Page 1

PROGRAMMABLE ATMOSPHERE AND TEMPERATURE

CONTROLLER

Series 9205

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

800-666-4330

Fax: 513-772-9466

www.supersystems.com

Page 2

Table of Contents

INSTALLATION SAFETY REQUIREMENTS ------------------------------------------------------------------------------------------------------ 4

CHAPTER 1 - OVERVIEW --------------------------------------------------------------------------------------------------------------------------- 7

MOUNTING ------------------------------------------------------------------------------------------------------------------------------------------- 8

DIMENSIONAL DRAWINGS --------------------------------------------------------------------------------------------------------------------------- 9

WIRING-----------------------------------------------------------------------------------------------------------------------------------------------11

ELECTRICAL INSTALLATION --------------------------------------------------------------------------------------------------------------------------11

PIN OUT ----------------------------------------------------------------------------------------------------------------------------------------------12

ANCILLARY ITEMS ------------------------------------------------------------------------------------------------------------------------------------12

SETUP ------------------------------------------------------------------------------------------------------------------------------------------------13

ADDITIONAL FEATURES ------------------------------------------------------------------------------------------------------------------------------13

ETHERNET CONNECTIONS ---------------------------------------------------------------------------------------------------------------------------13

INSTRUMENT START-UP -----------------------------------------------------------------------------------------------------------------------------14

FLASH CARD & FLASH CARD READER --------------------------------------------------------------------------------------------------------------14

OPERATOR INTERFACE SCREEN SAVER -------------------------------------------------------------------------------------------------------------14

DEFAULT STATUS SCREEN ---------------------------------------------------------------------------------------------------------------------------14

MENU ------------------------------------------------------------------------------------------------------------------------------------------------15

CHART ------------------------------------------------------------------------------------------------------------------------------------------------15

CHART SUB MENU ----------------------------------------------------------------------------------------------------------------------------------16

RECIPE ------------------------------------------------------------------------------------------------------------------------------------------------17

LOOPS ------------------------------------------------------------------------------------------------------------------------------------------------19

ACK (ALARM ACKNOWLEDGE) ----------------------------------------------------------------------------------------------------------------------19

DATA LOGGING USING FLASH CARD ----------------------------------------------------------------------------------------------------------------19

CHAPTER 2 - CONFIGURATION -----------------------------------------------------------------------------------------------------------------21

MENU (CONFIGURATION) --------------------------------------------------------------------------------------------------------------------------21

Logs ----------------------------------------------------------------------------------------------------------------------------------------------23

Probe Manager -------------------------------------------------------------------------------------------------------------------------------23

Slave Communications Status -------------------------------------------------------------------------------------------------------------23

Load TC/Auxiliary Analog Input ----------------------------------------------------------------------------------------------------------23

Manual Event Control -----------------------------------------------------------------------------------------------------------------------24

Shutdown ---------------------------------------------------------------------------------------------------------------------------------------24

Probe Burnoff Setup -------------------------------------------------------------------------------------------------------------------------24

PID Loop Setup --------------------------------------------------------------------------------------------------------------------------------25

Recipe Edit -------------------------------------------------------------------------------------------------------------------------------------27

Load T/C Configuration ---------------------------------------------------------------------------------------------------------------------28

Trend Chart Edit ------------------------------------------------------------------------------------------------------------------------------28

Communications Setup ---------------------------------------------------------------------------------------------------------------------29

Slave Instrument Setup ---------------------------------------------------------------------------------------------------------------------31

Zone Assignments ----------------------------------------------------------------------------------------------------------------------------33

Furnace Setup ---------------------------------------------------------------------------------------------------------------------------------35

Default Wait Limits --------------------------------------------------------------------------------------------------------------------------38

Alarm Setup ------------------------------------------------------------------------------------------------------------------------------------39

Thermocouple Check ------------------------------------------------------------------------------------------------------------------------40

Relay Assignments ---------------------------------------------------------------------------------------------------------------------------41

Analog Input Setup---------------------------------------------------------------------------------------------------------------------------42

Analog Output Setup ------------------------------------------------------------------------------------------------------------------------44

Alarm Polarity ---------------------------------------------------------------------------------------------------------------------------------45

Redundant TC Setup -------------------------------------------------------------------------------------------------------------------------45

Event Hold/Reset -----------------------------------------------------------------------------------------------------------------------------46

Security ------------------------------------------------------------------------------------------------------------------------------------------46

Series 9205 Operations Manual Rev - 1

Page 3

Curve Entry -------------------------------------------------------------------------------------------------------------------------------------48

Alternate PID Setup --------------------------------------------------------------------------------------------------------------------------49

Aux Analog Input Setup ---------------------------------------------------------------------------------------------------------------------49

Calibration -------------------------------------------------------------------------------------------------------------------------------------50

Configuration ----------------------------------------------------------------------------------------------------------------------------------52

A/I Module Offset Correction -------------------------------------------------------------------------------------------------------------56

Aux Setpoint Configuration ----------------------------------------------------------------------------------------------------------------56

T/C Extension Correction Curves ---------------------------------------------------------------------------------------------------------56

Generic Instruments -------------------------------------------------------------------------------------------------------------------------57

DF1 Configuration ----------------------------------------------------------------------------------------------------------------------------58

Tuning Assistant ------------------------------------------------------------------------------------------------------------------------------58

PLC Data Mapping ---------------------------------------------------------------------------------------------------------------------------59

Analog Input Correction Curves ----------------------------------------------------------------------------------------------------------60

Instrument Calculation ----------------------------------------------------------------------------------------------------------------------60

CHAPTER 3 – CONFIGURATOR 2.0 MENUS --------------------------------------------------------------------------------------------------63

BURNOFF ---------------------------------------------------------------------------------------------------------------------------------------------63

SLAVE INSTRUMENTS --------------------------------------------------------------------------------------------------------------------------------65

AUXILIARY ANALOG INPUT --------------------------------------------------------------------------------------------------------------------------65

MANUAL EVENT CONTROL --------------------------------------------------------------------------------------------------------------------------66

PROBE BURNOFF SETUP -----------------------------------------------------------------------------------------------------------------------------66

PID LOOP SETUP ------------------------------------------------------------------------------------------------------------------------------------68

EVENT RUN PROGRAM SETUP ----------------------------------------------------------------------------------------------------------------------70

ZONE/LOAD TC SETUP ------------------------------------------------------------------------------------------------------------------------------70

PORT SETUP ------------------------------------------------------------------------------------------------------------------------------------------71

SLAVE INSTRUMENT SETUP -------------------------------------------------------------------------------------------------------------------------71

ZONE ASSIGNMENTS --------------------------------------------------------------------------------------------------------------------------------72

FURNACE SETUP -------------------------------------------------------------------------------------------------------------------------------------74

DEFAULT WAIT LIMITS ------------------------------------------------------------------------------------------------------------------------------76

ALARM SETUP----------------------------------------------------------------------------------------------------------------------------------------77

THERMOCOUPLE CHECK -----------------------------------------------------------------------------------------------------------------------------78

RELAY SETPOINTS ------------------------------------------------------------------------------------------------------------------------------------79

RELAY ASSIGNMENTS --------------------------------------------------------------------------------------------------------------------------------80

ANALOG INPUT SETUP-------------------------------------------------------------------------------------------------------------------------------81

ANALOG OUTPUT SETUP ----------------------------------------------------------------------------------------------------------------------------83

PASSCODE AND ALARM -----------------------------------------------------------------------------------------------------------------------------84

IP ADDRESS ------------------------------------------------------------------------------------------------------------------------------------------85

REDUNDANT TC SETUP -----------------------------------------------------------------------------------------------------------------------------85

EVENT CONTROL -------------------------------------------------------------------------------------------------------------------------------------86

SET MENU SECURITY --------------------------------------------------------------------------------------------------------------------------------86

CURVE ENTRY ----------------------------------------------------------------------------------------------------------------------------------------87

ALTERNATE PID SETUP ------------------------------------------------------------------------------------------------------------------------------87

SSI ANALOG INPUT SETUP --------------------------------------------------------------------------------------------------------------------------88

SSI CONFIGURATION AND CALIBRATION -----------------------------------------------------------------------------------------------------------89

Overview ----------------------------------------------------------------------------------------------------------------------------------------89

Equipment needed ---------------------------------------------------------------------------------------------------------------------------89

Notes --------------------------------------------------------------------------------------------------------------------------------------------89

Calibrate Aux Analog Input ----------------------------------------------------------------------------------------------------------------89

9205 User Calibration -----------------------------------------------------------------------------------------------------------------------92

9205 Full Calibration ------------------------------------------------------------------------------------------------------------------------93

A/I MODULE OFFSET CORRECTION ----------------------------------------------------------------------------------------------------------------94

AUX SETPOINT CONFIGURATION -------------------------------------------------------------------------------------------------------------------95

TC EXTENSION CORRECTION CURVES --------------------------------------------------------------------------------------------------------------95

Series 9205 Operations Manual Rev - 2

Page 4

GENERIC INSTRUMENT SETUPS ---------------------------------------------------------------------------------------------------------------------96

Configure Generic Instruments -----------------------------------------------------------------------------------------------------------96

Configure IP Addresses ----------------------------------------------------------------------------------------------------------------------97

Configure Block Writes ----------------------------------------------------------------------------------------------------------------------97

DF1 CONFIGURATION -------------------------------------------------------------------------------------------------------------------------------97

TUNING ASSISTANT ----------------------------------------------------------------------------------------------------------------------------------98

PLC DATA MAPPING ------------------------------------------------------------------------------------------------------------------------------ 100

ANALOG INPUT CORRECTION CURVES ------------------------------------------------------------------------------------------------------------ 100

INSTRUMENT CALCULATION----------------------------------------------------------------------------------------------------------------------- 100

PROGRAMMER DESCRIPTION --------------------------------------------------------------------------------------------------------------------- 103

OPCODES ------------------------------------------------------------------------------------------------------------------------------------------- 103

WAIT ----------------------------------------------------------------------------------------------------------------------------------------------- 116

WAIT UP ------------------------------------------------------------------------------------------------------------------------------------------- 116

WAIT DOWN --------------------------------------------------------------------------------------------------------------------------------------- 117

WAIT IN A GUARANTEED SOAK ------------------------------------------------------------------------------------------------------------------- 118

GUARANTEE HIGH ASSIGNMENT ----------------------------------------------------------------------------------------------------------------- 119

SAMPLE EVENT ASSIGNMENTS -------------------------------------------------------------------------------------------------------------------- 120

FLASH CARD MANAGEMENT ---------------------------------------------------------------------------------------------------------------------- 120

SLAVE INSTRUMENT MAPPING ------------------------------------------------------------------------------------------------------------------- 124

Atmosphere Instruments ----------------------------------------------------------------------------------------------------------------- 124

Temperature Instruments ---------------------------------------------------------------------------------------------------------------- 127

Events Instruments ------------------------------------------------------------------------------------------------------------------------- 132

9205 DEFAULT CONFIGURATION ---------------------------------------------------------------------------------------------------------------- 135

9205 ANALOG INPUT BOARD JUMPER SETTINGS ----------------------------------------------------------------------------------------------- 151

APPENDIX A – WIRING DIAGRAM OF SERIES 9205 ------------------------------------------------------------------------------------- 153

APPENDIX B – GUIDE TO BUILDING A RECIPE -------------------------------------------------------------------------------------------- 155

Series 9205 Operations Manual Rev - 3

Page 5

!

!

Installation Safety Requirements

Safety Symbols

Various symbols are used on the instrument; they have the following meaning:

Caution, (refer to the accompanying documents)

Functional earth (ground) terminal!

The functional earth connection is required for safety purposes and to ground RFI

filters.

Personnel

Installation must only be carried out by technically qualified personnel.

Enclosure of live parts

To prevent hands or metal tools from touching parts that may be electrically live (powered), the

controller must be installed in an enclosure.

Caution:

Live sensors

Do not connect live (powered) sensors to any signal input on the controller. Live

sensors are sensors that must be connected to the main's supply. The controller has

transient protection circuits connected between the inputs and the earth connection

that might be damaged by live (powered) sensors.

Series 9205 Operations Manual Rev - 4

Page 6

Wiring

It is important to connect the controller in accordance with the wiring data given in this handbook.

Take particular care not to connect AC supplies to the low voltage power supply input. Use copper

wires for 24V DC power supply to the instrument. Ensure that the wiring of installations comply

with all local wiring regulations. For example in the United Kingdom use the latest version of the

IEE wiring regulations, (BS7671). In the USA use NEC Class 1 wiring methods.

Power Isolation

The installation must include a power isolating switch or circuit breaker. This device should be in

close proximity to the controller, within easy reach of the operator and marked as the

disconnecting device for the instrument.

Earth leakage current

Due to RFI Filtering there is an earth leakage current of less than 0.5mA. This may affect the

design of an installation of multiple controllers protected by Residual Current Device, (RCD) or

Ground Fault Detector, (GFD) type circuit breakers.

Over current protection

To protect the internal PCB tracking within the controller against excess currents, the AC power

supply to the controller and power outputs must be wired through a fuse or circuit breaker

specified in the technical specification.

Voltage rating

The maximum continuous voltage applied between any of the following terminals must not exceed

24V DC

relay or triac output to logic, DC or sensor connections;

any connection to ground.

The controller should not be wired to VAC. The 24V DC power supply voltage across the

connections and between the power supply and ground must not exceed 2.5kV. Where occasional

voltage over 2.5kV are expected or measured, the power installation to both the instrument

supply and load circuits should include a transient limiting device.

These units will typically include gas discharge tubes and metal oxide varistors that limit and

control voltage transients on the supply line due to lightning strikes or inductive load switching.

Devices are available in a range of energy ratings and should be selected to suit conditions at the

installation.

Series 9205 Operations Manual Rev - 5

Page 7

Conductive pollution

Electrically conductive pollution must be excluded from the cabinet in which the controller is

mounted. For example, carbon dust is a form of electrically conductive pollution. To secure a

suitable atmosphere in conditions of conductive pollution, fit an air filter to the air intake of the

cabinet. Where condensation is likely, for example at low temperatures, include a

thermostatically controlled heater in the cabinet.

Over-temperature protection

When designing any control system it is essential to consider what will happen if any part of the

system should fail In temperature control applications the primary danger is that the heating will

remain constantly on. Apart from spoiling the product, this could damage any process machinery

being controlled, or even cause a fire. Reasons why the heating might remain constantly on

include:

the temperature sensor becoming detached from the process;

thermocouple wiring becoming a short circuit;

the controller failing with its heating output constantly on;

an external valve or contactor sticking in the heating condition;

the controller set point set too high.

Where damage or injury is possible, we recommend fitting a separate over temperature

protection unit with an independent temperature sensor, which will isolate the heating circuit.

Please note that the alarm relays within the controller will not give protection under all failure

conditions.

Installation requirements for EMC

To ensure compliance with the European EMC directive certain installation precautions are

necessary as follows:

When using relay or triac outputs it may be necessary to fit a filter suitable for suppressing

the emissions. The filter requirements will depend on the type of load. For typical

applications we recommend Schaffner FN321 or FN612.

Routing of wires

To minimize the pick-up of electrical noise, the wiring for low voltage dc should be routed away

from high-current power cables. Where it is impractical to do this, use shielded cables with the

shield grounded at one end.

Series 9205 Operations Manual Rev - 6

Page 8

Chapter 1 - Overview

The 9205 is SSi’s versatile atmosphere programmable controller with Ethernet, RS485 Modbus,

and DF1 communications to various slave devices such as temperature controllers, flow meters,

and PLC’s. This instrument can be used to address many thermal processing applications where

temperature and carbon control along with event I/O management are necessary. The 9205 has

math block capability allowing custom calculations and custom Modbus mapping for

communications

The 9205 recipe programmer includes 24 independent steps per recipe with operational codes

(opcodes) to enable effective process control. The 9205 also supports multiple user interface

screens for more flexibility. Screen sizes include 3.5”, 5.7” and 12.1”. Functionality added to the

screens include “stylus” notes entry, user defined data points and trend charts for paperless

chart recording, zoom and pan touch screen control on the charting screen, and remote data

retrieval through Ethernet.

Series 9205 Operations Manual Rev - 7

Page 9

Approximate Box Dimensions

2.75" x 4" x 4.5"

Power Requirements

24VDC, 4 Watts

Digital Output Rating

300VAC / 1 AMP

Analog Output Load Rating

1000 Ohms (Total)

Controller Enclosure Rating

IP10 – hand protected

Number of RS232 Ports

Two (2)

Number of Ethernet Ports

One (1)

Number of RS485 Host Ports

One (1)

Number of RS485 Slave Ports

Two (2)

Number of Internal Relays

Eight (8)

Number of Analog Inputs

Three (3)

Number of Analog Outputs

Two (2)

Number of Digital Inputs

Four (4)

Number of Control Loops

Three (3)

!

The Model 9205 is powered by 24 VDC, not LINE Voltage. Please be careful when connecting

power to this controller. Connecting anything other than 24 VDC will cause serious damage.

The variety of input and output combinations allows SSi to configure the Model 9205 to control

temperature and atmosphere.

The product is available in three different screen sizes. 3.5”, 5.7” and 12”.

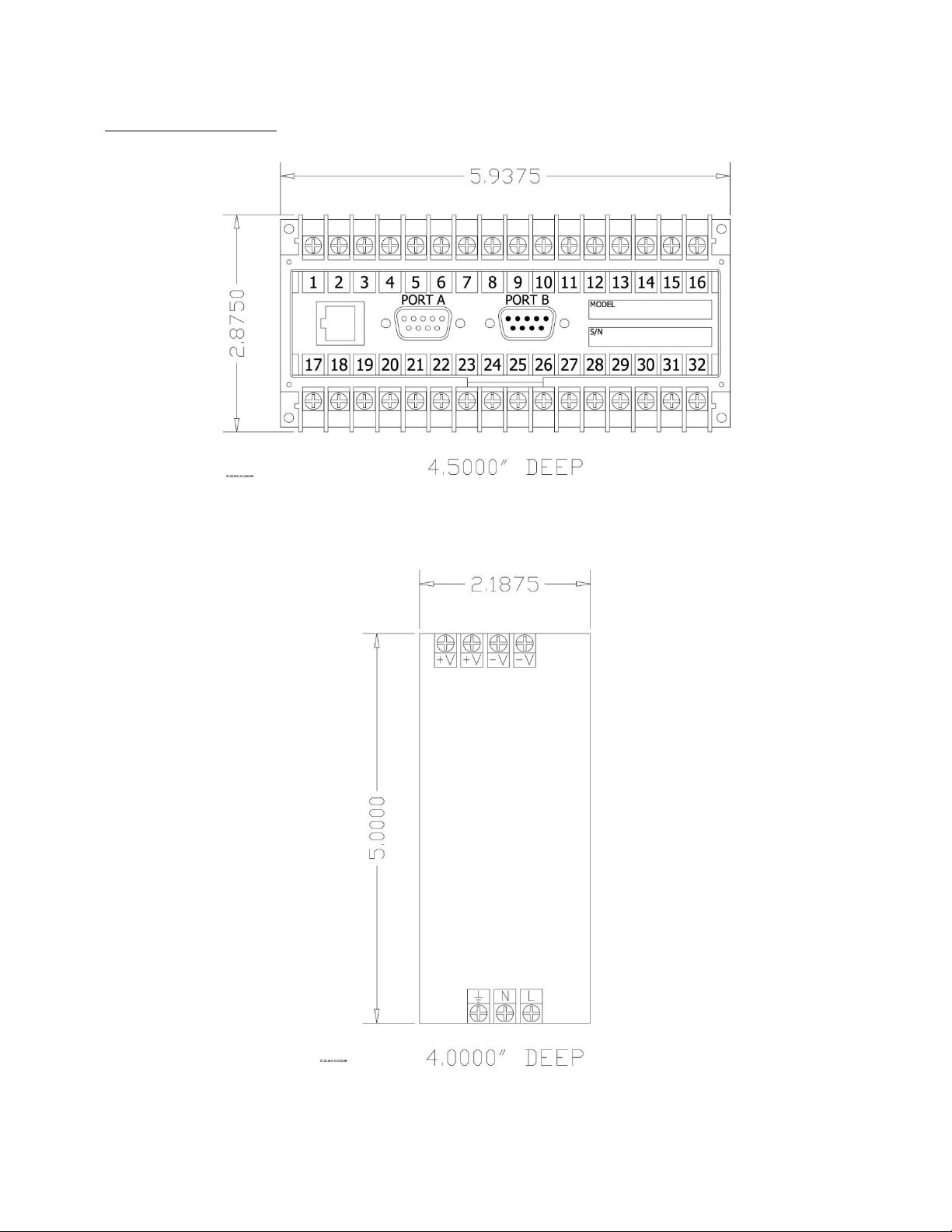

Mounting

The Series 9205 Operator Interface mounts into a panel or on a plate by using the enclosed

mounting brackets. A rectangular cutout is required; the size of the cutout is determined by the

operator interface size. These units, along with an optional SSi SR3, 6, or 9 analog input board,

will mount on a commercially available DIN rail. This can be mounted on the sub-panel on the

side of an enclosure for the convenience of the control system.

Series 9205 Operations Manual Rev - 8

Page 10

Dimensional Drawings

Series 9205 Controller Dimensions

24V DC Power Supply Dimensions

Series 9205 Operations Manual Rev - 9

Page 11

3.5” Operator Interface Cutout dimensions

5.7” Operator Interface Cutout dimensions

12” Operator Interface Cutout dimensions

Series 9205 Operations Manual Rev - 10

Page 12

Wiring

Wiring to the Series 9205 operator interface can be done using 232 or 485 to two connectors, comm1 (232)

or comm3 (485). The terminal strip on the lower right rear corner of the operator interface is used to

connect 24VDC power. The DB-9 port A connection is used to connect the display via 232 to the Series 9205

PID controller. The controller is connected via RS485 communication to the single-loop controllers.

Electrical Installation

The Model 9205 requires 24VDC, 4 Watt, 60 Hz, single-phase power. A 24 VDC power supply is

required and is generally included as part of the Model 9205 system. This power supply has a

universal input that can accept between 60 and 265VAC. Power should be applied in accordance

with the electrical drawings that have been supplied. Since each installation is unique to the site,

the customer is responsible for providing adequate power and making it available to the Model

9205 power supply.

SSi requirement:

MOV’s must be wired across the isolation relay coil terminals on all isolation relays that are

connected to solenoids. Further… MOV’s must be connected across the HOT and NEUTRAL wires

when the solenoid is wired to them. IT IS AN ABSOLUTE MUST to have the MOV’s at BOTH

LOCATIONS.

Series 9205 Operations Manual Rev - 11

Page 13

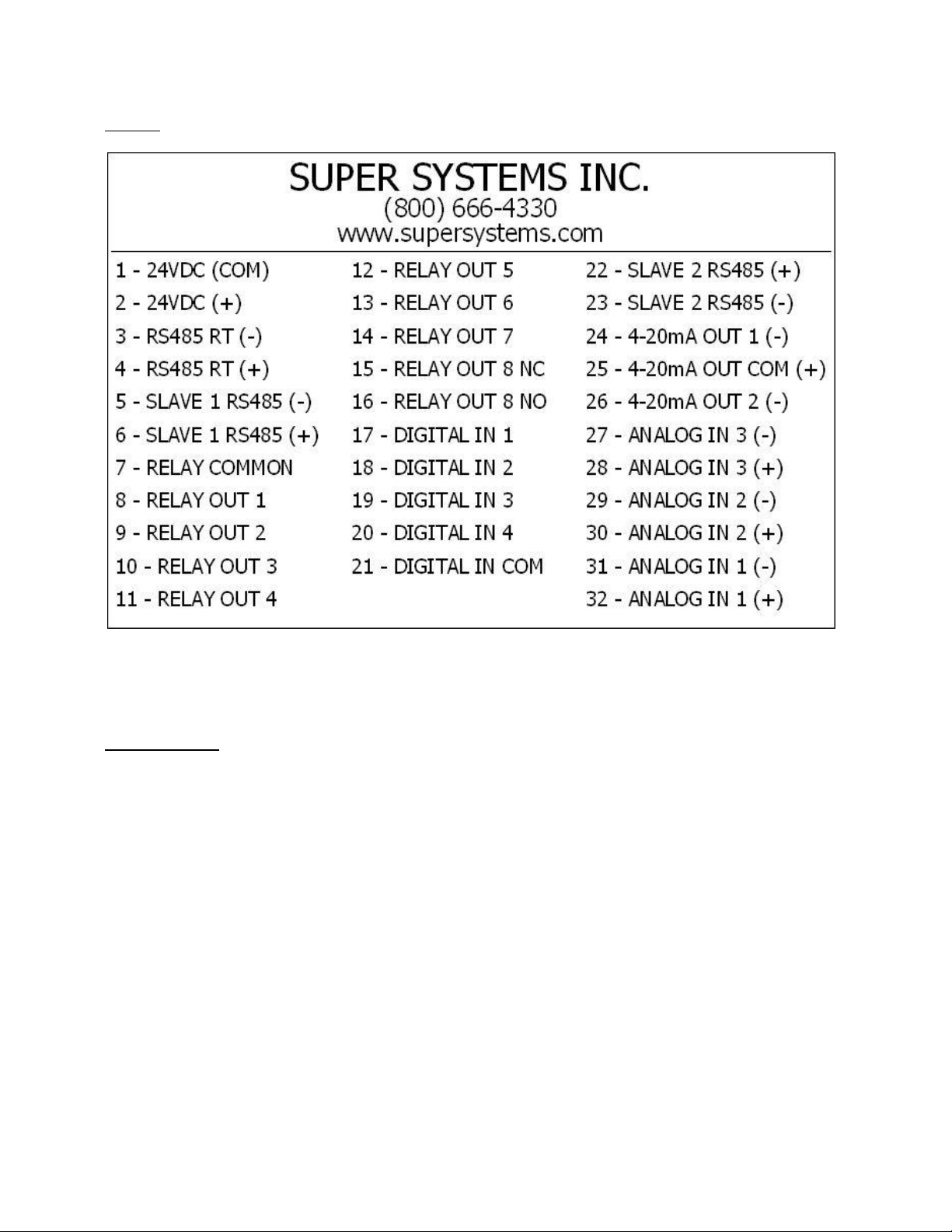

Pin Out

9205 Pin Out

A wiring diagram of the Series 9205 controller can be found in Appendix B.

Ancillary Items

The following items can be included with the Series 9205: a flash card, a flash card reader, a

touch screen, an RS232 cable, an RS485 cable, a 24V DC DIN rail mount power supply, and a

software CD with Configurator, the Configurator manual, TS Manager, and .NET 2.0. The flash

card installs the operator interface and the flash card reader connects to a Windows® based

computer.

The operator interface includes connections for a mouse and a keyboard. These may be

connected to the operator interface via USB, allowing the operators to use a mouse and keyboard

instead of the touch screen.

Series 9205 Operations Manual Rev - 12

Page 14

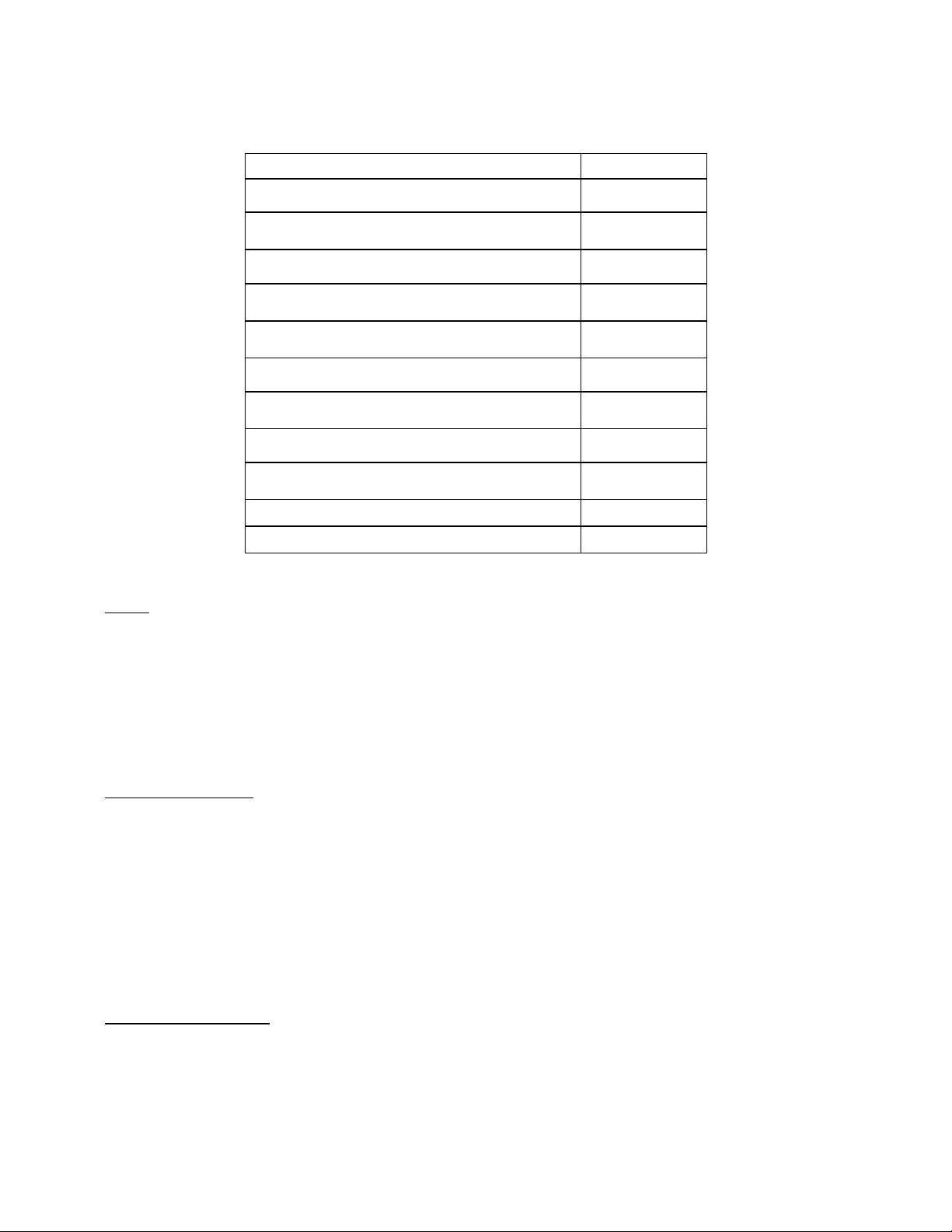

Part

Part Number

3.5" Operator Interface

13498

5.7" Operator Interface

13448

12" Operator Interface

13455

TS Manager/PC Configurator Software

13339

RS485 comms cable for 12.1” and 5.7 “

20576

RS485 comms cable for 3.5”

20635

Flash Card

13335

Flash Card Reader

13333

RS232 Cable

33027

24V DC Din Rail Mounted Power Supply

31135

9205 Controller

13443

The following table shows the ancillary items and their part numbers.

Setup

The Series 9205 setup consists of setting the local time if required. As shipped from the factory

the communications ports are set at 19200 baud in Modbus mode.

Time will be set for local time in Cincinnati, Ohio (EST /EDT) or time zone of location of city and

state on sales order. For instruction on adjusting these values, please see

Configuration

.

Chapter 3 -

Additional Features

The Operator Interface (touch screen) contains a removable compact Flash Card that can be used

to transfer data from the Model 9205 to a computer. It is located on the back of the touch screen

(see

Flash Card & Flash Card Reader

section for more details).

Also included is a Utility Software CD that includes SSi’s TS Manager. TS Manager is a utility

program that can be loaded onto any Windows® based computer (operating Windows 98® or

higher). This software will allow the computer to read the data from the TS Flashcard, and allow

it to be viewed in a manner that is similar to a strip chart recorder.

Ethernet Connections

The Ethernet connection has three distinct uses. First, should the Operator Interface fail, the

Ethernet connection allows a laptop to be connected via a crossover cable to the Series 9205 DIN

rail mounted unit using Internet Explorer Browser. This connection can act as a LIMITED

Series 9205 Operations Manual Rev - 13

Page 15

!

FUNCTION “operator interface” until the Operator Interface can be repaired or replaced. The

laptop needs to be operating a WINDOWS 98® or higher with Internet Explorer. The default IP

address is 192.168.0.200. If you are experiencing problems please call 800-666-4330 and talk with

our computer communications personnel. Secondly, the Ethernet port can be used for

communications to a SCADA software package. Call us at 800-666-4330 if you are interested in

this option. The third use for the Ethernet Port is the primary communications connection for the

Configurator 2.0 Software.

Instrument Start-up

On power-up, the Operator Interface will display a Microsoft Windows desktop screen for a few

seconds and then switch to the default Status screen.

Flash Card & Flash Card Reader

Never remove the flash card when the Operator Interface is “ON”.

To properly shut down the Operator Interface, press the Menu button on the default status

screen. Once the menu has been displayed, select the

to shut down the Operator Interface. See the

Chapter 2 – Configuration

Shutdown

option. At the prompt, press Yes

section for information on

navigating and using the menu system. This will display a conventional Microsoft Windows

screen. Sliding the black switch to the OFF position (located directly over the green power

connector, on the back of the Operator Interface) will turn off the power to the Operator Interface.

Once the Operator Interface is turned off, remove the compact flash card cover at the top of the

display unit, exposing the card. Press the black release button and the card will pop out of the

slot. To replace the flash card, simply return the card to the slot making sure that the release

button is in its UP position, and replace the flash card cover to its proper position. To restore

power to the unit, move the black switch to the right or ON position.

Operator Interface Screen Saver

The Operator Interface has a default screen saver. It automatically “blanks” the screen after ten

(10) minutes of non-activity. To disengage the screen saver, simply touch the screen and it will reappear.

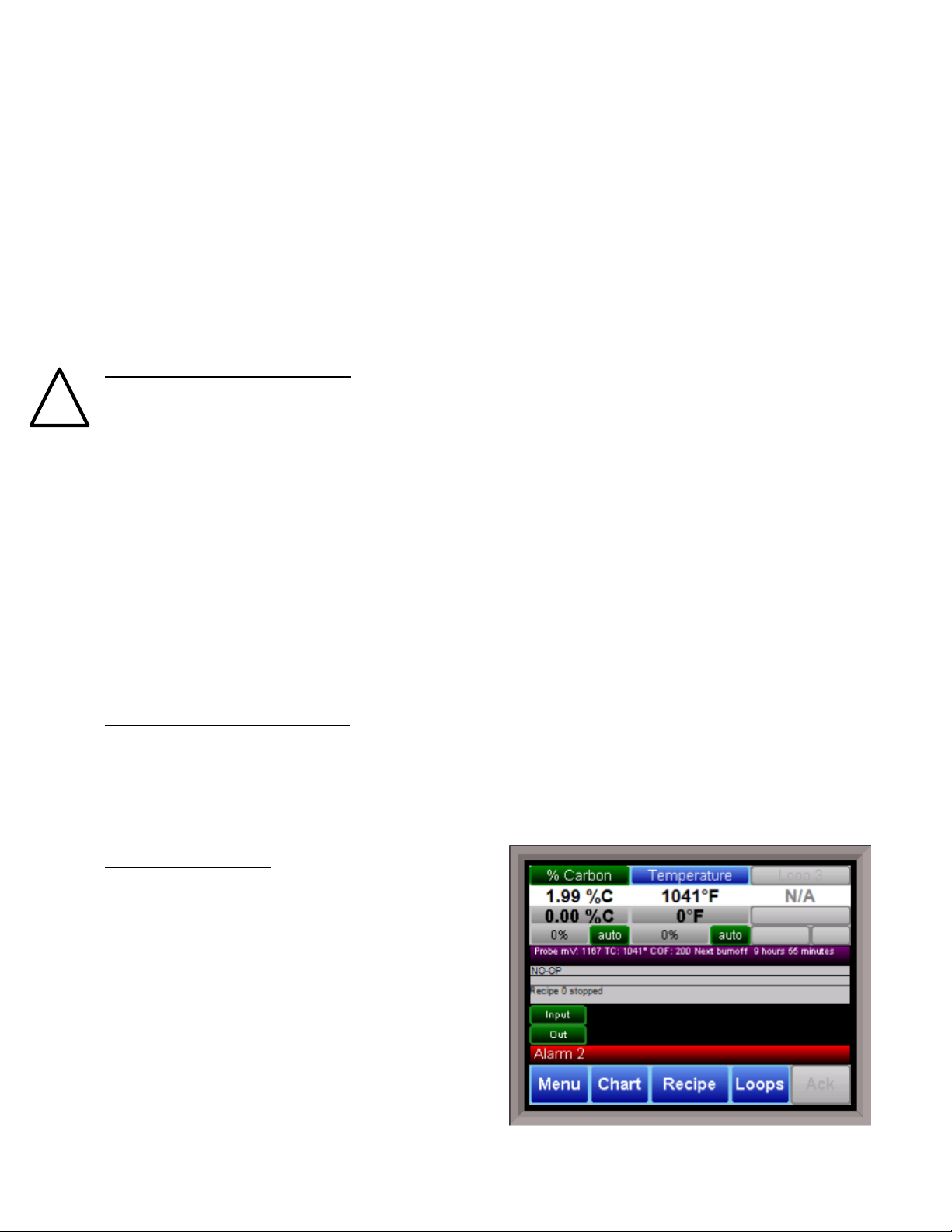

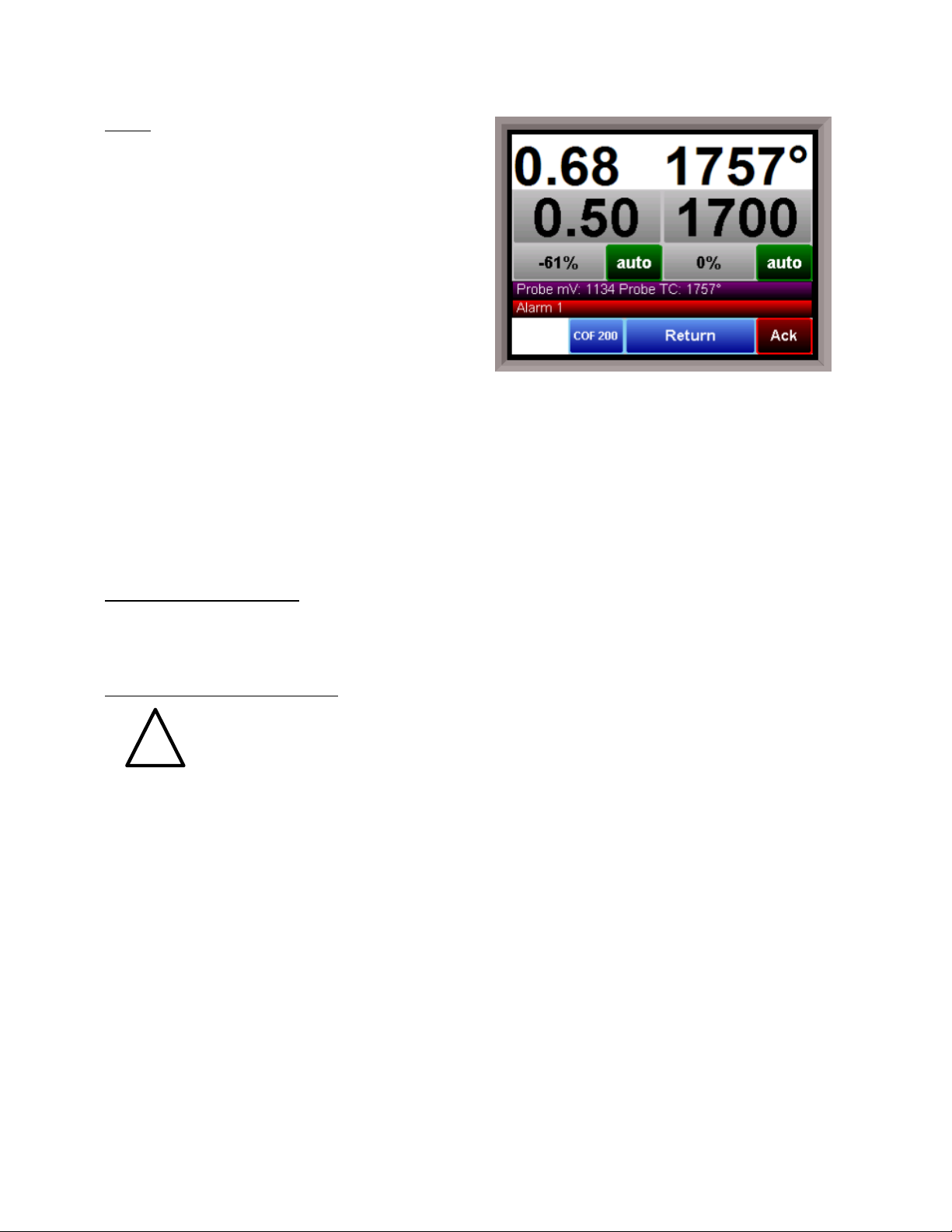

Default Status Screen

The Status Display shows the temperature controller

information as well as any auxiliary analog inputs, the

status of the timer, and an overview of the programmer.

There are five active buttons on the Status Display:

Menu, Chart, Recipe, Loops, and Ack.

The Menu button will display the

configuration menu.

The Chart button will display the video

recorder screen. Use of the Chart Display is

explained below.

Series 9205 Operations Manual Rev - 14

Page 16

The Recipe button will switch to the Program Display. This is a companion display to the status

screen and is described below.

The Loops button will display the main control loop, Temperature, as well as the timer status

and any auxiliary analog inputs.

The Ack (Alarm Acknowledge) button is used to acknowledge an alarm. The alarm message is

displayed directly under the recipe display. Is this only present when an alarm is going off.

Menu

There are three levels of menus in the Series

9205.

The first level is the

are functions or operations that are

typically handled by the furnace operator.

This menu is accessed without the need for

a pass code.

The second level is the

This level requires the entry of a level 1 or

a level 2-pass code.

The third level is the

This requires the level 2-pass code ONLY.

As shipped, the

level codes are set as 1 and 2 respectively. The pass codes can be changed at the Passcode and Alarm

Screen.

Note: Any level can access a lower level screen. For instance, the Administrator level passcode

supervisor

can access all of the Supervisor and Operator level screens

The menu items are explained in detail in

operator level

. These

supervisor level

administrator level

and

administrator

Chapter 2 – Configuration.

.

.

.

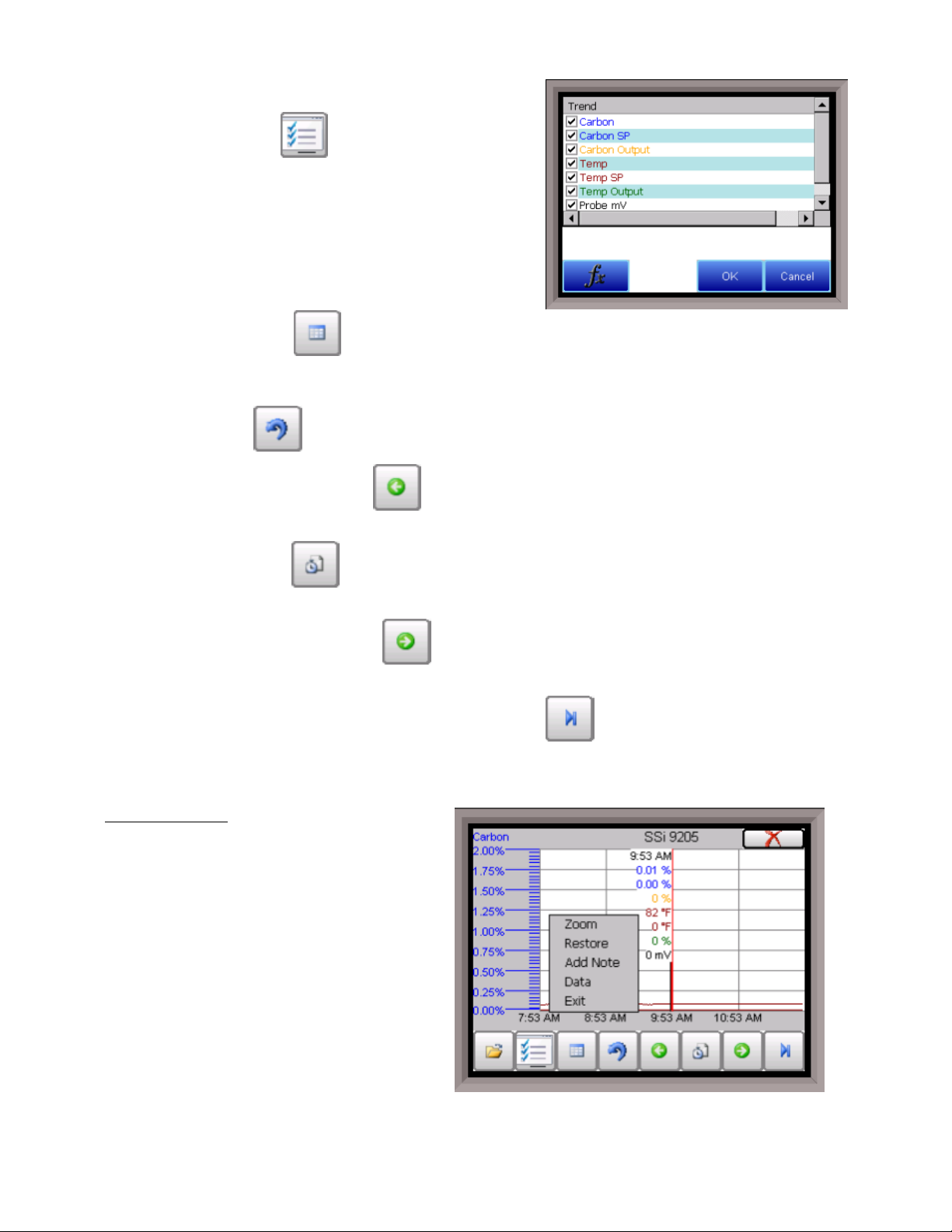

Chart

The Chart Display shows between 1 hour and 24

hours of process variable data on the screen and

can be scrolled back to view all of the data stored

on the hard drive. The vertical timelines change

as the time changes on the screen. Any trend

charts that have been created through the

Configuration menu are accessible here. See

the

Chapter 2 – Configuration

information on creating trend charts.

section for more

The function buttons run along the bottom of the

screen.

The folder button - -

Series 9205 Operations Manual Rev - 15

Page 17

The Trend Lines button - - will allow the user to

select or de-select the trend lines on the trend chart to

display. If the checkbox next to each trend line is checked,

then that trend line will be displayed.

`

The Datagrid View button - - will display a screen with

the trend data in a grid format instead of with trend lines. The trend data is shown in 1-minute intervals.

Clicking on the OK button on this screen will close the screen down and return to the Chart Display screen.

The Refresh button - - will refresh the screen’s trend data if the screen is not in real-time mode.

The left-pointing green arrow button - - will move the chart’s view backward in time by the

specified chart interval.

The chart interval button - - will determine the number of hours displayed on the trend chart. The

options are: 1 Hour, 2 Hours, 4 Hours, 8 Hours, 12 Hours, or 24 Hours.

The right-pointing green arrow button - - will move the chart’s view forward in time by the specified

chart interval.

The right-pointing arrow with the vertical line next to it button - - will put the chart into real-time

mode if it is not in real-time mode, or take the chart out of real-time mode if it is. When in real-time mode,

the chart will automatically be updated once a minute.

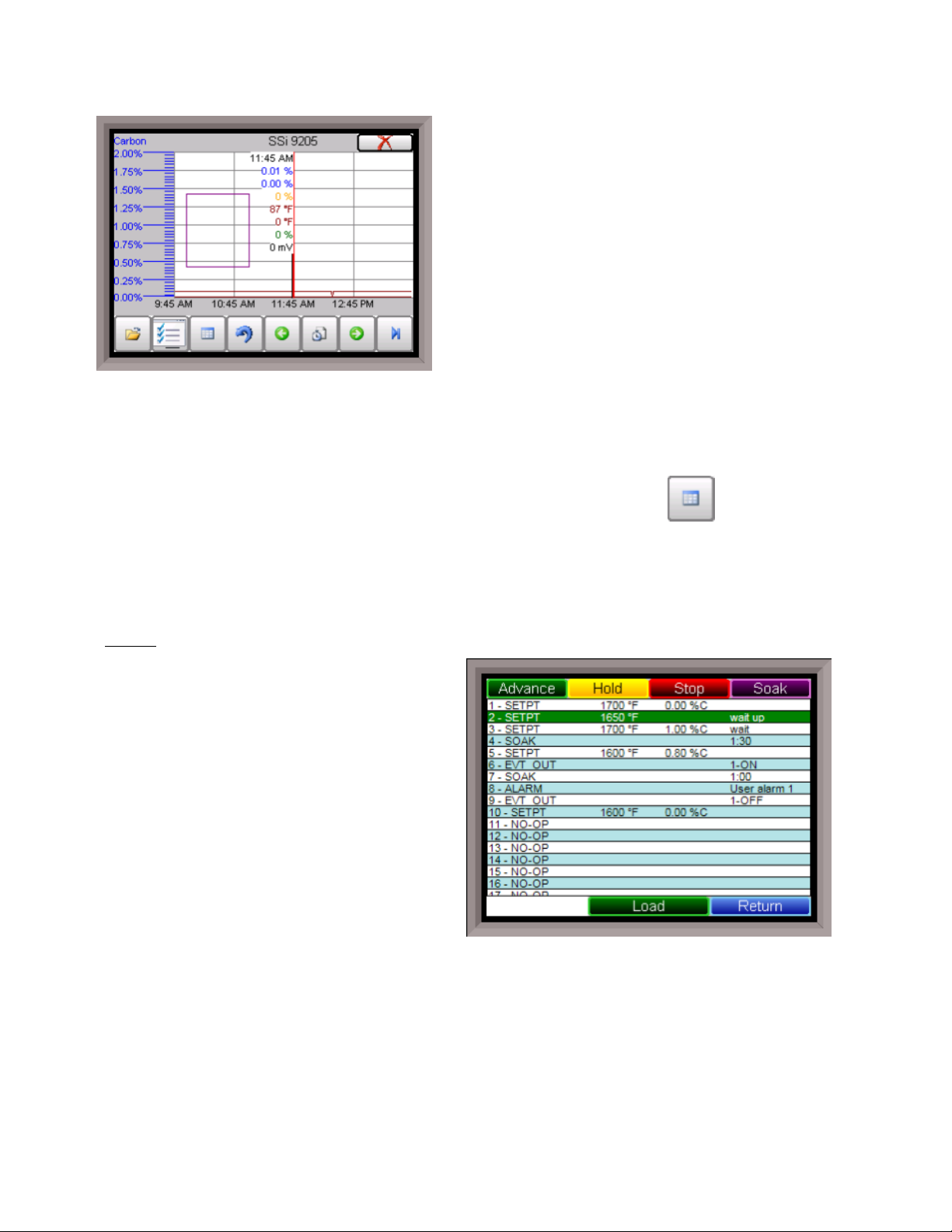

Chart Sub Menu

There is a sub-menu available by putting a

finger or a stylus anywhere on the chart and

holding it there for a couple of seconds. The

sub-menu will have the following options

available: Zoom, Restore, Add Note, Data, and

Exit.

Series 9205 Operations Manual Rev - 16

Page 18

The Zoom option will allow the user to zoom in on a

particular part of the screen. Once this has been

selected, the user can take a stylus or a finger and create

a box around the desired data. Once the user releases

the stylus or finger, a zoom is no longer possible, and the

user will need to re-select the option from the sub-menu

to zoom in again.

The Restore option will back out of any zoom options that

have been performed and display the chart screen as it

initially was.

The Add Note option allows the operator to enter a note

on the chart, similar to writing on a paper chart. The note

shows up when the chart is printed out using the utility

software included with the Series 9205 instrumentation. Pressing the Add Note option displays a screen

where the operator can enter the operator ID or initials and a note. The user has the option to enter a note

using the operator interface keyboard, where he or she will be able to type in the note; or the user can use

the Signature mode, which will allow them to write a note using a stylus.

The Data option will show the trend data as a data grid instead of the trend lines on a chart. This

functionality is exactly the same as if the user pressed the Datagrid View button - - from the chart

screen.

Exit will close out the sub-menu without selecting an item.

Pressing the red ‘X’ in the top right-hand corner of the screen will take the user back to the status screen.

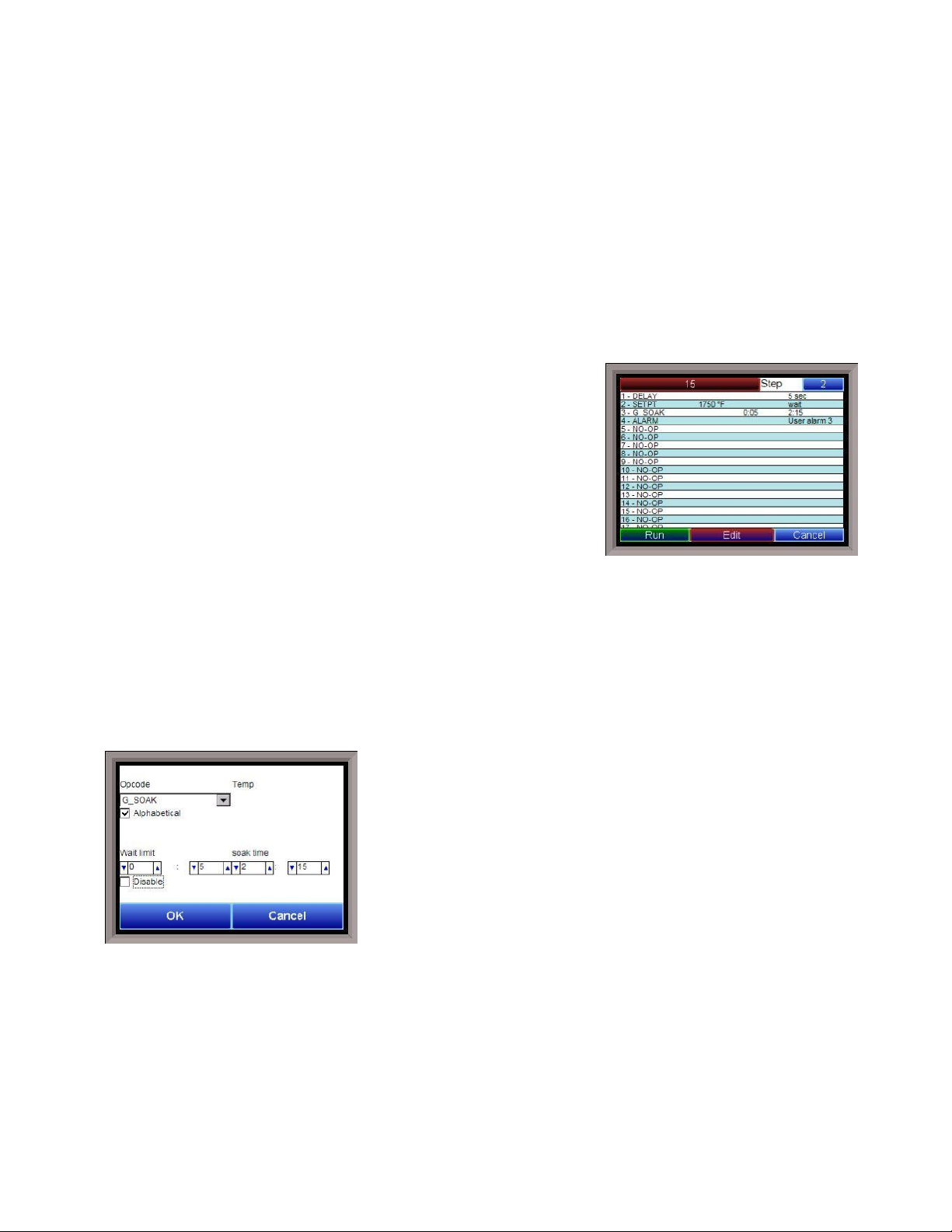

Recipe

Pressing the Recipe button on the main status

screen displays the recipe screen, which will

allow the user to load up an existing recipe and

start it, or see the currently running recipe.

The recipe screen shows the last program loaded

into the program run buffer and its status. If the

program is running, the active step number is

highlighted green. When the step is highlighted

green, then the recipe is running on that step.

When a step is highlighted yellow, the recipe is in

hold on that step. A red Acknowledge button in

the bottom left corner of the screen displays an

alarm condition.

Note – the main status screen

will also show the recipe running status, as well

as run time and remaining time for the step as

well as the entire recipe

The recipe screen has a total of seven buttons that will allow the user to load up a recipe, as well as control

the recipe and acknowledge an alarm.

.

The Advance button will advance the recipe to the next step in the recipe. The user will need to

confirm the advance command.

The Hold button places the displayed recipe program in hold. Once a decision is made that

affects the recipe, it may be continued by pressing the Resume button.

Series 9205 Operations Manual Rev - 17

Note – When a recipe is

Page 19

put into hold status, the text on the Hold button will change to “Resume”. When the step is

started up again, the text on the button will change back to “Hold”

hold status, the step will be highlighted yellow. The user will need to confirm the hold or

resume command.

The Stop button stops the recipe program that is currently running. Stop means exactly that! It

stops the program. It is NOT a hold button. See the description for the hold button above. To restart the program if it has been stopped you must use the Load button, enter the recipe

number, and then highlight the segment number of the recipe that you want to start with and

start the recipe again. The user will need to confirm the stop command.

The Soak button allows you to enter a new value for the time remaining in the current soak or

ramp cycle only – future soak or ramp cycle times cannot be modified. The step must be a soak

or ramp cycle for a change in soak/ramp time to be adjusted.

The Acknowledge button will acknowledge the alarm. In

most cases, it will be acknowledging

alarm must be acknowledged to allow the program to go

to the next step.

Note – The Acknowledge button is only

end of soak

. The

. When a recipe step is in a

visible when an alarm condition is present. Once the

condition is acknowledged, the Acknowledge button will

become invisible again

The Load button allows the operator to enter the recipe

number to be run and to view the recipe before pushing

the Run button. Pushing the Run button starts the recipe.

If a recipe program is running and the operator enters a new recipe program it can be viewed

and modified. The recipe does not become active until the Run button is pushed. Pressing Run

places the program currently being viewed in the active memory and will begin to run the new

recipe. To select the recipe to view or edit, click on the recipe number button in the top left

corner of the screen. This will display a screen where the user will be able to load up a valid

recipe (range 1 – 300). The program can be started in any step by clicking on the step number

button next to the “Step” text and entering the new step number (range 1 – 24), and then

pressing the Run key.

.

While reviewing the program that is about to be run, each step can be modified. Highlight a

step number and click on the Edit button. The opcode can be

changed with the drop down list at the top. This list can be sorted

alphabetically by click on the “Alphabetical” checkbox. The

parameters of the opcode can be modified on this screen as well.

See the

each opcode. Click on the OK button to accept the changes; click on

the Cancel button to ignore the changes.

Chapter 5 – Series 9205 Opcodes

recipe is a one-time edit, and will not affect the recipe that is saved

on the 9205 controller

Recipe screen to cancel loading a recipe and return to the main

recipe screen.

The Return button returns you to the main status screen.

Series 9205 Operations Manual Rev - 18

section for details about

Note – Any change to the

. Click on the Cancel button on the Load

Page 20

!

Loops

This screen will display the program loops for the

9205. Up to three loops can be displayed. The current

process variable is displayed at the top, with each loop

set point displayed beneath the process variable. The

operator can change the process set point by touching

the screen area below the large process variable

numbers. When pressing the Temperature set point, a

numeric keypad is displayed, showing the current

value and allowing the operator to enter a new set

point by simply pressing on the appropriate numeric

keys. Once the correct set point has been entered,

press the OK key to make the change. When the OK

key is pressed the display returns to the

Screen. Another active key within the

button toggles the controller’s mode between Auto and Manual. In the manual mode, pressing the percent

output button on the

output to control the “loop” in a manual mode to be entered. If a timer is running, the status will be

displayed at the top right of the screen. Any load T/Cs that are actively communicating will be listed in the

box to the right of the setpoint/percent output values. If an alarm condition is present, the alarm text will

be displayed below the loop information. If the alarm needs acknowledging, then the Alarm Ack button will

be displayed in the bottom left corner. If the alarm is part of a recipe step, the alarm will need to be

acknowledged before the recipe can move to the next step.

The Loops Screen also allows you to move back to the default Status Screen by pressing the Return.

Loops

Screen (next to the Auto/Man button) displays a numeric keypad, allowing a %

Loops

Loops

Screen is the Auto/Man (Auto/Manual) button. Pressing that

Ack (Alarm Acknowledge)

The Ack (Alarm Acknowledge) button will allow the user to acknowledge any alarms that have been

configured, or that have been made part of the recipes that run on the Series 9205. If a recipe has an alarm

as a step, the alarm must be acknowledged before the recipe will continue to the next step.

Data Logging using Flash Card

NOTE: See Warnings with respect to removing the Flash Card.

The Advantech TPC-642S/642-SE touch screen Operator Interface utilizing a Compact Flash

Card allows the unit to data log the parameters setup by a qualified SSi technician. Should a

customer not take the data offline in a timely manner, the data will be over-written, the oldest data being

over-written first. Here is how it works:

1. When the Operator Interface detects that there is less than 5% disk space left on the compact flash

card, an alarm will be displayed on the main interface screen stating "x% disk space remaining (overwrite

at 3%)". In the upper right corner, an ALM is indicated, but because it is not a communications alarm or a

9205 device alarm, the background remains green. This alarm will remain active until more than 5% of disk

space is available for writing data log files.

2. If the user does not copy the log data from the disk, it will eventually fall to 2% disk space. At this point,

the touch screen will select the oldest compressed file and delete it. It then checks to see if 3% remains. It

repeats this procedure until 3% disk space remains. At this point the alarm message changes to

"Overwriting data log data!” Because this allows the system to seesaw between 2% and 3%, it will continue

to display "Overwriting data log data!" until somebody offloads the files.

Technical concerns and details:

Series 9205 Operations Manual Rev - 19

Page 21

1. If there are not enough compressed files to bring the free space up to 3%, the system will hunt down and

kill hourly files. This should only happen if compression would not be running for some reason.

2. If all compressed files and hourly files have been removed and there is still not enough disk space

(perhaps a problem with the compact flash card), the data logger will not write to the disk until the

condition is remedied. (Alarms continue to display).

3. The data log data alarm is the lowest priority. The alarm priorities are touch screen communications,

then 9205 controller/programmer, then disk space.

See the Flash Card Management Section for more information.

Series 9205 Operations Manual Rev - 20

Page 22

Chapter 2 - CONFIGURATION

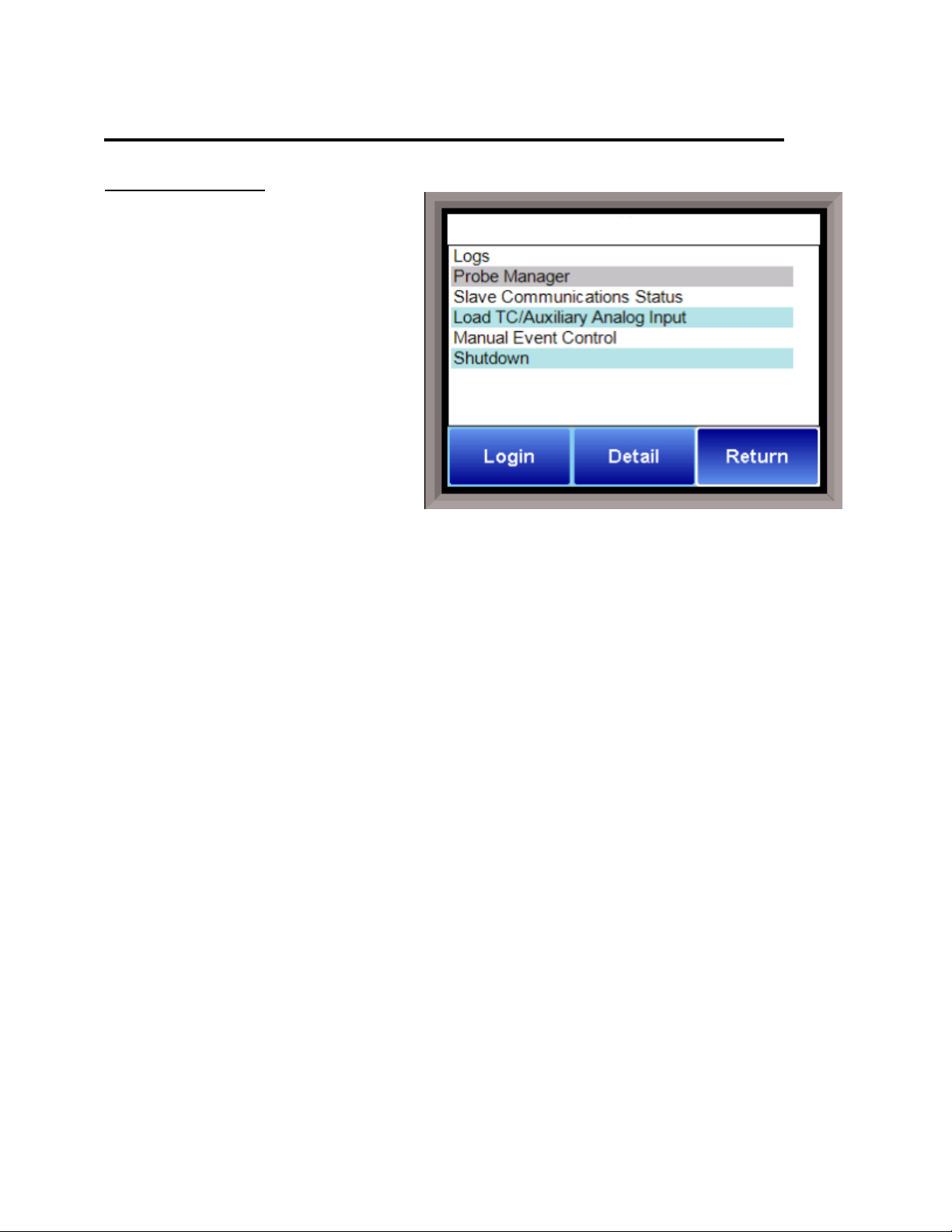

Menu (Configuration)

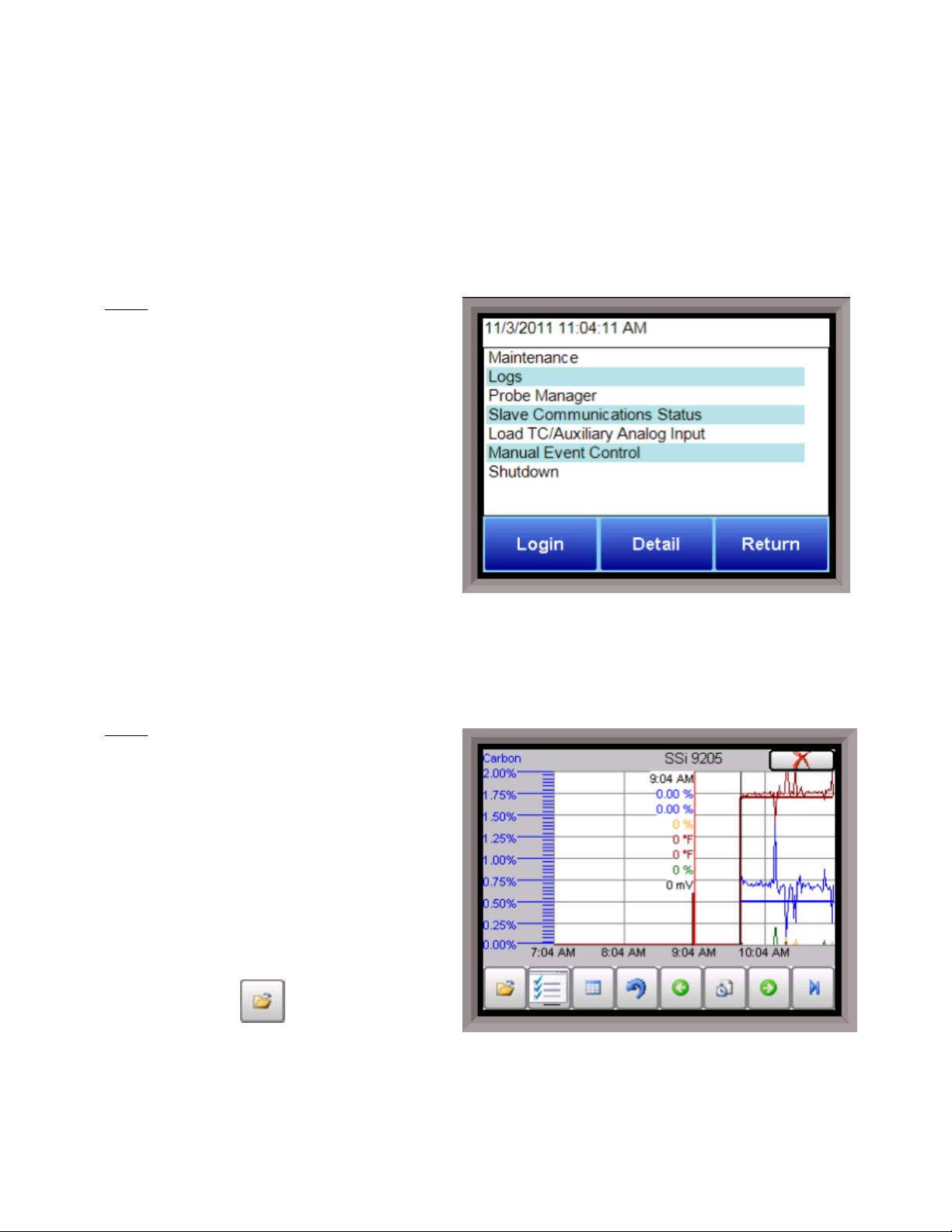

The Configuration Menu is entered through

the Menu key that is part of the four buttons

running along the bottom of the Default

Display Screen.

Pressing the Login key at the bottom of the

screen will allow the user to enter a login

user and password.

set up through the Security menu option in

this menu

case sensitive. There are three levels of

security for the menu system: Operator,

Supervisor, and Administrator. Pressing

the Login button will allow the user to enter

a user name and password to log in. When

the menu screen is first displayed, the

operator-level menu options are visible.

The list of the operator-level menu options

is:

The list of supervisor-level menu options is:

The list of administrator-level menu options is:

. User names and passwords are

Logs

Probe Manager

Slave Communications Status

Load TC/Auxiliary Analog Input

Manual Event Control

Shutdown

Logs

Probe Manager

Slave Communications Status

Load TC/Auxiliary Analog Input

Manual Event Control

Shutdown

Probe Burnoff Setup

PID Loop Setup

Recipe Edit

Load T/C Configuration

Trend Chart Edit

Logs

Probe Manager

Slave Communications Status

Load TC/Auxiliary Analog Input

Manual Event Control

Shutdown

Probe Burnoff Setup

PID Loop Setup

Recipe Edit

Note – users can be

Series 9205 Operations Manual Rev - 21

Page 23

Load T/C Configuration

Trend Chart Edit

Communications Setup

Slave Instrument Setup

Zone Assignments

Furnace Setup

Default Wait Limits

Alarm Setup

Thermocouple Check

Relay Assignments

Analog Input Setup

Analog Output Setup

Alarm Polarity

Redundant TC Setup

Event Hold/Reset

Security

Curve Entry

Alternate PID Setup

Aux Analog Input Setup

Calibration

Configuration

A/I Module Offset Correction

Aux Setpoint Configuration

T/C Extension Correction Curves

Generic Instrument Setup

DF1 Configuration

Tuning Assistant

PLC Data Matching

Analog Input Correction Curves

Instrument Calculation

The SSi code of the day can also be used to log in to the menu system. No user name will need to be

entered when entering this code. Currently, the menu list is identical to the administrator-level list. The

SSi code of the day is typically used for in-house configuration prior to shipment. The code can only be

provided by Super Systems at 800-666-4330.

To select any of the menu options, highlight that item by clicking on it, and click on the Detail button.

The Return button will return the user to the default display screen.

Series 9205 Operations Manual Rev - 22

Page 24

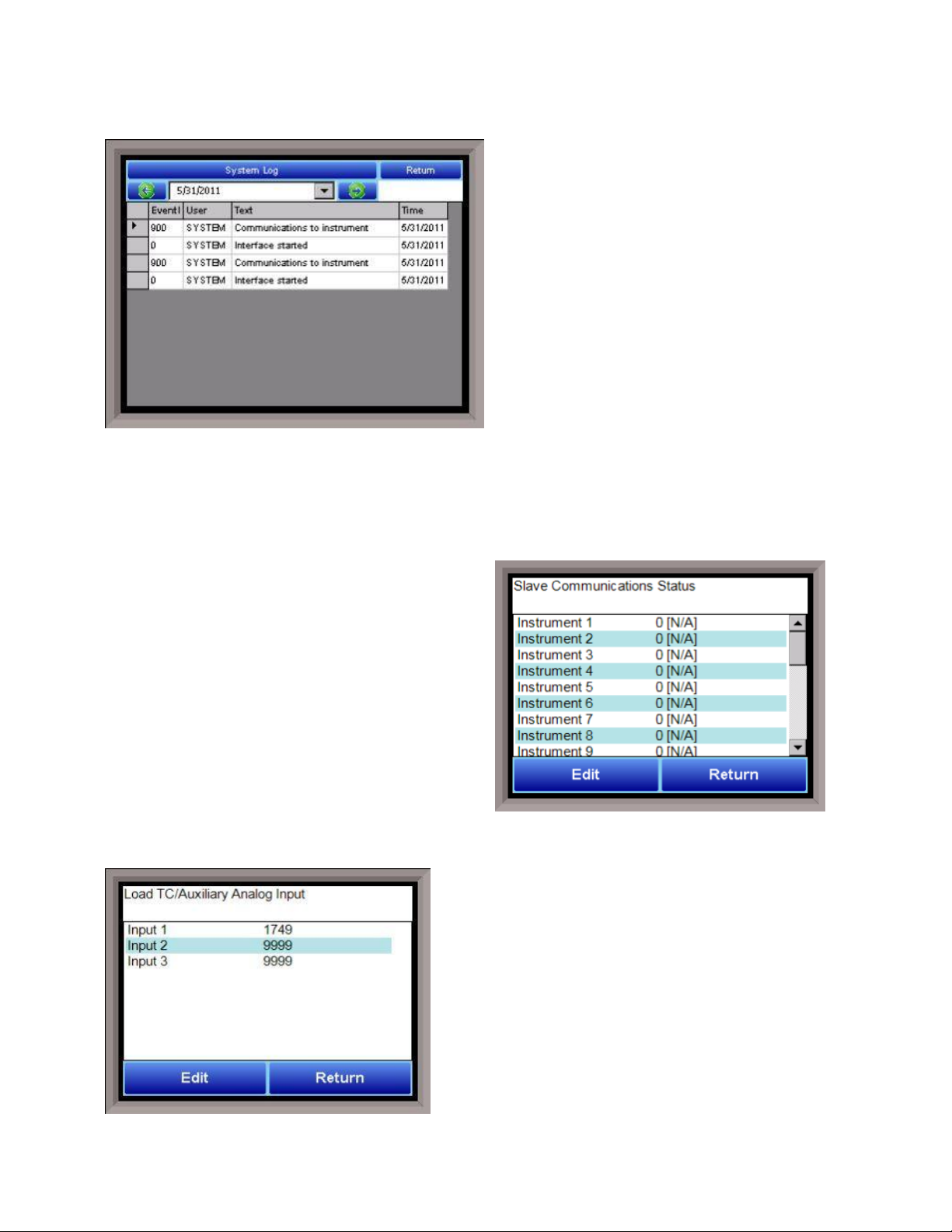

Logs

The Logs screen will allow the user to view three

different types of logs – System, Alarms, and

Cycle.

Clicking on the button that displays the log type

(System Log, Alarm Log, or Cycle Log) will allow

the user to select the type of log file to view.

The green directional arrows will display the

previous items in the log or the next items in the

log, if the log items are longer than one screen.

The drop down list in between the directional

arrows will allow the user to select the date of the

log items to view.

The Return button will return the user to the

menu screen.

Probe Manager

This option allows the user to register a probe within the 9205 by entering its serial number. Doing so

creates a tracking history of the probe burn-offs and impedance tests associated with it. Trends can be

monitored this way and the impedance of the probe can be traced to help estimate its life expectancy.

Slave Communications Status

This page is a display of the current process variables

of each of the slave instruments communicating with

the 9205 controller. These values are display-only,

and cannot be modified from this screen.

There are five possible messages that can occur to

describe the instrument communications status.

N/A – No instrument is connected

Bad – No communications exist

??? – Communications exist, but there are

frequent errors

?OK – Communications exist, but there

are occasional errors

OK – Communication is established and

working properly

For set-up of the auxiliary instruments go to the menu item “

The Return button will return the user to the menu screen.

Load TC/Auxiliary Analog Input

The Load TC/Auxiliary Analog Input screen will show the

values for the load TCs and the auxiliary analog inputs.

These values are display-only, and cannot be modified

from this screen.

Slave Instrument Setup

”

Series 9205 Operations Manual Rev - 23

Page 25

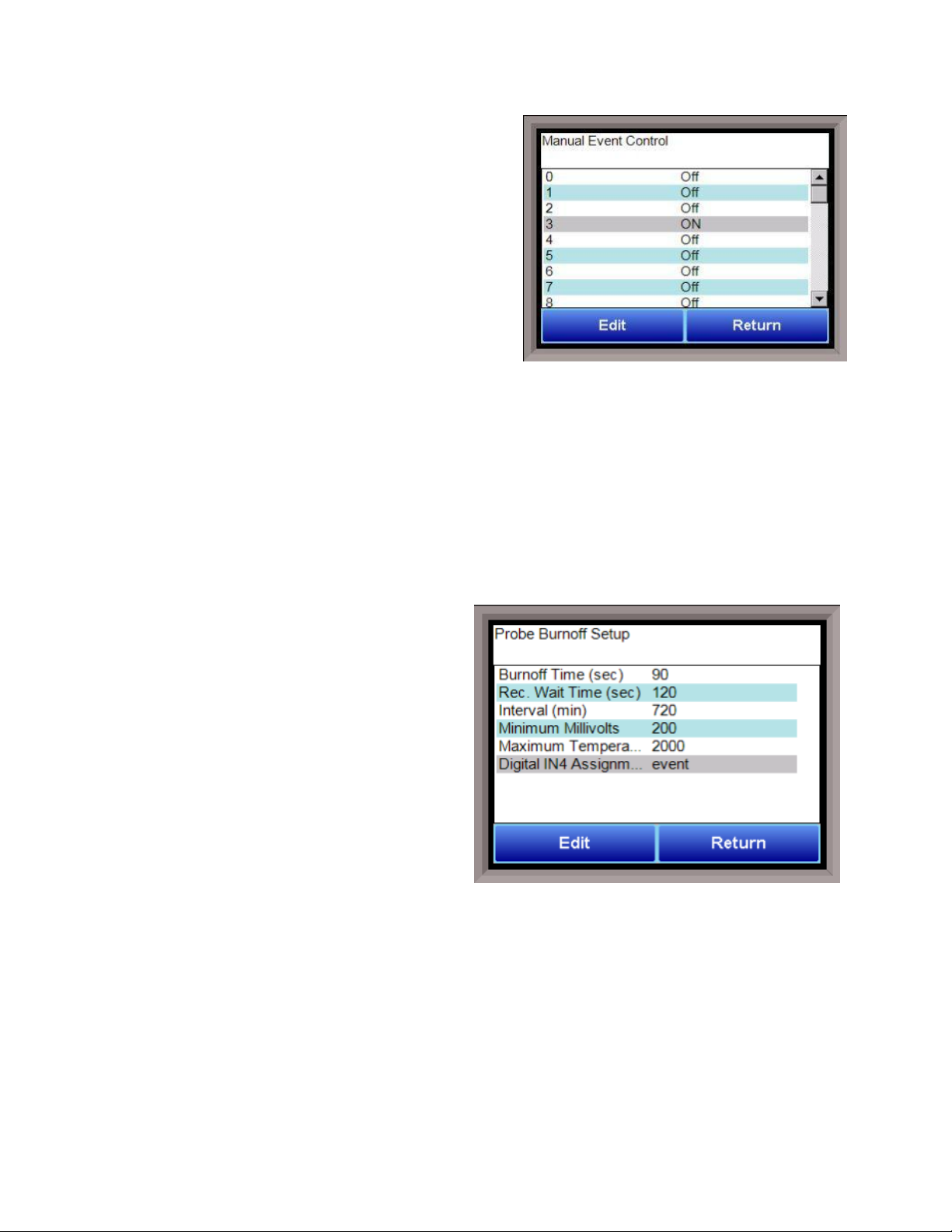

Manual Event Control

Events are assignable outputs, used in recipes/programs.

Typically, they are used to signal the recipe is complete, to

turn process gases off and on, and tell the equipment to

do a variety of tasks. The Manual Event Control submenu

allows the user to force the events off or on.

The Manual Event Control menu option shows the user all

of the events (0 – 47) and their current status. It also

allows the user to manually control the status of any

event by clicking on the value. To change the status,

highlight the specific event and click on the Edit button.

The user will be able to select either an On value or an Off

value.

Clicking on the OK button will set the value, while clicking on the Cancel button will cancel the action.

The Return button will return the user to the menu screen.

Shutdown

The Shutdown selection will display a screen asking whether or not to shutdown the interface of the Series

9205. When the operator interface is shutdown, the Series 9205 controller is still functioning. IT can be

monitored by connecting the ETHERNET connection to a laptop computer, using Internet Explorer, and

assigning a legitimate IP address. Choosing Yes displays a typical computer desktop screen with the Start

button in the bottom left-hand corner. The power to the operator interface can now be turned off without

upsetting any of the settings. Choosing No displays the initial Status Screen.

Operator Interface does not shutdown the Series 9205 Controller

.

Note -Shutting down the

Probe Burnoff Setup

When a probe is in a furnace, soot will collect in

the end of the probe, which will have a negative

effect on the performance of the probe. Burnoffs

are used to clean out the built-up carbon by

burning it off of the probe.

Burn off time: This is the duration of the burnoff

measured in seconds. SSi recommends a 90

second burnoff, and this will be the default value.

However, it can be adjusted by the operator. Click

on the OK button to set the new value, or click on

the Cancel button to cancel.

Rec Wait Time: The amount of time allotted to

allow the probe measurements to return to a

stable, accurate range after the burnoff is complete. This is measured in seconds. The control output is

held until this time is elapsed. Clicking on the value will allow the user to change the value.

Interval: This is the amount of time between the beginning of one burnoff and the beginning of the next

scheduled burnoff, in minutes. Default time for the instrument is 720 minutes (12 hours). However, the

amount of time between burnoffs should be determined by the application.

Minimum millivots: The minimum measured millivolt tolerance of the probe required to start a burnoff.

Clicking on the value will allow the user to change the value. SSi recommends the millivolt value gets down

to 200 mV.

Series 9205 Operations Manual Rev - 24

Page 26

Maximum Temperature: The maximum measured temperature allowed during a burnoff. If the

temperature value is exceeded the burnoff will stop. This is done to help maintain the life and the accuracy

of your probe. SSi recommends a value of 1800 degrees. Clicking on the value will allow the user to change

the value.

Digital IN 4 Assignment: The value for the digital input 4 assignment. Clicking on the value will allow the

user to change the value, which can be either event or Start Burnoff.

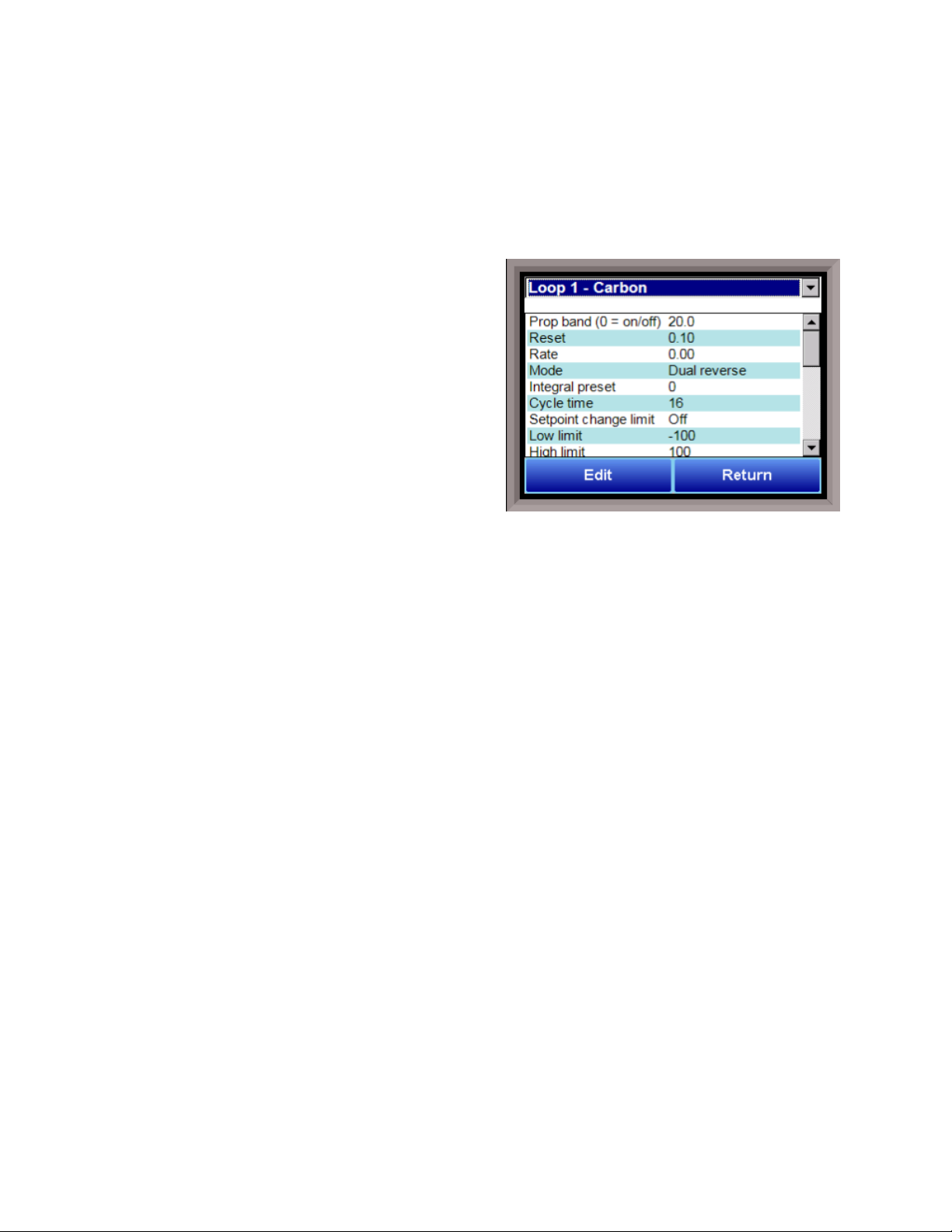

PID Loop Setup

PID is the tuning parameters entered for each Process

Variable loop.

Prop Band (0 for On/Off)

This is the proportional band field. P = Proportional

(Prop Band). This is a field in which you want to stay

around the setpoint. The range 0 – 3276.0.

Reset

This is the reset field. I = Integral (Reset). This is the

actual temperature being monitored over a period of

time and then averaged to keep within the Proportional

band. The reset is in repeats per minute. This affects

the output of the controller. It will be proportional to the amount of time the error is present. This helps to

eliminate offset. The range 0 – 327.67.

Rate

This is the rate field. D = Derivative (Rate). This is the sudden change or rate in the temperature. This rate

is in minutes. This affects the controller output which is proportional to the rate of change of the

measurement and will control the amount of output by time restraints. Thus derivative takes action to

inhibit more rapid changes of the measurement than proportional action. Derivative is often used to avoid

overshoot. The range 0 – 327.67. The rate is not typically used for heating/carbon.

Mode

This is the mode of the loop. The values are: Dual Reverse, Single Reverse, Dual Direct, or Single Direct.

Dual – This has two output relays which can increase and decrease to achieve the SP.

Single – This has one relay which works in only one direction to achieve the SP.

Direct - If the PV - SP equals a positive number and the output would bring the PV down toward setpoint

that is direct.

Reverse – If the PV - SP equals a negative number and the output would bring the PV up toward setpoint

then that is reverse

Example: If a 12 mA output drives a 0 degree F temperature (PV) UP to a 1200 degree F temperature (SP),

this would be

Temperature Loop is Single Reverse.

Integral Preset

This field provides an offset for the starting point for PID control, also referred to as “Load Line” or “Manual

Reset”. The range is –100 to 100.

Cycle Time

This field is typically set to the valve travel time multiplied by 1.5. The range is 0 – 500.

REVERSE

, and since this would take a

SINGLE

output from the controller, the Mode for the

Series 9205 Operations Manual Rev - 25

Page 27

Setpoint Change Limit

This is a smart time feature that allows Process Loop to use PB only without Reset until the Process

Variable drops below the percent output set under this category.

It is used to eliminate overshoot.

The Output percentage selected under this category

of the furnace at heat.

The options are: OFF, 80%, 70%, 60%, 50%, 40%, 30%, or 20%.

Example: If the furnace runs at 40% output at heat for the maximum load, the setpoint change limit should

be set to 60%.

Low Limit

This is the low limit for the loop. The range is –100 to 100.

High Limit

This is the high limit for the loop. The range is –100 to 100.

0 Setpoint Stops Control

If the Setpoint is zero, then all outputs are turned off. The option is either Yes or No.

IN1 high limit shuts down ctrl

If input 1’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

must

be above the normal operating output percentage

IN2 high limit shuts down ctrl

If input 2’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

IN3 high limit shuts down ctrl

If input 3’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

PID Auto Switch

This is the PID auto switch field. The value can either be Yes or No.

Switch Point PID 1 -> 2

This is the PID Switch Point field. This is used in conjunction with the PV Switching feature. See the

Switching

Switch Point PID 2 -> 3

This is the PID Switch Point field. This is used in conjunction with the PV Switching feature. See the

Switching

section for more information. The range is –300 to 4000.

section for more information. The range is –300 to 4000.

PV

PV

Overshoot Limit Gain

This is the Overshoot limit gain field. When calculating the control action, sometimes the calculation would

call for more than 100% which is not possible. The output is limited to 100% or whatever was set in the

High Limit field. The difference of the unlimited minus the limited is multiplied by the overshoot limit gain

and divided by 100. This is subtracted from the control output. If the gain is 0 there is no effect. Under

normal control the unlimited equals the limited and there is no effect. If there is a big change where the

control loop drives hard, then the effect is to limit the drive as it approaches setpoint and limit the

overshoot.

The limited is the values set in the upper and lower limits fields. The unlimited would be what is calculated

before limiting. For a big setpoint change, the calculations may compute 150% output, but the true output

is limited to the upper limit.

The range is 0 to 9999.

Series 9205 Operations Manual Rev - 26

Page 28

Setpoint Lower Limit

This is the lower limit of the setpoint. The range is –300 to 9999.

Setpoint Upper Limit

This is the upper limit for the setpoint. The range is –300 to 9999.

Cascade SP Lower Limit

This is the cascade setpoint low limit. The 9205 uses the difference between the cascade SP lower limit and

the cascade SP upper limit and multiplies that value by the % output of the load loop. It then offsets this

value by the cascade SP lower limit and feeds the furnace loop this value as a setpoint.

Cascade SP Upper Limit

This is the cascade setpoint upper limit. The 9205 uses the difference between the cascade SP lower limit

and the cascade SP upper limit and multiplies that value by the % output of the load loop. It then offsets

this value by the cascade SP lower limit and feeds the furnace loop this value as a setpoint.

Example:

Cascade SP Lower Limit: 0

Cascade SP Upper Limit: 2000

The load has a setpoint of 1700 and it is at 37 % output. The furnace setpoint will be calculated as follows:

(2000 – 0) * 0.37 + 0 = 740.

The Return button will return the user to the menu screen.

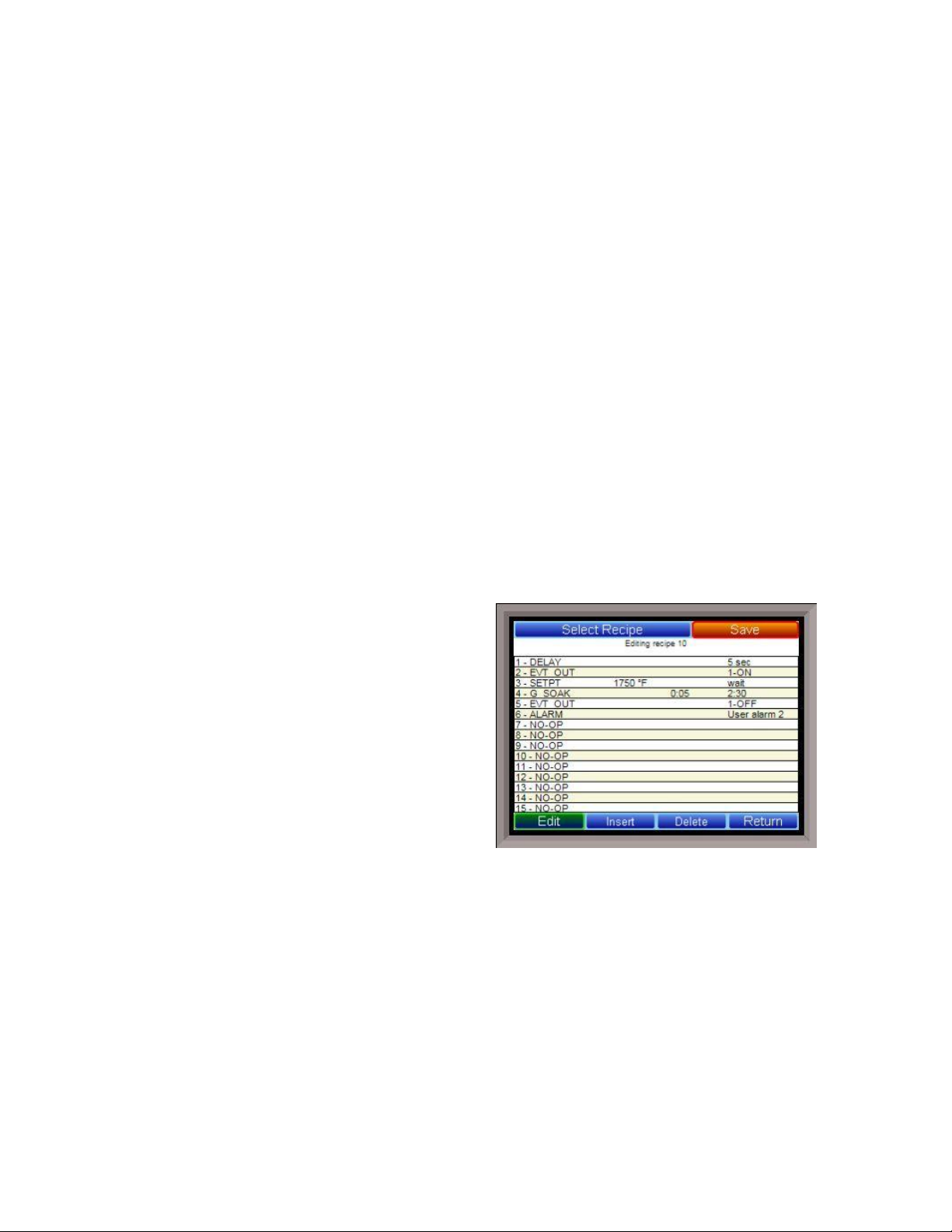

Recipe Edit

This option will allow the user to edit a recipe that is stored on the 9205 controller.

The Select Recipe button will allow the user to select

which recipe to load (1 – 300). Once the recipe has

been selected, the recipe will be displayed on the

screen.

The higher recipe steps can be viewed by holding a

finger or stylus on the screen and scrolling up or

down.

To edit a specific step, highlight that step and press

the Edit button. This will allow the user to select a

different Opcode to use, or to change the information

entered for the current Opcode. See the

Opcodes

and its purpose.

To insert a step into the program, highlight the step

number for the step, and press the Insert button. The user will have to confirm the insert. Once this has

been confirmed, the user will be able to select the Opcode to use.

section for more information on each Opcode

step after down one, so an Opcode at step 24 will be lost

To remove a step from the recipe, highlight the step number to remove, and press the Delete button. The

user will have to confirm the delete. Once the delete has been confirmed, the step will be deleted and every

step after will be moved up one step. Blank step numbers will be replaced with a NO-OP Opcode.

Press the Save button to save the changes that have been made. The recipe can be saved as any valid

recipe number (1 – 300). If the desired recipe number already contains a recipe, the user will have to

confirm the save before the old recipe will be overwritten.

If the user wishes to delete an entire recipe, they have one of two options. First, they could load up the

desired recipe and change every step to the NO-OP Opcode and save those changes; Or, they could save the

24-step “blank” (NO-OP) program that is loaded up when the

desired program number. This will save the “blank” recipe to the desired recipe number location.

Series 9205

.

Note – Inserting a step will push every

Recipe Edit

screen is first displayed as the

Series 9205 Operations Manual Rev - 27

Page 29

The Return button will return the user to the menu screen.

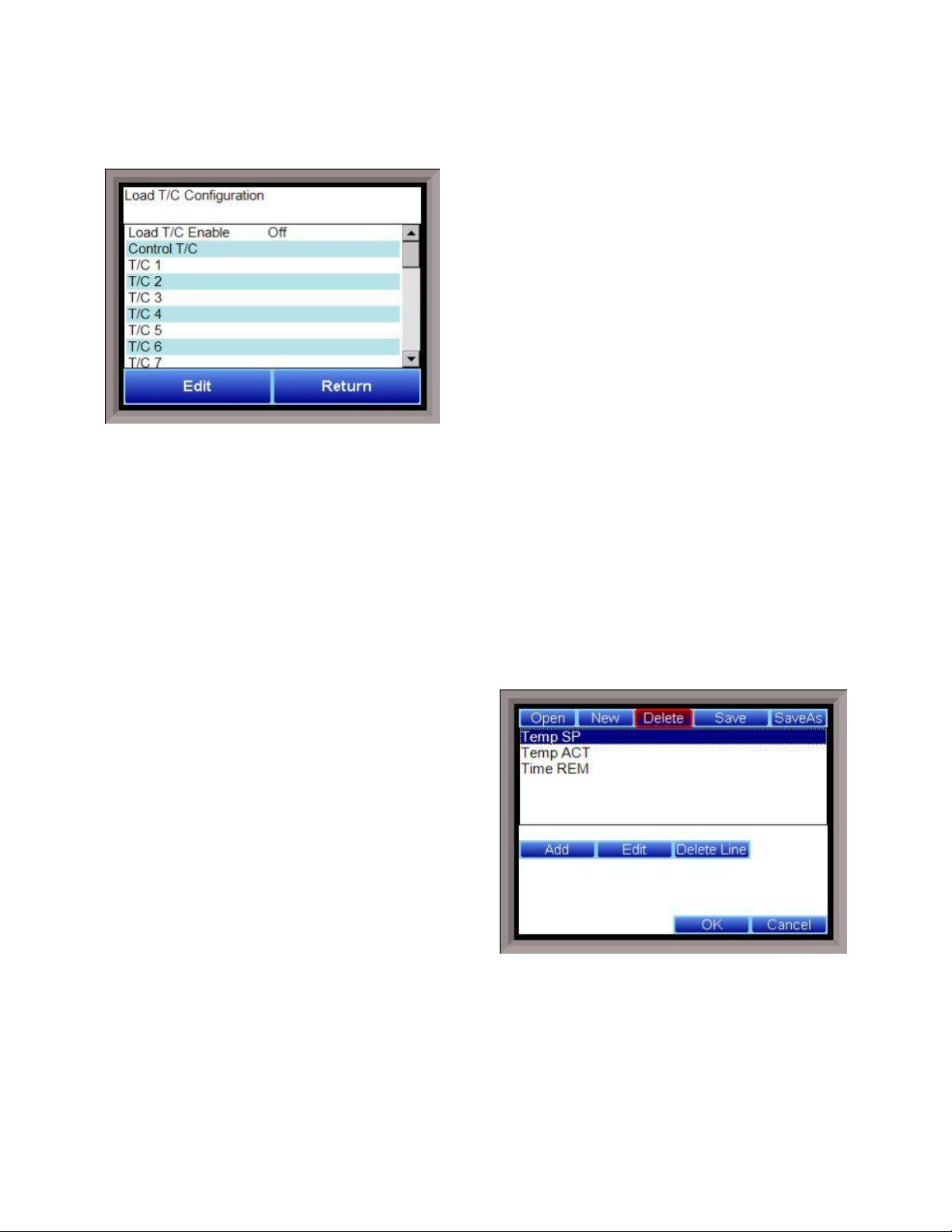

Load T/C Configuration

Configuration of any analog input device must be

completed under this menu item.

Load TC Enable

This value will manually toggle between on, on + alarms,

and off.

On – T/C Enabled

On + Alarms – T/C Enabled, Programmer alarm114

provided if out of band (Default wait limits)

Off – T/C not enabled

Control TC

This value allows the user to set the TC to be part of the

group of Load TCs that can hold the program if it is out

of band. The values are active or not active (shown as blank).

TC 1 – 30

This value allows the user to manually turn the T/C from active to not active, shown as blank, to be part of

the group of TCs that can hold the program if it’s out of band. TC 28 – TC 30 correspond to Analog Input 1 –

Analog Input 3. The values are active or not active (shown as blank).

Load T/C Alm On Delay (Sec)

This option will allow the user to set a delay time, in seconds, before the load T/C alarm is activated. The

range is 0 – 32767.

The Return button will return the user to the menu screen.

Trend Chart Edit

This menu option will allow the user to add, modify, or

delete trend lines in a trend chart file, as well as the

trend chart files themselves. The trend lines are the

number of variables displayed on one screen. For

example this could be a control, overtemp, or load

thermocouple on a batch furnace. Or it could be one

thermocouple from eight temper furnaces. There is

not a maximum for template selections, but the

number of variables displayed on one screen must be

a consideration in this process. The buttons across

the top of the screen – Open, New, Delete, Save, and

Save As – deal with the trend chart files themselves,

not the individual trend lines.

Open will allow the user to select a trend chart file to

open up to edit.

New will create a new trend chart file to begin adding trend lines to.

Delete will delete a specified trend chart file.

Save will save all changes to the current trend chart file that have been made.

Save As will allow the user to save the current trend chart file as a new file with a different name.

Once a new trench chart file has been created, or one has been opened, trend lines can be added, modified,

or deleted. Add will add a new trend line to the file. Edit will allow the user to edit the information for a

specific trend line. Delete Line will delete the specified line from the chart file.

Series 9205 Operations Manual Rev - 28

Page 30

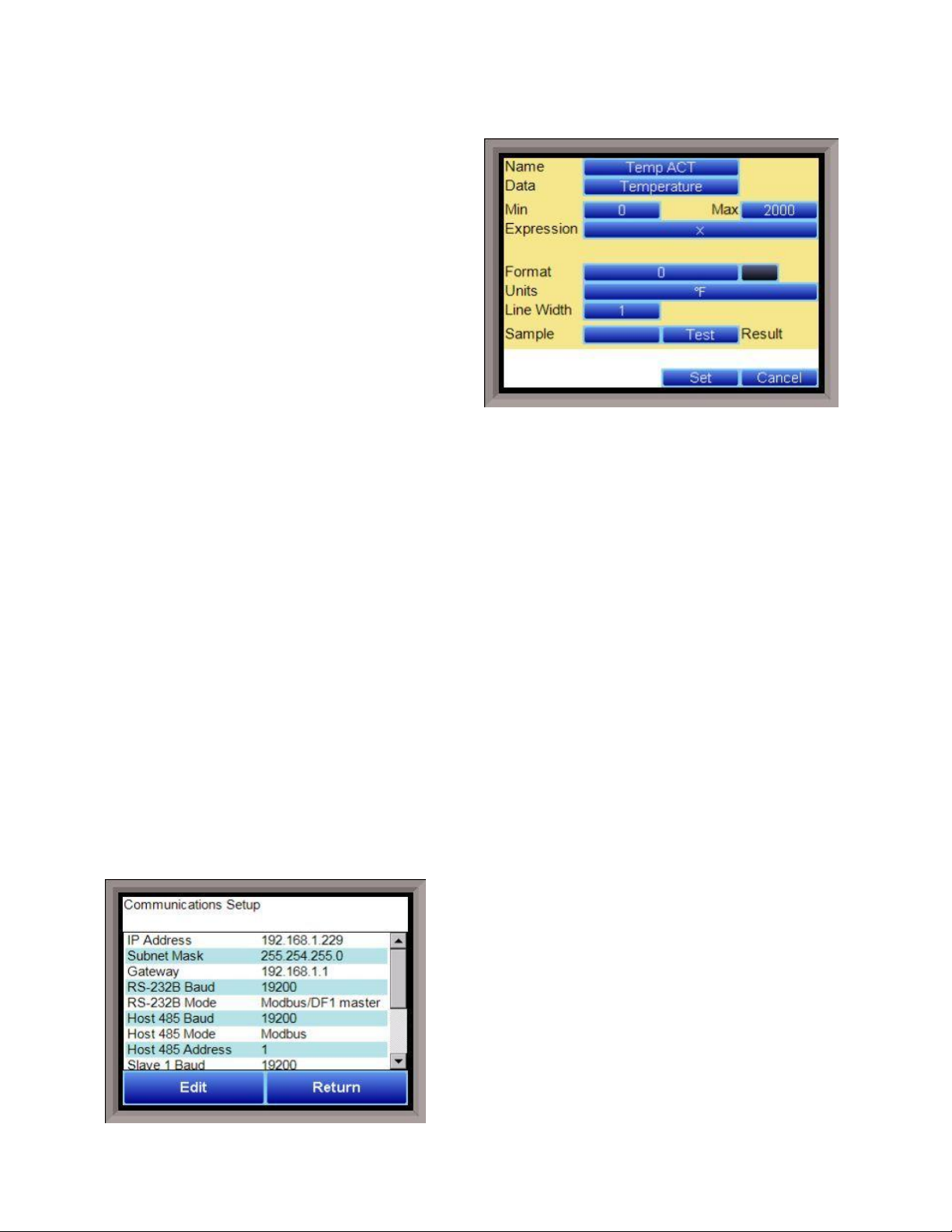

Adding or editing a trend line will involve the following parameters:

Name – the name of the input, for example “Temp

ACT” which would be the actual temperature of the

input. It is a good idea to shorten the names so that

they still make sense, but do not take up as much

space.

Data – This will determine where the data is coming

from. The user can click on the box to select from

the list of data logged points in the 9205. Some of

the points have a name, such as “Temperature” or

“Temperature SP”, but others will just show the

register in the 9205 that has been logged.

Min – the minimum displayed scale value on a chart.

Max – the maximum displayed scale value on a

chart.

Expression – every input requires an expression to

be calculated and displayed correctly. This is because the registers in the 9205 hold only integer values, so

any value that requires a decimal point needs to be set up properly for the display. For example an

expression for temperature would be x (1750 = 1750). For a value such as carbon or millivolts, the

expression would be x * 0.01 (150 = 1.50) or x * 0.1 (805 = 80.5).

Format – the value displayed on the chart display of the operator interface. A short custom description can

be added here. For example, to display one (1) decimal point, enter a value of “#0.0”. For carbon values,

enter a value of “#0.00” for 2 decimals. This would display a value like “0.81”. Entering “#.00” would

display a value of “.81”. #0 or 0 will display integer values.

Color – The box next to the format box will allow the user to apply a color to the trend line to differentiate it

from other trend lines on the chart.

Units – The type of units used for the trend.

Line Width – a numeric value for the thickness of the trend line. A 1 is a thin line; A higher value = thicker

line width.

Sample – a number is entered here to test the expression and verify that formatting is correct.

Test – Press the test button to calculate the expression with the value entered in the sample parameter.

For example with an expression of x*.1 and a value of 250 entered in the sample parameter will display a

25.0.

The Set button will save the values entered. The Cancel button will cancel the information and make no

changes.

The OK button will close the screen and prompt the user to save any changes if changes have been made.

The Cancel button will close the screen and return to the menu screen.

Communications Setup

Warning: Changes to this screen should not be made

without consulting SSi at 800-666-4330.

This screen will show the Ethernet and RS-232/RS-485

communications information for the 9205 controller.

IP Address

This will identify the IP address of the controller. Please

consult your Systems Administrator before changing this

value as it can affect communications to the 9205

controller or to other devices on your network. This is

necessary if the Touchscreen will be communicating to the

9205 over Ethernet communications. The IP address must

be in the “xxx.xxx.xxx.xxx” format.

Series 9205 Operations Manual Rev - 29

Page 31

Subnet Mask

This will identify the Subnet mask of the controller. The Subnet mask must be in the “xxx.xxx.xxx.xxx”

format.

Gateway

This will identify the IP gateway of the controller. The IP gateway must be in the “xxx.xxx.xxx.xxx” format.

RS-232B Baud

This will set the baud rate for RS-232 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. The list of options is:

1200 14400 57600

2400 19200 76800

4800 28800 115200

9600 38400

RS-232B Mode

This will set the mode for RS-232 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. The list of options is:

Modbus

Cal Term

Modbus/DF1 Master

Host 485 Baud

This will set the baud rate for RS-485 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. The list of options is:

1200 14400 57600

2400 19200 76800

4800 28800 115200

9600 38400

Host 485 Mode

This will set the mode for RS-485 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. This setting is fixed at Modbus.

Host 485 Address

This will set the address for RS-485 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. The range is 1 – 247.

Slave 1 Baud

This will set the baud rate for Slave 1 communications. The list of options is:

1200 14400 57600

2400 19200 76800

4800 28800 115200

9600 38400

Slave 1 Mode

This will set the mode for Slave 1 communications. This list of options is:

MMI

Modbus Master

Yokogawa

Modbus Host

Series 9205 Operations Manual Rev - 30

Page 32

Slave 2 Baud

This will set the baud rate for Slave 2 communications. The list of options is:

1200 14400 57600

2400 19200 76800

4800 28800 115200

9600 38400

Slave 2 Mode

This will set the mode for Slave 2 communications. This list of options is:

Modbus

SSi Analog Input Board

Yokogawa

PLC Type

The list of options is:

Micrologix Modbus

MCMmodule Modbus

DF1 PLC5

DF1 Slik

Passive

RS-232A Baud

This will set the baud rate for RS-232 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. The list of options is:

1200 14400 57600

2400 19200 76800

4800 28800 115200

9600 38400

RS-232A Mode

This will set the mode rate for RS-232 communications. This is necessary if the Touchscreen will be

communicating through the Com ports. This list of options is:

Modbus

Cal Term

Televac

The Return button will return the user to the menu screen.

Slave Instrument Setup

WARNING: This screen should not be changed

without consulting SSi at 800-666-4330.

This screen will allow the user to configure up to

twenty-five (25) slave instruments through the

9205 controller. To set up a slave instrument,

highlight the instrument number and click on the

Edit button.

The list of available slave instruments will be

shown on the screen. The list is color coded by

type – Blue for Atmosphere, Red for Temperature,

and Yellow for Events. Highlight an instrument to

select it as the instrument to use.

Series 9205 Operations Manual Rev - 31

Page 33

The list of controllers includes the following Atmosphere Controllers:

SSi AC20

Yokogawa 750

Honeywell UDC3300

Dualpro LP1 Modbus

Dualpro LP2 Modbus

Dualpro LP1 MMI

Dualpro LP2 MMI

Eurotherm 2402

Eurotherm 2500

Carbpro v3.5

Carbpro v3.0

CarbPC

9200 LP1

IR Base

MGA

This list of controllers includes the following Temperature Controllers:

SSi 7EK

Yokogawa 750

Honeywell UDC3300

Dualpro LP1 Modbus

Dualpro LP2 Modbus

Dualpro LP1 MMI

Dualpro LP2 MMI

Eurotherm 2402

Eurotherm 2500

Unipro v3.5

Unipro v3.0

Carbpro v3.5 Slave

Carbpro v3.0 Slave

10Pro

DualPro IN C

9200 LP1

9200 LP2

9200 LP3

9100 LP2

Eurotherm 2704 LP1

Eurotherm 2704 LP2

Eurotherm 2704 LP3

VC BASE 1

VC BASE 2

VC BASE 3

VC BASE 4

AIPC

SSi 7SL

AEC Flow Board

UMC800 Lp1

SSi Quad AO1

SSi Quad AO2

SSi Quad AO3

Series 9205 Operations Manual Rev - 32

Page 34

SSi Quad AO4

Yokogawa UT350

Yokogawa 750 Lp 2

Yokogawa UP350

Honeywell DCP551

Ascon 08

SSi X5

SSi M4L

SSi X5/timer

SSi SPUD

SSi AIB3

SSi H

cell

2

Flow Meter Short

SSi O

remote

2

SSi Dual Motor Board

SSi Smart AIB3

O

Block

2

Waukee Valvetronic +

This list of controllers includes the following Event Controllers:

SSi AC E

Yokogawa 750E

Mod Mux

Dualpro E Modbus

Dualpro E MMI

Carbpro E v3.5

Carbpro E v3.0

Eurotherm 2500

SSi 8-8

SSi 9200E