Page 1

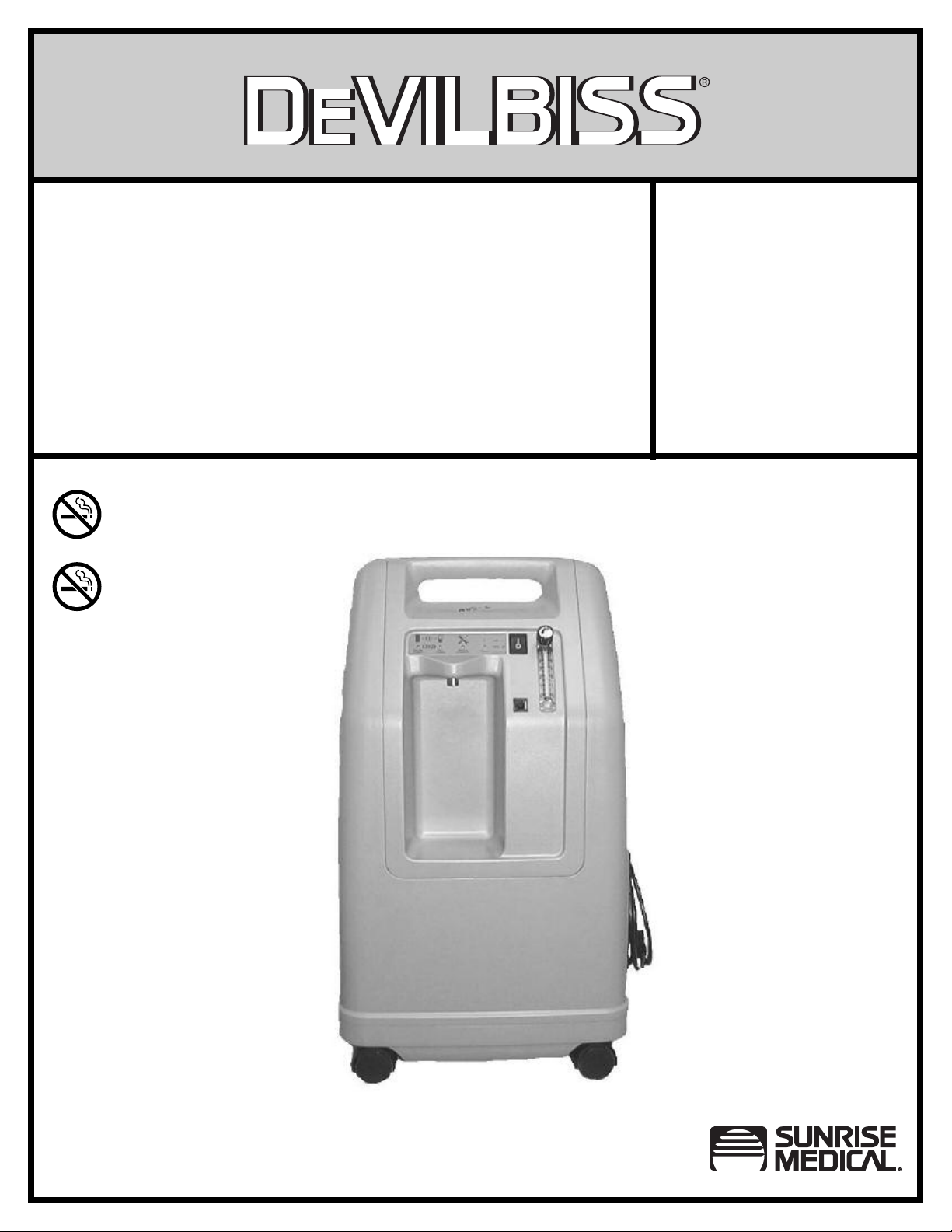

DeVilbiss®5-Liter Series Oxygen

Concentrator Service Manual

DeVilbiss®Concentrador de Oxígeno

Serie de 5 Litros Manual de Servicio

DANGER – NO

SMOKING

PELIGRO – NO

FUMAR

For Product Numbers:

Para productos Número:

515ADS

515ADZ

515AKS

515AKZ

CAUTION-Federal (U.S.A.) law restricts this device to sale by or on the order of a physician.

PRECAUCIÓN – Las leyes Federales (EE.UU.) restringen la venta de este equipo por o por orden

de un médico

Page 2

TABLE OF CONTENTS

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

GENERAL INFORMATION

ntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

I

Important Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions and General Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

UNPACKING AND SETUP

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

atient Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

P

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MAINTENANCE

Patient Alert System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Routine Patient Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Periodic Homecare Provider Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Between Patient Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Preventative Maintenance Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

TROUBLESHOOTING

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Normal Operating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Simplified Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Troubleshooting Chart A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Troubleshooting Chart B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting Chart C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting Chart D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting Chart E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting Chart F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

COMPONENT TESTING, REPAIR, AND REPLACEMENT

Proper Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cabinet Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Accumulator PressureTest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Final Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Hour Meter

Molecular Siev

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

e Beds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

er Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

w

o

P

e Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressur

18

Printed Circuit Board (PC board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

alve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

V

y

Rotar

e Bed Check V

Siev

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

es

alv

20

FIGURES, DIAGRAMS, AND VIEWS

Figure Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

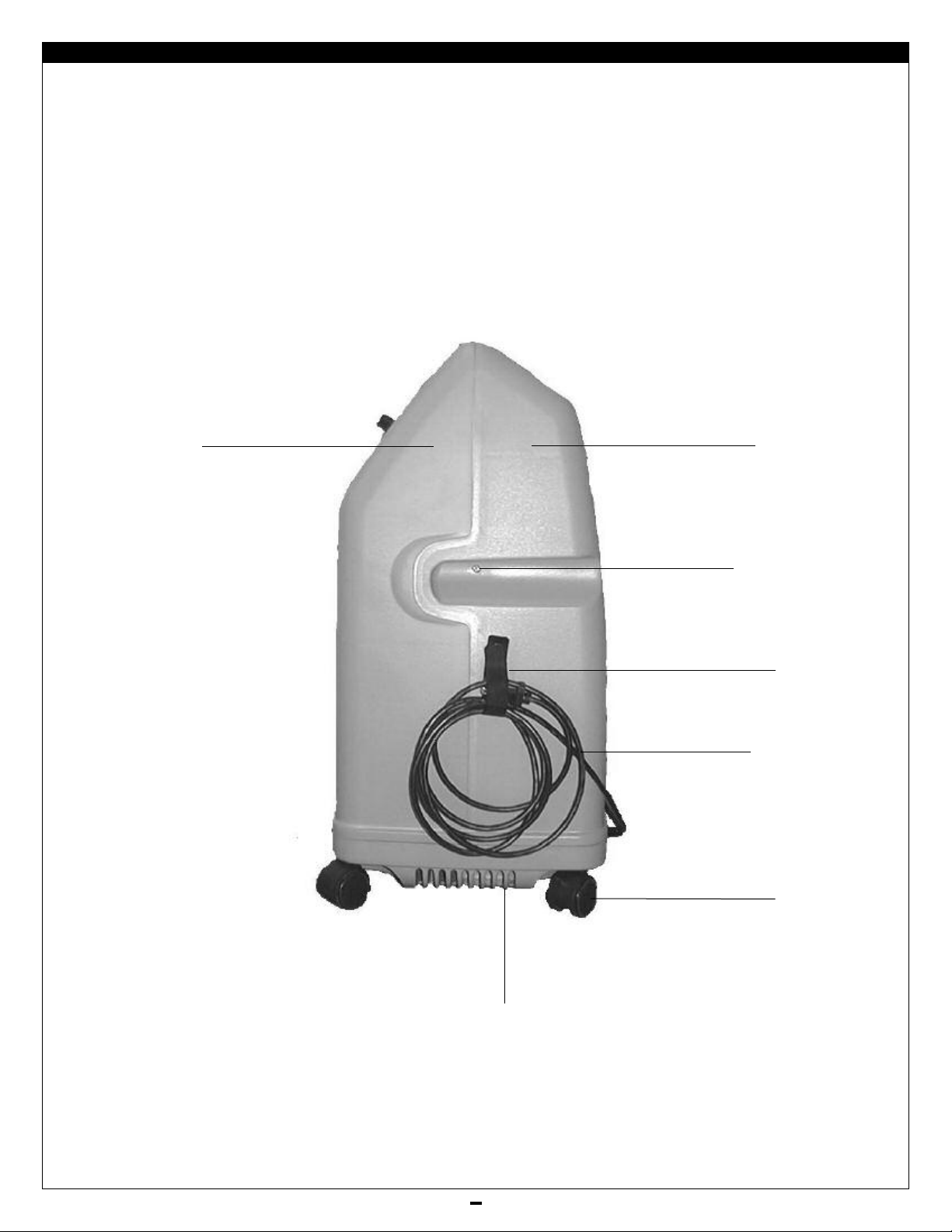

Exterior Vie

ws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-24

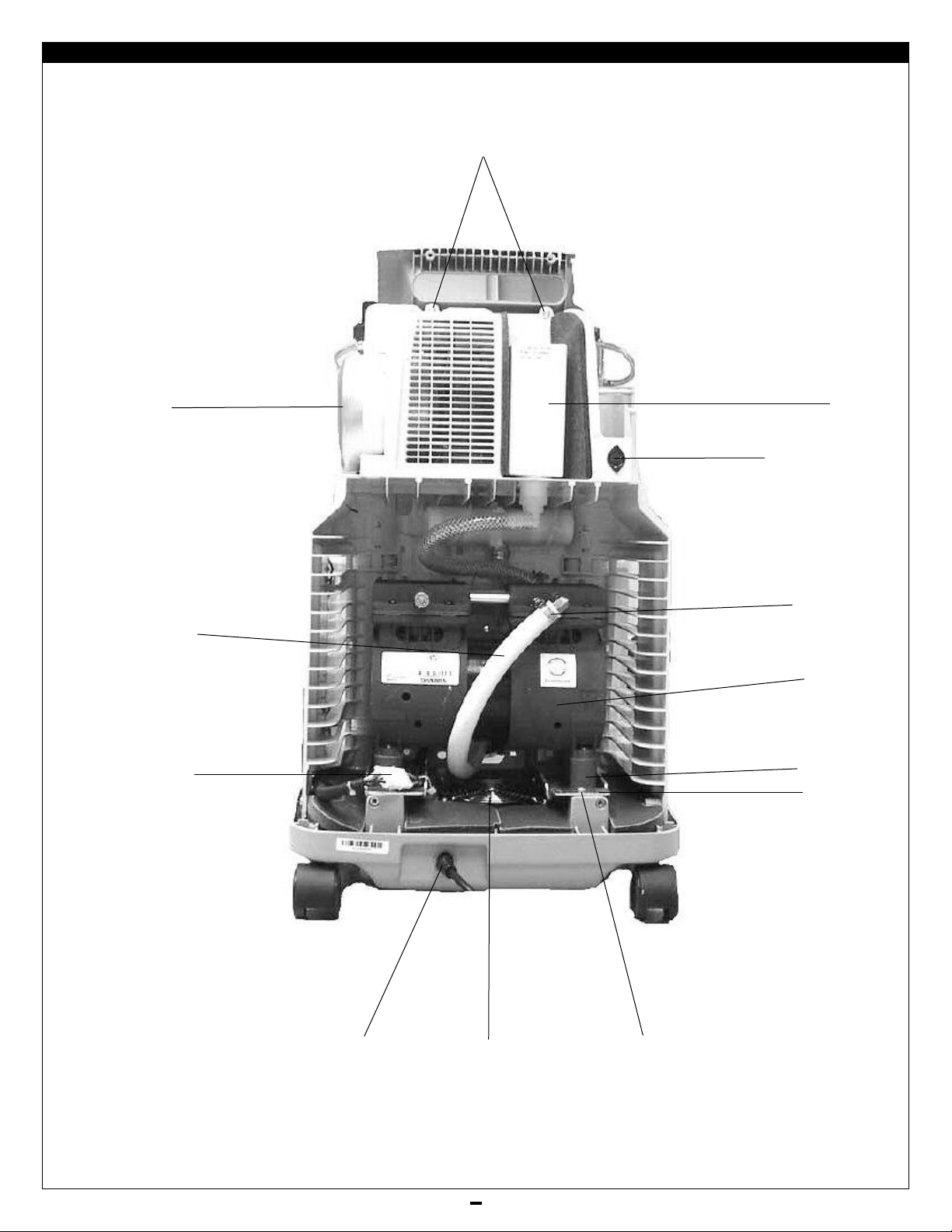

Interior Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-37

Other Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38-42

Pneumatic and

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43-44

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

ORDERING INFORMATION AND PARTS LIST

dering Inf

Or

ormation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

Parts Return and Ordering Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47-48

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

LT-1928

2

Page 3

GENERAL INFORMATION

INTRODUCTION

This service manual was designed to provide Sunrise Medical

Respiratory Products Division qualified service technicians

and homecare providers with the proper maintenance, service, safety, and repair procedures for the DeVilbiss Oxygen

Concentrator.

Read and understand all the information contained in this service manual before attempting to operate or perform any

aintenance on the concentrator.

m

An oxygen concentrator is a device that delivers highly con-

entrated oxygen for therapeutic applications.

c

Room air is a mixture of 78% nitrogen, 21% oxygen, 1% argon

and other gases.The concentrator draws in room air, separates

the nitrogen from the oxygen, and delivers concentrated oxygen to the patient through an oxygen port.

For more in-depth classroom type training, Sunrise Medical

holds oxygen concentrator service schools. For service

school information, contact the Respiratory Technical Service

Department at

NOTE:

1-800-333-4000 (814-443-4881).

Sunrise Medical reserves the right to alter or change the

design of the DeVilbiss Oxygen Concentrator series. Hence, slight

differences in construction or components may exist between the

unit in hand and what is described in this manual.

3

LT-1928

Page 4

GENERAL INFORMATION

IMPORTANT SAFEGUARDS

Read all instructions before operating the oxygen concentrator. Important information is highlighted by these terms:

WARNING: Safety information for hazards that might

cause serious injury or death.

AUTION: Information for preventing damage to

C

the product.

OTE:

N

nformation to which you should pay special attention.

I

SAFETY PRECAUTIONS AND GENERAL WARNINGS

A. Federal (U.S.A.) law restricts this device to sale by or on the

order of a physician.

B.

WARNING: Oxygen promotes rapid burning. Do

not smoke when using this unit or when near a

person receiving oxygen therapy. Do not operate the

oxygen concentrator within a minimum of five feet

(1.6m) from hot, sparking, or burning objects or naked

flames. Do not use in rooms heated by paraffin or

portable gas heaters.

C. Do not place a humidifier with an oxygen patient unless pre-

scribed by a physician and then only a bubble-type humidifier

should be used.

D. Do not connect the oxygen concentrator to an electrical out-

let controlled by a wall switch; the outlet should be independent of other appliances.

E. Do not use an electrical adapter or extension cord with the

oxygen concentrator.

F. Only operate the oxygen concentrator with all filters in place;

do not operate if the air filter is wet.

WARNING: Electric shock hazard. Do not remove cabi-

G.

et.The cabinet should only be removed by a qualified

n

Sunrise Medical homecare provider.

H. WARNING: Disconnect the power cord from the wall

outlet before attempting repairs on the unit. Extra

care should be taken if it is necessary to operate the

unit with the cabinet removed.

I. WARNING: Do not use oils, greases, or any petrole-

um-based solvents/cleaners on or near the unit. Use

only materials that are compatible with oxygen.

J. WARNING: Electric Shock Hazard.When replacing

the capacitor, do not touch the terminals or allow

metal objects to come in contact with the terminals

on the capacitor. The capacitor may hold a charge for

several days after the unit is turned off.The capacitor

is located in the base of the unit next to the cooling

fan.

K. Use only Sunrise Medical concentrator replacement parts and

accessories.

L. Do not use regenerated sieve material.

LT-1928

4

Page 5

UNPACKING AND SETUP

INITIAL INSPECTION

It is suggested that an initial inspection be performed upon

receiving the oxygen concentrator.

1. After removing the DeVilbiss Oxygen Concentrator from the

carton, examine it for any external damage. If shipping damage

has occurred, contact the Sunrise Medical Customer Service

Department at 1-800-333-4000 (814-443-4881) for specific

instructions. Save the carton for possible later return; note

the position of the unit and placement of the packing material.

2. Open the filter door (Figure 3) and record the number of

hours on the hour meter. Check to make sure the air filter is

n place.

i

3. Check to be sure the intake bacteria filter (Figure 4) is in place.

4. Plug the unit into an electrical outlet, turn the unit “On,” and

check the audible and visible alarms.

5. Set the flow meter to maximum recommended liter flow and

let the unit run for at least 20 minutes.

6. Use an oxygen analyzer to check the concentration.

NOTE: If the unit fails to operate properly (oxygen concen-

tration not within specification) or if internal damage is found,

contact the Sunrise Medical Customer Service Department at

1-800-333-4000 (814-443-4881).

PATIENT SETUP

1. Position the unit near an electrical outlet in the room where

the patient spends most of his or her time.

NOTE: Do not connect to an electrical outlet controlled by a

wall switch.The outlet should be independent of other appliances.

2. Position the unit at least 6 inches (16 cm) from walls,

draperies, or any other objects that might prevent the proper

flow of air in and out of the oxygen concentrator.

3. Locate the unit a minimum of 5 feet (1.6 meters) from fireplaces, radiators, heaters, and hot-air registers.

Oxygen Tubing Only Connection (Figure 1)

1. Thread the cannula fitting (part #CN100) onto the oxygen

utlet port.

o

2. Attach the 5/32” (4 mm) I.D. oxygen tubing (part #OST07,

OST15, OST25, or OST50).

Oxygen Tubing with Humidification Connection

If the physician has prescribed an oxygen humidifier as part of

the patient’s therapy, follow these steps:

1. Fill the humidifier bottle (part #HUM16) with distilled water.

Do not overfill. (If using a prefill, go to Step 3.)

2. Thread the wing nut located on the top of the humidifier bot-

tle to the oxygen outlet port so that it is suspended. Make

sure it is securely tightened.

3. Attach the 5/32" (4 mm) I.D. oxygen tubing (part # OST07,

OST15, OST25, or OST50), not to exceed 50 feet (15

meters), directly to the humidifier bottle outlet fitting.

NOTE: For optimum performance, the DeVilbiss Oxygen

Concentrator has a preset nominal output pressure of 8.5 psi

(58.6 kPa). Use only “bubble-type” humidifiers. Do not use

“jet-type” humidifiers.

NOTE: Condensation from the humidifier may occur in

longer lengths of tubing or if the tubing is laying on a cold

floor. This can be reduced by using a removable humidifier

stand (part #MC44DM-509).

To use the stand:

1. Attach a straight humidifier adapter fitting (part #444-506) to

the bottle by turning the wing nut on the humidifier until it is

tight on the fitting.

2. Secure the bottle in the strap.

3. Attach one end of the oxygen tubing to the oxygen outlet on

the unit and the other end to the plastic adapter fitting on the

humidifier. Locate the humidifier near the patient.

WARNING: Oxygen promotes rapid burning. Do

not smoke when using this unit or when near a

person receiving oxygen therapy. Do not operate the

oxygen concentrator within a minimum of 5 feet (1.6

meters) from hot, sparking, or burning objects or

naked flames. Do not use in rooms heated by paraffin

or portable gas heaters.

W

ARNING: Electric Shock Hazard. Only qualified

Sunrise Medical homecare providers may remove

the cabinet.

4. Attach the appr

opriate o

xygen accessories (o

xygen tubing or

humidifier) to the oxygen outlet port.

NOTE: A maximum of 50 feet (15 meters) of tubing plus 7

feet (2.1 meters) of cannula plus a bubble humidifier is allowed

between the concentrator and the patient.

When ready for operation

1. Attach the nasal cannula (part #CAN00), catheter, or face

mask to the oxygen tubing (per the man

2. Follow the

5

Operating Instructions on the next page.

ufacturer’s directions).

LT-1928

Page 6

UNPACKING AND SETUP

OPERATING INSTRUCTIONS

1. Remove the power cord completely from the strap. Make sure

the power switch is in the “Off” position.

2. 115 Volt Units– Insert the plug into an electrical outlet.The

DeVilbiss Oxygen Concentrator uses a two-prong polarized

plug and is double-insulated to protect against electric shock.

WARNING:The plug on the DeVilbiss 515ADZ and

515ADS concentrators has one blade wider than the

ther.To reduce the risk of electric shock, this plug is

o

intended to fit in a wall outlet only one way. Do not

attempt to defeat this safety feature.

WARNING: Improper use of the power cord and plugs

can cause a burn, fire, or other electric shock hazards.

Do not use the unit if the power cord is damaged.

WARNING: Oxygen promotes rapid burning. Do

not smoke when using this unit or when near a person receiving oxygen therapy. Do not operate the oxygen

concentrator within a minimum of five feet (1.6m) from

hot, sparking, or burning objects or naked flames. Do not

use in rooms heated by paraffin or portable gas heaters.

3. Press the power switch to the “On” position.When the unit is

turned on, the “Service Required” light will illuminate and an

audible signal will sound (the patient alert system) momentarily. The “Power” light also illuminates.

Only DeVilbiss Oxygen Concentrators with OSD

®

The OSD is an optional device within DeVilbiss concentrators

that monitors the o

xygen produced b

y the unit.The OSD

operates as follows:

• Normal Oxygen (green light) - oxygen purity normal

• Low Oxygen (yellow light) - oxygen purity low–requires servicing

NOTE: If the oxygen purity continues to fall, an audible signal

will sound intermittently. If the oxygen purity continues to fall

to a low enough level, the yellow “Low Oxygen” light will turn

off and the red “Service Required” light will turn on.

OTE:Refer to Specificationsfor specific alarm settings.

N

When the unit with the OSD is turned “On,” all four indicator

ights (Power, Service Required, Low Oxygen, and Normal

l

Oxygen) on the front panel will briefly illuminate. After a few

seconds, only the “Power” and “Normal Oxygen” lights will

remain on.

NOTE: After Power On, the OSD conducts a continuous

diagnostic evaluation to check for a fault in the piezo electronics. If this condition is detected by the OSD electronics at any

time during concentrator operation, the green “Normal

Oxygen” OSD light will turn off and the beeping audible and

blinking red “Service Required” light alarms activate.

Otherwise for the first fifteen minutes of operation, the

green “Normal Oxygen” light will remain illuminated

during the oxygen stabilization process.After that

time, the OSD will begin monitoring the oxygen purity

every second.

4. Slowly turn the flow meter knob until the flow meter ball is

centered on the line next to the appropriate flow rate.

NOTE:When the flow meter knob is turned clockwise, the

flow decreases (and eventually will shut off the oxygen flow).

When the knob is turned counter-clockwise, the flow increases.

NOTE: Use low output flow meter (part #515LF-607) for

flow rates under 1 lpm.

NOTE:The unit may require up to 20 minutes for the oxygen

concentration and flow rate to stabilize.The flow rate should

be monitored and readjusted if necessary.

5. The flow meter has a locking device. If it is necessary to preset

and lock in the prescribed flow rate, tighten the set screw

located on the hex nut just below the control knob using a

1/16" Allen bit. No adjustment can be made without loosening

the set scr

ew.

6. The DeVilbiss oxygen concentrator is now ready for use.

LT-1928

6

Page 7

MAINTENANCE

PATIENT ALERT SYSTEM

The DeVilbiss Oxygen Concentrator patient alert system will

detect unit component failure.This system is comprised of both

isible and audible alarms which signal the patient if a malfunction

v

should occur.

The visible alarm located on the front panel (Figure 1) reads

“Service Required.” The audible alarm system is internally

powered; no batteries are required.When the indicator lights

illuminate or the audible alarm sounds, other than during unit

start-up, a problem has occurred.

Non-OSD models:

Power Failure (Blinking red “Service Required” light

•

and pulsing audible alarm)

• Low Flow (Continuous red “Service Required” light and

audible alarm)

OSD models:

• Power Failure (Blinking red “Service Required” light

and pulsing audible alarm)

• Low Flow (Below 0.5 lpm) (Continuous red “Service

Required” light and audible alarm)

• Below Normal Oxygen (84% to 75%, yellow “Low Oxygen”

light. 75% to 60%, yellow “Low Oxygen” light and beeping

audible alarm. Less than 60%, red “Service Required” light

and beeping audible alarm.) Refer to

Specifications for spe-

cific alarm settings.

The visible and audible alarms will activate for approximately

15 minutes in a no power situation. If the unit is turned “On”

without power or power is removed later, no alarm will sound

for the first 10 seconds.After that time, the alarm will produce

an audible pulse every few seconds while the visible alarm

blinks. Power for this alarm is provided by a capacitor on the

PC board.

NOTE: If the concentrator has been unused for an extended

period, the unit must run several minutes before the power fail

alarm will activate.

The PC (printed cir

cuit) boar

d (Figure 5) is r

esponsible for

controlling the system and alarms.

TE:

NO

A high pr

(a “popping” sound) r

e located on the compressor head.

valv

essure condition is indicated b

elease of pr

essur

e fr

y the audible

om a pressur

e r

elief

ROUTINE PATIENT MAINTENANCE

The oxygen patient should perform the following maintenance:

Oxygen Humidifier (reusable bottles only)

The patient should clean the humidifier bottle daily. The patient

should follow the instructions supplied by the manufacturer. If

no cleaning instructions were supplied, these steps should be

followed:

• Wash the humidifier bottle in a solution of hot water and

dishwashing detergent.

• Soak the humidifier in a solution of one part white vinegar

to three parts hot water for 30-45 minutes.This solution

acts as a germicidal agent.

• Rinse thoroughly with hot tap water and refill with distilled

water for use. Do not overfill.

Cannula/Mask and Tubing

The patient should clean and replace the cannula or mask and

tubing as instructed by the manufacturer.

Air Filter and Oxygen Outlet Connector

The air filter (Figure 3) and oxygen outlet connector should

be cleaned at least once a week by the patient.To clean, these

steps should be followed:

1. Remove the air filter located in the door on the back of the unit.

Remove the oxygen outlet connector (if used) from oxygen outlet port (Figure 1).

2. Wash in a solution of warm water and dishwashing detergent.

3. Rinse thoroughly with warm tap water and towel dry.The filter should be completely dry before reinstalling.

WARNING: Do not attempt to operate the unit without the air filter or while the filter is still damp.

NOTE:

The air filter should be monitored more closely in

environments with abnormal amounts of dust and lint.

CAUTION: Operation of the DeVilbiss Oxygen

Concentrator in extr

air filter will pr

eme environments or without the

y occlude the intak

ematur

el

e bacteria

filter and cause a decrease in the unit performance.

Exterior Cabinet

The patient should clean the concentrator exterior cabinet by

using a damp cloth or sponge with a mild household cleaner

and wiping it dr

y.

WARNING: Do not apply liquids directly to the

y petroleum-based solvents or

cabinet or utiliz

e an

cleaning agents.

7

LT-1928

Page 8

MAINTENANCE

PERIODIC HOMECARE PROVIDER

PREVENTATIVE MAINTENANCE

Every DeVilbiss Oxygen Concentrator is tested at the factory.

o assure continued trouble-free performance, the following

T

preventative maintenance should be performed by the homecare provider during periodic oxygen patient visits.Failure to

roperly maintain the unit will void the warranty.

p

1. Check the oxygen concentration with an oxygen analyzer

(part #O2ANA)—every 3 months on non-OSD units or every

two years on OSD units.

a. Calibrate the oxygen analyzer prior to checking the oxy-

en concentration.The analyzer should be properly cali-

g

brated using the manufacturer’s recommended procedure.

NOTE: Changes in temperature, altitude, or humidity may

affect the analyzer’s oxygen concentration reading.The analyzer should be calibrated in similar conditions to the location of

the concentrator.

b. The concentrator must operate for a minimum of 20 min-

utes before checking the oxygen concentration.

c. Connect the analyzer to the unit’s oxygen outlet port

(Figure 1) and wait until the display stabilizes.

d. Record the reading.

2. Check the audible alarm and indicator lights every two years.

When the power switch is turned “On,” listen for the audible

alarm and check to see if the front panel indicator lights are

operating.

3. Change intake filter as follows:

a. Extended life intake bacteria filter (part # 515DZ-605) -

Inspect once a year. Change as necessary, not to exceed

8760 hours.

b. Open the filter door and replace filter as required.

4. Change the final bacteria filter (part #PV5LD-651) every

two years or 17,520 hours.

a. Unplug the unit, remove the cabinet, and loosen the bib.

. Remove the hose from each end of the filter (Figure 8) and

b

discar

d the filter

.

c. Install the new final bacteria filter with the “IN” fitting

toward the flow meter.

d. Tighten the bib and replace the cabinet.

5. Check the system performance every two years of operation

by measuring the accumulator pressure swing. Use the

Accum

ulator Pr

described in the cha

pter

Component

essure Test

Testing, Repair and Replacement.

NOTE: This PM Schedule reflects:

• 5000 hour usage equal to one year

• a normal, clean operating environment.

The homecare provider is responsible for:

• determining the condition of the concentrator operating

environment.

• determining a preventative maintenance interval frequency

(not to exceed the schedule stated above which takes into

consideration the specific operating environment).

BETWEEN PATIENT MAINTENANCE

1. Discard oxygen tubing, cannula & humidifier bottle.

. Wash or replace the cabinet air filter.

2

3. Wash the concentrator cabinet.

4. Check oxygen concentration. If the unit falls within specifica-

tion, the extended life intake bacteria filter does not need to

be replaced between patients.

PREVENTATIVE MAINTENANCE SUMMARY

Patient

Daily Clean the humidifier bottle (if used).

Weekly Clean air filter on back of unit.

Clean exterior of cabinet.

Other Clean and replace cannula/mask and tubing as

instructed by manufacturer.

Homecare Provider

Change intake bacteria filter as necessary following

requirements in step 3.

3 months Check oxygen concentration on non-OSD units.

Check the concentrator environment, and set a

maintenance interval of less than 3 months if

required.

2 years Check audible alarm and indicator lights.

Change final bacteria filter (change within 17,520

hours).

Check system performance.

Check oxygen concentration on OSD units.

LT-1928

8

Page 9

TROUBLESHOOTING

SYSTEM OPERATION

The DeVilbiss Oxygen Concentrator uses a pressure swing

adsorption system.The air is drawn into the unit through air

ilters and into a double-head compressor.

f

A pneumatic diagram of the system is shown in Figure 14.

The compressed air passes through a rotary valve (Figure 5),

which is cycled at a pre-determined rate, and is directed into

ne of two sieve beds.The sieve beds contain molecular sieve

o

material which is a synthetically-produced inorganic silicate. It is

very porous and has the unique ability to selectively adsorb

itrogen from the air as it passes through the sieve bed.

n

s one bed is being pressurized, the other bed is quickly

A

depressurized.This allows the nitrogen that was adsorbed

during its pressurization cycle to be exhausted from the

sieve material.

The nitrogen is released through exhaust ports located on the

rotary valve assembly.The ports are connected to a single piece

of hose running from the valve to the exhaust muffler.

Also during each bed pressurization, a small amount of oxygen

flows through an orifice (Figure 9) from the pressurized bed

into the depressurizing bed.The orifice is clamped inside a long

piece of blue tubing connecting the outlets of the two sieve

beds.This helps purge the nitrogen from the depressurizing bed.

The beds will continue to be alternately pressurized and

depressurized as the unit operates.

Oxygen leaving the sieve beds is directed through a check

valve to the accumulator tank.A pressure regulator (Figure 9)

on the tank controls the oxygen pressure as it leaves the accumulator and enters the flow meter.The flow meter allows the

oxygen flow to be controlled and adjusted to the level prescribed by the patient’s physician. From the flow meter the

oxygen passes through the final bacteria filter (Figure 8),a

check valve, and finally the oxygen outlet port to the patient.

The DeVilbiss Oxygen Concentrator operates on a timed

cycle.The cycling is controlled by the PC board.The PC board

will send voltage to the valve causing it to shift and alternately

essurize the sieve beds.

pr

The PC board also activates the electr

onic alarm system.

high pressure condition will be indicated with a “popping” type

sound produced by release of pressure from a pressure relief

e on the compressor head.

valv

w flow and po

Lo

wer failure are

indicated by audible and visible alarms.

The 515 OSD Models operating system incorporates “turn-

wn” technolog

do

y.The PC board constantly monitors the flow

rate and will decrease the cycle time whenever the flow rate

is less than 2.5 LPM.Therefore it “turns-down” the cycle based

er oxygen demand.As a result, the unit runs cooler

w

on lo

with less power consumption.

NORMAL OPERATING SEQUENCE

When the concentrator is turned “On,” the following cycling

sequence can be observed by attaching pressure gauges to the

ieve bed test points.

s

1. The rotary valve is quickly cycled several times to relieve residual bed pressure preventing a static condition in the compressor.This rapid cycling onl

y happens on start-up and is clearly

heard as pressure is being quickly exhausted several times

through the exhaust muffler that is connected to the valve.

2. The PC board applies a short DC voltage signal to the valve.

he valve will stop for approximately 7 seconds causing the

T

right bed to pressurize first while the left bed depressurizes to

approximately 2 PSI (14 kPa).

3. Voltage is again applied to the valve for a short time. The valve

will stop for approximately 0.7 seconds.During this time the

sieve bed pressures are equalized.

4. A short DC voltage signal is again applied to the valve.The

valve will stop for approximately 7 seconds causing the left

bed to pressurize while the right bed depressurizes to approximately 2 PSI (14 kPa).

5. A short DC voltage signal is again applied to the valve.The

valve will stop for approximately 0.7 seconds. During this time,

the sieve bed pressures are equalized.

6. The cycle then repeats with step 2.

NOTE:In the “turn-down” mode (OSD models only),the fixed

cycle time is decreased to approximately 3 seconds and the

bed pressure equalization time to approximately 0.3 seconds.

NOTE:High-end sieve bed pressure should not exceed 1/2 PSI

(4 kPa) above high-end accumulator pressures. Refer to

Specifications for normal pressures obtained during the cycle.

A

9

LT-1928

Page 10

TROUBLESHOOTING

SIMPLIFIED TROUBLESHOOTING

The key to simple troubleshooting is to recognize which type

of problem exists and select the most effective approach to

olving the problem.The different types of problems and the

s

approaches for solutions are as follows:

WARNING: Mechanical Hazard. Keep fingers, loose

clothing, etc. away when working on compressor.

Type I—The unit runs but a low pressure and flow or high

pressure condition exists.

NOTE:

Low pressure or flow are indicated by both a visible

and audible alarm. High pressure is indicated by a “popping”

sound caused by the pressure relief valve.

1. Connect test gauges to sieve bed tests points (Figure 7).

2. Refer to the

Normal Operating Sequence to make sure the unit

is cycling properly.

3. If bed pressure is rising slowly, check for occluded filters and

severe leaks. If filters are clean and there are no leaks, then the

compressor is defective.

4. If the pressure relief valve is releasing pressure, observe

whether the unit is cycling or not.

5. If the unit is not cycling or has uneven bed pressures, this indicates that the rotary valve is not operating correctly. Refer to

Rotary Valve Testing described in the chapter Component

the

Testing, Repair and Replacement.

6. If the unit is cycling in conjunction with very high bed pressures, this indicates defective sieve beds.

Type II—The compressor will not start when the unit is

turned on.

1. Verify that the cooling fan is running; if it is not, determine

where you are losing power.

2. Check for compressor voltage at the compressor connector.

3. If voltage is present, then the capacitor or compressor is

defective.

4. If voltage is not present, the wire harness is defective.

Type III—The concentrator runs and continues to cycle

but has low oxygen concentrations.

1. Connect test gauges and check for higher or lower than normal bed pressures.

a. High pressures indicate defective sieve beds.

. Low pressures indicate occluded filters, leaks, or defective

b

compressor.

c. Uneven bed pressures indicate valve is not operating cor-

rectly.

2. Check for oxygen leaks at:

• sieve beds • flow meter

• accumulator tank • final bacteria filter

• pressure regulator • final check valve

• outlet port

NOTE: Check for leaks using a certified leak detection solution such as Snoop

®

or equivalent (must not contain ethylene

glycol).Apply leak test solution to all fittings and hose connections with unit running. If an air leak is present, the solution

will bubble.All leaks should be repaired before putting the unit

back in service.

CAUTION: Do not apply leak test solution to any part

of the rotary valve or the main PC Board assembly.

3. Test accumulator tank pressure. If pressure is lower than normal, then sieve bed check valves are defective.

NOTE: For normal system pressures refer to Specifications.

LT-1928

10

Page 11

TROUBLESHOOTING

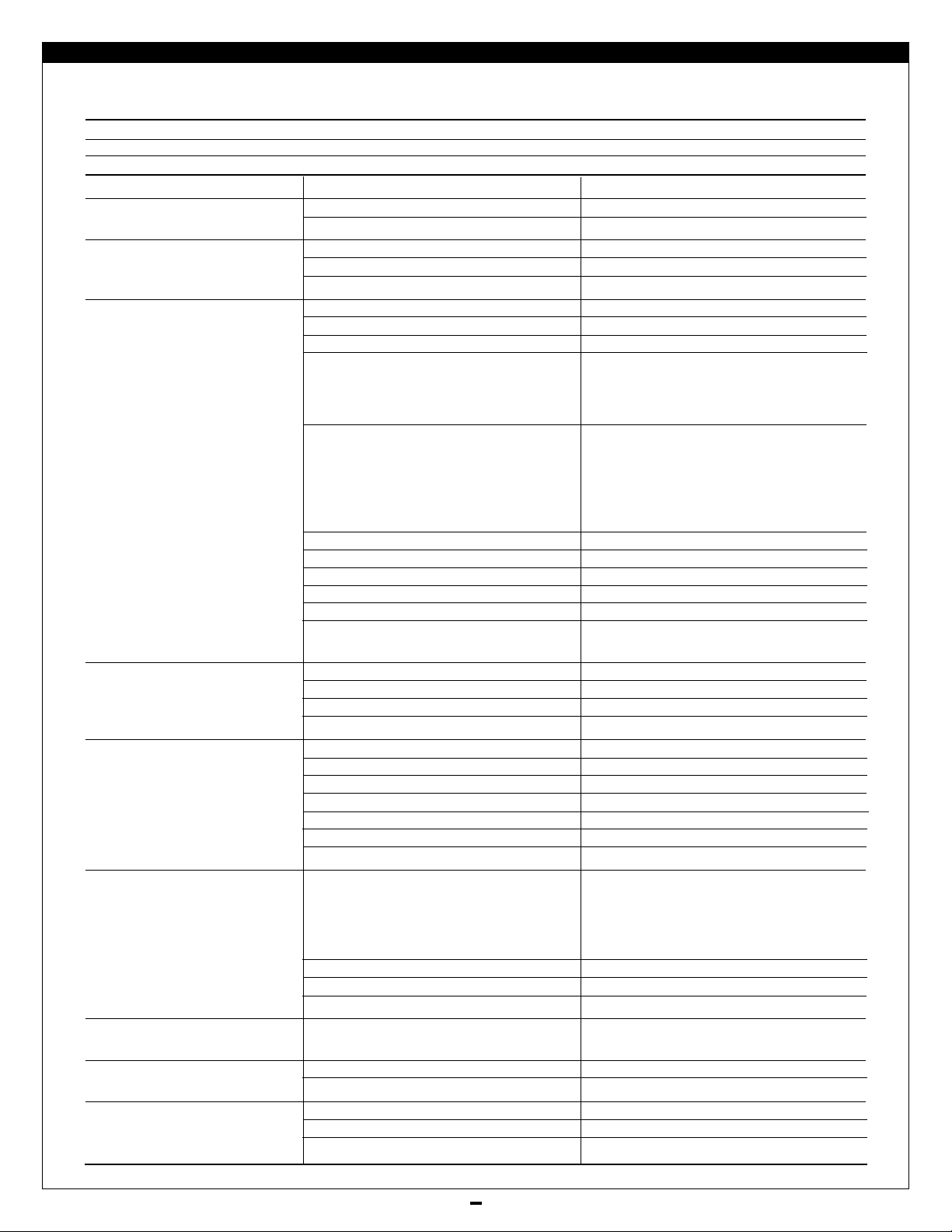

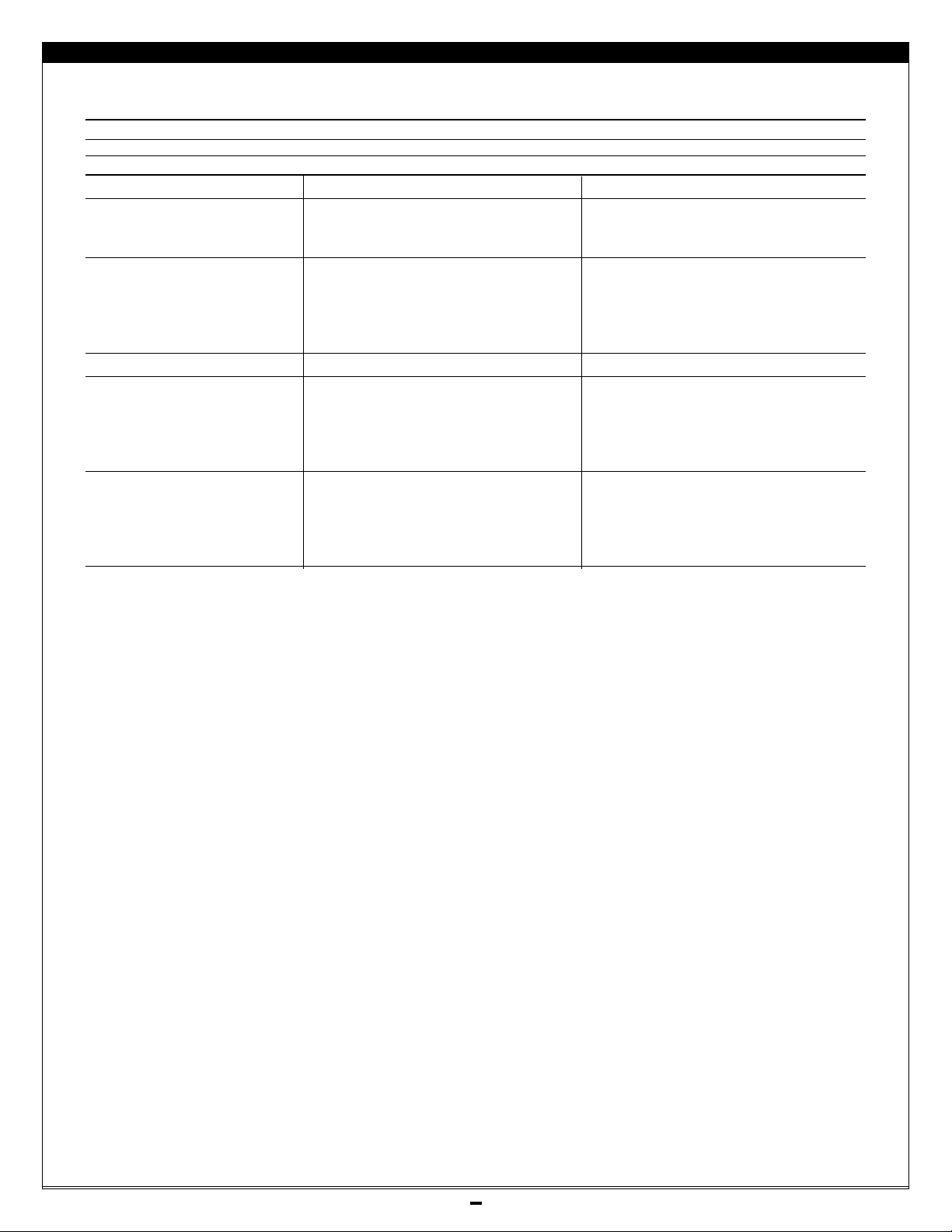

TROUBLESHOOTING CHART A

Visible Alarm Audible Alarm Compressor Power Light

OFF OFF ON ON

Other Symptoms Possible Cause Possible Remedy

Pulsating air noise Intake filter not in place or defective Check filter and replace if necessary

Compressor intake hose disconnected Reconnect hose

Excessive noise Loose or defective motor mounts Replace motor mounts

Defective compressor Replace compressor

efective cooling fan Replace cooling fan

D

luctuating oxygen flow Occluded humidifier Clean or replace humidifier

F

Use of improper humidifier Use only a bubble-type humidifier

Occluded filters Clean or replace filters

Occluded or defective cannula and tubing Detach cannula from oxygen delivery tubing. If

proper flow is not attained, check tubing for

kinks or other obstructions. Clean or straighten

as required or replace tubing if necessary.

Use of excess oxygen tubing The unit is designed to deliver 5 lpm with a

cannula on 50 feet (15 meters) of approximately

5/32” (4 mm) inside diameter tubing. Smaller

diameter tubing or the addition of any other

flow restriction may prevent obtaining the

desired flow rate.

Defective flow meter Replace flow meter

Leak in system Check for leaks in all hoses and fittings

Defective compressor Replace compressor

Defective compressor reed valve Replace compressor reed valve

Defective check valve Replace check valve

Pressure regulator not adjusted Adjust or replace pressure regulator

properly or defective

Little or no oxygen flow Flow meter not adjusted properly Adjust flow meter

Hose disconnected to flow meter Reconnect hose

Oxygen delivery tubing is kinked or blocked Straighten tubing or remove obstruction

Occluded humidifier Clean or replace humidifier

Low oxygen concentration Leak in system Check for leaks in all hoses and fittings

Defective sieve bed check valve Replace check valve

Defective compressor reed valve Replace compressor reed valve

Defective compressor Replace compressor

Rotary valv

Occluded filters Clean or replace filters

Contaminated sieve beds Replace sieve beds

Audible alarm does not

Unit has not been used for an extended Allow unit to run for 20 minutes and retry

sound during power failure period of time.

has been unused for an extended period,

the unit must run several minutes before

the power fail alarm will activate.

Def

Defective power switch Replace power switch

Defective wire harness Replace wire harness

Audible alarm does not sound when

Defective PC board Replace PC board

unit is turned “On”

Pressure relief valve activated - Defective PC board Replace PC board

“popping” sound

Defective rotary valve Replace valve

Service Required light does not Defective PC board Replace PC board

illuminate when unit is turned

“On”

Def

PC board connectors not properly latched Be sure tabs are pushed completely into place

e not operating correctly Replace valve

NOTE: If the concentrator

ective PC boar

e light

ectiv

d Replace PC board

Replace light

11

LT-1928

Page 12

TROUBLESHOOTING

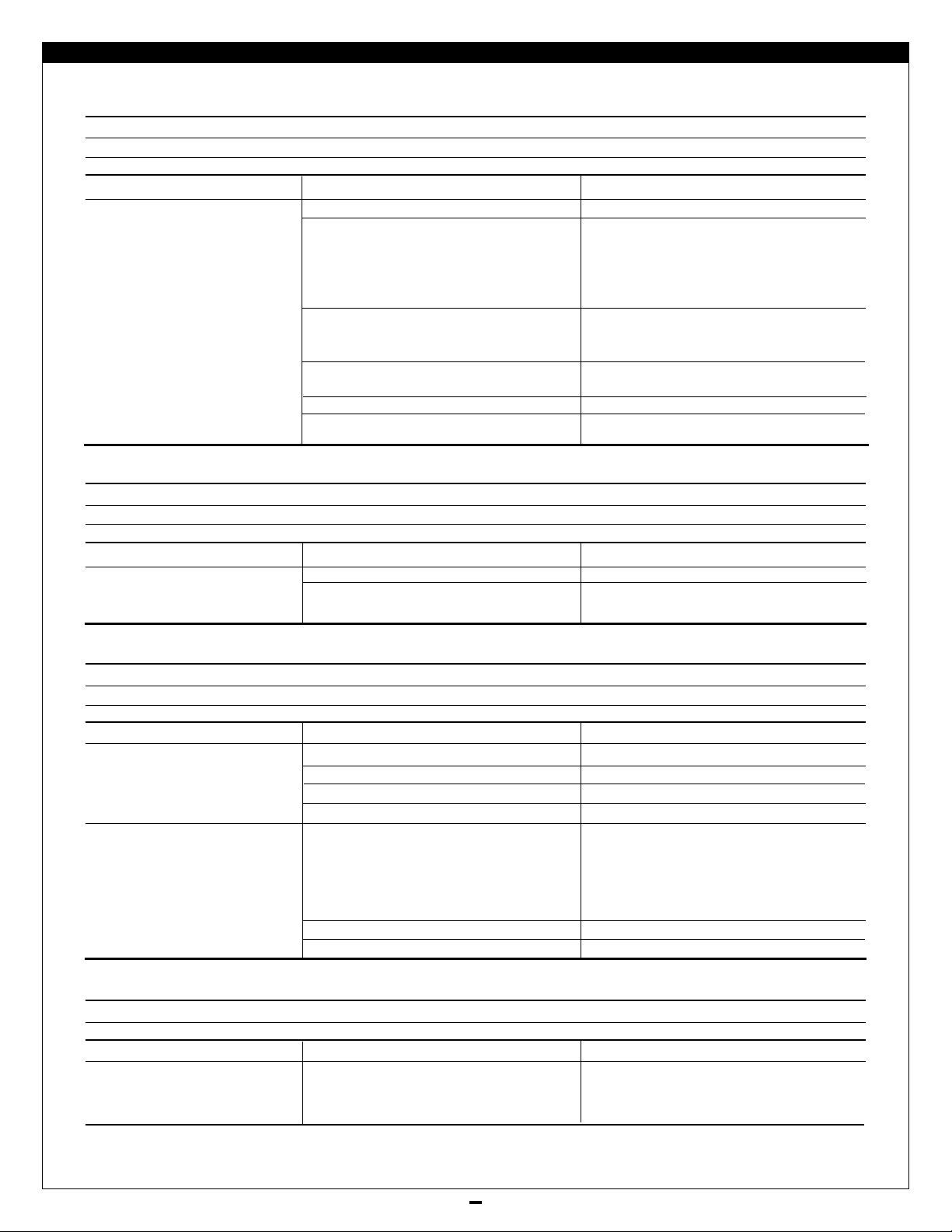

TROUBLESHOOTING CHART B

Visible Alarm Audible Alarm Compressor Power Light

Blinking Pulsing OFF OFF

Other Symptoms Possible Cause Possible Remedy

Fan off Line cord not properly installed or defective Insert plug in receptacle or replace line cord

No power at receptacle Check building circuit breaker or fuse, or have

ouse wiring checked by qualified electrician

h

Circuit may be fully loaded with other

appliances and another receptacle

may be required

xygen concentrator circuit breaker activated Press the circuit breaker reset button

O

If unit circuit breaker opens again,check

internal wiring

Line cord quick-connect terminal inside Reconnect quick-connect terminal

unit is disconnected

Defective power switch Replace power switch

Defective circuit breaker Replace circuit breaker

TROUBLESHOOTING CHART C

Visible Alarm Audible Alarm Compressor Power Light

Blinking Pulsing ON ON/OFF

Other Symptoms Possible Cause Possible Remedy

Fan and compressor operating. Blown fuse on PC board Replace fuse

Pressure relief valve activated – Defective PC board Replace PC board

“popping” sound

TROUBLESHOOTING CHART D

Visible Alarm Audible Alarm Compressor Power Light

ON ON OFF ON

Other Symptoms Possible Cause Possible Remedy

Fan operating Main wiring harness disconnected/defective Reconnect/replace wiring harness

Loose compressor wire Tighten or attach wire

Defective capacitor Replace capacitor

Defective compressor Replace compressor

Unit warm to the touch and cannot Compressor overheated due to:

veral minutes Occluded filters Clean or replace filters

estarted f

be r

TROUBLESHOOTING CHART E

Visible Alarm Audible Alarm Compressor Power Light

ON ON

Other Symptoms

Fluctuating or no flow System pressure below 9 psi (62.1 kPa) due to:

or se

Restricted input or output air passage Remove obstruction

Low or high line voltage Check line voltage; use alternate circuit

independent of other a

Defective cooling fan Replace cooling fan

Defective compressor Replace compressor

ON

le Remedy

ossib

le Cause

ossib

P

Leak in system Check for leaks in all hoses and fittings

ective compressor Replace compressor

Def

P

ppliances

ON

LT-1928

12

Page 13

TROUBLESHOOTING

TROUBLESHOOTING CHART F (OSD UNITS ONLY)

Compressor Power Light

ON ON

Other Symptoms Possible Cause Possible Remedy

No OSD lights are illuminated. Defective OSD. Check concentration with an oxygen analyzer.

If the concentration is within specification, replace

the PC board.

No OSD lights are illuminated, Oxygen level is low* Check concentration with an oxygen analyzer.

ut red “Service Required” light is If the concentration is within specification, replace

b

lluminated accompanied by a the PC board. If the concentration is low,

i

beeping audible alarm. refer to low oxygen concentration

symptom in

Both OSD lights are illuminated. Defective OSD Replace PC board.

Yellow Low Oxygen light Oxygen level is low* Check concentration with an oxygen analyzer.

is illuminated. If the concentration is within specification, replace

the PC board. If the concentration is low,refer to

low oxygen concentration symptom in

Troubleshooting Chart A.

Yellow Low Oxygen light Oxygen level is low* Check concentration with an oxygen analyzer.

is illuminated and an intermittent If the concentration is within specification, replace

audible alarm sounds every the PC board. If the concentration is low,refer to

five seconds. low oxygen concentration symptom in

Troubleshooting Chart A.

*Refer to Specifications page for oxygen purity levels.

Troubleshooting Chart A.

13

LT-1928

Page 14

COMPONENT TESTING, REPAIR, AND REPLACEMENT

PROPER REPAIR PROCEDURES

The DeVilbiss Oxygen Concentrator is designed for ease of

service.To aid service personnel, a Service Kit (part #444-501)

s available which contains the necessary gauges, tools, and

i

testing instruments to properly service the oxygen concentrator. On parts that are sold separately, the part number is indi-

ated in parenthesis.

c

The following parts are included in the Service Kit:

Slotted bit

1

1 #1 Phillips bit

1 #2 Phillips kit

7/16” Socket l/4” Drive

1

1 Crescent wrench

1 8” Duckbill pliers

1 T-10 Bit

1 5/32” Allen bit

1 5/64” Allen bit

1 9/64” Allen bit

1 7/64” Allen bit

2 Presure/Vacuum gauge (part #PVO2D-601)

1 Tool box

2 Test Fittings (part #303DZ-637)

1 Torx screwdriver w/bits

1 AC/DC test light

1 1/4” Ratchet wrench

1 3mm Hexbit

1 T-15 Torx “L” wrench

1 10mm Socket l/4” Drive

1 1/4” Drive extension

1 Plastic storage case

1 Plastic error indicator tool

In addition to the Service Kit, an oxygen analyzer (part #O2ANA)

is needed to periodically check oxygen concentration levels. A voltmeter will be needed for more accurate voltage testing.

NOTE: Be sure to read all of the steps involved before beginning any of the procedures in this manual.

NOTE:After repairing or replacing a component run the unit for

20 minutes,

check the oxygen concentration and test for leaks.

Test for leaks using a certified leak detection solution such as

SWAGELOK #MS-Snoop

®

or equivalent (must not contain

ethylene glycol).Apply leak test solution to all fittings and hose

connections with the unit running.

If an air leak is pr

esent, the

solution will bubble.All leaks should be repaired before putting

the concentrator back in service.

y leak test solution to an

CAUTION:

Do not a

ppl

of the rotary valve or the main PC Board assembly.

WARNING:When servicing the DeVilbiss Oxygen

Concentrator

tools ar

, be absolutely certain that the correct

e fr

e used and that the par

ts ar

ee of oil and

grease or any material not compatible with oxygen.

®

Teflon

the male thr

tape is recommended and must be applied to

eads omitting the first thr

ead to eliminate

y part

the possibility of tape particles entering the oxygen system. LOX-8™ sealant may be used in place of Teflon

tape.

WARNING: Electric shock hazard. Do not remove cabinet.The cabinet should only be removed by a qualified

unrise Medical homecare provider.

S

WARNING: Disconnect the power cord from the wall

outlet before attempting repairs on the unit. Extra

care should be taken if it is necessary to operate the

unit with the cabinet removed.

CABINET REMOVAL

To remove front and back cabinets (Figures 2 & 3):

1. Ensure the unit is unplugged from the wall outlet.

2. Using a screwdriver, remove the six screws that hold the back

cabinet to the internal structure and the bib.

NOTE: All six screws are the same size.

3. Remove the back cabinet by sliding it toward the rear until clear.

4. Remove the front cabinet by pushing the top shoulders toward

the back of the unit, then outward away from behind the bib.

Tilt the top of the front cabinet forward until it can be pulled

out of the base of the unit.

The majority of all the servicing and repairs can be done without removing the front bib. However, to gain access to the

components behind the bib, it may be loosened or removed.

To loosen the bib (Figure 4):

1. Remove the two screws (located directly above the hour

meter) that hold the bib to the unit’s internal structure.This

will allow access to the components behind the bib.

To remove the bib completely (Figure 8):

Remove the two screws as above.

1.

2. Disconnect the ribbon connector from the PC board.

3. Disconnect the lines from the power switch and circuit break-

.

Mark these wires accor

.

er

dingly

4. Tilt the top of the bib forward to release it from the slot in

the body of the concentrator.

5. Remove the hose connected to the bottom of the flow meter.

To reassemble bib:

Reconnect the wir

1.

2. Insert the bib tab into the slot above the rotary valve, and

push until it snaps into place.

3. Secure bib with two screws.

eflon® is a r

T

X-8™ is a trademark of Fluoramics,

LO

Snoop® is a r

es and hose.

ed trademark of DuP

egister

ed trademark of SW

egister

ont.

Inc

A

.

GELOK

LT-1928

14

Page 15

COMPONENT TESTING, REPAIR, AND REPLACEMENT

ACCUMULATOR PRESSURE TEST

To check accumulator pressures:

. Make sure the unit is “Off.”

1

2. Remove front and back cabinets.

. Use the pressure-vacuum gauge (part #PVO2D-601) and pressure

3

test assembly (part #303DZ-637) included in the Service Kit.

. Remove the tubing cap from the accumulator tank fitting and

4

attach the 1/16" (1.6 mm) diameter tubing from the gauge to

the accumulator tank fitting just vacated above.

5. Turn the unit “On” with the flow rate set to maximum recom-

mended flow.

During each timed cycle, the average pressure in the oxygen

accumulator will rise and fall.

NOTE: Normal pressures observed depend on altitude and

flow rate. Increases in altitude and flow rate will slightly

decrease accumulator pressures.Decreases in the two variables

will slightly increase accumulator pressures. Acceptable accumulator pressure swing ranges at various altitudes at the maximum recommended flow are identified in the

NOTE: A defective check valve may cause a rapid drop in

accumulator pressure below the minimum value.

NOTE: A defective compressor will be indicated by slowly

rising pressure. Pressure may only reach a certain level and

then stop.

Low oxygen concentration levels and accumulator pressures

higher than normal may indicate defective sieve beds. Severely

contaminated beds may also cause the pressure relief valve on

the compressor to open.

NOTE: A malfunctioning rotary valve will also cause high

accumulator tank pressure and activation of the pressure relief

valve. In this case it should be determined whether the problem is with the sieve beds, valve, or both.

CITOR

APA

C

The capacitor enables the compressor to start and run by sup-

oltage to the windings of the compressor motor. A

plying v

def

ectiv

e capacitor will r

esult in the compressor running slo

or not starting.

CAUTION: The 515ADS and 515ADZ concentrators

use either a Thomas compressor with a 15 mfd capacitor or a GSE compressor with a 22 mfd capacitor. If

replacement is necessary,be sure the correct capacitor is installed

.

CAUTION: The 515AKS and 515AKZ concentrators

use a GSE compressor with a 10 mfd capacitor. If

r

eplacement is necessar

tor is installed

.

y, be sure the correct capaci-

Specifications.

er

w

WARNING: Electric Shock Hazard.When replacing

the capacitor, do not touch the terminals or allow

metal objects to come in contact with the terminals

on the capacitor.The capacitor may hold a charge for

several days after the unit is turned off.

If a defective capacitor is suspected, a new one must be

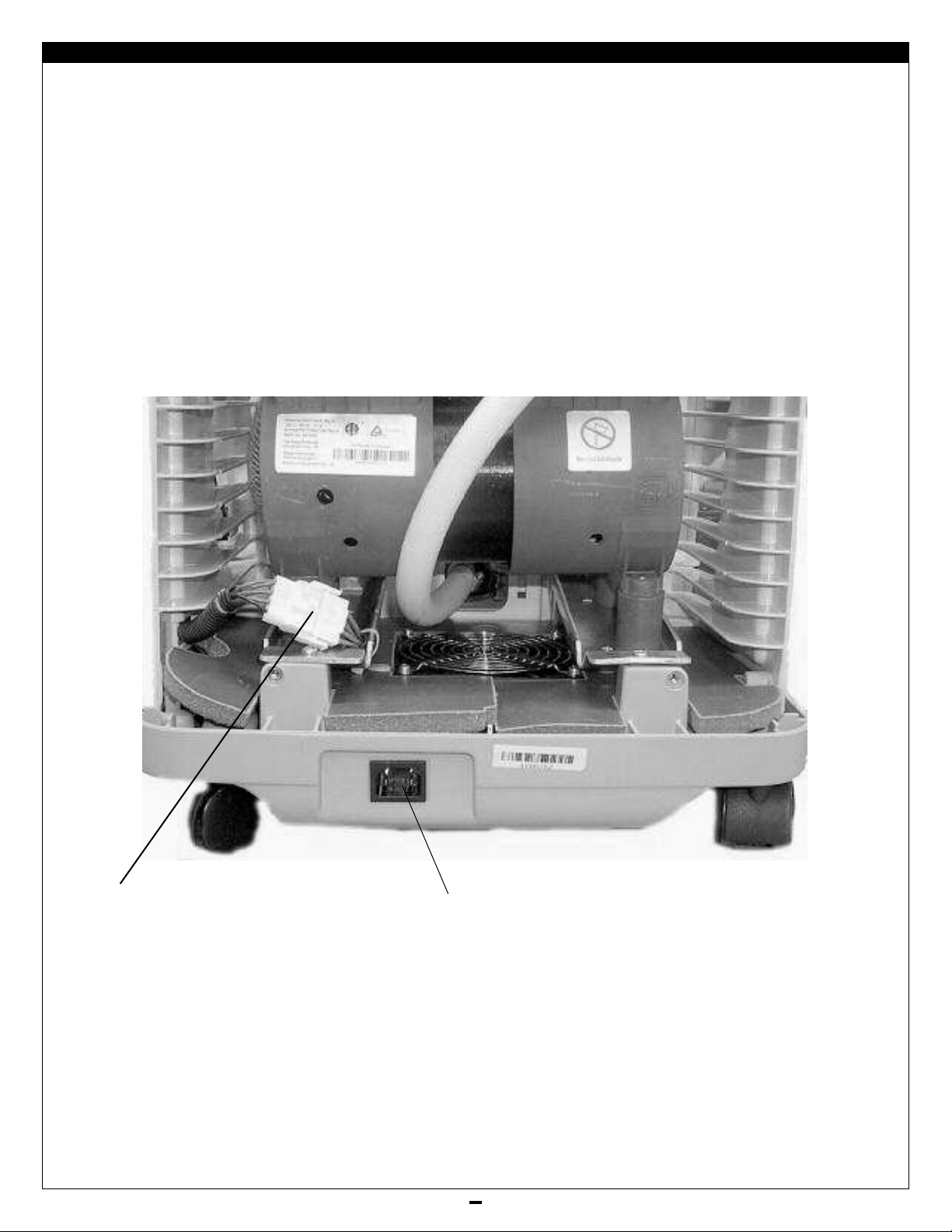

installed.The capacitor is strapped into a well molded into the

ottom of the unit (Figure 10) next to the cooling fan.

b

To replace the capacitor:

1. Make sure the unit is unplugged from the wall outlet.

2. Remove the front and back cabinets.

3. Remove the compressor.

4. Disconnect the two wires from the terminals on the capacitor.

5. Cut the nylon cable tie holding the capacitor in place and

remove the capacitor.

6. Reconnect the wires to the new capacitor.

7. Install the new capacitor and secure with a new cable tie.

8. Replace the compressor.

9. Replace the front and back cabinets and secure with the

six screws.

COMPRESSOR

The DeVilbiss Oxygen Concentrator uses a double-head, oilfree compressor.The compressor is secured to the compressor plate with four rubber motor mounts.

A compressor that is worn or defective may:

• cause pressure to rise slowly.

• cause excessive noise and/or vibration.

• cause lower oxygen concentrations.

A worn or defective compressor can be caused by a defective

internal component such as:

• reed valve

• o-ring

• gasket

• cup seal

These components are included in the Compressor Service

Kit (part #515DZ-643,Thomas or #515ADZ-643, GSE).

CAUTION:

a Thomas compressor or a GSE compressor. Be sure

der the correct part number when rebuilding the

to or

compressor

NOTE:

off if it becomes overheated.This protects the compressor from

damage caused by heat build-up. (Some models have an auxiliary

thermostat mounted within the compr

NOTE: A pressure relief (PR) valve is located on the pressure

head to prevent high pressure build up in the system should a

component malfunction occur.

The 515A series concentrators use either

.

A built-in thermal cutoff switch will shut the compressor

essor compar

tment.)

15

LT-1928

Page 16

COMPONENT TESTING, REPAIR, AND REPLACEMENT

To test the compressor operating voltage (Figure 4):

The compressor requires line voltage to operate. If the com-

ressor does not start when the unit is turned on, the voltage

p

input must be tested:

1. This voltage can be checked at the compressor connector

using a voltmeter or test light connected to the brown and

blue wires.The voltmeter is the best way to test.

2. If no voltage is detected, disconnect power and check for

loose or broken wires between the compressor connector

nd switch or wire harness.

a

3. If there is voltage at the compressor connector, then either

the capacitor or the compressor itself is defective.

To test the compressor for proper output:

NOTE: If the compressor is not providing a high enough

output the patient alert system may be activated.

1. Remove the front and back cabinets.

2. Connect pressure-vacuum gauges to the sieve bed test points.

See the

and Replacement

defective compressor will be indicated by slowly rising pressure. Pressure may only reach a certain level and then stop.

Sieve Bed Pressure Test in the Component Testing, Repair,

section for details on attaching the gauge.A

If these conditions are observed then:

• The unit filter(s) may be occluded—check the air filter and

intake filter for occlusions.

• There may be a severe leak in the system—check for air

leaks using a leak detection solution such as Snoop

equivalent (must not contain ethylene glycol).

CAUTION: Do not apply leak test solution to any part

of the rotary valve or the main PC Board assembly.

• The compressor reed valves, cup seal, or the compressor

itself may be defective (Figures 11A & 12A).

If the filters are not occluded and no leaks are found, the compressor m

ust then be removed and repaired or replaced.

®

or

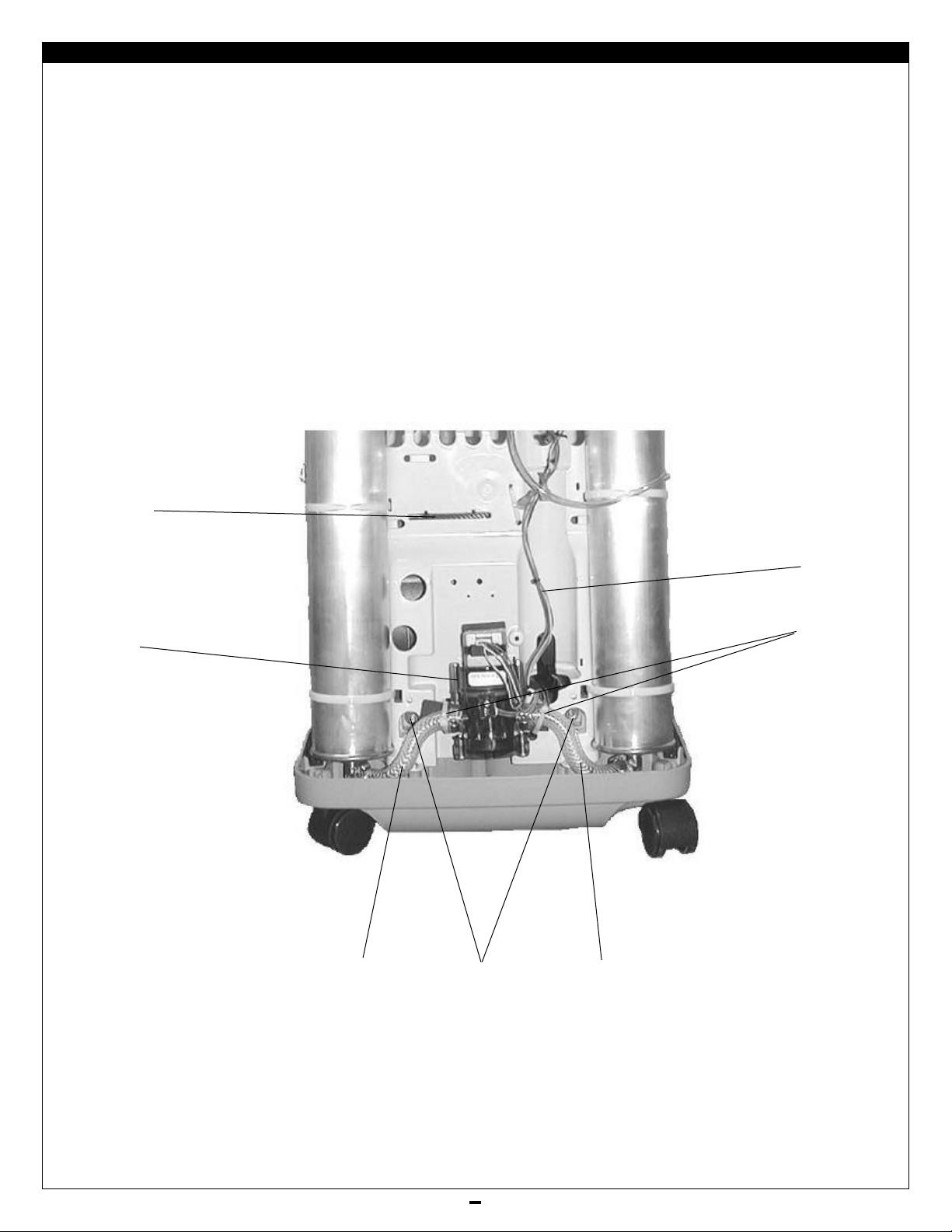

To remove the compressor:

1. Make sure the unit is unplugged from the wall outlet.

y disconnecting the com-

Disconnect the compressor wir

2.

pressor electrical connector (Figure 4).

3. Remove the ladder clamp and hose from the outlet fitting on

the compressor (Figure 4).

4. Remove the two screws from the back of the compressor

mounting plate(s) (Figure 4).

ve the two 10 mm hex nuts that secure the mounting

Remo

5.

plate to the front of the compressor housing (Figure 6).These

nuts are located on each side of the rotary valve.

6. Lift compressor and mounting plate up and out of the com-

pressor housing area.

7. Remove the tubing from the compressor intake port fitting.

CAUTION: If the unit has been running recently, the

compressor may be hot.

es b

To inspect and/or replace internal components (

11A & 12A)

. Remove the eight screws that hold the compressor heads in

1

place.When removing the heads, be sure to keep each head

and its components with the correct compressor side.

2. Check for proper placement of or damage to the gaskets on

the bottom of the compressor heads. Replace if damaged.

3. Remove reed valve plates.A reed valve is located on each side

of the valve plate.

4. The compressor reed valves should be flush with the valve

plate. If the valve is broken or not flush with the valve plate, or

foreign matter is detected inside the head, clean or replace the

compressor reed valves.

:

Figures

To replace the compressor reed valves (Figures 11A

& 12A)

5. Check for proper placement of or damage to the rubber oring on the bottom of the valve plate. Replace if damaged.

6. Remove piston sleeves by pulling upward and inspect cup seal

on pistons. Replace if badly worn or damaged.

:

a. Remove the screw holding the compressor reed valves in

position on the valv

. Position the new reed valves so that they are centered and

b

completely cover the holes in the valve plate.

c. Place the metal retainer on the reed valves and secure

with the reed valve screw.

e plate and discard the used reed valves.

To replace cup seal (Figures 11A & 12A):

a. Remove rod screw from top of piston.

b. Remove the cup retainer plate.

c. Discard defective cup seal.

d. Place new cup seal into position.

e. Replace cup retainer plate.

f. Secure with screws.

7. Reposition sleeve on piston.

NOTE: In some cases, it may be easier to position sleeve on

piston bef

8. Place valve plates on the compressor so that heads of reed

valve screws are aligned with the indentation in top of pistons.

Install the compressor heads so that the holes in the heads are

9.

aligned with the holes in the compressor housing.

10. Secure compressor heads with the screws.

o replace the compressor:

T

NOTE: For mounting plate and motor mount removal, refer

to sections below.Also refer to steps used in removing the

compressor.

CA

use either a Thomas compressor with a 15 mfd capacitor or a GSE compr

515AKS and 515AKZ concentrators use a GSE com

pressor with a 10 mfd capacitor. If replacement is necessar

ore installing a new cup seal and retainer plate.

UTION:

The 515ADS and 515ADZ concentrators

essor with a 22 mfd ca

y, be sure the correct capacitor is installed

pacitor.The

-

.

LT-1928

16

Page 17

COMPONENT TESTING, REPAIR, AND REPLACEMENT

1. Inspect the motor mounts. Replace if damaged. Secure the

mounting plate(s) to the bottom of the new compressor using

the four compressor mounting hex nuts.

2. Inspect the capacitor to determine if replacement is necessary

capacitor is included w/compressor purchase). If capacitor is

(

wrong value for compressor or replacement is desired, refer

to

Capacitor section.

3. Reconnect tubing to the compressor intake fitting.

4. Position compressor on the base of the unit so that the studs

n the mounting plates are aligned with notches on the front

o

of the unit base.

5. Secure mounting plate with two screws on the back and install

nuts on the front side of the plate.

6. Reconnect hose to the fitting at compressor outlet.

7. Reconnect the compressor electrical connector.

To remove compressor from the mounting plate:

1. Turn compressor upside down so that it is resting on the heads.

2. Remove the four compressor mounting hex nuts and mounting plate.

To remove motor mounts:

1. Unscrew studded motor mounts from compressor feet by

hand.

COOLING FAN

The cooling fan provides a constant air flow to cool the

compressor.The cooling fan is located in the bottom of the

unit below the compressor (Figure 10).

A defective cooling fan may cause the compressor’s internal

thermo-protective device to activate and shut the compressor

off. Should this condition occur, the compressor will require

several minutes for the thermo-protective device to reset.

If the cooling fan is defective, it must be replaced:

Make sure the unit is unplugged from the wall outlet.

1.

2. Remove the front and back cabinets.

3. Remove the compressor.

Disconnect the cooling fan terminals.

4.

5. Note the position of the fan and fan guard before removing

the four retaining screws that secure the fan to the base of

the unit.

6. Remove the defective fan and secure the replacement fan in

position with the four retaining screws.

NOTE:When installing the fan, be sure the air flow directional

ow on the side of the fan is directed away from the compressor

arr

and fan guard is reinstalled properly.

Reconnect the electrical connector

7.

.

Reinstall the compr

8.

essor

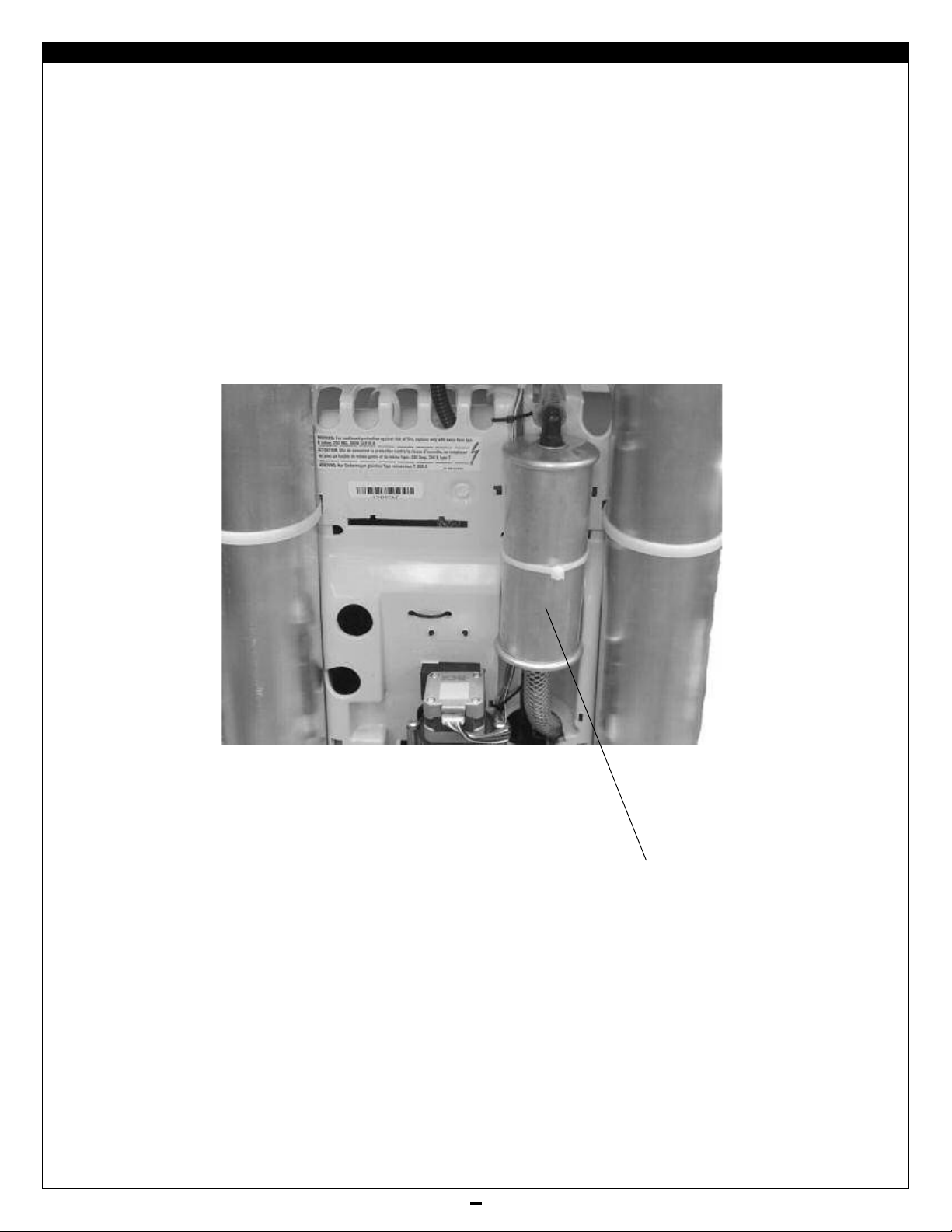

FINAL CHECK VALVE

This check valv

xygen outlet fitting.

the o

e is located betw

This check valv

.

een the final bacteria filter and

xygen to

ws o

e allo

flow only out of the unit.When the unit is turned off and oxygen flow stops, the check valve closes to prevent water from

being drawn into the unit.

A defective final check valve may allow water to be drawn in

rom the humidifier bottle when the unit is turned off.This

f

may occlude the final bacteria filter and/or the flow meter

causing a restriction of flow and making it difficult to adjust

he flow rate.

t

To replace the final check valve (Figure 8):

1. Make sure the unit is unplugged from the wall outlet.

2. Remove the front and back cabinets and loosen or remove the bib.

3. Remove the hose from the outlet side of the final bacteria filter.

4. Remove the two screws from the back of the oxygen outlet

fitting assembly and remove the assembly.

5. Remove the hose from each end of the final check valve.

6. Attach the hoses to a new check valve. Make sure that the

flat side of the check valve is directed toward the oxygen

outlet fitting.

7. Replace the outlet fitting assembly and connect the hose to

the filter.

8. Replace the bib and front and back cabinets.

FLOW METER

The pressure-compensated flow meter has an accuracy level of

±5% at full scale (exception: +0%,-5% at 5 lpm).The flow

meter on the DeVilbiss Oxygen Concentrator is designed for

use at 8.5 psi (58.6 kPa) at flow rates up to 5 lpm.

To check for leaks in the flow meter tubing:

1. Check for leaks using a certified leak detection solution such

as Snoop

2. Apply leak test solution to all fittings and hose connections

with the unit running.

CAUTION: Do not apply leak test solution to any part

of the rotary valve or the main PC Board assembly.

3. If an air leak is present, the solution will bubble.All leaks should be

epair

r

W

leak testing near electrical connections.

®

or equivalent (must not contain ethylene glycol).

e putting the concentrator back in service.

ed befor

ARNING: Electric Shock Hazard. Use caution when

To replace the flow meter (Figure 8):

1. Make sure the unit is unplugged from the wall outlet.

e the front and back cabinets.

v

Remo

2.

3. From behind the bib remove the 2 hoses from the flow meter.

4. While squeezing tabs on flow meter brackets, push the flow

meter through the bib.

5. Install new flow meter in bib and reconnect hoses.

17

LT-1928

Page 18

COMPONENT TESTING, REPAIR, AND REPLACEMENT

HOUR METER

To replace the hour meter (Figure 9):

. Make sure the unit is unplugged from the wall outlet.

1

2. Remove the front and back cabinets and loosen the bib.

. Disconnect the hour meter connector from the PC board.

3

4. Remove the meter by carefully inserting a small flat screwdriv-

r under the outer edge of meter and prying upward.

e

5. Install a new hour meter by applying downward pressure until

it snaps into position.

6. Connect the hour meter to the PC board.

CAUTION: Do not apply any force or flex the PC

Board when connecting or disconnecting electronic or

pneumatic components. Damage to the electronic

assembly is possible.

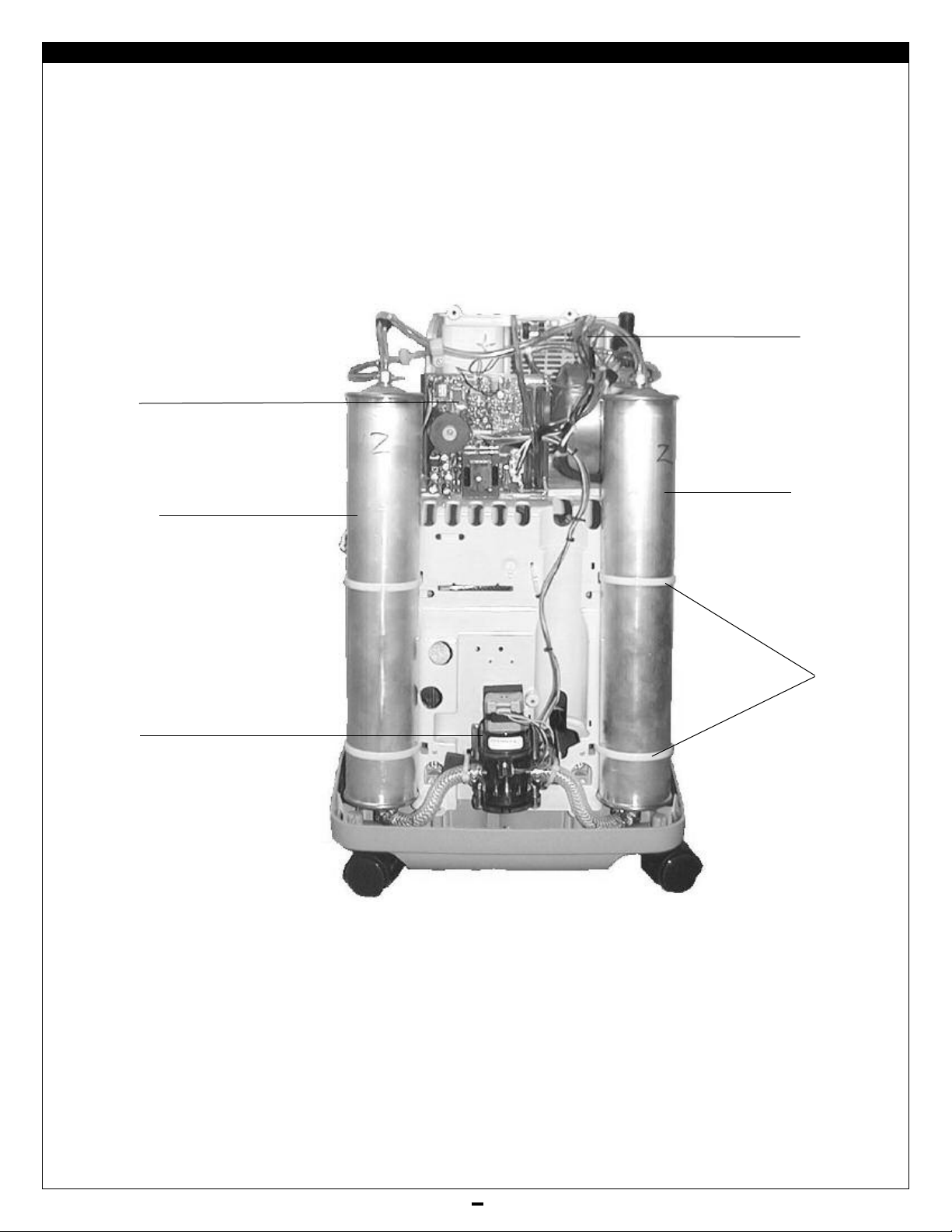

MOLECULAR SIEVE BEDS

The two molecular sieve beds alternately remove the nitrogen

from the air passing through them and provide the patient

with a constant supply of oxygen.

The efficiency of the molecular sieve material will be impaired

if it becomes contaminated by moisture. Contamination causes

the molecular sieve material to lose its nitrogen adsorbing

properties resulting in a decrease in oxygen concentration.The

unit should run for a minimum of 20 minutes before turning

"Off" to prevent problems associated with moisture contamination in the system.

To test the sieve beds:

1. Remove the 1/16" plugged piece of tubing from the top of

each sieve bed.

2. Connect the pressure-vacuum gauges to the sieve bed test

points (Figure 9) in order to observe unit cycling and bed

pressures. Refer to the section on

Normal Operating Sequence.

3. If it is determined that the valve did not shift, refer to the sec-

tion on

Rotary Valve testing. However, if the unit is cycling prop-

erly allow unit to run while observing the sieve bed pressures.

After 20 minutes of operation, check the oxygen concentra-

4.

tion levels. Low oxygen concentration and high pressures indicate contaminated sieve beds.

NOTE:If the molecular sieve material is found to be no longer

effective, first locate the source of the malfunction or cause

(such as leaks) for contamination and take corrective action.

To replace the molecular sieve beds (Figures 5, 6, &7):

1.

Make sure any contamination problem has been corrected

before replacing.

Make sure the unit is unplugged from the wall outlet.

2.

3. Cut the plastic cable ties that secure the sieve beds to the

internal structure of the unit.

e the tubing from the fittings at the top of each sieve bed.

v

Remo

4.

ve the hose clamps and hose from the bottom of the

Remo

5.

sieve beds.

6. Install new sieve beds in reverse order using new plastic cable

ties. Position the new beds so that the bed serial number label

is at the top of the unit.

NOTE: Make sure that the sealing caps remain on the new

ieve beds until just prior to connecting hoses and tubing.

s

7. Leak test all connections with a certified leak detection solution

®

uch as Snoop

s

r equivalent (must not contain ethylene gly-

o

col).Apply leak test solution to all fittings and hose connections with unit running. If an air leak is present, the solution

will bubble.All leaks should be repaired before putting the unit

back in service.

CAUTION: Do not apply leak test solution to any part

of the rotary valve or the main PC Board assembly.

POWER CORD

To replace the power cord - 115 volt units only

(Figure 4):

1. Make sure the unit is unplugged from the wall outlet.

2. Remove the back cabinet.

3. Disconnect the power cord connector.

NOTE: Loosening or removing the compressor mounting

plate may make it easier to service the power cord.

4. Note wire colors and socket locations before removing wires.

5. Using a pair of duckbill pliers, squeeze the power cord strain

relief and pull it out of the base of the unit.

6. Insert a new power cord through the hole in the base of the

unit and secure with strain relief.

7. Insert sockets into connector housing and then reconnect the

power cord connector.

8. Replace back cabinet and secure with the six screws.

POWER SWITCH

To replace the power switch (Figure 8):

e sure the unit is unplugged fr

1. Mak

2. Remove the front and back cabinets and loosen the bib.

3. Note the position of the wires and switch before removing

the wires from the switch terminals.

4. While squeezing the locking tabs on the sides of the switch,

push the switch out of the front of the bib.

5. Install the new switch in the correct orientation making sure

that it locks into position.

6. Reconnect the wires to the switch terminals.

PRESSURE REGULATOR

The pr

essure regulator stabilizes the flow of oxygen to the

patient and establishes back pressure on the system. It is preset at 8.5 psi (58.6 kPa) and should not have to be adjusted in

the field.

om the wall outlet.

To test the pressure regulator:

urn the unit

T

1.

Set the flo

2.

“On.”

w meter at 2 lpm.

LT-1928

18

Page 19

COMPONENT TESTING, REPAIR, AND REPLACEMENT

3. Use a pressure-vacuum gauge (part #PVO2D-601) and a fitting

suitable to fit on the oxygen outlet or on a short piece of tubing connected to the outlet.

4. If the pressure-vacuum gauge reads anything other than 8.5 ±

5 psi (58.6 ± 5.9 kPa) with gauge outlet blocked, adjustment

.

to the pressure regulator may be required. If so, call Sunrise

Service Department at

NOTE:

Make sure no leaks exist before adjusting the

1-800-333-4000 (814-443-4881).

pressure regulator. by using a certified leak detection solution

such as Snoop

®

or equivalent (must not contain ethylene gly-

col).

CAUTION: Do not apply leak test solution to any part

of the rotary valve or the main PC Board assembly.

A malfunction in the pressure regulator will cause either a loss

or fluctuation in the oxygen flow which will be seen on the

flow meter or a decrease in oxygen concentration.

To replace the pressure regulator (Figure 9):

1. Make sure the unit is unplugged from the wall outlet.

2. Remove the front and back cabinets.

3. Remove the tubing clamp and tubing from the pressure regulator.

4. Unscrew the regulator from the accumulator tank.

5. Install a new regulator on the accumulator tank and attach the

tubing and tubing clamp.

6. Replace the front and back cabinets.

PRINTED CIRCUIT BOARD

The printed circuit (PC) board is responsible for monitoring

and controlling the DeVilbiss Oxygen Concentrator.

The PC board has preset alarms for low flow and power failure. Should any of the alarm values be exceeded, the patient

alert system will activate.

NOTE: If the concentrator has been unused for an extended

period, the unit must run 20 minutes before the power fail

alarm will be enabled.

This alarm is powered by a capacitor on

the PC board.

UTION: Do not apply any force or flex to the PC

CA

Board when connecting or disconnecting electronic or

pneumatic components. Damage to the electronic

assemb

ly is possible.

To remove and replace the PC board (Figure 7):

1. Make sure the unit is unplugged from the wall outlet.

2. Remove the front and back cabinets and the bib.

terminals and connectors.

3. Disconnect all wir

4. Remove the 1/8" (3.2mm) tubing attached to the sensor.

e the screw that secures the board to the unit and

v

Remo

5.

e the PC boar

v

emo

r

6. Install the new PC board and secure it using the screw.

Reconnect all electrical wir

7.

tubing to the sensor

8. Replace the bib and front and back cabinets.

es ,

d.

terminals,

es,

connectors and the

.

ROTARY VALVE (Figure 13)

The timed rotary valve alternately distributes pressure supplied by the compressor to the sieve beds.While one bed is

eing pressurized the other bed is being exhausted through

b

the valve. Exhaust gases go through the valve exhaust port and

exit through the exhaust muffler.

The valve contains two revolving discs powered by a stepper

motor to cycle the pressure between the beds.DC voltage is

supplied by the PC board to the motor windings causing the

internal discs to turn and direct pressure to the proper sieve bed.

If the rotary valve does not shift properly the same bed may

ontinue to pressurize causing the pressure relief valve to

c

release the excess pressure.

There are several reasons why the rotary valve could malfunction; therefore the cause of failure must be determined before

corrective action can be taken.

To test the rotary valve (Figures 6 & 7):

1. Remove the front cabinet.

2. Connect pressure gauges to the test points at the top of the

sieve beds in order to observe unit cycling and bed pressures.

Refer to the section on

3. If it is determined that the valve did not shift properly or the

bed pressures are uneven, continue testing with step 4.

4. The stepper motor on the rotary valve has multiple windings

so there are several voltage readings that need to be checked

in order to determine if the problem is being caused by the

PC board or the valve itself.Testing for proper voltage is done

at the wire harness connectors on the valve or on the PC

Board using a voltmeter. Below are the valve voltage test positions and voltages that should be present at each one:

Negative Lead Positive Lead Voltage Reading

Orange Yellow or White 12 VDC

Orange Gra

Orange Brown 5 VDC

Black or Green or

Red or Blue

TE:

NO

The 2-3

cycles. 515A Series have a fixed cycle time of approximately 7

seconds. However, when the ADS model (with OSD) goes into

“turn-do

its