Sunstar Fortuna AC Servo Motor V Manual

USER S MANUAL

PARTS BOOK

1) For at most use with easiness, please certainly read this manual before starting use.

2) Keep this manual in safe place for reference when the machine breaks down.

From the library of: Superior Sewing Machine & Supply LLC

Quality |

|

Best |

Price |

Best |

Service |

Best |

|

1.Thank you for purchasing our product. Based on the rich expertise and experience accumulated in industrial sewing machine production, SUNSTAR will manufacture industrial sewing machines, which deliver more diverse functions, high performance, powerful operation, enhanced durability, and more sophisticated design to meet a number of user’s needs.

2.Please read this user’s manual thoroughly before using the machine. Make sure to properly use the machine to enjoy its full performance.

3.The specifications of the machine are subject to change, aimed to enhance product performance, without prior notice.

4.This product is designed, manufactured, and sold as an industrial sewing machine. It should not be used for other than industrial purpose.

R

From the library of: Superior Sewing Machine & Supply LLC

From the library of: Superior Sewing Machine & Supply LLC

USER S

MANUAL

From the library of: Superior Sewing Machine & Supply LLC

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Safety instruction |

6 |

||||

2. Precautions before use |

8 |

||||

3. Locating and using parts of the controller box |

10 |

||||

4. Installation |

11 |

||||

5. Wiring and grounding |

20 |

||||

6. Connection the earth wire of the sewing machine and motor |

23 |

||||

7. Things to be checked after installation |

23 |

||||

8. Program unit part names and method of use |

24 |

||||

9. Simple operation unit part names and method of use |

40 |

||||

10. Fortuna series 5 full function software method of use |

45 |

||||

11. Breakdown and troubleshooting |

70 |

||||

12. How to place for controller |

71 |

||||

13. Block diagram |

72 |

||||

|

|

|

|

|

73 |

From the library of: Superior Sewing Machine & Supply LLC

Be sure to read and keep in mind the following instructions before you install and use thr FORTUNA SERVO MOTOR.

1) Use and Purpose

This product is designed, manufactured, and sold as an industrial sewing machine. It should not be used for other than industrial purpose.

2) Working Environment

Power Source

Power Source

It is desirable that voltage of the power source be kept within the range of

It is desirable that voltage of the power source be kept within the range of  10% of the rated voltage.

10% of the rated voltage.

It is desirable that frequency of the power source be kept within the rage of

It is desirable that frequency of the power source be kept within the rage of  10% of the rated frequency. (50/60

10% of the rated frequency. (50/60 )

)

The SERVO MOTOR can be expected to work normaly only in case the foregoing things are kept.

The SERVO MOTOR can be expected to work normaly only in case the foregoing things are kept.

Electromagnetic Noise

Electromagnetic Noise

It is desirable that those equipments causing strong electromagnetic field or high frequency not use the same electrical outlet as this on and stay away from it.

It is desirable that those equipments causing strong electromagnetic field or high frequency not use the same electrical outlet as this on and stay away from it.

Temperature and Humidity

Temperature and Humidity

Keep the ambient temperature above 5 degrees and below 40 degrees Centigrade.

Keep the ambient temperature above 5 degrees and below 40 degrees Centigrade.

Never use it outdoors and avoid direct ray of light.

Never use it outdoors and avoid direct ray of light.

Keep it away from an hot object like a stove.

Keep it away from an hot object like a stove.

30%

30%

95%.

95%.

Never use it near gases and explosives.

Never use it near gases and explosives.

Do not use it at a spot located 1,000m or higer above sea-level.

Do not use it at a spot located 1,000m or higer above sea-level.

Keep the storage temperature higher than 25 degrees below zero and lower than 55 degrees Centigrade when not in use.

Keep the storage temperature higher than 25 degrees below zero and lower than 55 degrees Centigrade when not in use.

3) Installation

Follow the instruction carefully when installing it.

Be sure to start installing it after pulling the power plug off the outlet.

Be sure to start installing it after pulling the power plug off the outlet.

Fix the cable so that it may not move, and do not allow the moving parts like belts to be interfered with.(keep distance of at least 25mm from them.)

Fix the cable so that it may not move, and do not allow the moving parts like belts to be interfered with.(keep distance of at least 25mm from them.)

Be sure to have the Controller, the Motor and the sewing Machine grounded.

Be sure to have the Controller, the Motor and the sewing Machine grounded.

Be sure that the voltage of power source fits the specification of the Controller before the power is on

Be sure that the voltage of power source fits the specification of the Controller before the power is on  Be sure to use Safety Extra Low Voltage when an extra item or an accessory is fitted into the Controller.

Be sure to use Safety Extra Low Voltage when an extra item or an accessory is fitted into the Controller.

4) Disassembly

Indisassembling it, be sure to wait at least 360 seconds before taking any action after pulling the plug off the power source after turning it off.

Indisassembling it, be sure to wait at least 360 seconds before taking any action after pulling the plug off the power source after turning it off.

When pulling off the plug from the power source, be sure to hole the plug itself instead of the wire connected to the plug.

When pulling off the plug from the power source, be sure to hole the plug itself instead of the wire connected to the plug.

6

From the library of: Superior Sewing Machine & Supply LLC

5) Service and Maintenance

Make sure that service and maintenance are carried out by a skilled technician.

Make sure that service and maintenance are carried out by a skilled technician.

Never try to operate with the Motor and the Controller open.

Never try to operate with the Motor and the Controller open.

When inserting a thread into or touching the machine, be sure to turn the power off and step down from the platform.

When inserting a thread into or touching the machine, be sure to turn the power off and step down from the platform.

Be sure to use standard products specified for replacement of parts.

Be sure to use standard products specified for replacement of parts.

6) Other Safety Instructions

Tack care not to let your fingers touch any moving parts including belts.

Tack care not to let your fingers touch any moving parts including belts.

In case of remodelling or fitting of additional device, be sure to follow safety standards and do not ever try to go ahead based on your own judgments.

In case of remodelling or fitting of additional device, be sure to follow safety standards and do not ever try to go ahead based on your own judgments.

Do not try to operate with the safety device removed.

Do not try to operate with the safety device removed.

Take care not to let water or coffee or something like those admitted into the Controller or the Motor.

Take care not to let water or coffee or something like those admitted into the Controller or the Motor.  Never drop the Controller or the Motor to the ground.

Never drop the Controller or the Motor to the ground.

The instructions presented above are for the safer and more proper operation of the Fortuna Servo Motor. Ignoring such instructions could cause damage to the machine or physical injury of the user. Pleasefollowalltheinstructionswhenoperatingthemachine.

The instructions presented above are for the safer and more proper operation of the Fortuna Servo Motor. Ignoring such instructions could cause damage to the machine or physical injury of the user. Pleasefollowalltheinstructionswhenoperatingthemachine.

7

From the library of: Superior Sewing Machine & Supply LLC

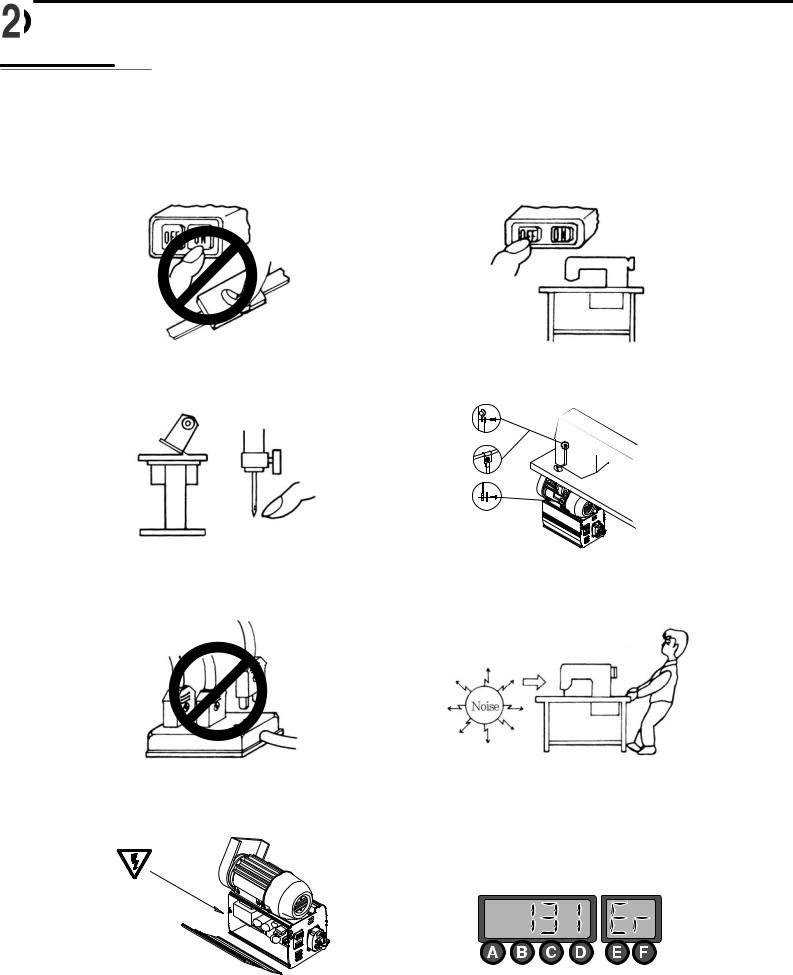

1. Do not turn on the power while stepping on the pedal.

3.Turn off the power when servicing the servomotor or changing the needle.

5.Do not connect multiple servomotor power plugs to the same power strip.

7.Avoid electrical shock when servicing the controller box. (Wait for 6 minutes before opening the cover after turning off the power.)

2. Turn off the power when leaving the servomotor overnight.

4. Be sure to keep the servomotor securely grouned.

6.Install the servomotor away from noise sources, such as highfrequency equipments and welding machines.

8. When an error message Er sppears on the digital display, take a note of the Er code, and then turn on and off before resuming operation(Contact the local dealer if Er message persists on the display)

8

From the library of: Superior Sewing Machine & Supply LLC

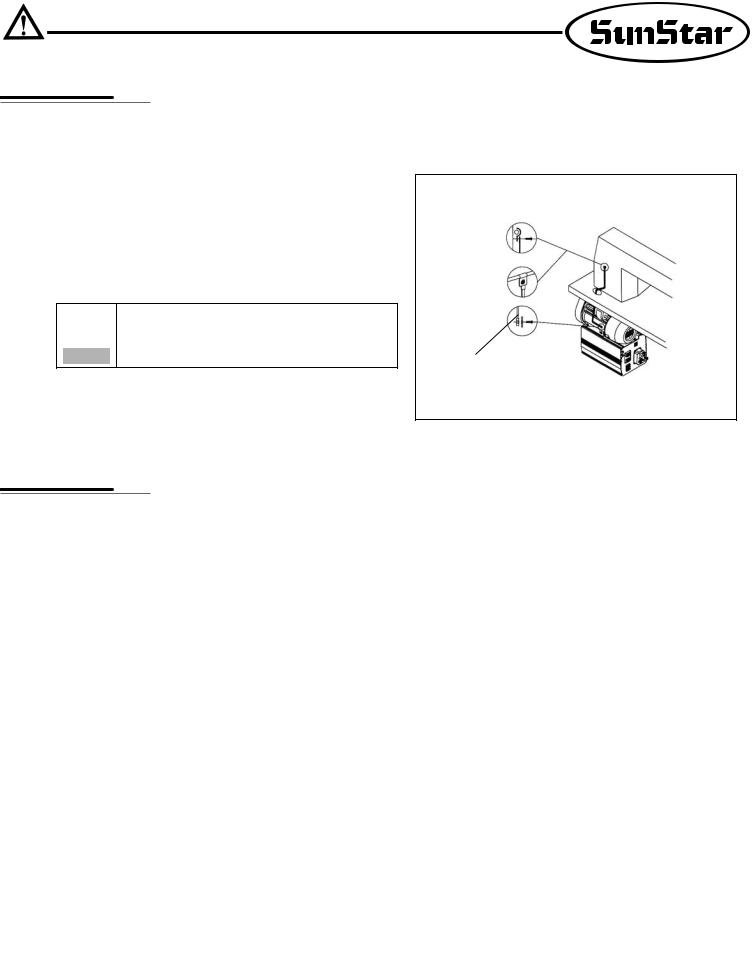

9. Adjust the belt tension to the optimum level.

Belt-tension adjustment should be performed after the motor is mounted on the table : First, loosen both the upper and lower anchoring bolts( , ). The belt tension will then be adjusted by the weight of servo motor itself. Fasten both anchoring bolts.

11.When replacing the fuse, use a standard item, opening the cover as shown in the diagram.

10.Clean it every two or three weeks so that no dirt or a dirty substance may be piled up.

12.Make the length of the cable connected with an outside parts like stand-up pedal as short as possible.

F1 |

250V/6.3A |

|

|

F2 |

250V/6.3A |

|

|

F3 |

250V/6.3A |

|

|

F4 |

250V/1A |

|

|

9

From the library of: Superior Sewing Machine & Supply LLC

1) Left and right side of control box

Control box left side |

Control box right side |

Motor Power Cable |

|

|

Encoder Connector |

|

(Green) |

AC Power switch |

|

Standard Solenoid |

OPTION |

|

|

Connector |

|

Switch and Lamp |

Connector for Position |

|

Sensor(Black) |

Foot-lift Solenoid(Green) |

|

Right lift Solenoid(Blue) |

Program Unit |

|

Connector(White) |

Tension-release and |

|

Auxiliary solenoid(White) |

|

2) Rear panel

Caution |

Motor |

AC INPUT |

10

From the library of: Superior Sewing Machine & Supply LLC

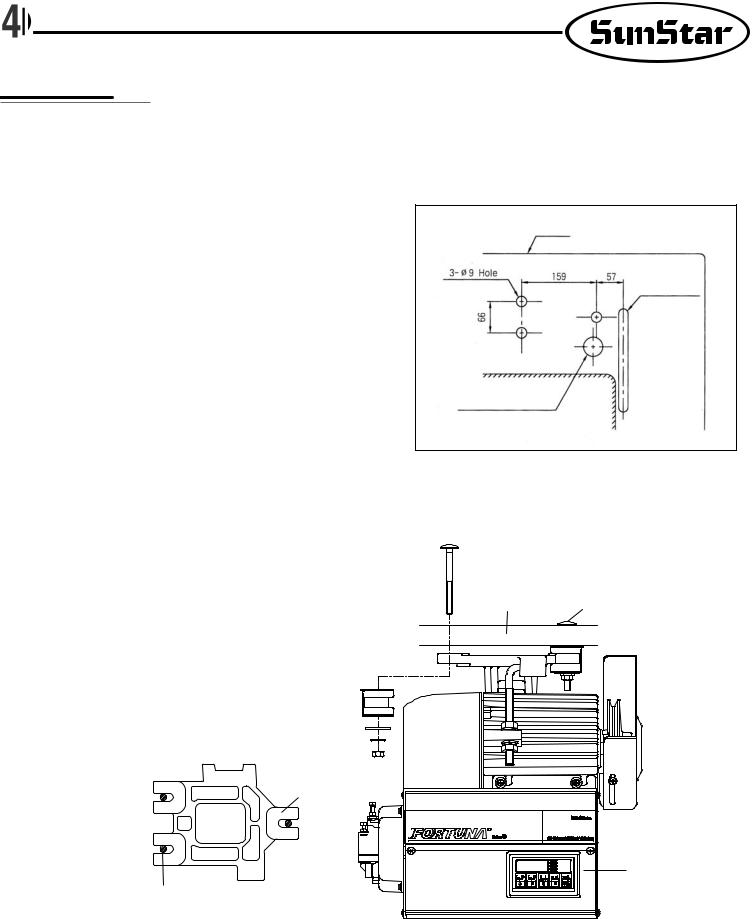

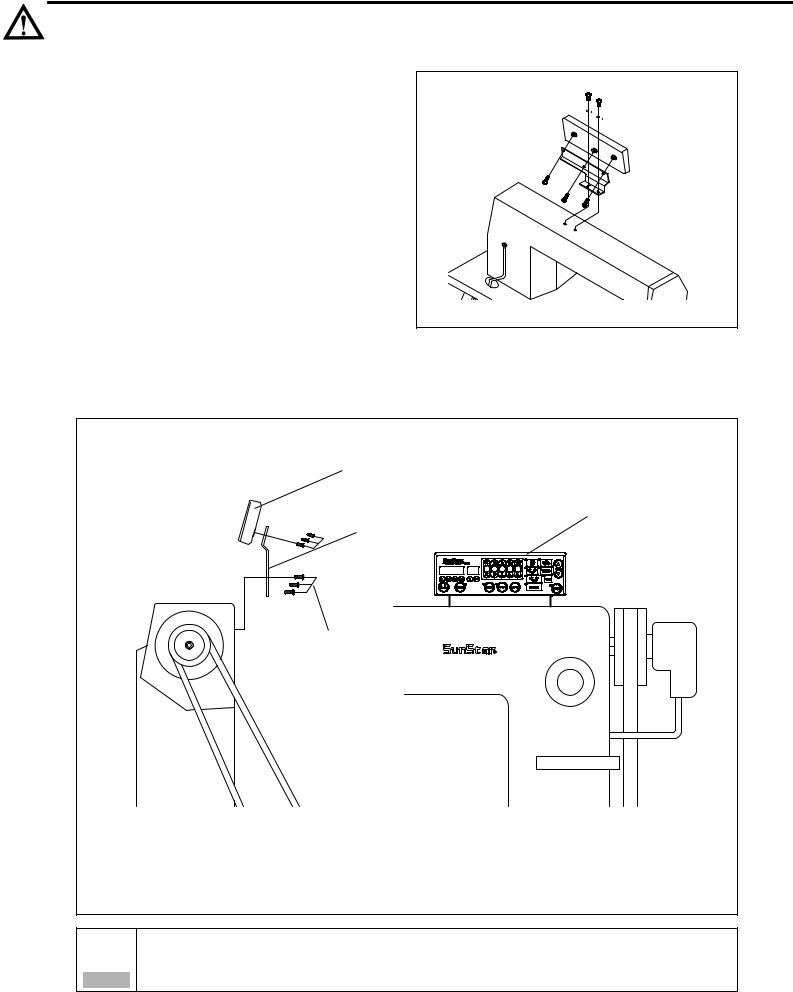

1) Mounting your Servo Motor on the table

Make sure that the holes are bored on the table as shown in the figure.

Make sure that the holes are bored on the table as shown in the figure.

Table

Belt Hole

41 Cable-Hole

Insert three motor-fixing bolts through the three holes on the table. Attach the motor base padded with vibration-proof rubber, and slide flat and spring washers over the bolt stems, and then fasten the bolts with nuts.

Insert three motor-fixing bolts through the three holes on the table. Attach the motor base padded with vibration-proof rubber, and slide flat and spring washers over the bolt stems, and then fasten the bolts with nuts.

Motor-Fixing Bolts

Table |

Motor-Fixing Bolts(3ea) |

Vibration-Proof rubber

Flat Waser

Spring Waser

Nut

Base

R

Controller Box

Motor-Fixing Bolts(3ea)

Make sure that the center of motor pulley is matched to that of the sewing machine before tightening the motor-fixing bolts and nuts.

Make sure that the center of motor pulley is matched to that of the sewing machine before tightening the motor-fixing bolts and nuts.

11

From the library of: Superior Sewing Machine & Supply LLC

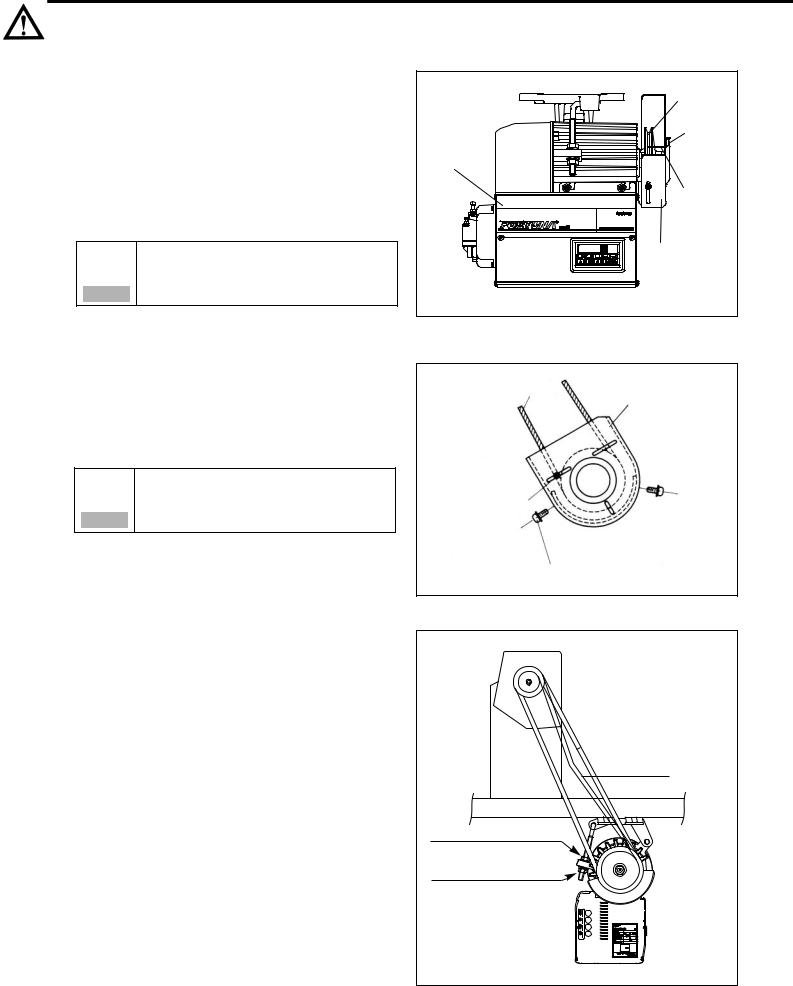

2)Assembling the belt cover and adjusting the belt tension

(1) Belt cover assembling procedure

Upon the completion of the motor mounting, bring the two pulleys of motor and sewing machine closer to each other, by pulling back the sewing machine. You can then mount the belt easily as shown in the figure.

Upon the completion of the motor mounting, bring the two pulleys of motor and sewing machine closer to each other, by pulling back the sewing machine. You can then mount the belt easily as shown in the figure.

Make sure that the power is off before

assembly.

Warning

Place the belt cover B , making sure that the belt cover does not contact the belt, and then fasten the cover with the fixing screw.

Place the belt cover B , making sure that the belt cover does not contact the belt, and then fasten the cover with the fixing screw.

Do not remove the belt cover.

If a finger slips into the belt, it might be broken or

Warning cut off.

Pulley

Belt Guide

Fixing

Screw

Controller Box

Belt Guide

Belt Cover A

A

Belt

Belt Cover B

Belt Guide Fixing Screw

Belt Cover Fixing Screw

(2) Adjusting the belt tension

Optimum Tension Level

Optimum Tension Level The optimum tention level is achieved when the belt is pushed by 5-10mm when the top surface portion of the belt at about 30-50mm above the tabletip is pressed by a finger with a force of~1

The optimum tention level is achieved when the belt is pushed by 5-10mm when the top surface portion of the belt at about 30-50mm above the tabletip is pressed by a finger with a force of~1 m/sec2 or 1 Newton.

m/sec2 or 1 Newton.

Adjusting the Tension Level

Adjusting the Tension Level If the tension level is out of the optimum range, adjust the tension as follows. First, loosen both the upper and lower nuts for the anchor bolt, letting the belt be stretched by the motor weight itself. Second, tighten the upper nut only to the extent that the motor does not move. Third, fasten the bottom nut tightly so that the motor is securely fixed.

If the tension level is out of the optimum range, adjust the tension as follows. First, loosen both the upper and lower nuts for the anchor bolt, letting the belt be stretched by the motor weight itself. Second, tighten the upper nut only to the extent that the motor does not move. Third, fasten the bottom nut tightly so that the motor is securely fixed.

5~10mm

5~10mm

30~50mm

Upper Nut for the Anchor Bolt

Lower Nut for the Anchor Bolt

12

From the library of: Superior Sewing Machine & Supply LLC

3) Mounting and adjusting the foot-lift solenoid

(1) SunStar KM-235 Model

Attach the main power switch first since the power switch is located normally in between the solenoid brackets.

Attach the main power switch first since the power switch is located normally in between the solenoid brackets.

By referring to the figure on the right and the mounting instructions enclosed in the packaging box, locate the insertion surface of the oil pan, and then attach the foot-lift solenoid.

By referring to the figure on the right and the mounting instructions enclosed in the packaging box, locate the insertion surface of the oil pan, and then attach the foot-lift solenoid.

No. |

Solenoid No. |

Applicable Models |

|

|

|

1 |

SPF-2 |

KM-235A, B |

|

|

|

(2) SunStar KM-250 Model

First, assemble a panel for the attachment of presser foot solenoid on the back of KM-250.

First, assemble a panel for the attachment of presser foot solenoid on the back of KM-250.

Attach the presser foot solenoid to a bracket A .

Attach the presser foot solenoid to a bracket A .

Attach the bracket

Attach the bracket A with the presser foot solenoid to the panel above.

A with the presser foot solenoid to the panel above.

Attch a crank to a solenoid shaft and then connect it to a sewing machine.

Attch a crank to a solenoid shaft and then connect it to a sewing machine.

Place a cover on the solenoid.

Place a cover on the solenoid.

(3) SunStar Special-specification models

The same mounting procedure for KM-235 model is applicable

for other models listed below.

No. |

Solenoid No. |

Applicable Models |

1 |

|

KM-750-7, KM-750BL-7 |

2 |

SPF-3 |

KM-790-7, KM-790BL-7 |

3 |

|

KM-857-7, KM-867-7 |

4 |

SPF-4 |

KM-560-7 |

5 |

SPF-6 |

KM-957-7, KM-967-7 |

6 |

SPF-8 |

KM-757-7 |

7 |

SPF-9 |

KM-640BL-7 |

(4)Adjusting the stroke(Gap) of the automatic foot-lift solenoid

Check point

Check point

Check to make sure that the stroke-adjusting screw is located at the center of the solenoid axis, i.e., the solenoid should be assembled in parallel with the bottom surface of the table. If the solenoid is not in paralle, make an adjustment so that the screw is in parallel with the center of the solenoid axis using the connection link-fixing screw.

Adjusting Procedure

Adjusting Procedure

The verical travel distance of the presser foot can be adjusted by the stroke-adjusting screw. First, Loosen the two fixing screws, and adjsut the vertical stroke using the stroke-adjusting screw. loosening and tightening the stroke-adjusting screw will decrease and increase the verical stroke of the presser foot respectively. After the adjustment, fasten the fixing screw tightly.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting Position |

||

|

|

|

for Legs(4) |

||

|

|

|

|

|

|

|

Oil Pan Insertion Surface |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting Position(4) |

|

|

|

|

|

for Automatic |

|

|

|

|

|

Foot-Lift Solenoid |

|

|

|

|

|

|

|

|

|

|

|

Belt Holes |

|

|

|

|

|

|

|

Specification viewed from the table bottom |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Solenoid Bracket A |

Cover for Foot-Lift Solenoid |

|||

|

|

|

|||

KM-250 Rear Panel

Oil Pan Insertion Surface

Mounting Position(4)

for Automatic

Foot-Lift Solenoid

Belt Holes

Specification viewed from the table bottom

Connection Link-

Fixing Screw

Oil Pan |

Stroke-Adjusting Screw |

Solenoid Axis

Fixing Nuts

13

From the library of: Superior Sewing Machine & Supply LLC

4)Mounting the position sensor (Synchronizer) and setting the film

(1)Mounting the position sensor(Synchronizer)

SunStar thread-cutting sewing machine.

SunStar thread-cutting sewing machine.

All SunStar thread-cutting sewing machines are equipped with a position sensor. Users, therefore, are required to the adjust the film position, if necessary, as shown in the figure.

L Wrency

Pulley

Synchro shaft-fixing screw(2)

Synchro shaft

Photo film

(Adjusted left and right)

Photo INTERRUPT

Upper Shaft

COVER

P.C.B Holder

All other sewing machines(including other manufacturers’ brands)

All other sewing machines(including other manufacturers’ brands)

First, attach the position sensor-mounting adapter to the upper shaft of the sewing machine. Second, attach the position sensor-fixing plate to the body of the sewing machine as shown below in the figure. Third, secure the position sensor to the adapter with the fixing screws.

Adapter

Position Sensor-Fixing Bolts |

Pulley |

|

Position Sensor-

Fixing Plate(Type A)

Position Sensor

Cable

Position Sensor-Fixing Plate(Type B)

Nylon Cable Tie

Fiixing Bolt for Position

Sensor-Fixing Plate

14

From the library of: Superior Sewing Machine & Supply LLC

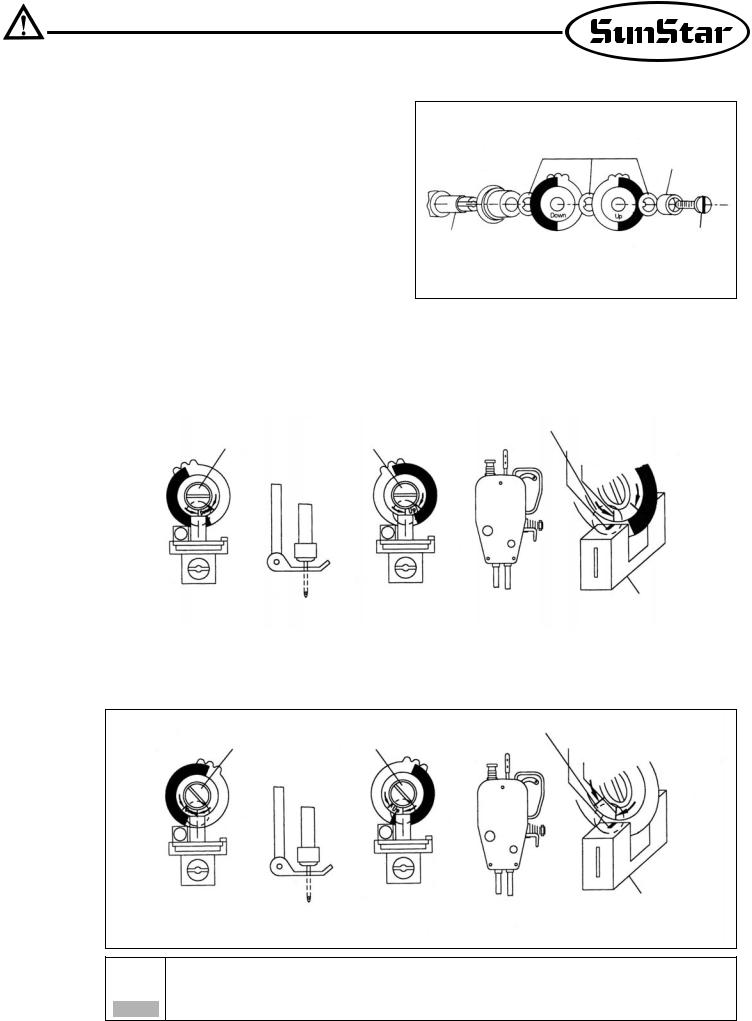

(2) Adjusting the film of the position sensor

Assemble the films and position sensor in the order as shown in the figure.

Assemble the films and position sensor in the order as shown in the figure.

Fixing Washer

Fixing Bushing

Position Sensor Shaft |

Film-Fixing Screw |

Upon the completion of the assembling, position the needle shaft tight at the rising point from the lowest needle position by manually rotating the pulley. Loosen the film-fixing screw, and adjust the DOWN film so that the film-adjsting line and the sensor housing calibration line are matched. Tighten the film-fixing screw just to the extent that the film can not be rotated. Likewise, position the thread take-up at the highest position. Loosen the film-fixing screw, and adjust the UP film as shown in the figure, while using caution not to move the DOWN film which is already adjusted earlier. Tighten the adjusted film with the fixing screw.

Upon the completion of the assembling, position the needle shaft tight at the rising point from the lowest needle position by manually rotating the pulley. Loosen the film-fixing screw, and adjust the DOWN film so that the film-adjsting line and the sensor housing calibration line are matched. Tighten the film-fixing screw just to the extent that the film can not be rotated. Likewise, position the thread take-up at the highest position. Loosen the film-fixing screw, and adjust the UP film as shown in the figure, while using caution not to move the DOWN film which is already adjusted earlier. Tighten the adjusted film with the fixing screw.

|

|

|

Setting Position |

Fixing Nut |

|

Fixing Nut |

Sensor Calibration Line |

|

|

|

Film-Adjusting Line |

|

2mm turning around |

|

Sensor Housing |

Down Film Adjustment |

from the lowest |

Up Film Adjustment |

The highest position |

|

position of needle bar |

of take-up lever |

|

|

|

||

|

|

|

|

(3) Adjustion the films of reverse rotation sewing machines

For reverse-rotation sewing machines, the film-adjusting lines located at right edge of the UP and DOWN film should be matched to the center line of the sensor.

For reverse-rotation sewing machines, the film-adjusting lines located at right edge of the UP and DOWN film should be matched to the center line of the sensor.

|

|

Setting Position |

Fixing Nut |

Fixing Nut |

Sensor Calibration Line |

|

|

Film-Adjusting Line(Reverse Rotation) |

Down Film Adjustment 2m turning around from the lowest

position of needle bar

Sensor Housing

Up Film Adjustment The highest position of take-up lever

After adjustment the film of the position detector, be sure to rotate the motor for 3~5 seconds by pedalling so

that the Controller may remember location of the film.

Caution

15

From the library of: Superior Sewing Machine & Supply LLC

5)How to equip and adjust a built-in location detector(synchronizer)

(1)How to equip the built-in location detector (synchronizer)

In case of a SunStar thread trimmer

In case of a SunStar thread trimmer

When a built-in location detector(synchronizer) for the sewing machine with the SunStar thread trimmer is equipped, all that the users need to do is to simply adjust the location of magnetic for detection according to their needs.

Locate detector

(synchronizer)

Position magnetic up

Upper

Shaft

Position magnetic down

Position magnetic up

Locate detector Sewing machine (synchronizer) pulley

Sewing machine

Position magnetic down

16

From the library of: Superior Sewing Machine & Supply LLC

(2) How to adjust the magnet of the location detector

Locate detector(synchronizer)

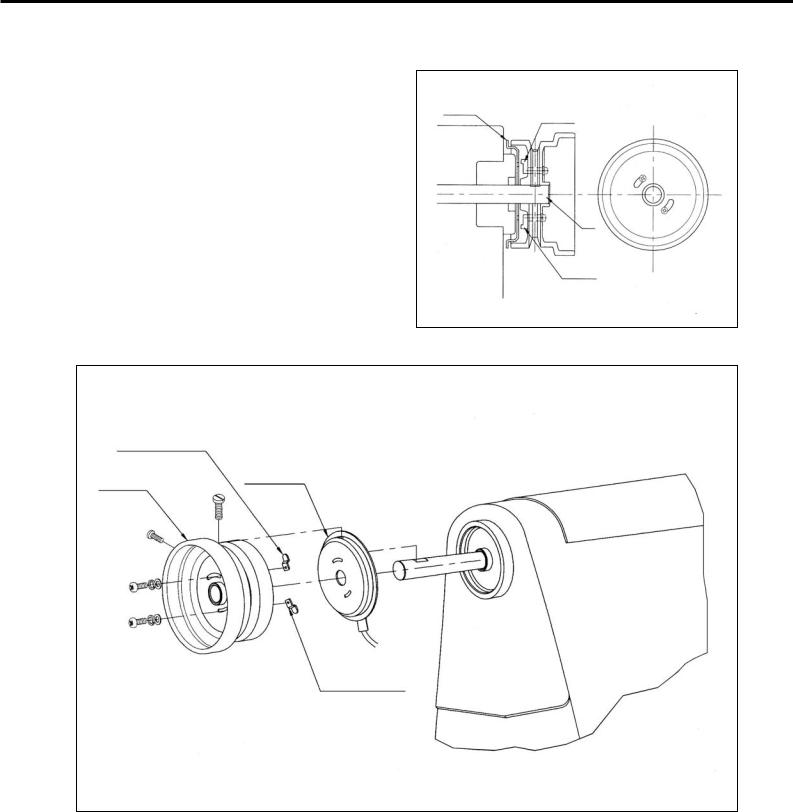

Assemble the detector in order following the pictures.

Once assembling is completed, power the controller on and step on the pedal. At this time, make sure that the needle moves up and down. Stop the needle at a desired location by moving the magnet back and forth along the location where the needle stops.

Once assembling is completed, power the controller on and step on the pedal. At this time, make sure that the needle moves up and down. Stop the needle at a desired location by moving the magnet back and forth along the location where the needle stops.

The highest position of take-up lever

Normal rotation |

Normal rotation |

direction |

direction |

Locate detector |

2mm turning around |

(synchronizer) |

from the lowest |

|

position of needle bar |

(3)How to adjust a location detector in case of a reverse rotation sewing machine

It is the same as that used for the normal rotation direction

It is the same as that used for the normal rotation direction

The highest position of take-up lever

Reverse rotation |

Reverse rotation |

direction |

direction |

Locate detector |

2mm turning around |

(synchronizer) |

from the lowest |

|

position of needle bar |

After adjusting a location detector, rotate the motor by stepping on the pedal for 3~5 seconds so that a

controller can remember the location.

Caution

17

From the library of: Superior Sewing Machine & Supply LLC

6) Mounting the Program Unit(P/U)

(1) SunStar KM-235 Sewing Machine

First, attach the P/U bracket to the P/U using three fixing screws and a supporting bolt with nut attached on it as shown in the figure. Second, securely attach the P/U to the head of the sewing machine using two fixing screws and washers, keeping a 3~4mm distance between the bottom surface of the nut and the base of the supporting bolt.

(2) Other SunStar thread-machine

First, attach the P/U bracket to the P/U using the four fixing screws. Second, attach the P/U to the main body of the sewing machine using the three bracket-fixing screws as shown in the figure.

Program Unit

Program Unit

P/U Bracket

P/U Bracket-Fixing

Screw(3)

Fix the cable using the cable tie so that cable is not in the way of the belt.

Caution

18

From the library of: Superior Sewing Machine & Supply LLC

7) An example of installing the SunStar sewing machine

19

From the library of: Superior Sewing Machine & Supply LLC

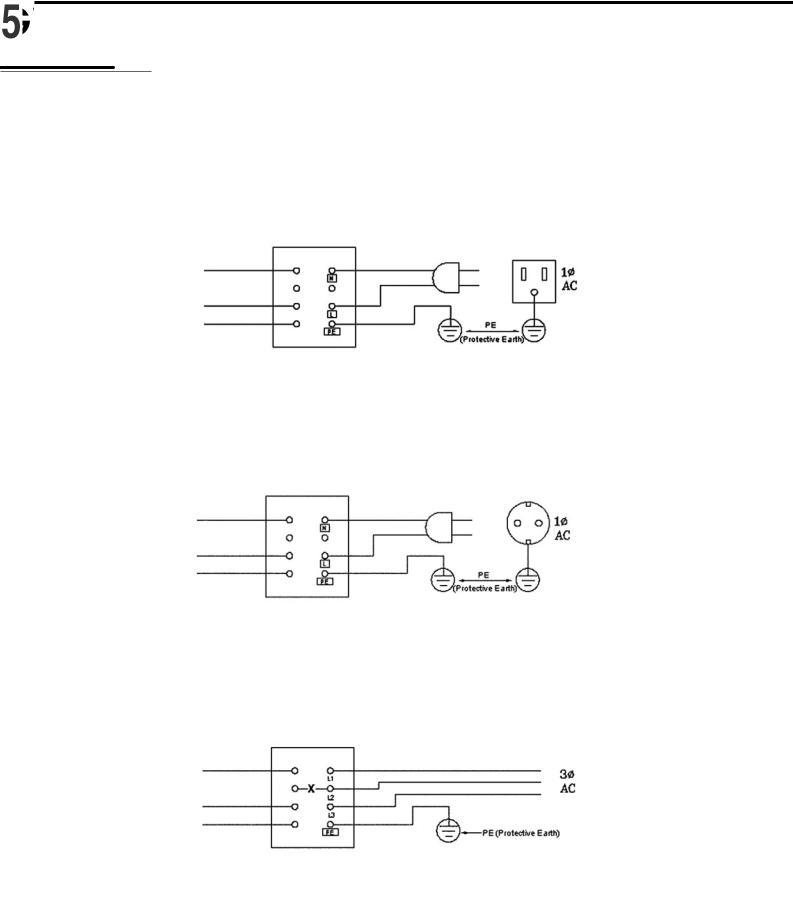

1)Specification of the power plug

(1)Single phase 100V~120V

|

Switch Box |

Control Box |

110V |

|

EARTHV |

|

|

(2) Single phase 200V~240V |

|

|

|

|

Switch Box |

Control Box |

220V |

|

EARTHV |

|

|

(3) Three phase 200V~240V |

|

|

|

|

Switch Box |

Control Box |

220V |

|

EARTHV |

|

|

Be sure to connect Protective Earth |

|

2) Specification of electric current in wiring of power plug

Be sure to use wiring materials which can stand electric current of higher than 15A.

20

From the library of: Superior Sewing Machine & Supply LLC

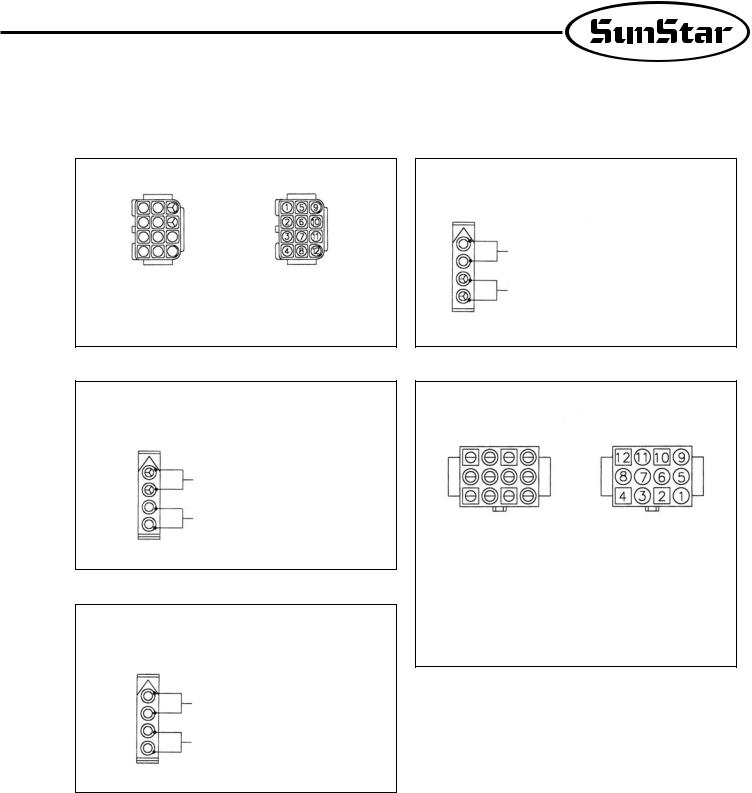

3) Name and description on the outside connector of control box

Standard solenoid connector

Standard solenoid connector

[ Shape of pin ] |

[ No. of pin ] |

1, 5 |

Back Tack Solenoid |

4, 8 |

GND, VDC |

|

2, 6 |

Thread-Cutting Solenoid |

|

(DC 46V or DC 32V) |

|

3, 7 |

Wiper Solenoid |

9, 10 |

Button |

to insert/delete the |

|

|

|

back-tack operation |

|

|

|

11, 12 Button |

for manual back- |

|

|

|

|

tack operation |

|

Tension-release and auxiliary solenoid

Tension-release and auxiliary solenoid

Connector Color White

Auxiliary Solenoid

Tension-Release Solenoid

Foot-lift solenoid

Foot-lift solenoid

Connector Color Green

Foot-Lift Solenoid Switch

Foot-Lift Solenoid

Right/Left solenoid(Used in twin-needle sewing machine)

Right/Left solenoid(Used in twin-needle sewing machine)

Connector Color Blue

Right-Needle Control Solenoid

Left-Needle Control Solenoid

Switch and lamp(Used in twin-needle sewing machine)

Switch and lamp(Used in twin-needle sewing machine)

[ Shape of pin ] |

[ No. of pin ] |

5V |

GND |

5V |

4/4 (N.C) |

L LED |

3/4 (N.C) |

R LED |

2/4 (N.C) |

L S/W |

1/4 (N.C) |

R S/W |

(N.C) |

4) How to change the electric voltage supplied for solenoid (The factory installed setting is J2)

J2)

This is to make the movement of solenoid smooth in times of fluctuation in the incoming electric voltage.

This is to make the movement of solenoid smooth in times of fluctuation in the incoming electric voltage.  Set Value for electric voltage supplied (for 220V series) for Solenoid against the incoming voltage.

Set Value for electric voltage supplied (for 220V series) for Solenoid against the incoming voltage.

For 30V-regular Solenoid

Incoming Voltage |

Set Value |

|

|

Below 210V |

J5 |

|

|

210V~230V |

J6 |

|

|

Above 230V |

J7 |

|

|

For 24V-regular Solenoid

Incoming Voltage |

Set Value |

|

|

Below 180V |

J5 |

|

|

180V~190V |

J6 |

|

|

Above 190V |

J7 |

|

|

21

From the library of: Superior Sewing Machine & Supply LLC

Set Value for electric voltage suplied (for 110V series) for Solenoid against the incoming voltage.

Set Value for electric voltage suplied (for 110V series) for Solenoid against the incoming voltage.

For 30V-regular Solenoid

Incoming Voltage |

Set Value |

|

|

Below 100V |

J5 |

|

|

100V~120V |

J6 |

|

|

Above 120V |

J7 |

|

|

For 24V-regular Solenoid

Incoming Voltage |

Set Value |

|

|

Below 90V |

J5 |

|

|

90V~100V |

J6 |

|

|

Above 100V |

J7 |

|

|

Setting of pin

Setting of pin

22

From the library of: Superior Sewing Machine & Supply LLC

Method

Method

Connect the motor and sewing machine using the ground wire (green, green/yellow) as shown in the figure. Make sure that the factory-connected ground wire between the controller box and motor is securely in place.

Failure to ground the motor can cause abnormal operations, such as overspeed rotation or unwanted

Caution stitching.

1) Before the power is on...

Make sure that the incoming voltage is in accordance with that shown in the name plate of the Control box.

Make sure that the incoming voltage is in accordance with that shown in the name plate of the Control box.

Check whether the following connectors are connected.

Check whether the following connectors are connected.

Connector for incoming AC power source

Connector for incoming AC power source

Connector for motor power

Connector for motor power

Connector for motor encoder

Connector for motor encoder

Connector for pedal

Connector for pedal

Connector for position detector

Connector for position detector

Connector for others (option, knee-lift, program unit etc.)

Connector for others (option, knee-lift, program unit etc.)

Check to see whether the belts are in touch with the wiring.

Check to see whether the belts are in touch with the wiring.

Check the tensile strength of the belts.

Check the tensile strength of the belts.

Check to see the fixing nuts for pulley are tightly fastened.

Check to see the fixing nuts for pulley are tightly fastened.

Check whether the sewing machines are right kinds (Chain Stitch S/M, Lock Stitch S/M)

Check whether the sewing machines are right kinds (Chain Stitch S/M, Lock Stitch S/M)

Check the rated voltage for Solenoid (Refer to How to change the electric voltage supplied for Solenoid ))

Check the rated voltage for Solenoid (Refer to How to change the electric voltage supplied for Solenoid ))

2) After the power is on...

Check whether the lamp for the position detector is on. (Except in the case of built-in position detector)

Check whether the lamp for the position detector is on. (Except in the case of built-in position detector)

Check whether the program unit is working.

Check whether the program unit is working.

Check the direction of rotation of the Sewing Machine.

Check the direction of rotation of the Sewing Machine.

In case the direction of rotation is not right, action shall be taken to change set it right, referring to

In case the direction of rotation is not right, action shall be taken to change set it right, referring to the methods of changing the program and the list of changing functions (N. 65 in Group A )

the methods of changing the program and the list of changing functions (N. 65 in Group A )

Check to see whether there are abnormal heat, smell or noise nearby.

Check to see whether there are abnormal heat, smell or noise nearby.  In case there are, turn the power off and call our regional office.

In case there are, turn the power off and call our regional office.

23

From the library of: Superior Sewing Machine & Supply LLC

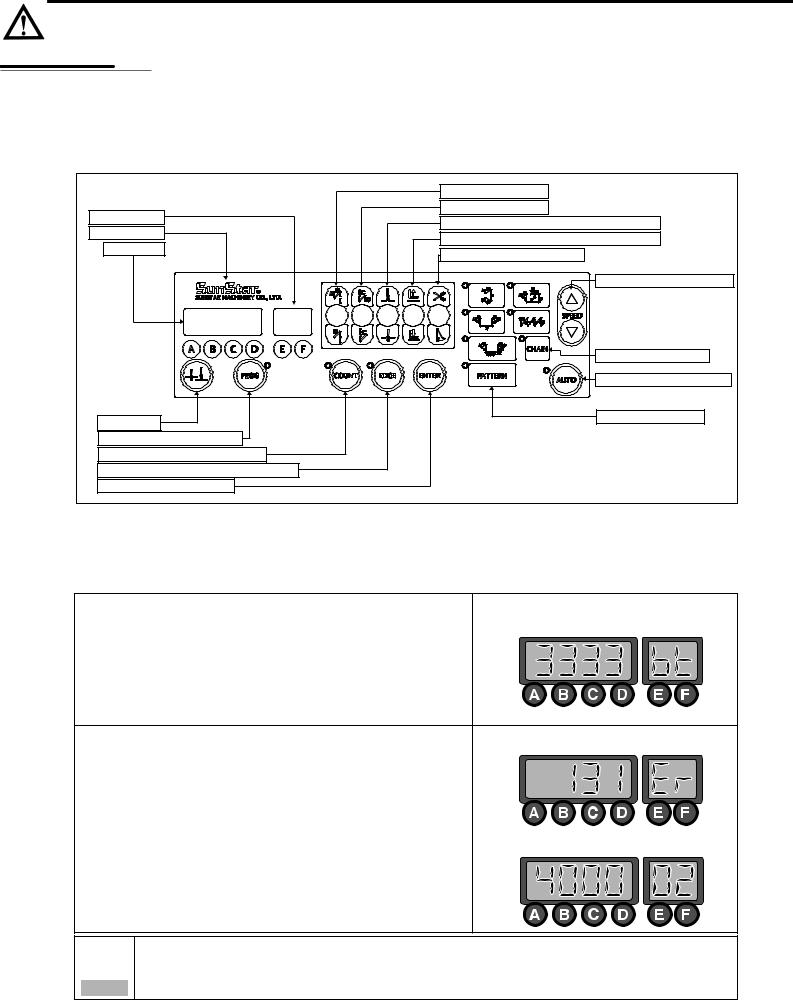

1) Program unit part names

|

Start B/T Selection Button |

|

2--Digit Displayer |

End B/T Selection Button |

|

Button to Select Needle Plate Location When Machine Stops |

||

Sunstar Logo |

||

Button to Select Presser Foot-lift Location When Machine Stops |

||

4-Digit Displayer |

||

Thread-trimmer and Wiper Selection |

||

|

||

|

Button to Change the Sewing Speed Installation |

|

|

Pattern Work Connecting Button |

|

|

Constant Sewing Speed Selection Button |

|

1/2 Stitch Button |

Pattern Work Selection Button |

|

|

||

Button for Program Change |

|

|

Button for Counter Use after Counter Programming |

|

|

Button to use Edge Sensor Selection after Edge Sensor Programming |

|

|

Button to Save Program Changes |

|

2)Program Unit Method of Use

(1)4-Digit Displayer and 2-Digit Displayer Functions and Method of Use

A. 4-Digit Displayer and 2-Digit Displayer Functions

<Initializing screen>

When you turn the power on, you will see a screen as shown in the figure. The 4-digit displayer shows the start and end B/T sewing and the 2-digit displayer shows the current abbreviation for the letters or numbers shown in the 4-digit displayer (bt: the abbreviation for back tack),

When you turn the power on, you will see a screen as shown in the figure. The 4-digit displayer shows the start and end B/T sewing and the 2-digit displayer shows the current abbreviation for the letters or numbers shown in the 4-digit displayer (bt: the abbreviation for back tack),

<Example of error detection>

The 4-digit displayer shows the error number for each type of error discovered and also shows the programmed value after it has been

The 4-digit displayer shows the error number for each type of error discovered and also shows the programmed value after it has been

programmed. The 2-digit displayer shows the number of the parameter <Example of selection of number 2 item in Group A> specific item's content or name which is shown in the 4-digit displayer.

The 4-digit displayer and 2-digit displayer show the current condition. Therefore the user should always check it

before using the machine.

Caution

24

From the library of: Superior Sewing Machine & Supply LLC

B.Method of Use: 4-Digit Displayer and 2-Digit Displayer

a. Method to change the start and end B/T stitch numbers

In order to change the start B/T stitch numbers which is programmed when you first purchase this machine, you must use the  ,

,  buttons. If you want to

buttons. If you want to

change the end B/T stitch numbers, you must use the  ,

,  buttons. The program range is from 0 to 9.

buttons. The program range is from 0 to 9.

(Ex: How the screen looks when changing both start and end B/T stitch numbers to 4).

b. Method to check or change the specifics of the parameter

Press the

Press the  button and as you press it, also press the

button and as you press it, also press the  button. Then you can either check or change the programming items for the parameter of group A. (A group

button. Then you can either check or change the programming items for the parameter of group A. (A group  , B group

, B group  , C group

, C group  D group

D group  )

)  Users should turn the machine off to select B, C, or D group. While pressing the

Users should turn the machine off to select B, C, or D group. While pressing the  button, turn the power switch on. The screen will be changed to the initial screen after showing the "PrEn" message. Then, the users can select B, C, or D group by pressing B, C, or D button while

button, turn the power switch on. The screen will be changed to the initial screen after showing the "PrEn" message. Then, the users can select B, C, or D group by pressing B, C, or D button while

holding program  button.

button.

You can move to the parameter item you want with the

You can move to the parameter item you want with the  and

and  buttons. The parameter item number will appear in the 2-digit displayer and the wanted value will appear in the 4-digit displayer.

buttons. The parameter item number will appear in the 2-digit displayer and the wanted value will appear in the 4-digit displayer.

(Ex) Screen showing the maximum speed limit preset in the item 2 of A group)

After using the

After using the  (increase) button and

(increase) button and  (decrease) button to choose the value you want, press the

(decrease) button to choose the value you want, press the  (Enter) button and save the value you chose. (Ex: Reducing the maximum sewing speed limit from 4000RPM to

(Enter) button and save the value you chose. (Ex: Reducing the maximum sewing speed limit from 4000RPM to

3000RPM).

After saving, press the

After saving, press the  button and go back to the initial screen.

button and go back to the initial screen.

Be aware that if you don't press  after changing the programmed value for the parameter item, the value will not be saved. When the B, C, or D group selection is completed, users should turn off the machine first and restart to secure the selected group.

after changing the programmed value for the parameter item, the value will not be saved. When the B, C, or D group selection is completed, users should turn off the machine first and restart to secure the selected group.

Caution If the user changes the programmed value from the parameter specifics carelessly, the user may cause break down or physical damage to the machine. The user must therefore be well-trained before changing the parameter group.

(2) Method of Use |

Stitch Button Function |

When necessary, make

When necessary, make  stitches by pressing the

stitches by pressing the  stitch (

stitch ( ) button.

) button.

When the needle plate makes a down stop, shortly press the

When the needle plate makes a down stop, shortly press the  stitch (

stitch ( And when the needle plate makes an up stop, shortly press the

And when the needle plate makes an up stop, shortly press the  stitch (

stitch (

) button once and the needle plate will make an up stop. ) button once and the needle plate will make a down stop.

Be aware that if you are continuously pressing the  (

( ) button, the machine will keep on moving at the

) button, the machine will keep on moving at the  stitch

stitch

( ) speed.

Caution

25

From the library of: Superior Sewing Machine & Supply LLC

(3) Method of Use: Start B/T Button

This button is used when the user wants to prevent threads from loosening at the end of the sewing work. If the user presses this button in sequence, the location on the lights will change. This button offers the following three functions.

When sewing starts, B/T sewing is operated with

When sewing starts, B/T the sewing does not operate.

button

When sewing starts, B/T sewing is operated with the

button

Using the A, B buttons in the 4-digit displayer, the user can program the B/T number of stitches he/she wants.

Be aware that if the start B/T stitch is set to '0' in the 4-digit displayer, the start B/T sewing is impossible.

Caution

(4) Method of use: End B/T Button

This button is used when the user wants to prevent threads from loosening at the end of the sewing work. If the user presses this button in sequence, the location on the lights will change. This button offers the following three functions.

|

When sewing ends, B/T |

|

sewing can be operated |

When sewing ends, B/T |

with the |

sewing does not operate. |

|

|

button. |

|

|

When sewing ends, B/T sewing can be operated with the

button.

Using the C, D buttons in the 4-digit displayer, the user can program the B/T number of stitches he wants.

Be aware that if the end B/T stitch is set to '0' in the 4-digit displayer, the start B/T sewing is impossible.

Caution

(5) Method of Use: The Needle Plate Position Selection Button When the Sewing Machine Stops

When the user turns the power on, one of the up stop or down stop lights in the program unit panel needle plate is always left on. The user can change the stop location by pressing the button.

When machine stops while sewing, the needle plate makes an up stop.

When machine stops while sewing, the needle plate makes a down stop.

26

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...