Subaru EH36 User Manual

CONTENTS

Section

Title

Page

1

.

SPECIFICATIONS

.......................................................................................................

1

2

.

PERFORMANCE

........................................................................................................

3

2-1 MAXIMUM OUTPUT

........................................................................................................

3

2-2

CONTINUOUS RATED OUTPUT

....................................................................................

3

2-3 MAXIMUM TORQUE

.......................................................................................................

3

2-4 PERFORMANCE CURVES

.............................................................................................

4

3

.

FEATURES

..................................................................................................................

6

4

.

GENERAL DESCRIPTION OF ENGINE COMPONENTS

..........................................

7

4-1 CYLINDER AND CRANKCASE

.......................................................................................

7

4-2 MAIN BEARING COVER

.................................................................................................

7

4-3 CRANKSHAFT

..................................................................................................................

7

4-4 CONNECTING ROD AND PISTON

.................................................................................

8

4-5 PISTON

RINGS

...............................................................................................................

8

4-6 CAMSHAFT

.....................................................................................................................

8

4-7 VALVE ARRANGEMENT

.................................................................................................

9

4-8 CYLINDER HEAD

............................................................................................................

9

4-9 GOVERNOR SYSTEM

....................................................................................................

9

4-10 COOLING SYSTEM

.....................................................................................................

10

4-11 LUBRICATION SYSTEM

..............................................................................................

10

4-12 IGNITION SYSTEM

.....................................................................................................

10

4-13 CARBURETOR

.............................................................................................................

11

4-14 AIR CLEANER

..............................................................................................................

11

4-1

5

BALANCER

...................................................................................................................

11

4-16 DECOMPRESSION SYSTEM

.....................................................................................

12

4-17 SECTIONAL VIEW OF ENGINE

..................................................................................

13

5

.

DISASSEMBLY AND REASSEMBLY

.......................................................................

15

5-1 PREPARATIONS AND SUGGESTIONS

........................................................................

15

5-2 SPECIALTOOLS

...........................................................................................................

15

5-3

DISASSEMBLY PROCEDURES

....................................................................................

16

5-4 REASSEMBLY PROCEDURES

.....................................................................................

31

5-5

BREAK-IN OPERATION

................................................................................................

43

6 .

MAGNETO

................................................................................................................

43

6-1

OPERATION AND FUNCTION

......................................................................................

43

6-2

BASIC THEORY

............................................................................................................

43

6-3

WIRING DIAGRAM

........................................................................................................

45

Section

Title

Page

7 . AUTOMATIC DECOMPRESSION SYSTEM

............................................................

46

8

.

CARBURETOR

........................................................................................................

47

8-1

OPERATION AND CONSTRUCTION

............................................................................

47

8-2 DISASSEMBLY AND REASSEMBLY

.............................................................................

48

9

.

STARTING SYSTEM

................................................................................................

50

9-1 RECOIL STARTER

........................................................................................................

50

9-2 ELECTRIC STARTER

....................................................................................................

54

10

.

TROUBLESHOOTING

...........................................................................................

56

10-1 STARTING DIFFICULTIES

..........................................................................................

56

10-2 ENGINE MISFIRE

........................................................................................................

57

10-3 ENGINE

STOPS

..........................................................................................................

57

10-4 ENGINE OVERHEAT

...................................................................................................

58

10-5 ENGINE KNOCKS

.......................................................................................................

58

10-6 ENGINE BACKFIRES THROUGH CARBURETOR

.....................................................

58

11

.

INSTALLATION

.....................................................................................................

59

11-1 INSTALLING

.................................................................................................................

59

11-2 VENTILATION

..............................................................................................................

59

11 -3 EXHAUST GAS DISCHARGE

.....................................................................................

59

11 -4 POWER TRANSMISSION TO DRIVEN MACHINES

...................................................

59

12

.

SERVICE DATA

.......................................................................................................

60

12-1 CLEARANCE DATAAND LIMITS

................................................................................

60

12-2 TORQUE SPECIFICATIONS

.......................................................................................

66

12-3 OIL GRADE CHART

....................................................................................................

66

13

.

MAINTENANCE AND STORAGE

..........................................................................

67

13-1 DAILY MAINTENANCE

................................................................................................

67

13-2 INITIAL

20

HRS . MAINTENANCE

...............................................................................

67

13-3 EVERY

50

HRS

.

(10 DAYS) MAINTENANCE

.............................................................

67

13-4 EVERY

100-200

HRS . (MONTHLY) MAINTENANCE

.................................................

68

13-5 EVERY

500-600

HRS . MAINTENANCE

......................................................................

68

13-6 EVERY 100

HRS

.

(YEARLY) MAINTENANCE

............................................................

68

13-7 ENGINE STORAGE

...........................................

:

.........................................................

68

I

EH36

1

MODEL

~~~ ~ ~

EH36B

EH36DS EH36D

EH36BS

I

I

I

Type

Air-Cooled, 4-Cycle, Single-Cylinder,

Horizontal P.T.O. Shaft, OHV Gasoline Engine

Bore

x

Stroke

8.3

Compression Ratio

404 cm3 (24.65 cu.in.)

Piston Displacement

89

x

65 mm (3.50 x 2.56 in.)

Continuous

6.3

kW

(8.5 HP)

/3600

r.p.m. 6.3 kW (8.5

HP)

/I800

r.p.m.

output

Max.

8.5 kW (1 1.5

HP)

/3600 r.p.m.

8.5 kW

(1

1.5

HP)

/1800 r.p.m.

~

Max. Torque

54.9

N

-

m

(5.60

kgf

-

m)

/1250 r.p.m.

27.4

N

-

m (2.80 kgf m)

/2500

r.p.m.

I

Direction

of

Rotation

1

Counterclockwise As Viewed From P.T.O.

Shaft

Side

I

____~

Cooling system

Valve Arrangement

Forced Air Cooling

Automobile Oil SAE

#20,

#30 or 1OW-30 ; Class

SE

or higher

Lubricant

Splash Type Lubrication

Overhead Valve

~_____

Capacity of Lubricant 1.2 liters (0.32

U.S.

gal.)

Carburetor

I

Horizontal Draft, Float Type

Fuel

Fuel Tank Capacity

Gravity Type

Fuel Feed System

31

0

g/kW

-

h

(230 g/HP

-

h)

At Continuous Rated Output Fuel Consumption Ratio

Automobile Unleaded Gasoline

7.0 liters

(1.85

U.S.

gal.)

Ignition System

I

Flywheel Magneto (Solid State)

I

Spark Plug NGK BP6ES

Charging Capacity

-

-

1/2

Camshaft Drive

Speed Reduction

Starting System

12V-1.3A

-

1

2V-

1.3A

Governor System

Centrifugal Flyweight Type

Air Cleaner

Double Element Type

Recoil

Starter

&

Recoil Stafler

&

Recoil Starter

Recoil

Starter

Electric Starter

Electric Starter

Dry Weight

I

32.0 kg (70.6

Ib.)

I

35.0 kg (77:2 Ib.) I 31

.O

kg (68.4 Ib.) I 34.0 kg

(75.0

Ib.)]

~_____

Dimensions

(L

x W x

H)

389 mm x 431 mm x 433 mm (15.31

in.

x

16.97 in.

x

17.05

in.)

I

Specifications are subject

to

change

without

notice.

-

1-

EH41

I

MODEL

EH41 B

EH41

DS

EH41

D

EH41 BS

Air-Cooled, 4-Cycle, Single-Cylinder,

Horizontal P.T.O. Shaft, OHV Gasoline Engine

I

Bore x Stroke

89

x

65

mm

(3.50 x 2.56 in.)

btonbisplacement

404 cm3 (24.65 cu.in.)

1

Empression Ratio

~~

8.3

I

Continuous

7.0 kW

(9.5

HP) 13600 r.p.m.

7.0 kW

(9.5

HP) /1800 r.p.m.

Output

Max.

9.9

kW (13.5 HP) /3600 r.p.m.

9.9

kW (13.5 HP) /1800 r.p.m.

,

Max. Torque

56.8

N

m

(5.80 kgf - m)

I

28.4

N

-

m (2.90 kgf m)

/1250 r.p.m.

/2500

r.p.m.

Direction

of

Rotation

Cooling system

Counterclockwise

As

Viewed From P.T.O. Shaft Side

Splash Type

Lubrication

Overhead Valve

Valve Arrangement

Forced Air Cooling

(Lubricant

I

Automobile Oil

SAE

#20, #30 or low-30 ; Class

SE

or

higher

I

Capacity

of

Lubricant

310 g/kW

-

h (230 g/HP - h) At Continuous Rated Output

Fuel Consumption Ratio

Automobile Unleaded Gasoline

Fuel

Horizontal Draft, Float Type

Carburetor

1.2 liters (0.32

U.S.

gal.)

/

7

I

Fuel Feed System

T~-

Gravity Type

1

7.0 liters (1.85

US.

gal.)

Ignition System

Spark Plug

Flywheel Magneto (Solid State)

12V-1.3A 12V-1.3A

-

Charging Capacity

NGK

BPGES

Starting System

Speed Reduction

1/2 Camshaft Drive

-

Governor System

Centrifugal Flyweight Type

Air Cleaner

Double Element Type

Electric Starter

&

Recoil Starter

Recoil

Starter

&

Recoil Starter

Recoil

Starter

Electric Starter

Dry Weight

Dimensions

(L

x W x

H)

389 mm x 431 mm

x

433 mm (1 5.31 in. x 16.97 in. x 17.05 in.)

~ ~~

32.0 kg (70.6

Ib.)

34.0 kg

(75.0

Ib.)

31.0 kg (68.4

Ib.)

35.0 kg (77.2

Ib.)

Specifications

are

subject

to change without

notice.

/"

-

2-

2.

PERFORMANCE

2-1

MAXIMUM OUTPUT

The maximum output is the output of an engine with its throttle valve fully opened under the condition that

all

the moving parts are properly broken in after the initial break-in period.

A

new engine may not produce full maximum output while its moving parts are still not broken-in.

NOTE

:

Power curves shown in the following charts are made in conformity with

SAE

internal combustion engine

standard test code

J

1349.

2-2

CONTINUOUS

RATED

OUTPUT

The continuous rated output

is

the output of an engine at optimum governed speed which is most favor-

able from the view point of engine's life and fuel consumption.

When the engine is installed on a certain equipment, it is recommended that the continuous output

required from the engine be kept below this continuous rated output.

2-3

MAXIMUM TORQUE

The maximum torque is the torque at the output shaft when the engine is producing maximum output at

certain revolution.

-

3-

2-4

PERFORMANCE

CURVES

EH36

( )

for

type

B

t

kgf-m

(5.6) 2.8

(5.4) 2.7

(5.2) 2.6

!!j

(5.0) 2.5

(4.8) 2.4

(4.6)

2.3

(4.4) 2.2

HP

12

11

10

9

8

7

6

5

4

3

Nom

:54) 27

:52) 26

:50)

25

:48) 24

:46)

23

(44) 22

kW

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

24

(1 2)

28

(1

4)

32

(1

6)

36

(1

8)

REVOLUTION

r.p.m.

-

4-

EH41

kgfom

(5.8)

2.9

1

w

(5.6) 2.8

-

(5.2) 2.6

I-

HP

14

13

12

11

10

9

8

7

6

5

4

3

(

for

tvpe

B

Nom

(56)

28

(54)

27

(52)

26

kW

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

20

24 28 32 36

x10

’

(10)

(12) (14) (16) (18)

REVOLUTION

r.p.m.

-

5-

1.

The overhead valve design offers a compactness, light weight and ideal combustion characteristics

resulting in more power from less fuel and prolonged engine life.

2.

The adoption of an inclined cylinder offers low height

of

engine, making the arrangements for installing

the engine much easier for various powered equipments.

3.

The vibration, free design with a balancer system and lighter reciprocating parts.

4.

Combustion and mechanical noises have been analized acoustically and improved

for

better tonal

quality and lower engine noise.

5.

The automatic decompression system lightens the recoil pull force by

50%

comparing to the conven-

tional

SV

engine.

-

6-

4.

GENERAL DESCRIPTION

OF

ENGINE COMPONENTS

4-1

CYLINDER AND CRANKCASE

The cylinder and crankcase is a single piece alu-

minum die-casting.

The cylinder liner, made of special cast iron, is

molded into the aluminum casting.

The crankcase has a mounting surface on the out-

put shaft side, where the main bearing cover is

attached.

I

Fig.

4-

1

4-2

MAIN BEARING

COVER

The main bearing cover is an aluminum die-cast-

ing, which is mounted on the output shaft side of

the crankcase.

Remove the main bearing cover to inspect inside

of

the engine.

Pilots and bosses are machined

on

the cover for

direct mounting

of

the engine onto such machines

as generators and pumps.

Oil gauges (fillers) are on both sides of the cover

for easy maintenance.

I

OilGAUGE

-

Fig.

4-2

4-3

CRANKSHAFT

The crankshaft

is

forged carbon steel, and the

crank pin is induction-hardened.

The output end

of

the shaft has a crankshaft gear

and balancer gear that are pressed into position.

Fig.

4-3

-

7-

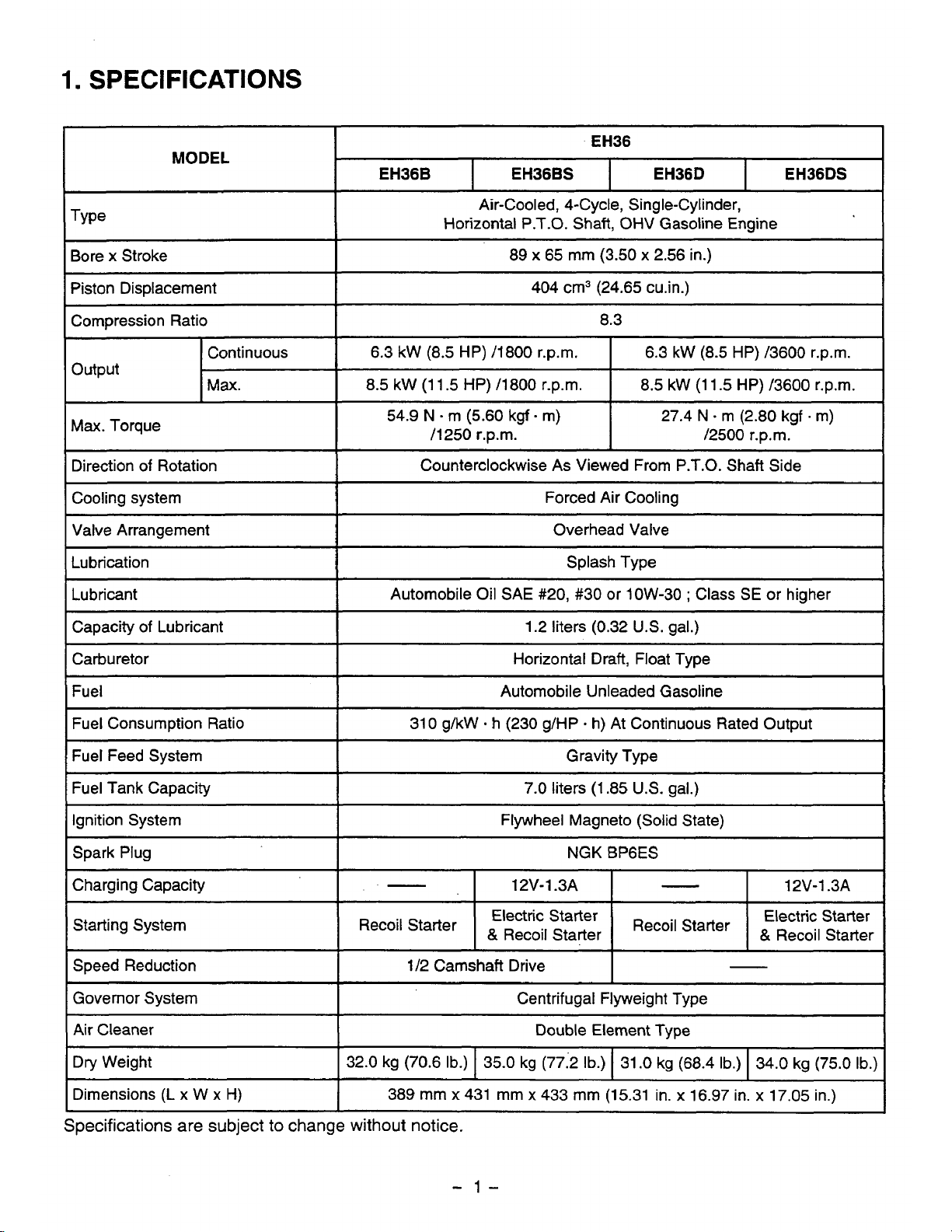

4-4

CONNECTING ROD AND

PISTON

The connecting rod is an aluminum alloy die-casting and its large and small ends function as bear-

ings.

The piston is an aluminum alloy casting, and car-

ries

two

compression rings and one oil ring.

4-5

PISTON

RINGS

The piston rings are made

of

special cast iron.

The profile of the top ring is a barrel face and the

second ring has a tapered face.

The oil ring is designed for better sealing and less

Fig.

4-4

oil consumption, in combination with 3 pieces.

TOP

BARREL

@

RING

TAPER

@

RING

OIL

COMBINATION

@

RING

RING

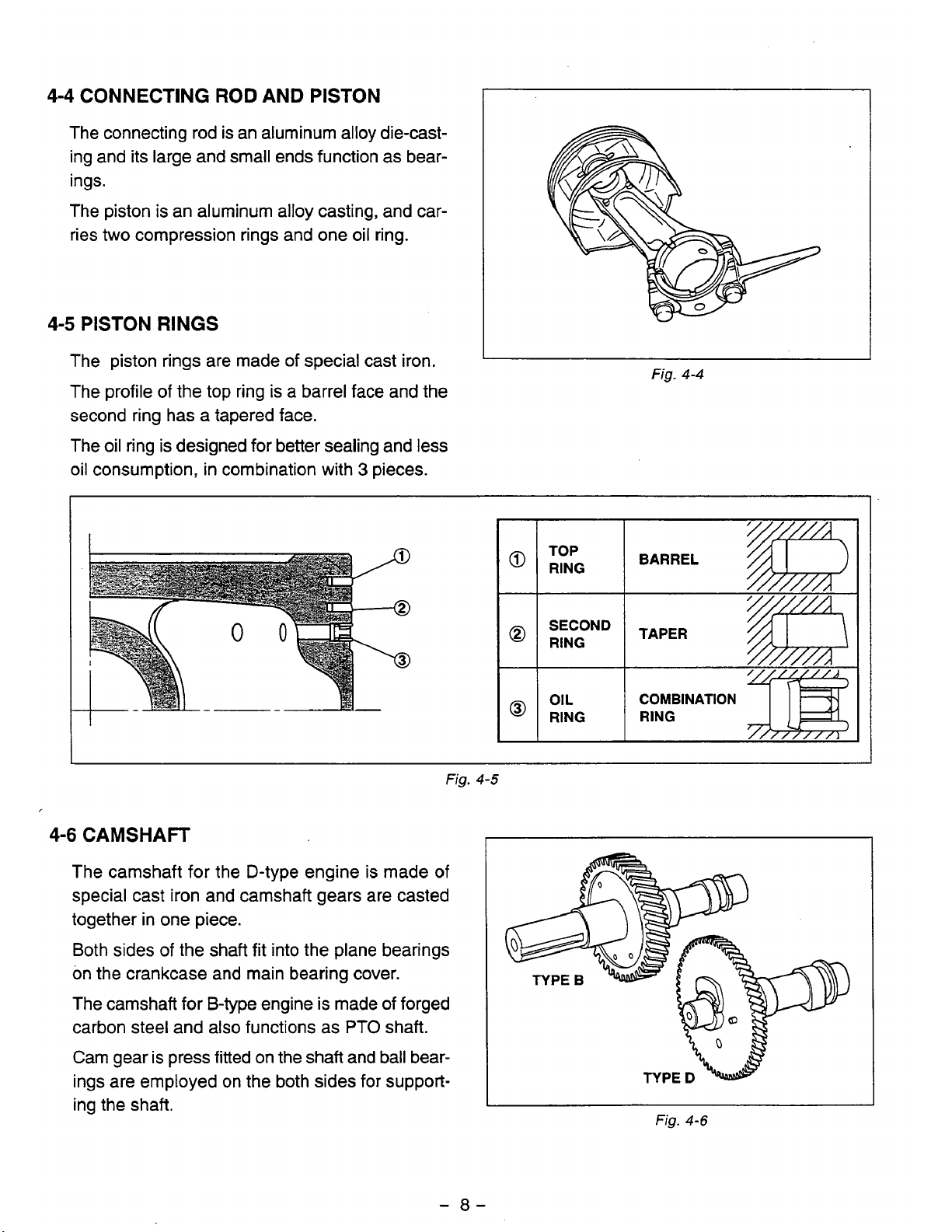

4-6

CAMSHAFT

The camshaft for the D-type engine is made of

special cast iron and camshaft gears are casted

together in one piece.

Both sides

of

the shaft fit into the plane bearings

on the crankcase and main bearing cover.

The camshaft for B-type engine is made of forged

carbon steel and also functions as

PTO

shaft.

Cam gear

is

press fitted on the shaft and ball bearings are employed on the both sides for supporting the shaft.

I

I

Fig.

4-5

Fig.

4-6

-

8-

The intake valve is located on flywheel side of the

cylinder head.

Hard alloy valve seats are molded in the cylinder

head and stellite is fused to the exhaust valve face.

The cylinder baffle leads cooling air to the exhaust

valve area for the optimum cooling.

EXHAUST VALVE INTAKE VALVE

Fig.

4-7

4-8

CYLINDER

HEAD

The cylinder head is an aluminum die-casting

which utilizes semi-spherical type combustion

chamber for the high combustion efficiency.

Fig.

4-8

4-9

GOVERNOR

SYSTEM

The governor is a centrifugal flyweight type which

ensures constant operation at the selected speed

against load variations.

The governor gear with governor weights is in-

stalled on the main bearing cover.

~

"

GOVERNOR

GEAR

/

Fig.

4-9

-

9-

4-10

COOLING

SYSTEM

The large fins on the flywheel provide sufficient

cooling air capacity for the inlet and exhaust area

and cylinder.

The cylinder baffle helps the cooling air flow effi-

ciently.

4-11

LUBRICATION

SYSTEM

All

the rotating and sliding parts are splash- lubri-

cated by the

oil

splasher on the connecting rod.

I

OIL

SPLASHER

4-12

IGNITION SYSTEM

The ignition system is a transistor controlled rnag-

net0 system which consists of a flywheel and an

ignition coil with a built-in transistor mounted

on

the crankcase.

This system has an automatic ignition timing advance characteristic for easy starting.

Fig.

4-

10

FLYWHEEL

I

Fig.

4-

11

P

-

10-

.

4-13 CARBURETOR

The engine is equipped with a horizontal draft car-

buretor that has a float controlled fuel system and

a

fixed main jet.

The carburetors are calibrated carefully for sure

starting, good acceleration, less fuel consumption

and sufficient output.

For

details, refer to page

47,

section

"8

CARBU-

RETOR''.

4-1 4 AIR CLEANER

Air-cleaner

ment system

(semi-wet) and secondary one

per element.

is

a heavy-duty type with a dual ele-

;

the primary one is an urethane foam

is

a dry type pa-

KNOB

&

Fig.

4-72

URETHANE

FOAM

4-15 BALANCER

Unbalanced inertia force is cancelled

ancer which rotates in the same speed as the

crankshaft to effectively reduce vibration.

by

the bal-

I

CLEANER

CASE

Fig.

Fig.

4-

13

4-14

ELEMENT

-

11

-

4-16

DECOMPRESSION

SYSTEM

AUTOMATIC

DECOMPRESSION

SYSTEM

An automatic decompression mechanism which

opens exhaust valve before the piston reaches

compression top

is

assembled

on

the

camshaft

for

easy starting.

RETURN SPRING

Fig.

4-

15'

-

12-

4-17

SECTIONAL VIEW

OF

ENGINE

MUFF

P.T.O.

MAIN

BEARING

COVER

Fig.

4-16

FLYWHEEL

-

13-

FUEL TANK SPARK PLUG

I

BALANCER SHAFT

\

CRANKSHAFT CRANKCASE

Fig.

4-17

CAMSHAFT

-

14-

5.

DISASSEMBLY AND REASSEMBLY

5-1

PREPARATIONS

1)

When disassembling the engine, memorize the locations

reassembled correctly.

attached

2)

Have boxes ready to keep disassembled parts by group.

3)

To

prevent losing and mispfacing, temporarily assemble each group

4)

Carefully handle disassembled parts, and clean them with washing oil

5)

Use the correct

SPECIAL TOOLS

5-2

to

Tool

them.

No.

AND

tools

SUGGESTIONS

If

you are uncertain

in the correct way.

of

of

identifying some parts, it

Tool

individual parts

is

suggested that tags be

of

disassembled parts.

if

necessary.

so

that they can be

Use

209-95004-07

FLYWHEEL

PULLER

with

bolt

For pulling

off

the flywheel Flywheel puller

-

15-

5-3

DISASSEMBLY

PROCEDURES

fi

Step

Fasteners

Remarks

and

procedures

Parts

to remove

Engine oil drain

(2)

To

discharge oil quickly, remove

(1)

Remove

oil drain plug

and

drain

1

oil.

oil gauge.

OIL LEVEL

GASKET

I

OIL

DRAIN

PLUG

GAUGE

Fig.

5-2

-

16-

Step

2

3

Parts

Air cleaner cover and elements

Air cleaner base and gasket

to remove

Remarks and procedures

Remove breather

head.

pipe

from

cylinder

v

Fasteners

cap

nut

M6

flange nut

2

pcs.

M6

x

28

:

1

CAP

:

pce.

NUT

fig.

-

17-

5-3

Step

4

Parts

to

remove

Fuel tank

.r

Stop

switch

M8

BOLT

AND

WASHER

ASSY

:

Remarks and procedures

(1)

Close fuel cock.

(2)

Loosen the

nut

of

fuel strainer

and

remove it.

(3)

Disconnect fuel pipe from

fuel

strainer.

*

Wipe

off

spilt

fuel thoroughly.

Disconnect wire complete.

Fasteners

M8 x 20

;

4

pcs.

Remove

stop switch.

I

screw

;

2

pcs.

RUBBER

PIPE

Fig.

5-4

-

18-

Parts to remove

Control

box,

Diode rectifier,

Magnetic switch

and

Electric

starter (Option)

Remarks and procedures

(1)

Disconnect wires

and

remove

(2)

Remove

black

wires from electric

(3)

Loosen

two

bolts and remove

control

box.

starter.

electric starter.

Fasteners

I

M8

;

2

pcs.

WIRE

2

M6

NU1

M6

FLANGE BOLT

:

1

me.

1

M6

SCREW

(PANHEAD)

:

1

pce.

Fig.

5-5

-

19-

Step

Fasteners

Remarks

and

procedures

Parts

to

remove

7

Muffler and muffler bracket Be careful not

to

lose muffler gasket.

M8

nut

;

2

pes.

M8

x

16

;

2

pcs.

Remove carburetor carefully

spring from governor lever.

8

unhooking governor rod and rod

Carburetor

M6

TAPPING

SCREW

:

5

DCS.

M8

FLANGE

FFLER

UNIT

A

Fig.

5-6

-

20-

Loading...

Loading...