Page 1

Operating Instructions • Warning Information • Parts Break down

WARNING

ALWAYS READ INSTRUCTIONS BEFORE

USING POWER TOOLS

ALWAYS WEAR SAFETY GOGGLES

WEAR HEARING PROTECTION

AVOID PROLONGED EXPOSURE TO VIBRATION

SPECIFICATIONS

Collet Opening ........... 0.401" (10.19mm)

Blows per Minute .................2,200 BPM

Bore Diameter.....................3/4" (19mm)

Piston Stroke ............. 3-3/4" (95.25mm)

Weight ........................ 4.6 Lbs. (2.09 kg)

Length ........................ 8.88" (225.55mm)

Average Air

Consumption .............. 4 CFM (91 l/min)

Air Inlet .....................................1/4" NPT

Minimum

Hose Size ..................... 3/8" I.D. (10mm)

Sound Level ..............................110 dBA

SX243

Heavy

duty long

barrel air

Hammer

witH quick

cHange cHiSel

retainer

SX243: Parts Breakdown & Operating Manual 1 Rev. 09/20/11

Page 2

To reduce the risk of injury, anyone using, repairing, maintaining, or changing accessories on this tool must

WARNING

read and understand these instructions before performing any of these tasks.

Always inspect, operate, and maintain this tool in

accordance with American National Standards Institute

Safety Code of Portable Air Tools (ANSI B186.1) and any

other applicable safety codes and regulations.

These tools are rated at 90 psi / 6.2 bar max air

pressure for safety, top performance, and maximum

durability of parts; do not exceed this pressure while

the tool is running.

Always shut off air supply, drain hose of air pressure

and disconnect tool from air supply when not in use,

before changing accessories, or when making repairs.

Never direct air at yourself or anyone else.

Always wear impact-resistant eye and face protection

when operating or performing maintenance on this tool.

High sound levels can cause permanent hearing loss.

Always use hearing protection when using this tool as

recommended by your employer or OSHA regulation.

Do not wear jewelry or loose fitting clothes.

Do not use quick disconnect couplings at tool. See

operating instructions for proper set up.

Whipping hoses can cause serious injury. Always

carefully check for damaged or loose hoses and

fittings before operating this tool.

Never operate a tool unless the accessory is retained in

the tool with a proper retainer that has been approved

by Sunex Tools®.

To avoid injury, retainer parts must be replaced when

they become worn, cracked, or distorted.

Avoid direct contact with accessories during and after

use. Gloves should be worn to reduce the risk of cuts or

burns.

Never run the tool off of the work. Accessory must be

held firmly against work surface before tool is throttled.

Slipping, tripping, and/or falling while operating air tools

can be a major cause of serious injury or death. Be

aware of your surroundings and any excess hose left on

the walking or working surface.

Pneumatic tools can cause vibration in use. Vibration,

repetitive motions or uncomfortable positions over

extended periods of time may be harmful to your hands

and arms. Discontinue use of tool if discomfort, tingling

feeling or pain occurs. Consult a physician before

resuming use if any of these symptoms occur.

Do not stretch or overreach while using this tool.

If tool appears to malfunction, remove from service

immediately and arrange for repair.

Never use tool if there is any chance of coming into

contact with line electricity.

Use only Sunex certified spare parts for any repair made

to tool. Repairs should only be performed by properly

trained persons.

Do not lock, tape or wire the tool valve in the "on/off"

position.

Do not allow the exhaust air to come in contact with hot

surfaces or flames.

Avoid inhaling dust or handling debris from the work

process, which can be harmful to your health. Use dust

extraction and wear respiratory protective equipment

when working with materials which produce airborne

particles.

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains

chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

Some examples of these chemicals are:

- Lead from lead based paints

- Crystalline silica bricks and cement and other

masonry products

- Arsenic and chromium from chemically-treated

lumber

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter

out microscopic particles.

Additional Safety Warnings

Do not modify this tool or its accessories.

This tool is not recommended for use in explosive

atmospheres or underwater use.

Operators and maintenance personnel must be

physically able to handle the bulk, weight, and power

of this tool.

This tool is for professional use only.

SAFETY INSTRUCTIONS - DO NOT DISCARD - GIVE TO USER

SX243: Parts Breakdown & Operating Manual 2 Rev. 09/20/11

Page 3

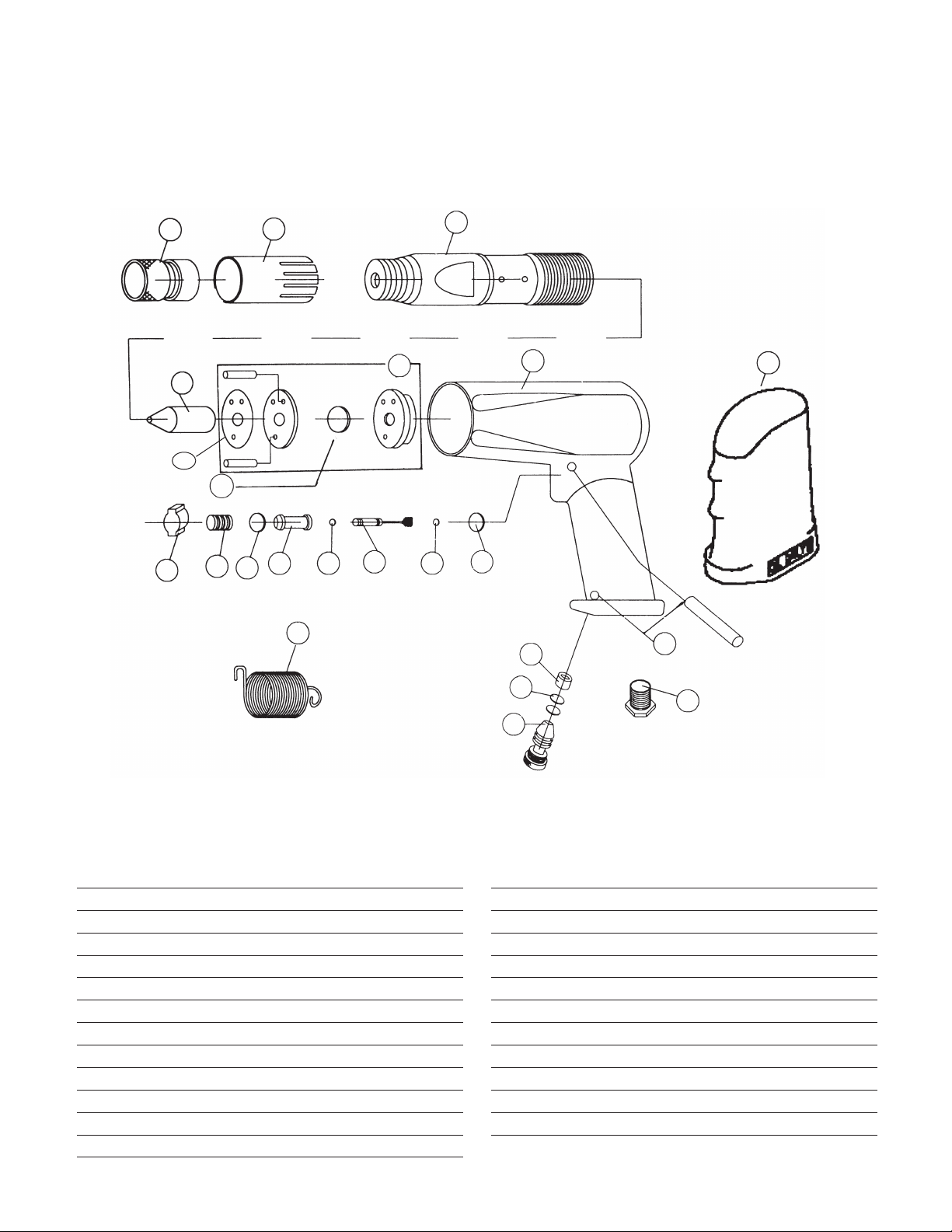

SX243

Heavy duty long barrel air Hammer

witH quick cHange cHiSel retainer

25

20

15 -1

17

14

13

12

24

15

11

10

23

8

21

1

9

7

4

2

22

REF. PART DESCRIPTION QTY.

NO. NO.

1 RS243001 Housing (incl. #2-14, 22) 1

2 RS848002 Roll Pin (3 x 18mm) 2

3 RS848003 Inlet Bushing 1

4 RS848004 Cap 1

5 RS848005 O-Ring (4.9 x 2.2mm) 2

6 RS848006 Regulator 1

7 RS848007 O-Ring (11 x 2.4mm) 1

8 RS848008V Valve Stem 1

9 RS848009 O-Ring (3.8 x 1.9mm) 1

10 RS848010 O-Ring (3.5 x 1.5mm) 1

11 RS848011 Valve Bushing 1

12 RS848012 O-Ring (12 x 2mm) 1

5

3

6

REF. PART DESCRIPTION QTY.

NO. NO.

13 RS848013 Spring 1

14 RS848014 Trigger Button 1

15-1 RS848015S-1 Metal Disk Plate 1

15 RS171815 Valve Block Assembly 1

17 RS171816 Valve Disk 1

20 RS848019 Piston 1

21 RS848320 Cylinder 1

22 RS248022B Comfort Grip 1

23 RS87301 Retainer Spring (optional)

24 RS848023 Exhaust Deflector 1

25 RS248025 Quick Change Chuck 1

SX243: Parts Breakdown & Operating Manual 3 Rev. 09/20/11

Page 4

FIGURE 1

Air Supply...

Tools of this class operate on a wide range of air pres sures. It is

recommended that air pres sure of these tools mea sures 90 PSI at the

tool while running free. Higher pres sure (over 90 psig; 6.2 bar) will

short en the tool life and can cause accessory failure due to over speed.

Always use clean, dry air. Dust, corrosive fumes and/or water in the air

line will cause damage to the tool. Drain the air tank daily. Clean the

air inlet filter screen on at least a weekly schedule. The rec om mend ed

hookup pro ce dure can be viewed in figure 1.

Lubrication...

Lubricate the tool each day after use with quality SAE #10 air motor oil.

Add the oil to the air inlet or into the hose at the nearest connection to

the air supply then run the tool until all excess oil is expelled from the

exhaust. Total oil quantity needed for this procedure is approximately

1 ounce.

Troubleshooting...

Other factors outside the tool may cause loss of power or erratic

action. Reduced compressor output, excessive drain on the air line,

moisture or restrictions in air pipes or the use of hose connections of

improper size or poor conditions may reduce air supply. Grit or gum

deposits in the tool may cut power and may be corrected by

cleaning the air strainer and flushing out the tool with gum

solvent oil or an equal mixture of SAE #10 and kerosene. If outside

conditions are in order, disconnect tool from hose and take tool to

your nearest authorized service center.

Operation...

Always place a chisel in the hammer and hold the tool down to

the work before operating. Damage to the tool or the retainer may

result if this precaution is not followed.

The chisel retainers are not designed for complete safety against

accidental release of cutters or hammers. To avoid injury, the

throttle (trigger) must never be depressed unless the chisel is

held firmly against the work place. When tool is not in actual use,

the chisel must be removed. During operation, safety goggles

should ALWAYS be used to guard against flying rust and chips.

When using tool, regulate the speed so that the chisel is not being

driven out of the cylinder. If piston is allowed to strike the cylinder

wall, internal damage will result.

Limited Warranty...

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS® BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective workmanship

or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product. This product carries a

ONE-YEAR warranty. During this warranty period, Sunex Tools® will repair or replace at our option any part or unit which proves to be defective in material or

workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or replacement made

by anyone other than Sunex Tools® or its authorized warranty service centers. The foregoing obligation is Sunex Tools® sole liability under this or any implied

warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Return equipment or parts to Sunex Tools®, or an authorized warranty service center, transportation prepaid. Be certain to include your name and address,

evidence of the purchase date, and description of the suspected defect.

If you have any questions about warranty service, please write to Sunex Tools®. This warranty gives you specific legal rights and you may also have other rights

which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools® products regardless of whether or not the product is

still covered by a warranty plan.

SHIPPING ADDRESS: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

MAILING ADDRESS: Sunex Tools • P.O. Box 1233 • Travelers Rest, SC 29690

SX243: Parts Breakdown & Operating Manual 4 Rev. 09/20/11

Page 5

• Instrucciones de Operación • Información de Advertencia • Revisión de Refacciones

ADVERTENCIA

LEER SIEMPRE LAS INSTRUCCIONES ANTES

DE USAR LAS HERRAMIENTAS NUEMÁTICAS

USAR SIEMPRE ANTEOJOS PROTECTORES

USAR PROTECCIÓN PARA LOS OÍDOS

EVITAR EXPOSICIÓN PROLONGADA A LAS

VIBRACIONES

ESPECIFICACIONES

Abertura de collarín ... 0.401" (10.19mm)

Golpes por minuto ...............2,200 BPM

Diámetro de calibre ............3/4" (19mm)

Subida del pistón ...... 3-3/4" (95.25mm)

Peso ........................... 4.6 Lbs. (2.09 kg)

Longitud ..................... 8.88" (225.55mm)

Consumo de air

promedio ..................... 4 CFM (91 l/min)

Entrada de aire ........................1/4" NPT

Tamaño de manguera

recomendada ..... 3/8" diám. int. (10mm)

Nivel sonoro ..............................110 dBA

SX264

martillo

neumÁtico

Para

Servicio

PeSado

con SuJetador

Para cincel de

cambio rÁPido

SX243: Vue éclatée des pièces et mode d'emploi 5 Rev. 09/20/11

Page 6

Para reducir el riesgo de lesiones, cualquier persona quien usa, repara, da servicio o cambia los accesorios en

ADVERTENCIA

esta herramienta debe leer y comprender estas instrucciones, antes de realizar cualquiera de estas tareas.

Siempre inspeccione, opere y realice servicio a esta

herramienta de acuerdo con el Código de Seguridad de las

herramientas neumáticas portátiles del Instituto de Normas

Nacionales Americanas (ANSI B186.1) y cualquier otro código

y norma de seguridad aplicable. Inspect, operate, and

maintain this tool in accordance with American National

Standards Institute Safety Code of Portable Air Tools

(ANSI B186.1) and any other applicable safety codes

and regulations.

Estas herramientas son clasificadas a unas 90 psi / 6.2

barras de máxima presión de aire para su seguridad, mayor

rendimiento y una máxima durabilidad de partes; no exceda

esta presión de aire mientras que la herramienta esté

prendida.

Siempre apague el suministro de aire, vacíe la manguera de

cualquier presión de aire y desconecte la herramienta del

suministro de aire cuando la herramienta no está en uso,

antes de cambiar los accesorios, o al momento de hacer las

reparaciones.

Nunca dirija el aire hacia usted o hacia ninguna otra persona.

Siempre lleve protección de ojos y cara resistentes al

impacto, al momento de operar o realizar mantenimiento

a esta herramienta.

Los altos niveles sonoros pueden ocasionar la pérdida

auditiva permanente. Siempre lleve puesto protección de

los oídos al momento de usar esta herramienta, según se

recomienda por parte de su empleador o las normas de OSHA.

No lleve puesto joyería ni ropa floja.

No use uniones de desconexión rápida c la herramienta.

Consulte las instrucciones de operación para el ensamble

adecuado.

Las mangueras de látigo pueden ocasionar lesiones serias.

Siempre revise cuidadosamente por mangueras o accesorios

dañados o sueltos antes de operar esta herramienta.

Nunca opere una herramienta al menos que se mantenga

el accesori o en la herramienta con un sujetador adecuado

aprobado por parte de Sunex Tools

Para evitar lesiones, las partes del sujetador deben ser

repuestas cuando éstas están desgastadas, agrietadas o

distorcionadas.

Evite el contacto directo con los accesorios durante o después

del uso. Se deben usar guantes para reducir el riesgo de

cortes o quemaduras.

Nunca deje la herramienta prendida fuera del área de trabajo.

El accesorio debe sostenerse firmemente contra la superficie

de trabajo antes de que se estrangule la herramienta.

El deslizamiento, los tropiezos y/o las caídas durante la

operación de las herramientas neumáticas pueden ser una

causa de lesiones serias o la muerte. Esté consciente de sus

alrededores y de cualquier manguera en exceso dejada en el

camino o sobre la superficie de trabajo.

Las herramientas neumáticas pueden ocasionar vibraciones

durante el uso. Las vibraciones, movimientos repetitivos o las

®

.

posiciones incómodas mantenidas durante periodos

extendidos de tiempo pueden ser dañinos para las manos

y los brazos. Deje de usar la herramienta si se dé alguna

incomodidad, sensación de hormigueo, o dolor. Consulte

un médico antes de continuar el uso si se dé cualquiera

de dichas síntomas.

No se estire ni intente extenderse demasiado al momento

de usar esta herramienta.

Si la herramienta aparenta fallarse, deje de usarla

inmediatamente y prepare la reparación de la misma.

Nunca use la herramienta si haya posibilidades de que tenga

contacto con una línea de electricidad.

Use solo piezas de repuesto certificadas de Sunex para

cualquier reparación hecha a la herramienta. Las

reparaciones hechas deben ser realizadas solo por parte

de personal adecuadamente capacitado.

No cierre ni use cinta ni alambre para bloquear la válvula de

la herramienta en la posición de encendido/apagado.

No deje que el aire del escape haga contacto con las

superficies calientes ni con las llamas.

Evite inhalar el polvo o los escombros de la maniobra

proveniente del proceso del trabajo, los que pueden ser

dañinos para la salud. Lleve puesto equipo protector para

la respiración y para la extracción de polvo al momento

de trabajar con los materiales que producen partículas

suspendidas en el aire.

El polvo creado por el trabajo de lijado neumático,

serrado, esmerilado, perforación y otras actividades de

la construcción contiene químicos conocidos en el Estado

de California por ocasionar el cáncer y defectos congénitos

u otros daños de la reproducción. Algunos ejemplos de dichos

químicos son:

- El plomo proveniente de las pinturas con base

de plomo

- Ladrillos de sílice cristalino y el cemento y otros

productos de mampostería

- Arsénico y cromo de madera tratada con químicos

Su riesgo de exposición varía, dependiendo de qué tan

frecuentemente usted realice este tipo de trabajo. Para

disminuir su exposición a dichos químicos: trabaje en un

área bien ventilada y use equipo de seguridad aprobado, tal

como las máscaras anti-polvo las que están específicamente

diseñadas para filtrar las partículas microscópicas.

Advertencias adicionales de seguridad

No haga ninguna modificación a esta herramienta ni a los

accesorios.

Esta herramienta no se recomienda para uso en ambientes

explosivos ni debajo del agua.

Los operadores y el personal de mantenimiento deben estar

físicamente capaces de manejar el volumen, el peso, y la

potencia de esta herramienta.

Esta herramienta está destinada para uso profesional

solamente.

INSTRUCCIONES DE SEGURIDAD – NO LAS DESCARTE – DÉSELAS AL USUARIO

SX243: Desglose de piezas y manual de operación 6 Rev. 09/20/11

Page 7

FIGURA 1

Alimentación de aire...

Herramientas de esta clase operan bajo un rango amplio de presión

de aire. Se recomienda que la presión de aire en estas herramientas

mida 90 PSI en la herramienta al momento de correr libremente. Una

alta presión (mayor a 90 psig; 6.2 barras) disminuirá la vida útil de

la herramienta y podría ocasionar la falla del accesorio debido a una

velocidad excesiva.

Siempre use aire limpio y seco. El polvo y los humos corrosivos y/o el

agua en la línea de aire ocasionará daños en la herramienta. Vacíe el

tanque de aire diariamente. Limpie la pantalla del filtro de la entrad de

aire al menos una vez por semana. El procedimiento recomendado de

conexión puede verse en la figura 1.

Lubricación...

Lubrique la herramienta cada día después del uso con aceite motor

neumático de calidad SAE #10. Agregue el aceite a la entrada de

aire o en la manguera en la conexión más cercana al suministro de

aire, luego deje que la herramienta corra hasta que todo se purgue el

aceite excesivo del escape. La cantidad total de aceite requerida para

este procedimiento es de aproximadamente 1 onza.

Localización y corrección de fallas...

Puede haber otros factores ajenos a la herramienta que sean causa de

pérdida de corriente o acción errática. La potencia reducida de salida

del compresor, el drenaje excesivo en la tubería de aire, humedad

o restricciones en las cañerías de aire o el uso de conexiones de

manguera de tamaño inadecuado o en malas condiciones puede reducir

el suministro de aire. Depósitos de arenilla o goma en la herramienta

pueden cortar la potencia y pueden corregirse limpiando el aspirador

de aire y limpiando a chorro la herramienta con aceite que disuelva

la goma o una mezcla de partes iguales de SAE #10 y querosén. Si

no hay ningún problema con las condiciones externas, desconecte la

herramienta de la manguera y llévela al centro autorizado de servicio

más próximo.

Operación...

Coloque siempre un cancel en el martillo y coloque la herramienta

sobre el área donde va a trabajar antes de comenzar la operación. Si

no se toma esta precaución podrá dañarse la herramienta o el retén.

El diseño de los retenes de cincel no provee una seguridad completa

contra la posibilidad de que se suelten accidentalmente los cortadores

o los martillos. Para impedir lesiones no deberá apretarse nunca el

obturador (gatillo) a menos que el cancel esté firmemente apoyado

contra el área de trabajo. Cuando no se está usando la herramienta

deberá quitarse el cincel. Durante la operación deberán usarse

SIEMPRE gafas de seguridad para protegerse del óxido y de las astillas

que se desprendan. Al usar la herramienta regule la velocidad para

que no se empuje el cancel fuera del cilindro. Si se deja que el pistón

golpee la pared interna del cilindro, puede causar daños internos.

GARANTÍA LIMITADA

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS CON LA

MARCA DE LA EMPRESA SUNEX TOOLS NO CONTIENEN DEFECTOS EN SU MANO DE OBRA NI MATERIAS PRIMAS.

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio debido a que la

mano de obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de garantía descritos a continuación y

asignados a ese producto específico. Este producto tiene una garantía de UN AÑO. Durante ese periodo de garantía, Sunex Tools® reparará o sustituirá, como

así opte por hacerlo, cualquier componente o unidad que se compruebe tener decectos en su materia prima o mano de obra.

Otra importante información de la garantía...

Esta garantía no cubre ningún daño al equipo o herramientas, si este surge como resultado de su alteración, abuso, o mal uso o daños ni tampoco cubre

las reparaciones o reposiciones hechas por cualquier persona ajena a los centros de servicio de garantía autorizados y que no sean de Sunex Tools®. La

obligación antes mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o de cualquier garantía implícita y bajo ninguna

circunstancia quedará bajo su responsabilidad cualquier garantía implícita ya bajo ninguna circunstancia quedará bajo su responsabilidad cualquier daño

incidental o consecuencial.

Nota: Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo tanto la limitación o exclusión

arriba mencionada quizá no pudiera serle pertinente a usted. Devuelva el equipo o componentes a Sunex Tools®, un centro de servicio de

garantía autorizado, con elflete pagado. Asegúres haber incluido su nimbre y dirección, la evidencia de la fecha de adquisición y la descripción

del defecto que se sospeche tener. Si tiene alguna duda relacionada con elservicio de garantía, por favor escríbale a Sunex Tools®. Esta garantía

le concede derechos jurídicos específicos y quizá otros derechos que varían de un estado a otro, Sunex Tools® tiene a su disposición los juegos

de reparación y refacciones de repuesto para muchos de sus productos, sin importar si el producto continúe o no bajo el plan de la garantía.

DIRECCIÓN A EMBARCARSE: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

DIRECCIÓN DE CORREOS: Sunex Tools • P.O. Box 1233 • Travelers Rest, SC 29690

SX243: Desglose de piezas y manual de operación 7 Rev. 09/20/11

Page 8

• Instructions de fonctionnement • Avertissement • Pièces

AVERTISSEMENT

LISEZ TOUJOURS LES INSTRUCTIONS AVANT

D’UTILISER LES OUTILS MOTORISÉS.

PORTEZ TOUJOURS DES LUNETTES

DE SÉCURITÉ.

PORTEZ UNE PROTECTION POUR

LES OREILLES.

ÉVITEZ L’EXPOSITION PROLONGÉE

AUX VIBRATIONS.

SPÉCIFICATIONS

Ouverture à collet ......0.401" (10.19 mm)

Coupes par minute ............... 2,200 CPM

Diamètre d'alésage ....... 3/4 po (19 mm)

Course du piston ... 3-3/4 po (95.25 mm)

Poids ........................... 4,6 Lbs. (2,09 kg)

Longueur ................8,88 po (225,55 mm)

Consommation

d'air moyenne ......... 4 PI³/MIN (91 l/min)

Entrée d'air ...........................NPT 1/4 po

Dimension de boyau

recommandée ..........3/8 po I.D. (10 mm)

Niveau sonore ........................... 110 dBA

SX243

marteau

Pneumatique

rÉSiStant À

long canon

avec diSPoSitiF de

retenue du burin À

cHangement raPide

SX243: Parts Breakdown & Operating Manual 8 Rev. 09/20/11

Page 9

Pour réduire les risques de blessure, toute personne chargée de la réparation, de l’entretien ou du remplacement des

AVERTISSEMENT

accessoires de cet outil doit au préalable lire et comprendre ces instructions avant d’effectuer l’une de ces tâches.

Effectuez toujours l’inspection, la mise en fonction et

l’entretien de cet équipement conformément au Code de sécurité de l’American National Standards Institute Safety Code

of Portable Air Tools (ANSI B186.1) et à tout code et toute

réglementation applicables.

Ces outils sont calculés à 90 psi / 6,2 bar de pression

maximale de l’air pour des raisons de sécurité, de rendement

optimal et de longévité maximale ; ne pas dépasser cette

pression pendant le fonctionnement de l’outil.

Toujours couper l’alimentation en air, arrêter la pression d’air dans le tuyau de vidange et débrancher le tuyau

d’alimentation d’air lorsque l’outil n’est pas utilisé, avant tout

remplacement d’accessoires ou toute intervention sur l’outil.

Ne jamais diriger l’air sur vous-même ou sur quelqu’un

d’autre.

Toujours porter des lunettes résistant aux impacts ou un

écran facial lors du fonctionnement ou de l’entretien de l’outil.

Des niveaux acoustiques élevés peuvent causer une perte

auditive permanente. Toujours porter un dispositif de

protection antibruit lors de l’utilisation de cet outil suivant

les recommandations de votre employeur ou de la

réglementation OSHA.

Eviter de porter des bijoux ou des vêtements amples.

Ne pas utiliser des raccords rapides sur l’outil. Voir la notice

d’emploi pour une installation appropriée.

Le fait de fouetter les tuyaux peut causer des blessures

graves. Toujours examiner l’outil attentivement pour identifier

d’éventuels dommages ou des tuyaux ou ajustements libres

avant de mettre l’outil en marche.

N’actionnez jamais l’outil à moins que l’accessoire soit maintenu dans l’outil avec un dispositif de retenue approprié qui a

été approuvé par Sunex Tools

Afin d’éviter des blessures, les pièces du dispositif de retenue

doivent être remplacées lorsqu’elles sont usées, fendues ou

tordues.

Eviter le contact direct avec les accessoires pendant et après

l’utilisation. Le port des gants est obligatoire pour réduire les

risques de coupures ou de brûlures.

Ne jamais utiliser l’outil hors du service. L’accessoire doit être

tenu fermement contre la surface de travail avant que l’outil

soit actionné.

Le glissement, le desserrage et/ou la chute pendant le

fonctionnement des outils pneumatiques peuvent être une

cause majeure de blessures ou de pertes en vies humaines.

Faire attention à l’environnement et à tout excédent de tuyau

laissé sur le chemin ou sur la plate-forme de travail.

Les outils pneumatiques peuvent causer des vibrations

lorsqu’ils sont utilisés. Les vibrations, les mouvements

répétitifs ou les positions inconfortables pendant de longues

périodes peuvent présenter des dangers pour vos mains et

vos bras. Utiliser l’outil de manière discontinue en cas de

gêne, de sensation de picotements ou de douleurs. Consulter

un médecin avant de reprendre le travail si l’un de ces

symptômes se manifeste.

®

.

Ne pas étirer ou tendre le bras trop loin lors de l’utilisation

du matériel.

Si l’outil ne fonctionne pas convenablement, mettez-le hors

service immédiatement et prenez des mesures pour sa

réparation.

Ne jamais utiliser l’outil si le contact avec des câbles

électriques est possible.

Utiliser seulement les pièces de rechange certifiées par

Sunex pour toute intervention sur l’outil. Les réparations

doivent être effectuées uniquement par le personnel formé à

cet effet.

Ne pas bloquer, condamner ou monter la vanne dans la

position « marche/arrêt.

Ne pas permettre le contact entre l’air vicié et les surfaces

chaudes ou les flammes.

Eviter d’inspirer de la poussière ou de toucher des débris

issus du travail, lesquels peuvent être dangereux pour

la santé. Utilisez les procédés de dépoussiérage et les

équipements respiratoires et de protection lorsque vous

êtes en contact avec des substances qui produisent des

particules en suspension dans l’air.

Certaines particules solides créées par des activités liées au

ponçage mécanique, au sciage, au broyage, au forage et à

d’autres activités de construction contiennent des produits

chimiques classés par l’Etat de Californie comme des causes

de cancer, d’anomalies congénitales ou d’autres troubles

de la reproduction. Au nombre de ces produits chimiques

figurent :

- le plomb provenant des peintures au plomb

- parpaings, ciment et autres produits de

maçonnerie contenant la silice cristalline

- l’Arsenic et le chrome provenant du bois traité avec un

produit chimique

Les risques que vous courez lors de l’exposition à ces

substances varient en fonction du nombre de fois où vous

faites ce type de travail. Pour réduire votre exposition à ces

substances chimiques : travaillez dans un local bien ventilé et

revêtez des équipements de sécurité approuvés, tels que les

masques anti-poussière conçus spécialement pour éliminer

les particules microscopiques.

Avertissements supplémentaires pour renforcer la sécurité

Ne pas modifier cet outil ou ses accessoires.

Cet outil n’est pas conçu pour être utilisé dans une

atmosphère explosive ou sous l’eau.

Les opérateurs et le personnel chargé de son entretien doivent avoir les ressources physiques nécessaires pour

supporter le vrac, le poids et la puissance de cet outil.

Cet outil ne doit être utilisé que par des spécialistes en la

matière.

CONSIGNES DE SECURITE – NE PAS JETER – DONNER A L’UTILISATEUR

SX243: Vue éclatée des pièces et mode d'emploi 9 Rev. 09/20/11

Page 10

FIGURE 1

Entrée D'air...

Les outils de cette classe fonctionnent sur une grande plage de

pression d’air. Il est recommandé d’utiliser une pression de 90 lb/po2

pour l’outil lorsqu'il fonctionne librement. Une pression plus élevée

(plus de 90 psig; 6,2 bars) raccourcira la vie de l'outil et peut causer

l'échec de l’accessoire dû à une survitesse.

Utilisez toujours de l’air propre et sec. La poussière, les fumées

corrosives et/ou l’eau dans la conduite d’air endommageront l’outil.

Évacuez le réservoir d’air quotidiennement. Nettoyez le filtre de

l’entrée d’air au moins une fois par semaine. Vous pouvez consulter la

procédure de connexion recommandée sur la figure 1.

Lubrification...

Lubrifier l’outil au quotidien après son utilisation avec de l’huile

pneumatique à moteur de qualité SAE #10. Ajouter l’huile dans

l’entrée d’air ou dans le tuyau au niveau du raccord le plus proche de

l’alimentation en air, puis faire fonctionner l’outil jusqu’à la vidange de

tout excédent d’huile du tuyau. La quantité d’huile totale requise pour

cette procédure est d’environ 1 once.

Dépannage...

Des facteurs extérieurs à l’outil peuvent causer des baisses de

puissance ou d’autres problèmes. Un débit réduit du compresseur, un

drainage excessif du conduit d’air de l’humidité ou des limitations dans

le boyau d’air ou l’utilisation de raccords de dimensions inadéquates

ou en mauvaise condition peuvent réduire l’alimentation d’air. Des

résidus d’abrasif ou des dépôts accumulés dans l’outil peuvent

diminuer la puissance, ceci peut être corrigé en nettoyant le filtre à air

et en nettoyant l’outil avec du solvant à l’huile pour dépôts, ou avec un

mélange en parts égales d’huile SAE #10 et du kérosène. Si toutes les

conditions extérieures sont excellentes, débrancher l’outil du boyau et

apportez-le à l’atelier de service agrée le plus près.

Mode d’emploi...

Il faut toujours installer un ciseau dans le marteau et déposer l’outil

sur la surface de travail avant de le faire fonctionner. Omettre de suivre

cette directive peut entraîner des dommages à l’outil ou au dispositif

de fixation.

Le système de fixation du ciseau n’est pas conçu pour assurer une

sécurité complète contre les relâchements accidentels des couteaux

ou marteaux. Pour éviter les blessures, le levier (gâchette) ne doit

jamais être enclenché sans que le ciseau soit appuyé fermement

contre la surface de travail. Lorsque l’outil n’est pas utilisé, le ciseau

doit être enlevé. Lors de cette opération, il faut TOUJOURS utiliser des

lunettes de sécurité pour se protéger des éclats de rouille. Lors de

l’utilisation de l’outil, régler la vitesse pour éviter que le ciseau sorte

du cylindre. Si le piston frappe la paroi du cylindre, des dommages

internes se produiront.

Garantie limitée...

SUNEX INTERNATIONAL, INC. GARANTIT À SES CLIENTS QUE LES OUTILS DE MARQUE SUNEX TOOLS SONT EXEMPTS

DE DÉFAUTS DE MAIN D'ŒUVRE ET DE MATÉRIAU

Sunex International, Inc. réparera ou remplacera ses outils de marque Sunex Tools® qui ne donnent pas un service satisfaisant à cause d'un défaut de main d'œuvre

ou de matériau, selon les termes et conditions décrits ci-dessous dans les plans de garantie correspondant à ce produit spécifique. Ce produit a une garantie de UN

AN. Pendant la période de garantie, Sunex Tools

un défaut de matériau ou de main d'œuvre.

Autres informations importantes sur la garantie...

Cette garantie ne couvre pas les dommages à de l'équipement ou à des outils modifiés, sujets à des abus ou à une utilisation incorrecte, ou encore endommagés;

elle ne couvre pas les réparations ou le remplacement effectué par quiconque autre que Sunex Tools® ou ses centres de services de garantie autorisés. L'obligation

qui précède constitue la seule responsabilité de Sunex Tools® en vertu de cette garantie ou de toute garantie implicite; et en aucun cas Sunex Tools® ne pourra être

responsable pour des dommages indirects ou consécutifs. Remarque : Certaines juridictions ne permettent pas l'exclusion ou la limitation des dommages indirects ou

consécutifs; la limitation ou l'exclusion ci-dessus pourrait donc ne pas s'appliquer à votre cas. Retourner l'équipement ou les pièces à Sunex Tools®, ou à un centre

de service de garantie autorisé, port prépayé. S'assurer d'inclure votre nom, votre adresse, une preuve de la date d'achat et la description de la défaillance présumée.

Veuillez adresser par écrit toutes vos questions sur le service de garantie à Sunex Tools®. Cette garantie donne à l'acheteur des droits juridiques spécifiques ainsi

que certains autres droits qui peuvent varier selon la juridiction. Après échéance de la garantie de remplacement direct d'un an, certaines pièces de service seront

disponibles à l'achat par l'entremise des options de services normaux de Sunex Tools®.

ADRESSE D'EXPÉDITION: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

ADRESSE POSTALE: Sunex Tools • P.O. Box 1233 • Travelers Rest, SC 29690

SX243: Vue éclatée des pièces et mode d'emploi 10 Rev. 09/20/11

®

réparera ou remplacera, à sa seule discrétion, toute pièce ou tout appareil dont il a été déterminé qu'il comporte

Loading...

Loading...