Page 1

More Power Less Noise

WARNING

ADVERTENCIA

AVERTISSEMENT

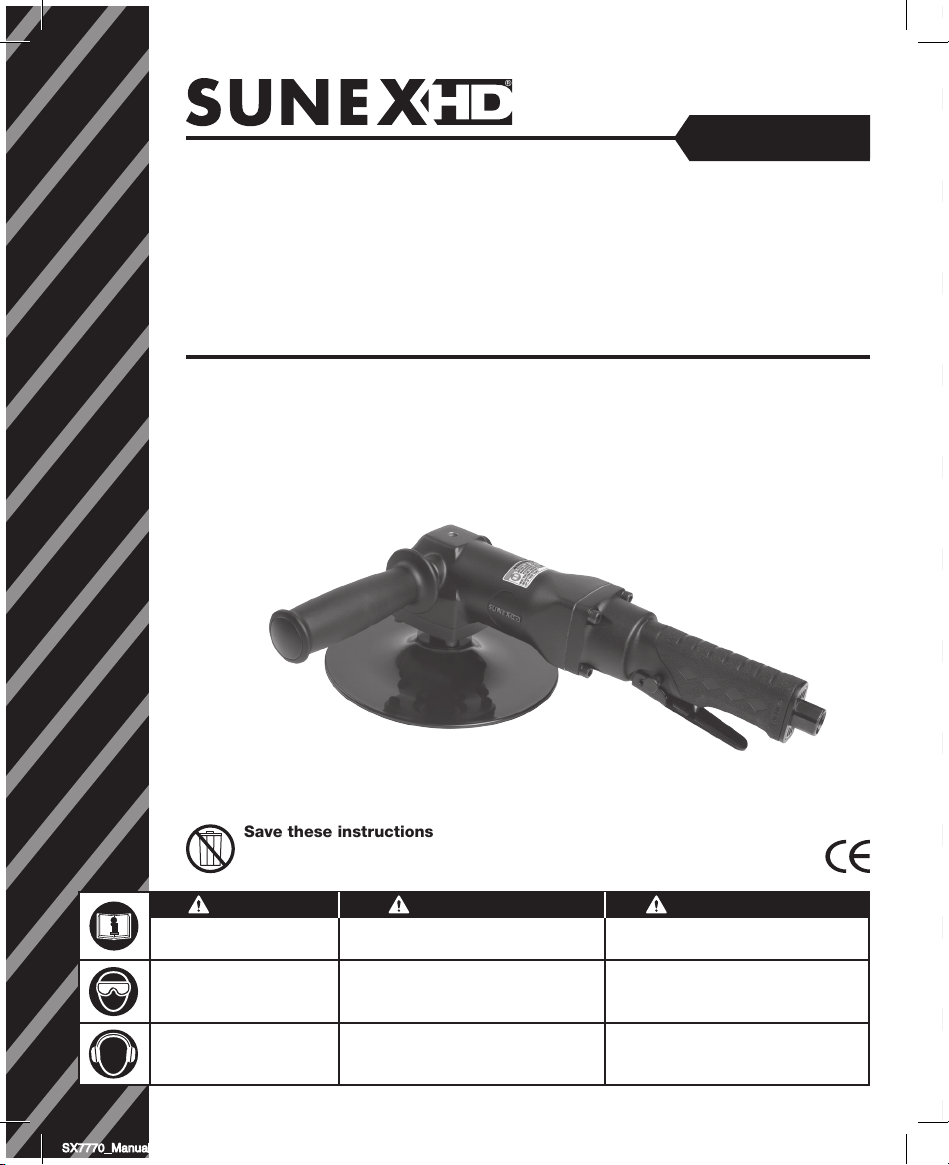

7" HORIZONTAL POLISHER

PULIDORA HORIZONTAL 7"

POLISSEUSSE HORIZONTALE 7 PO

Product Safety Information

Información de seguridad del producto

Informations de sécurité liées au produit

SX7770

Save these instructions

Guarde estas instrucciones

Sauvegarder ces instructions

Read this manual before

operating tool.

Always wear eye protection

when operating or performing

maintenance on this tool.

Always wear hearing

protection when operating

this tool.

SX7770_Manual_012412.indd 1 1/27/12 9:07 AM

Lea este manual antes de operar esta

herramienta.

Siempre lleve puesto protección de

ojos al momento de operar o realizar

mantenimiento a esta herramienta.

Siempre lleve puesto protección del oído

al momento de operar esta herramienta.

Sauvegarder ces instructions.

Veuillez lire le présent manuel avant

d’utiliser l’outil.

Toujours porter le dispositif de

protection antibruit lorsque vous

utilisez cet équipement.

Page 2

To reduce the risk of injury, anyone using, repairing, maintaining, or

WARNING

changing accessories on this tool must read and understand these

instructions before performing any of these tasks.

Always inspect, operate, and maintain this tool in

accordance with American National Standards Institute

Safety Code of Portable Air Tools (ANSI B186.1) and any

other applicable safety codes and regulations.

These tools are rated at 90 psi / 6.2 bar max air pressure

for safety, top performance, and maximum durability of

parts; do not exceed this pressure while the tool is running.

Always shut off air supply, drain hose of air pressure and

disconnect tool from air supply when not in use, before

changing accessories, or when making repairs.

Never direct air at yourself or anyone else.

Always wear impact-resistant eye and face protection when

operating or performing maintenance on this tool.

High sound levels can cause permanent hearing loss.

Always use hearing protection when using this tool as

recommended by your employer or OSHA regulation.

Do not wear jewelry or loose fitting clothes.

Do not use quick disconnect couplings at tool. See operating

instructions for proper set up.

Whipping hoses can cause serious injury. Always carefully

check for damaged or loose hoses and fittings before

operating this tool.

Avoid direct contact with accessories during and after use.

Gloves should be worn to reduce the risk of cuts or burns.

Never run the tool off of the work. The tool may run too fast

and cause the accessory to be thrown off of the tool.

Never use a backing pad, drum or abrasive with a permitted

speed lower than the air sander speed.

Use only recommended sizes and types of abrasives.

Ensure that sanding disks are mounted concentrically.

Never mount a grinding wheel on a sander. A grinding

wheel that burst can cause serious injury or death when not

properly guarded.

Inspect backing pad before each use. do not use if cracked

or damaged.

Never run the tool unless the abrasive is in contact with the

workpiece.

There is a risk or electrostatic discharge if used on plastic

and other non-conductive materials.

Slipping, tripping, and/or falling while operating air tools can

be a major cause of serious injury or death. Be aware of

your surroundings and any excess hose left on the walking

or working surface.

Pneumatic tools can cause vibration in use. Vibration,

repetitive motions or uncomfortable positions over extended

periods of time may be harmful to your hands and arms.

Discontinue use of tool if discomfort, tingling feeling or pain

occurs. Consult a physician before resuming use if any of

these symptoms occur.

Do not stretch or overreach while using this tool.

If tool appears to malfunction, remove from service

immediately and arrange for repair.

Never use tool if there is any chance of coming into contact

with line electricity.

Use only Sunex certified spare parts for any repair made to

tool. Repairs should only be performed by properly trained

persons.

Do not lock, tape or wire the tool valve in the "on/off"

position.

Do not allow the exhaust air to come in contact with hot

surfaces or flames.

Avoid inhaling dust or handling debris from the work

process, which can be harmful to your health. Use dust

extraction and wear respiratory protective equipment when

working with materials which produce airborne particles.

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains

chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm. Some

examples of these chemicals are:

- Lead from lead based paints

- Crystalline silica bricks and cement and other

masonry products

- Arsenic and chromium from chemically-treated

lumber

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Additional Safety Warnings

Do not modify this tool or its accessories.

Daily measure the air tool speed with tachometer to make

sure it is not greater than the RPM stated on the backing

pad, drum or abrasive.

This tool is not recommended for use in explosive

atmospheres or underwater use.

Operators and maintenance personnel must be physically

able to handle the bulk, weight, and power of this tool.

This tool is for professional use only.

SAFETY INSTRUCTIONS - DO NOT DISCARD - GIVE TO USER

SX7770: Parts Breakdown & Operating Manual 2 1/24/12

SX7770_Manual_012412.indd 2 1/27/12 9:07 AM

Page 3

Instruction Manual

This tool is designed for polishing. No other use is permitted.

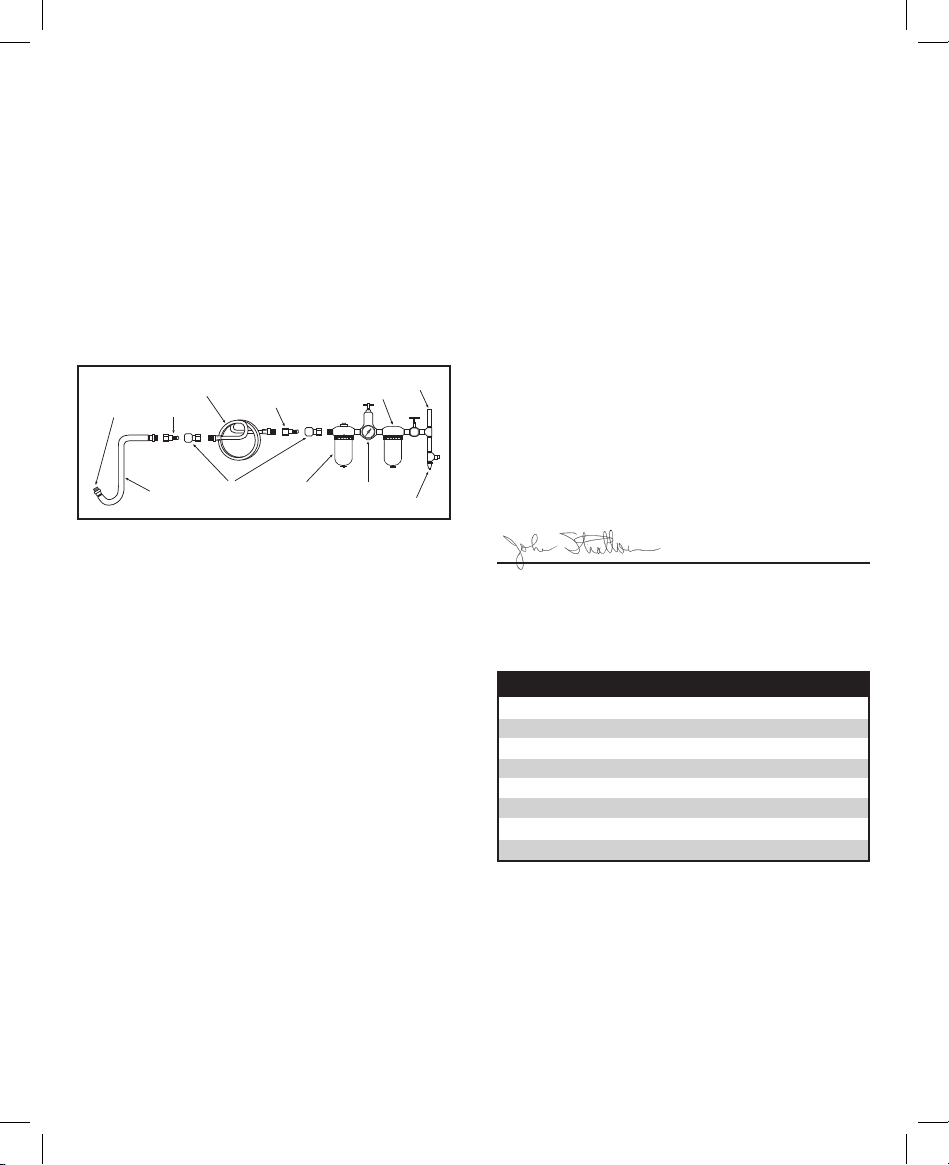

Air Supply Requirements

Tool is designed to operate at 90 psi (6.2 bar) at free speed

measured at the tool, of clean, dry air. Operating this tool at

higher pressures will drastically reduce the tool life and could

cause injury.

The air inlet thread on this tool is a standard 1/4" NPT.

Line pressure should be increased for any unusually long

air hose run (over 25 feet). Minimum hose diameter should

be 3/8" I.D. and all fittings should have the same inside

diameter. See diagram below for proper air supply setup.

Do Not Install

Quick Coupling

Here

Hose

Nipple

Whip Hose

Nipple

Regulator Oiler Quick Coupler Leader

Filter

Air Supply

Drain Daily

Lubrication

Lubricate the tool each day after use with quality SAE #10

air motor oil. Add the oil to the air inlet or into the hose at the

nearest connection to the air supply, then run the tool until

all excess oil is expelled from the exhaust. Total oil quantity

needed for this procedure is approximately 1 ounce. If using

an air line lubricator adjust to two drops per minute.

EC DECLARATION OF CONFORMITY

We, Sunex International Inc., 315 Hawkins Rd, Travelers Rest,

SC 29690, declare under our sole responsibility that the

product to which this declaration relates, is in conformity with

the requirements of the Council Directive of June 1998 on the

approximation of the laws of the Member States relating to

machinery. (EN792, 98/37/EC)

Harmonized Standards Applied:

EN 792-6

National Standards Applied:

ISO 8662-7, ISO 15744-2002

Machine Name:

SX7770 Horizontal Polisher

Serial No.:

MS012010 or higher

Techical Data:

Pad Diameter: 7"

Spindle Thread Size: 5/8"-11

Free Speed: 2,500 RPM

Air Pressure: 90 psi (6.2 bar)

Noise and Vibration Declaration

Tool produces a noise level (no load) of 85 dBA sound pressure

with 3 dBA uncertainty per EN ISO15744-2002. Vibration level

is <2.5 m/s² tested per EN 28662-1 & EN28662-7:1997

Signature of Issuer:

Name and Position of Issuer: John Stratton, Product Manager

Sunex International Inc.

Date of Issue: January 4, 2012

Specifications

Pad Diameter ......................................................7" (178mm)

Spindle Thread Size .................................................. 5/8"-11

Free Speed .......................................................... 2,500 RPM

Length ..............................................................12" (305mm)

Weight ............................................................ 4.4 Lbs. (2 kg)

Avg. Air. Cons. .............................................6 cfm (170 l/min)

Air Inlet ................................................................... 1/4" NPT

Min. Hose Size ............................................ 3/8" I.D. (10mm)

SX7770: Parts Breakdown & Operating Manual 3 1/24/12

SX7770_Manual_012412.indd 3 1/27/12 9:07 AM

Page 4

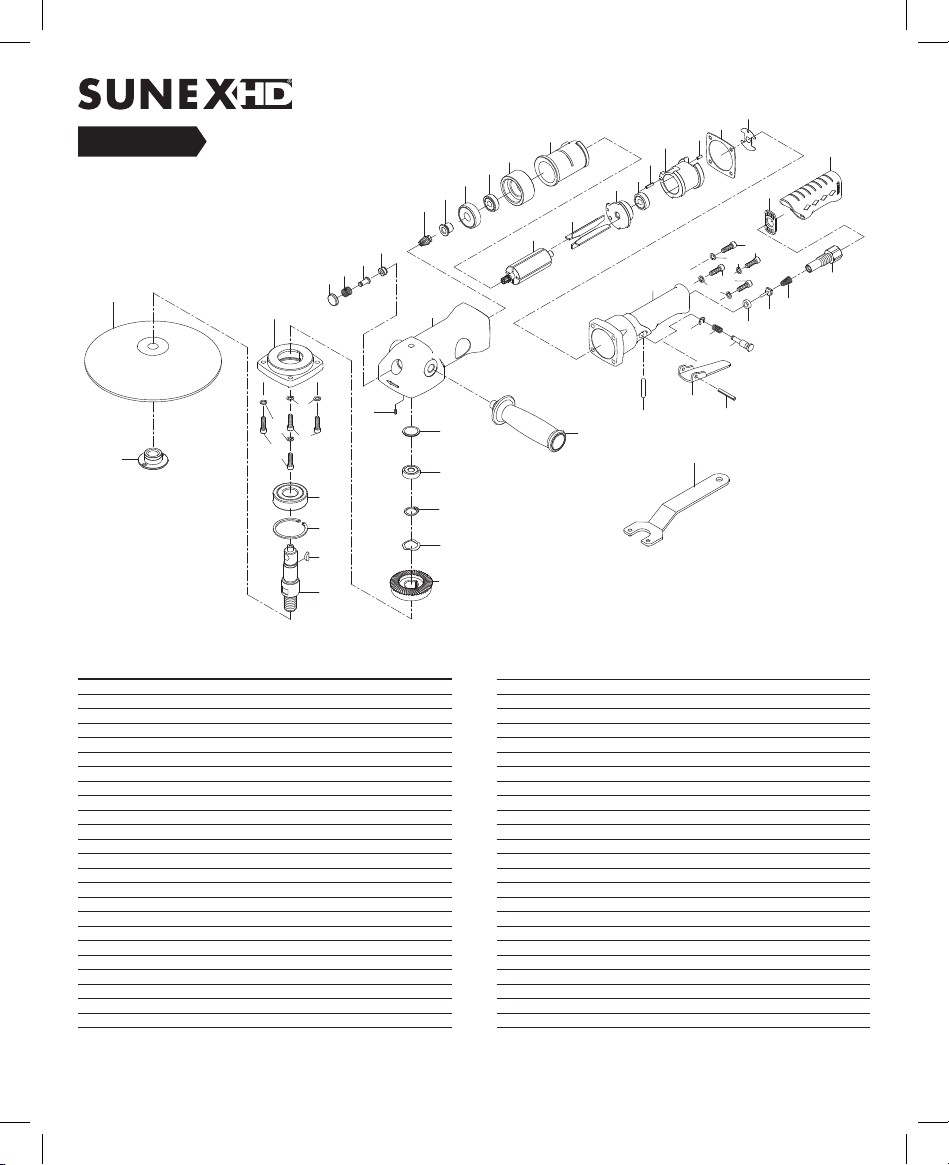

SX7770

7" HORIZONTAL POLISHER

42

36

33

46

20

18

19

23

32

45

27

48

40

41

16

15

23

14

1

21

17

22

39

38

12

13

2

12

13

6

9

7

10

11

3

8

13

13

12

37

12

47

35

30

31

24

REF. PART

NO. NO. DESCRIPTION QTY.

1 RS787001 Motor Housing 1

2 RS787002 Valve Housing 1

3 RS787003 Air Inlet 1

4 RS787004 Throttle Lever 1

5 RS787005 Valve Pin 1

6 RS24051 Valve 1

7 RS24050 Valve Seat 1

8 RS24052 Spring 1

9 RS787009 E-Ring (ETW-4) 1

10 RS787010 Spring 1

11 RS787011 Safe Lever 1

12 RS787012 Screw (M5 x 22L) 8

13 RS187144 Washer (M5) 8

14 RS787014 End Plate 1

15 RS787015 Rotor 1

16 RS21125 Rotor Blade 4

17 RS787017 Exhaust Deflector 1

18 RS787018 Cylinder 1

19 RS21120 Front End Plate 1

20 RS787020 Gasket 1

21 RS787021 Spring Pin (3 x 6L) 1

22 RS787022 Spring Pin (3 x 12L) 1

23 RS30524 Ball Bearing (608ZZ) 3

24 RS787024 Spindle (5/8"-11) 1

4

29

43

5

34

44

23

25

26

28

REF. PART

NO. NO. DESCRIPTION QTY.

25 RS787025 Retaining Ring (STW-16) 1

26 RS787026 Spring Washer (WW-16) 1

27 RS777027 Pinion Gear 1

28 RS787028 Bevel Gear 1

29 RS787029 Spacer 1

30 RS787030 Retaining Ring (RTW-40) 1

31 RS787031 Key (3 x 13) 1

32 RS21118 Ball Bearing (6201Z) 1

33 RS787033 Spindle Cap 1

34 RS787034 Spring Pin (4 x 25L) 1

35 RS21438 Ball Bearing (6203ZZ) 1

36 RS787036 Back Disc (5/8"-11) 1

37 RS787037 Disc Nut (5/8"-11) 1

38 RS787038 Exhaust Diffuser 1

39 RS787039 Rubber Grip 1

40 RS787040 Shaft 1

41 RS787041 Spring 1

42 RS787042 Press Button 1

43 RS41255 Handle 1

44 RS41254 Pin Wrench 1

45 RS777045 Bushing 1

46 RS787045 Motor Gasket 1

47 RS787046 Set Screw 1

48 RS787047 Bushing 1

SX7770: Parts Breakdown & Operating Manual 4 1/24/12

SX7770_Manual_012412.indd 4 1/27/12 9:07 AM

Page 5

Warranty Service Centers:

Air & Hydraulic Repair

315 Hawkins Road

Travelers Rest, SC 29690

TEL# 877-786-3939

Power Tool Repair

891 Moe Drive Suite H

Akron, OH 44310

TEL# 330-630-0022

Discount Tool Repair

3433 Losee Road #1

North Las Vegas, NV 89030

TEL# 702-657-6570

Tri-County Power Tool, Inc.

4597 Pearl Rd.

Cleveland, OH 44109

(216) 398-6120

Diversified Power Inc.

90 Buttermill Avenue,

Vaughan, Ontario

L4K 3X7 Canada

Tel: 905-760-9077

Toll Free: 800-821-7975

Limited 2 Year Warranty:

SUNEX INTERNATIONAL INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX HD® AIR TOOLS ARE FREE FROM

DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International Inc. will repair or replace its Sunex HD® air tools which fail to give satisfactory service due to defective

workmanship or materials, based upon the terms and conditions of the following described warranty plan. This product carries

a TWO-YEAR warranty. During this warranty period, Sunex Tools® will repair or replace at our option any tool which proves to be

defective in material or workmanship.

Other important warranty information….

This warranty does not cover damage to tools arising from alteration, abuse, misuse, damage and does not cover any repairs or

replacement made by anyone other than an authorized Sunex HD® service center from the list above. The foregoing obligation is

Sunex International Inc.’s sole liability under this or any implied warranty, and under no circumstances shall we be liable for any

incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

Return the tool to your nearest authorized Sunex HD® warranty service center, transportation prepaid. Be certain to include your

name, address, and proof of purchase date, along with a description of the suspected defect. If you have any questions about

warranty service, please contact Sunex Tools® at 1-800-833-7869, or on the internet at www.sunextools.com. This warranty

gives you specific legal rights and you may also have other rights which vary from state to state.

Shipping Address:

Sunex Tools® • 315 Hawkins Rd. • Travelers Rest, SC 29690

Mailing Address:

Sunex Tools® • P.O. Box 1233 • Travelers Rest, SC 29690

SX7770: Parts Breakdown & Operating Manual 5 1/24/12

SX7770_Manual_012412.indd 5 1/27/12 9:07 AM

Page 6

Para reducir el riesgo de lesiones, cualquier persona quien usa, repara, da

ADVERTENCIA

servicio o cambia los accesorios en esta herramienta debe leer y comprender

estas instrucciones, antes de realizar cualquiera de estas tareas.

Siempre inspeccione, opere y realice servicio a esta herramienta

de acuerdo con el Código de Seguridad de las herramientas

neumáticas portátiles del Instituto de Normas Nacionales

Americanas (ANSI B186.1) y cualquier otro código y norma de

seguridad aplicable. Inspect, operate, and maintain this tool in

accordance with American National Standards Institute Safety Code

of Portable Air Tools (ANSI B186.1) and any other applicable safety

codes and regulations.

Estas herramientas son clasificadas a unas 90 psi / 6.2 barras de

máxima presión de aire para su seguridad, mayor rendimiento y

una máxima durabilidad de partes; no exceda esta presión de aire

mientras que la herramienta esté prendida.

Siempre apague el suministro de aire, vacíe la manguera de

cualquier presión de aire y desconecte la herramienta del suministro

de aire cuando la herramienta no está en uso, antes de cambiar los

accesorios, o al momento de hacer las reparaciones.

Nunca dirija el aire hacia usted o hacia ninguna otra persona.

Siempre lleve protección de ojos y cara resistentes al impacto, al

momento de operar o realizar mantenimiento a esta herramienta.

Los altos niveles sonoros pueden ocasionar la pérdida auditiva

permanente. Siempre lleve puesto protección de los oídos al momento de usar esta herramienta, según se recomienda por

parte de su empleador o las normas de OSHA.

No lleve puesto joyería ni ropa floja.

No use uniones de desconexión rápida c la herramienta.

Consulte las instrucciones de operación para el ensamble adecuado.

Las mangueras de látigo pueden ocasionar lesiones serias. Siempre

revise cuidadosamente por mangueras o accesorios dañados o

sueltos antes de operar esta herramienta.

Evite el contacto directo con los accesorios durante o después

del uso. Se deben usar guantes para reducir el riesgo de cortes o

quemaduras.

Nunca deje la herramienta prendida fuera del área de trabajo. La

herramienta puede correr demasiado rápido y ocasionar que se tire

el accesorio de la herramienta.

Nunca use una almohadilla de respaldo, tambor o abrasivo con una

velocidad permitida menor a la de la velocidad de la herramienta.

Use solamente discos abrasivos de tamaños y tipos recomendados.

Asegúrese que los discos de lijado estén montados

concéntricamente.

Nunca monte un disco de esmeril sobre una lijadora. Un disco de

esmerilado puede explotarse y ocasionar lesiones serias o aún la

muerte cuando éste no está adecuadamente almacenado.

Inspeccione la almohadilla de respaldo previo a cada uso. No la use

si está agrietada o dañada.

Nunca deje correr la herramienta al menos que el abrasivo esté en

contacto con la pieza de trabajo.

Existe un riesgo de una descarga electrostática si se usa sobre

plástico u otros materiales no conductivos.

El deslizamiento, los tropiezos y/o las caídas durante la operación

de las herramientas neumáticas pueden ser una causa de lesiones

serias o la muerte. Esté consciente de sus alrededores y de

cualquier manguera en exceso dejada en el camino o sobre la

superficie de trabajo.

Las herramientas neumáticas pueden ocasionar vibraciones durante

el uso. Las vibraciones, movimientos repetitivos o las posiciones

incómodas mantenidas durante periodos extendidos de tiempo

pueden ser dañinos para las manos y los brazos. Deje de usar la

herramienta si se dé alguna incomodidad, sensación de hormigueo,

o dolor. Consulte un médico antes de continuar el uso si se dé

cualquiera de dichas síntomas.

No se estire ni intente extenderse demasiado al momento de usar

esta herramienta.

Si la herramienta aparenta fallarse, deje de usarla inmediatamente

y prepare la reparación de la misma.

Nunca use la herramienta si haya posibilidades de que tenga

contacto con una línea de electricidad.

Use solo piezas de repuesto certificadas de Sunex para cualquier

reparación hecha a la herramienta. Las reparaciones hechas

deben ser realizadas solo por parte de personal adecuadamente

capacitado.

No cierre ni use cinta ni alambre para bloquear la válvula de la

herramienta en la posición de encendido/apagado.

No deje que el aire del escape haga contacto con las superficies

calientes ni con las llamas.

Evite inhalar el polvo o los escombros de la maniobra proveniente del proceso del trabajo, los que pueden ser dañinos para la

salud. Lleve puesto equipo protector para la respiración y para la

extracción de polvo al momento de trabajar con los materiales que

producen partículas suspendidas en el aire.

El polvo creado por el trabajo de lijado neumático, serrado,

esmerilado, perforación y otras actividades de la construcción

contiene químicos conocidos en el Estado de California por

ocasionar el cáncer y defectos congénitos u otros daños de la

reproducción. Algunos ejemplos de dichos químicos son:

- El plomo proveniente de las pinturas con base de plomo

- Ladrillos de sílice cristalino y el cemento y otros

productos de mampostería

- Arsénico y cromo de madera tratada con químicos

Su riesgo de exposición varía, dependiendo de qué tan

frecuentemente usted realice este tipo de trabajo. Para disminuir

su exposición a dichos químicos: trabaje en un área bien ventilada

y use equipo de seguridad aprobado, tal como las máscaras

anti-polvo las que están específicamente diseñadas para filtrar las

partículas microscópicas.

Advertencias adicionales de seguridad

No haga ninguna modificación a esta herramienta ni a los

accesorios.

Mida diariamente la velocidad de la herramienta neumática con

un tacómetro para asegurar que no sea mayor a la de las RPM

declaradas en la almohadilla de respaldo, tambor o abrasivo

Esta herramienta no se recomienda para uso en ambientes

explosivos ni debajo del agua.

Los operadores y el personal de mantenimiento deben estar

físicamente capaces de manejar el volumen, el peso, y la potencia

de esta herramienta.

Esta herramienta está destinada para uso profesional solamente.

.

INSTRUCCIONES DE SEGURIDAD – NO LAS DESCARTE – DÉSELAS AL USUARIO

SX7770: Desglose de partes y manual de operación 6 1/24/12

SX7770_Manual_012412.indd 6 1/27/12 9:07 AM

Page 7

Manual de instrucción

Esta herramienta está diseñada para el trabajo de pulido. No

se permite ningún otro uso.

Los requerimientos del suministro de aire

La herramienta está diseñada para operarse a unas 90 psi

(6.2 barras) a una velocidad libre, medida en la herramienta,

de aire seco limpio. La operación de esta herramienta a altas

presiones reducirá la vida útil de la herramienta en forma

significativa y podría ocasionar lesiones.

La rosca de la entrada de aire en esta herramienta es de

NPT 1/4" estándar. La presión de la línea debe aumentarse

por cualquier manguera de una longitud anormalmente larga

(mayor a 25 pies). El diámetro mínimo de manguera debe ser

de un diámetro interior de 3/8" y todas las conexiones deben

contar con el mismo diámetro interior. Consulte el diagrama a

continuación por el ensamble adecuado del suministro de aire.

No instale aquí el

acoplamiento de

conexión rápida

Conexión

macho

Primera

Manguera

Manguera

que azota

conexión rápida

Conexión

macho

ReguladorCaja de aceiteAcoplamiento de

Abastecimiento

Filtro

de aire

Drane

diariamente

DECLARACIÓN EC DE CONFORMIDAD

Nosotros, Sunex International Inc., 315 Hawkins Rd,

Travelers Rest, SC 29690, declaramos bajo nuestra única

responsabilidad que el producto al cual se refiere esta

declaración, está en conformidad con los requerimientos de

la directriz del consejo de junio del 1988 en la aproximación

de las leyes de los estados miembros relacionado a la

maquinaria. (EN792, 98/37/EC)

Las normas armonizadas aplicadas:

EN 792-6

Normas nacionales aplicadas:

ISO 8662-7, ISO 15744-2002

Nombre de la máquina:

Pulidora horizontal SX7770

Número de serie:

MS012010 ó mayor

Datos técnicos:

Diámetro de almohadilla: 7"

Tamaño del eje de rosca: 5/8"-11

Velocidad libre: 2,500 RPM

Presión de aire: 90 psi (6.2 barras)

Declaración sobre ruidos y vibraciones

La herramienta produce una nivel sonoro (sin carga) de 85

dBA de presión sonora, con 3 dBA de incertidumbre según

EN ISO15744-2002. El nivel de vibraciones es de <2.5 m/s²,

comprobado por EN 28662-1 & EN28662-7:1997.

Fecha del emisión:

Lubricación

Nombre y puesto: John Stratton, Gerente de productos

Sunex International Inc.

Lubrique la herramienta cada día después del uso con aceite

Fecha de emisión: 4 de enero de 2012

motor neumático de calidad SAE #10. Agregue el aceite a la

entrada de aire o en la manguera en la conexión más cercana

al suministro de aire, luego deje que la herramienta corra

hasta que todo se purgue el aceite excesivo del escape. La

cantidad total de aceite requerida para este procedimiento

es de aproximadamente 1 onza. Si se está usando un

lubricador de línea de aire, ajústela a dos gotas por minuto.

Especificaciones

Diámetro de almohadilla .....................................7" (178mm)

Tamaño del eje de rosca ...........................................5/8"-11

Velocidad libre ..................................................... 2,500 RPM

Longitud ...........................................................12" (305mm)

Peso ............................................................... 4.4 Lbs. (2 kg)

Consumo de aire promedio. ........................6 cfm (170 l/min)

Entrada de aire ....................................................... 1/4" NPT

Tamaño mín. de manguera ................Diám. Int. 3/8" (10mm)

SX7770: Desglose de partes y manual de operación 7 1/24/12

SX7770_Manual_012412.indd 7 1/27/12 9:07 AM

Page 8

Centros de servicio de la garantía:

Air & Hydraulic Repair

315 Hawkins Road

Travelers Rest, SC 29690

TEL# 877-786-3939

Power Tool Repair

891 Moe Drive Suite H

Akron, OH 44310

TEL# 330-630-0022

Discount Tool Repair

3433 Losee Road #1

North Las Vegas, NV 89030

TEL# 702-657-6570

Tri-County Power Tool, Inc.

4597 Pearl Rd.

Cleveland, OH 44109

(216) 398-6120

Diversified Power Inc.

90 Buttermill Avenue,

Vaughan, Ontario

L4K 3X7 Canada

Tel: 905-760-9077

Toll Free: 800-821-7975

Garantía limitada de 2 años:

SUNEX INTERNATIONAL INC. BRINDA LA GARANTÍA A SUS CLIENES QUE LOS PRODUCTOS NEUMÁTICOS DE LA COMPAÑÍA

SUNEX HD® SON LIBRES DE DEFECTOS EN CUANTO A MATERIALES Y MANO DE OBRO SE REFIERE. FROM DEFECTS IN

WORKMANSHIP AND MATERIALS.

Sunex International Inc. reparará o repondrá sus herramientas neumáticas Sunex HD® las cuales dejan de brindar un servicio

satisfactorio debido a defectos en cuanto a material o mano de obra, con base en los términos y condiciones del plan de garantía

descritos a continuación. Este producto lleva una garantía de DOS AÑOS. Durante este periodo de garantía, Sunex Tools® repondrá

o reparará, a su discreción, cualquier herramienta la cual demuestra ser defectuosa en cuanto a material o mano de obra.

Información adicional importante de garantía …

Esta garantía no cubre daños provenientes de modificaciones, abuso, el mal uso, o daños y no cubre las reparaciones ni repuestos

hechos por ningún individuo que no sea un centro de servicio autorizado de Sunex HD®, de la lista anterior. La obligación anterior es

la única responsabilidad de Sunex International Inc. bajo esta garantía o cualquier garantía implicada y no seremos responsables por

ningún daño incidental ni consecuencial bajo ninguna circunstancia.

Nota: Algunos estados ni permiten la exclusión ni limitación de los daños incidentales ni consecuenciales, por lo que la limitación

o exclusión anterior puede no aplicar a usted.

Devuelva su herramienta al centro de servicio garantizado autorizado Sunex HD® más cercano, con el flete pre-pagado.

Asegúrese de incluir su nombre, dirección y comprobación de compra, junto con una descripción del defecto supuesto. Si

usted tiene dudas acerca del servicio de garantía, comuníquese por favor con Sunex Tools® al 1-800-833-7869, o por el

sitio web en www.sunextools.com. Esta garantía le brinda derechos legales específicos y usted puede contar con derechos

adicionales, los cuales varían de estado a estado.

Dirección de envío:

Sunex Tools® • 315 Hawkins Rd. • Travelers Rest, SC 29690

Dirección de correo:

Sunex Tools® • P.O. Box 1233 • Travelers Rest, SC 29690

SX7770: Desglose de partes y manual de operación 8 1/24/12

SX7770_Manual_012412.indd 8 1/27/12 9:07 AM

Page 9

Pour réduire les risques de blessure, toute personne chargée de la réparation,

AVERTISSEMENT

de l’entretien ou du remplacement des accessoires de cet outil doit au préalable

lire et comprendre ces instructions avant d’effectuer l’une de ces tâches.

Effectuez toujours l’inspection, la mise en fonction et l’entretien de

cet équipement conformément au Code de sécurité de l’American

National Standards Institute Safety Code of Portable Air Tools (ANSI

B186.1) et à tout code et toute réglementation applicables.

Ces outils sont calculés à 90 psi / 6,2 bar de pression maximale

de l’air pour des raisons de sécurité, de rendement optimal et de

longévité maximale ; ne pas dépasser cette pression pendant le

fonctionnement de l’outil.

Toujours couper l’alimentation en air, arrêter la pression d’air dans le

tuyau de vidange et débrancher le tuyau d’alimentation d’air lorsque

l’outil n’est pas utilisé, avant tout remplacement d’accessoires ou

toute intervention sur l’outil.

Ne jamais diriger l’air sur vous-même ou sur quelqu’un d’autre.

Toujours porter des lunettes résistant aux impacts ou un écran facial

lors du fonctionnement ou de l’entretien de l’outil.

Des niveaux acoustiques élevés peuvent causer une perte auditive

permanente. Toujours porter un dispositif de protection antibruit lors

de l’utilisation de cet outil suivant les recommandations de votre

employeur ou de la réglementation OSHA.

Eviter de porter des bijoux ou des vêtements amples.

Ne pas utiliser des raccords rapides sur l’outil. Voir la notice

d’emploi pour une installation appropriée.

Le fait de fouetter les tuyaux peut causer des blessures graves.

Toujours examiner l’outil attentivement pour identifier d’éventuels

dommages ou des tuyaux ou ajustements libres avant de mettre

l’outil en marche.

Eviter le contact direct avec les accessoires pendant et après

l’utilisation. Le port des gants est obligatoire pour réduire les risques

de coupures ou de brûlures.

Ne jamais utiliser l’outil hors du service. L’outil peut fonctionner à

grande vitesse et les accessoires peuvent se détacher du produit.

N’utilisez jamais un tampon, un tambour ou un abrasif de support

avec une vitesse autorisée plus basse que la vitesse de l’outil.

Utilisez que les dimensions et sortes d’abrasifs recommandés

Assurez-vous que les disques abrasifs sont fixés de manière

concentrique.

Ne fixez jamais une meule sur une ponceuse-meuleuse. Une meule

qui éclate peut causer des blessures sérieuses ou même entraîner

la mort lorsqu’elle n’est pas sécurisée correctement.

Inspectez le tampon de support avant chaque utilisation. Ne l’utilisez

pas s’il est fissuré ou endommagé.

Ne faites jamais fonctionner l’outil à moins que l’abrasif soit en

contact avec l’objet sur lequel vous travaillez.

Il y a un risque de décharge électrostatique si utilisé sur du plastique

et d’autres matériaux non conducteurs.

Le glissement, le desserrage et/ou la chute pendant le

fonctionnement des outils pneumatiques peuvent être une cause

majeure de blessures ou de pertes en vies humaines. Faire attention

à l’environnement et à tout excédent de tuyau laissé sur le chemin

ou sur la plate-forme de travail.

Les outils pneumatiques peuvent causer des vibrations lorsqu’ils

sont utilisés. Les vibrations, les mouvements répétitifs ou les

positions inconfortables pendant de longues périodes peuvent

présenter des dangers pour vos mains et vos bras. Utiliser l’outil de

manière discontinue en cas de gêne, de sensation de picotements

ou de douleurs. Consulter un médecin avant de reprendre le travail

si l’un de ces symptômes se manifeste.

Ne pas étirer ou tendre le bras trop loin lors de l’utilisation

du matériel.

Si l’outil ne fonctionne pas convenablement, mettez-le hors

service immédiatement et prenez des mesures pour sa réparation.

Ne jamais utiliser l’outial si le contact avec des câbles

électriques est possible.

Utiliser seulement les pièces de rechange certifiées par Sunex pour

toute intervention sur l’outil. Les réparations doivent être effectuées

uniquement par le personnel formé à cet effet.

Ne pas bloquer, condamner ou monter la vanne dans la position «

marche/arrêt.

Ne pas permettre le contact entre l’air vicié et les surfaces chaudes

ou les flammes.

Eviter d’inspirer de la poussière ou de toucher des débris

issus du travail, lesquels peuvent être dangereux pour

la santé. Utilisez les procédés de dépoussiérage et les

équipements respiratoires et de protection lorsque vous

êtes en contact avec des substances qui produisent des particules

en suspension dans l’air.

Certaines particules solides créées par des activités liées au

ponçage mécanique, au sciage, au broyage, au forage et à d’autres

activités de construction contiennent des produits chimiques classés

par l’Etat de Californie comme des causes de cancer, d’anomalies

congénitales ou d’autres troubles de la reproduction. Au nombre de

ces produits chimiques figurent :

- le plomb provenant des peintures au plomb

- parpaings, ciment et autres produits de

maçonnerie contenant la silice cristalline

- l’Arsenic et le chrome provenant du bois traité avec un

produit chimique

Les risques que vous courez lors de l’exposition à ces substances

varient en fonction du nombre de fois où vous faites ce type de

travail. Pour réduire votre exposition à ces substances chimiques :

travaillez dans un local bien ventilé et revêtez des équipements de

sécurité approuvés, tels que les masques anti-poussière conçus

spécialement pour éliminer les particules microscopiques.

Avertissements supplémentaires pour renforcer la sécurité

Ne pas modifier cet outil ou ses accessoires.

Mesurez quotidiennement la vitesse de l’outil pneumatique avec

un tachymètre afin de vous assurer qu’elle n’est pas supérieure au

tr/min indiqué sur le tampon, le tambour ou l’abrasif de support.

Cet outil n’est pas conçu pour être utilisé dans une atmosphère

explosive ou sous l’eau.

Les opérateurs et le personnel chargé de son entretien doivent avoir

les ressources physiques nécessaires pour supporter le vrac, le

poids et la puissance de cet outil.

Cet outil ne doit être utilisé que par des spécialistes en la matière.

CONSIGNES DE SECURITE – NE PAS JETER – DONNER A L’UTILISATEUR

SX7770: Répartition des pièces & manuel d’utilisation 9 1/24/12

SX7770_Manual_012412.indd 9 1/27/12 9:07 AM

Page 10

Mode d’emploi

Cet outil est conçu pour le polissage. Ne doit pas être utilisé à

d’autres fins.

Exigences en matière d’approvisionnement en air

Cet outil doit fonctionner sous une pression de 90 psi

(6,2 bar), à une vitesse en régime libre mesurée en fonction

de l’outil et dans un milieu atmosphérique limpide et sec.

L’utilisation de cet outil à des pressions plus élevées réduira

considérablement sa durée de vie et pourrait causer des

blessures graves.

Le filetage d’entrée d’air de cet outil est un filetage standard

de 1/4 NPT. La pression de fluide doit être augmentée pour

l’utilisation de tout tuyau d’air à longueur exceptionnelle (plus

de 25 pieds). Le diamètre minimum du tuyau doit être de

3/8 Di et tous les raccords doivent avoir le même diamètre

intérieur. Voir le schéma ci-dessous pour une bonne mise au

point de l’alimentation en air.

Gachette à

vitesse wariable

Filtre

quotidiennement

Purger

N´installez pas

l´accuoplement

Mamelon

Tuyau

de chef

Tuyau

de fouet

rapide

Mamelon

RégulateurGraisseurCoupleur

Lubrification

Lubrifier l’outil au quotidien après son utilisation avec de

l’huile pneumatique à moteur de qualité SAE #10. Ajouter

l’huile dans l’entrée d’air ou dans le tuyau au niveau du

raccord le plus proche de l’alimentation en air, puis faire

fonctionner l’outil jusqu’à la vidange de tout excédent

d’huile du tuyau. La quantité d’huile totale requise pour

cette procédure est d’environ 1 once. Si vous utilisez un

lubrificateur pour conduite d’air, ajustez à deux gouttes

par minute.

DECLARATION DE CONFORMITE CE

Nous, Sunex International Inc., 315 Hawkins Rd, Travelers Rest,

SC 29690, déclarons, sous notre seule responsabilité, que le

produit faisant l’objet de la présente déclaration est conforme

aux exigences des directives du Conseil de juin 1998 portant

sur le rapprochement des législations des Etats membres en

matière d’équipements. (EN792, 98/37/EC)

Normes harmonisées appliquées :

EN 792-6

Normes nationales appliquées :

ISO 8662-7, ISO 15744-2002

Nom de la machine :

Polisseusse horizontale SX7770

N° de série :

MS012010 ou supérieur

Données techniques :

Diamètre du tampon: 7 po

Dimension des filets de la broche: 5/8 po - 11

Vitesse en régime libre : 2 500 T/M

Pression de l’air : 90 psi (6,2 bar)

Déclaration relative aux bruits et aux vibrations

L’outil produit un niveau de bruits (charge nulle) de 85 dBA

de pression pression acoustique avec 3 dBA d’incertitude par

EN ISO15744-2002. Le niveau de vibration est de <2,5 m/s²

testé par EN 28662-1 & EN28662-7:1997

Signature de l’émetteur :

Nom et poste de l’émetteur : John Stratton, Gestionnaire

de produit

Sunex International Inc.

Date de délivrance : 4 janvier 2012

Spécifications

Diamètre du tampon .......................................7 po (178 mm)

Dimension des filets de la broche ........................5/8 po - 11

Vitesse en régime libre ......................................... 2 500 T/M

Longueur ......................................................12 po (305 mm)

Poids .............................................................. 4,4 Lbs. (2 kg)

Consommation

d’air moyenne. ............. 6 pieds cubes par minute (170 l/min)

Entrée d’air .......................................................... NPT 1/4 po

Dimension minimale du tuyau ................... 3/8 po Di (10 mm)

SX7770: Répartition des pièces & manuel d’utilisation 10 1/24/12

SX7770_Manual_012412.indd 10 1/27/12 9:07 AM

Page 11

Centres de service de garantie :

Air & Hydraulic Repair

315 Hawkins Road

Travelers Rest, SC 29690

TEL# 877-786-3939

Power Tool Repair

891 Moe Drive Suite H

Akron, OH 44310

TEL# 330-630-0022

Discount Tool Repair

3433 Losee Road #1

North Las Vegas, NV 89030

TEL# 702-657-6570

Tri-County Power Tool, Inc.

4597 Pearl Rd.

Cleveland, OH 44109

(216) 398-6120

Diversified Power Inc.

90 Buttermill Avenue,

Vaughan, Ontario

L4K 3X7 Canada

Tel: 905-760-9077

Toll Free: 800-821-7975

Années de garantie limitées à 2 ans :

SUNEX INTERNATIONAL INC. ASSURE SA CLIENTELE QUE LES OUTILS PNEUMATIQUES SUNEX HD® DE LA SOCIETE NE

PRESENTENT AUCUN DEFAUT EN TERMES DE FABRICATION ET D’ELEMENTS MATERIELS.

Sunex International Inc. réparera ou remplacera ses outils pneumatiques Sunex HD® dont le rendement ne donnera pas satisfaction

à l’utilisateur en raison d’un défaut de fabrication ou d’éléments matériels, sur la base des conditions générales du plan de garantie

décrit suivant. Ce produit bénéficie d’une garantie de DEUX ANS. Au cours de cette période de garantie, Sunex Tools® réparera ou

remplacera à notre option, tout outil qui se révèle défectueux en termes d’éléments matériels ou de fabrication..

Renseignements utiles supplémentaires relatifs à la garantie...

Cette garantie ne couvre pas, d’une part, les dommages de l’outil dus à sa modification, son mauvais traitement, sa mauvaise

utilisation, sa dégradation, et d’autre part les réparations ou le remplacement de pièces effectués par toute personne autre qu’une

station technique Sunex HD® autorisée figurant sur la liste ci-dessus. L’obligation qui précède constitue la seule responsabilité de

Sunex International Inc. dans ce cadre ou dans toute garantie tacite. Sunex ne sera donc en aucun cas responsable d’un quelconque

dommage consécutif ou indirect.

Remarque : Certains Etats ne permettent pas l’exclusion ou la restriction des dommages consécutifs ou indirects ; ainsi, il est

possible que la restriction ou l’exclusion ci-dessus ne s’applique pas à votre cas.

Renvoyez l’outil au centre de service de garantie Sunex HD® agréé le plus proche, le transport est payé d’avance. N’oubliez pas

d’inclure vos noms, adresse et preuve de date d’achat, plus une description du défaut soupçonné. Si vous avez une question quelconque sur le service de garantie, veuillez contacter Sunex Tools® à cette adresse téléphonique 1-800-833-7869, ou par son

site web www.sunextools.com. La présente garantie vous donne droit à des garanties juridiques spécifiques et vous pouvez par

ailleurs jouir d’autres droits en fonction de votre Etat.

Adresse d’expédition :

Sunex Tools® • 315 Hawkins Rd. • Travelers Rest, SC 29690

Adresse postale :

Sunex Tools® • P.O. Box 1233 • Travelers Rest, SC 29690

SX7770: Répartition des pièces & manuel d’utilisation 11 1/24/12

SX7770_Manual_012412.indd 11 1/27/12 9:07 AM

Loading...

Loading...