Page 1

atmosphere

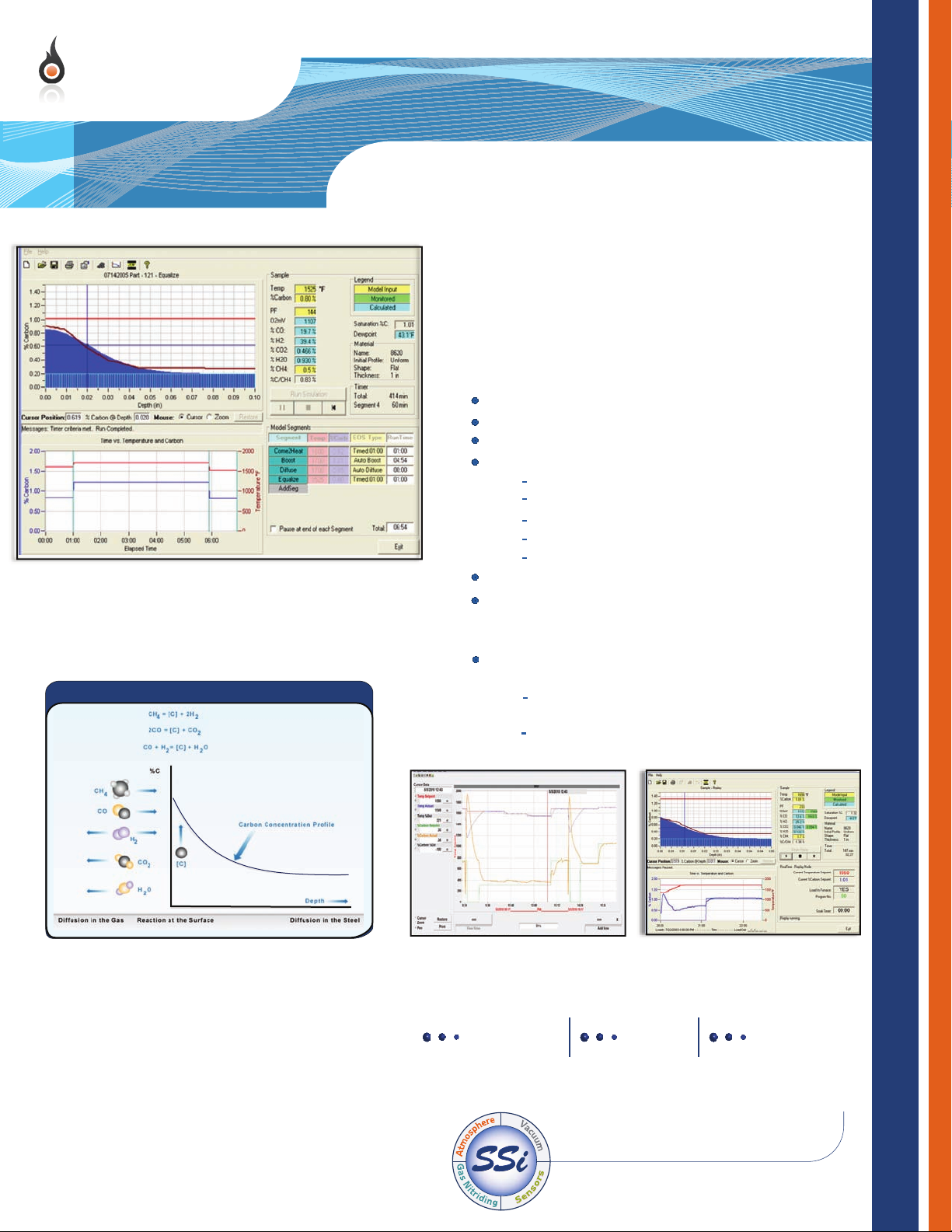

Calculated times for boost and diffuse segments. Simulation

process with the total allotted time is displayed in the lower

right-hand corner.

Diffusion and Transport in the Gas Phase

TM

CarbCALC II

Heat Treat Cycle Simulation Software

Software package designed to optimize a heat treat cycle using

input parameters of the type of steel, temperature, atmosphere,

and the specifications for case depth and carbon at case depth.

Run CarbCALC II for cycle simulation, for real-time simulation

and replay analysis. Use actual data log data to run through for

determining the carbon profile.

Optimize carburizing process

Predict precise case depth

Computer aided design of heat treatment processes

User entered parameters

Quickly perform process experiments

Accurately predict the carbon content below the

surface of the part. Input process variables for

simulation

Automatic segment calculation for Boost and Diffuse

carburizing cycles based on case depth requirements

Temperature and %C

%C at case depth

Alloy number (steel composition)

Time

Circulation

Let the program provide you with the time

for each segment based on desired results

Modify parameters and compare results

In order for carbon to be made available to the steel surface,

the carburizing reactant gases ( CO, CH , H ) must get to

the surface while carburizing product gases ( CO ,H 0, H )

are trying to escape from the surface. CarbCALC II uses a

numerical solution to Fick’s 2nd law for carbon diffusion into

the steel.

4 2

2 2 2

INNOVA TI V E S O LU T I O N S WO R L D W I D E

A12-02201123-001

Converts superdata logdata into a CarbCALC %C

trend profile giving the ability to re-work free loads.

Real-Time

Replay

SuperSystems

The screen image above shows the simulation

real time process running.

Simulation

incorporated

Page 2

Atmosphere Control

Heat Treat Cycle Simulation Software

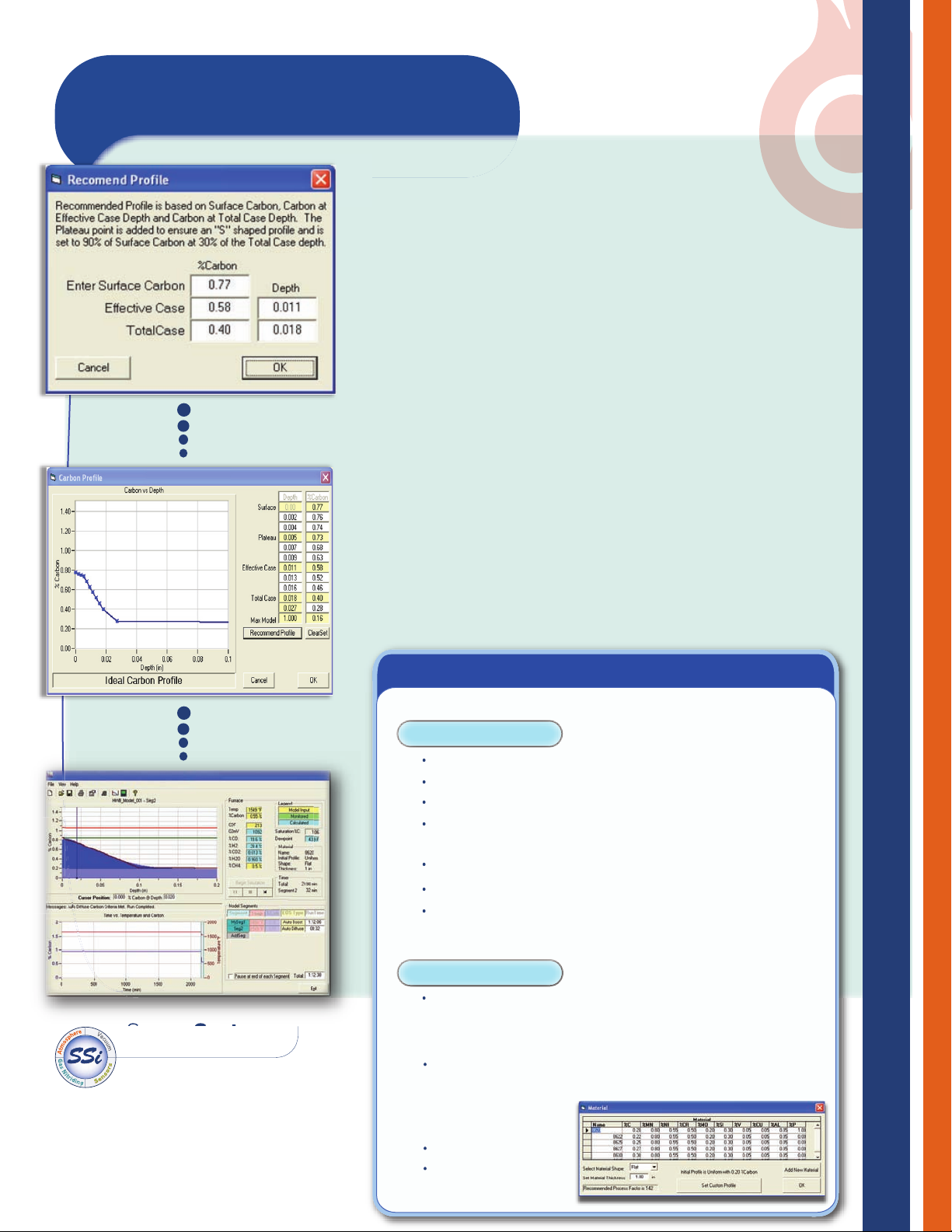

Simulation programs provide heat treaters with a blueprint to the end result of a cycle

leading to precise case depth and a consistent carbon gradient delivering the best results.

CarbCALC II allows the operators to input material type, part thickness, shape, desired

surface carbon, case depth and total case and builds boost and diffuse time based on the

desired temperature and carbon potential. Using the Auto Boost and Auto Diffuse segments

the program completes these steps. Auto Boost will complete when the amount of carbon

above the desired carbon blueprint (aka carbon gradient) is equal to the deficient carbon.

The Auto Diffuse segment ends when the carbon above the carbon blueprint is depleted.

This provides you the time to run each segment for these steps of the cycle.

Additional segments can be added for heat-up and cool down or additional steps necessary

based on equipment and part requirements. “What-if” analysis can be performed by changing

temperatures or carbon potential to see the effects on the overall cycle. When used in control

mode, CarbCALC II will modify the time in the boost and diffuse segments based on actual

results. Data is gathered in real-time and if the steps require more or less time to reach the

end of the step, adjustments are made automatically.

TM

CarbCALC II

SuperSystems

incorpo rated

7205 Edington Drive

Cincinnat i , OH 4524 9

513.772.0060 phone

513.772.9466 fax

CarbCALC II Features

Benefits

Ability to develop recipes for re-working

Real-Time process monitoring

Real-Time control and process replay

“What if” analysis change to gauge impact of an existing process

or material

Recipe development

Higher quality and shorter process times via process optimization

Tools needed to empower your employees when working in heat

treating

Configuration

User Defined Furnaces

-Ability to simulate loads in multiple furnaces

-Configured communications and channel selection

Alloy Database

-Most common materials used in metal treating

-Create new material

-Custom profile

User Configured Parts

Real-time / Replay Mode

www.supersyst ems.c om 800.666.4 330

Loading...

Loading...