Page 1

atmosphere

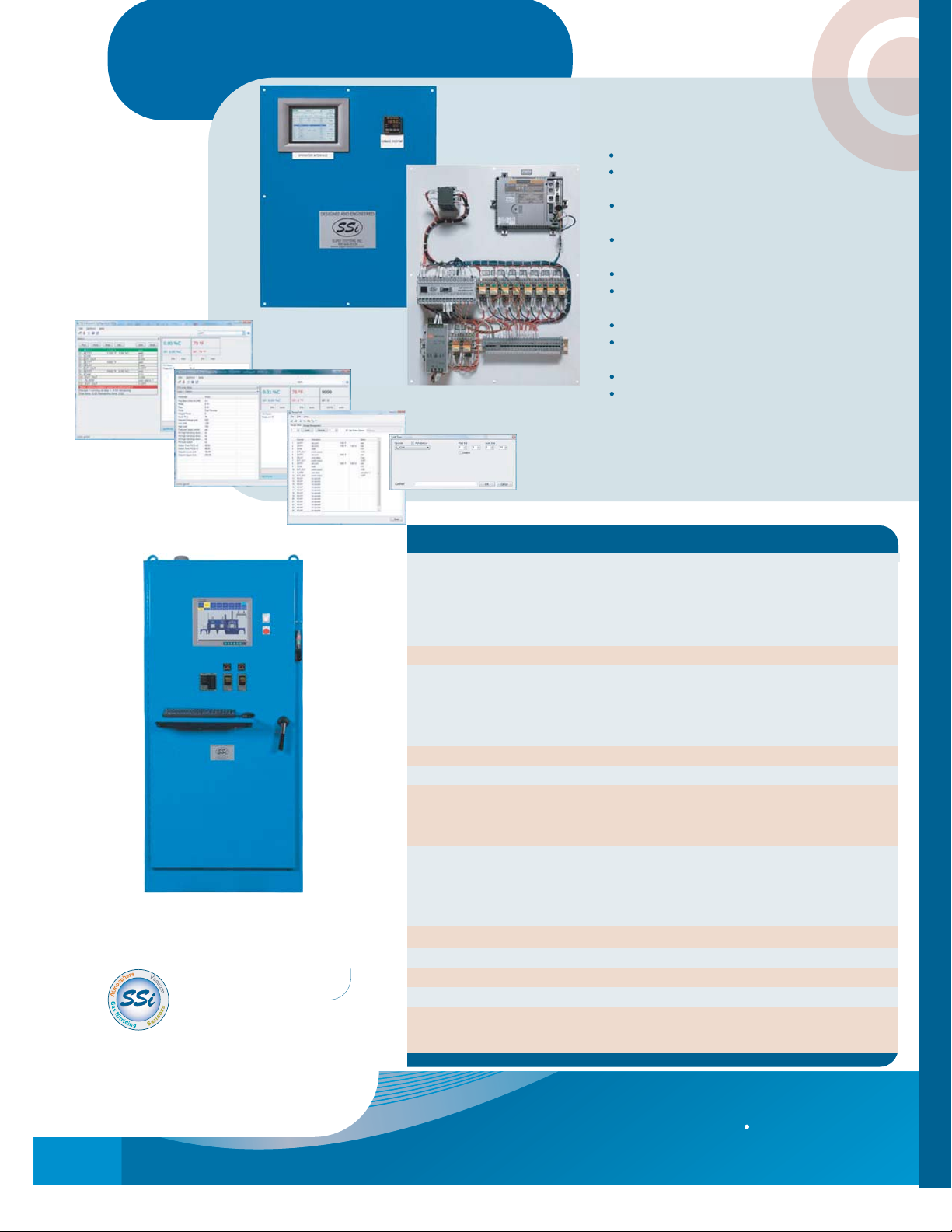

Series 9205

E-mail Alarm

Notification

Mini Batch

Load tracking in controller

Load history

Remote software

Part

Online Carbon Diffusion

Control your load based

on carbon modeling

View carbon profile in real

time

Number

Alarm log with e-mail capabilities

Easy to use recipe programmer

Universal MODBUS communications

Configurable event management

Digital data recorder

Optional batch database for load tracking

Measured Gas

OH

State-of-the-art temperature and atmosphere PID

controller engineered for batch furnace applications

Programmable Atmosphere

and Temperature Controller

Atmosphere Control Solutions

Universal recipe programmer, Modbus protocol

Easy editing of set point, soak times, and events

ETHERNET - Modbus TCP, TS232, RS485 port for SCADA

interface

Stores 300 12-step recipes

Utility software for remote configuration of recipes and

data log reporting

Temperature, quench temperature, and carbon control

loops

Events such as end of soak, ammonia addition, probe

maintenance

Built in video recorder with data storage and NOTES

Recipe Screen - Operator Interface

SuperDATA Batch Furnace

Screen

East integration with

SCADA packages

Trend Screen - Operator Interface

INNOVATIVE SOLUTIONS WORLDWIDE

A08-06201014-002

SuperSystems

incorporated

Page 2

Atmosphere Control

Unique Features

16 PIDs via program opcode

3 PID sets / loop with defined

temperature switch point

T/C comparison with offset available

for T/C checks

Multiple alarms assigned to individual

relays or a single relay

Probe burnout and impedance test

"0.00" set point deactivates control

output

Band limits for each process variable

Guarantee soak timer based on

auxiliary load thermocouples

Remote set point for third input

Custom analog input correction curves

used for certified wire correction or

known offsets through input range.

Can be used on auxiliary inputs (load

TCs) or control inputs.

SuperSystems

7205 Edington Drive

Cincinnati, OH 45249

513.772.0060 phone

513.772.9466 fax

incorporated

Control Loops

Analog Inputs

Analog Outputs

Digital Inputs

Digital Outputs

Communication Ports

Display

Programmable

Events

Web Browser Enabled

Mounting

Power

Model 9200 Features

Three loop PID controller

Temperature and Carbon Potential

Temperature and Dew Point

Millivolt

Three

Two (0-20mA or 4-20mA), Analog

outputs module for 4 additional

outputs using SSi QuadDAC module

PN 31548

Four

Eight relay outputs

One - RS232

Three - RS485

ETHERNET

5.25" color touch screen

Video recorder with "NOTES"

Removable storage media

PC interface with SuperDATA

300 12-step recipes

User defined

Remote PC view - standard browser

DIN rail or sub-panel mounting

24VDC (SSi part number 31135 90VAC to 230VAC input)

www.supersystems.com

800.666.4330

Loading...

Loading...