Page 1

ELECTRIC COUNTER TOP

IL1420

CONVECTION OVEN

CCOHS-3

CCOQS-3

Installation and

Operation

Instructions

2M-Z11295 Rev. C 2/24/2012

CCOQS-3

CCOHS-3

1

Page 2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

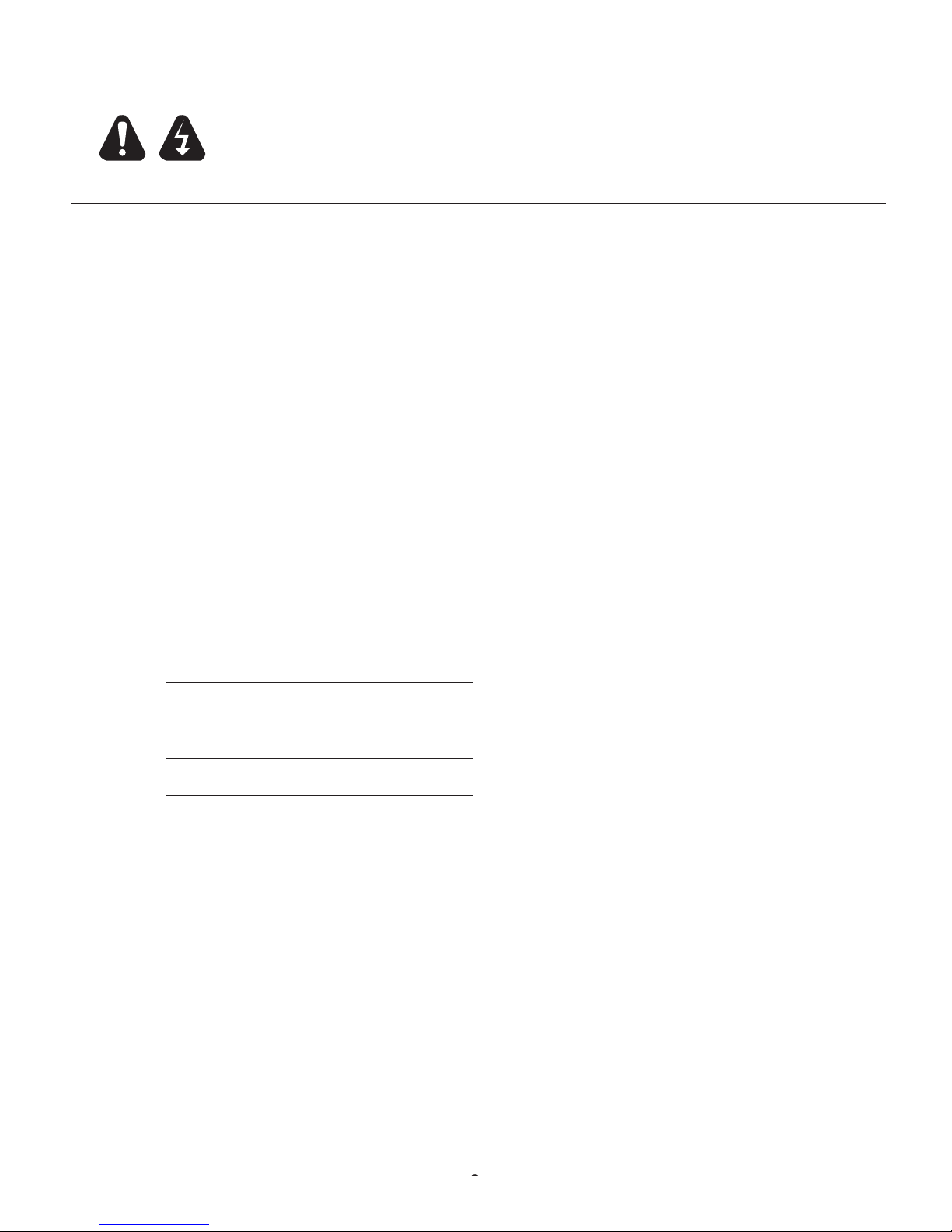

SPECIFICATIONS

B

A

C

Superior Countertop Convection Ovens are

constructed of highly polished

stainless steel with high performance

heating elements and rear fans,

stainless steel door handle, chrome plated

wire racks and rack slides. The bake

chamber is made of stainless steel or

porcelain. The oven door is double pane

tempered glass and features a heavy-duty

hinge mechanism. Thermostat range is

175°F / 79°C to 500°F / 260°C. Timer

range is 0 to 120 minutes. Oven features a

heat indicator light and door interlock switch.

Oven holds either 3 or 4 standard size

baking sheets. Units available in various

voltages and is shipped with a NEMA

plug installed.

Mode “A” Width “B” Height “C” Depth Approximate

No. Inches/CM Inches/CM Inches/CM Ship Weight

CCOHS-3 24.4in / 62cm 21.5in / 54.6cm 23.4in / 59.4cm 86lbs / 39.1kg

CCOQS-3 19in / 48.3cm 15in / 38.1cm 20.4in / 51.8cm 47lbs / 21.4kg

ELECTRICAL SPECIFICATIONS

Model No. Voltage Wattage Amps NEMA Plug

CCOHS-3 120V 1,440 12 5-15

CCOQS-3 120V 1,440 12 5-15

OVEN FEATURE CCOQS-3 CCOHS-3

Number of Racks 3 3

Domestic Sheet Size 1/4 1/2

Inner Oven Chamber Stainless Steel Stainless Steel

Number of Motors/Fan(s) 1 1

Reversible Motors no no

Number of Interior Lights 0 1

Top Browning Element no yes

Steam Feature no no

Manual Reset Hi-Limit Protection yes yes

Door Interlock Switch yes yes

Timer

Single “Ding” yes yes

Electronic no no

3

Page 4

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED. FAILURE TO

GROUND THE APPLIANCE COULD RESULT IN ELECTROCUTION AND DEATH.

WARNING

NOTICE

NOTICE

NOTICE

CAUTION

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED TO WORK

WITH ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE

INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

The data plate is located on the lower right side panel of the unit. The oven voltage,

wattage, serial number, and clearance specications are on the data plate. This

information should be carefully read and understood before proceeding with the

installation.

The installation of this unit must conform to applicable national, state and locally

recognized installation standards.

The installation of any components such as a vent hood, grease extractors, re

extinguisher systems, must conform to their applicable National, State and locally

recognized installation standards.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ THE

WARNING AND FOLLOW THE DIRECTIONS OF THE LABEL OF THE CLEANER TO BE

USED.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR HOSE

CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

WARNING

NOTICE

NOTICE

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THE APPLIANCE WHEN

THE UNIT IS PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE REPLACING

ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY.

Never use chlorine sanitizer in contact with stainless steel surfaces longer than 10

minutes. Longer contact can cause corrosion.

Service this, or any other Superior appliance must be performed by qualied

personnel only. Consult your authorized service station directory or call the factory

(at 1-800-807-9054), or log onto www.star-mfg.com for the service agent nearest you.

4

Page 5

CAUTION

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated

with the unit prior to putting it into operation. Make sure all people associated with its use

understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed.

This unit has been tested and carefully packaged to insure delivery of your unit in perfect

condition. If equipment is received in damaged condition, either apparent or concealed, a claim

must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked,

a request for inspection of concealed damage must be made with carrier within 15 days.

Be certain to retain all contents plus external and internal packaging materials for inspection.

The carrier will make an inspection and will supply necessary claim forms.

PURCHASER’S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the electric services for the oven are installed on site in accordance with

the manufacturer’s specications and in compliance with all local codes.

2. To unload, un-crate, and install the oven in its proper location and in accordance with

this installation operation manual.

CAUTION

3. To see that electric services are connected properly by a qualied installer of your

choice.

UN-CRATING

The oven will arrive completely assembled and ready to use. Prior to un-crating move the

oven as close to its nal location as practical. This will protect it from damage associated with

moving (scratches, dings, dropping).

These ovens weigh between 47 & 140 lbs. For safe handling, installer should obtain help as

needed, or employ appropriate materials handling equipment (such as a forklift, dolly, or pallet

jack) to remove the unit from the container and move it to the place of installation.

ANY STAND COUNTER OR OTHER DEVICE ON WHICH THE OVEN WILL BE LOCATED

MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE OVEN.

NEVER lay oven with the control side down, this will damage the controls.

5

Page 6

WARNING

INSTALLATION

LOCATION

Do not install the Holman Counter top Convection Oven directly on the Floor.

Superior has stands available to accommodate your new oven.

CAUTION

DO NOT install oven closer than 1" on the control side, from another oven.

DO NOT install oven closer than 12" on the control side, from a uncontrolled heat source

(char broiler, open ame, griddle, etc.), unless a Hi-Temperature Spacer is installed then

it can be reduced to 1".

ELECTRICAL

The ovens are equipped for the voltage indicated on the nameplate mounted on the

lower right side panel of the oven. They will operate on alternating current (AC) only.

A cord & plug is provided installed.

All electrical connections must be made by a licensed electrician and in accordance with local

codes or in the absence of local codes with NFPA No. 70 latest edition (in Canada use: CSA

STD. C22.1)

DO NOT CONNECT TO DIRECT CURRENT (DC).

DO NOT CONNECT TO ANY OTHER TYPE OF CURRENT THAT IS OTHERWISE SPECIFIED

FOR THIS SPECIFIC UNIT, OR MACHINE WILL BE SERIOUSLY DAMAGED.

AIR SUPPLY

Make certain not to obstruct the ow of combustion (gas) and ventilation air. Provisions for

adequate air supply must be furnished.

LEVELING THE UNIT

This Superior Oven comes with legs installed at the factory, proper leveling is essential to receive

a proper baking performance. Level unit by adjusting the (4) feet which have an adjustment

of 1-3/4” (43.75mm) for accurate leveling.

6

Page 7

OPERATION

CCOFS-4

CCOHS-3

CCOHS-4

CCOQS-3

A A A AB BB BCC C CD D DF E

IL1421

INTI AL USE

Before using your Superior Counter Top Convection Oven for the rst time, clean the unit using

mild detergent and warm water, then heat for approximately 30 minutes. The grill may emit a small

amount of smoke as the cooking surfaces reach 300-350°F (149-177°C). Do not be alarmed, as

the smoke is caused by oils associated with the manufacturing process and will stop when the

oven reaches 400°F (204°C).

OVEN COMPONENTS DESCRIPTION

A: Timer: This can be set at any range between 0 thru 120 minutes, when the timer

reaches 0 the unit will turn itself off. It also has a manual feature which will allow it to run

continuously until it is removed from this setting.

B: Temperature: This sets the cooking temperature between 175°F to 500°F (79°C to 260°C).

C: Indicator Light: This light will illuminate when the oven is being brought up to the desired

temperature, it will turn off when the desired set temperature is reached.

D: On/Off Switch: Makes it easy to see at a glance when the oven is operating.

E: 1-Shot Steam: Provides a single shot of steam into the cooking chamber. The oven must be

at operating temperature to receive this benet, and should only be used in shots of

5 seconds periods.

F: Top Broiler Element: Provides intense heat for broiling, browning and nishing menu items.

G: Hi-Limit Reset: Mounted on the rear of the unit, it monitors the inside cooking temperature

and will only trip when the unit reaches a high temperature due to the unit being in an enclosed environment with no air cooling circulation.

TYPICAL OPERATION SEQUENCE

ACTION RESULT

Press the ON/OFF switch. Button lights up.

Adjust Temperature to desired setting Fan, heat and indicator light comes on.

and move timer to manual position. Fan will reverse only on CCOF-4 model.

Indicator lights shuts off. Oven has reached desired temperature.

Load product into oven. See Hints & Suggestions - “Loading the Oven”

Fan will shut off when door is opened,

this minimizes the heat loss.

Set Timer to desired cook time. Timer starts timing down.

1-Shot Steam (CCOFS-4 model only) See Convection Oven Baking Guide,

Convection Ovens In General

Cooking timer times out. When 0 is reached the fan and heat shuts off,

and the ON/OFF switch remains lit.

Unload Oven See Hints & Suggestions - “Unloading the Oven”

7

Page 8

MAINTENANCE

Fan

Rear Panel

Screw

IL1372

Contact the factory, a service representative or a local service company for service or

required maintenance. Replacement cord sets must be purchased from Star Manufacturing

International, Inc.

• Oven interiors should be wiped down daily and thoroughly cleaned weekly using warm water

and mild detergent. DO NOT use caustic cleaners.

CLEANING

• Always start with a cold oven.

• The stainless exterior can easily be cleaned using stainless steel cleaner.

• Always follow the cleaner manufacturer’s instructions when using any cleaner.

• Care should be taken to prevent caustic cleaning compounds from coming in contact with

the fan wheel.

• The oven racks, rack slides, may be cleaned outside the oven cavity using oven cleaner.

• Using any harsh chemicals will result in the removal of the ETC coating and etching of the

porcelain below it. The oven interior should only be cleaned using a mild soap and a non

metal scouring pad. DO NOT use caustic cleaners.

• Always apply stainless steel cleaners when the oven is cold and rub in the direction of the

metal’s grain.

WARNING

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO WEAR

RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING.

CAREFULLY READ THE WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

NEVER LEAVE A CHLORINE SANITIZER IN CONTACT WITH STAINLESS STEEL

SURFACES LONGER THAN 10 MINUTES. LONGER CONTACT CAN CAUSE

CORROSION.

CLEANING THE FAN

The fan located behind the rear panel

should be cleaned periodically.

Depending on the amount and type of

use the unit receives, dirt & grime will

build up on the fan, causing it to

possibly shorten the life of the motor.

To clean simply:

1. Unplug unit and allow to cool.

2. Loosen screws shown here and

remove rear panel.

3. Using damp cloth, wipe fan until

clean.

4. Reassembly and test for proper

operation.

8

Page 9

CONVECTION OVEN BAKING GUIDE

CONVECTION OVENS IN GENERAL

• Convection ovens constantly circulate air over the product. This strips away the thin layer of moisture laden air

from the top of the product allowing heat to penetrate more quickly. This allows cooking times to be shortened

and cooking temperatures reduced in convection ovens. Introducing steam into the cooking process prevents

the bake from loosing moisture and allows for a better product.

• Applying steam to dough during rst 5 minutes, allows the yeast to work a little longer, allowing for better oven

spring and loaf volume keeping the outer layer exible and moist. Once the outside layer of the dough sets,

gases in the loaf can no longer expand to increase the loaf size.

• Steaming the dough as it bakes also gelatinizes starch on the outside layer, producing a bread with a crisp crust

and a brown crust color in varying degrees; too much steam results in an undesirable crust. Steam also helps

to prevent wild breaks in the loaves because it delays the setting of the bread’s crust, allowing it more time to

bake and brown. However, in contrast, during the last stages of baking, a dry oven is required when the crust is

browning; after the steam is removed, the gelatinized layer dries out forming a thick crunchy crust.

• The convection oven is an electromechanical piece of equipment and is designed to produce a consistent result. Variations in results are therefore more likely due to differences in the preparation process.

BAKING HINTS

• Always maintain a consistent cooking process. Establish a process that works for you, write it down and stick

to it. Consistency in your cooking processes is very important to the quality of your bake.

• Always weigh your product. This will give you a more consistent size, color and quality.

• Do not overload pans or space product unevenly in the pan as this will create a uneven bake.

• Bent or warped pans can greatly affect the evenness of the bake.

• Always use the oven lights to view the product through the oven door windows. Do not open the oven doors

during baking as this will change the baking characteristics and produce erratic results.

• If using baker’s parchment, be sure the parchment does not blow over the product or obstruct air ow in any

way. This will create a uneven bake. Never use aluminum foil in your convection oven.

• Use proper sheet pans for baking. Aluminum pans have better heat transference than steel pans and

therefore yield much better bake results.

LOADING THE OVEN

• When loading the oven, stage products and racks so the oven doors are opened for the least amount of time

during the loading process to minimize the loss of heat inside the oven.

• Center each pan on the oven shelves. Spaces should be maintained equally between the pan edges and the

oven walls, front and back. This will allow for an even distribution of airow. The better the air ow around the

product, the better and more consistent the bake.

• Load the pans on the shelves as close to equal distant apart as possible. Even vertical spacing of the pans on

shelves 1 thru 3 or 4 inside the oven is important to the proper circulation of air and therefore will have an effect

on the quality of your bake.

• When loading the oven randomly, (Different times for different shelves) load the oven from the

center shelf out with even vertical spacing.

• When loading multiple pans at the same time, load the shelves spaced as equal distant as possible with

even vertical spacing.

UNLOADING THE OVEN

• Unload the top shelf before the bottom shelves. This is necessary because it is a characteristic of all

ovens that, after the fan shuts down, rising heat and the hot oven ceiling causes the top shelf to

bake quicker. This characteristic is more pronounced when baking at higher temperatures and/or for

prolonged periods of time.

• Always stage your product racks so that you can unload quickly with the door open for a

minimal amount of time. This is to preserve the temperature inside the oven cavity for your next round of

baking.

ALWAYS KEEP THE AREA NEAR THE UNIT FREE FROM COMBUSTIBLE MATERIALS.

CAUTION

CLEAN IMMEDIATELY TO AVOID THE DANGER OF SLIPS OF FALLS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS OCCUR,

9

Page 10

2M-4497-2 6/1312

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in which

the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the transportation

company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the Ultra-Max, Hot Plates, Griddles, Charbroilers is (3) years parts & labor.

* The warranty period for the Star-Max, Charbroilers, Griddles, Hot Plates, Fryers & Finishing Oven is (2) years parts & labor.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted, the labor to replace the part is NOT warranted.

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

* The Model 510FD, 510FF Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

10

Page 11

CCOQS-3 Convection Oven

11

Page 12

CCOHS-3 Convection Oven

12

Page 13

MODEL:

CCOQS-3 Electric Countertop Convection Oven

SK2266 Rev. A 9/12/2012

8

9

10

12

14

11

17

19

20

21

26

37

29

30

27

31

34

35

36

41

42

38

25

28

33

32

22

23

24

16

18

39

18

12

13

43

16

6

15

1

2

40

3

4

5

13

Page 14

PARTS LIST February 24, 2012, Rev. C

CCOQS-3

COUNTER TOP CONVECTION OVEN

Number

Key

Number

1 F9-Z10707 1 BODY WRAP

2 F9-Z10710 1 REAR, OVEN CHAMBER

3 2N-Z10735 1 ELEMENT 1400W, 120V

4 2U-Z10736 1 MOTOR/FAN ASSEMBLY

5 F9-Z10713 1 PANEL, AIR DISTRIBUTOR

6 2B-Z10743 2 L/R RACK SUPPORT

7 F9-Z10712 1 PANEL, REAR COVER-OVEN

8 2E-Z8861 1 CORD, POWER, 120V

9 2E-Z10730 1 STRAIN RELIEF

10 2E-Z10731 1 TERMINAL BLOCK

11 F9-CN0006 1 BODY BOTTOM PLATE ASSY

12 2E-Z10732 1 HIGH LIMIT

13 F9-CN0005 1 VENT TUBE

14 2B-Z10744 3 RACK

15 F9-Z10716 1 BRACKET, TSTAT PROBES

16 2T-Z10733 1 THERMOSTAT

17 2R-Z1485 4 FOOT 1” ADJUSTABLE

18 2E-Z10727 3 INDICATOR, RED RUBBER

19 2R-Z10724 1 KNOB, TEMPERATURE

20 2J-Z2329 1 PILOT LIGHT

21 2R-Z10723 1 KNOB, TIMER

22 F9-Z10711 1 PANEL, CONTROL

23 2E-Z10734 1 TIMER, OVEN

24 F9-Z10703 1 SUPPORT, DOOR RIGHT

25 F9-Z10705 1 SUPPORT, DOOR BOTTOM

26 2Q-Z10721 1 GLASS, OUTER

27 F9-Z10702 1 SUPPORT, DOOR LEFT

28 F9-Z10704 1 SUPPORT, DOOR TOP

29 2V-Z10741 1 ROD, HANDLE

30 2I-Z10726 2 HANDLE-END, DOOR

31 2C-1557 2 SCREW 10-24X1 1/2 RHP STL np

32 2C-Z10749 2 THUMBSCREW, SHELF

33 2C-Z10750 2 SCREW, SHELF RIVET

34 2I-Z10770 1 GASKET, DOOR

35 F9-Z10709 1 OVEN CHAMBER, BOTTOM

36 F9-Z10717 1 OVEN CHAMBER, TOP

37 2Q-Z10722 1 INNER GLASS, TEMPERED

38 PS-CN0064 1 CCOQ-3 DOOR SWITCH KIT (BRACKET, WIRE, SWITCH)

39 2M-Z10358 1 HOLMAN LOGO

40 F9-Z10763 1 HEAT SHIELD

41 2F-Z10745 2 HINGE, DOOR

42 2F-Z10769 2 RECEIVER, HINGE DOOR

43 2P-Z7670 2 HALF CLIP

NI 2C-Z10474 50 SCREW (BODY)

NI 2C-Z10748 3 SCREWS, MOTOR MOUNTING

NI 2C-Z10753 2 SCREW, TIMER

NI 2C-Z10756 6 SCREW, HINGE

NI 2C-Z10754 6 WASHER, HINGE

NI 2C-Z10757 2 SCREW, THERMOSTAT

NI 2C-Z10758 2 SCREW, BLOCK TERMINAL

NI F9-CN0002 1 DOOR ASSEMBLY COMPLETE

Part

Number

Per

Unit

Description

14

Page 15

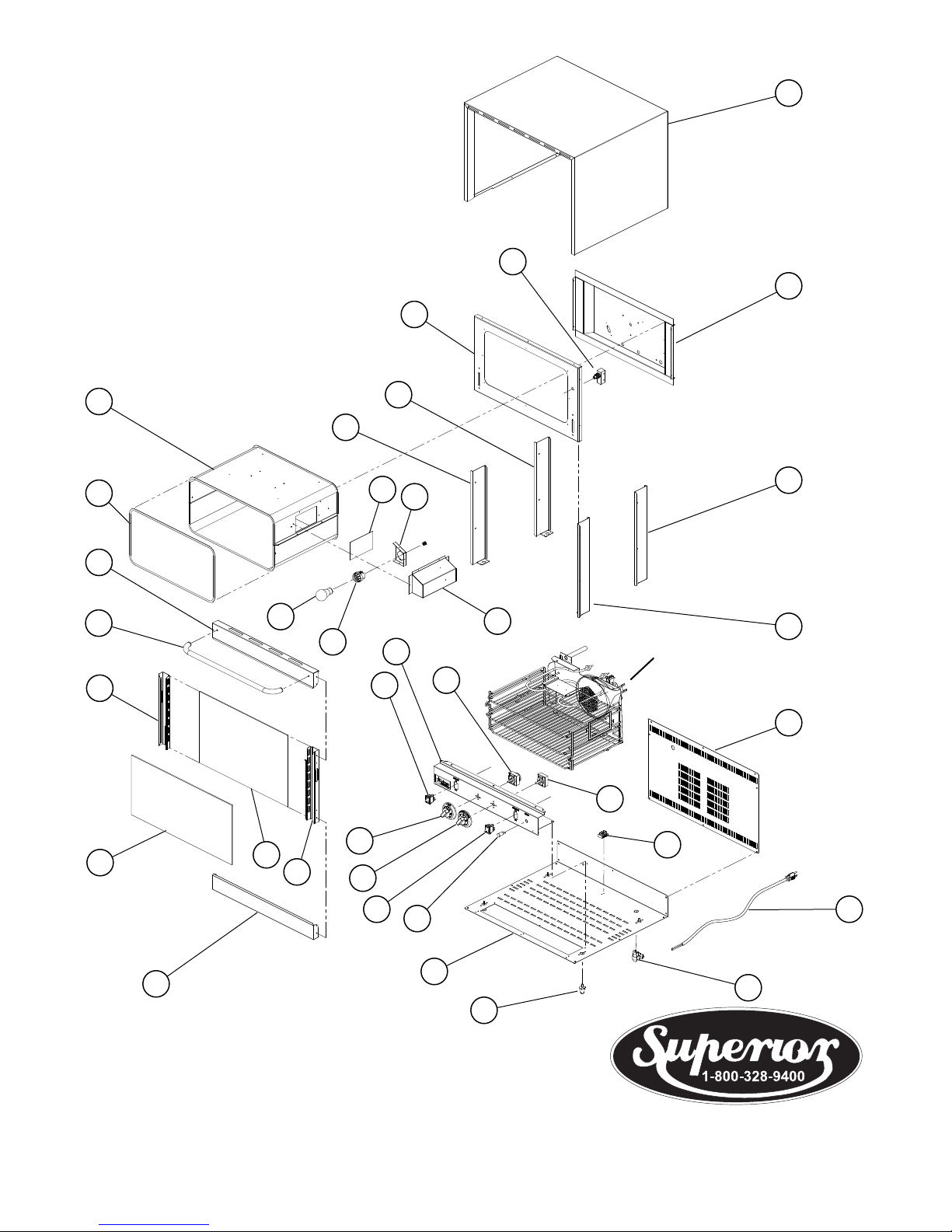

MODEL:

CCOHS-3 Electric Countertop Convection Oven

SK2267 Rev. A 9/16/09

1

2

4

4

6

8

11

12

9

10

20

21

24

22

30

23

25

26

28

34

5

5

3

29

31

32

33

27

17

19

18

16

15

14

13

7

SEE DETAIL

A

15

Page 16

38

39

39

39

40

41

38

37

36

42

Detail

A

35

43

MODEL:

CCOH-3

SK2268 Rev. - 8/1/07

16

Page 17

PARTS LIST July 16, 2010, Rev. C

CCOHS-3

COUNTER TOP CONVECTION OVEN

Number

Key

Number

1 F9-Z10915 1 BODY WRAP

2 F9-Z10907 1 REAR, OVEN CHAMBER

3 F9-Z10906 1 FRONT FACE, OVEN CHAMBER

4 F9-Z10910 2 SUPPORT, OVEN CHAMBER RIGHT

5 F9-Z10909 2 SUPPORT, OVEN CHAMBER LEFT

6 F9-Z10913 1 PANEL, REAR COVER-OVEN

7 D9-Z8861 1 CORD, POWER, 120V

8 2E-Z10730 1 STRAIN RELIEF

9 2R-Y5092 4 FOOT

10 F9-Z10911 1 PLATE, BOTTOM OVEN

11 2E-Z10731 1 TERMINAL BLOCK

12 2T-Z10733 1 THERMOSTAT

13 2J-Z2329 1 PILOT LIGHT

14 2E-Z10950 1 SWITCH, BROILER

15 2R-Z12007 1 KNOB, TEMPERATURE

16 2R-Z10935 1 KNOB, TIMER

17 2E-Z10942 1 SWITCH, ON/OFF

18 2E-Z10734 1 TIMER, OVEN

19 F9-Z10912 1 PANEL, CONTROL

20 F9-Z10903 1 SUPPORT, DOOR BOTTOM

21 2Q-Z10932 1 GLASS, OUTER

22 F9-Z10901 1 SUPPORT, DOOR RIGHT

23 F9-Z10900 1 SUPPORT, DOOR LEFT

24 2Q-Z10933 1 GLASS, INNER

25 2V-Z10943 1 ROD, HANDEL

26 F9-Z10902 1 SUPPORT, DOOR TOP

27 F9-Z10917 1 LIGHT HOUSING

28 2I-Z10937 1 GASKET, DOOR

29 2E-Y9184 1 SOCKET, LIGHT

30 2S-1279 1 LIGHT BULB

31 2Q-Z10934 1 GLASS, LAMP COVER

32 F9-Z10916 1 LIGHT SOCKET HOLDER

33 PS-CN0063 1 CCOH-3 DOOR SWITCH KIT (BRACKET, WIRE, SWITCH)

34 F9-CN0019 1 OVEN CHAMBER WELD ASSY

35 2U-Z10736 1 MOTOR/FAN ASSEMBLY

36 2N-Z10735 1 ELEMENT 1400W, 120V

37 2E-Z10732 1 HIGH LIMIT

38 2B-Z10945 2 L/R RACK SUPPORT

39 2B-Z10944 3 RACK

40 F9-Z10919 1 TOP HEATING ELEMENT BRACKET

41 F9-Z10918 1 BRACKET, SUPPORT HEATING ELEMENT

42 2N-Z10939 1 ELEMENT, TOP, 1400W/120V

43 F9-Z10908 1 PANEL, AIR DISTRIBUTOR

NI 2F-Z10946 2 HINGE, DOOR

NI F9-CN0016 1 DOOR ASSEMBLY COMPLETE

Part

Number

Per

Unit

Description

17

Page 18

Page 19

Page 20

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Loading...

Loading...