Page 1

User Manual for Sunways

Solar Inverters NT 2600, NT 4000 and

NT 6000

Page 2

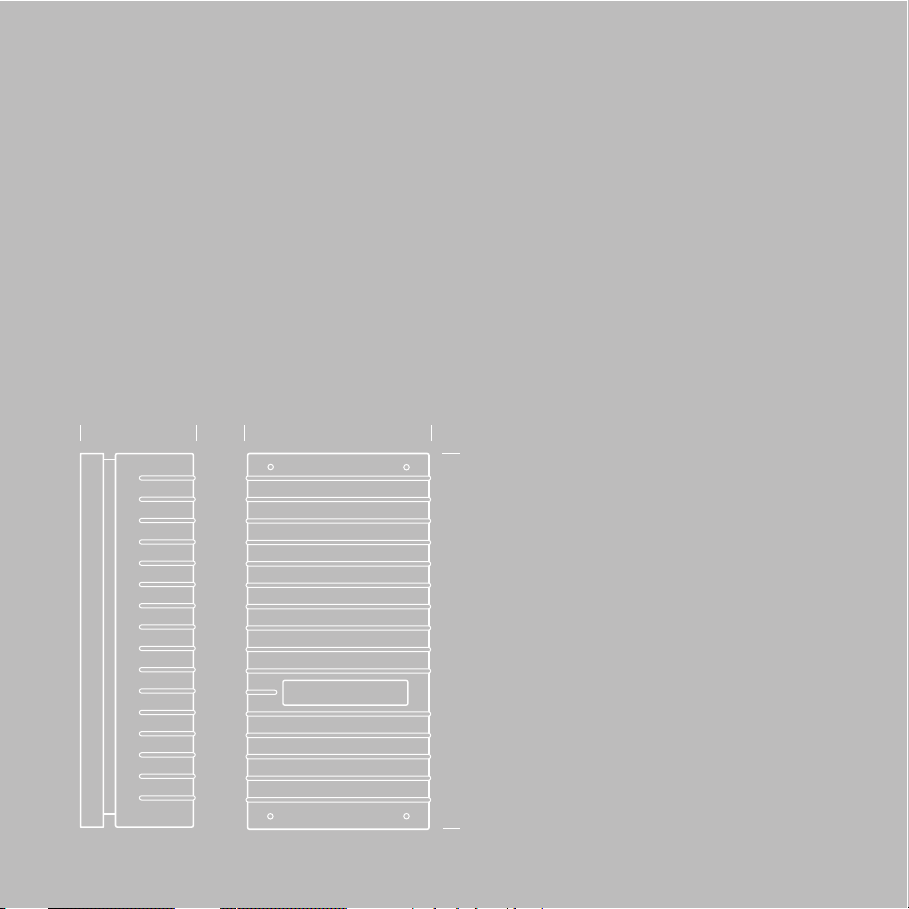

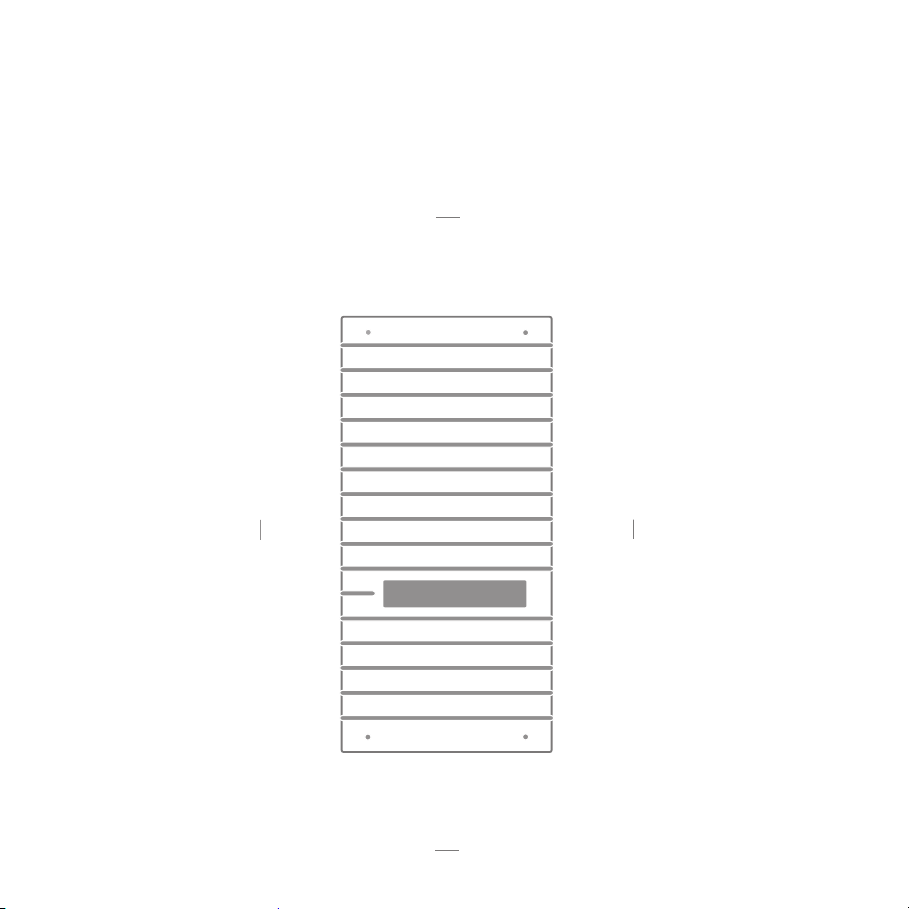

300 mm

510 mm

180 mm

Page 3

EN

List of Contents

1.0 General information

1.1 Safety information

1.2 Sunways Solar Inverters

NT 2600, NT 4000 and NT 6000

2.0 Information on installation

2.1 Safety information

2.2 Installation

General safety information

Opening the unit

Scope of supply, inspecting the delivery

Integration into the PV system

Design of the PV generator

Standard components of a PV system

Protection concept

Electrical safety

Mechanical safety

Information on cleaning

Requirements on the place of installation

Electrical connection and cable entry

Grid connection

PV generator connection

Important Information

Communication connections

Connecting the sensors

83

84

85

86

87

88

90

91

93

94

95

97

98

100

102

79

Page 4

2.3 Commissioning

3.0 Information on operation

3.1 Monitoring and diagnosis

3.2 Sunways NT Monitor software

3.3 Fault indications

3.4 Fault diagnosis

3.5 Warranty terms and conditions

Switching the solar inverter on and off

Configurations

Structure and menu levels for configuration

Display

Data memory

General information

Initialising the remote modem

Connection and circuitry options

Configuring the interface cables

Sunways NT Monitor data acquisition

Operation of Sunways NT Monitor

Screen displays

Indications, causes and remedies

Warranty period

Terms and exclusion of liability for

solar inverters

104

106

108

111

112

113

114

115

120

122

123

125

127

130

80

Page 5

EN

4.0 Appendix

4.1 Subject and abbreviation index

4.2 Function and information index

Designation and description

Functional principle and explanations

Block diagram

Technical data

TYCO SOLARLOK connectors

Conformity and safety declarations

General exclusion of liability, rights,

registered trademarks

133

135

138

140

144

146

150

81

Page 6

82

1.0 General information

Page 7

General safety information

All safety hints contained in this section

and throughout the User Manual must

be complied with at all times to guarantee

the user's safety. The described product

must not be operated if any mechanical

or electrical components are defective.

Before commissioning the system, we

strongly advise you to carefully read and

heed the instructions! Non-compliance

can have serious consequences, for example damage to the unit or other property

or physical injuries with possible loss of

life.

The solar inverter must be installed by a

trained, qualified electrician. The electrician must be approved by the competent

electricity board (EB).

The relevant tasks to be carried out are

identified by an additional adjacent

symbol in the respective chapter headings.

83

EN

1.1 Safety information

The User Manual contains safety hints.

These are identified by a triangle with an

exclamation mark.

!

Page 8

Opening the unit

Before opening the cabinet, the unit must

always be disconnected from the grid and

from the PV generator.

The unit continues to conduct a hazardous

voltage internally and at the connection

sockets for ca. five minutes after disconnecting from the PV generator. The energy

storage capacitors are only fully discharged

after this period.

After disconnecting the unit from the grid

and from the PV generator, you must wait

at least five minutes before opening the

unit.

84

!

Page 9

85

EN

1.2 Sunways Solar Inverters NT 2600,

NT 4000 and NT 6000

Scope of supply

· Sunways Solar Inverter in the NT series

· Installation frame

· Manual, setup, warranty card, CD-Rom

with software

· 2 pairs of TYCO SOLARLOK connectors

Inspecting the delivery

The condition of our products is checked

prior to delivery. Although our products

are carefully packed in recyclable packing,

transportation damages can still occur.

These are generally the transport company's responsibility.

Please inspect the delivered solar inverter

thoroughly!

If you discover any damage to the packing

or the solar inverter, please inform the

transport company immediately. Your

specialist dealer will be glad to assist you

if required. Any damages must always be

reported to the transport company in writing seven days after receipt of the goods

at the latest.

Page 10

Integration of the solar inverter into the

PV system

Design of the PV generator

The technical data of the selected PV

generator must be within the specification of the solar inverter (see Technical

Data). The Sunways NT Sundim design

program for the PV generator may be

helpful. Sunways NT Sundim is available

on the enclosed CD or from our website, www.sunways.de.

Please take account of the following

points before planning your system:

· Pay attention to the skyward alignment

of the modules. You will obtain maximum yield in Central Europe with a

module inclination of 30° to the horizontal and a direct southerly alignment

of the generator field.

· The output of the cells decreases as the

module temperature increases. Install

your PV generator with adequate rear

ventilation.

· Check your PV generator for soiling ca.

every three years. This occurs particularly

at the lower edge of the modules and

forms a film, which even heavy rain cannot wash away. Decreases in yield can be

prevented by cleaning with a wet cloth

or a brush.

· Avoid shading of individual modules or

solar cells in your system. This can result

in heavy losses in yield.

86

Page 11

87

EN

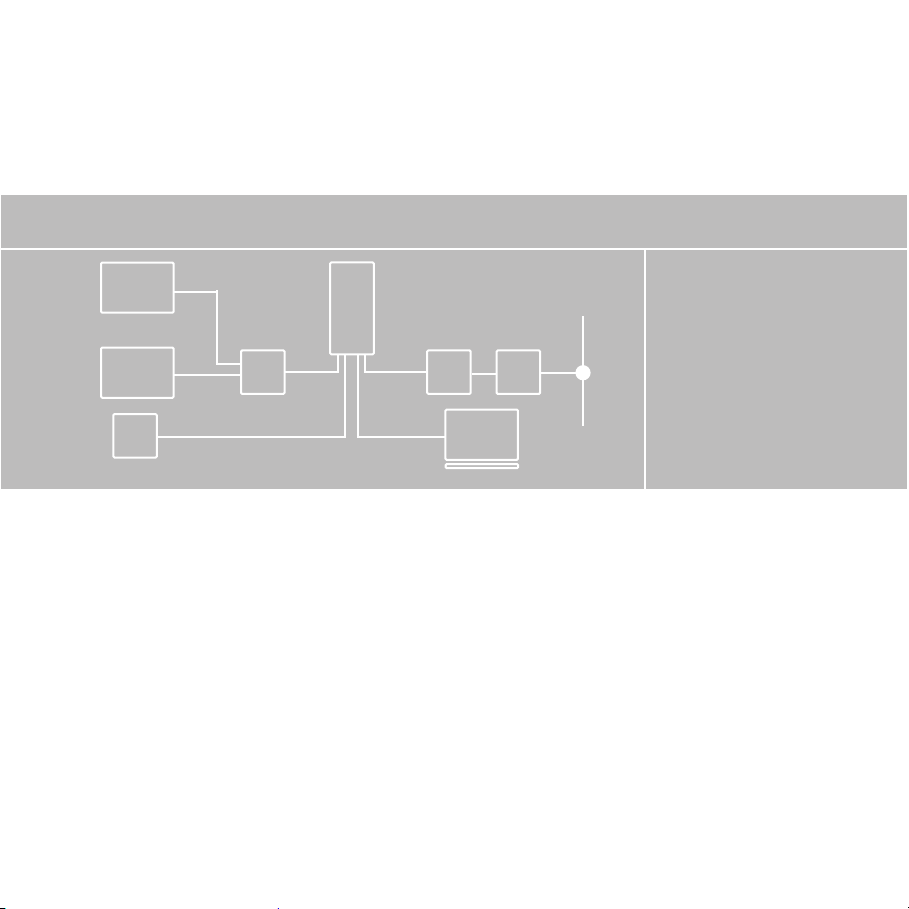

Standard components of a PV system

Depending on the recommendations of

your electrician, your PV system will consist of the following components:

PC

(3)

SUNWAYS

NT

PV

PV

(1)

(2)

(4)

(1) PV generator switch

(2) Irradiation sensor with

integrated temperature

sensor

(3) Mains fuse

(4) Energy meter

Grid

PV generator switch:

Designed as DC load break cut-out to cut

off the PV generator from the solar inverter.

Dimensioning: min. 800 V, ≥ 16 A

Grid connection:

3-phase (Feed-in: 1-phase; grid monitoring:

3-phase)

Standard components of the PV system

Page 12

Protection concept The following parameters are monitored

continuously and in parallel by the microcontroller and displayed on the screen:

· AFI error (ground fault)

· Overheating of the cooling element

· DC overvoltage

· AC undervoltage/overvoltage

In the event of a fault, the conversion is

immediately blocked and the grid relay

disconnected.

In addition, the following protective devices are provided on both grid and PV

generator side:

· Grid-side varistors

Protect the power semiconductors from

high-energy, time-limited voltage spikes on

the grid and provide for a reduction of

energy in the throttle in the event of grid

disconnection.

· Generator-side varistors

Thermally monitored varistors provide protection against atmospheric overvoltages

(e.g. due to remote strikes during storms).

88

Page 13

89

2.0 Information on installation

Page 14

Electrical safety

Before opening the cabinet, the solar

inverter must be disconnected from the

grid and from the PV generator.

The solar inverter continues to conduct

a hazardous voltage internally and at the

connection sockets for the PV generator

for ca. five minutes after disconnecting

from the PV generator. The energy storage

capacitors are only fully discharged after

this period.

After disconnecting the solar inverter from

the grid and PV generator, you must wait

at least five minutes before opening the

solar inverter.

Mechanical safety

During installation, make sure that the

cables or connection lines fitted to the

solar inverter are securely laid and that

suitable mechanical cable supports

(cable ducts etc.) are used.

2.1 Safety information

!

90

Page 15

91

EN

Information on cleaning

Before cleaning, disconnect the system

from the power grid by opening the grid

breaker (main fuse) and open the DC

switch on the PV generator, in order to

exclude the danger of electric shocks.

Use a soft, dry cloth to clean the system.

Never use corrosive, solvent-containing

or abrasive cleaners or polishes.

!

Page 16

2.2 Installation

The solar inverter must be installed by a trained, qualified electrician. A special tool is

necessary for installation. Please read this chapter very carefully.

92

➟

150 mm

Cool

Air

Warm

Air

300 mm

300 mm

150 mm

➟

➟

➟

Page 17

93

EN

If installing the solar inverter in a switch

box, ensure adequate heat dissipation.

The ambient temperature must not fall

below or exceed –25°C or +40°C.

The solar inverter should not be exposed to

direct solar irradiation, so as to protect it

from unnecessary external heating.

· Protection from damp and foreign bodies

The IP54 high protection class permits installation both inside and in roofed outdoor

areas, but the solar inverter must not be

exposed to direct rain.

Make sure that the solar inverter cannot be

exposed to foreign bodies (deposits of dust

and dirt).

Requirements on the place of installation

· Mechanical bearing capacity

During installation please bear in mind

that the solar inverter weighs 26 kg. The

installation base must be firm and capable

of continuously bearing the weight.

· Thermal interaction

The installation base must consist of

flame-retardant material (e.g. no wood or

plastic in the base; concrete and brickwork

are suitable), as the heat sink emits temperatures up to max. 85°C.

A minimum distance of 300 mm must be

maintained above and below the cabinet,

and 150 mm on right and left from other

units, cabinets, ceilings, cable ducts etc..

The solar inverter must be installed vertically, so as not to hinder adequate free

convection.

Several solar inverters must not be installed on top of each other, so as to prevent

reciprocal heating.

Page 18

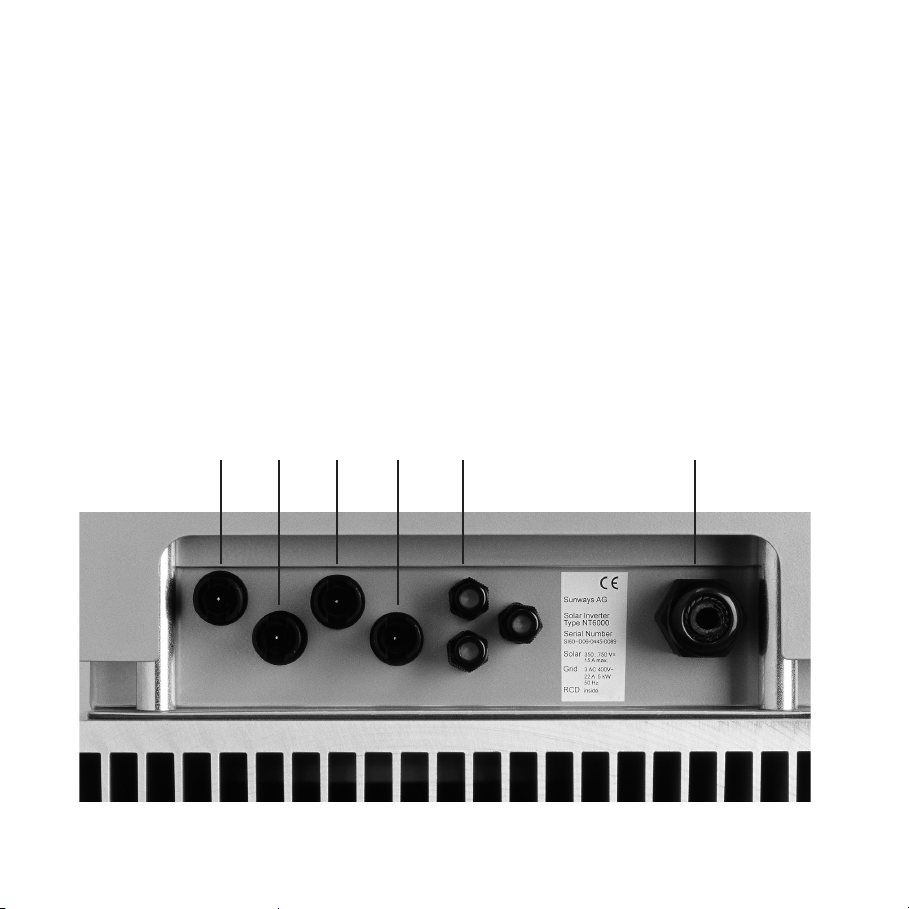

Electrical connection and cable entry

For installation, please observe the

instructions in the "Setup" leaflet!

94

!

If the solar inverter is fixed to the installation frame, the electrical connection can

be led through. The unit may only be opened by a qualified electrician. The cabinet

cover must first be released and removed.

The following cable inlets are located on

the underside:

–DC +DC

RS 232, RS 485,

Irradiation sensor with integrated temperature sensor

cable

AC wiring loom

L1, L2, L3, N, PE

–DC

+DC

Fig.: Inlets on the unit underside

Page 19

95

EN

Grid connection

The grid connection of the solar inverter

must have 5 wires (L1, L2, L3, PE, N). Cable

cross-sections of 5 x 4 mm2 are recommended.

The solar inverter is connected to the

supply grid via the circuit board terminals

inside the unit.

!

As line safety element in the grid feed-in

direction, we recommend a 3 x 25 A automatic cut-out. No consumption units must

be connected to the feed line from the

solar inverter to the automatic cut-out.

The solar inverter only feeds in via terminal L1.

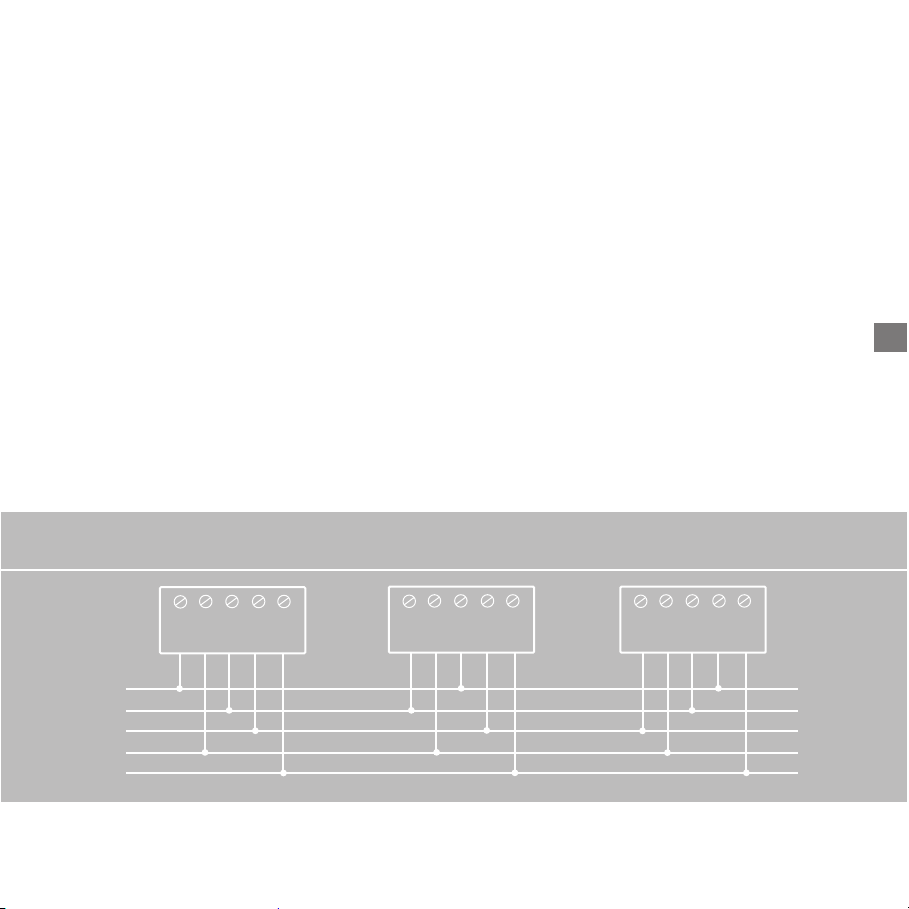

If several solar inverters are operated in

parallel, the feed-in phase L1 of the unit

must be evenly distributed over grid

phases L1, L2 and L3 (see figure below).

L1 N L2 L3 PE

L1 N L2 L3 PE L1 N L2 L3 PE

L1

L2

L3

N

PE

Three-phase grid connection distributed over three units

Page 20

96

You must use adequately dimensioned

cable cross-sections in order to avoid a

considerable increase in the grid impedance between the domestic distribution and

the solar inverter. The terminal range of

the AC terminals is 0.5 to 6 mm2 for rigid

cables and 0.5 to 10 mm2 for flexible

cables. With a high grid impedance, i.e.

with a long line or too small a crosssection, the voltage increases at the grid

terminal during feed-in.

If the terminal voltage exceeds the permissible value, the solar inverter is disconnected from the grid.

Carefully perform the following steps:

· Check that there is no voltage before

introducing the supply main into the

unit.

· Lead the 5-core AC cable (outer diameter 9 – 17 mm) through the M25 threaded cable gland.

· Connect cables L1, L2, L3, PE and N to

the relevant circuit board terminal with

the help of a slot-head screwdriver (see

figure below).

· Tighten the M25 screw connection, so

that the cable cannot exert any mechanical

force on the circuit board terminal.

Page 21

97

EN

PV generator connection

· Preparation

Execute the DC cabling according to your

electrician's system dimensioning. Check

each PV string for correct functioning

by performing a no-load voltage current

and short-circuit current measurement.

To achieve the necessary protection

against hazardous contact voltage during

the installation of PV systems, the positive and negative conductors must be kept

separate from the ground potential (PE).

Contactable, conductive parts of the PV

generator (e.g. metal frame, supporting

structure etc.) must be earthed (connected to PE).

Check that the generator is free from

ground faults.

Make the electrical connection to the

solar inverter.

!

· Connection

The PV generator is connected via the

externally accessible, shock-proof TYCO

SOLARLOK connectors, which are enclosed

with the delivery. The TYCO SOLARLOK

connectors are designed for a cable crosssection of 4 mm2 and must be crimped

(see data sheet and connector assembly

with TYCO crimping tool on page 144).

Connect the two right DC female connectors

with «+», the two left DC female connectors

with «-» of the PV generator (see figure

below).

Page 22

98

Important information

· The direct PV generator voltage is available internally after connecting the PV

generator to the solar inverter via the

DC connectors and switching on the PV

generator switch!

· Please note that the input capacitors are

still charged even after switching off the

PV generator switch or removing the PV

generator plug connection!

· After disconnecting the AC and DC side,

the solar inverter still conducts voltage

for up to ca. five minutes!

· Therefore, wait for at least five minutes

until the internal voltage has dissipated.

Then you can work on the terminals!

Please note the general safety information on pages 83 and 84!

!

Page 23

99

EN

· The DC voltage can be up to 750 V. The

unit may only be opened by a qualified

electrician!

· Always disconnect the PV generator side

first by opening the PV generator switch,

and then the grid connection by isolating

the relevant mains fuse!

· If you do not have a PV generator switch

in your PV system, you must disconnect

the grid connection first of all by isolating the relevant mains fuse. However, a

«grid error» will be entered in the error

memory of the solar inverter!

· Disconnection of the PV generator by

removing the TYCO SOLARLOK DC connectors must never be performed under

load. In the event of non-compliance, the

connectors could be damaged by a strong

electric arc. In this case, the relevant connectors must be replaced!

Page 24

100

Communication connections

Via the communication connections (interfaces), operating data can be retrieved

from the data memory with an external

computer and specific operating settings

made. Two interfaces are available:

RS 232 and RS 485.

The standard communication interface is

the RS 232 interface, which is installed in

all current PCs and notebooks. This interface allows you to establish contact with

your PC immediately, using a connecting

cable. The use of more than one solar

inverter or cable lengths of more than

50 m requires the use of the RS 485

interface.

The connections for the RS 232 or RS 485

interface supply cable are also made via

circuit board terminals and via the M12

screwed cable glands in the cabinet.

!

A 3-core cable is used for signal transmission via the RS 232, and a 2-core cable for

the RS 485 interface

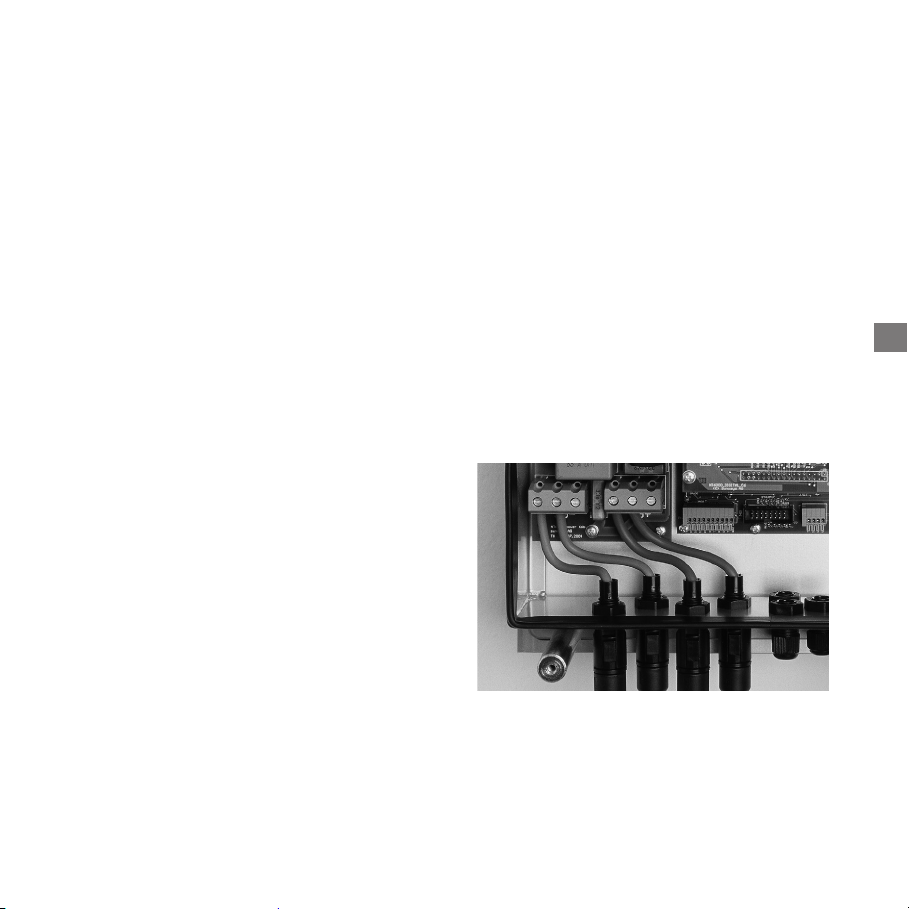

(Top figure) RS 232 and RS 485 interfaces

with the signals (from left to right):

RS 485+, RS 485+, RS 485-, RS 485-, GND_G,

TX, RX, GND_G, TX 2, RX 2.

Attention: RS 485+ and RS 485- are duplicated. This means that the cable entry and

exit are additionally clamped.

Page 25

101

EN

· Connection

Remove the cover of the solar inverter

before connecting an interface cable. Pay

heed to all safety hints (Pages 90 and 91).

You will find the necessary cable terminal

block with the RS 485+, RS 485-, GND_G,

TX, RX, GND_G, TX 2, RX 2 connections on

the board in the centre, bottom left

(see figure on the left). Note the following

terminal configuration:

RS 232: GND, RX, TX

RS 485: RS 485+, RS 485-

(The remaining signals, TX2 and RX2, are

only for service purposes.)

Use a small screwdriver. Press the orange

terminal. The terminal will open.

Insert the cable stripped to a minimum of

11 mm into the respective terminal hole.

Release the screwdriver. The cable is fixed

in the connection.

Once again, check that the cable connection is firmly located.

Seal the unrequired cable glands by

placing a spare piece of cable in the gland

hole and tightening with the screw clamp.

Please heed the description on the

Sunways NT Monitor software in

Chapter 3.2.

Page 26

102

Connecting the sensors

· Optional irradiation sensor

The optional addition of an irradiation

sensor (type Si-01TC-T from Ing.-Büro

Mencke & Tegtmeyer ) with integrated

PT-100 temperature sensor for temperature measurement enables recording of

the irradiation data and the corresponding module temperature in the cycle

of the internal data memory.

This additional measuring unit helps with

analysis of the system. On the basis of the

values, possible errors in the PV generator,

such as e.g. shading or failure of solar cells,

can be detected.

For demonstration purposes, the irradiation sensor and the corresponding data

can be used to show how a PV system

functions. In conjunction with the

Sunways NT Monitor visualisation software, the stored data can be displayed.

!

Before you connect an irradiation sensor,

you must remove the cover of the solar

inverter. Pay heed to all safety hints on

pages 90 and 91. Please note that the

inputs and outputs are not short-circuit

resistant.

The optional irradiation sensor with

temperature sensor is connected to the

corresponding terminals at the bottom

right of the middle board.

(Top figure) Connection block for

temperature sensor cables with the signals:

Temp, Solar, V+ and V-.

Page 27

EN

Configuration of the cable terminal block:

Temperature sensor

measuring signal: Temp

Solar radiation

measuring signal: Solar

Positive supply, 5V: V+

Supply, GND: V-

Using a small screwdriver, press the orange

terminal. The terminal will open.

Insert the cable stripped to a minimum of

11 mm into the respective terminal hole.

Loosen the screwdriver. The cable is fixed

in the connection.

Once again, check that the cable connection is firmly located.

Seal the unrequired cable glands by

placing a spare piece of cable in the gland

hole and tightening the screw clamp.

103

Page 28

104

2.3 Commissioning

Connect the solar inverter internally via

the ground cable (yellow-green) to the

cabinet cover. (See also Setup, step 7)

Put the cabinet cover on.

Screw it down tightly with the four

screws on the front.

Do not place any objects (e.g. this manual) on the cabinet of the solarinverter.

Free ventilation behind the solar inverter

must be able to take place unimpeded.

If the unit is installed in the open air,

please take special care to ensure that the

screwed cable glands are properly sealed

and that the cabinet cover is precisely

located.

Switching the solar inverter on and off

· Switching on

When the solar inverter is mechanically

installed and connected to the electrical

cables, the unit can be commissioned as

follows:

Switch the grid connection on through

the external safety cutouts.

Switch the PV generator voltage on by

closing the PV generator switch. The solar

inverter will start up with adequate

PV power. If the PV input voltage is high

enough, the solar inverter will begin operation and feed the solar energy into the

electrical grid. You can see the operation

on the display. The current feed-in power

is shown here.

The solar inverter is supplied by the PV

generator. The solar inverter switches on

in the morning and off again in the evening. The relevant switching on and switching off thresholds are defined for the

PV generator. If the solar energy is not

sufficient to supply the electronics, several

switch-on attempts may have to be made

Page 29

EN

105

in cloudy weather. This is normal, and does

not affect either the yield or the mode of

functioning of the solar inverter.

· Switching off

Disconnect the PV generator side first by

opening the PV generator switch, and

then the grid connection by isolating the

relevant mains fuse.

If your PV system does not have a PV

generator switch, you must disconnect

the grid connection first of all by isolating

the relevant mains fuse. When you do

this, a "grid error" will be entered in the

error memory of the solar inverter.

If the solar inverter is to be completely

disconnected (e.g. removal) from the PV

system, reconfigured or extended, the

cabinet cover must be removed. Pay heed

to all safety hints (Pages 90 and 91).

Open the main switch for the PV DC

voltage and the mains fuse as described

above. After a waiting period of at least

five minutes, the solar inverter will be

voltage-free.

Disconnection of the PV generator by

removing the TYCO SOLARLOK connectors

must never be performed under load. In

the event of non-compliance, the connectors could be damaged by a strong electric

arc. In this case, the relevant connectors

must be replaced!

Remove the cabinet cover.

Check that the grid connection terminals

are voltage-free.

!

Page 30

However, language setting, LCD contrast

and total energy offset (only to be used

in the event of replacement) must be

configured directly on the unit. If you wish

to configure the solar inverter without

an external laptop or PC, or to change the

language setting, please follow the

instructions below:

Disconnect the solar inverter by isolating

the mains fuse from the grid. The direct

configuration of the solar inverter occurs

with PV operating voltage present!

Please note that the unit is under DC

voltage for configurations via the keys.

Danger to life!

Please observe all essential regulations for

«Working under voltage»!

106

Configurations

The solar inverter is basically configured

with the Sunways NT Monitor program,

using a laptop or PC (see enclosed CD).

In this regard please read the chapter

«System Monitoring and Diagnosis» and

«Sunways NT Monitor».

!

Page 31

107

EN

This is the only exception for which work

may be performed on the open unit under

voltage!

Remove the cabinet cover to carry out the

configuration.

The following settings can be performed

using the illustrated keys:

PLUS

UP/DWN

RST

Fig.: The setting keys are located beneath the display.

MINUS

ESC/CUR

· Address of the solar inverter: address

«1» is stored in the memory at the

factory. In the case of several solar inverters, consecutive numbering must be set.

For three solar inverters e.g. the addresses «1», «2» and «3».

· Date

· Time

· Language (German or English)

Page 32

108

SOLAR INVERTER

ADDRESS

PERFORMANCE

AND

OPERATING DATA

DATE TIME

HOURS

ESC

CUR

UP/

DWN

+

–

MINUTES

+

–

SECONDS

+

–

SAVE

ESC

CUR

ESC

CUR

ESC

CUR

UP/

DWN

ADDRESS

1 ... 99

+

–

DAY

+

–

MONTH

+

–

YEAR

+

–

UP/

DWN

UP/

DWN

ESC

CUR

ESC

CUR

UP/

DWN

UP/

DWN

ESC

CUR

UP/

DWN

ESC

CUR

+/–

+/–

+/–

START

Structure and menu levels for configuration

▲

Use insulating material to press the keys

(e.g. a plastic rod). Avoid direct contact

with the printed circuit board, so that the

electronics cannot be damaged by electrostatic charging. The reset key (RST) only

resets the data recording program to its

original status. This does not affect the

operation of the solar inverter.

Starting from the current display on the

Page 33

109

LANGUAGE

SOFTWARE

VERSION

ENG./GER.

+

–

UP/

DWN

UP/

DWN

LCD CONTRAST

CONTRAST

+

–

UP/

DWN

UP/

DWN

TOTAL POWER

OFFSET

kWh

+

–

UP/

DWN

UP/

DWN

INCREMENT

(100 OR 1)

ESC

CUR

+/–

+/–

+/–

screen, you can reach the next menu level

with the UP/DOWN key. The illustrated

structure facilitates settings on the menu

levels. Then save your settings by pressing

the ESC/CUR key.

Page 34

110

3.0 Information on operation

Page 35

3.1 Monitoring and diagnosis

Display

The dot matrix LCD display is integrated

into the cabinet of the solar inverter so

that it is easily visible. The display consists

of 16 characters and 2 lines. The top line 1

shows the current feed-in power of the

solar inverter. The bottom line 2 outputs

operating data. The data can be displayed

in the German or English language.

(* if the optional irradiation sensor with

integrated temperature sensor is connected.)

111

EN

Line 1 Current fed-in power Power kW

Line 2 AC voltage U-AC V

DC voltage U-DC V

Daily yield in Wh W_TAG Wh

Total yield in kWh W_GES kWh

Irradiation in W/m2 (*) SOLAR Wm2

PV generator temperature in °C (*) TEMP-PAN C

Time

Page 36

Data memory

Your solar inverter is equipped with an

internal data memory as standard. This

data memory provides you with a detailed

view of the mode of functioning and the

relevant values of your solar power supply

at all times. You can access these data

with the help of the NT Monitor software

described below. The following measured

values can be determined:

· DC voltage

· AC voltage and AC current (power calculation)

· Irradiation and module temperature

(if a sensor is connected)

· Time and date

The following values can be accumulated,

stored and successively overwritten:

· 15 minute values for AC current, DC and

AC voltages, irradiation and temperature

· 120 times storage of 15-minute average

values in the recirculating storage;

storage depth: three days on average,

then overwriting of values

· Storage of accumulated daily work in

Wh and of 40 daily values in the recirculating storage and successive overwriting

of values

· Storage of accumulated monthly work in

kWh and of 13 monthly values in the

recirculating storage, then overwriting

of values

· Storage of faults with max. ten values,

then successive overwriting of values

Please note that all displayed performance

data are displayed with a nominal measuring accuracy of maximum 5 %. The energy

counter of your EVU should be used as

absolute reference for the fed-in energy.

112

Page 37

113

EN

3.2 Sunways NT Monitor software

General information

The Sunways NT Monitor visualisation software was developed for PV system monitoring and configuration of the solar inverter

using PC. It is contained on the enclosed CD

and can also be downloaded free of charge

on the Internet from www.sunways.de.

System prerequisites are:

· Intel Pentium from 100 MHz or higher

· Microsoft Windows 95/98/2000/NT

· At least 6 MB free hard disk storage space

· At least 16 MB main memory

· VGA monitor with at least 800 x 600

(120 dpi) resolution

All measured values can be transferred

to a PC and visualised with the Sunways NT

Monitor software. Online, fault, minute,

daily and monthly values are available.

For connecting to your PC, Sunways solar

inverters in the NT series are equipped with

the RS 232 and RS 485 interfaces as standard. In the case of larger distances between PV system and PC, the data can also

be transferred via a modem. We recommend using two external analogue

modems made by ACER. If other modems

are used, the functional reliability cannot

always be guaranteed.

The modem (remote modem) installed

in the solar inverter must be initialised

prior to installation with the help of the

Sunways NT Monitor software. Note the

"Help" function in the program in this

regard.

The second modem (local modem) is

connected to the RS 232 interface of your

PC. This modem must not be initialised.

Different interface cables are required,

depending on the type of connection.

These are included in the accessories.

Up to 99 solar inverters can be monitored

and read out by means of a connection

via the RS 485 interface.

If the data are read out via the RS 485

interface and converted to RS 232 with

an interface converter, we recommend

the converter type «I-7520 Converter»

Page 38

114

from ICP-Deutschland, (available from your

specialist dealer), which will guarantee

reliable data transfer.

The addresses of the solar inverter must

be input in the solar inverter using the

Sunways NT Monitor software or input

directly with the keys illustrated on

page 107.

Initialising the remote modem

If a remote modem is installed in the solar

inverter, it must be initialised using a PC

and the Sunways NT Monitor software.

· Connect the powered remote modem to

the PC via the COM port. Use the interface cable provided with the modem for

this purpose. Start the Sunways NT

Monitor and set «Acer Modem» under

the «Settings/Remote Modem» menu.

· Click «Perform initialisation» and wait

until the scroll bar has come to an end.

The modem can now be switched off

and connected to the solar inverter via

the RS 232 interface.

· Attention! Do not initialise the local

modem!

· The remote modem is now initialised

so that it automatically accepts a connection after two rings and connects at

9600 Baud.

Page 39

115

Individual PV system with maximum distance of 50 m between solar inverter and PC

RS 485+

RS 485+

RS 485–

RS 485–

GND_G

TX

RX

GND_G

TX2

RX2

Yellow

Green

Brown

Connection to PC via RS 232

A single solar inverter can be directly connected

to a PC via the RS 232 interface

Stripped length: 11 mm

Jumper JP400: open

PC

INVERTER

(1)

PV

RS 232

Connection and circuitry options

(1) This connection can be used to read out

an individual solar inverter if the distance

from the PC used does not exceed 50 m. To

do this, cable type A is stripped to 11 mm

and connected to the solar inverter.

Page 40

(2) Individual PV system with modem for remote inquiry

RS 485+

RS 485+

RS 485–

RS 485–

GND_G

TX

RX

GND_G

TX2

RX2

Green

Yellow

Brown

Connection to modem via RS 232

When connecting an individual solar inverter,

the remote modem is connected directly to

the RS 232 signal.

Stripped length: 11 mm

Jumper JP400: open

(see page 121)

116

INVERTER

(1)

PV

PC

MODEM

MODEM

RS 232

RS 232

(2) To install the remote inquiry of an individual solar inverter, the RS 232 signal can

be routed directly from the solar inverter

to the remote modem.

Cable type B is used for this purpose. For

the RS 232 connection between solar inverter and modem, a cable length of 50 m

should not be exceeded.

Page 41

(3) PV system for 2 to 99 solar inverters with interface converter (I C)

Connection to PC via RS 485/RS 232

In order to connect several solar inverters to a

PC, the RS 485 signal is looped through from

inverter to inverter, until it is led into the interface converter. From here, the RS 232 signal is

conducted to the PC. Jumper JP400 is connected

to the solar inverter that is furthest away

from the interface converter. It must be open

for all other solar inverters.

Stripped length: 11 mm

Jumper JP400: see above

(3) Up to 99 solar inverters can be connected together and read out using this

connection. In this case, there is a maximum cable length of 500 m between

117

PC

IC

INVERTER

(2 to 99)

INVERTER

(1)

PV

PV

RS 232

RS 485

RS 485+

RS 485+

RS 485–

RS 485–

GND_G

TX

RX

GND_G

TX2

RX2

RS 485+

RS 485+

RS 485–

RS 485–

the interface converter and the furthest

solar inverter. The individual solar inverters

are connected together via the RS 485

interface.

Page 42

118

The signal is looped through all units. Two

«RS 485+» terminals and two «RS 485-»

terminals are located on each terminal

block. This means that the signal can be led

into the solar inverter at one terminal and

out of the solar inverter at the other terminal. The RS 485 signal is led out of the last

solar inverter in the series into the interface

converter using the following configuration:

«RS 485+» to «DATA+» and «RS 485-» to

«DATA-».

The interface converter generates an

RS 232 signal. It is connected to the PC with

the standard modem cable type D. Jumper

JP400 must be closed at the solar inverter

that is furthest away from the interface

converter. For all other solar inverters it

must be open. An address must be allocated, to enable identification of the individual solar inverters. This is described in

Chapter 2.3 Commissioning, under

«Configuration».

PC

IC

INVERTER

(2 to 99)

INVERTER

(1)

PV

PV

MODEM

MODEM

RS 232

RS 232

RS 485

(4) PV system for 2 to 99 solar inverters with interface converter (IC) and modem for

remote inquiry

Page 43

119

RS 485+

RS 485+

RS 485–

RS 485–

GND_G

TX

RX

GND_G

TX2

RX2

RS 485+

RS 485+

RS 485–

RS 485–

Connection to modem via RS 485/RS 232

In order to connect several solar inverters to

the remote monitoring, the interface converter

is connected directly to a modem via RS 232.

Jumper JP400 is connected to the solar inverter

that is furthest away from the interface converter. It must be open for all other solar inverters.

Stripped length: 11 mm

Jumper JP400: see above

(4) If several solar inverters are to be connected to the remote inquiry, then the

individual inverters are connected together

by means of the RS 485 signal, as when

reading out several units locally. This signal

is converted by the interface converter

into the RS 232 signal, from where it is led

to the modem using cable type C. Jumper

JP400 must be closed at the solar inverter

that is furthest away from the interface

converter. For all other solar inverters it

must be open. An address must be allocated, to enable identification of the individual solar inverters. This is described in

Chapter 2.3 Commissioning, under

«Configuration».

Page 44

120

1

2

3

4

5

6

7

8

9

Configuring the interface cables

Cable type A

Female

connector to PC,

9-pole

Signal cables

to the solar inverter

on X400

TX

RX

GND

1

2

3

4

5

6

7

8

9

Cable type B

Connector

to modem,

9-pole

Signal cables

to solar inverter

on X400

RX

TX

GND

Page 45

Locating jumper JP400 in the Sunways

Solar Inverter

Please check the correct position of jumper JP400, depending on your selected

communication circuit. You will find this

jumper above the communication connections (see figure opposite).

1

2

3

4

5

6

7

8

9

Cable type C

Connector

to modem,

9-pole

Connector

to interface

converter

5

4

3

2

1

9

8

7

6

121

Page 46

Sunways NT Monitor data acquisition

· Online values

DC voltage (U_DC), AC voltage (U_AC),

AC current (I_AC), date, time, AC power,

module temperature, module irradiation,

«fed-in today», «fed-in since commissioning», error.

· 15 minute values

DC voltage (U_DC), AC voltage (U_AC),

AC current (I_AC), date, time, temperature,

irradiation, «fed-in in 15 minutes», accumulated daily total of all 15 minute average

values.

Representation as graphic or print; Option

of saving as bitmap; Fade-in of graphics

possible. Individual solar inverters can be

called up with the scroll menu.

· Daily values

Date and daily energy in the solar inverter.

Representation as graphic or print; Option

of saving as bitmap; Zoom-in of graphics

possible. Individual solar inverters can be

called up with the scroll menu.

· Monthly values

Date in the solar inverter, fed-in since

commissioning and monthly energy.

Representation as graphic or print; Option

of saving as bitmap; Zoom-in of graphics

possible. Individual solar inverters can be

called up with the scroll menu.

· Fault data

Date, time and type of fault (for the

last ten faults)

· Calendar

Date and time in the solar inverter

· Modem

Selection of the modem type and input

of the address signal

If required, detailed information on

Sunways NT Monitor can be found under

the «Help» menu item in the program

software.

122

Page 47

123

EN

Operation of Sunways NT Monitor

After installing the Sunways NT Monitor

software on your PC, you can start the

program. The word «Sunways» will now

appear on your screen.

On the menu bar at the top, you will see

the four menu areas «Program», «Data»,

«Settings» and «Help».

· Setting menu

To configure your solar inverter, open the

«Settings» menu by clicking on it with

the mouse, and click on the «Inverter» key.

Enter the address number that you have

defined for your solar inverter next to

«Inverter». For example, the number «1»

for one solar inverter. In the case of

several units, select «all».

Then enter the desired date and time. The

settings are transferred to the solar inverter by clicking on the «Make change» key.

If you are using several solar inverters and

wish to make a change to the numbering,

you can enter the old number of the

solar inverter in the top section of the

right window half and the new number

beneath it. The numbering is changed

by clicking on the «Make change» key.

Exit the window with the «Close» key.

You will go back to the «Setting» menu.

You can set the interface configuration

with your PC by clicking on the «Connection» key.

By clicking on the «Remote modem»

key, you can configure an optional modem

(e. g. if you wish to retrieve data by

remote inquiry).

· Data menu

In the «Data» menu, you can call up

the current accumulated performance and

energy of the solar inverter by clicking

on the «Online» key.

You can display the data measured at

15 minute intervals by clicking on the

«Minute values» key. The data and values

are graphically visualised by clicking on

the «Graphic representation» key.

Page 48

124

You can call up «Daily values» and

«Monthly values» in the same way, by

clicking on the respective keys.

Exit the window with the «Close» key.

You will return to the «Settings» menu.

· Help menu

You will find further helpful information

on operating the Sunways NT Monitor

software in the «Help» menu.

Page 49

3.3 Fault indications

Your solar inverter operates fully automatically and maintenance-free. However, if

operational faults occur due to external or

internal causes, these will be displayed on

the screen.

· AC over/undervoltage (3-phase)

Your solar inverter monitors the limits of

minimum and maximum permissible

3-phase grid voltage. If these limits are

exceeded (Umin = 184 V, UN = 230 V,

Umax = 264 V), the solar inverter will switch

off and will only start up again when the

voltage value is within the limits. The

fault cut-out can be triggered even by very

brief overvoltages and undervoltages.

Display for AC overvoltage:

125

EN

Line 1 Error: UAC_3

Line 2 Overvoltage

Display for AC undervoltage:

· AC over/undervoltage (1-phase)

Your solar inverter monitors the limits of

minimum and maximum permissible grid

voltage in the feed-in phase. If these limits

are exceeded, the solar inverter will switch

off and will only start up again when the

voltage value is within the limits.

Display for AC overvoltage:

Display for AC undervoltage:

Line 1 Error: UAC_3

Line 2 Undervoltage

Line 1 Error: UAC_1

Line 2 Overvoltage

Line 1 Error: UAC_1

Line 2 Undervoltage

Page 50

Display for AFI error protection:

· Overheating fault

Your solar inverter is designed for an

ambient temperature of up to +40°C.

When the maximum upper temperature

threshold is reached, the feed-in is stopped. When the heat sink temperature

has decreased, the solar inverter starts

up again automatically.

126

· DC overvoltage

A maximum no-load voltage of 750 V is

permitted for the PV generator.

All components of the DC input are adequately dimensioned with a safety factor.

If the threshold is exceeded, the solar

inverter stops the feed-in and a «DC overvoltage error» is displayed.

Display for DC overvoltage:

· AFI residual current

The AFI residual current (insulation error,

ground fault) is displayed if a residual

current has occurred in the PV system and

the solar inverter has subsequently disconnected from the grid. Ground faults are

monitored on both the AC and DC side

(universal current-sensitive FI). If this error

message is displayed, the entire PV system

must be checked for insulation errors. The

AFI residual current operated device only

monitors the phase into which feed-in

occurs.

Line 1 Error: UDC

Line 2 Overvoltage

Line 1 Error: AFI

Line 2 Residual current

Line 1 Error: TEMP

Line 2 Overtemperature

Page 51

127

3.4 Fault diagnosis

Fault display

Overtemperature

UDC

Overvoltage

Causes

The maximum permissible

ambient temperature of

40°C has been exceeded.

The necessary air circulation

was not taken into account

during installation.

Objects have been stored on

the heat sink, impeding free

convection.

The maximum DC voltage

has been exceeded.

Too many modules are connected in series.

Remedies

The installation location is not suitable.

Please find another installation location.

Clean the solar inverter if dirt is

impeding the cooling unit.

Remove the objects.

Check the dimensioning of your

PV generator.

Reduce the number of modules and

re-commission the system.

Page 52

128

Fault display

UAC_1

UAC_3

AC under/overvoltage

Causes

The grid voltage is too low

or too high.

The cable cross-section in

the AC feed line to the solar

inverter is too small.

Your solar system feeds into

a spur line, which is inadequately dimensioned.

Remedies

The solar inverter monitors the limits of

the minimum and maximum permissible

3-phase grid voltage. If the values exceed

or fall below these limits (Umin = 184 V,

Umax = 264 V), the solar inverter switches off and only restarts automatically

when the voltage value has returned

within the limits. The fault cut-out can

be triggered even if the values only

exceed or fall below the limits very

briefly (up to ca. 1 ms).

Ask your electricity board about grid

stability and design.

Check the format of your grid connection

(energy counter) and the grid feed-in

point to your electricity board.

Page 53

129

Fault display

AFI

Residual current

Incorrect time,

date are stored

in Sunways NT

Monitor with

incorrect time

data.

Causes

The AFI error is displayed if

a residual current has occurred in the PV system and

the solar inverter has subsequently disconnected

from the grid.

The battery is empty.

Remedies

The entire PV system must be checked

for insulation errors.

Have the battery (button cell) replaced

by an expert.

The battery is located on the LCD display

board.

Page 54

3.5 Warranty terms and conditions

· Warranty period

The warranty period is five years from

purchase of the solar inverter by the end

user. Please complete the enclosed warranty card and return it to Sunways AG.

Please keep the original invoice with the

date of purchase in a safe place. This will

be required as proof, in addition to the

warranty card, in the event of a claim.

· Conditions

During the warranty period, the solar

inverter will be repaired free of labour

and material costs in Constance. Installation costs are borne by the customer,

unless agreed otherwise. The completed

warranty card must be sent to Sunways

AG, Constance within seven days of

purchase.

Please notify us of any warranty claims

by telephone (technical hotline:

+49 7531 99677577), stating your name,

address, telephone and serial number,

and your email address if applicable.

Sunways AG must be allowed the necessary

time to eliminate the defect. Sunways AG

will endeavour to eliminate the defect

within 14 days of receipt of the unit. If this

is not possible, the customer will be informed of the reason and the time when the

defect will be eliminated will be specified.

Please preserve the original packing,

even after expiry of the warranty period.

Carriers may only accept solar inverters in

transport-safe original packing. Therefore,

please inform us before collection if you

have lost the original packing. We will

gladly provide you with new packing for

a charge.

130

Page 55

131

EN

· Exclusion of liability

Warranty claims and liability are excluded

for direct or indirect damages due to:

· Interventions, modifications or attempted

repairs

· Inadequate ventilation

· Force majeure (e.g. lightning strike, water

damage, vandalism, fire, overvoltage,

thunderstorms etc.)

· Inappropriate transport

· Non-observance of pertinent regulations

or incorrect installation or commissioning

· Leakage of overvoltages from the varistors on the DC side on the PV generator

More extensive or other claims for direct

or indirect damages, particularly claims

for damages, including those arising from

positive contract violation, are excluded,

unless legally prescribed.

Page 56

4.0 Appendix

132

Page 57

4.1 Subject and abbreviation index

133

EN

Designation

AC

AFI, RCD

DC

EMV

EB

I

NDC

IP

kW

LCD

MPP

Description

Alternating Current: grid current

Operator protection in the event of residual currents

AFI: Universal Sensitive Residual Current

RCD: Residual Current Device

Direct Current

PV generator side of the solar inverter

Electromagnetic Compatibility

Electricity Board

Current used to operate the solar inverter

Identification of class of protection against external

environ-mental influences (penetration of water and

mechanical foreign bodies)

Kilowatt

Liquid Crystal Display

Maximum Power Point

Page 58

134

Designation

Grid impedance

P

NDCPNAC

PT

PV

PV generator switch

U

NDC

Description

AC resistance of grid, impedance

DC and AC rated power:

Power which the inverters can permanently consume

(DC) or emit (AC).

Temperature sensor

Photovoltaic

DC load break switch to cut off the PV generator from

the solar inverter

Voltage: specifies the normal operating voltage at which

the solar inverter is operated

Page 59

135

EN

4.2 Function and information index

Functional principle and explanations

The electrical energy of the PV generator

is buffered by a capacitive storage, from

where it is fed into the public grid via a

solar inverter synchronised with the grid,

with an ideal phase angle of [cos phi = 1].

A sinusoidal current with a very low harmonic distortion is injected into the public

grid by the current injection inductor. This

improves the grid quality.

Thanks to the HERIC

®

technology (patent

applied for) in the self-commutated

Sunways Solar Inverter, the hysteresis losses

in the current injection inductors that

occur in conventional solar inverters and

the switching losses in the semiconductors

are considerably reduced. Consequently,

Sunways Solar Inverters achieve a peak

efficiency during conversion. The concept

of the Sunways Solar Inverter is completed

by a rapid MPP control, which maintains

the MPP point with a very high adaptation

efficiency.

· DC and AC filters

The DC and AC filters are specially designed

EMC filters, which are integrated as direct

components on the board. They guarantee

compliance with the EMC limit values on

the AC side and on the PV generator side.

High-frequency emissions are avoided by

the filters on the PV generator side.

· Differential measurement

The generator current and the voltage are

recorded via a current transformer and a

differential measurement. The values are

important input values for the regulation

and setting of the correct working point.

· Solar inverter with HERIC

®

technology

The heart of the solar inverter with the

power semiconductors serves for conversion of the current from direct into

alternating current. Peak efficiencies are

achieved, thanks to the HERIC

®

technology. The switching frequency (PWM) is

16 kHz.

Page 60

· Sensor interface

An irradiation sensor with integrated

temperature sensor can be optionally connected to the relevant interface. This

allows first time users to quickly grasp the

mode of functioning of their PV system,

and facilitates monitoring of the PV

system for professionals.

· AFI universal sensitive residual current

device

The universal (DC and AC) sensitive residual current device (AFI) monitors the solar

system for residual currents. To do this,

it disconnects the solar inverter from the

grid by means of a relay as soon as a residual current occurs on the PV generator

side or on the AC side in the solar inverter.

After cutoff by the relay and as soon as

the residual current has stopped, the AFI

automatically attempts to reconnect the

solar inverter to the grid. The AFI of the

Sunways solar inverter complies with

standard DIN V VDE V 0126-1-1.

In addition, the AFI of Solar Inverters NT

2600, NT 4000 and NT 6000 has an absolutely time-independent effective value

136

· Grid protection

The grid protection is a powerful relay

which ensures reliable grid disconnection

in the case of error and for night switchoff. This relay fulfils the requirement for

trouble-free grid disconnection.

· Microcontroller

As well as system management, the

efficient microcontroller undertakes

additional tasks, such as saving data

and communication.

· LCD display

Important information for the operator

about the system operation and status is

displayed on an LCD display of 2 x 16

characters.

· RS 485 and RS 232 interfaces

The two RS 485 and RS 232 interfaces

installed as standard serve for communication with the solar inverter and the PV

system. The system can be visualised via

the Sunways NT Monitor software.

Page 61

137

EN

cutoff threshold, which is dependent on

the performance class. The NT 2600 model

is switched off at an absolute residual current of 130 mA, the NT 4000 model at an

absolute residual current of 200 mA and

the NT 6000 model at an absolute residual

current of 300 mA. The AFI triggers within

< 0.2 seconds.

· MPP control

The solar inverter has a rapid MPP control,

which maintains the MPP point with a very

high adaptation efficiency. If surplus power

is provided by the PV generator, the solar

inverter limits this by shifting the working

point of the characteristic curve of the PV

generator, so as not to exceed the maximum permissible AC feed-in power in

accordance with VDEW.

Page 62

DC-FILTER

CAPACITIVE STORAGE

Block diagram

HERIC

®

=

≈

DIFFERER. MEASUREMENT

R

T

IRRADIATION SENSOR AND

TEMPERATURE SENSOR

(OPT.)

RS 232

RS 485

MICRO-

CONTROLLER

CONTROL

DATAPRO

TEMP CONTROLLER

I

DC

U

DC

RADIATION

AND

TEMPERATURE

DATA

PV-GENERATOR

138

Page 63

CURRENT IMPRESSION

INDUCTOR

AC FILTER GRID PROTECTION

RESIDUAL CURRENT

AFI

DIFFERER. MEASUREMENT

LCD-DISPLAY

(2 LINES)

KEYBOARD

AND

CESSING

AFI

U

AC

I

AC

GRID

L1, L2,LE

N, P E

139

Page 64

140

Technical data

Solar Inverter NT 2600

Recommended PV generator power

Rated input power

Stand-by consumption

Night-time consumption

AC energy generated from

Nominal voltage

U

MPP

voltage range

Open-circuit voltage

Switch-on voltage

Switch-off voltage

Maximum current

Nominal current

Number of inputs

Maximum efficiency

European efficiency (weighted)

HERIC

®

topology

Rated continuous output power Pn

Maximum power Pp

Nominal frequency

Grid voltage

Grid voltage tolerance range

Nominal current

Max. current

Distortion factor at Pn

Reactive power factor (cos phi)

Output current

Model

1500 bis 2750 W

2300 W

9 W

< 0.005 W

15 W

400 V

350 ≤ U

MPP

≤ 650 V

750 V

410 V

340 V

7 A

5.75 A

2 (with adapter: 4)

97 per cent

96.5 per cent

yes

2200 W

2200 W

50 Hz +/- 0.2

230 V

- 20 to +15 per cent

9.6 A

9.6 A

< 3 per cent

~1

sinusoidal

DC

AC

Page 65

141

Solar Inverter NT 4000 Solar Inverter NT 6000

2000 bis 4125 W

3400 W

9 W

< 0.005 W

15 W

400 V

350 ≤ U

MPP

≤ 650 V

750 V

410 V

340 V

10 A

8.5 A

2 (with adapter: 4)

97 per cent

96.4 per cent

yes

3300 W

3300 W

50 Hz +/- 0.2

230 V

- 20 to +15 per cent

14.3 A

14.3 A

< 3 per cent

~1

sinusoidal

4000 bis 6250 W

5200 W

9 W

< 0.005 W

15 W

400 V

350 ≤ U

MPP

≤ 650 V

750 V

410 V

340 V

15 A

13 A

2 (with adapter: 4)

97 per cent

96.3 per cent

yes

4600 W

5000 W

50 Hz +/- 0.2

230 V

- 20 to +15 per cent

20 A

21.7 A

< 3 per cent

~1

sinusoidal

Page 66

142

Grid voltage monitoring

Earth fault protection

Output characteristic

Grid connection fuse layout

Required number of grid connection phases

Number of feed-in phases (230 V single-phase)

Data interfaces

Sensor interfaces

Display

System of protection against envir. influences

Relative air humidity, max.

Cooling

Ambient temperature (Celsius)

Dimensions (height x width x depth)

Weight

Noise development

Standard warranty period (option)

threephase

RCD (universally sensitive)

current source

16 A

3

1

RS 232, RS 485

irradiation, temperature

LCD, 2 x 16 characters

IP 54

95 per cent

free convection

-25°C to 40°C

510 x 300 x 180 mm

26 kg

silent (< 35 dB (A))

5 years (10 years)

Page 67

143

threephase

RCD (universally sensitive)

current source

25 A

3

1

RS 232, RS 485

irradiation, temperature

LCD, 2 x 16 characters

IP 54

95 per cent

free convection

-25°C to 40°C

510 x 300 x 180 mm

26 kg

silent (< 35 dB (A))

5 years (10 years)

threephase

RCD (universally sensitive)

current source

25 A

3

1

RS 232, RS 485

irradiation, temperature

LCD, 2 x 16 characters

IP 54

95 per cent

free convection

-25°C to 40°C

510 x 300 x 180 mm

26 kg

silent (< 35 dB (A))

5 years (10 years)

Page 68

TYCO SOLARLOK connectors

The TYCO SOLARLOK connectors

are only approved for connection to

permanently laid cables!

They must not be disconnected

under load!

The circuit must be interrupted at

a suitable point! The cables must be

provided with a suitable adhesive

label close to the TYCO SOLARLOK

connector!

The TYCO SOLARLOK connectors must

always be disconnected from other

voltage sources on all sides during

assembly, in order to protect against

electric shock.

144

!

Fig.: Manual crimping tool for assembly of

TYCO SOLARLOK connectors

Page 69

Any type of soiling (dust, humidity etc.)

will negatively affect the operation of the

system over the desired period of use.

This applies particularly for the usability

of the seals and crimping of the contacts.

The utmost care must therefore be taken

to work cleanly during installation.

Different circular contacts are used for

different conductor cross-sections for the

TYCO SOLARLOK connectors. The correct

tool insert must be used, depending on

this cross-section. The enclosed TYCO

SOLARLOK connectors are equipped with

circular contacts for a cable cross-section

of 4 mm. The enclosed seals have internal

dimensions of 6 (for cables of 5.3 to 6.2

mm sheath diameter) and 8 mm (for

145

EN

cables of 7.2 to 8.0 mm sheath diameter).

The seal must be matched to the sheath

diameter of the cables used.

The following sequence must be observed

for assembly of TYCO SOLARLOK connectors:

1. Strip the voltage-free cable by 8 mm.

2. Crimp on the circular contact.

3. Push the cable gland, clamping piece

and seal onto the cable.

4. Engage the contact in the connector

housing.

5. Screw on the clamping nut.

6. Tightening torque of the threaded cable

gland is 1.5 Nm.

Page 70

Declaration of Conformity as per EG Low Voltage Guidelines 73/23/EWG,

attachment III B

We herewith declare that the following product including the required accessories has

been manufactured according to the EG guidelines 73/23/EWG and 93/68/EWG:

146

Product

Manufacture

Type

From date of manufacture

Applied standards

Standard

Title

Edition

Solar Inverter

Sunways AG, Photovoltaic Technology

Macairestr. 3-5, D - 78467 Konstanz

Sunways NT 6000, NT 4000, NT 2600

2003-05-15

EN 50178

Electronic equipment for use in power

installations

1998

Explanation

This product is a component intended for further assembly. Due to the features resulting therefrom, the product cannot initially

meet requirements made of finished products, machines or plants. It must thus be used for mounting / assembly only.

An evaluation of electrical and mechanical safety and of environmental conditions (e.g. extrinsic objects and / or humidity) must

be performed after mounting / assembly in the finished plant.

The EMC characteristics of this product can change in a mounted / assembled state. An EMC check must thus be made for the

PV-System by the manufacturer of the PV-System.

City, Date Roland Burkhardt,CEO

Konstanz, 2004-08-05

Page 71

147

EN

Declaration of Conformity as defined by the EMC guideline 89/336/EWG with

revisions 91/263/EWG and 93/68/EWG.

We herewith declare that the following product has been manufactured according to

the requirements outlined in the EG requirements on 89/336/EWG (EMC guideline with

revisions 91/263/EWG)

Product

Manufacturer

Type

from date of manufacture

applied standards

Standard

Solar Inverter

Sunways AG, Photovoltaic Technology

Macairestr. 3-5, D - 78467 Konstanz

Sunways NT 6000, NT 4000, NT 2600

2003-05-15

EN 50082-2 (EN 61000-4-2, -4-3, -4-4, -4-6, -4-8)

EN 55014-1; EN 55011; EN 61000-3-2;

EN 61000-3-3; E DIN VDE 0126

Explanation

Maintaining the EMC guideline assumes an EMC adapted installation of the component within the plant or the machine.

Please pay attention to the installation notes of the technical specifications. Tests were carried out using a typical construction in

a test assembly that conforms with the stands. The legal requirements with regard to resistance to interference and to emission

of interference, limit values and standards are outlined in the above mentioned documentation.

These Sunways products are intended for installation into a PV-System. The test results are not applicable to every installed state

in every PV-System. This declaration therefore does not guarantee the EMC characteristics of the end product.

City, Date Roland Burkhardt,CEO

Konstanz, 2004-08-05

Page 72

148

Declaration of Conformity of

nominal power and maximum output power

of solar inverters.

Product

Manufacturer

Type Sunways

Nominal power S

N

Maximum output power S

max10Min

S

max10Min/SN

Solar Inverter

Sunways AG, Photovoltaic Technology

Macairestr. 3-5, D - 78467 Konstanz

Explanation

The maximum output power of the solar inverter has to be declarated as a max. 10 minute average.

Ort, Datum Roland Burkhardt,CEO

Konstanz, 2004-08-05

NT 4000

3,3 kVA

3,3 kVA

1

NT 2600

2,2 kVA

2,2 kVA

1

NT 6000

4,6 kVA

5 kVA

1,08

Page 73

149

EN

Declaration of Conformity as defined by the guidelines for connection

and grid feeding in parallel of in-plant generation on low-voltage-guidelines

(VDEW 4. Edition 2001).

We herewith declare that the following product has been manufactured according to

the requirements outlined in the guidelines for connection and grid feeding in parallel

of in-plant generation on low-voltage-guidelines:

Product

Manufacturer

Type

From date of manufacture

Applied standard

Standard

Title

Edition

Solar Inverter

Sunways AG, Photovoltaic Technology

Macairestr. 3-5, D - 78467 Konstanz

Sunways NT 6000, NT 4000, NT 2600

2003-05-15

In-plant generation on low-voltageguidelines

4. Edition 2001

Explanation

The NT series of solar inverters from Sunways are monophase inverters that are not capable of isolated operation. They are

equipped with a voltage monitor and three phase monitoring of the line voltage for undervoltage in accordance with section

2.4.2 of the VDEW Guideline (4th edition 2001). A constantly accessible isolation point is therefore not required (see section

2.1.2 Switching point with isolating function). Observation of the cut-off values of the threephase undervoltage protection

is undertaken by means of a routine check test on each device

City, Date Roland Burkhardt,CEO

Konstanz, 2004-08-05

Page 74

150

General exclusion of liability

Although the accuracy and completeness

of the information contained in these

instructions have been checked with the

utmost care, no liability can be accepted

for errors or omissions.

· Sunways AG reserves the right to modify

the hardware and software features

described here at any time, without

prior notice.

· These instructions may not be duplicated, passed on, copied or translated in

to other languages, either in whole or

in part, in any form or by any means,

without prior written permission of

Sunways AG.

· Sunways AG does not provide any warranty for damages due to defective or

lost data, incorrect operation or malfunctioning of the solar inverter, the

software, additional equipment or PCs.

All rights reserved. © Sunways AG

The products specified in the title are

copyright-protected and are sold with

licences. No part of this document may

be reproduced in any form, without prior

written permission of Sunways AG and

the Sunways licensors.

Registered trademarks

Sunways NT 2600, NT 4000 and NT 6000

and the Sunways logo are registered

trademarks of Sunways AG, Constance.

HERIC

®

is a registered trademark of

Fraunhofer, Munich.

Page 75

Concept and design: Denklabor Kommunikationsbüro GmbH, Lucerne/Switzerland

Page 76

Sunways AG

Photovoltaic Technology

Macairestraße 3 - 5

D-78467 Konstanz

Telefon +49 7531 996770

Fax + 49 7531 99677444

E-Mail info@sunways.de

www.sunways.de

9-1-03-0-0 Version 03/05

Loading...

Loading...