Page 1

Operating Instructions • Warning Information • Parts Break down

SX76

HIGH PRESSURE

SPRAY GUN

WARNING

ALWAYS READ AND KEEP

INSTRUCTIONS BEFORE

USING THIS EQUIPMENT

SPRAY GUNS CREATE

FLYING PARTICLES.

ALWAYS WEAR SAFETY

GOGGLES AND BREATHING

APPARATUS (USERS AND

BYSTANDERS). FLYING

PARTICLES CAN CAUSE

INJURY

SPECIFICATIONS

Fluid Orifice .............................................. 1.4mm

Air Inlet .................................................. 1/4" NPT

Fluid (Water) Delivery .............. 180-240 ML/MIN

Avg. Air Consumption ......................... 12.5 CFM

Nozzle Pressure ........................................ 50 PSI

Cup Size .................................................1000 ML

© Copyright 2012, Sunex Tools

SX76: Parts Breakdown & Operating Manual 01/07/13

®

Page 2

To reduce the risk of injury, anyone using, repairing, maintaining, or changing accessories on this tool must

WARNING

read and understand these instructions before performing any of these tasks.

Read THIS INSTRUCTION MANUAL Carefully and understand ALL

INFORMATION Before Operating THIS Tool. KEEP FOR FUTURE USE.

Always operate, inspect and maintain this spray gun in

accordance with American National Standards Institute Safety

Code of Portable Air Tools (ANSI B186.1) and any other applicable

safety codes and regulations.

During use and while cleaning and flushing spray gun solvents

can be expelled. Some solvents can cause eye injury. Always

wear eye protection.

Be sure all in the area are wearing impact-resistant eye and

face protection.

Even small projectiles can injure eyes and cause blindness.

High sound levels can cause permanent hearing loss. Protect

yourself from noise. Noise levels vary with work sur face. Wear

ear pro tec tion.

Repetitive work motions, awkward positions and exposure to

vibration can be harmful to hands and arms.

Air under pressure can cause severe injury. Al ways shut off air

supply, drain hose of air pressure and disconnect tool from air

supply when not in use, before changing accessories or when

making repairs. Never direct air at yourself or anyone else.

Whipping hoses can cause serious injury. Al ways check for

damaged or loose hoses and fittings. Never use quick change

couplings at tool. They add weight and could fail due to vibration.

Instead, add a whip hose and connect coupling between air

supply and whip hose, or between whip hose and leader hose.

Do not exceed maximum air inlet pressure of 50 PSI.

Always use spray gun at a safe distance from other people in

work area.

Maintain spray gun with care. Keep tools clean and oiled for

best and safest performance. Follow instructions for lubricating

and chang ing accessories. Wiping or cleaning rags and other

flammable waste materials must be placed in a tightly closed

metal container and disposed of later in the proper fashion.

Do not wear loose or ill-fitting clothing; remove watches and rings.

Do not over reach. Keep proper footing and balance at all times.

Slipping, tripping and falling can be a major cause of serious

injury or death. Be aware of excess hose left on the walking or

work surface.

Do not abuse hoses or connectors. Never carry spray gun by the

hose or yank hose to disconnect from air supply. Keep hoses from

heat, oil and sharp edges. Check hoses for weak or worn condition

before each use, making certain that all connections are secure.

When possible, secure work with clamps or vise so both hands

are free to operate tool.

Solvent and paint coatings can be highly flammable when

sprayed. Adequate ventilation exhaust must be provided to keep

air free of accumulations of flammable materials. Smoking must

never be allowed in the spray area. Fire extinguishing equipment

must be present in the paint spray area.

Certain painting solvent materials may be harmful if inhaled, or if

there is contact with the skin. Always follow the requirements of

the Material Safety Data Sheet supplied by your coating material

manufacturer. Adequate exhaust ventilation must be provided to

keep the air free of accumulations of toxic materials. Always use a

mask or respirator whenever there is a chance of inhaling sprayed

materials. The mask must be compatible with the material being

sprayed and its concentration. Respirator equipment must be

NIOSH approved.

Halogenated hydrocarbon solvents - for example: methylene

chloride and 1,1,1,-Trichlorethene are not chemically compatible

with the aluminum that might be used in spray gun components.

The chemical reaction caused by these solvents reacting with

aluminum can become violent and lead to an equipment

explosion. Guns with stainless steel internal passageways may

be used with these solvents. However, aluminum is widely used

in other spray application equipment. Check all equipment items

before use and make sure they can also be used safely with these

solvents. Read the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating or cleaning

material is compatible, contact your material supplier.

Spray gun operators should be given adequate training in the

safe use and maintenance of the equipment. Users must comply

with all local and national codes of practice and insurance

company requirements governing ventilation, fire precautions,

operation, maintenance, and housekeeping. These are OSHA

Sections 1910.94 and 1910.107 and NFPA-33.

Use of spray guns may cause cumulative trauma disorders

(CTD's). CTD's, when using spray guns, tend to affect the upper

extremities. Factors which may increase the risk of developing a

CTD include:

1. High frequency of the activity.

2. Excessive force, such as gripping, pinching, or pressing

with the hands and fingers.

3. Extreme or awkward finger, wrist, or arm positions.

4. Excessive duration of the activity.

5. Vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD's can also be caused by sports activities. Pain, tingling, or

numbness in the shoulder, forearm, wrist, hands, or fingers,

especially during the night, may be early symptoms of a CTD.

Do not ignore them. Should you experience any such symptoms,

see a physician immediately. Other early symptoms may include

vague discomfort in the hand, loss of manual dexterity, and

nonspecific pain in the arm. Ignoring early symptoms and

continued repetitive use of

to a serious disability.

the arm, wrist, and hand can lead

SAFETY INSTRUCTIONS - DO NOT DISCARD - GIVE TO USER

SX76: Parts Breakdown & Operating Manual 2 01/07/13

Page 3

WARNING

(

CONTINUED

)

To reduce the risk of injury, anyone using, repairing, maintaining, or changing accessories on this tool must

read and understand these instructions before performing any of these tasks.

Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known to

the State of California to cause cancer and birth defects or other

reproductive harm. Some examples of these chemicals are:

- Lead from lead based paints

- Crystalline silica bricks and cement and other

masonry products

- Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

Handling the brass parts of this product will expose you to lead, a

chemical known to the State of California to cause birth defects

and other reproductive harm. Wash hands after handling.

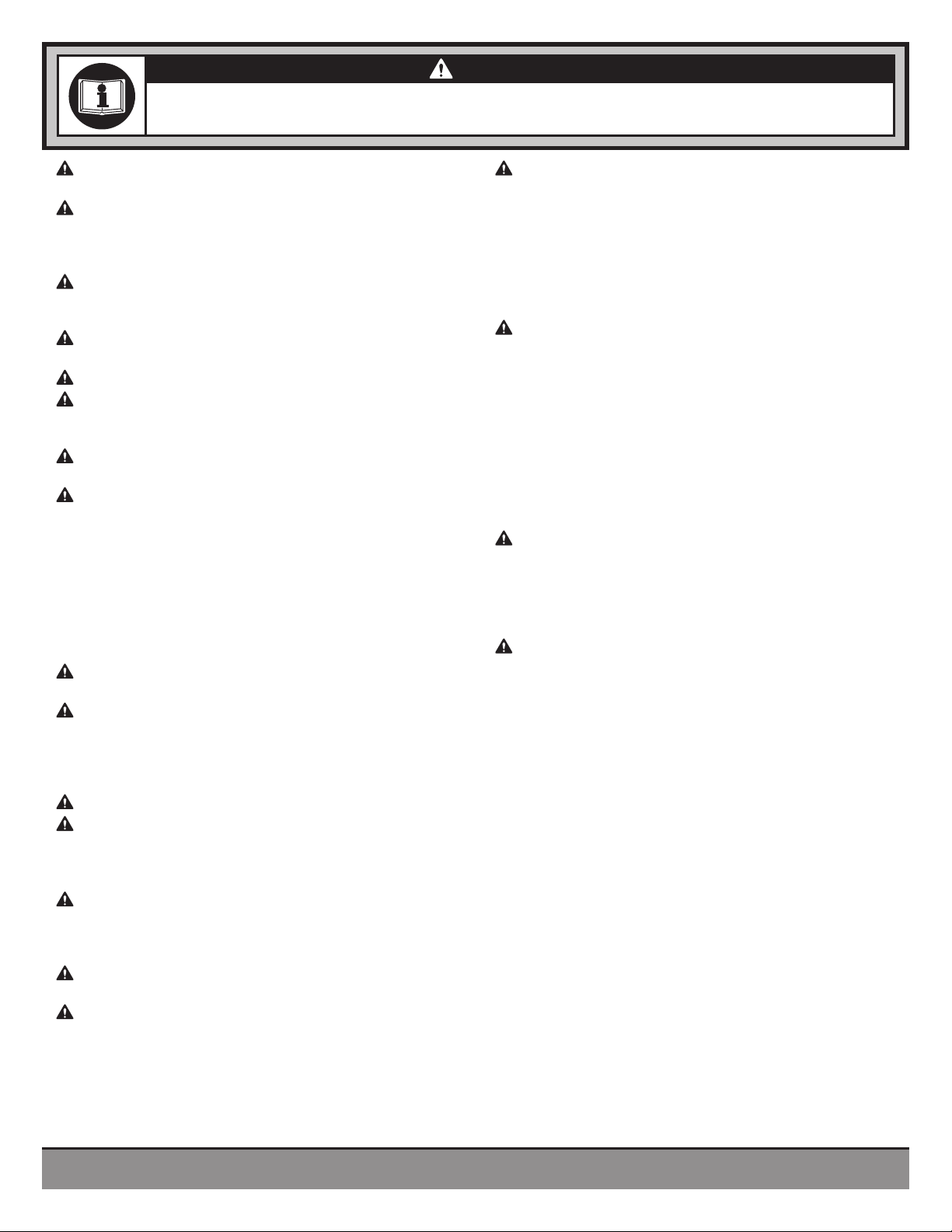

AIR SUPPLY

IMPORTANT PRECAUTION INFORMATION -

READ BEFORE USING THIS SPRAY GUN:

SPRAY GUN DESCRIPTION

The SX76 is a light weight, general purpose conventional spray

gun designed for use in various types of spraying applications.

IMPORTANT: This spray gun may be used with most common

coating and finishing materials. It is designed for use with mildly

corrosive and non-abrasive materials. If used with other high

corrosive or abrasive materials, it must be expected that frequent

and thorough cleaning will be required and the necessity for

replacement of parts will be increased.

Pitch pipe back

toward air receiver

Air

Flow

CFM

10

20

30

40

50

70

Length of Pipe (ft.)

50 100 150 200

1/2"

3/4"

3/4"

1"

1"

1"

3/4"

3/4"

3/4"

1"

1"

1"

3/4"

3/4"

1"

1"

1"

1-1/4"

3/4"

3/4"

1"

1"

1"

1-1/4"

Compressor Unit

Drain

Install drain at

each low point

Oil & Water

Extractor

25 Feet

or More

Oil and Water Extractor should be at least 25 ft.

from the compressor, farther if possible.

Never mount oil and water extractor on or near the air com pres sor.

During compression, air temperature is greatly increased. As the air cools down to room tem per a ture, moisture condenses in the air line, on

its way to the spray gun. Therefore, always mount the oil and water extractor at a point in the air supply system where the compressed air

temperature is lowest.

Drain air lines properly.

Pitch all air lines back towards the com pres sor so that con densed mois ture will flow back into the air receiver where it can be drained off.

Each low point in an air line acts as a water trap. Such points should be fitted with an easily accessible drain. See diagram above.

Drain

SAFETY INSTRUCTIONS - DO NOT DISCARD - GIVE TO USER

SX76: Parts Breakdown & Operating Manual 3 01/07/13

Page 4

INSTALLATION

This spray gun is rugged in construction, and is built to

yield exceptional value. The life of this product and the

efficiency of its operation depend upon a knowledge of

its construction, use and maintenance.

SUCTION FEED CUP HOOK UP

Air pressure for atomization is reg u lat ed at ex trac tor.

Amount of fluid is adjusted by fluid control screw on

gun, viscosity of paint, and air pressure.

HVLP

Fluid

Suction Cup

Fluid Control Screw

Air Inlet

Atomization

Pressure

Gauge

Air Hose

FOR BEST PERFORMANCE, PLEASE BE SURE TO DO THE FOL LOW ING

BEFORE USING THIS SPRAY GUN

•Tightentheguntothecupsecurelywiththenutandfittingsupplied.

•Besuretohavetheproperairpressureattheguntooperate.Properairpressureforthistoolshouldnotexceed50PSI

•Adjustfluidcontrolscrewandspraywidthadjustmentscrewtoyourdesiredpatternbeforeusingonproduction.

•Cleanallpartsafteruse.

Oil and

Water

Extractor

ADJUSTMENTS

HIGH PRESSURE SPRAY GUN

The model you have purchased is a professional high

volume spray gun. It is designed to spray very efficiently

with virtually no overspray. To accomplish this, the inlet

pressure regulation is critical. Please be sure to read

pressure requirement carefully.

Spray width adjustment screw

Turn right for round, left for fan.

Fluid control screw

Turn right to decrease flow, left to increase.

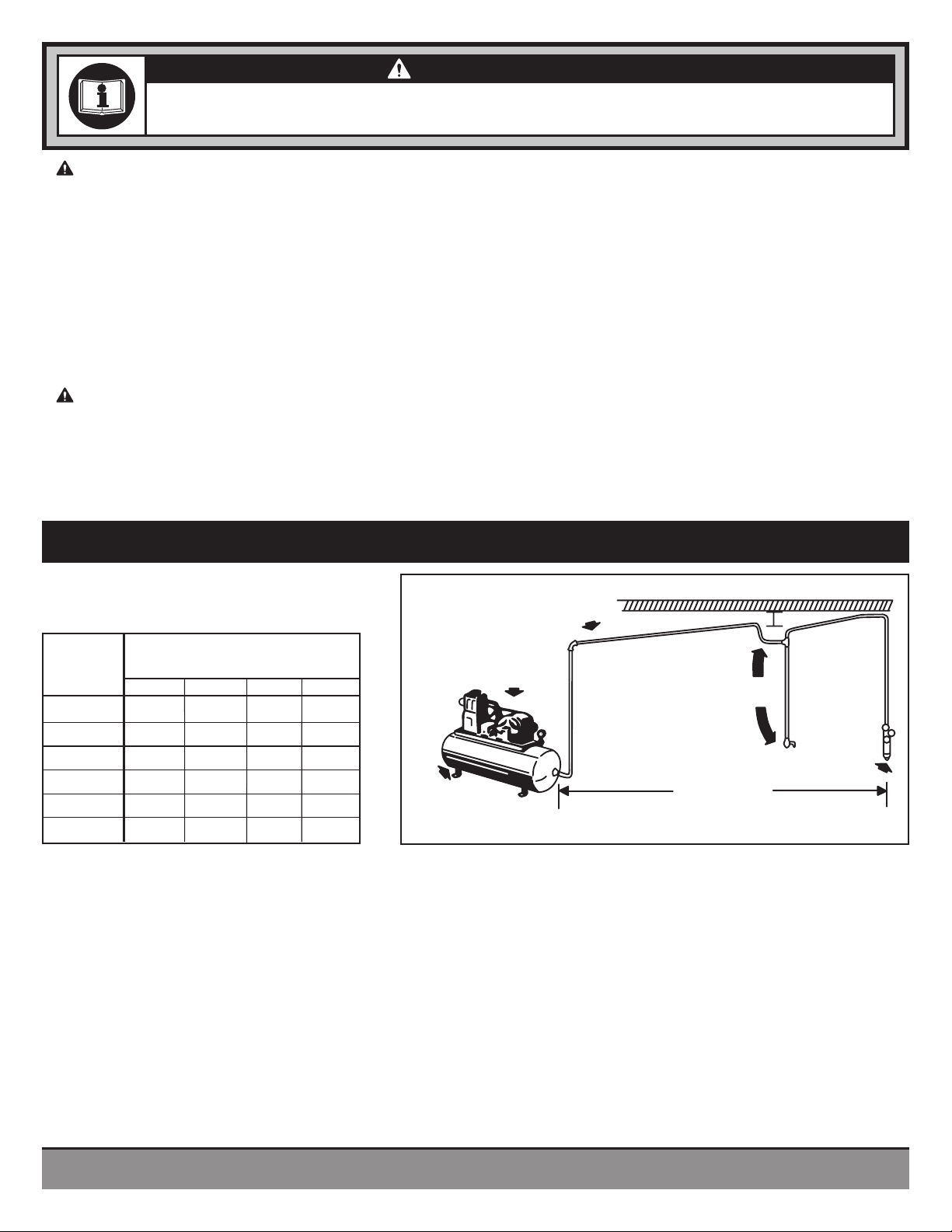

SPRAYING

In normal use, the nozzle wings are hor i zon tal as shown here. This pro vides a ver ti cal fan-shaped pat tern which

gives max i mum, even ma te ri al coverage as the gun is moved back and forth par al lel to the sur face being fin ished.

Set inlet pressure at no more than 50 PSI. For op ti mum per for mance,

some ma te ri als may spray better at PSI ratings below 50 PSI. If unsure,

always test at PSI ratings before using on final production. Try spray.

If it is too fine, de crease the air pres sure or open fluid control screw. If

the spray is too thick, close the fluid control screw. Reg u late the pat tern

width and repeat ad just ment of spray as needed.

Spray pattern may be in fi nite ly adjusted

from round to flat.

SX76: Parts Breakdown & Operating Manual 4 01/07/13

Page 5

OPERATION

Proper han dling of the gun is essential for ob tain ing a good finish. The gun should be held at a right angle to the sur face being cov ered, and moved

par al lel with it. For precise con trol of the gun and material, the trigger should be re leased before the end of the stroke.

Hold the gun from 6 to 12 inches away from the surface depending on ma te ri al and at om iz ing pres sure. For a uniform finish, lap each stroke over the

pre ced ing stroke, making sure the spray is smooth and wet.

Light Coat Heavy Coat

Start

stroke

6 to 12 inches

Pull

trig ger

RIGHT

Even and wet coat

Release

trigger

End of

Stroke

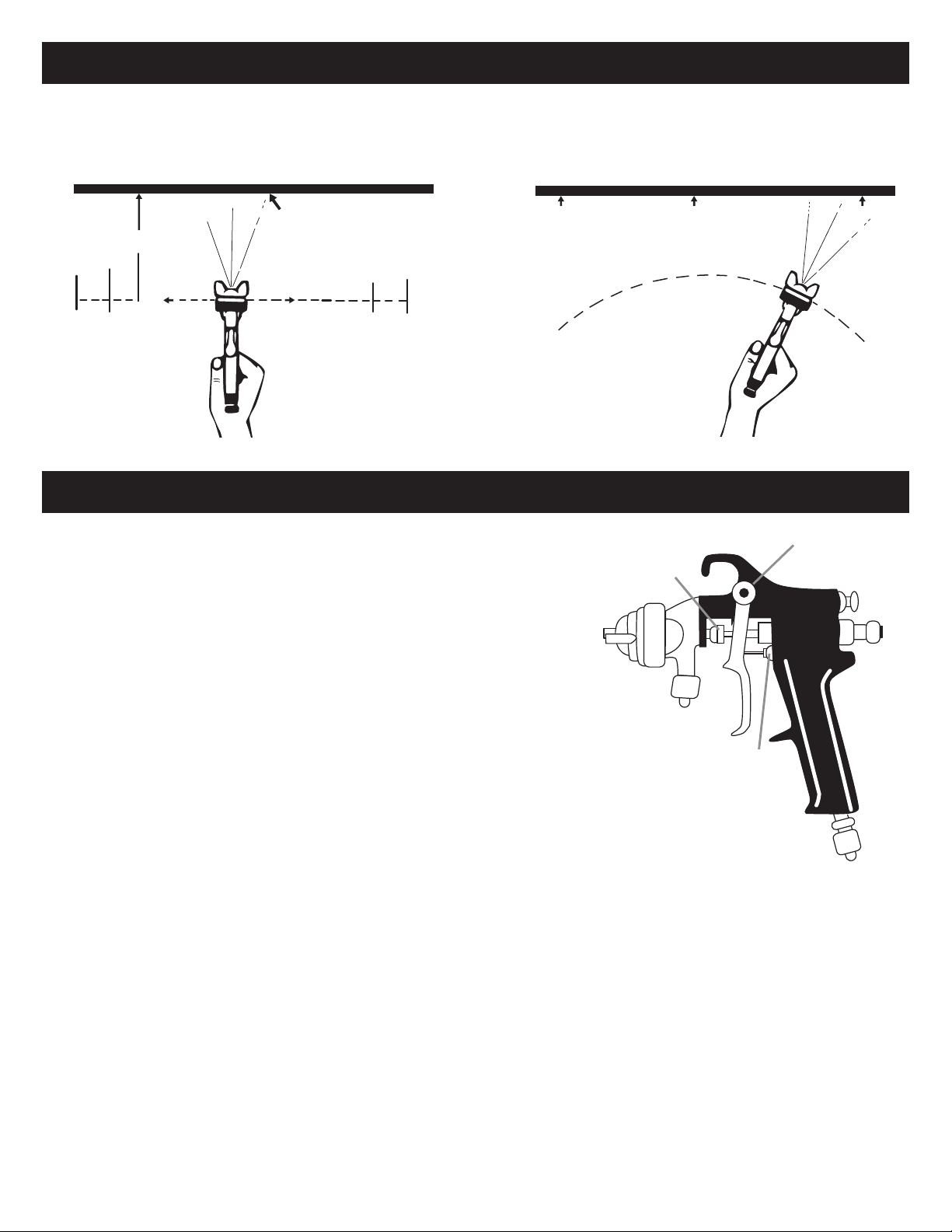

CLEANING AND MAINTENANCE

SPRAY GUN

1. Submerge the front end of the gun in solvent just until the fluid connection is covered.

2. Paint that has built up on the gun should be removed using a bristle brush and solvent.

3. Never submerge all of the spray gun in sol vent be cause:

• Thiswilldissolvethelubricantinthepackingsandonwearsurfaces,causing

them to dry out and resulting in difficult operation and faster wear.

• Airpassagesinthegunwillbecomecloggedwithdirtysolvent.

4. Using a rag moistened with solvent, wipe down the outside of the gun.

5. Oil gun daily. Use a drop of lightweight machine oil on:

A. fluid needle packing

B. air valve packing

C. trigger pivot point

See Fig. 1 for Location of Above Points.

6. NOTE: Do not soak rubber o-rings or seals in paint thinner. O-rings and seals

can be wiped clean with paint thinner but soaking can cause these items to

deteriorate over time.

7. Caution: Do not use lubricants which contain sil i cone.

Sil i cone may cause defects in the finish ap pli ca tion.

WRONG

C

A

B

FIG. 1

CAUTION…

To avoid cross-threading, all spray gun parts should be screwed in hand tight initially. If the parts can not easily be turned by hand, be sure you have

the correct parts, un screw, re align, and try again. NEVER use excessive force in match ing parts.

AIR NOZZLE, FLUID NOZZLE, AIR VALVE ASSEMBLY

1. All nozzles and needles are made to exact stan dards. They should be han dled carefully.

2. To clean nozzles, immerse them in sol vent until any dried material is dissolved, then blow them clean.

3. Do not use metal or sharp instrument to probe any of the holes in the nozzles.

4. Air flow should occur before fluid-flow when the gun is triggered. It may be necessary to adjust the fluid control screw to make sure air flows

before fluid.

5. Do not alter the gun in any way.

SUCTION FEED

Turn off air supply. Remove cover of cup. Empty the cup of material. Clean the cup and cover. Turn on air sup ply and spray with proper cleaning

solvent. Repeat with clean solvent if nec es sary. Remove solvent, dis con nect gun, re move air cap and clean. Wipe gun and cup with rag dampened

with sol vent.

SX76: Parts Breakdown & Operating Manual 5 01/07/13

Page 6

TROUBLESHOOTING

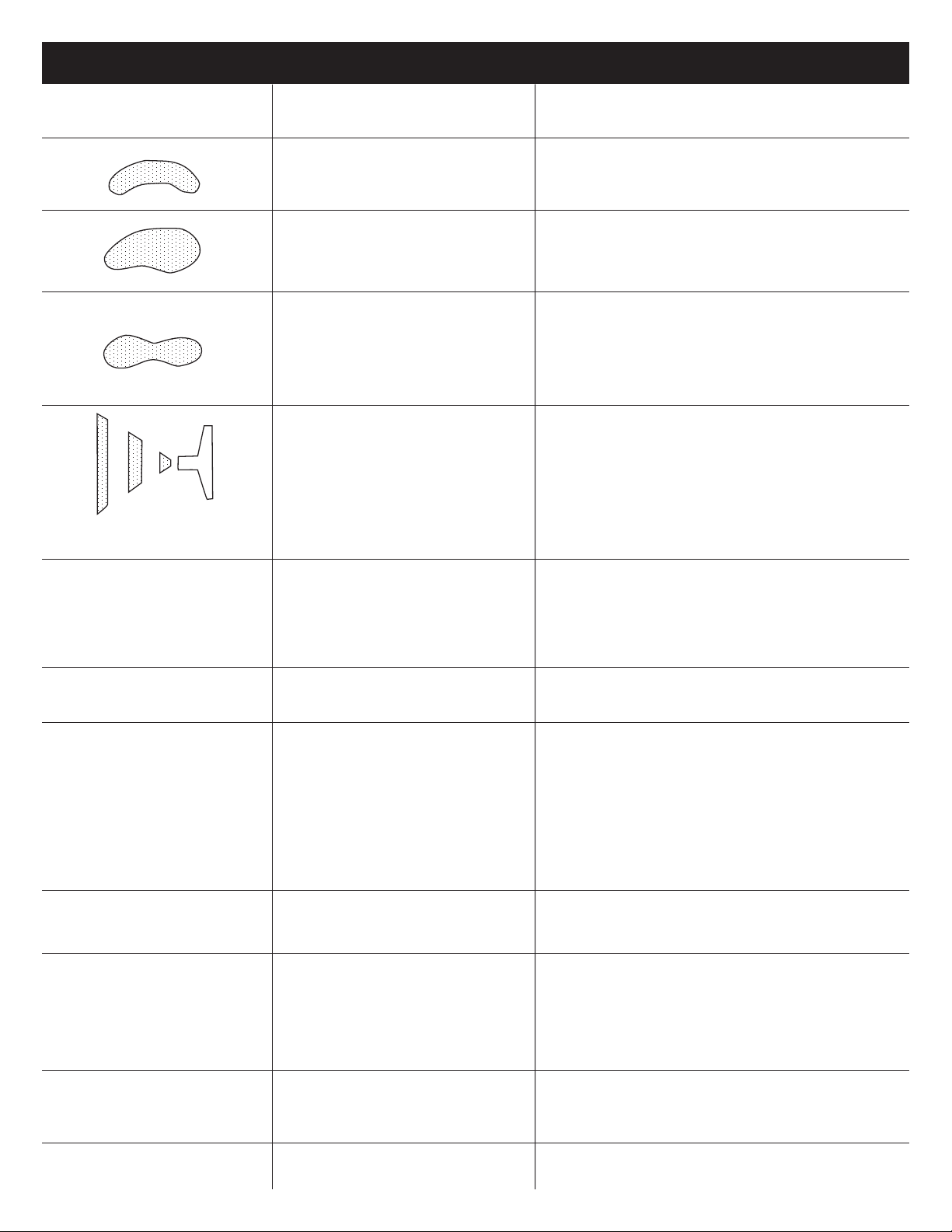

CONDITION

Spitting

PROBLEMSPRAY PATTERN/

One side of nozzle wing is clogged.

A.) Loose air nozzle.

B.) Material around outside of

air nozzle has dried.

A.) Atomization air pressure is set

too high.

B.) Trying to spray a thin material

in too wide a pattern.

A.) Packing around needle valve

is dried out.

B. Fluid nozzle loosely installed,

or dirt between nozzle

and body.

C.) Loose or defective swivel nut

on siphon cup.

SOLUTION

Soak nozzle in solvent to loosen clog, then blow air through

until clean. To clean orifices use a broom straw or toothpick.

Never try and detach dried material with sharp tool.

A.) Tighten air nozzle.

B.) Take off air nozzle and wipe off fluid tip,

using rag moistened with thinner.

A.) Reduce air pressure.

B.) Increase material control by turning fluid

control screw to left, while reducing spray

width by turning spray width adjustment

screw to right.

A.) Back up knurled nut, put a few drops of

machine oil on packing, re-tighten nut.

B.) Take off fluid nozzle, clean rear of nozzle and

seat in gun body. Replace nozzle and bring in

tight to body.

C.) Tighten or change out swivel nut.

Improper spray pattern.

Unable to get round spray.

Will not spray.

Fluid leakage from

packing nut.

Dripping from fluid tip.

A.) Gun improperly adjusted.

B.) Dirty air cap.

C.) Fluid tip obstructed.

D.) Sluggish needle.

Fan adjustment screw not

seating properly.

A.) No air pressure at gun.

B.) Fluid pressure too low with

internal mix cap and

pressure tank.

C.) Fluid control screw not

open enough.

D.) Fluid too heavy.

A.) Packing nut loose.

B.) Packing worn or dry.

A.) Dry packing.

B.) Sluggish needle.

C.) Tight packing nut.

D.) Worn fluid nozzle or needle.

A.) Readjust gun. Follow instructions carefully.

B.) Clean air cap.

C.) Clean.

D.) Lubricate.

Clean or replace.

A.) Check air supply and air lines.

B.) Increase fluid pressure at tank.

C.) Open fluid control screw.

D.) Thin material or change to pressure feed.

A.) Tighten, but not so tight as to grip needle.

B.) Replace packing or lubricate.

A.) Lubricate.

B.) Lubricate.

C.) Adjust.

D.) For pressure feed, replace with new fluid nozzle

and needle.

A.) Gun held too far from surface.

Thin, sandy coarse finish.

Thick, dimpled finish

resembling orange peel.

SX76: Parts Breakdown & Operating Manual 6 01/07/13

B.) Atomization pressure set

too high.

Gun held too close to surface.

A.) Move gun closer to surface.

B.) Adjust atomization pressure.

Move gun further from surface.

Page 7

50

51

49

52

53

54

48

11

34

32

33

44

16

15

24

17

23

22

21

25

6

7

8

9

10

1

2

5

30

31

41

45

33

29

3

26

27

28

37

38

35

39

41

40

13

12

18

36

42

14

19

20

15

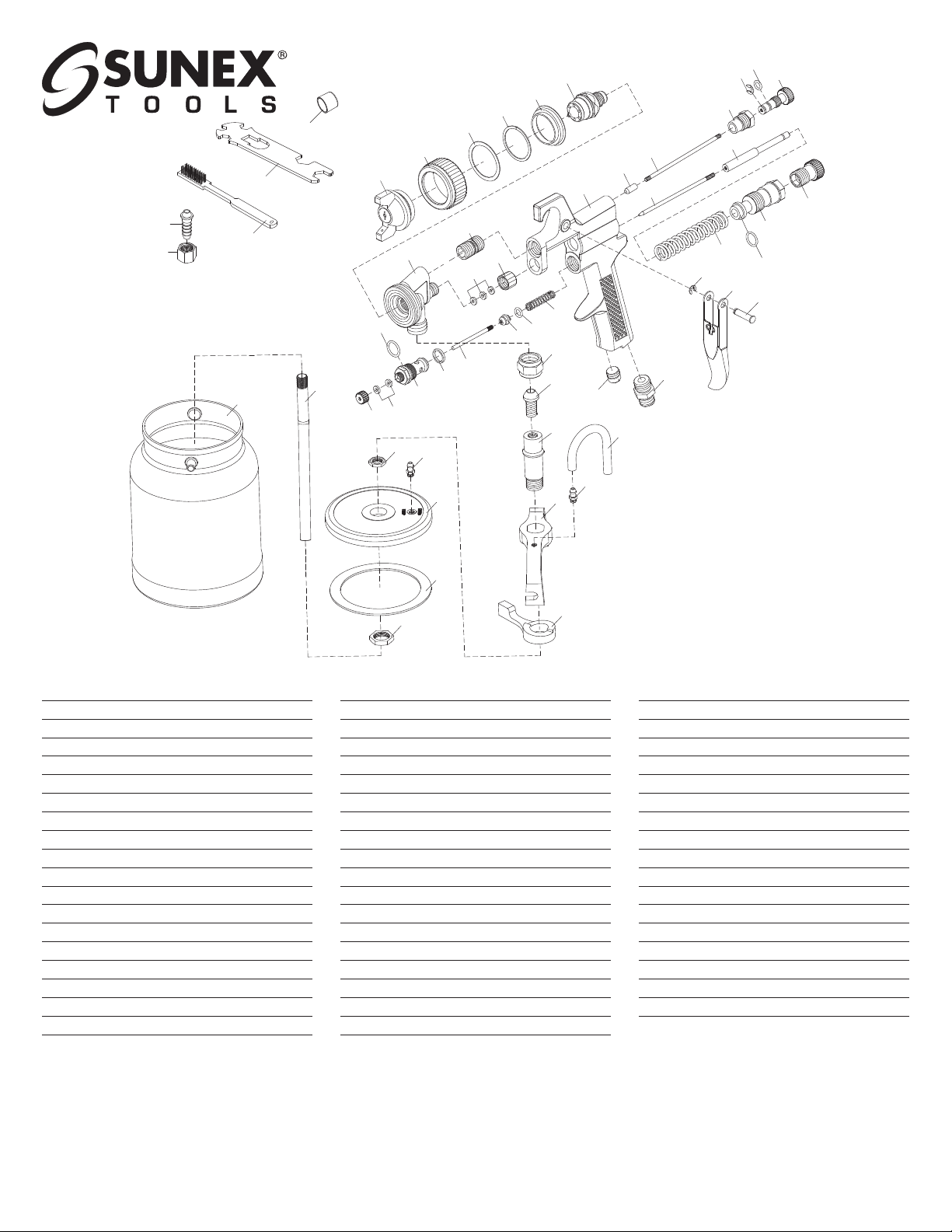

REF. DESCRIPTION QTY.

NO.

1 Gun Body 1

2 Connector Screw 1

3 Sealing Seat 1

5 Gun Head 1

6 Material Nozzle 1

7 Locking Knob Sealing Gasket 1

8 Circlip 1

9 Air Nozzle Gasket 1

10 Air Cap Ring 1

11 Air Nozzle 1

12 Pattern Adjustment Stopper 1

13 Pattern Adjustment Stem 1

14 Pattern Adjustment Seat 1

15 Opening Stopper 4 2

16 O-Ring 4.0 x 4.8 1

17 Pattern Adjustment Knob 1

18 Needle 1

19 Needle Seat 1

46

47

43

REF. DESCRIPTION QTY.

NO.

20 Needle Adjustment Spring 1

21 O-Ring 9.0 x 1.8 1

22 Needle Sleeve 1

23 Needle Adjustment Knob 1

24 Trigger 1

25 Trigger Pin 1

26 Air Valve Spring 1

27 O-Ring 4.5 x 1.8 1

28 Air Valve Seat 1

29 Air Valve Stem 1

30 Air Valve Sealing Gasket 1

31 Air Valve Body 1

32 O-Ring 10.0 x 1.8 1

33 Sealing Gasket 5

34 Air Valve Sealing Gasket 1

35 Gun Body Sealing Screw 1

36 Air Inlet Connector 1

37 Connector Nut 1

REF. DESCRIPTION QTY.

NO.

38 Connector Screw 1

39 Material Tube 1

40 Pothook 1

41 Screw 2

42 Aerate Tube 1

43 Handwheel 1

44 Hex Head Nut 1

45 Cup Cover 1

46 Sealing Gasket 1

47 Nut 1

48 Material Tube 1

49 Cup Subassembly 1

50 Connector 1

51 Nut 1

52 Brush 1

53 Spanner 1

54 Rubber Boot 1

Only items identified by part numbers are available separately.

Replacement Parts Available:

RS76NK: 1.4mm Air Nozzle/Fluid Nozzle/Needle Kit (incl. #6-11, 18, 19)

RS76AIC: Air Inlet Connector (#36)

RS76LA: Lid Assembly (incl. #37-48)

RS76SG: Gasket (#46)

RS76C: Cup (#49)

RS76RK: Repair Kit (incl. # 13, 15, 16, 22, 25-30, 32, 33)

SX76: Parts Breakdown & Operating Manual 7 01/07/13

Page 8

LIMITED WARRANTY...

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS® BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective

workmanship or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product.

This product carries a 90 day warranty. During this warranty period, Sunex Tools will repair or replace at our option any part or unit which proves

to be defective in material or workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or

replacement made by anyone other than Sunex Tools or its authorized warranty service centers.The foregoing obligation is Sunex Tools’ sole

liability under this or any implied warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you. Please contact your local Sunex distributor for proper warranty handling procedures.

If you have any questions about warranty service, please write to Sunex Tools. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools products regardless of

whether or not the product is still covered by a warranty plan.

Shipping Address: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Mailing Address: Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

SX76: Parts Breakdown & Operating Manual 8 01/07/13

Page 9

Instrucciones de operación • Información de advertencia • Desglose de partes

SX76

PISTOLA

PULVERIZADORA

DE ALTA PRESIóN

ADVERTENCIA

SIEMPRE LEA Y MANTENGA

LAS INSTRUCCIONES ANTES

DE USAR ESTE EQUIPO

LAS PISTOLAS PULVERIZADORAS

CREAN PARTÍCULAS VOLANTES.

SIEMPRE LLEVE PUESTO GOGLES

DE SEGURIDAD Y DISPOSITIVOS

DE RESPIRACIÓN (USUARIOS

Y ESPECTADORES). LAS

PARTÍCULAS VOLANTES PUEDEN

OCASIONAR LESIONES.

ESPECIFICACIONES

Orificio de fluidos ..................................... 1.4mm

Entrada de aire ..................................... 1/4" NPT

Entrega fluida (agua) .............. 180-240 ML/MIN

Consumo promedio de aire ................ 12.5 CFM

Presión de la boquilla .............................. 50 PSI

Tamaño del vaso ...................................1000 ML

© Copyright 2012, Sunex Tools

SX76: Desglose de piezas y manual de operación 9 01/07/13

®

Page 10

ADVERTENCIA

Para reducir el riesgo de lesiones, cualquier persona quien usa, repara, da servicio o cambia los accesorios en

esta herramienta debe leer y comprender estas instrucciones, antes de realizar cualquiera de estas tareas.

Lea ESTE MANUAL INSTRUCTIVO cuidadosamente y comprenda

TODAS LA INFORMACIÓN antes de operar ESTA herramienta.

CONSÉRVELO PARA USO FUTURO.

Haga funcionar, verifique y mantenga esta herramienta de

acuerdo con el código ANSI (Organización nacional americana

de normalización) para herramientas portátiles con aire (ANSI

B186.1) y cualesquiera otros códigos de seguridad y

regulaciones aplicables.

Durante la limpieza y purga, los solventes podrían ser expelidos

con fuerza por los pasajes de líquidos y aire. Algunos solventes

pueden lesionar los ojos. Siempre lleve puesto protección de ojos.

Asegúrese que todas las personas que se hallen en el área usen

gafas y máscaras de protección para la cara, resistentes

al impacto.

Aun los proyectiles pequeños pueden lesionar los ojos y causar

la ceguera.

Los altos niveles de sonido pueden causar la sordera

permanente. Protéjase contra el ruido. Los niveles de ruido

varían con la superficie de trabajo. Use protectores para los

oídos.

Los movimientos repetitivos de trabajo, las posturas incómodas y

la exposición a las vibraciones pueden ser dañinos para las

manos y los brazos.

El aire bajo presión puede causar lesiones graves. Antes de

cambiar los accesorios o al momento de hacer reparaciones,

siempre cierre el suministro de aire, vacíe la presión de aire de

la manguera y desconecte la herramienta del suministro de aire

cuando no ésta está en uso. Nunca dirija el flujo de aire hacia

usted ni hacia otra persona. Los latigazos de manguera pueden

causar lesiones graves. Verifique siempre que las mangueras y

las acoplaciones no estén dañadas ni sueltas. Jamás use

acoplaciones de cambio rápido con la herramienta, ya que

agregan peso y podrían fallar debido a vibraciones. En cambio,

agregue un latiguillo de manguera y conecte la acoplación entre

el suministro de aire y el latiguillo de manguera, o entre el

latiguillo de manguera y la manguera principal. No exceda la

presión máxima de entrada de aire de 50 PSI.

Siempre use la pistola pulverizadora a una distancia segura de

otras personas en el área de trabajo.

Mantenga la pistola pulverizadora con cuidado

limpias y aceitadas para asegurar el mejor rendimiento y uno

más seguro. Siga las instrucciones para lubricar y cambiar

los accesorios. Los paños de limpieza y otros materiales

inflamables de desecho deberán ser colocados en un

recipiente de metal herméticamente cerrado y desechados

luego de forma adecuada.

No use ropa demasiada holgada ni suelta, quítese los relojes

y anillos.

No se esfuerce en alcanzar lo que está fuera de su alcance.

Mantenga el equilibrio en todo momento. Los resbalos, tropiezos

y caídas pueden ser de las principales causas de lesiones graves

o la muerte. Fíjese si haya manguera sobrante que está

obstruyendo el camino o la superficie de trabajo.

No maltrate las mangueras y conectadoras. Nunca lleve

ninguna pistola pulverizadora por la manguera ni la jale para

desconectarla del suministro de aire. Mantenga las mangueras

lejos del calor, de aceite y de los bordes afilados. Antes de cada

uso, verifique que las mangueras no estén des gastadas ni

debilitadas y asegúrese que todas las conexiones estén seguras.

. Manténgalas

Cuando sea posible, sujete el trabajo con abrazaderas o un

banco de trabajo con el fin de que ambas manos estén libres

para operar la herramienta.

Los recubrimientos de disvolente y pintura pueden ser altamente

inflamables cuando sean pulverizados. Se deberá brindar una

ventilación de escape adecuada con el fin de mantener el aire

libre de acumulaciones de materiales inflamables. Nunca se

deberá permitir fumar en el área de pulverización. Se debe de

mantener en el área de pulverización de pintura un equipo

extintor de fuegos.

Ciertos materiales de disolvente de pintua pueden ser dañinos si

sean inhalados o si haya contacto con la piel. Siempre siga

los requerimientos de la Hoja de Datos de Seguridad de los

Materiales provisto por su fabricante de material de

recubrimiento. Una ventilación de escape adecuada debe ser

provista para así mantener el aire libre de acumulaciones de

materiales tóxicos. Siempre use una máscara o respirador

cuando exista una posibilidad de inhalar los materiales

pulverizados. La máscara debe ser compatible con el material

a pulverizarse y con la concentración del mismo. El equipo

respiratorio debe ser aprobado por NIOSH.

Los disvolentes de hidrocarburo halogenados - por ejemplo:

el cloruro de metileno y el 1,1,1,-tricoloretano no son

químicamente compatibles con el aluminio, el cual podrá usarse

con los componentes de la pistola pulverizadora. La reacción

química ocasionada por dichos disolventes reaccionando con el

aluminio puede volverse violenta y ocasionar una explosión del

equipo. Las pistolas con pasajes internos de acero inoxidable

pueden usarse con dichos disolventes. Sin embargo, el aluminio

es usado ampliamente en otros equipos de aplicación de

pulverización. Revise todos los artículos del equipo antes del uso

y asegúrese que también puedan usarse seguramente con

dichos disolventes. Lea la etiqueta y hoja de datos para el

material el cual se pretende pulverizar. Si tiene cualquier duda

en cuanto a la compatibilidad del material de limpieza o de

recubrimiento, comuníquese con el proveedor de materiales.

Los operadores de las pistolas pulverizadoras deben recibir una

adecuada capacitación en el uso y mantenimiento seguros del

equipo. Los usuarios deben cumplir con todos los códigos de

práctica locales y nacionales y con los requerimientos de las

compañías de seguros los que rigen la ventilación, precauciones

de incendio, operación, mantenimiento y tareas domésticas.

Dichos códigos incluyen las secciones 1910.94 y 1910.107 de

OSHA y NFPA-33.

El uso de las pistolas pulverizadoras puede ocasionar trastornos

de trauma culmulativo (CTD, por sus siglas en inglés). Al

momento de emplear las pistolas pulverizadoras, dichos

trastornos CTD tienden a afectar las extremidades superiores.

Los factores los que pueden aumentar el riesgo de desarrollar

un transtorno CTD incluyen:

1. Alta frecuencia de la actividad.

2. Fuerza excesiva, tal como agarrar, pellizcar or presionar

con las manos y dedos.

3. Posiciones extremas o incómodas de los dedos, muñecas

o brazos.

4. Duración excesiva de la actividad.

5. Vibraciones.

6. Presión repetida en alguna parte del cuerpo.

7. Trabajo en temperaturas bajas.

INSTRUCCIONES DE SEGURIDAD – NO LAS DESCARTE – DÉSELAS AL USUARIO

SX76: Desglose de piezas y manual de operación 10 01/07/13

Page 11

ADVERTENCIA

(CONTINUADO)

Para reducir el riesgo de lesiones, cualquier persona quien usa, repara, da servicio o cambia los accesorios en

esta herramienta debe leer y comprender estas instrucciones, antes de realizar cualquiera de estas tareas.

Los trastornos de trauma cumulativo también pueden ser

ocasionados por actividades deportivas. El dolor, hormigueo,

o adormecimiento en el hombro, antebrazo, muñeca, manos

o dedos, especialmente durante la noche, pueden ser

síntomas de un transtorno CTD. No los ignore. Si se llegara

a experimentar cualquiera de dichos síntomas, consulte un

médico inmediatamente. Otros síntomas tempranos pueden

incluir la incomodidad ligera en la mano, la pérdida de la

dexteridad manual y otro dolor no específico en el brazo.

Al ignorar los síntomas tempranos y el uso repetitivo

continuo del brazo, muñeca o mano, se pueden ocasionar

incapacidades serias.

El polvo creado por el trabajo de lijado neumático, serrado,

esmerilado, perforación y otras actividades de la construcción

contiene químicos conocidos en el Estado de California por

ocasionar el cáncer y defectos congénitos u otros daños de

la reproducción. Algunos ejemplos de dichos químicos son:

- El plomo proveniente de las pinturas con base de plomo

- Ladrillos de sílice cristalino y el cemento y otros

productos de mampostería

- Arsénico y cromo de madera tratada con químicos

Su riesgo de exposición varía, dependiendo de qué tan

frecuentemente usted realice este tipo de trabajo. Para

disminuir su exposición a dichos químicos: trabaje en un

área bien ventilada y use equipo de seguridad aprobado, tal

como las máscaras anti-polvo las que están específicamente

diseñadas para filtrar las partículas microscópicas.

La manipulación de las piezas de bronce de este producto lo

expondrá al plomo, un compuesto químico conocido en el Estado

de California como causante de malformaciones congénitas y

otros daños a la salud reproductiva. Lávese las manos después

de manipular estas piezas.

INFORMACIÓN IMPORTANTE DE PRECAUCIONES -

LEA ANTES DE USAR ESTA PISTOLA PULVERIZADORA

DESCRIPCIÓN DE LA PISTOLA PULVERIZADORA

La SX76 es una pistola pulverizadora convencional ligera y de

uso general diseñada para uso en varios tipos de aplicaciones de

pulverización.

IMPORTANTE: La pistola pulverizadora puede usarse con los

materiales más comunes de acabado y recubrimiento. Está

diseñada para uso con materiales ligeramente corrosivas

y no abrasivas. Si se usa con otros materiales altamente

corrosivos o abrasivos, se deberá anticipar el requerimiento

de una limpieza frecuente y comprensiva y también se

aumentará la necesidad de reposición de piezas.

SUMINISTRO DE AIRE

Escuadre el tubo hacia

el receptor de aire

Pies cúbicos

por minuto

(CFM) de

flujo de aire

10

20

30

40

50

70

Longitud del tubo

(pies)

50 100 150 200

1/2"

3/4"

3/4"

1"

1"

1"

3/4"

3/4"

3/4"

1"

1"

1"

3/4"

3/4"

1"

1"

1"

1-1/4"

3/4"

3/4"

1"

1"

1"

1-1/4"

Drenaje

Unidad de

compresión

Instalar drenaje en

cada punto bajo

Aceite y agua

Extractor

Drenaje

25 pies o más

El extractor de aceite y aqua deberá estar a una distancia

de al menos 25 pies del compresor, más lejos si es posible.

Nunca monte el extractor de aceite y agua en o cerca del compresor de aire.

Durante la compresión, la temperatura del aire se aumenta considerablemente. En la medida que el aire se enfríe, hasta llegar a la temperatura

ambiente, la humedad se condensa en la tubería de aire, en su camino hacia la pistola de pintar. Por lo tanto, siempre monte el extractor de

aceite y agua en un punto del sistema de suministro de aire donde la temperatura del aire comprimido sea la más baja.

Drene adecuadamente las tuberías de aire.

Arroje todas las tuberías de aire hacia el compresor para que la humedad condensada fluya de regreso al receptor de aire donde ésta puede

ser drenada. Cada punto bajo en una tubería de aire funciona como trampa de agua. Dichos puntos deben ser acoplados con un drenaje de

fácil acceso. Ver el diagrama anterior.

INSTRUCCIONES DE SEGURIDAD – NO LAS DESCARTE – DÉSELAS AL USUARIO

SX76: Desglose de piezas y manual de operación 11 01/07/13

Page 12

INSTALACIÓN

Esta pistola de pintar es de construcción robusta, concebida

para rendir un valor excepcional. La vida útil de este producto y

la eficiencia de su funcionamiento dependen del conocimiento

de su construcción, su uso y su mantenimiento.

CONEXIÓN DE COPA DE

ALIMENTACION POR SUCCIÓN

Se regula la presión de aire para la atomización en el

extractor. Se ajusta la cantidad de fluidos por la perilla

reguladora en la pistola, la viscosidad de la pintura y

la presión de aire.

Copa de

succión de

fluidos

HVLP

Tornillo de control

de líquidos

Entrada de aire

Indicador de

presión de

atomización

Manguera de aire

Extractor

de aceite

y agua

PARA EL MEJOR RENDIMIENTO, ASEGÚRESE DE SEGUIR LOS PASOS A CONTINACIÓN

ANTES DE USAR LA PISTOLA PULVERIZADORA

•Conlatuercayacoplaciónprovistas,ajustefirmementelapistolaalacopa.

•Asegúresedecontarconlapresióndeaireadecuadaenlapistolaparaoperarla. La presión de aire adecuada para esta herramienta no debe

exceder las 50 PSI.

•Antesdeusarlaenlaproducción,ajusteeltornillodecontroldelíquidosyeltornillodeajustedelanchoderociadohastaelpatróndeseado.

•Limpietodaslaspartesdespuésdeluso.

AJUSTES

PISTOLA PULVERIZADORA

DE ALTA PRESIÓN

El modelo el cual usted compró es una pistola

pulverizadora profesional de alto volumen y

baja presión. Está diseñada para pulverizar

muy eficientemente con prácticamente ninguna

salpicadura. Para lograr esto, es crítica la

regulación de presión de entrada. Asegúrese

de leer cuidadosamente los requerimientos

de presión.

Rociado con tornillo de ajuste

Girarlo hacia la derecha para rociar en redondo,

hacia la izquierda para rociar en abanico.

Tornillo de control del fluido

Girarlo hacia la derecha para disminuir el flujo,

hacia la izquierda para aumentarlo.

ROCIADO

Con el uso normal, las orejetas de la tobera están en posición horizontal, según se demuestra aquí. Esto provee un patrón

vertical en forma de abanico que brinda la máxima cobertura uniforme del material, en la medida que se mueva la pistola

de un lado a otro y de forma paralela a la superficie que se está acabando.

Ajuste la presión de admisión a no más de 50 PSI. Para un rendimiento

óptimo, algunos materiales podrán rociarse a una capacidad menor a las

50 PSI. Si usted no está seguro, siempre haga prueba a las capacidades

de PSI antes de usarla en la producción final. Pruebe el rociado. Si es

demasiado fino, disminuya la presión de aire o abra el tornillo de control

de líquidos. Si el rociado sale muy grueso, cierre el tornillo de control de

líquidos. Regule el ancho del patrón y repita el ajuste del rociado según

sea necesario.

El patrón de rociado puede ajustarse

infinitamente de redondo a plano.

SX76: Desglose de piezas y manual de operación 12 01/07/13

Page 13

OPERACIÓN

Para obtener un buen acabado, es esencial operar la pistola correctamente. La pistola debe sujetarse formando un ángulo recto contra la superficie

que se está cubriendo y se debe mover paralela a ésta. Para un control preciso de la pistola y del material, el gatillo debe estar suelto antes de

terminar el recorrido.

Sostenga la pistola de 6 a 12 pulgadas a distancia de la superficie, según el material que se use y la presión de atomización. Para obtener un

acabado uniforme, traslape cada recorrido sobre el recorrido anterior, asegurándose que el rociado salga liso y mojado. El uso de la presión de

atomización más baja posible reducirá el exceso de rociado y se obtendrá una máxima eficiencia.

Capa ligera Capa pesada

MAL

Comenzar

el recorrido

6 a 12 pulgadas

Apretar

el gatillo

CORRECTO

Capa uniforme y mojada

Soltar el

gatillo

Fin del

recorrido

LIMPIEZA Y MANTENIMIENTO

PISTOLA DE PINTAR

1. Sumerja el extremo delantero de la pistola en solvente justo hasta cubrir la conexión de líquidos.

2. Se debe quitar la pintura acumulada en la pistola al usar un cepillo de cerda y solvente.

3. Nunca sumerja la pistola de pintar entera en el solvente porque:

• Estopuededisolverellubricanteenlosempaquesdecueroyenlassuperficies

de desgaste, haciendo que se resequen, así dificultando la operación y

apresurando el desgaste.

• Lospasajesdeairedelapistolaquedaránobstruidosconelsolventesucio.

4. Usando un paño humedecido con solvente, limpie la parte externa de la pistola.

5. Engrase su pistola de a diario. Use una gota de aceite ligero para maquinaria en:

A. el empaque de la aguja de líquidos

B. el empaque de la válvula de aire

C. el punto de pivote del gatillo

Vea la Fig. 1 para la ubicación de los puntos anteriores mencionados.

6. NOTA: No remoje los sellos tipo “O” o sellos en el diluyente de pintura. Los sellos

tipo “O” y los sellos pueden ser enjuagados con diluyente de pintura, sin embargo,

con el tiempo, el remojo puede causar el deterioro de estos artículos.

7. Precaución: No use lubricantes que contienen siliconas. Las siliconas pueden causar

defectos en la aplicación del acabado.

C

A

B

FIG. 1

PRECAUCIÓN...

Para evitar la cruce de roscas, todas las partes de la pistola de pintar deben ser atornilladas, apretadamente a mano, en primer estancia. Si no se

pueden ajustar las partes fácilmente a mano, asegúrese que usted cuente con las partes correctas, destorníllelas, alinéelas de nuevo e inténtelo

una vez más. NUNCA ejerza fuerza excesiva en la alineación de las partes.

TOBERA DE AIRE, TOBERA DE LÍQUIDOS, ENSAMBLE DE LA VÁLVULA DE AIRE

1. Todas las toberas y agujas se fabrican conforme a normas exactas. Éstas deben ser tratados con cuidado.

2. Para limpiar las toberas, sumérjalas en solvente hasta que se haya disuelto el material reseco, luego límpielas con un soplador.

3. No use instrumentos afilados ni de metal para probar cualquiera de los orificios de las toberas.

4. Cuando se dispara el gatillo de la pistola, el flujo de aire debe darse antes del flujo de líquidos. Puede ser necesario ajustar el tornillo de control

de líquidos para asegurar que el aire fluya antes que fluya el líquido.

5. No se debe hacer ninguna modificación a la pistola.

ALIMENTACIÓN POR SUCCIÓN

Apague el abastecimiento de aire. Quite la tapa del vaso. Vacíe todo material del vaso. Limpie el vaso y cúbrelo. Prenda el abastecimiento de aire y

rocíe con el disolvente apropiado de limpieza. Repita con disolvente limpio según sea necesario. Quite el disolvente, desconecte la pistola, quite la

tapa de aire y límpiela. Enjuague la pistola y el vaso con un trapo remojado con disolvente.

SX76: Desglose de piezas y manual de operación 13 01/07/13

Page 14

LOCALIZACIÓN Y CORRECCIÓN DE FALLAS

ROCIADO/ESTADO

Pequeñas salpicaduras

(escupidas) de fluido

PROBLEMAPATRÓN DE

Un lado de la orejeta de la boquilla

está atascado.

A.) Boquilla de aire suelta.

B.) El material alrededor de la parte

externa de la boquilla está reseco.

A.) La presión de aire de atomización

está ajustada muy alta.

B.) Intentando rociar un material fino

en un patrón demasiado amplio.

A.) La empaquetadura alrededor de la

válvula de la aguja está reseca.

B. La boquilla del fluido ha que dado

suelta, o hay suciedad entre la

boquilla y el cuerpo.

C.) Tuerca giratoria suelta o defectuosa

en el casquillo del sifón.

SOLUCIÓN

Remoje la boquilla en solvente para aflojar el atascamiento, luego

sople aire por la boquilla hasta que quede limpia. Para limpiar los

orificios use una pajita de escoba o un escarbadientes. No intente

nunca despegar material reseco con una herramienta afilada.

A.) Ajuste la boquilla de aire.

B.) Saque la boquilla de aire y pásele un paño,

humedecido con diluyente por la punta.

A.) Reduzca la presión de aire.

B.) Aumente el control del material girando el tornillo de control

del fluido hacia la izquierda, mientras reduce la amplitud

del rocío ajustando el tornillo hacia la derecha.

A.) Mueva la tuerca estriada hacia atrás, coloque unas gotas

de aceite para maquinaria en la empaquetadura, vuelva a

ajustar la tuerca.

B.) Saque la boquilla del fluido, limpie la parte trasera de la

boquilla y el asiento en el cuerpo de la pistola. Vuelva a

colocar la boquilla y afírmela bien al cuerpo.

C.) Ajuste o cambie la tuerca giratoria.

Patrón de rociado incorrecto.

Imposible obtener un rociado en

redondo.

No aspersionará

Fuga de fluido de la tuerca de

empaquetadura.

Goteo de la punta del fluido.

A.) Pistola incorrectamente ajustada.

B.) Cubierta del aire sucia.

C.) Punta del fluido obstruida.

D.) Aguja lenta.

El tornillo de ajuste del ventilador no está

bien asentado.

A.) No hay presión de aire en la pistola.

B.) La presión del fluido está demasiado

baja con la cubierta de mezcla

interna y el tanque de presión.

C.) El tornillo de control del fluido no

está suficientemente abierto.

D.) Fluido demasiado espeso.

A.) Tuerca de empaquetadura suelta.

B.) Empaquetadura gastada o reseca.

A.) Empaquetadura reseca.

B.) Aguja lenta.

C.) Tuerca de empaquetadura muy

ajustada.

D.) Boquilla o aguja del fluido gastada.

A.) Reajuste la pistola. Siga cuidadosamente las instrucciones.

B.) Limpie la cubierta del aire.

C.) Limpie.

D.) Lubrique.

Límpielo o reemplácelo.

A.) Verifique el suministro de aire y las tuberías de aire.

B.) Aumente la presión del fluido en el tanque.

C.) Abra el tornillo de control del fluido.

D.) Material delgado o cambia a alimentación a presión.

A.) Ajuste pero no tan firmemente que agarre la aguja.

B.) Reemplace o lubrique la tuerca de empaquetadura.

A.) Lubrique.

B.) Lubrique.

C.) Ajuste.

D.) Para la alimentación a presión, reemplácela con

una nueva boquilla y aguja del fluido.

A.) Se mantiene la pistola demasiado

Acabado delgado, arenoso, áspero.

Acabado grueso, poroso, semejante

a una cáscara de naranja.

SX76: Desglose de piezas y manual de operación 14 01/07/13

lejos de la superficie.

B.) La presión de atomización está

ajustada muy alta.

Se mantiene la pistola demasiado cerca

de la superficie.

A.) Mueva la pistola más cerca de la superficie.

B.) Ajuste la presión de atomización.

Mueva la pistola más lejos de la superficie.

Page 15

GARANTÍA LIMITADA

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS CON LA

MARCA DE LA EMPRESA SUNEX TOOLS NO CONTIENEN DEFECTOS EN SU MANO DE OBRA NI MATERIAS PRIMAS.

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio

debido a que la mano de obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de

garantía descritos a continuación y asignados a ese producto específico. Este producto tiene una garantía de noventa días. Durante ese periodo

de garantía, Sunex Tools reparará o sustituirá, como así opte por hacerlo, cualquier componente o unidad que se compruebe tener decectos en

su materia prima o mano de obra.

Otra importante información de la garantía...

Esta garantía no cubre ningún daño al equipo o herramientas, si este surge como resultado de su alteración, abuso, o mal uso o daños ni tampoco

cubre las reparaciones o reposiciones hechas por cualquier persona ajena a los centros de servicio de garantía autorizados y que no sean de

Sunex Tools. La obligación antes mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o de cualquier

garantía implícita y bajo ninguna circunstancia quedará bajo su responsabilidad cualquier garantía implícita ya bajo ninguna circunstancia

quedará bajo su responsabilidad cualquier daño incidental o consecuencial.

Note: Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo tanto la limitación o exclusión

arriba mencionada quizá no pudiera serle pertinente a usted. Devuelva el equipo o componentes a Sunex Tools, un centro de servicio de garantía

autorizado, con elflete pagado. Asegúres haber incluido su nimbre y dirección, la evidencia de la fecha de adquisición y la descripción del defecto

que se sospeche tener. Si tiene alguna duda relacionada con elservicio de garantía, por favor escríbale a Sunex Tools. Esta garantía le concede

derechos jurídicos específicos y quizá otros derechos que varían de un estado a otro, Sunex Tools tiene a su disposición los juegos de reparación

y refacciones de repuesto para muchos de sus productos, sin importar si el producto continúe o no bajo el plan de la garantía.

Dirección a embarcarse: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Dirección de correos: Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

SX76: Desglose de piezas y manual de operación 15 01/07/13

Page 16

Instructions d'utilisation • Avertissements • Liste des pièces

SX76

PISTOLET

PULVÉRISATEUR

À HAUTE

PRESSION

AVERTISSEMENT

LIRE LES DIRECTIVES AVANT

D'UTILISER CET OUTIL ET LES

CONSERVER POUR CONSULTATION.

LES PISTOLETS PULVÉRISATEURS

PROJETTENT DES PARTICULES

QUI PEUVENT CAUSER DES

BLESSURES. L'UTILISATEUR ET LES

AUTRES PERSONNES À PROXIMITÉ

DEVRAIENT TOUJOURS PORTER

DES LUNETTES DE SÉCURITÉ ET UN

APPAREIL RESPIRATOIRE.

SPÉCIFICATIONS

Orifice du fluide ....................................... 1,4 mm

Entrée d'air .......................................NPT 1/4 PO

Débit du liquide (eau) .............. 180-240 ML/MIN

Cons. moyenne d'air ....................... 12,5 pi³/min

Pression de la buse .............................. 50 lb/po²

Taille du godet ....................................... 1000 mL

© Copyright 2012, Sunex Tools

SX76: Vue éclatée des pièces et mode d'emploi 16 01/07/13

®

Page 17

AVERTISSEMENT

Pour réduire les risques de blessure, toute personne chargée de la réparation, de l’entretien ou du remplacement des

accessoires de cet outil doit au préalable lire et comprendre ces instructions avant d’effectuer l’une de ces tâches.

Lisez attentivement ce MANUEL D’INSTRUCTIONS et assurez-vous

de bien comprendre TOUTES LES INFORMATIONS avant d’utiliser

CET instrument. CONSERVEZ LE MANUEL POUR TOUTE RÉFÉRENCE

FUTURE.

Toujours utiliser, examiner et entretenir ce pistolet pulvérisateur

conformément aux consignes de sécurité portant sur les outils

pneumatiques portatifs de l'American National Standards Institute

(ANSI B186.1) et à toute autre consigne de sécurité

ou tout règlement en vigueur.

Du solvant peut être évacué lors de l'utilisation, du nettoyage et

du rinçage du pulvérisateur. Certains solvants peuvent

causer des blessures aux yeux. Toujours porter des lunettes

de protection.

Assurez-vous que toutes les personnes autour ont un protecteur

résistant au choc pour le visage et les yeux.

Même les plus petits projectiles peuvent causer des blessures

aux yeux ou la cécité.

Un niveau sonore élevé peut causer une perte d’audition

permanente. Protégez-vous du bruit. Le niveau sonore peut varier

en raison de la surface de travail. Porter une protection auditive.

Les mouvements répétitifs, des positions inconfortables et une

exposition aux vibrations peuvent causer des dommages aux

bras et aux mains.

L’air sous pression peut causer de graves blessures. Toujours

fermer l’alimentation d’air, enlever la pression dans le tuyau d’air

et débrancher l’outil de toute source d’alimentation lorsqu’il n’est

pas utilisé, lors d’un changement d’accessoire ou lors de

réparations. Ne jamais diriger le jet d’air vers vous ou quelqu’un

d’autre. Les boyaux flexibles peuvent causer de graves blessures.

Toujours s’assurer qu’il n’y a pas de pièces endo magées ou

desserrées. Ne jamais utiliser de raccord rapide directement du

côté de l’outil. Ils ajoutent du poids et pourraient causer un

mauvais fonctionnement à cause des vibrations. Ajoutez plutôt un

boyau flexible et un raccord entre l’alimentation d’air et le boyau

flexible, ou entre le boyau flexible et le tuyau d’arrivée. Ne pas

dépasser 50 psi de pression d’air.

Toujours utiliser le pistolet pulvérisateur à une distance

sécuritaire des autres personnes dans l’espace de travail.

Entretenez le pistolet pulvérisateur avec soin. Garder les outils

bien huilés et propres pour obtenir les meilleures performances

sécuritaires. Bien suivre les directives pour la lubrification et les

changements d’accessoires. Les chiffons et les autres déchets

inflammables doivent être mis dans un contenant de métal

étanche et jeté ensuite de façon adéquate.

Ne pas porter de vêtement ample, ou malajusté, enlever montre

et bagues.

Garder l’équilibre. Conserver un bon équilibre en tout temps. Les

faux pas, les chute et les pertes d’équilibre sont les principales

causes de décès et de blessures graves. Faire attention au

surplus de boyau par terre ou sur la surface de travail.

Prendre soin des boyaux et des raccords. Ne pas transporter le

pulvérisateur en tirant sur le boyau ni tirer brusquement sur le

boyau pour le débrancher de la prise d'air. Tenir les boyaux loin

des sources de chaleur, de l’huile et des bords tranchants. Avant

chaque utilistion, rechercher les signes de bris ou d’usure des

boyaux, assurez-vous que tous les raccords sont bien fixés.

Les solvants et la peinture peuvent être hautement inflammables

lorsqu'ils sont pulvérisés. Un système de ventilation adéquat doit

être en place pour éviter l'accumulation de produits inflammables

dans l'air. L'interdiction de fumer doit être en vigueur dans l'aire

de travail. Des extincteurs doivent également être placés à

proximité.

Il est préférable, lorsque c’est possible, d’attacher fermement la

pièce de travail avec des pinces ou un étau afin d’avoir les deux

mains libres pour manipuler cet outil.

Certains solvants peuvent être nocifs s'ils sont inhalés ou s'ils

entrent en contact avec la peau. Toujours suivre les directives

figurant sur la fiche signalétique fournie par le fabricant du

produit de revêtement utilisé. Un système de ventilation adéquat

doit être en place pour éviter l'accumulation de produits toxiques

dans l'air. Toujours utiliser un masque ou un respirateur lorsqu'il

y a risque d'inhalation du produit pulvérisé. Le masque doit

convenir au type de produit pulvérisé et à sa concentration.

Le respirateur doit être homologué NIOSH.

Les solvants à base d'hydrocarbure halogéné comme le

chlorure de méthylène et le trichloro-1,1,1 éthane ne sont

pas chimiquement compatibles avec l'aluminium qui est

parfois utilisé pour la fabrication des composants du pistolet

pulvérisateur. La réaction chimique causée par ces solvants

au contact de l'aluminium peut être violente et entraîner une

explosion. Les pistolets dotés de canalisations internes en acier

inoxydable peuvent être utilisés pour ces solvants. Toutefois,

l'aluminium étant grandement utilisé dans d'autres applications

d'équipement de pulvérisation, il convient de vérifier tous les

composants d'un équipement avant d'utiliser ces solvants pour

assurer que l'usage se fera en toute sécurité. Lire l'étiquette ou

la fiche technique du produit à pulvériser. En cas de doute sur

la compatibilité du produit de revêtement ou de nettoyage,

communiquer avec le fournisseur du produit.

Les opérateurs de pistolets pulvérisateurs doivent suivre une

formation adéquate sur l'utilisation et l'entretien sécuritaire de

l'équipement. Les utilisateurs doivent respecter les règles locales

et nationales en vigueur ainsi que les exigences des compagnies

d'assurance en matière de ventilation, de protection contre

l'incendie, d'utilisation, d'entretien et de nettoyage, notamment

les sections 1910,94 et 1910,107 de l'OSHA, et la section

NFPA-33.

L'utilisation de pistolets pulvérisateurs peut causer des lésions

dues aux mouvements répétitifs (LMR). Chez les utilisateurs de

pistolets pulvérisateurs, les LMR se situent habituellement dans

les extrémités supérieures. Les facteurs qui peuvent accroître le

risque de LMR comprennent :

1. Fréquence élevée de l'activité.

2. Effort excessif, par exemple, serrage, pincement ou pression

avec les mains et les doigts.

3. Position extrême ou inhabituelle des doigts, du poignet ou

du bras.

4. Durée excessive de l'activité.

5. Vibrations.

6. Pression répétée sur une partie du corps.

7. Utilisation à des températures froides

CONSIGNES DE SECURITE – NE PAS JETER – DONNER A L’UTILISATEUR

SX76: Vue éclatée des pièces et mode d'emploi 17 01/07/13

Page 18

AVERTISSEMENT

(CONTINUÉ)

Pour réduire les risques de blessure, toute personne chargée de la réparation, de l’entretien ou du remplacement des

accessoires de cet outil doit au préalable lire et comprendre ces instructions avant d’effectuer l’une de ces tâches.

Les LMR peuvent aussi être causées par la pratique d'un sport.

De la douleur, un fourmillement ou un engourdissement dans

l'épaule, l'avant-bras, le poignet, les mains ou les doigts,

particulièrement durant la nuit, peuvent être des symptômes

précoces de LMR. Il ne faut pas ignorer ces symptômes. Si

de tels symptômes apparaissent, consulter un médecin

immédiatement. Un vague inconfort de la main, une perte

de la dextérité de la main et une douleur imprécise dans

le bras sont d'autres symptômes précoces. Le fait d'ignorer

des symptômes précoces et de continuer des mouvements

répétitifs du bras, du poignet et de la main peut causer de

graves invalidités.

Certaines particules solides créées par des activités liées au

ponçage mécanique, au sciage, au broyage, au forage et à

d’autres activités de construction contiennent des produits

chimiques classés par l’Etat de Californie comme des causes de

cancer, d’anomalies congénitales ou d’autres troubles de la

reproduction. Au nombre de ces produits chimiques figurent :

- le plomb provenant des peintures au plomb

- parpaings, ciment et autres produits de

maçonnerie contenant la silice cristalline

- l’Arsenic et le chrome provenant du bois traité

avec un produit chimique

Les risques que vous courez lors de l’exposition à ces

substances varient en fonction du nombre de fois où vous

faites ce type de travail. Pour réduire votre exposition à ces

substances chimiques : travaillez dans un local bien ventilé

et revêtez des équipements de sécurité approuvés, tels que

les masques anti-poussière conçus spécialement pour

éliminer les particules microscopiques.

Les composants de laiton de ce produit contiennent du plomb, un

produit reconnu par l’État de la Californie comme pouvant causer

des anomalies congénitales ou nuire d’une autre manière à la

reproduction. Se laver les mains après avoir utilisé le produit.

MISES EN GARDE IMPORTANTES – LIRE AVANT L'UTILISATION

DU PISTOLET PULVÉRISATEUR :

DESCRIPTION DU PISTOLET PULVÉRISATEUR

Le SX76 est un pistolet pulvérisateur conventionnel léger et à

usage général conçu pour divers types de pulvérisations.

IMPORTANT : Ce pistolet pulvérisateur convient à la plupart des

produits courants de revêtement et de finition. Il est conçu pour

être utilisé avec des produits légèrement corrosifs et non

abrasifs. Si l'appareil est utilisé avec des produits hautement

corrosifs ou abrasifs, il sera nécessaire de le nettoyer à fond et

fréquemment. Aussi, la fréquence de remplacement des pièces

sera accrue.

ALIMENTATION D'AIR

Placer le tuyau versle

réservoir d’air comprimé

Débit

d'air

PCM

10

20

30

40

50

70

Longueur du

tuyau (pi)

50 100 150 200

1/2 po

3/4 po

3/4 po

1 po

1 po

1 po

3/4 po

3/4 po

3/4 po

1 po

1 po

1 po

3/4 po

3/4 po

1 po

1 po

1 po

1-1/4 po

3/4 po

3/4 po

1 po

1 po

1 po

1-1/4 po

Drain

Compresseur

Install drain at

each low point

Séparateur

eau/huile

7,6 m (25 pi)

ou plus

Le séparateur eau/huile doit être à une distance

d’au moins 7,6 m (25pi), et même plus loin du

compresseur si possible.

Drain

Ne jamais installer un séparateureau/huile sur un compresseur d'air ou près de celui-ci.

Pendant la compression, la température de l’airaugmente beaucoup. Lorsque l’air retourne à la température ambiante, l’humidité se condense dans

la canalisation d’air, en direction du pistolet pulvérisateur. Par conséquent, il faut toujours installer le séparateur eau/huile à un endroit du sytème

d’arrivée d’air où la température de l’air est la plus basse.

Vidanger adéquatement les canalisations d’air.

Envoyer les canalisations d’air vers le compresseur pour que le condensat retourne vers le réservoir d’air comprimé où il sera évacué. Chaque

point bas le long de la canalisation d’air emprisonne l’eau. Ces points bas doivent être raccordés à un drain accessible facilement. Voir le schéma

ci-dessus.

CONSIGNES DE SECURITE – NE PAS JETER – DONNER A L’UTILISATEUR

SX76: Vue éclatée des pièces et mode d'emploi 18 01/07/13

Page 19

INSTALLATION

Ce pistolet pulvérisateur est de construction robuste,

et est bâtit pour offrir un rendement exceptionnel.

La durée de vie de ce produit et l’efficacité de son

fonctionnement dépendent des connaissances de

sa construction, son utilisation et son entretien.

RACCORDEMENT DU RÉSERVOIR

D’ALIMENTATION DE LA POMPE

La pression d’air pour la pulvérisation est réglée à

l’extracteur. La quantité de liquide s’ajuste par la

vis de contrôle du liquide sur le pistolet et selon

la viscosité de la peinture et la pression d’air.

HVLP

Réservoir

à liquide

Vis de contrôle

du liquide

Entrée d'air

Indicateur de

pression de

pulvérisation

Boyau d’air

POUR UNE PERFORMANCE OPTIMALE, SUIVRE LES DIRECTIVES

SUIVANTES AVANT D'UTILISER LE PISTOLET PULVÉRISATEUR

•Bienfixerlepistoletetlegodetavecleraccordetl’écroufournis.

•Assurez-vousd’avoirlapressiond’airappropriéeaupistoletpourlefonctionnement.Lapressiond’airappropriéepourcetoutilne

doit pas dépasser 50 PSI.

•Réglerlavisdecontrôleduliquideetlavisdelargeurdepulvérisationpourobtenirlemotifdésiréavantdel’utilisersurlapièce.

•Biennettoyertouteslespiècesaprèsl’utilisation.

Séparateur

eau/huile

RÉGLAGES

PISTOLET PULVÉRISATEUR À

HAUTE PRESSION

Le modèle que vous avez acheté est un pistolet

à peinture professionnel à haut volume et basse

pression. Il est conçu pour vaporiser la peinture de

manière très efficace avec pratiquement aucune

perte de peinture à la pulvérisation. Pour y arriver,

il est crucial de régler la pression d’admission d’air.

Assurez-vous de lire attentivement les exigences

relatives à la pression d’air.

Vis de réglage de la largeur de pulvérisation

Tourner vers la droite pour un jet rond,

et vers la gauche pour un jet en éventail.

Vis de contrôle du liquide

Tourner vers la droite pour diminuer le

débit et vers la gauche pour l’augmenter.

PULVÉRISATION

Pour une utilisation normale, les ailettes de la buse doivent être placées horizontalement comme illustré ici. Ceci vous

donne un jet en éventail vertical qui permet un rendement en surface maximum en déplaçant le pistolet de gauche à

droite parallèlement à la surface à peindre.

Régler la pression de pulvérisation à moins de 50 psi. Pour obtenir des

résultats optimums, certains produits se pulvérisent mieux à un niveau

inférieur à 50 psi. Il faut toujours faire un essai si vous n’êtes pas certain du

calibrage psi, avant de faire l’application sur la pièce. Essayer le jet. Si le jet

est trop fin, diminuer la pression d’air ou ouvrir la vis de contrôle du liquide.

Si la pulvérisation est trop épaisse, fermer la vis de contrôle de liquide.

Régler la largeur du jet et recommencer les réglages du jet au besoin.

Le jet de pulvérisation peut être réglé

à l’infini d’un jet rond à un jet plat.

SX76: Vue éclatée des pièces et mode d'emploi 19 01/07/13

Page 20

FONCTIONNEMENT

Un maniement adéquat du pistolet est nécessaire pour obtenir une belle finition. Le pistolet doit être tenu à angle droit par rapport à la surface à

traiter et il doit se déplacer parallèlement à celle-ci. Pour un contrôle précis du pistolet et du produit, la gâchette doit être relâchée avant la fin du

mouvement.

Tenir le pistolet entre 15 et 30 cm (6 à 12 po) de la surface selon le type de produit et la pression de pulvérisation. Pour un fini uniforme, faire

chevaucher chaque pulvérisation sur la précédente en s’assurant que le jet est lisse et humide.

Amorcer le

mouvement

15 à 30 cm (6 à 12 po)

Appuyer sur

la gâchette

DROIT

Couche uniforme

et humide

Relâcher

la gâchette

Couche

Mince

Fin du

mouvement

MAL

Manteau

Lourd

NETTOYAGE ET ENTRETIEN

PISTOLET PULVÉRISATEUR

1. Submergez l’avant pistolet dans le solvant jusqu’à ce que le raccordement du fluide soit recouvert.

2. La peinture qui c’est accumulé dans le pistolet devrait être retiré en utilisant une brosse en

soies de porc et un solvant.

3. Ne jamais submerger le pistolet en entier dans le solvant parce que :

• Cecidissoudraitlelubrifiantdanslagarnitured’étanchéitédecuiretsurlessurfaces

d’usures, causant l’assèchement et ayant comme résultat le fonctionnement difficile

et une usure prématurée.

• Lespassagesd’airdanslepistoletdeviendrontengorgésavecdusolvantsale.

4. Utilisez un chiffon humide avec un peu de solvant pour essuyer l’extérieur du pistolet.

5. Huilez le pistolet quotidiennement. Utilisez une goutte d’huile à machine légère sur :

A. Garniture d’étanchéité de l’aiguille du fluide

B. Garniture d’étanchéité de la valve d’air

C. point du pivot de la gâchette

Voir Fig. 1 pour l’emplacement de ces points.

6. REMARQUE : Ne pas tremper les joints toriques en caoutchouc ou les raccords dans

le solvant à peinture. Les joints toriques et les raccordspeuvent être essuyé avec du

solvant à peinture mais ne peuvent pas tremper dans le solvant à peinture car cela

peut causer une détérioration avec le temps.

7. Avertissement : Ne pas utiliser de lubrifiants qui contiennent du silicone. Le silicone

peut causer des défauts dans l’application finale.

A

FIG. 1

C

B

MISE EN GARDE…

Pour éviter la déformation du filetage, toutes les pièces devraient être vissées fortement à la main au départ. Si les pièces ne se vissent pas

facilement à la main, s’assurer que vous avez les bonnes pièces, les dévisser, les réaligner et recommencer. Ne JAMAIS utiliser la force sur

es pièces.

BUSE D’AIR ET DE LIQUIDE ET VALVE D’AIR

1. Toutes les buses et aiguilles sont fabriquées selon des normes très strictes. Veuillez les manipuler avec soin.

2. Pour nettoyer les buses, les immerger dans le solvant jusqu’à ce que tous les produits secs se dissolvent, ensuite les nettoyer à l’air comprimé.

3. Ne pas utiliser des instruments pointus ou métalliques pour nettoyer les orifices des buses.

4. Le débit d’air doit se produire avant le débit de produit lorsqu’on appuie sur la gâchette. Il peut être nécessaire d’ajuster la vis de contrôle de

liquide pour s’assurer que l’air passe avant le produit.

5. Ne jamais modifier le pistolet d’aucune façon.

ALIMENTATION PAR POMPE

Fermez l'approvisionnement d'air. Retirez le couvercle du godet. Videz la substance contenue dans le godet. Nettoyez le godet et le couvercle.

Rétablir l'approvisionnement d'air et pulvérisez avec le solvant de nettoyage adéquat. Répétez avec du solvant propre si nécessaire. Retirez le

solvant, débranchez le pistolet, retirez le bouchon d'air et le nettoyez. Essuyez le pistolet et le godet avec un chiffon imbibée de solvant.

SX76: Vue éclatée des pièces et mode d'emploi 20 01/07/13

Page 21

DÉPANNAGE

PULVÉRISATION/

CONDITION

Éclaboussures

PROBLÈMEPATRON DE

Un côté des ailettes de la buse est bloqué.

A.) Buse d’air mal fixée.

B.) À l’extérieur de la buse, il y a

des résidus de produits

A.) La pression d’air pour la

pulvérisation est trop élevée.

B.) Pulvérisation d’un produit trop clair

en jet trop large.

A.) La garniture d’étanchéité autour de

la valve du pointeau est sèche.

B.) La buse de liquide n'est pas assez

vissée ou il y a de la saleté entre la

buse et le corps du pistolet.

C.) L’écrou tournant est mal vissé ou

défectueux sur le godet.

SOLUTION

Mettre la buse dans le solvant pour enlever le blocage, ensuite

faire passer de l'air jusqu'à ce qu'elle soit propre. Pour nettoyer les

orifices, utiliser un brin de paille ou un cure-dent. Ne jamais utiliser

d’outil pointu pour enlever des résidus de produit.

A.) Resserrer la buse d’air.

B.) Enlever la buse à air et essuyer le bout pour le

liquide en utilisant un chiffon et du diluant.

A.) Réduire la pression d’air.

B.) Augmenter la quantité de produit en tournant la vis

de contrôle de liquide vers la gauche, tout en réduisant

la largeur du jet en tournant la vis de réglage du jet.

A.) Dévisser l’écrou à molette, mettre quelques gouttes

d’huile à machine sur la garniture d’étanchéité et revisser

l’écrou.

B.) Enlever la buse à liquide, nettoyer l’arrière de la buse et

l’endroit où elle s’insère sur le pistolet. Remettre la buse

en place et bien la visser.

C.) Resserrer ou remplacer l’écrou à molette.

A.) Le pistolet est mal réglé.

B.) Le bouchon à air est sale.

Jet inadéquat.

Impossible d’obtenir un jet rond. La vis de réglage n’est pas bien installée. La nettoyer ou la remplacer.

Aucun jet.

Fuite de liquide en provenance de

l’écrou de presse-garniture.

La pointe du liquide fuit.

C.) La pointe du liquide est obstruée.

D.) Le pointeau bouge lentement.

A.) Aucune pression d’air au pistolet.

B.) La pression du liquide est trop basse au

niveau du chapeau de mélange interne

et dans le réservoir sous pression.

C.) La vis de contrôle de liquide n’est

pas assez ouverte.

D.) Liquide trop lourd.

A.) L’écrou de presse-garniture n’est pas

assez vissé.

B.) La garniture d’étanchéité est sèche

ou usée

A.) Garniture d’étanchéité sèche.

B.) Le pointeau bouge lentement.

C.) L’égout de presse-garniture est

trop serré.

D.) La buse de liquide ou le pointeau

sont usés.

A.) Refaire les réglages du pistolet. Bien suivre les directives.

B.) Nettoyer le bouchon à air.

C.) Nettoyer.

D.) Lubrifier.

A.) Vérifier l’alimentation et les canalisations d'air.

B.) Augmenter la pression du liquide au réservoir.

C.) Ouvrir la vis de contrôle du liquide.

D.) Éclaircir le produit ou passer à l’alimentation par pression.

A.) Resserrer, mais pas trop, pour ne pas endommager

le pointeau.

B.) Remplacer ou lubrifier la garniture d'étanchéité.

A.) Lubrifier.

B.) Lubrifier.

C.) Régler.

D.) Pour l’alimentation par pression, remplacer la buse de

liquide et le pointeau.

A.) Le pistolet est trop loin de la surface.

Finition mince grossière et rugueuse.

Finition épaisse et bosselée

ressemblant à de la peau d’orange.

SX76: Vue éclatée des pièces et mode d'emploi 21 01/07/13

B.) La pression de pulvérisation est trop

haute.

Le pistolet est trop près de la surface.

A.) Rapprocher le pistolet de la surface.

B.) Régler la pression de pulvérisation.

Éloigner le pistolet de la surface.

Page 22

GARANTIE LIMITÉE...

SUNEX INTERNATIONAL, INC. GARANTI À SES CLIENTS QUE LES PRODUITS DE L’ENTREPRISE SUNEX TOOLS® SONT

EXEMPTS DES DÉFAUTS DE MAIN-D’ŒUVRE ET DE MATÉRIAUX.

Sunex International, Inc. réparera ou remplacera ses outils de marque Sunex Tools® qui ne donnent pas un service satisfaisant à cause d'un

défaut de main d'œuvre ou de matériau, selon les termes et conditions décrits ci-dessous dans les plans de garantie correspondant à ce produit

spècifique. Ce produit a une garantie de quatre-vingt-dix jours. Pendant la période de garantie, Sunex Tools réparera ou remplacera, à sa seule

discrétion, toute pièce ou tout appareil dont il a été déterminé qu'il comporte un défaut de matériau ou de main d'œuvre.

Autres informations importantes sur la garantie...

Cette garantie ne couvre pas les dommages à de l'équipement ou à des outils modifiés, sujets à des abus ou à une utilisation incorrecte, ou

encore endommagés; elle ne couvre pas les réparations ou le remplacement effectué par quiconque autre que Sunex Tools ou ses centres

de services de garantie autorisés. L'obligation qui précède constitue la seule responsabilité de Sunex Tools en vertu de cette garantie

ou de toute garantie implicite; et en aucun cas Sunex Tools ne pourra être responsable pour des dommages indirects ou consécutifs.

Remarque : Certaines juridictions ne permettent pas l'exclusion ou la limitation des dommages indirects ou consécutifs; la limitation ou

l'exclusion ci-dessus pourrait donc ne pas s'appliquer à votre cas. Retourner l'équipement ou les pièces à Sunex Tools, ou à un centre de service

de garantie autorisé, port prépayé. S'assurer d'inclure votre nom, votre adresse, une preuve de la date d'achat et la description de la défaillance

présumée. Veuillez adresser par écrit toutes vos questions sur le service de garantie à Sunex Tools. Cette garantie donne à l'acheteur des droits

juridiques spécifiques ainsi que certains autres droits qui peuvent varier selon la juridiction. Les trousses de réparation et de remplacement sont

disponibles pour plusieurs produits Sunex Tools, peu importe si le produit est encore sous garantie.

Adresse d'expédition : Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Adresse postale : Sunex Tools • P.O. Box 4215 • Greenville, SC 29608

SX76: Vue éclatée des pièces et mode d'emploi 22 01/07/13

Loading...

Loading...