Sensor

Theory).

GOLD PROBE MANUAL

ZIRCONIA O2 RESPONSE

Ec = 0.0276TR log (Pf /Pa) millivolts (1)

Zr PROBE ALGORITHM

%C= ( EC , %CO, TR) mVDC (2)

Where: means ‘is a function of’

%C is the carbon potential

%CO is carbon monoxide percentage

TR is the absolute temperature in degrees

Rankine (deg. F + 460).

All competitive probes will invariably agree

within one or two millivolts when exposed to the

same atmosphere under equilibrium conditions.

Differences in values listed by probe vendors

relate to differences in manufacturers’ source

data, but the true value of the zirconia probe is its

repeatability.

and E

is the probe output in millivolts.

C

3

Page 6

GOLD PROBE MANUAL

INSTALLATION

If your new probe is to be installed in an existing

probe entry, be advised that your warranty

requires that the probe should extend no more

than 4" (101mm) into the furnace chamber. This

is because, at operating temperatures, the sheath

can sag enough to cause breakage of the zirconiasensing element.

For new installations, an entry fitting must be

provided at the furnace wall to permit the probe

to extend from 2" to 4" (51mm to 101mm) into

the furnace chamber. Listed here are several

conditions that should be considered when

choosing a location for the entry fitting. Most of

these conditions allow for some compromise, and

represent, at best, recommendations.

A variety of fittings have been used to provide

the 1" (25.4mm) NPT entry. The simplest is the 1

1/2" (38mm) coupling, as shown in Fig. 4.

NOTE:

Your Gold Probe™ has been thoroughly

tested in our controlled atmosphere furnace.

Therefore, the sheath shows evidence of

thermal discoloration.

ENTRY FITTING LOCATION

♦ In top third of work zone......

♦ Close to control thermocouple......

♦ Distant from radiant tubes......

♦ Away from carrier gas entry......

♦ Clear of work baskets......

The furnace is prepared by drilling a 1 1/2"

(38mm) diameter hole through the wall and the

insulation. The hole must be at right angles to the

wall to avoid interference with probe insertion.

The fitting is then welded or screwed to the wall

to provide a gas-tight entry.

Your Gold Probe™ has been shipped with an o-

ring compression fitting which allows you to

adjust the insertion. Manual tightening of the cap

is adequate for side mounting. A wrench should

be used for vertical mounting to assure probe will

not move. When installing in a hot furnace, insert

the first four inches directly, then at a rate of 2"

(51mm) per minute in order to avoid thermal

shock fracture.

4

WARNING

Zirconia is thermal shock sensitive. Insert

into hot furnace no faster than 2" (51mm)

per minute (after first 4 inches or 101

millimeters).

Page 7

INSTALLATION (CONT’D)

If you already have a control system for your

carbon sensor, you have been provided with a

reference air supply and perhaps a probe

conditioning system as well (see Fig. 6). It is

important to emphasize that the reference air be

clean and dry. Any combustibles or moisture in

the reference air will cause the sensor to read low,

resulting in over-carburization. Avoid the use of

lubricated plant compressed air. Air connection at

the sensor should be silicone rubber tubing to

avoid problems related to the high temperatures

normally encountered at the sensor connection

block.

Your final installation should look similar to that

of Fig. 4.

GOLD PROBE MANUAL

Fig. 4

MAINTENANCE

Furnace conditioning: The destructive effect of

carbon and temperature at high levels is conceded

by manufacturers who normally instruct in the art

of “gentle burnout”. SSi engineers have

developed an even gentler routine that shortens or

eliminates the time required to “season” the

furnace after a burnout has been completed. The

recommended routine for burnout is to set the

temperature to 1500°F (815°C), discontinue the

carrier gas, and start to add air at a rate that will

not cause a large increase in temperature. A flow

rate of about 10% of the normal flow of carrier

gas has been found adequate. Eventually, the

Gold Probe™ output will fall to 200 mV. At this

point, discontinue the air and observe the probe

output. If the output rises above 250 millivolts in

less than 15 minutes, turn the air on and repeat

the routine until the mV level remains below 250

for more than 15 minutes. Burnoff is complete.

See Fig.5.

600

500

400

Ec

millivolts

300

250

200

100

VALVE OPEN

VALVE CLOSED

TYPICAL FURNACE BURNOUT

BURNO UT COMPLETE

TIME

Fig. 5

15 MIN

5

Page 8

GOLD PROBE MANUAL

Maintenance (con’t)

The reason this technique is superior is that the

carbon retained in the pores of the refractory is

what constitutes “seasoning”. Complete burnout,

however gentle, removes this carbon and requires

that it be added during a Monday morning startup seasoning routine, in order to achieve

operating levels.

Probe conditioning: While periodic furnace

burnout is desirable, the process by which solid

carbon or ‘soot’ is deposited continues in the

probe, and must be remedied more frequently to

keep the probe in peak operating condition. SSi

technical staff has pioneered in techniques to

achieve this. Soot deposition occurs in two

critical locations; the annular space between the

sheath and the measuring surface and at the

measuring junction between the zirconia and the

contact point with the sheath, which is the

measuring electrode. The probe is burnt out by

the flowing air into this space through the burnout

fitting provided. The flow of air must be set at a

rate that allows a temperature rise of no more

than 100 degrees Farenheit (38 degrees Celsius).

If possible the flow should be set high enough to

overcome the effect of the work chamber fan and

drop the output voltage well below 800 MV,

preferably < 200 MV. Conducting this process for

a 90 second period before or after each batch, or

every six to twelve hours in a continuous furnace,

will provide adequate conditioning in most cases.

See Fig. 6.

TYPICAL PROBE BURNOUT SYSTEM

Fig. 6

6

Page 9

TROUBLE SHOOTING

GOLD PROBE MANUAL

When trouble arises with a furnace control

system, it is important to establish where the

problem is located; the probe, signal

transmission lines, the control instrument, or

the furnace itself. Several simple tests can help

to isolate the problem quickly. It is most

important to first understand the nature of the

fault. Aside from erratic behavior like cycling,

or failure to stabilize at the set point, the most

common symptom is non-conformity of the

work pieces to quality assurance

specifications.

To evaluate most faults, the recommended

tools are:

1. a good 3 ½ digit millivolt meter with at

least 10 megΩ input impedance and 0

to 1999 mV range,

2. a temperature calibrator and,

3. a simulator to output 0 to 1300

millivolts at less than 50 megohms

output impedance.

Probe troubleshooting: In order to establish

the source of problems in your installation,

first resist the temptation to remove the Gold

Probe from the furnace. All of the following

meaningful questions must be answered while

your Gold Probe (or any other carbon sensor)

is in the furnace, at temperature, and exposed

to a normal atmosphere under manual control:

1. Does an Alnor dew point reading (or

shim stock analysis) verify the indicated

value from the probe? If there is reasonable

correlation, the problem is NOT the probe.

2. Are the connections from the T/C

extension wire and sensor cable clean and

firmly attached at the correct probe and

control instrument terminals? Note that the

shield wire in the sensor cable should be

connected to ground at the control

instrument end only!

SYMPTOM POSSIBLE CAUSE

High % C ♦Low reading due to:

• High probe resistance

• Cracked zirconia

• Dirty reference air

• Faulty cable insulation

• Instrument calib./ calc.

• Air leak to burnoff fitting

• Furnace air leak at probe

♦Oily parts or sooted furnace

♦Wrong recipe time/temp

Low % C ♦High Reading due to

• Probe plugged with soot

• Instrument calib./calc.

♦Wrong recipe time/ temp

Erratic ♦Faulty signal due to

• Bad sensor connections

• Electrical noise source

• Radiant tube leak

• Bad Endo

• Mixing valve setting

• Instrument setting

Sooted fce ♦Endo not cracked (temp too

Low in generator or

Catalyst inactive)

3. Is the control instrument CO or H2 factor set to

the appropriate value? This “factor” is referred

to by various manufacturers as Zone Factor,

Process Factor, Gas, Furnace Factor, CO

Factor, Calibration Factor, etc. This factor may

require adjustment in order to make the

calculated %C or dew point agree with other

measurements.

4. Do the actual Gold Probe temperature and O

mV signal, as measure by the temperature

calibrator, and digital voltmeter, agree with the

displayed values on the control instrument? If

not, and instrument calibration problem is

likely.

2

7

Page 10

GOLD PROBE MANUAL

TROUBLESHOOTING (cont’d)

5. Is the probe impedance less than 50

kilohms at temperatures above 1550ºF

(843°C)? Conduct the test shown in Fig. 3

using a shunt resistor greater than 50

kilohms. Measure the voltage E

before

C

shunting, then EM with the shunt in place.

Calculate RP. If it exceeds 50 kilohms,

proceed to step 8, below.

6. How quickly does the probe react to a

change in O2 concentration? Read the

probe millivolts with the controller or the

digital meter. Short the probe for 5

seconds, remove the short and measure the

time required to return to within 1% of the

original reading. If it exceeds 30 seconds,

proceed to step 8, below.

7. Is there a leak in the zirconia substrate? To

test this property, turn off the reference air

for one minute. Measure the probe mV as

indicated by the controller or a digital

voltmeter. Turn the air back on and

measure the mV again. If there is a

difference greater than 25 mV, replace the

probe.

8. If probe resistance or response times are

questionable as indicated in steps 5 and 6, we

recommend that the probe be burned off.

Introduce 10 to 15 CFH of air to the burnoff

fitting for about 90 to 120 seconds, and then

repeat the tests. Should problems persist, it

may be necessary to conduct a thorough

furnace burnout so that all potentially

contributing contamination is removed from

all parts of the furnace, including the Gold

Probe. Burning off the probe will not harm

this product provided the probe temperature

does not exceed 2000ºF (1093°C) during the

burnoff procedure.

9. Should it be necessary to remove your Gold

Probe from a hot furnace, do so carefully.

UNDER NO CIRCUMSTANCES should

it be removed faster than 2" (51mm) per

minute.

10. Failing resolution of your atmosphere control

problems our technical support staff is

available Mon. - Fri. 7:00 a.m. to 7:00

p.m. to assist and serve our heat treating

customers. Call us at (800) 666-4330.

CONTROL SYSTEMS

If you are using the Gold Probe as a

replacement in an existing system, you will

find that performance is as good as or better

than you are accustomed to. If you plan on a

new system to upgrade your controls, you can

rely on Super Systems to provide you with

exactly what you need. From the simplest

on/off controls to the most sophisticated

programmable PID controls with computer

interface, data logging, production tracking,

recipe design, scheduling, reports, integrated

8

order entry and invoicing. Fig. 7 and Fig. 8

illustrate simple control and probe

conditioning systems as supplied by Super

Systems. SSi is positioned to provide a “plug

and play” system that is operator friendly.

Components such as valves, flow meters,

cable and tubing are supplied with each SSi

system so that no search and purchase effort

is involved in installation.

Page 11

CONTROL SYSTEMS (cont’d)

GOLD PROBE MANUAL

ENLARGED VIEW OF

GENERATOR INSTALLATIO N.

HOT FACE,

GENERATOR

COMBUSTION

CHAMBER.

FILE- GENRHT2..DWG

CHILLED ENDO

FILTERED SAMPLE

OR BURNOFF AIR

TO RETORT

BURNOFF SYSTEM

REFERENCE

AIR

REFERENCE AIR

SENSOR CABLE AND

T/C EXTENSION WIRE.

CARBURETOR

(MIXING VALVE)

GENERATOR MANIFOLD

SSi

SUPER SYSTEMS INC.

CINCINNATI, O H

BURNOFF

AIR

POWER

MAIN

MAIN

GAS

AIR

AIR/GAS MIXING PUMP

SAMPLE

GAS

3-WAY VALVE

FILTER

CONTROL SYSTEM

SSi

SUPER SYSTEMS INC.

CINCINNATI, OH

TRIM

GAS

ENDO TO FURNACE

TRIM

AIR

CONTROL OUTPUTS

AIR

ENDOTHERMIC GENERATOR REHEAT WELL SAMPLING, CONDITIONING AND CONTROL SYSTEM

Fig. 8

9

Page 12

GOLD PROBE MANUAL

Super Systems Inc. (SSi), as manufacturer of the Gold Probe™, warrants it

to be free from defects in material and workmanship under normal use and

service. SSi’s obligation under this warranty is limited to repairing or

replacing, at its option, the sensor described herein, should failure occur

within the one-year warranty period. The warranty period shall commence

on installation of the sensor, as certified by receipt of the postage free

Registration Card accompanying the sensor. If premature failure occurs, the

sensor, along with the Warranty Claim Report, must be returned in the

complete, original packaging to SSi. Upon receipt, SSi will conduct an

examination as to the cause of failure, at which time appropriate action will

be taken.

There are no warranties, expressed or implied, by the distributors or

representatives for the Gold Probe™, except the expressed warranty against

defects described above. There will be no applicable warranty in the event of

breakage resulting from thermal or mechanical shock. Additionally there

will be no applicable warranty for a probe that has been subject to misuse,

negligence or accident.

WARRANTY

For sensors operating at elevated temperatures, the warranty period is

prorated such that full warranty is granted for operation below 1850°F

(1010°C); six months warranty for temperatures between 1850°F (1010°C)

and 1950°F (1065°C); three months warranty between 1950°F (1065°C) and

2050°F (1121°C), and no warranty above 2050°F (1121°C).

This warranty cannot be honored unless the Registration Card is received at

SSi prior to the Warranty Claim Report, and the use and installation is

accomplished according to the techniques and procedures described in the

Gold Probe™ Manual. SSi shall in no way be liable for special or

consequential damages related to the use of this sensor.

10

Page 13

GOLD PROBE MANUAL

We suggest that you use this space to keep a record of installation date, test data and

experiences with your Gold Probe™.

NOTES

CARBON vs. DEW POINT WITH TEMPERATURE

11

Page 14

GOLD PROBE MANUAL

%CO = 20.0 %H2 = 40.0 Af = 1.00 Note: Dewpoint shown in degrees Farenheit.

TEMP

→

% C

↓

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

1450F

(788C)

142 137 133 129 124 120 117 113 109 106 103 99 96

117 113 108 104 101 97 94 90 87 84 81 78 75

103 99 95 91 88 84 81 77 74 71 68 66 63

93 89 86 82 78 75 72 69 66 63 60 57 55

86 82 78 75 71 68 65 62 59 56 53 51 48

80 76 73 69 66 63 60 57 54 51 48 46 43

75 71 68 64 61 58 55 52 49 46 44 41 39

71 67 64 60 57 54 51 48 45 43 40 37 35

67 63 60 57 53 50 47 45 42 39 37 34 32

64 60 57 53 50 47 44 41 39 36 34 31 29

60 57 54 50 47 44 41 39 36 33 31 28 26

58 54 51 48 45 42 39 36 33 31 28 26 24

55 52 48 45 42 39 36 34 31 28 26 24 21

1475F

(802C)

1500F

(815C)

1525F

(829C)

1550F

(843C)

1575F

(857C)

1600F

(871C)

1625F

(885C)

1650F

(899C)

1675F

(913C)

1700F

(927C)

1725F

(940C)

1750F

(954C)

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

1.35

1.40

1.45

53 49 46 43 40 37 34 31 29 26 24 21 19

50 47 44 41 38 35 32 29 27 24 22 19 17

48 45 42 39 36 33 30 27 25 22 20 18 15

46 43 40 37 34 31 28 25 23 20 18 16 14

44 41 38 35 32 29 26 24 21 19 16 14 12

42 39 36 33 30 27 25 22 19 17 15 12 10

41 37 34 31 28 26 23 20 18 15 13 11 9

39 36 33 30 27 24 21 19 16 14 12 9 7

37 34 31 28 25 22 20 17 15 12 10 8 6

36 32 29 26 24 21 18 16 13 11 9 6 4

34 31 28 25 22 19 17 14 12 10 7 5 3

3329262421181513118642

312825221917141297520

30272421181513108631-1

2825221917141197420-2

272421181513108531-1-3

1.50

26232017141197420-2-5

Compliments of Super Systems, Inc., Cincinnati, OH 45249 800-666-4330

For use with SSi Models DP2000 and DPC2500

CARBON vs. MILLIVOLTS WITH TEMPERATURE

12

Page 15

%CO= 20.0 Note: Dewpoint shown in degrees Farenheit

GOLD PROBE MANUAL

TEMP

→

% C

↓

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

1450F

(788C)

961 963 965 967 968 970 972 974 976 978 979 981 983

993 996 998 1000 1002 1005 1007 1009 1011 1014 1016 1018 1020

1012 1015 1018 1020 1023 1025 1028 1030 1033 1035 1038 1040 1043

1026 1029 1032 1034 1037 1040 1042 1045 1048 1050 1053 1056 1059

1037 1040 1043 1046 1048 1051 1054 1057 1060 1063 1065 1068 1071

1046 1049 1052 1055 1058 1061 1064 1067 1070 1073 1076 1078 1081

1054 1057 1060 1063 1066 1069 1072 1075 1078 1081 1084 1087 1090

1061 1064 1067 1070 1073 1076 1079 1082 1086 1089 1092 1095 1098

1067 1070 1073 1076 1079 1083 1086 1089 1092 1096 1099 1102 1105

1072 1075 1079 1082 1085 1089 1092 1095 1098 1102 1105 1108 1112

1077 1080 1084 1087 1091 1094 1097 1101 1104 1107 1111 1114 1117

1082 1085 1089 1092 1095 1099 1102 1106 1109 1113 1116 1119 1123

1086 1090 1093 1097 1100 1104 1107 1110 1114 1117 1121 1124 1128

1475F

(802C)

1500F

(815C)

1525F

(829C)

1550F

(843C)

1575F

(857C)

1600F

(871C)

1625F

(885C)

1650F

(899C)

1675F

(913C)

1700F

(927C)

1725F

(940C)

1750F

(954C)

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

1.35

1.40

1.45

1090 1094 1097 1101 1104 1108 1111 1115 1119 1122 1126 1129 1133

1094 1098 1101 1105 1108 1112 1116 1119 1123 1126 1130 1134 1137

1098 1102 1105 1109 1112 1116 1120 1123 1127 1131 1134 1138 1141

1101 1105 1109 1112 1116 1120 1123 1127 1131 1134 1138 1142 1146

1105 1109 1112 1116 1120 1123 1127 1131 1135 1138 1142 1146 1149

1108

1111 1115

1114 1118 1122 1126

1117 1121 1125 1129 1133 1137

1120 1124 1128 1132 1136 1140 1144

1123 1127 1131 1135 1139 1143 1147 1151

1126 1130 1134 1138 1142 1146 1150 1154 1158 1162

1128 1132 1136 1140 1144 1149 1153 1157 1161 1165 1169

1131 1135 1139 1143 1147 1151 1155 1159 1164 1168 1172 1176 1180

1134 1138 1142 1146 1150 1154 1158 1162 1166 1171 1175 1179 1183

1136 1140 1144 1149 1153 1157 1161 1165 1169 1173 1178 1182 1186

1112 1116 1119 1123 1127 1131 1134 1138 1142 1146 1149 1153

1119 1123 1126 1130 1134 1138 1142 1145 1149 1153 1157

1130 1133 1137 1141 1145 1149 1153 1157 1160

1141 1144 1148 1152 1156 1160 1164

1148 1151 1155 1159 1163 1167

1155 1159 1162 1166 1170

1166 1170 1174

1173 1177

1.50

1139 1143 1147 1151 1155 1160 1164 1168 1172 1176 1180 1185 1189

COMPLIMENTS OF SUPER SYSTEMS INC., CINCINNATI, OH 45249 800-666-4330

Note: mV values in italic bold correspond to saturation limits of carbon in steel

13

Page 16

Page 17

SSiSUPER SYSTEMS INC.

7205 Edington Drive Cincinnati, Ohio 45249

1-513-772-0060 1-800-666-4330 FAX 1-513-772-9466

Loading...

Loading...