Page 1

SX232B 1 Rev. 08/29/07

SX232B

1/4" Dr.

ANGLE

DIE GrINDEr

Max. Free Speed.................20,000 RPM

Collet Size (In.) ................................1/4"

Air Inlet ....................................1/4" NPT

Rec. Hose Size ..........................3/8" I.D.

Rec. Air Pressure .......................90 PSIG

Avg. Air Consumption...................4 CFM

Length .............................................6.2"

Sound Level .............................93.6 dBA

Shipping Weight ....................... 1.11 lbs.

SPECIFICATIONS

ALWAYS READ

INSTRUCTIONS

BEFORE USING

POWER TOOLS

ALWAYS WEAR

SAFETY GOGGLES

WEAR HEARING

PROTECTION

AVOID PROLONGED

EXPOSURE TO

VIBRATION

Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from

chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

Operating Instructions • Warning Information • Parts Breakdown

• MAXIMUM RPM OF 20,000

• MAX AIR PRESSURE:

90 PSIG, 6.2 BAR

• RPM OF THE ACCESSORY

MUST EXCEED TOOL RPM

SX232B_manual_082907.indd 1 8/31/07 1:58:41 PM

Page 2

SX232B 2 Rev. 08/29/07

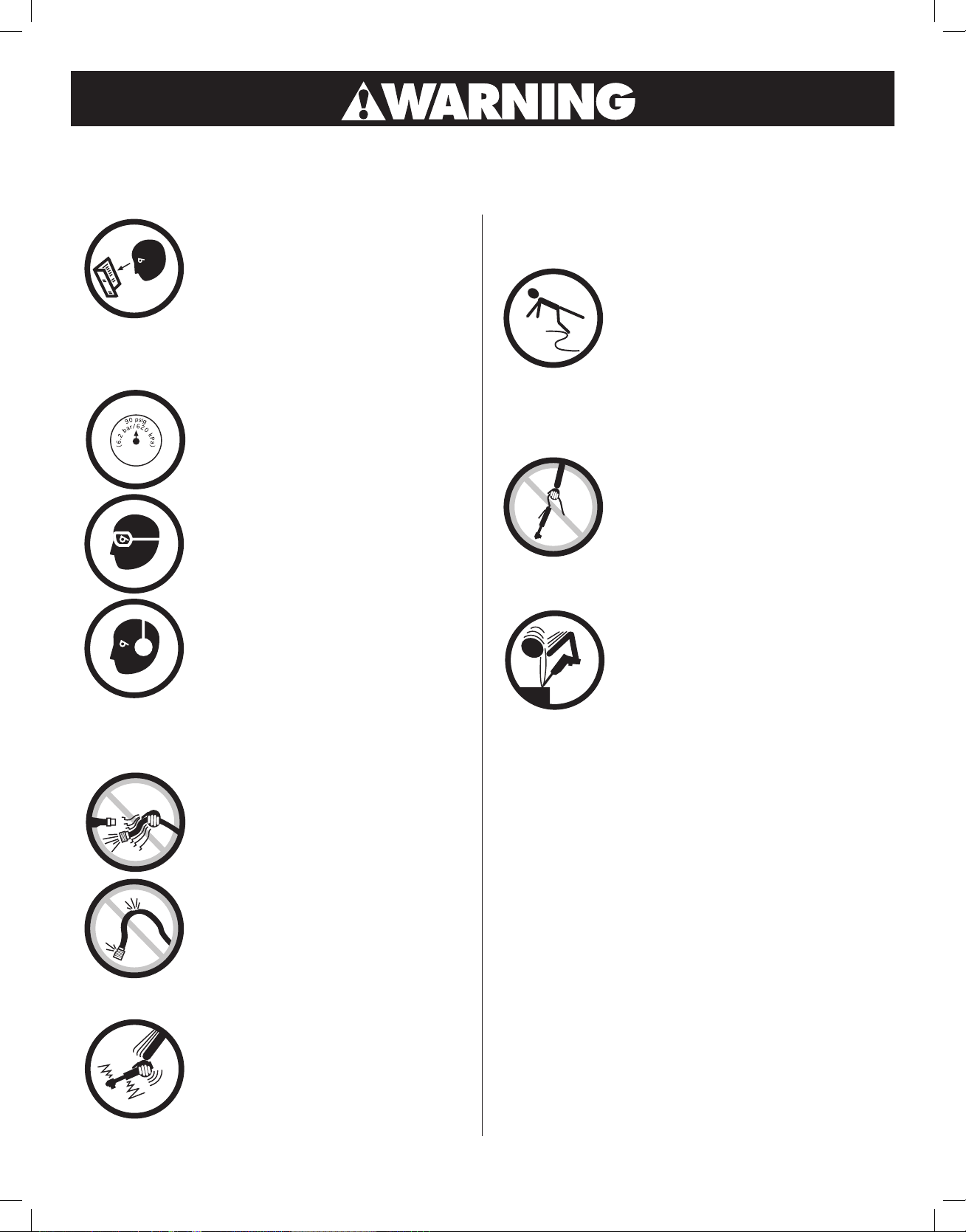

This Instruction Manual Contains Important

Safety Information.

READ THIS INSTRUCTION MANUAL CAREFULLY

AND UNDERSTAND ALL INFORMATION BEFORE

OPERATING THIS TOOL.

• Always operate, inspect and maintain this

tool in accordance with American

National Standards Institute Safety

Code of Portable Air Tools (ANSI

B186.1) and any other applicable safety

codes and regulations.

• For safety, top performance and

maximum durability of parts, operate

this tool at 90 psig; 6.2 bar max

air pressure with 3/8" diameter air supply

hose.

• Always wear impact-resistant eye and face

protection when operating or performing

maintenance on this tool.

• Always wear hearing protection when using

this tool. High sound levels can cause

permanent hearing loss. Use hearing

protection as recommended by your

employer or OSHA regulation.

• Keep the tool in efficient operating

condition.

• Operators and maintenance personnel

must be physically able to handle the bulk,

weight and power of this tool.

• Compressed air can cause severe injury. Never

direct air at yourself or others.

Always turn off the air supply, drain

hose of air pressure and detach tool

from air supply before installing, removing

or adjusting any accessory on this tool,

or before performing any maintenance

on this tool. Failure to do so could result

in injury. Whip hoses can cause serious injury.

Always check for damaged, frayed or loose

hoses and fittings, and replace immediately.

Do not use quick detach couplings at tool.

See instructions for correct set-up.

• Air powered tools can vibrate during use.

Vibration, repetitive motions or

uncomfortable positions over extended

periods of time may be harmful to your

hands and arms. Discontinue use of tool if

discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

• Place the tool on the work before starting

the tool. Do not point or indulge in any

horseplay with this tool.

• Slipping, tripping and/or falling while

operating air tools can be a major cause

of serious injury or death. Be aware of

excess hose left on the walking or

work surface.

• Keep body working stance balanced and

firm. Do not overreach when operating

the tool.

• Anticipate and be alert for sudden changes

in motion during start up and operation

of any power tool.

• Do not carry tool by the hose. Protect the

hose from sharp objects and heat.

• Tool shaft may continue to rotate briefly

after throttle is released. Avoid direct

contact with accessories during and after

use. Gloves will reduce the risk of cuts

or burns

• Keep away from rotating end of tool.

Do not wear jewelry or loose clothing.

Secure long hair. Scalping can occur if

hair is not kept away from tool and

accessories. Choking can occur if neckwear

is not kept away from tool and accessories.

• Correct grinding wheel mounting is

necessary to prevent injury from broken

wheels. Do not use chipped or cracked

grinding wheels. Grinding wheels should be

a free fit on the spindle to prevent stress

at the hole. Use only wheel collars that come

with the grinder for mounting the grinding

wheel. Flat washers or other adapters may

over stress the wheel. Always use heavy

paper blotter discs between the wheel

collars and the grinding wheel. Tighten the

wheel on the spindle to prevent spin off

when the air grinder is turned off.

• Do not lubricate tools with flammable or

volatile liquids such as kerosene, diesel or

jet fuel.

• Do not force tool beyond its rated capacity.

• Do not remove any labels. Replace damaged

labels.

• Use accessories recommended by

Sunex Tools®.

FAILURE TO OBSERVE THESE WARNINGS

COULD RESULT IN INJURY

SX232B_manual_082907.indd 2 8/31/07 1:58:43 PM

Page 3

SX232B 3 Rev. 08/29/07

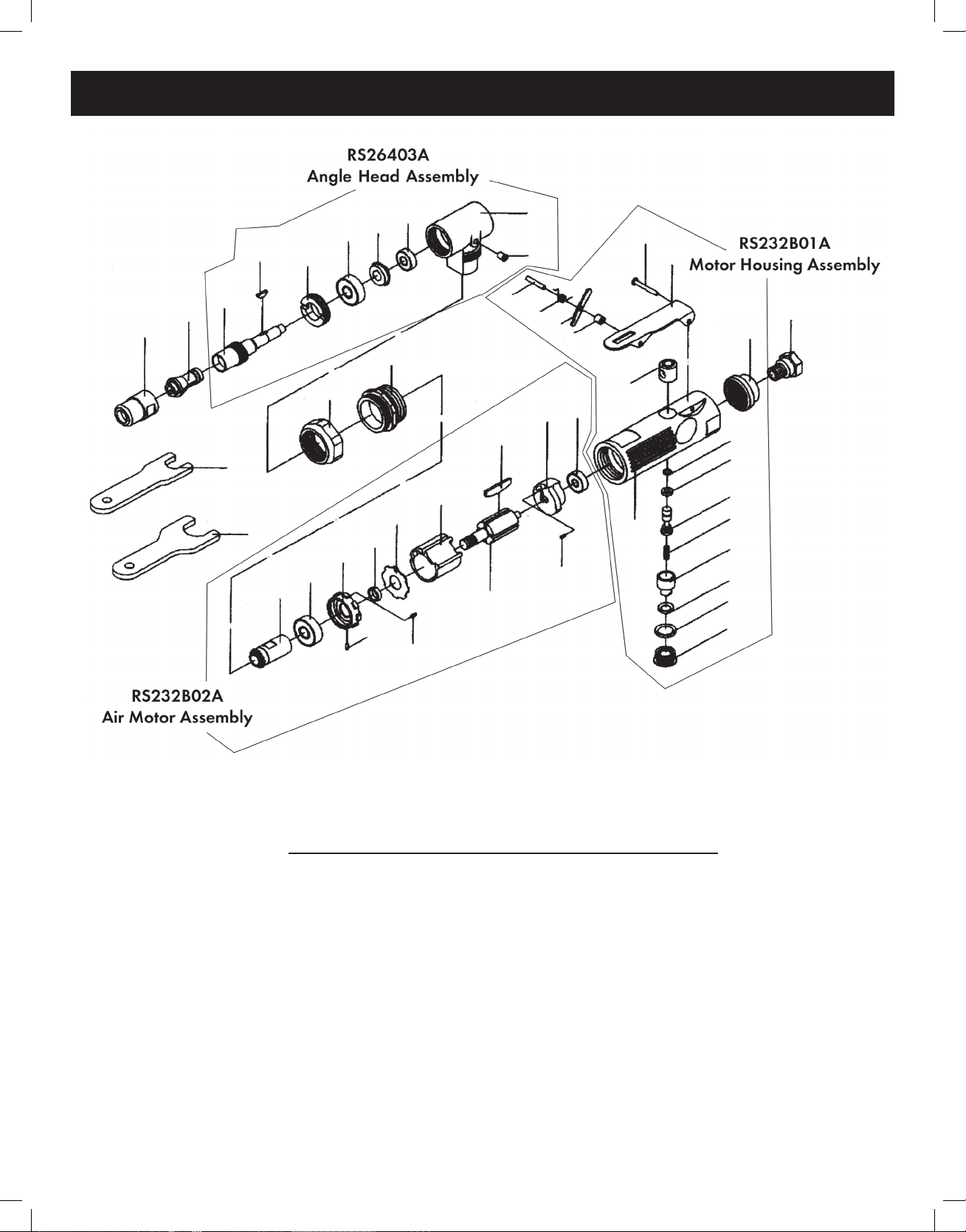

DESCRIPTION

PART

NO.

REF.

NO.

1-17 RS232B01A Motor Housing Assembly

19-30 RS232B02A Air Motor Assembly

29, 33-38 RS26403A Angle Head Assembly

18 RS232B18 Air Inlet

31 RS232B31 Connect Nut

32 RS26429 Clamp Nut

40 RS26437 1/4" Collet

41 RS26438 Collet Nut

42 RS26439 Wrench

43 RS26440 Wrench

SX232B: 1/4" DR ANGLE DIE GRINDER

1

2

6

4

5

7

34

33

35

36

29

37

39

38

40

41

42

43

32

31

30

29

27

26

25

24

23

20

19

28

21

22

21

9

10

11

12

13

14

15

16

17

18

3

8

SX232B_manual_082907.indd 3 8/31/07 1:58:45 PM

Page 4

SX232B 4 Rev. 08/29/07

Air Supply...

Tools of this class operate on a wide range of air pressures. It is

recommended that air pressure of these tools measures 90 PSI at

the tool while running free. Higher pressure (over 90 psig; 6.2 bar)

raises performance beyond the rated capacity of the tool; which will

shorten tool life because of faster wear and could cause injury.

Always use clean, dry air. Dust, corrosive fumes and/or water

in the air line will cause damage to the tool. Drain the air tank

daily. Clean the air inlet filter screen on a weekly schedule. The

recommended connection procedure can be viewed in the

above figure.

The air inlet used for connecting air supply, has standard 1/4" NPT.

Line pressure should be increased to compensate for unusually

long air hoses (over 25 feet). Minimum hose diameter should be

3/8" I.D. and fittings should have the same inside dimensions and

be tightly secured.

Lubrication...

Lubricate the air motor daily with quality air tool oil. If no air line

oiler is used, run a half ounce of oil through the tool. The oil can

be inserted into the tool air inlet or into the hose at the nearest

connection to the air supply, then run the tool. The amount of oil

to be used is 1/2 oz. Overfilling will cause a reduction in the power

of the tool.

Other factors outside the tool may cause loss of power or erratic

action. Reduced compressor output, excessive drain on the air line,

moisture or restrictions in air pipes or the use of hose connections

of improper size or poor condition may reduce air supply. Grit or

gum deposits in the tool may cut power and may be corrected by

cleaning the air strainer and flushing out the tool with gum solvent

oil or an equal mixture of SAE #10 oil and kerosene. If outside

conditions are in order and the tool continues erratic action or low

power, disconnect tool from hose and take tool to your nearest

authorized service center.

Operation...

When using the grinder, be careful not to exert excessive force. Too

much force may be hazardous if it causes the cutting tool spindle to

bend or break.

The burning of the work piece or excessive speed reduction

indicates too much force being applied. Changing to a free cutting

tool may be better for the desired rate of speed and stock removal.

Avoid hazardous condition by making sure there is sufficient

gripping force on the spindle of the cutting tool by placing the

spindle 7/16" or more inside the collet.

Limited Warranty...

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS® BRANDED PRODUCTS ARE FREE FROM DEFECTS IN

WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools® branded products which fail to give satisfactory service due to defective workmanship or materials,

based upon the terms and conditions of the following described warranty plans attributed to that specific product. This product carries a ONE-YEAR warranty.

During this warranty period, Sunex Tools® will repair or replace at our option any part or unit which proves to be defective in material or workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or replacement made

by anyone other than Sunex Tools® or its authorized warranty service centers. The foregoing obligation is Sunex Tools’ sole liability under this or any implied

warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note:

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Return equipment or parts to Sunex Tools®, or an authorized warranty service center, transportation prepaid. Be certain to include your name and address,

evidence of the purchase date, and description of the suspected defect.

If you have any questions about warranty service, please write to Sunex Tools®. This warranty gives you specific legal rights and you may also have other rights

which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools® products regardless of whether or not the product is

still covered by a warranty plan.

Shipping Address: Sunex Tools

®

• 315 Hawkins Rd. • Travelers Rest, SC 29690

Mailing Address: Sunex Tools

®

• P.O. Box 4215 • Greenville, SC 29608

%SBJO%BJMZ

3FHVMBUPS0JMFS2VJDL$PVQMFS-FBEFS

)PTF

/JQQMF

%P/PU*OTUBMM

2VJDL$PVQMJOH

)FSF

/JQQMF

'JMUFS

"JS4VQQMZ

8IJQ)PTF

Operating Instructions • Warning Information • Parts Breakdown

SX232B_manual_082907.indd 4 8/31/07 1:58:46 PM

Page 5

SX232B 5 Rev. 08/29/07

Lea siempre Las

instrucciones

antes de usar

herramientas

neumáticas.

use siempre gafas

de seguridad.

use protección

para Los oídos.

evite exponerse

proLongadamente

a Las vibraciones

SX232B

ESMErILADOrA

ANGULAr

DE TrOQUEL

ENCAJE 1/4"

Velocidad libre máx ............20,000 RPM

Tamaño del collar (pulg.) ..................1/4

Admisión de aire .............. 1/4 pulg. NPT

Tamaño de manguera

recomendado .....................3/8 pulg. I.D.

Presión de aire

recomendada .............................90 PSIG

Consumo promedio

de aire..........................................4 CFM

Longitud ................................... 6.2 pulg.

Nivel de presión sonoro ..............93 dBA

Peso ......................................... 1.11 lbs.

ESPECIFICACIONES

Lijar, cortar, esmerilar, taladrar y otras actividades propias de las obras en

construcción, con equipo neumático pudieran crearse ciertos polvos identificados

como causantes de cáncer, defectos en el nacimiento u otras lesiones en los

órganos reproductores. Entre algunos de los ejemplos de estos productos

químicos están:

• El plomo en las pinturas con base de plomo,

• Sílice cristalina en los ladrillos y cemento así como en otros productos

de albañilería,

• Arsénico y cromio proveniente de la madera tratada con productos químicos.

Los peligros al exponerse a estos productos varía, dependiendo de qué tan

frecuentemente se hagan esos tipos de trabajos. Si desea disminuir su exposición

a estos productos químicos: trabaje en un lugar con buena ventilación y hágalo

con el equipo de seguridad aprobado, como lo son las mascarillas cubrepolvo

que fueron diseñadas especialmente para filtrar las partículas microscópicas.

Instrucciones operativas • Información precautoria • Esquema de los componentes

• rpm máximas de 20,000

• máxima presión de aire: 90

psig, 6.2 bar

• Las rpm deL accesorio

deberán exceder Las rpm de

La herramienta

SX232B_manual_082907.indd 5 8/31/07 1:58:46 PM

Page 6

SX232B 6 Rev. 08/29/07

OMITIR RESPETAR ESTAS ADVERTENCIAS PUDIERA

DAR COMO RESULTADO LESIONARSE.

Este manual instructivo contiene información

importante relacionada con su seguridad.

LEA CUIDADOSAMENTE ESTE MANUAL

INSTRUCTIVO Y ENTIENDA TODALA

INFORMACIÓN ANTES DE OPERARATION

ESTA HERRAMIENTA

• Opere, inspeccione y mantenga siempre esta

herramienta de acuerdo con el Código de

Seguridad del Instituto Americano de Estándares

Nacionales para las Herramientas Portátiles

Neumáticas (ANSI B186.1) y cualquier otro

código o regulación aplicables.

• Por seguridad, desempeño superior y durabilidad

máxima de las refacciones, opere esta

herramienta a la máxima presión de aire al

90 psig; 6.2 barg. con una manguera de

alimentación de aire de 3/8" en diámetro.

• Al operar o al realizar el mantenimiento de esta

herramienta, lleve siempre la protección de ojos

y cara resistentes al impacto.

• Al usar esta herramienta, lleve siempre

protección para los oídos. Los altos niveles de

ruido pueden ocasionar la pérdida permanente

del oído. Use protección para los oídos

según lo recomendado por su empleador o

regulación OSHA.

• Mantenga esta herramienta en condición

eficiente de operación.

• Los operadores y personal de mantenimiento

deben poder físicamente manejar el volumen,

peso y potencia de esta herramienta.

• El aire comprimido puede ocasionar lesiones

serias. Nunca dirija el aire hacia usted ni a

otros. Siempre apague la alimentación de aire,

vacíe toda la presión de aire de la manguera

y desconecte la herramienta del suministro de

aire antes de instalar, quitar o ajustar cualquier

pieza o accesorio de esta herramienta, o antes

de realizar cualquier mantenimiento de ella.

Caso omiso en hacerlo podría ocasionar alguna

lesión. Las mangueras de látigo pueden ocasionar

heridas serias. Siempre revise las mangueras

y herrajes por daños, deshilachas o solturas, y

si es necesario, repóngalos inmediatamente. No

opere ninguna herramienta dañada ni

deteriorada. No use los acoplamientos de

separación rápida con la herramienta. Vea las

instrucciones para la instalación correcta.

• Las herramientas neumáticas pueden vibrar

durante su uso. Si uno está expuesto a las

vibraciones, movimientos repetitivos o posturas

incómodas por períodos extendidos de tiempo

durante el uso, esto puede dañar a sus manos

y brazos. Suspenda el uso de la herramienta si

usted experimenta molestias, hormigueo o

dolor. Pida alguna asistencia médica antes de

continuar el uso de la herramienta.

• Coloque la herramienta sobre el trabajo antes de

prenderla. No la apunte ni haga payasadas

con esta herramienta.

•

Resbalarse, tropezarse y/o caerse durante la

operación de herramientas neumáticas puede

ser una causa mayor de lesión seria o la muerte.

Sea consciente de la manguera excedente,

dejada por la superficie para caminar o trabajar.

• Mantenga balanceada y firme la postura

corporal de trabajo. No se extra limite al operar

esta herramienta.

• Anticipe y sea alerto por cambios repentinos de

movimiento durante el arranque inicial y

operación de cualquier herramienta neumática.

• No lleve la herramienta por la manguera. Proteja

la manguera de objetos afilados y del calor.

• El eje de la herramienta puede seguir rotando

brevemente después de que se libere la

válvula reguladora. Evite el contacto directo

con los accesorios durante y después del uso.

Los guantes reducirán el riesgo de alguna

cortada o quemadura.

• Manténgase lejos del extremo rotador de la

herramienta. No lleve puesto ni joyería ni ropa

suelta. Fije el pelo largo. Se puede arrancar

el cabello si no se lo mantenga a distancia de la

herramienta y accesorios. Mantenga a distancia

de la herramienta y de los accesorios los

accesorios del cuello para evitar el

ahogamiento.

• El montaje adecuado del disco de esmeril es

necesario para prevenir las lesiones ocasionadas

por los discos rotos. No use los discos de

esmeril agrietados ni desconchados. Los discos

de esmeril deben caber libremente en el árbol

para prevenir estrés en el agujero. Use sólo los

collarines de esmeril que vienen con el amolador

para el montaje del disco de esmeril. Las

arandelas planas u otros adaptadores pueden

poner presión excesiva sobre el disco. Siempre

use discos de papel secante pesado entre

los collarines de esmeril y el disco de esmeril.

Apriete el disco en el árbol para prevenir la

proyección de fragmentos volantes al momento

de apagar el amolador neumático.

• No lubrique las herramientas con soluciones

inflamables ni volátiles, tales como el

queroseno, el gasóleo ni el combustible para

aviones.

• Nunca haga que la herramienta vaya cortando

más rápido o por material de tamiz más pesado

de lo de su capacidad nominal.

• No quite ninguna etiqueta. Reponga las

etiquetas dañadas.

• Utilice los accesorios recomendadas por

Sunex Tools®.

SX232B_manual_082907.indd 6 8/31/07 1:58:47 PM

Page 7

SX232B 7 Rev. 08/29/07

Abasto de aire...

Las herramientas de esta clase operan en una amplia gama de

presiones neumáticas. Se recomienda que la presión neumática para

esta clase de herramientas mida 90 psig en la herramienta mientras

la herramienta funciona sin carga. La presión neumática más elevada

(más de 90 psig, 6.2 barios) eleva su rendimiento operativo más allá de

la capacidad calculada de la herramienta y esto acortará la vida útil de

la herramienta debido al desgaste más rápido, además de la posibilidad

de sufrir una lesión.Utilice siempre aire comprimido limpio y seco.

El polvo, los humos corrosivos y/o el agua en la tuberÌa del aire pueden

causarle daños a la herramienta. Vacía diariamente el tanque del aire

comprimido. Limpie la malla del filtro de entrada de aire una vez por

semana. El procedimiento recomendado de conexión puede observarse

en la figura anterior.

La entrada del aire para conectar el abasto de aire es de 1/4" NPT

estándar. La presión en la tubería deberá incrementarse como medio

de compensación cuando se utilicen mangueras largas más allá de lo

común (más de 25 pies). El diámetro interior mínimo de la manguera

deberá ser de 3/8" y sus accesorios deberán tener las mismas

dimensiones interiores y además estar firmemente apretados

.

Lubricación...

Lubrique diariamente el motor neumático con aceite de calidad para

herramientas neumáticas. Si no se usa algún engrasador de conducto

de aire, deje correr una media onza de aceite por la herramienta. El

aceite puede ser introducido por la entrada de aire de la herramienta

o por la manguera en la conexión más cercana al suministro de aire,

luego prenda y dejar correr la herramienta. Sobrellenarla con lubricante

puede causar una disminución de la potencia de la herramienta.

Factores ajenos a la herramienta pueden ocasionar la pérdida de

potencia o alguna acción irregular. La salida reducida del compresor,

la purga excesiva de la línea de aire, la humedad, o restricciones en

los tubos de aire o el uso de conexiones de manguera del tamaño

inadecuado o en malas condiciones puede reducir el suministro de

aire. Depósitos de arena o goma en la herramienta pueden cortar la

potencia y puede corregirse al limpiar el colador de aire y al purgar

la herramienta con aceite de solvente de goma o con una mezcla

equivalente de aceite SAE #10 y keroseno. Si las condiciones

externas son adecuadas y la herramienta continúa la acción irregular

o de baja potencia, desconecte la herramienta de la manguera y

lleve la herramienta al centro de servicio autorizado más cercano.

Operación...

Al momento de usar la esmeriladora, tenga cuidado de no ejercer

fuerza excesiva. Una fuerza excesiva puede ser peligrosa si es que

ocasione que el eje de la herramienta de corte se doble o que se

rompa.

Quemaduras en la pieza de trabajo o una reducción excesiva de

velocidad indican que se está aplicando demasiado fuerza. Puede ser

recomendable que se cambie a una herramienta de corte libre para

lograr la velocidad deseada y la extracción del producto.

Evite las condiciones peligrosas al asegurar que haya suficiente

fuerza de agarre en el eje de la herramienta de corte, al colocar el eje

un 7/16" ó más dentro de la pinza.

GARANTíA LIMITADA

SUNEX INTERNATIONAL, INC., LE GARANTIZA A SUS CLIENTES QUE LAS HERRAMIENTAS Y PRODUCTOS CON LA MARCA DE LA EMPRESA SUNEX TOOLS® NO

CONTIENEN DEFECTOS EN SU MANO DE OBRA NI MATERIAS PRIMAS.

Sunex International, Inc., reparará o sustituirá sus productos con la marca Sunex Tools® que reflejen fallas en el funcionamiento satisfactorio debido a que la mano

de obra o las materias primas estén defectuosas, tomando como base las cláusulas y condiciones de los planes de garantía descritos a continuación y asignados

a ese producto específico. Este producto tiene una garantía de UN AñO. Durante ese periodo de garantía, Sunex Tools® reparará o sustituirá, como así opte por

hacerlo, cualquier componente o unidad que se compruebe tener decectos en su materia prima o mano de obra.

Otra importante información de la garantía...

Esta garantía no cubre ningún daño al equipo o herramientas, si este surge como resultado de su alteración, abuso, o mal uso o daños ni tampoco cubre las

reparaciones o reposiciones hechas por cualquier persona ajena a los centros de servicio de garantía autorizados y que no sean de Sunex Tools®. La obligación antes

mancionada queda bajo la responsabilidad exclusiva de Sunex Tools® según se menciona o de cualquier garantía implícita y bajo ninguna circunstancia quedará

bajo su responsabilidad cualquier garantía implícita ya bajo ninguna circunstancia quedará bajo su responsabilidad cualquier daño incidental o consecuencial.

Note:

Algunos estados no permiten la exclusión o limitación de los daños incidentales o consecuenciales, por lo tanto la limitación o exclusión arriba

mencionada quizá no pudiera serle pertinente a usted. Devuelva el equipo o componentes a Sunex Tools®, un centro de servicio de garantía autorizado, con

elflete pagado. Asegúres haber incluido su nimbre y dirección, la evidencia de la fecha de adquisición y la descripción del defecto que se sospeche tener.

Si tiene alguna duda relacionada con elservicio de garantía, por favor escríbale a Sunex Tools®. Esta garantía le concede derechos jurídicos específicos y quizá otros

derechos que varían de un estado a otro, Sunex Tools® tiene a su disposición los juegos de reparación y refacciones de repuesto para muchos de sus productos,

sin importar si el producto continúe o no bajo el plan de la garantía.

DIRECCIÓN A EMBARCARSE: Sunex Tools

®

• 315 Hawkins Rd. • Travelers Rest, South Carolina 29690

DIRECCIÓN DE CORREOS: Sunex Tools

®

• P.O. Box 4215 • Greenville, South Carolina 29608

Instrucciones operativas • Información precautoria • Esquema de los componentes

SX232B_manual_082907.indd 7 8/31/07 1:58:48 PM

Page 8

SX232B 8 Rev. 08/29/07

Lea siempre Las

instrucciones

antes de usar

herramientas

neumáticas.

use siempre gafas

de seguridad.

use protección

para Los oídos.

evite exponerse

proLongadamente

a Las vibraciones

SX232B

MEULEUSE

À MATrICE

ANGULAIrE À

ENTrAÎNEMENT

1/4"

Vitesse Max. à vide .......... 20000 tr/min

Dimension de la pince .................1/4 po

Entrée d’air .......................... 1/4 po NPT

Dimension de boyau

recommandée ........................3/8 po I.D.

Pression d'air

recommandée ............................90 PSIG

Consommation d’air

moyenne ......................................4 CFM

Longueur......................................6.2 po

Niveau sonore ..........................93.6 dBA

Poids ......................................... 1,11 lbs

SPÉCIFICATIONS

Certains types de poussières produites par le sablage, le sciage, le

meulage et d'autres activités de construction contiennent des produits

chimiques cancérigènes, qui causent des anomalies congénitales ou

d'autres dangers pour la reproduction. Parmi ces produits chimiques

on compte :

• le plomb des peintures à base de plomb,

• la silice cristalline des briques et du ciment et d'autres

produits de maçonnerie, et

• l'arsenic et le chrome du bois traité chimiquement.

Les risques associés à ces expositions varient selon la fréquence et le

type de travail. Afin de réduire votre exposition à ces produits chimiques :

travailler dans un endroit bien ventilé, avec de l'équipement de sécurité

approuvé, comme des masques antipoussières conçus spécialement pour

filtrer les particules microscopiques.

Instructions d'utilisation • Avertissements • Liste des pièces

• MAXIMUM de 20000 tr/min

• PRESSION D’AIR MAXIMALE

: 90 PSIG, 6,2 BAR

• LE NOMBRE DE tr/min D’UN

ACCESSOIRE DOIT DÉPASSER

LE NOMBRE DE tr/min

DE L’OUTIL

SX232B_manual_082907.indd 8 8/31/07 1:58:48 PM

Page 9

SX232B 9 Rev. 08/29/07

NÉGLIGER D'OBSERVER CES AVERTISSEMENTS PEUT

ENTRAŒNER DES BLESSURES

LE PRÉSENT MANUEL D’INSTRUCTIONS

CONTIENT DES RENSEIGNEMENTS

IMPORTANTS POUR LA SÉCURITÉ.

LISEZ LE PRÉSENT MANUEL D’INSTRUCTIONS

SOIGNEUSEMENT ET COMPRENEZ BIEN TOUS

LES RENSEIGNEMENTS AVANT D’UTILISER CET

OUTIL.

• Utilisez, inspectez et entretenez cet outil

conformément au document American

National Standards Institute Safety Code of

Portable Air Tools (ANSI B186.1) et tout

autre code et règlement de sécurité

applicable.

• Pour la sécurité, un rendement supérieur et

un maximum de durabilité des pièces,

faites fonctionner cet outil à 90 lb/po2 6,2

bars de pression d’air maximale avec un

tuyau d’air de 3/8 po de diamètre.

• Portez toujours des lunettes résistant aux

impacts et une protection faciale quand

vous utilisez ou entretenez cet outil.

• Portez toujours une protection des oreilles

quand vous utilisez cet outil. Les bruits

forts peuvent entraîner une perte permanente

de l’ouïe. Utilisez la protection des oreilles

recommandée par votre employeur ou le

règlement de l’OSHA.

• Gardez l’outil en bon état de

fonctionnement.

• Le personnel qui utilise ou entretient l’outil

doit être physiquement capable de le

manipuler compte tenu de sa grosseur, de

son poids et de sa puissance.

• L’air comprimé peut causer de graves

blessures. Évitez de diriger le jet d’air vers

vous ou vers d’autres personnes. Avant

d’installer, de retirer ou d’ajuster une pièce

ou un accessoire, ou de faire l’entretien de

l’outil, assurez-vous de toujours fermer

la source d’alimentation en air, de purger l’air

du boyau et de débrancher l’outil de sa

source d’alimentation. Une négligence sur

ce plan pourrait causer des blessures.

Les tuyaux souples peuvent causer de

graves blessures. Vérifiez toujours les

boyaux et les raccords et remplacez-les

s’ils sont endommagés, fissurés ou lâches.

Évitez d’utiliser un outil endommagé ou

usé. Évitez d’utiliser des raccords rapides

avec cet outil. Pour installer correctement

l’outil, consulter les directives.

• Les outils pneumatiques peuvent vibrer

pendant l’utilisation. Une exposition

prolongée aux vibrations, les mouvements r

épétitifs, ou une posture inconfortable lors

de l’utilisation peuvent être nuisibles pour

vos mains et vos bras. Arrêtez d’utiliser

l’outil en cas d’inconfort ou si vous ressentez

des picotements ou de la douleur. Consultez

un médecin avant de recommencer à

utiliser l’outil.

• Avant de mettre l’outil en marche, placez le sur la surface de travail. Ne le pointer

pas ou ne vous livrez pas à des jeux

avec cet outil.

• Une glissade, un trébuchage et/ou

une chute lors de l’utilisation d’outils

pneumatiques peut causer de sérieuses

blessures ou la mort. Prenez garde aux

boyaux qui traînent par terre dans l’aire

de travail.

• Votre posture doit être stable. Évitez de

travailler à bout de bras.

• Calculez vos mouvements et prenez garde

aux changements brusques de position

quand vous utilisez un outil électrique.

• Ne tenez pas l’outil par le boyau

d’alimentation. Protégez le boyau des objets

tranchants et de la chaleur.

• La tige de l’outil peut continuer à tourner

brièvement après le relâchement de la

détente. Évitez tout contact direct avec les

accessoires pendant ou après l’utilisation.

Le port de gants réduit les risques de

coupures ou de brûlures.

• L’arbre de l’outil continue de tourner

brièvement quand la gâchette est lâchée.

Évitez le contact direct avec les accessoires

durant et après l’utilisation. Les gants

réduisent le risque de coupures et

de brûlures.

• Il est nécessaire de corriger le montage de la

meule pour prévenir les blessures qui

pourraient survenir à cause de meules

endommagées. Ne pas utiliser de meules

émoussées ou craquées. Les meules

devraient être bien ajustées sur l’axe afin

de prévenir la contrainte au niveau de

l’orifice. N’utiliser que des colliers de roue

qui sont fournis avec la rectifieuse à des

fins de montage sur cette dernière. Les

rondelles plates ou d’autres adaptateurs

peuvent produire un dépassement de

contrainte sur la roue. Toujours utiliser des

disques buvards en véritable papier entre

les colliers de roue et la meule. Serrer la

roue sur l’axe afin d’éviter qu’elle tourne

dans le vide lorsque la rectifieuse

pneumatique ne fonctionne pas..

• Ne lubrifiez pas les outils avec des produits

inflammables ou volatiles comme le

kérosène, le carburant diesel ou le

carburant aviation.

• Ne forcez jamais l’outil à couper plus

rapidement ou à travers du matériel d’une

épaisseur plus grande que la capacité

indiqué.

• N’enlevez pas les étiquettes. Remplacez les

étiquettes endommagées.

• Utilice los accesorios recomendadas por

Sunex Tools®.

SX232B_manual_082907.indd 9 8/31/07 1:58:49 PM

Page 10

SX232B 10 Rev. 08/29/07

Instructions d'utilisation • Avertissements • Liste des pièces

Alimentation en air...

Les outils de cette catégorie fonctionnent sur une grande plage de

pressions d'air. Il est recommandé que la pression d'air de ces outils

mesure 6,2 bars (90 PSI) lorsque l'outil fonctionne en régime libre.

Une pression supérieure à 6,2 bars (90 psig) accroît la performance

au-delà de la capacité nominale de l'outil, ce qui réduit sa durée de

vie utile étant donné que les pièces s'usent plus rapidement, et ce

qui peut entraîner des blessures.

Toujours utiliser de l'air propre et sec. La poussière, les fumées

corrosives et / ou de l'eau dans la conduite d'air endommage l'outil.

Purger le réservoir d'air quotidiennement. Nettoyez l'écran du filtre

d'admission d'air toutes les semaines. La figure ci-dessus présente la

procédure de connexion recommandée.

L'entrée d'air utilisée pour connecter l'alimentation en air est munie

d'un élément standard de 1/4 NPT. Augmenter la pression de la

conduite pour compenser une longueur de flexible supérieure à 7,6 m

(25 pi). Le diamètre intérieur minimal du flexible doit être de 3/8 po

et le raccord doit être de mêmes dimensions et être fixé fermement.

Lubrification...

Lubrifiez le moteur pneumatique quotidiennement avec une huile

pour outil pneumatique de qualité. Si vous n'utilisez pas d’huileur

pour la conduite d’air, faites passer une demi-once d’huile dans

l'outil. Vous pouvez mettre de l'huile dans le trou d'entrée d'air ou

dans le tuyau se trouvant le plus près de la connexion d'alimentation

d'air et ensuite faire fonctionner l'outil. Une quantité excessive

d'huile réduit la puissance de l'outil.

D'autres facteurs en dehors de l'outil peuvent causer la perte

de puissance ou une action erratique. Le rendement réduit du

compresseur, le drainage excessif de la conduite d’air, l'humidité,

des restrictions dans les conduites d'air ou l'utilisation de

raccordements de boyau de dimension inexacte ou en mauvaise

condition peuvent réduire l'alimentation en air. Les dépôts de grain

ou de gomme dans l'outil peuvent couper la puissance et peuvent

être corrigés en nettoyant le tamis d'air et en rinçant l'outil avec

de l'huile dissolvante de gomme ou un mélange équivalent de

pétrole et de kérosène SAE #10. Si les conditions extérieures

sont respectées et que l'outil continue de démontrer une action

erratique ou une puissance faible, débranchez l'outil du tuyau et

apportez l'outil à votre centre de service autorisé le plus près.

Fonctionnement...

En utilisant la meuleuse, faites attention de ne pas exercer une

force excessive. Une force excessive peut être dangereuse si elle

fait plier ou casser l’axe de l'outil de coupe.

La brûlure de la pièce de travail ou la réduction excessive de la

vitesse indique que trop de force est appliquée. Le changement

pour un outil de décolletage peut s’avérer meilleur pour le rapport

de vitesse désiré et le retrait du matériel.

Évitez les conditions dangereuses en vous assurant qu’il y a

suffisamment de force de serrage sur l’axe de l'outil de coupe en

plaçant l'axe à 7/16"ou plus à l'intérieur de la bague de serrage.

Garantie limitée...

SUNEX INTERNATIONAL, INC. GARANTIT À SES CLIENTS QUE LES OUTILS DE MARQUE SUNEX TOOLS SONT EXEMPTS DE DÉFAUTS DE MAIN D'ŒUVRE

ET DE MATÉRIAU

Sunex International, Inc. réparera ou remplacera ses outils de marque Sunex Tools® qui ne donnent pas un service satisfaisant à cause d'un défaut de main

d'œuvre ou de matériau, selon les termes et conditions décrits ci-dessous dans les plans de garantie correspondant à ce produit spècifique. Ce produit a une

garantie de UN AN. Pendant la période de garantie, Sunex Tools® réparera ou remplacera, à sa seule discrétion, toute pièce ou tout appareil dont il a été déterminé

qu'il comporte un défaut de matériau ou de main d'œuvre.

Autres informations importantes sur la garantie...

Cette garantie ne couvre pas les dommages à de l'équipement ou à des outils modifiés, sujets à des abus ou à une utilisation incorrecte,

ou encore endommagés; elle ne couvre pas les réparations ou le remplacement effectué par quiconque autre que Sunex Tools®

ou ses centres de services de garantie autorisés. L'obligation qui précède constitue la seule responsabilité de Sunex Tools® en vertu de cette

garantie ou de toute garantie implicite; et en aucun cas Sunex Tools® ne pourra être responsable pour des dommages indirects ou consécutifs.

Remarque :

Certaines juridictions ne permettent pas l'exclusion ou la limitation des dommages indirects ou consécutifs; la limitation ou l'exclusion ci-dessus

pourrait donc ne pas s'appliquer à votre cas. Retourner l'équipement ou les pièces à Sunex Tools®, ou à un centre de service de garantie autorisé, port prépayé.

S'assurer d'inclure votre nom, votre adresse, une preuve de la date d'achat et la description de la défaillance présumée. Veuillez adresser par écrit toutes vos

questions sur le service de garantie à Sunex Tools®. Cette garantie donne à l'acheteur des droits juridiques spécifiques ainsi que certains autres droits qui peuvent

varier selon la juridiction. Les trousses de réparation et de remplacement sont disponibles pour plusieurs produits Sunex Tools®, peu importe si le produit est

encore sous garantie.

Adresse d'expédition : Sunex Tools

®

• 315 Hawkins Rd. • Travelers Rest, SC 29690

Adresse postale : Sunex Tools

®

• P.O. Box 4215 • Greenville, SC 29608

SX232B_manual_082907.indd 10 8/31/07 1:58:50 PM

Loading...

Loading...