Page 1

INSTALLATION

INSTRUCTIONS

STANDARD SERIES

Unvented Decorative Gas Fireplaces

P/N 904538 REV. E 02/2004

MODELS

CF5500-CMN CF6500-CMN

CF5500-CMP CF6500-CMP

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING: IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY: Do not store or use gasoline

or other flammable vapors or liquids in the vicinity

of this or any other appliance.

FOR YOUR SAFETY: What to do if you smell gas:

• DO NOT light any appliance.

• DO NOT touch any electrical switches.

• DO NOT use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone.

Follow your gas suppliers instructions.

• If your gas supplier cannot be reached, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

FOR USE ONLY WITH DECORATIVE TYPE UNVENTED ROOM

HEATERS.

DO NOT BUILD A WOOD FIRE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE INJURY OR PROPERTY DAMAGE. REFER TO THIS MANUAL.

FOR ASSISTANCE OR ADDITIONAL INFORMATION CONSULT A QUALIFIED INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

WARNING: DO NOT BURN WOOD OR OTHER MATERIAL IN

THESE APPLIANCES.

CAREFULLY REVIEW THE INSTRUCTIONS SUPPLIED WITH

THE DECORATIVE TYPE UNVENTED ROOM HEATER FOR

THE MINIMUM FIREPLACE SIZE REQUIREMENT.

DO NOT INSTALL THE APPLIANCE IN THIS FIREBOX, UNLESS THIS FIREBOX MEETS THE MINIMUM DIMENSIONS

REQUIRED FOR THE INSTALLATIONS.

This is an unvented gas-fired heater. It uses air

(oxygen) from the room in which it is installed.

Provisions for adequate combustion and ventilation air must be provided. Refer to Combustion

and Ventilation Air Section, Page 3.

Due to high temperatures, the appliance should be located out

of traffic and away from furniture or draperies.

Do not place clothing or other materials on or near this appliance.

IMPORTANT: READ AND UNDERSTAND THESE INSTRUCTIONS

COMPLETELY BEFORE INSTALLING YOUR UNVENTED ROOM

HEATERS.

1

Page 2

TABLE OF CONTENTS

General Information......................... page 2

Inventory ......................................... page 2

Tools and Building Supplies ............ page 2

Installation Applications .................. page 2

Important Safety Information .......... page 2

Codes .............................................. page 3

Combustion and Ventilation Air ....... page 3

Location of Fireplace ....................... page 4

Clearances ....................................... page 4

Preinstallation.................................. page 5

Installation Steps ............................. page 5

Framing Dimensions........................ page 6

Connecting Gas Line........................ page 6

Electrical Wiring – Optional Blower . page 7

Gas Pressure Check......................... page 7

Finished Wall Details ....................... page 8

Log Installation ................................ page 8

Flame Appearance ........................... page 10

Optional Equipment ......................... page 11

Forced Air Kit ................................... page 11

Cleaning and Servicing .................... page 13

Accessories/Components ................ page 14

Appliance Specifications .................. page 15

Troubleshooting Guide .................... page 16

Lighting Instructions ....................... page 17

Replacement Parts List.................... page 18

Replacement Parts .......................... page 19

Warranty.......................................... page 20

This installation manual will help you obtain a

safe, efficient, dependable installation for your

CF-5500 or CF-6500 appliance. Please read

and understand these instructions completely

before beginning your installation.

This document covers four models of Catalytic

Fireplaces. Instructions are provided for all

models and many alternative installations for

each. Therefore, certain details may not be

applicable to your model and may not be required for your application.

GENERAL INFORMATION

The Catalytic Fireplaces covered in this manual

feature ceramic fiber split logs which glow

realistically when the heater is operating.

The Millivolt appliances covered in this manual

are manually controlled and can be incrementally adjusted through a range between High

and Low settings.

Input of the CF5500 Millivolt appliance is 24,000

BTU/hr maximum modulated to 19,000 BTU/hr

at the low flame setting for both natural and

propane gas models.

Input of the CF6500 Millivolt appliance is 31,000

BTU/hr maximum modulated to 24,000 BTU/hr

at the low flame setting for natural gas models.

Input for propane gas models is 29,000 BTU/hr

maximum modulated to 22,000 BTU/hr at the

low flame setting.

Both CF5500 and CF6500 models feature a

spark ignition system (piezo) that allows the

appliances pilot gas to be lit without the use of

matches or batteries. This manual systems

provides continued service in the event of a

power outage.

These appliances are fitted with a specially

designed pilot oxygen depletion sensor (ODS)

which responds to the amount of oxygen available in the room and shuts the appliances off

before the oxygen level drops below 18.5%.

The pilot can be re-lit only when fresh air is

available. Refer to the Combustion and Ventilation Air section.

The Catalytic Fireplace Models covered in this

manual designed to be built into a framed wall,

and finished out with standard construction

materials and practices.

Inventory

Unvented Gas Fireplace

Gas connection fittings

Installation and Operating Instructions

Tools and Building Supplies

Normally Required

Tools Should Include:

Phillips screwdriver

Hammer

Saw and/or Sabersaw

Measuring tape

Electric drill and bits

Pliers

Square

Piping complying with local codes

Pipe wrench

Tee joint

Pipe compound

Building Supplies Should Include:

Framing materials

Wall finishing materials

Caulking materials (noncombustible)

Fireplace surround materials

Check the inventory list to be sure that you have

all the necessary parts in usable condition. Also

check for concealed damage.

IMPORTANT SAFETY INFORMATION

INSTALLER: PLEASE LEAVE THESE INSTRUCTIONS WITH THE OWNER.

OWNER: PLEASE RETAIN THESE INSTRUCTION FOR FUTURE REFERENCE.

WARNING: FAILURE TO COMPLY WITH

THE INSTALLATION AND OPERATING INSTRUCTIONS PROVIDED IN THIS DOCUMENT WILL RESULT IN AN IMPROPERLY

INSTALLED AND OPERATING APPLIANCE, VOIDING ITS WARRANTY. ANY

CHANGE TO THIS APPLIANCE AND/OR

ITS OPERATING CONTROLS IS DANGEROUS. IMPROPER INSTALLATION OR USE

OF THIS APPLIANCE CAN CAUSE SERIOUS INJURY OR DEATH FROM FIRE,

BURNS, EXPLOSION OR CARBON MONOXIDE POISONING.

Carbon Monoxide Poisoning: Early signs of

carbon monoxide poisoning are similar to the

flu with headaches, dizziness and/or nausea.

If you have these signs, obtain fresh air immediately. Turn off the gas supply too the appliance and have it serviced by a qualified professional, as it may not be operating correctly.

WARNING: DO NOT USE A BLOWER

INSERT, HEAT EXCHANGER INSERT OR

OTHER ACCESSORY NOT APPROVED FOR

USE WITH THIS HEATER.

IMPORTANT: BEFORE STARTING YOUR

HEATER INSTALLATION, READ THESE INSTALLATION INSTRUCTIONS CAREFULLY,

IN THEIR ENTIRETY TO BE SURE YOU UNDERSTAND THEM COMPLETELY. FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD

CAUSE AN APPLIANCE MALFUNCTION RESULTING IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

IMPORTANT: THE INSTALLATION MUST CONFORM WITH LOCAL CODES OR, IN THE ABSENCE OF LOCAL CODES WITH THE NATIONAL

FUEL GAS CODE, ANSI Z223.1.

• Due to high temperatures, the appliance

should be located out of traffic and away from

furniture and draperies.

2

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 3

• Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room with the

appliance.

• Do not place clothing or other flammable

material on or near the appliance.

• Never operate this appliance without first

ensuring that the glass enclosure panel is securely in place.

• Do not burn solid fuels in this listed unvented

gas room heater.

• Installation and repair should only be completed by a qualified service person. The appliance should be inspected before use and at

least annually by a professional service person.

More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc. It is important that control compartments, burners and circulating air passageways of the appliance be kept clean.

• Allow the appliance to cool before servicing.

Always shut off the gas to the appliance while

performing service work.

• Do not install these appliances in a bedroom

or bathroom as all units exceed maximum

allowable BTU/hr input of 10,000.

• The appliance and its individual shut-off valve

must be disconnected from the gas supply

piping system while performing any tests of the

gas supply piping system at pressures in excess of ¹⁄₂ psig.

• The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ¹⁄₂ psig.

• Keep appliance area clear and free from

combustible materials, gasoline and other flammable vapors and liquids.

• Do not use this appliance if any part has been

under water. Immediately call a qualified service technician to inspect the appliance and to

replace any part of the control system and any

gas control which has been under water.

• Operation of these catalytic systems at altitude will result in sporadic nuisance outages of

the pilot system due to lack of sufficient oxygen,

increasing in frequency as the altitude increases

above 4,500 feet. Although this situation is not

dangerous, pilot outages cannot be tolerated.

• These catalytic appliances are rated for

use at altitudes no greater than 5,500 feet. Do

not install and use this appliance in locations

in excess of this altitude.

• Ensure that the appliance is clean when

operating. Excessive dust accumulation on the

burner and logs will increase the amount of

carbon monoxide formation and could lead to

carbon monoxide poisoning and death.

• Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

• These appliances are designed to operate on

natural or propane gas only. The use of other

fuels will degrade the performance of this system and may be dangerous.

• Do not tamper with the appliance in any way.

Any modifications will result in a voided warranty and could result in CO poisoning or death.

CODES

These appliances comply with American National Safety Standards and are tested and

listed by IAS Services to AGA/ANSI Z21.11.2b1995 as an “Unvented Room Heater.”

Adhere to all local codes or in their absence the

latest edition of The National Fuel Gas Code

ANSI Z223.1 or NFPA54 which can be obtained

from The American National Standards Institute, Inc. (1430 Broadway, New York, NY,

10018) or National Fire Protection Association,

Inc. (Batterymarch Park, Quincy, MA, 02269).

All electrical wiring must be in accordance with

local codes or in the absence of local codes the

latest edition of the National Electrical Code,

ANSI/NFPA 70.

COMBUSTION AND VENTILATION AIR

These heaters shall not be installed in a confined space. The heater may be located in

unusually tight construction provided the

space is unconfined, or if confined, is provided with two permanent openings communicating directly with an additional room(s)

of sufficient volume so that the combined

volume of all connected spaces meets the

criteria for an unconfined space, (National

Fuel Gas Code ANSI Z223.1 1992, Section

5.3). Generally 50 ft3 per 1,000 BTU input of

all operating appliances in the space.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

The National Fuel Gas Code defines a confined space as a space whose volume is less

than 50 ft

3

per 1,000 BTU/Hr (4.8 m3 per kw)

of the aggregate input rating of all appliances

installed in that space and an unconfined

space as a space whose volume is not less

than 50 ft3 per 1,000 BTU/Hr (4.8 m3 per kw)

of the aggregate input rating of all appliances

installed in that space. Rooms communicating directly with the space in which the appliances are installed, through openings not

furnished with doors, are considered a part of

the unconfined space.

Unusually tight construction is defined as construction where:

a. wall and ceilings exposed to the outside

atmosphere have a continuous water vapor

retarder with a rating of one perm or less with

openings gasketed or sealed, and

b. weather stripping has been added on operable windows and doors, and

c. caulking or sealants are applied to areas such

as joints around window and door frames,

between sole plates and floors, between wallceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas lines,

and at other openings.

Use the following equations to determine if you

have a confined or unconfined space.

1. Determine the volume of space — ft3.

Length x Width x Height = _____ ft

3

(Include adjoining rooms with doorless passageways or ventilation grills between

rooms.)

Example: 24' (L) x 16' (W) x 8' (H) = 3072 ft

2. Divide the volume of space by 50 ft3 to

determine the maximum BTU/hr the space

can support.

______ (volume of space – ft3)/ 50 ft3 x

1000 = (Maximum BTU/hr the space can

support)

Example: 3072 ft3 / 50 ft3 x 1000 = 61.44

or 61,440 BTU/hr the space can support.

3

3

Page 4

3. Add the BTU/hr of all the fuel burning appli-

ances in the space.

Vent-Free heater (Max.) ______ BTU/hr

Gas appliance #1* ______ BTU/hr

Gas appliance #2 + ______ BTU/hr

Total = ______ BTU/hr

Example:

CF6500 Catalytic heater 29,000 BTU/hr

Gas appliance #1 34,000 BTU/hr

(water heater)

Total = 63,000 BTU/hr

* Do not include direct-vent gas appliances.

Direct-vent is sealed combustion and draws

combustion air from the outdoors.

4. Compare the maximum BTU/hr the space

can support with the actual amount of BTU/

hr used.

_________ BTU/hr

(max. the space can support)

_________ BTU/hr

(actual amount of BTU/hr used)

Example:

61,440 BTU/hr

(max. the space can support)

63,000 BTU/Hr

(actual amount of BTU/hr used)

The space in the above example is a confined

space because the actual BTU/hr used is more

than the maximum BTU/hr the space can support. You must provide additional fresh air.

WARNING: IF THE AREA IN WHICH THE

HEATER MAY BE OPERATED IS SMALLER

THAN THAT DEFINED AS AN UNCONFINED SPACE OR IF THE BUILDING IS OF

UNUSUALLY TIGHT CONSTRUCTION,

PROVIDE ADEQUATE COMBUSTION AND

VENTILATION AIR BY ONE OF THE METHODS DESCRIBED IN THE NATIONAL FUEL

GAS CODE, ANSI Z223.1 1992, SECTION

5.3 OR APPLICABLE LOCAL CODES.

Your options are:

a. Rework equations adding the space of ad-

joining room(s). If the extra volume provides an unconfined space, then remove

door or add ventilation grills between rooms.

Refer to National Fuel Gas Code, ANSI Z223.1

1992, Section 5.3.

b. Vent room directly to the outdoors. Refer to

National Fuel Gas Code, ANSI Z223.1 1992,

Section 5.3.

c. Install a lower BTU/hr heater, such as the

24,000 BTU/hr CF5500, to make the area an

unconfined space.

If the actual BTU/hr used is less than the

maximum BTU/hr the space can support, then

the space is an unconfined space. You will need

no additional fresh air ventilation for an unconfined space.

LOCATION OF FIREPLACE

Carefully select the best location for installation

of your Catalytic Fireplace. The following factors should be taken into consideration:

• Clearance to side wall, ceiling, woodwork

and windows.

• Location must not be affected by drafts

caused by kitchen exhaust fans, return air registers for forced air furnaces/air conditioners,

windows or doors.

• Installation must provide adequate combustion air.

• Do not install these appliances in a sleeping

room or bathroom.

• Never obstruct the front opening of the heater

or restrict the flow of combustion air.

• Minimize modifications to existing construction. Refer to

• This appliance may be installed in an aftermarket* manufactured (Mobile) Home, where

not prohibited by state or local codes.

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer.

• This appliance is only for use with the type of

gas indicated on the rating plate. This appliance is not convertible for use with other gases.

Figure 1

for location suggestions.

To ensure even heat distribution, it is best to

position the heater centrally against the longest

wall of the room. Make sure there is adequate

ventilation where the heater is installed. The

gas appliance will shut off if the oxygen level

falls below 18.5%.

These appliances are uniquely suited for installations requiring a utility shelf positioned directly above the fireplace. Utility shelves like

these are commonly used for locating television sets and decorative plants.

To provide for the lowest possible shelf surface, combustible materials used to support a

utility shelf directly above these appliances

should be positioned just above the appliance

top spacers. The minimum height from the

base of the CF5500 to the underside of combustible materials used to construct a utility

shelf is 37” (940 mm). The minimum height

from the base of the CF6500 to the underside of

combustible materials used to construct a utility shelf is 42” (1067 mm).

The appliance should be mounted on a fully

supported base extending the full width and

depth of the unit. The appliance may be located

on or near conventional construction materials.

However, if installed on combustible materials,

such as carpeting, vinyl tile, etc., a metal or

wood barrier covering the entire bottom surface must be used.

If the appliance is to be elevated above floor

level, a solid continuous platform must be

constructed.

WARNING: MAINTAIN MINIMUM CLEARANCES.

Do not install in the vicinity of gasoline or other

flammable liquids. The heater must be kept

clear and free from these combustible materials and may not be located near where they are

stored.

Clearances

WARNING: DO NOT INSTALL THESE

APPLIANCES IN SLEEPING QUARTERS,

OR IN RECREATIONAL VEHICLES.

Figure 1

4

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 5

WARNING: DO NOT INSTALL THESE

APPLIANCES:

• WHERE CURTAINS, FURNITURE,

CLOTHING OR OTHER FLAMMABLE

OBJECTS ARE LESS THAN 42" FROM

THE FRONT OF THE UNVENTED ROOM

HEATER.

• IN HIGH TRAFFIC AREAS.

• IN WINDY OR DRAFTY AREAS.

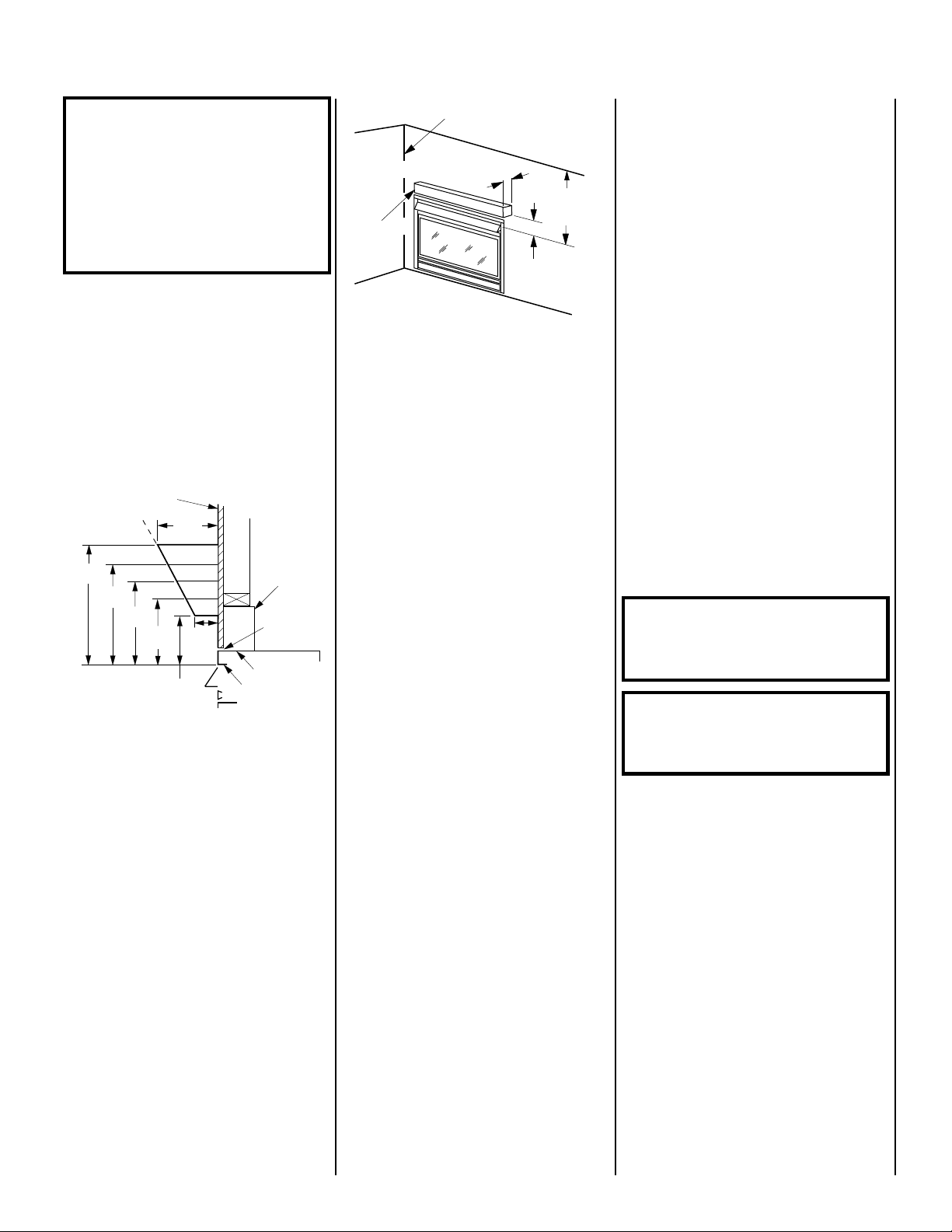

Ensure the minimum clearances shown in

ures 2, 3 and 4 thru 9

(whatever applicable) are

maintained.

Minimum clearance to combustibles are:

Appliance: side and back - 0"

floor - 0"

adjacent wall - 6"

ceiling - 37 ¹⁄₂” (953 mm)

Combustible

Finished Wall

Materials

12"

(305mm)

10''

(254mm)

11 ¹⁄₄"

8''

(203mm)

6''

(152mm)

2"

(51mm)

7 ¹⁄₂"

(286mm)

CF5500 and CF6500 Models

Top of Hood

16 ⁵⁄₈"

(422mm)

14 ³⁄₄"

(375mm)

13"

(330mm)

(191mm)

Figure 2

A hearth extension is not required with this

appliance. If a hearth extension is used, do not

block the lower control compartment door. Any

hearth extensions used is for appearance only

and does not have to conform to standard

hearth extension installation requirements.

Note: Combustible wall finish materials and/or

surround materials must not be allowed to

encroach the area defined by the appliance

front face (black sheet metal). Never allow

combustible materials to be positioned in front

of or overlapping the appliance front face.

A combustible mantel shelf projecting a maximum of 8" (203 mm) from the wall may be

installed a minimum distance of 13"

(330 mm) from the top of the hood (

Fig-

Spacer

¹⁄₄" Gap

Required

Top of Appliance

Figure 3

).

6" Clearance

to Combustible

Side Wall

Max. Projection (See Fig 2)

37 ¹⁄₂" Min.

to Ceiling

Combustible

Mantel

(953 mm)

(See Fig 2)

Figure 3

PREINSTALLATION

Check that all listed parts have been received.

Carefully inspect the heater case and contents

for shipping damage and immediately inform

the dealer from whom you purchased the gas

fireplace if any damage is found.

The appliance is shipped with all gas controls

and components installed and pre-wired. Remove the shipping carton, exposing the optional (if installed) front glass door frame. Remove wood slats and remove and discard the

wood slat mount brackets. Loosen and remove

the three (3) ¹⁄₄"-20 x 1" Phillips pan head

screws at the three (3) tabs located along the

door frame top edge. Tilt the glass door frame

assembly outward and disengage the three (3)

tabs along the bottom of the door from the three

(3) brackets at the bottom of the firebox opening. Remove the door and set the panel aside

protecting it from inadvertent damage. Retain

the three (3) screws for use on reassembly.

Check Gas Type

This appliance can only be connected to the gas

type specified on the appliance data plate. This

appliance can not be modified in the field for a

different gas type. If the gas type to be used is

not the one specified contact the dealer to

obtain the correct gas appliance.

Note: Illustrations shown in this manual reflect

“typical” installations with nominal dimensions

and are for design and framing reference only.

Actual installations may vary due to individual

design preferences. However, always maintain

minimum clearances to combustible materials

and do not violate any specific installation requirements.

Note: The following steps represent the normal

sequence of installation. Each installation is

unique, however, and might require a different

sequence.

CAUTION: HEATERS CREATE WARM AIR CURRENTS. THESE CURRENTS MOVE HEAT TO

WALL SURFACES NEXT TO HEATER. INSTALLING HEATER NEXT TO VINYL OR CLOTH WALL

COVERINGS OR OPERATING HEATER WHERE

IMPURITIES IN THE AIR (SUCH AS TOBACCO

SMOKE) EXISTS, MAY DISCOLOR WALLS.

Step 1. Position heater in desired location

(onto surround base or into prepared framing)

and secure.

Step 2. Plumb gas line. (Gas connections should

only be performed by an experienced, licensed/

certified tradesman.)

Step 3. Assemble logs and test flame appearance.

Step 4. Complete finish wall material, surround

and optional hearth extension to your individual

taste.

INSTALLATION STEPS

WARNING: DO NOT ALLOW FANS TO

BLOW DIRECTLY INTO THE FIREPLACE.

AVOID ANY DRAFTS THAT ALTER

BURNER FLAME PATTERNS.

WARNING: DO NOT USE A BLOWER INSERT, HEAT EXCHANGER INSERT OR

OTHER ACCESSORY NOT APPROVED

FOR USE WITH THIS HEATER.

This appliance must not be operated without

a front glass panel installed.

Do not burn solid fuels in this listed unvented

gas room heater.

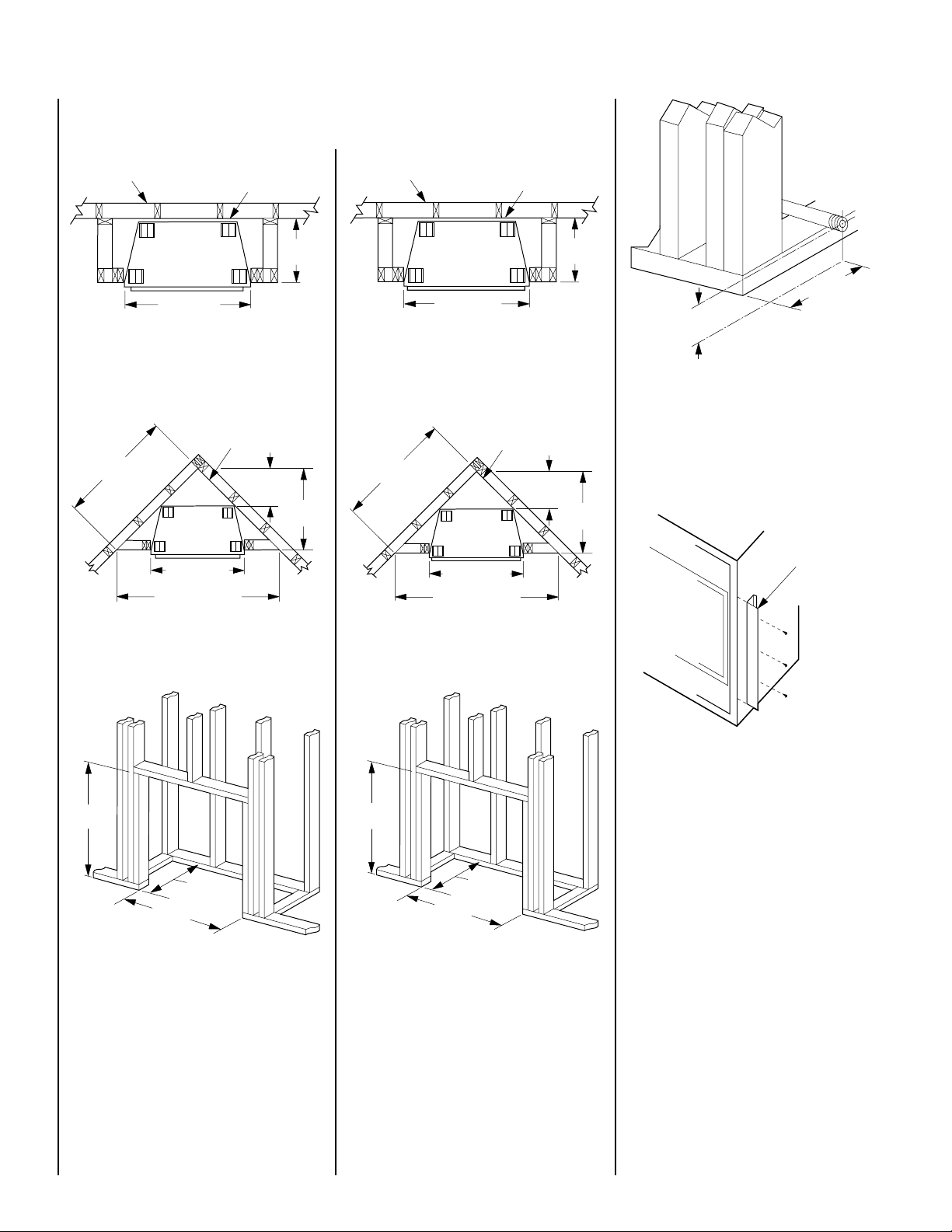

Step 1. Frame CF5500 appliance enclosures

as illustrated in

CF6500 appliance enclousures as illustrated

in

Figures 7, 8 and 9

Note: The framed depth (15

³⁄₄

" for a corner CF5500 and 19

for a CF6500) must always be measured from

a finished surface. If a wall covering such as

drywall is to be attached to the rear wall, then

the dimension must be measured from the

drywall surface.

Figures 4, 5 and 6

.

¹⁄₂

" for a flat wall, 29

¹⁄₂

" and 33

. Frame

⁷⁄₈

"

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

5

Page 6

Note: Framing dimensions in Figures 4 - 9 are calculated for a nailing flange depth of

3"

(76 mm)

CF6500 - 8¹⁄₂"

(216 mm)

CF5500 - 7¹⁄₂"

(191 mm)

¹⁄₂

" (13 mm).

Outside Wall

Figure 4

41"

(1041mm)

37" (940mm)

Back Wall of

Chase/Enclosure

Including Finishing

Materials If Any.

37" (940mm)

58 ¹₂" (1473mm)

Back Wall of

Chase/Enclosure

Including Finishing

Materials If Any.

15¹⁄₂"

(394mm)

CF5500

13 ¹₂"

(343mm)

29"

(737mm)

CF5500

Outside Wall

Figure 7

47 ⁷₈"

(1216mm)

41" (1041mm)

Back Wall of

Chase/Enclosure

Including Finishing

Materials If Any.

41" (1041mm)

67 ³₄" (1721mm)

Back Wall of

Chase/Enclosure

Including Finishing

Materials If Any.

19 ¹⁄₂"

(495mm)

CF6500

14 ¹₄"

(362mm)

33 ⁷₈"

(860mm)

CF6500

Figure 10

Step 3. Remove the nailing flanges from the

lower control compartment and install in place

with three (3) screws each. Align with the

three holes on each side of the appliance (see

Figure 11

).

Nailing Flange

Figure 5

37 ¹⁄₄"

(946 mm)

15 ¹⁄₂"

(394 mm)

37"

(940 mm)

CF5500

Figure 6

The header may be in direct contact with the top

metal spacers, but must not rest on them or be

notched to fit around them.

Step 2. Route a ¹⁄₂" (13 mm) gas line along the

left or right side framing (

see Figure 10

).

Figure 8

42 ³⁄₈"

(1076 mm)

19 ¹⁄₂"

(495 mm)

41"

(1041 mm)

CF6500

Figure 9

All appliances have a 3" long ³⁄₈" NPT nipple

installed at the valve. To quickly and easily

complete the gas line routing, use the gas flex

line kit, Model GFLV.

Figure 11

All units come complete from the factory with

an installed hood. Ensure that the hood is

installed. If required, position the hood in the

open area above the appliance door covering

the diverter baffles. Insert the tabs, on each end

of the hood, into the bracket at each end. Bend

the two tabs over to secure.

Step 4. Position appliance into prepared framing, secure with 6d nails at the nailing flange

along each side.

Step 5. Connecting Gas Line – Make gas line

connections. All codes require a shut-off valve

mounted in the supply line.

Figure 12

illustrates two methods for connecting the gas

supply. Installation methods and materials

must be in compliance with local codes.

6

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 7

¹₂" x ³₈" Flare

Shut-Off Valve

Gas Flex Line Kit, Model GFLV

³₈" Flex Tubing

³₈" NPT x ³₈"

Flare Fitting

Gas Valve

³₈" Nipple, Standard

with all Units

Standard Wiring Diagram

If any of the original wire as supplied must be replaced, it

must be replaced with Type AWM 105°C – 18 GA. wire.

TPTH TP TH

Blu

Red

Wht

Blk

Thermopile

Gas Stub

³₈" Shut-Off Valve

¹₂" x ³₈" Reducer

Figure 12

The gas control valve is located in the lower

control compartment. To access the valve open

the lower control compartment door (

13

). The control valve has a ³⁄₈" NPT thread inlet

Figure

port and is fitted with a 3" (76 mm) long nipple,

³⁄₈" NPT on both ends. Plan the connections

accordingly.

Control

Valve

Lower Control

Compartment Door

Figure 13

Secure all joints tightly using appropriate tools

and sealing compounds (ensure propane resistant compounds are used in propane applications). Turn on gas supply and test for gas leaks

using a soapy water solution. Never use an

open flame to check for leaks.

A. Mix a 50% dish soap, 50% water solution.

B. Light the appliance (refer to safety and

lighting instructions on page 17).

C. Brush all joints and connections with the

soapy water solution to check for leaks. If

bubbles are formed, or gas odor is detected,

turn the gas control knob to the “OFF” position.

Either tighten or refasten the leaking connection and retest as described above.

³₈" Union

³₈" Close Nipple

D. When the gas lines are tested and leak free,

observe the individual tongues of flame on the

burner. Make sure all ports are open and producing flame evenly across the burner. If any

ports are blocked, or partially blocked, clean

out the ports.

An external regulator must be used on all propane (L.P.G.) heaters, in addition to the regulator within the gas valve, to reduce the supply

tank pressure to 13" w.c. (maximum).

WARNING: CONNECTING DIRECTLY TO

AN UNREGULATED PROPANE TANK CAN

CAUSE AN EXPLOSION.

Step 6. Wiring – The wiring diagram is detailed

Figure 14

in

optional wall switch. All electrical wiring must

be in accordance with local codes or, in the

absence of local codes the latest edition of the

National Electrical Code, ANSI/NFPA 70. The

heater must be electrically grounded.

Step 7. Installing the Optional Remote Wall

Switch – The standard millivolt system comes

from the factory wired as shown in

Select a convenient location for the remote wall

switch and connect the wiring to the appliance

(

Figure 15

CAUTION: DO NOT CONNECT THE OPTIONAL REMOTE SWITCH TO A 120V

POWER SUPPLY.

Note: The optional rocker switch is mounted to

the appliance and wired in the same way as the

remote wall switch.

. Refer to

Figure 15

to field wire

Figure 14

).

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Door

Switch

Red

* For On/Off Switch Attachment.

*

Blk

Figure 14

Optional Wiring Diagram

If any of the original wire as supplied must be replaced, it

must be replaced with Type AWM 105°C – 18 GA. wire.

TPTH TP TH

Door

Switch

Blu

Red

Red

Factory Wired

Wht

Blk

Optional

ON/OFF

Rocker

Switch

Figure 15

Step 8. Installing the Optional Forced Air Blower

Kit Wiring – An electrical outlet box is provided

for the installation of the FAB-1100 forced air

blower kit (optional). Electrical power must be

provided to this box to operate the blower.

.

Route a 3-wire, 120Vac power line with control

switch to the lower right rear corner of the

appliance. Make connections to the receptacle as

shown in

Figure 16

.

IMPORTANT: Ground lead must be connected

to the green screw located on the junction box

cover plate. Failure to do so will prevent the

appliance from operating. The appliance must

be electrically grounded in accordance with local

codes or, in the absence of local codes, the

National Electrical Code, ANSI/NFPA 70- latest

edition. (In Canada, the current CSA C22-1 Canadian Electrical Code.)

Thermopile

Field Wired

7

Page 8

OFF/ON Blower

Wall Switch

Note: The header may rest on the top spacers

but must not be notched to fit around them.

To Fuse or

Circuit Breaker

Blower Wiring Diagram

120V

AC

}

60Hz

120 Vac

60 Hz

Ground Wire

Connection

White

(Supply)

Black

(Supply)

Red Wire

Bipolar

Terminal

Screw

Receptacle

Fireplace

Junction Box

Black

White

Black

Wire

Blower

(Lower)

Outlet

Mating

Connectors

Note: Supply wires may be alternatively connected to the outlet using the screw terminals, however

the black supply wire must be ganged wired to the same terminal that the pre-wired black wire is

attached to and the white supply wire must be connected to the opposite side of the outlet.

Figure 16

Evenly Spread Dime Sized Pieces Of Rockwool

Over 85% Of This Area (Small Burner Holes)

No Rockwool Material

Behind This Point

In order to install the appliance facing flush with

the finished wall, position the framework to

accommodate the thickness of the finished wall

(

Refer to Figures 2 and 3

).

If you live in a cold climate, seal all cracks

around your appliance with noncombustible

material and wherever cold air could enter the

room. It is especially important to insulate

outside chase cavity between studs and under

floor on which appliance rests, if floor is above

ground level.

WARNING: DO NOT ADD EXTRA LOGS OR

ORNAMENTS SUCH AS PINE CONES, VERMICULITE OR ROCK WOOL. USING THESE

ADDED ITEMS CAN CAUSE SOOTING.

WARNING: DO NOT PLACE ANY LAVA

ROCK ON LOGS OR BURNERS. THIS MAY

CAUSE SOOTING.

Step 9. Ember Coal, Rockwool and Log Installation – The logs are packaged in a carton

packed inside the firebox. Remove the ceramic fiber coals from their packaging and

spread evenly in the area in front of the burner.

Place the rockwool over the front half of the

burner ports, avoiding the two groups of five

larger holes (

coals in the confined area in front of the burner

and behind the appliance front lip. Reinstall

the log grate removed in preparing the insert.

Secure the grate with the two (2) screws

previously removed.

refer to Figure 17

). Place ember

Keep Both Of These Five Hole Pattern

Areas Free Of Rockwool Materials

Figure 17

The forced air blower kit may be mounted at

initial appliance installation or at any time

thereafter. Follow the instructions provided

with the blower kit.

8

Burner

Top View

Front

Ember Chunks In

This Confinement

Finished Wall Details

It is sometimes best to frame the appliance

after it has been positioned in place. Frame with

2 x 4s or heavier lumber. Always frame in

accordance with local building codes.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

WARNING: FAILURE TO POSITION THE

PARTS IN ACCORDANCE WITH THESE

DIAGRAMS OR FAILURE TO USE ONLY

PARTS SPECIFICALLY APPROVED WITH

THIS HEATER MAY RESULT IN PROPERTY DAMAGE OR PERSONAL INJURY.

Carefully position and center the fiber logs

onto the burner in the manner illustrated (

ure 18

). Positioning pins indicate log location.

The flames should not impinge on the logs.

Install the logs beginning with the right rear

log first (a). Engage it as shown over the pin

located at the back of the right log rack bar

(

Figure 18

).

Next, install the main log assembly (b) over the

pin located at the back of the left log rack bar.

The charred right nose of the main log rests

directly on the burner pan positioned against

the extension protruding from the right log

rack bar, and the end of the short (second from

the right) log rack bar.

Fig-

Page 9

a.

Step 10. Checking the System – After the gas

line is installed, logs are in place and the

system is leak checked, run initial system

checkout before closing up the front of the

unit. Follow the pilot lighting instructions on

pages 16 and 17.

On propane models the last ³⁄₈" (10mm) of the

pilot generator should be engulfed in the pilot

flame. The propane thermocouple is attached

to the side of the pilot burner tube.

Replace logs if removed for pilot inspection.

c.

c.

d.

b.

d.

b.

a.

Note: Instructions are also found on the pull out

panel located on the bottom surface of the

appliance.

When first lighting the appliance, it will take a

few minutes for the line to purge itself of air.

Once purging is complete, the pilot and burner

will light and operate as indicated in the instruction manual.

Subsequent lightings of the appliance will not

require such purging. Inspect the pilot flame

(remove logs, if necessary, handling carefully).

The flame should be steady, not lifting or floating. Flame should be blue in color with traces

of orange at the outer edge.

For natural gas units the last ³⁄₈" (10 mm) of the

pilot generator (thermopile) and the top ¹⁄₈" (3.2

mm) min (tip) of the quick drop out thermocouple should be engulfed in the pilot flame

(

Figure 19

).

³⁄₈"

Min

Thermopile

Pilot

Flame

¹

Thermocouple

Natural

Shown

⁄₈"

Min

Figure 19

To light the pilot, manually depress and hold the

door safety switch (

Figure 21

) and rotate the

control knob counterclockwise to the “PILOT”

position and press in and light by pressing the

piezo button (refer to lighting instructions on

page 17 and

Figure 20

).

Note: The door safety switch must be held

closed and the rocker switch must be "ON" for

burner operation (Figure 21 ).

Door

Swtich

Rocker Swtich

(Optional)

Figure 21

To obtain proper operation, it is imperative

that the main burner characteristics are steady.

The flame should produce a clear, bright orange/yellow flame. No smoke or soot elements

should be visible. If questionable, check with

your service man or gas supplier. The flames

should not impinge on the logs, reposition

them if necessary.

Figure 18

Position the front log assembly (c) over the pin

located at the front of the left log rack bar and

the back pin of the short (second from the

right) log rack bar. Install the remaining right

front log (d) over he last two pins located at the

front of the right log rack bar and the short log

rack bar respectively.

The installation of the logs should be complete

and resemble

Figure 18

.

Gas Control Knob

Piezo Ignitor

Figure 20

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

N

O

T

O

it

L

I

P

O

F

F

EA

Honeywell

Millivolt Valve

Flame Adjustment Knob

T

O

L

I

P

Gas Control Knob

SIT Millivolt

Valve

TPTH TP TH

O

N

P

I

L

O

O

F

F

T

L

O

I

H

Spark Ignitor

9

Page 10

The flame height and BTU input may be altered

by rotating the flame control valve from low to

high.

CAUTION: DO NOT ATTEMPT TO REDUCE OR

ALTER THE FLAME BY POSITIONING THE

GAS VALVE IN OTHER THAN THE FULL “ON”

POSITION.

The air shutter on the venturi tube has been set

at the factory for both natural and propane gas

models, refer to

Figure 22

for air shutter set-

tings.

Orifice

Air Shutter

Opening

Burner

Manifold

Air Shutter

Opening

(Not Adjustable)

CF-5500

Natural Gas - ¹⁄₁₆" Open

Propane Gas - ¹⁄₈" Open

CF-6500

Natural Gas - ¹⁄₁₆" Open

Propane Gas - ³⁄₁₆" Open

Figure 22

Flame Appearance

REFER TO THE OPERATING INSTRUCTIONS

LOCATED AT THE BACK OF THIS MANUAL

BEFORE LIGHTING THE HEATER TO OBSERVE

THE FLAMES.

Note: Instructions are also found on the pull-

out panel located in the l ower control compartment of the appliance.

Note: The door switch must be held closed for

burner operation when testing.

Flames from the pilot and main burner should

be visually checked when the appliance is

installed. In addition a periodic visual check of

the flames should be made throughout the life

of the appliance. The pilot flame should always

be present when the heater is in operation and

should just envelope the tip of the thermocouple (

Figure 23

). The main burner flames

must not impinge on the logs with the exception of the charred areas, flame appearance

should be as shown in

Figure 24

.

Thermopile

Pilot

Flame

Thermocouple

Natural Pilot

Thermopile

Pilot

Flame

Thermocouple

Propane Pilot

Figure 23

WARNING: NO ADJUSTMENTS ARE TO

BE MADE TO THE ODS PILOT SYSTEM.

TAMPERING WITH THIS SYSTEM WILL

VOID THE WARRANTY AND CAN BE EXTREMELY HAZARDOUS.

A pilot flame that does not envelope the thermocouple tip, will cause the main burner to

function improperly. If the pilot flame does not

envelope the thermocouple tip as shown in

Figure 23

, contact your service representative.

In normal operation after 15 minutes the following main burner flame appearance should

be observed (

Figure 24

).

Low Flame

High Flame

Figure 24

Rear Burner Flames – The rear flames rising in

front of center and rear logs should be yellow

and extend about 2 ¹⁄₂ – 3" above the large logs

for natural gas and 1 ¹⁄₂ – 2 ¹⁄₂” above for

propane gas.

Front Burner Flames – The flames at the front

of the main burner will be blue becoming

yellowish as they hit the bark-like texture on the

front face of the front base log.

Low flame setting observable characteristics

are approximately 2" to 2 ¹⁄₂” shorter than the

flames are on high.

Refer to the Operation and Maintenance instructions on page 12 of this manual for flame

adjustment procedures.

Appliance Operation

WARNING: THE LOWER CONTROL COMPARTMENT AREA AND LOWER CONTROL

COMPARTMENT ACCESS DOOR ARE EXTREMELY HOT WHEN THE APPLIANCE IS

IN OPERATION. EXERCISE EXTREME CARE

WHEN ACCESSING THIS AREA. TOUCH

ONLY THE FAR ENDS OF THE LOWER

CONTROL COMPARTMENT DOOR WHEN

OPENING WHILE THE APPLIANCE IS HOT.

Step 11. Checking the System – With gas line

installed run initial system checkout before

closing up the front of the unit. Follow the pilot

lighting instructions on pages 17.

Note: Instructions are also found on the pull

out panel located in the lower control compartment of the appliance.

To light the burner; turn “ON” the optional

remote wall switch (if installed) and rotate the

gas valve control knob counterclockwise to the

“ON” position.

Note: The door switch must be held closed for

burner operation when testing.

When first lighting the appliance, it will take a

few minutes for the line to purge itself of air.

Once purging is complete, the pilot and burner

will light and operate as indicated in the instruction manual. Subsequent lightings of the appliance will not require such purging. Inspect the

pilot flame (remove logs, if necessary, handling

carefully).

The pilot flame should be steady, not lifting or

floating. Flame should be blue in color with

traces of orange at the outer edge.

10

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 11

The last ³⁄₈" (10 mm) of the pilot generator

(thermopile) should be engaged with the pilot

flame.

Replace logs if removed for pilot inspection.

Step 11. Installing the Glass Door Frame –

Retrieve the glass door frame visually. Position

the door frame in front of the firebox opening,

with the joint in the gasket down. Locate the

three (3) tabs at the bottom edge of the door

frame into the three (3) brackets at the base of

the fireplace front opening. Lean the door frame

back towards the fireplace ensuring that the

frame seats evenly as it draws shut.

Install the three (3) ¹⁄₄"-20 x 1" Phillips pan head

screws removed previously and tighten to secure. Ensure that the tab on the bottom of the

door frame engages the door switch.

Make sure the screws are tightened equally to

avoid torquing the door (

Screws

Figure 25

).

Figure 25

OPTIONAL EQUIPMENT

An incomparable package of options are available for use with these appliances. These options can both customize the operation of these

unique appliances and enhance their beauty

and charming appeal. All options are available

in kit form, are easy to install and are packaged

complete with all required parts and instructions. Some of the option kits need to be fitted

prior to completing the installation of the appliance. The following paragraphs detail the kit

options available for use with the appliances

covered in this manual.

These outstanding optional items can be added

individually or in sets of two or more to customize your appliance to fit your homes unique

needs. Kit model numbers are provided on

page 14 along with descriptive illustrations.

The appliances covered in this manual are

heater rated and produce a great deal of heat.

Decorative brass trim pieces and hoods may

tarnish because of their proximity to the heater

opening and front face. Tarnishing of these

pieces is normal, unavoidable and should be

expected.

Forced Air Kit

The FAB-1100 assembly (

a forced air circulation feature for your appliance. This kit mounts directly into the lower

intake chamber, behind the blower shield, with

an electrical connection made at the receptacle provided (

Figure 27

must have an independent 120Vac power line

incorporated at the time of installation. Place

the blower against the back wall of the appliance within its chamber behind the blower

shield. The blower shield has to be removed

for blower insertion and replaced before the

installation is complete. The instructions provided with the blower kit detail all wiring and

operation concerns.

The blower shield located at the back of the

appliance lower control compartment isolates

the blower chamber from the control area in

front. The blower shield is secured in place

with two screws that must be removed and

retained for reuse. Pull the bottom of the

shield forward and bring the top down to

remove the shield horizontally, flat against the

appliance bottom and below the gas controls,

piping, and wiring. The blower may be inserted around the right side of the gas controls

after any intervening connecting field installed

gas line has been re-routed or removed. Place

the blower within the chamber, (Refer to the

diagrams provided with the blower Kit) and

reinstall the blower shield. Ensure the blower

wire is routed through the notch in the bottom

edge of the shield.

Access to the blower chamber at the rear of the

lower control compartment in CF-5500 appliances is restricted due to its compact design,

by the interfering tubing of the gas controls

assembly. To provide clearance for the blower,

the spudplate assembly must be lifted up

slightly to allow the blower to be inserted into

its chamber under it. To allow the spudplate to

be lifted, remove the four screws securing it to

the appliance firebox floor. The screws must

be accessed from within the firebox. Refer to

Page 5 and Step 11 for door removal and

replacement, refer to Step 9 for log removal,

handling and placement instructions.

Figure 26

)provides

). The appliance

Figure 26

Blower Motor

Grounded

to Appliance

Motor Plug

Receptacle

120V

Appliance Junction Box

Figure 27

Wall Switch Kit

An optional wall switch kit can be installed

along with all CF appliances. The kit consists of

a standard UL wall switch with cover plate. This

kit provides for remote (wall) operation of the

appliance. Replace the wall switch and cover

plate of this kit with the components of the RCK

and you can have true remote control of your

direct vent appliance, turning it on and off from

your favorite easy chair. The wall switch kit

should be installed along with the appliance.

Refer to

Figure 15

and Step 7 for detailed

installation instructions.

Rocker Switch Switch Kit

An optional rocker switch kit can be installed

directly on all CF series appliances to provide

for On and Off operation in lieu of a wall switch.

This kit is designed to install in the lower control

compartment out of view and is perfect for use

in high volume areas such as lobbies and model

homes where limited access to the appliance

On/Off switch is desirable. This kit can be

retrofitted to previously installed appliances

and may be temporarily installed in place of

other switch circuitry.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

11

Page 12

Screen Panel Kit

An optional screen panel can be installed on the

CF door. This screen panel is easy to install

using the provided hardware. The screen panel

can be installed with both ceramic and tempered glass in the door. This kit can be retrofitted to previously installed appliances. The screen

panel kit may not be used in conjunction with

the one piece decorative arch kits.

Remote Control Kit

The Model RCK adds the convenience of remote control for your appliance. The kit includes a wireless, hand held transmitter and a

receiver that replaces the wall switch. This

special receiver permits either manual or remote control modes. Both receiver and transmitter operate on standard 9 volt batteries (not

included). Refer to the RCK installation instruction for specific details.

Brass Hood Kit

An attractive brass hood is available to be used

on the CF appliance. These hoods are designed

to be fitted to the face of the appliance above the

door. In addition to providing an aesthetically

pleasing appearance to your appliance installation, the hood reduces heat effects to decorative mantles and finish materials located directly above the fireplace opening. The hood kit

includes the necessary attaching hardware. This

kit can be retrofitted to previously installed

appliances.

Brass Square Surround Kit

Decorative brass square surround kits are available for use with these appliances. The BSK-5

and BSK-6 are designed to attach directly to the

front face of the appliance at its extreme edges.

The brass square surround kits provide a picture frame finish for the appliance 2 ¹⁄₂" wide.

Use the BSK-5 with CF5500 appliances and the

BSK-6 with CF6500 appliances. The brass

square surround kit can be retrofitted onto

previously installed appliances.

Brass Louver Kit

Decorative brass louvers are available for use

these appliances. These louvers are designed

to replace the standard black louvers that are

provided with the appliance. The brass louver

louver kit includes three (3) plated louvers and

a fourth (black) louver, that simply snap into

place. They provide a touch of elegance to the

CF appliance. This kit can be retrofitted to

previously installed appliances.

Wall Thermostat Kit

A wall thermostat kit is available for use with

these appliances. The wall thermostat is designed to be wired directly to the appliance

millivolt gas control circuit and provide automatic On/Off control of the appliance to maintain a desired temperature within the room.

Decorative Volcanic Stone

The decorative volcanic stone, Model DVS, can

be used to enhance the look of your appliance.

Spread the decorative volcanic stone evenly

around the bottom of the firebox.

One Piece Arch Kit

A one piece complete door arch kit is available

for use with these CF appliances. The kit is easy

to install and does not require hardware to

attach it to the standard door frame. This kit can

be retrofitted to previously installed appliances.

The one piece decorative arch kit can not be

used in conjunction with the screen panel kit.

Gas Flex Line with Valve

A gas flex line kit is available to aid in attaching

this appliance to the gas supply. This kit can

only be used where local codes permit. The kit

includes a ¹⁄₂" NPT to ³⁄₈" flare in line shut-off

valve, a 12" flex line ³⁄₈" female flare through and

a ³⁄₈" flare to ³⁄₈" NPT fitting. The components of

this kit are rated for both natural and propane

gas. This kit is designed to be used as an aid in

installing the appliance.

WARNING: CHILDREN AND ADULTS

SHOULD BE ALERTED TO THE HAZARDS

OF HIGH SURFACE TEMPERATURES. USE

CAUTION AROUND THE APPLIANCE TO

AVOID BURNS OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE SUPERVISED WHEN THEY ARE IN THE SAME

ROOM AS THE APPLIANCE.

OPERATION AND CARE OF YOUR

APPLIANCE

1. Appliance operation is controlled through

an on/off switch. Separate switches may

provide independent control for the optional

forced air kit and fireplace operation (see

Optional Equipment).

2. To light the appliance refer to the lighting

instructions located at the back of this manual.

Note: Instructions are also found on the pullout panel located in the lower control compartment of the appliance.

3. Flame Adjustments – These appliances

are equipped with a two stage, High (HI), Low

(LO) gas control valve. This valve provides

for easy flame height adjustment. To adjust

the burner between the HI and LO settings,

rotate the HI/LO knob, located in the center of

the valve front face, clockwise and counterclockwise respectively.

4. When lit for the first time, the appliance will

emit a slight odor for an hour or two. This is

due to the “burn-in” of the internal paints and

lubricants used in the manufacturing process.

Additionally, when lit for the first time, this

appliance may produce smoke, this is normal

and should be expected. For the first few

hours, operate the appliance with doors and

windows open to encourage the dissipation of

smoke and fumes.

5. Upon each lighting of the appliance, condensation may occur and fog the inside of the glass

enclosure panel. This condition is normal and

will disappear as the glass surface heats.

6. Always keep the appliance area clear and free

from combustible materials, gasoline and other

flammable liquids.

7. Remember, these appliances have a continuous burning pilot flame. Exercise caution

when using products with combustible vapors.

WARNING: OBSERVE CAUTION NEAR THE

GLASS ENCLOSURE PANEL. THE GLASS

MAY SHATTER UNEXPECTEDLY OR IF

STRUCK WITH AN OBJECT.

8. CAUTION: DO NOT OPERATE THIS APPLIANCE WITH A BROKEN GLASS PANEL. Where

broken glass exists, the complete glass enclosure panel must be replaced. See the Replacement Parts List on page 18 for correct replacement part numbers. Glass enclosure panel removal and installation instructions are described

on pages 5 and 10 respectively.

12

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 13

Maintenance

CAUTION: DO NOT OPERATE THE APPLIANCE

WITH A BROKEN, DAMAGED OR MISSING

CATALYTIC COMPONENT.

The appliance should be inspected before use

and at least annually by a professional service

person. Replace the catalytic component if CO

levels measured at the appliance vent outlet

exceed 1/1000 of 1% after (10 Min) of burning. Replacement of the catalytic component

should only be completed by a qualified service person at least every 20 years.

Ensure the air shutter openings are not obstructed (

see Figure 22

).

Alternatively, at least annually, the glass enclosure panel should be removed and the inside of

the firebox and the control compartments

cleaned using a vacuum cleaner to remove

dust. Remove the top and bottom logs, gently

handling by holding each log at each end and

set on a piece of paper or cloth to avoid getting

any debris on carpet or floor. Use the vacuum

cleaner to remove the embers from the base

and walls of the firebox and from around the

burners. More frequent cleaning may be required due to excessive lint from carpeting

material, etc. It is important that control compartments, burners and circulating air passageways of the heater be kept clean. Replace

the logs as detailed in Step 9 Log Assembly.

Place Rockwool on screen of front burner.

Intentional misuse or deliberately fragmenting

the material could be hazardous to health by

inhaling.

These CF appliances are intended for use as a

gas heater as described in these instructions

and should not be used for any other purpose.

Repair and work involving replacing parts

should only be carried out by a qualified service person.

Always shut off the gas supply and allow the

appliance to cool before beginning any service

work.

Always check for gas leaks after servicing.

Cleaning and Servicing

WARNING: TURN OFF THE APPLIANCE

AND ALLOW TO COOL BEFORE CLEANING.

WARNING: ALWAYS TURN OFF THE GAS

SUPPLY TO THE PILOT BEFORE CLEANING. BEFORE RE-LIGHTING, REFER TO

THE LIGHTING INSTRUCTIONS IN THIS

MANUAL. INSTRUCTIONS ARE ALSO

FOUND ON THE PULL-OUT PANEL LOCATED IN THE APPLIANCE LOWER CONTROL COMPARTMENT. ONLY LIMITED

CLEANING WILL BE REQUIRED UNDER

THE NORMAL USE OF THE APPLIANCE.

THE EXTERNAL CASE SHOULD BE OCCASIONALLY DUSTED AND WIPED WITH A

DAMP SOAPY CLOTH.

Clean the glass only when necessary. Wipe

surface with a clean, dampened, soft cloth.

Follow with a dry, soft towel as desired. Take

care not to scratch the glass surface.

WARNING: DO NOT USE ABRASIVE

CLEANERS. NEVER CLEAN THE GLASS

WHEN IT IS HOT.

If, after a period of use, the flames start to

exhibit unusual shapes and behavior, or the

burners fail to ignite smoothly, then the burner

holes may require some cleaning. If this occurs, it is preferable to contact your nearest

dealer to service the appliance.

CAUTION: REPLACE THE GLASS ENCLOSURE

PANEL BEFORE USING THE APPLIANCE (REFER TO STEP 11).

IMPORTANT SAFEGUARDS

Even though your CF appliance gives a very

realistic appearance of a wood-burning fire, it

must not be used for burning wood or other

similar materials. To avoid damage to the appliance or possible personal injury, matches, paper, garbage or any other material must not be

placed or thrown on top of the logs or into the

flames. Always ensure that the appliance glass

enclosure panel is firmly fixed in place. Do not

remove the glass enclosure panel during normal operation of the appliance.

To avoid personal injury, do not touch hot

surfaces when the appliance is operating. Close

supervision of children is necessary when the

appliance is in use.

SPECIAL WARNINGS

Do not open the louvered control compartment

access panel from the middle when unit is hot.

Only the ends of the louvers are cool to the

touch.

The glowing logs are manufactured from bonded

ceramic fiber which is commonly used material

in the heating industry worldwide.

If any major repair or service is required, the

qualified service person must contact the SFC,

INC. service department before proceeding.

REPLACEMENT PARTS

Exploded views of the appliances with numbered parts and parts lists can be found on

pages 18 and 19. All parts should be ordered

through your SFC distributor or dealer. Parts

will be shipped at prevailing prices at time of

order. When ordering repair parts, always

give the following information:

1. The model number of the appliance.

2. The serial number of the appliance.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the appliance.

If you encounter any problems or have any

questions concerning the installation of this

system, please contact your distributor. For the

name of your nearest distributor contact:

SFC

1110 West Taft Avenue

Orange, CA 92865

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

13

Page 14

ACCESSORIES AND COMPONENTS

Forced Air Kit FAB-1100

Remote Control Kit RCK

Decorative

Volcanic Stone DVS

CO Sensor Kit CMSK

SPK-5000

Screen Panel Kits SPK-6000

VF5-PBH

Brass Hood Kit VF6-PBH

Gas Flex Line Kit GFLV

Brass Square BSK-5

Surround Kits BSK-6

Wall Switch Kit WSK

Rocker Switch Kit RS

Bottom Brick Liner

(CF-5500) BBL-5

14

Brass Louver Kits VF6-BRLK

VF5-BRLK

Bottom Brick Liner

(CF-6500) BBL-6

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

1-Piece Decorative DAT-5000-1

Arch Frame Kit DAT-6000-1

Thermostat WTK

Page 15

42 ¹⁄₈"

(1070 mm)

40" (1016 mm)

34" (864 mm)

36 ⁵⁄₈"

(930 mm)

20"

(508 mm)

Front View

(CF6500)

40" (1016 mm)

19 ¹⁄₂"

(495 mm)

Top View

28 ¹⁄₂"

(724 mm)

Left Side View

(Right Side View - Opposite)

Gas Line

Opening

11"

(279 mm)

19 ¹⁄₂" (495 mm)

¹⁄₂"

(13 mm)

5 ¹⁄₂"

(140 mm)

J Box

Opening

(Left Side

Only)

3 ³⁄₄"

(95 mm)

3 ¹⁄₂"

(89 mm)

3"

(76 mm)

42 ¹⁄₈"

(1070 mm)

36 ⁵⁄₈"

(930 mm)

CF5500 SPECIFICATIONS

31 ¹⁄₂"

(800 mm)

30" (762 mm)

36" (914 mm)

Front View

(CF5500)

15"

(381 mm)

37"

(940 mm)

CF6500 SPECIFICATIONS

37"

(940 mm)

Gas Line

(203 mm)

Opening

(Right Side View - Opposite)

¹⁄₂"

(13 mm)

(95 mm)

8"

3"

(89 mm)

(76 mm)

15 ¹⁄₂" (394 mm)

Left Side View

27"

(686 mm)

3 ³⁄₄"

3 ¹⁄₂"

(140 mm)

(800 mm)

5 ¹⁄₂"

31 ¹⁄₂"

J Box

Opening

(Left Side

Only)

Figure 28

36"

(914 mm)

Top View

15 ¹⁄₂"

(394 mm)

Figure 29

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

15

Page 16

TROUBLESHOOTING THE CF MILLIVOLT GAS CONTROL SYSTEM

Note: Before troubleshooting the gas control system, be sure external gas shut off valve (located at gas supply inlet) is in the “ON” position.

1. Spark ignitor will not light

pilot after repeated

triggering of black button.

2. Pilot will not stay lit after

carefully following the

lighting instructions.

3. Pilot burning, no gas to

burner, Valve knob “ON,”

Wall Switch “ON.”

POSSIBLE CAUSES

A. Defective ignitor

(no spark at electrode).

B. Defective or misaligned electrode

at pilot (spark at electrode).

C. Gas supply pressure errant.

D. Pilot orifice plugged.

A. Defective pilot generator (thermo-

couple).

A. Wall switch or wires defective.

CORRECTIVE ACTIONSYMPTOM

Check for spark at electrode and ODS; if no spark and

electrode wire is properly connected, replace ignitor.

Using a match, light pilot. If pilot lights, turn off pilot and

trigger the red button again. If pilot lights, an improper gas

mixture caused the bad lighting and a longer purge period is

recommended. If pilot will not light – check gap at electrode

and pilot - should be ¹⁄₈" to have a strong spark. If gap

measures ¹⁄₈", replace ODS system (

Check inlet gas pressure. It should be within the limits as

marked on the rating plate.

Clean or replace ODS orifice.

Check pilot flame, it must impinge on thermocouple (

19

). Clean and/or replace or adjust ODS for maximum flame

on thermocouple. Ensure that the connection between the

valve and thermocouple are tight and secure.

Check wall switch and wires for proper connections. Jumper

wire across terminals at wall switch, if burner comes on,

replace defective wall switch. If okay, jumper wires across

wall switch wires at valve, if burner comes on, wires are faulty

or connections are bad.

Figure 19

).

Figure

16

4. Frequent pilot outage

problem.

5. Frequent burner outage

problem.

B. Thermopile may not be generating

sufficient millivoltage.

C. Plugged burner orifice.

D. Defective door switch (located at

lower right corner of door frame).

A. Pilot flame may be too low or

blowing (high) causing the pilot

safety to drop out.

A. Pilot flame may be too low or

blowing (high) causing the valve

safety to drop out.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Check thermopile with millivolt meter. Take reading at thermopile terminals of gas valve. Should read 325 millivolts

minimum with optional wall switch “OFF.” Replace faulty

ODS system if reading is below specified minimum.

Check burner orifice for stoppage and remove.

Remove door frame (see instructions).

Remove two (2) screws from switch mounting bracket, pull

switch out.

Jumper wire across terminals of door switch.

If burner comes on, door switch is defective. Replace.

Clean and/or adjust pilot flame for maximum flame impingement on thermocouple (

Clean and/or adjust pilot flame for maximum flame impingement on thermopile (

Figure 19

Figure 19

).

).

Page 17

LIGHTING INSTRUCTIONS – MILLIVOLT

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE OPERATING smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Extinguish any open flame.

• Open windows.

• Do not light any appliance.

• Do not touch any electrical switches.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this page.

2. Access left side louver.

3. Turn remote wall switch to “OFF.”

4. Verify main line shut-off valve is open.

5. Push in gas control knob slightly and turn clockwise

to “OFF.”

N

O

T

O

it

L

I

P

O

F

F

EA

Gas Control Knob

Flame Adjustment Knob

T

O

L

I

P

O

N

P

I

L

O

O

F

F

T

SIT Millivolt

Valve

TPTH TP TH

Spark Ignitor

L

O

I

H

Gas Control Knob

Piezo Ignitor

Honeywell

Millivolt Valve

Note: Knob cannot be turned from “PILOT” to “OFF”

unless the knob is pushed in slightly. Do not force.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

• If your gas supplier cannot be reached, call the fire department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

do not try to repair it, call a qualified service technician. Force

or attempted repair may result in a fire or an explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

6. Wait five (5) minutes to clear out any gas. If you then smell

gas, STOP! Follow “B” in the safety information above on this

page. If you do not smell gas, go to the next step.

7. Push in gas control knob slightly and turn counterclockwise

to “PILOT.”

8. Push in control knob all the way and hold in. Immediately

light the pilot by triggering the spark ignitor (pushing red

button) until pilot lights. Continue to hold the control knob in

for about 1 ¹⁄₂ minutes after the pilot is lit. Release knob and

it will pop back up. Pilot should remain lit. If it goes out,

repeat steps 5 through 8.

• If knob does not pop up

Thermopile

when released, stop and

immediately call your

Thermocouple

service technician or gas

supplier.

Ignitor

• If pilot will not stay lit after

several tries, turn the control knob to “OFF” and call your

service technician or gas supplier.

9. Turn gas control knob counterclockwise to “ON.”

10. Close the side louver.

Note: If the gas valve is turned directly from the “ON” to “OFF”

position, the valve will latch in the “OFF” position for 60 seconds.

TO TURN OFF GAS TO APPLIANCE

1. Turn remote wall switch “OFF.” The pilot will remain lit for

normal service.

2. For complete shutdown, turn remote wall switch to “OFF.”

3. Access the left side louver.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

4. Depress gas control knob slightly and turn clockwise

to “OFF.” Do not force.

5. Close the side louver.

17

Page 18

REPLACEMENT PARTS LIST — MILLIVOLT

CF5500-CMN CF5500-CMP CF6500-CMN CF6500-CMP

No. DESCRIPTION Part No. Qty. Part No. Qty. Part No. Qty. Part No. Qty.

1. Gas Fireplace Assembly 128231 1 128232 1 128551 1 128552 1

2. Bar, Louver (Black) 024504 4 024504 4 104951 4 104951 4

3. Hood (Black), Clean Face 108951 1 108951 1 108971 1 108971 1

4. Screw 000861 3 000861 3 000861 3 000861 3

5. Replacement Glass Panel with Gasket 064099 1 064099 1 064101 1 064101 1

6. Door Switch 094468 1 094468 1 094468 1 094468 1

7. Pan Burner Assembly 128281 1 128281 1 128661 1 128661 1

8. Log Grate 126461 1 126461 1 128831 1 128831 1

9. Log Set (Split, Complete) 904555 1 904555 1 904556 1 904556 1

a. Log, Rear Right 903923 1 903923 1 904563 1 904563 1

b. Log, Rear 903921 1 903921 1 904561 1 904561 1

c. Log, Front 903922 1 903922 1 904562 1 904562 1

d. Log, Front Right 903924 1 903924 1 904564 1 904564 1

10. Venturi Tube 097506 1 097506 1 097506 1 097506 1

11. Gasket 900272 1 900272 1 900272 1 900272 1

12. Bag of Rockwool/Ember Coals 125013 1 125013 1 125013 1 125013 1

13. Refractory Liner, Rear 903502 1 903502 1 903499 1 903499 1

Refractory Liner, Side Panel 903500 2 903500 2 903497 2 903497 2

18

GAS CONTROLS — MILLIVOLT

CF5500-CMN CF5500-CMP

CF6500-CMN CF6500-CMP

No. DESCRIPTION Part No. Qty. Part No. Qty.

20. Gas Valve - SIT 901916 1 901917 1

Gas Valve - Honeywell 67L0101 1 67L0201 1

21. Piezo Igniter 111061 1 111061 1

22. Orifice/CF5500 903461 1 901694 1

Orifice/CF6500 903883 1 901699 1

23. Pilot Assembly (ODS) 901914 1 901915 1

24. Regulator 903218 1 112081 1

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

Page 19

REPLACEMENT PARTS

11

9

3

a.

2

8

b.

c.

1

d.

7

13

10

24

22

23

20

(SIT Valve Shown)

7

6

21

12

2

5

4

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

19

Page 20

Catalytic Gas Fireplace

Manufacturer's Limited Warranty 10 Years

THE WARRANTY

The manufacturer warrants the components of this Catalytic Gas Fireplace manufactured by SFC, INC. (hereinafter, SFC) to be free from defects in

materials and workmanship at the time of manufacture.

REMEDY AND EXCLUSIONS

The coverage of this Warranty is limited to all components of the Catalytic Gas Fireplace manufactured by SFC. SFC warrants the components of this

factory-built system manufactured by SFC to be free from defects in material and workmanship at the time of manufacture.

1) During the first five years of this warranty, SFC will, at its option and except for the components listed in subparagraphs (a) through (e) below

provide replacement or repair components of the factory-built gas insert manufactured by SFC, at no charge, and will also pay for reasonable labor

costs incurred in replacing or repairing such components. If repair or replacement is not commercially practicable, SFC will, at its option, refund

the purchase price of the gas insert and chimney components and accessories. With respect to the components listed below, the remedies of this

paragraph (1) are available only for the period of time indicated. Thereafter, however, until the expiration of 10 years from the date of installation,

SFC will provide replacement parts at no charge but will not pay any labor costs. All replacement parts will be shipped F.O.B. factory.

(a) Gas logs, ember coals, brass-tone finishes, paint and fiber ceramic simulated brick side panels are not warranted with the exception of defects

in material or workmanship.

(b) Unvented Gas Room Heater electrical components, such as fan motors and blowers, electrical cord and electrical switches – one year from the

date of installation.

(c) Gas components, such as gas valves, pilot assembly, igniter, micro door switch and CO Sensor kit – one year from the date of installation.

(d) Tempered glass – one year from the date of installation.

(e) Catalyst assembly – 2 years parts and labor, 3-5th. year, parts only from the date of installation.

This warranty covers only parts and labor as provided above. In no case shall SFC be responsible for materials, components, or construction which

are not manufactured or supplied by SFC, or for the labor necessary to install, repair or remove such materials, components or construction.

QUALIFICATIONS TO THE WARRANTY

The Unvented Gas Room Heater Warranty outlined above is further subject to the following qualifications:

(1) The Unvented Gas Room Heater must be installed in accordance with SFC installation instructions and local building codes. The Warranty on this

Unvented Gas Room Heater covers only the component parts manufactured by SFC. The use of components manufactured by others with this