Subaru EA190V User Manual

EA190V

SERVICE MANUAL

This manual contains information on how to routine maintain and how to do troubleshooting.

Keep service manual handy, so you can refer to it at any time.

This service manual describes correct methods of maintaining this engine. As a result of person casualty

and equipment damaged caused by the disregard for the rules, our company does not assume any

responsibility.

NOTICE:

Copyright reserved, and no part of this publication may be reproduced without Fuji Heavy Industries Ltd’s

written permission.

Safety Messages

Your safety and the safety of others are very important. We have provided important safety messages in

this manual and on the engine. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

preceded by a safety alert symbol and one of three words: DANGER, WARNING, or CAUTION.

These mean:

You WILL be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow instructions.

Your engine or other property could be damaged if you don’t follow instructions.

I. PARTS DESCRIPTION.......................................................................................................................................................1

1-1 Part description.........................................................................................................................................................1

1-1-1 Feature...........................................................................................................................................................1

1-1-2 Model & serial number..................................................................................................................................1

1-2 Specification .............................................................................................................................................................2

1-3 Service limit..............................................................................................................................................................3

II. DIMENSION AND TORQUE...........................................................................................................................................4

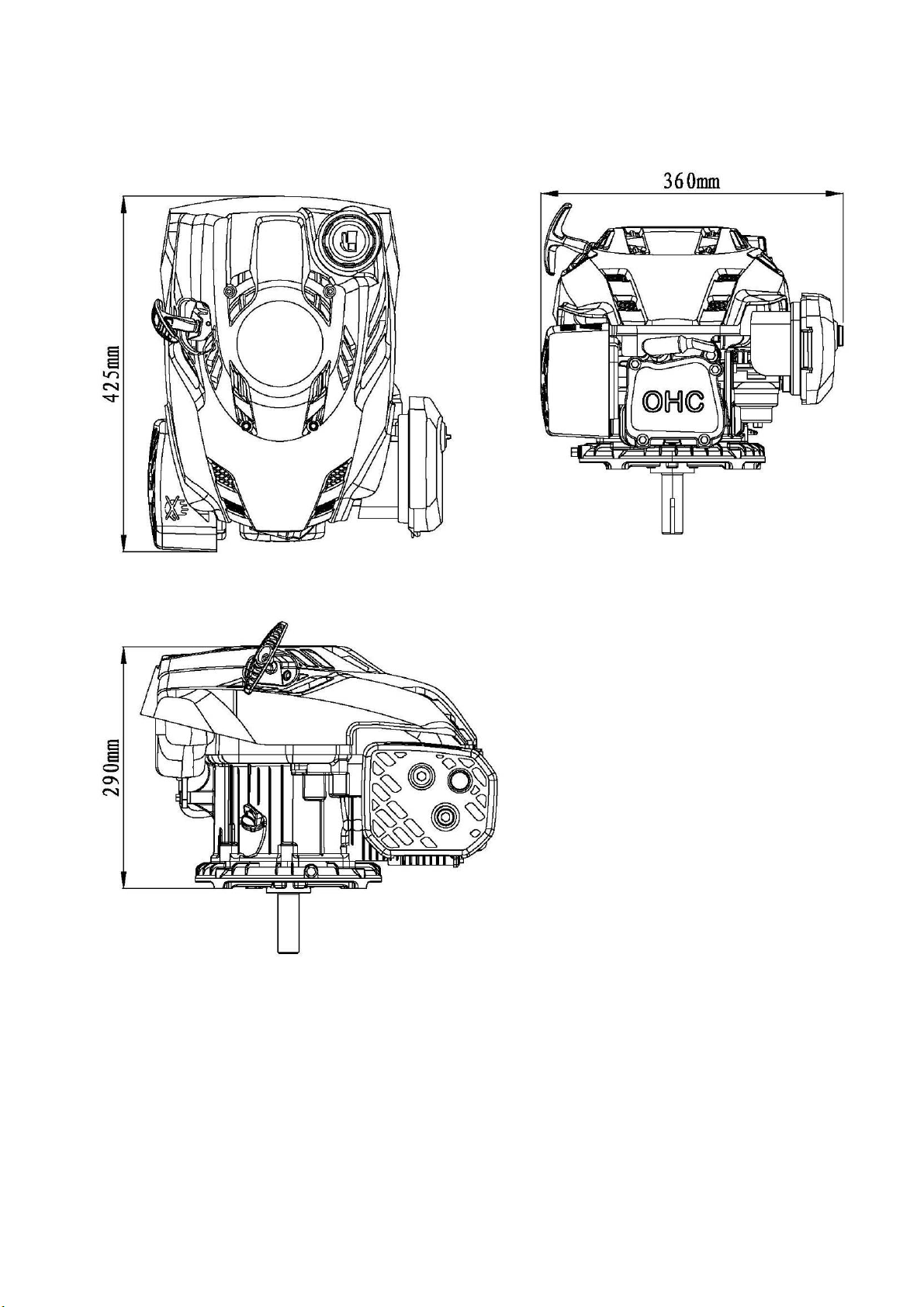

2-1 Engine dimension ..................................................................................................................................................... 4

2-1-1 Appearance dimension................................................................................................................................... 4

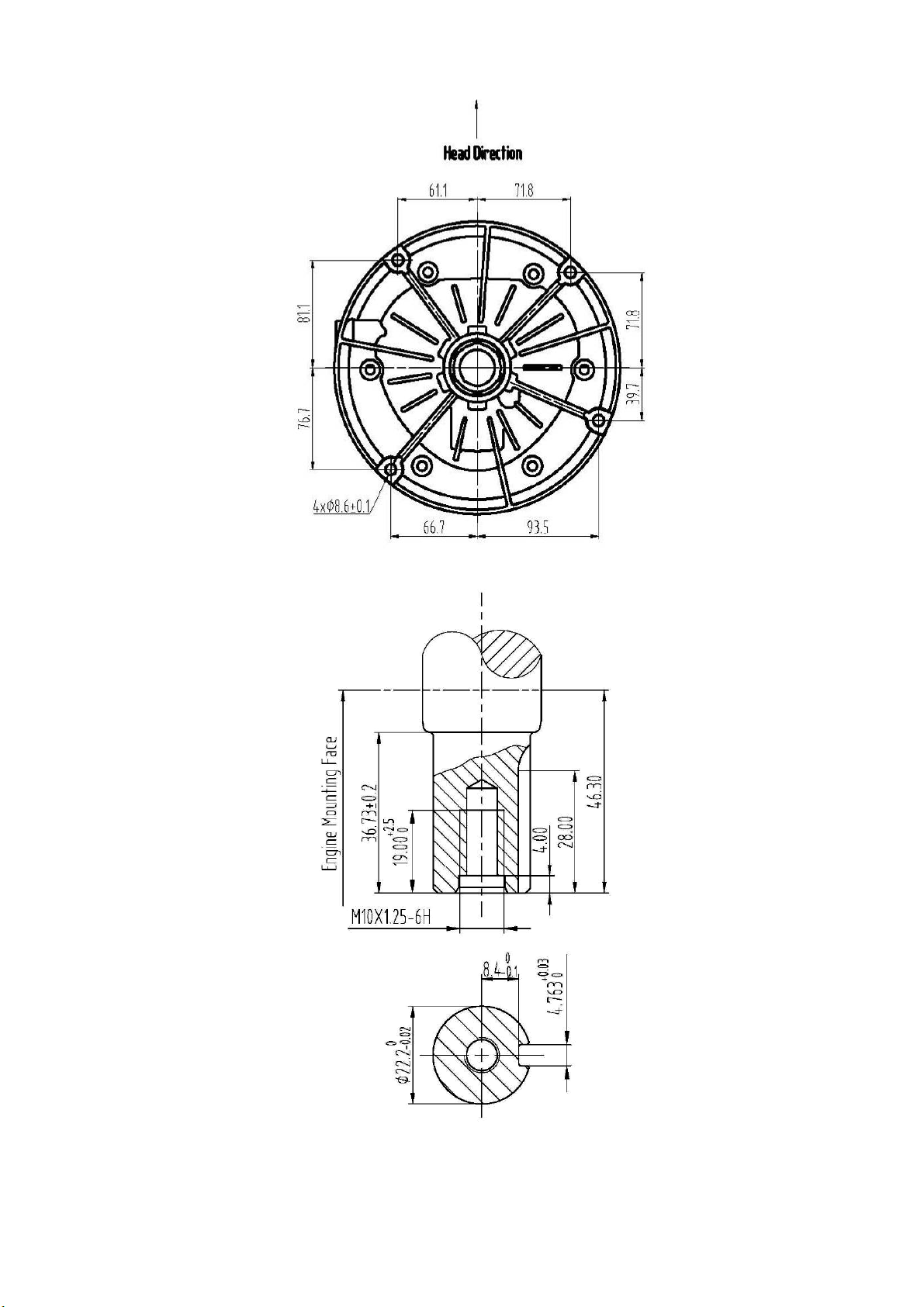

2-1-2 Installation hole position ...............................................................................................................................5

2-1-3 P.T.O dimension figure ..................................................................................................................................5

2-2 Torque value .............................................................................................................................................................6

2-3 Standard torque value ...............................................................................................................................................7

2-4 Important bolt torque value.......................................................................................................................................7

III. MAINTENANCE .............................................................................................................................................................8

3-1. Maintenance schedule.............................................................................................................................................. 8

3-2 Change oil................................................................................................................................................................. 9

3-3 AIR CLEANER......................................................................................................................................................10

3-4 Fuel parts ................................................................................................................................................................10

3-4-1 Strainer clean...............................................................................................................................................10

3-4-2 Fuel check....................................................................................................................................................11

3-5 Spark Plug Service..................................................................................................................................................12

3-6 Valve clearance adjustment.....................................................................................................................................13

3-7 Governor adjusting .................................................................................................................................................14

IV. DISASSEMBLING AND SERVICING.........................................................................................................................16

4-1 Troubleshooting...................................................................................................................................................... 16

4-1-1 Starting difficult........................................................................................................................................... 16

4-1-2 Power lack...................................................................................................................................................17

4-1-3 Speed unstable.............................................................................................................................................18

4-1-4 Unable igniting............................................................................................................................................ 19

4-1-5 Engine overheat...........................................................................................................................................19

4-1-6 Abnormal sound ..........................................................................................................................................20

4-1-7 Exhaust gas color abnormal......................................................................................................................... 20

4-2 Preparation of servicing.......................................................................................................................................... 21

4-2-1 Safety precautions .......................................................................................................................................21

4-2-2 Special tools..............................................................................................................................................21

4-3 Engine .....................................................................................................................................................................22

4-3-1 Recoil starter /housing.................................................................................................................................22

4-3-2 Fuel tank......................................................................................................................................................23

4-3-3 Ignition coil/flywheel ..................................................................................................................................24

4-3-4 Muffler.........................................................................................................................................................26

4-3-5 Air cleaner ...................................................................................................................................................27

4-3-6 Carburetor....................................................................................................................................................28

4-3-7 Throttle control............................................................................................................................................32

4-3-8 Cylinder head/valve train............................................................................................................................. 33

4-3-9 Crankcase cover/governor gear ...................................................................................................................38

4-4-10 Crankshaft/piston/crankcase......................................................................................................................39

4-5 Electric diagram......................................................................................................................................................46

I. PARTS DESCRIPTION

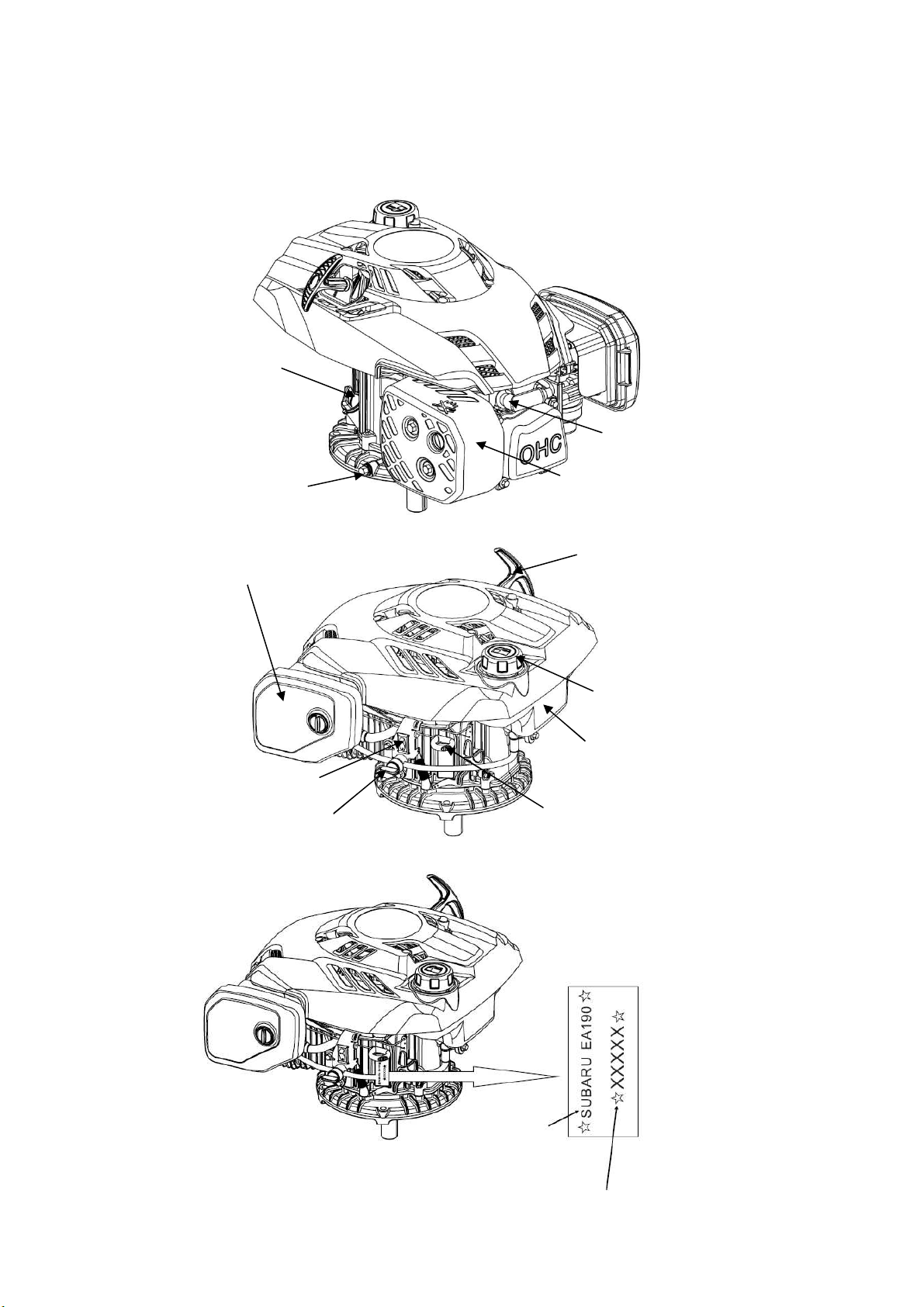

1-1 Part description

1-1-1 Feature

Oil dipstick

Spark plug

Drain plug

Muffler

Starter handle

Air cleaner

Fuel tank cap

Engine stop switch

Fuel Valve

Fuel tank

Choke

1-1-2 Model & serial number

Engine model

Serial number

1

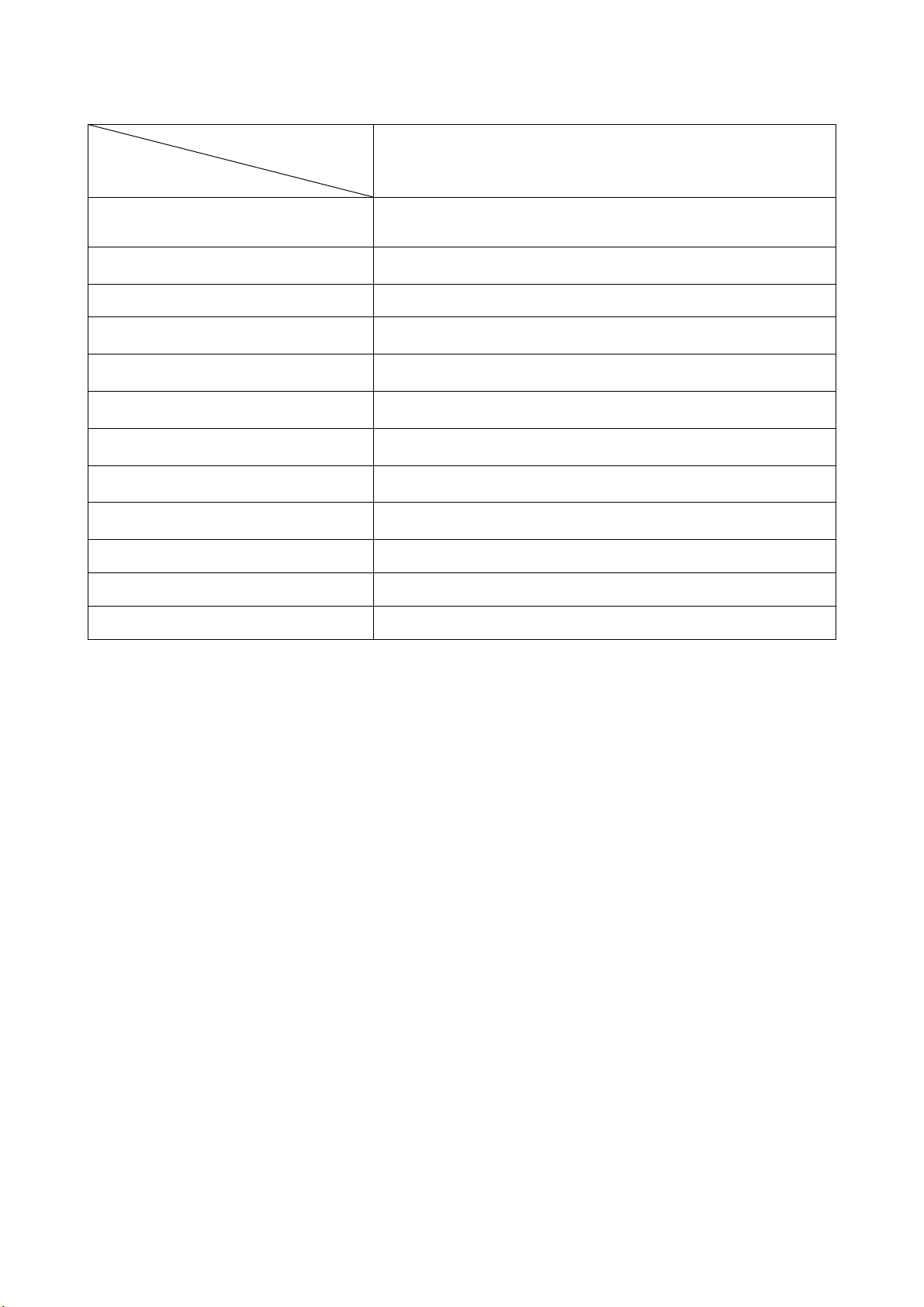

1-2 Specification

L×W×H(not including crankshaft output

Model

Specification

EA190

terminal)

Dry Weight

Engine Type

Displacement

Bore × Stroke 68mm×52mm

Theoretical Maximum Power 3.72kW/3,600r/min

Recommended Using Power 3.5 kW/3,400r/min

Maximum Torque 11.2N·m /2,500r/min

Fuel Consumption 395g/Kw·h

Cooling System Forced air

Ignition System Capacitance discharge type

PTO Shaft Rotation Counterclockwise view from P.T.O. side

14kg (iron flywheel) or 13kg (aluminum flywheel)

Single cylinder vertical,4-stroke,(OHC)

425×360×290mm

189ml

2

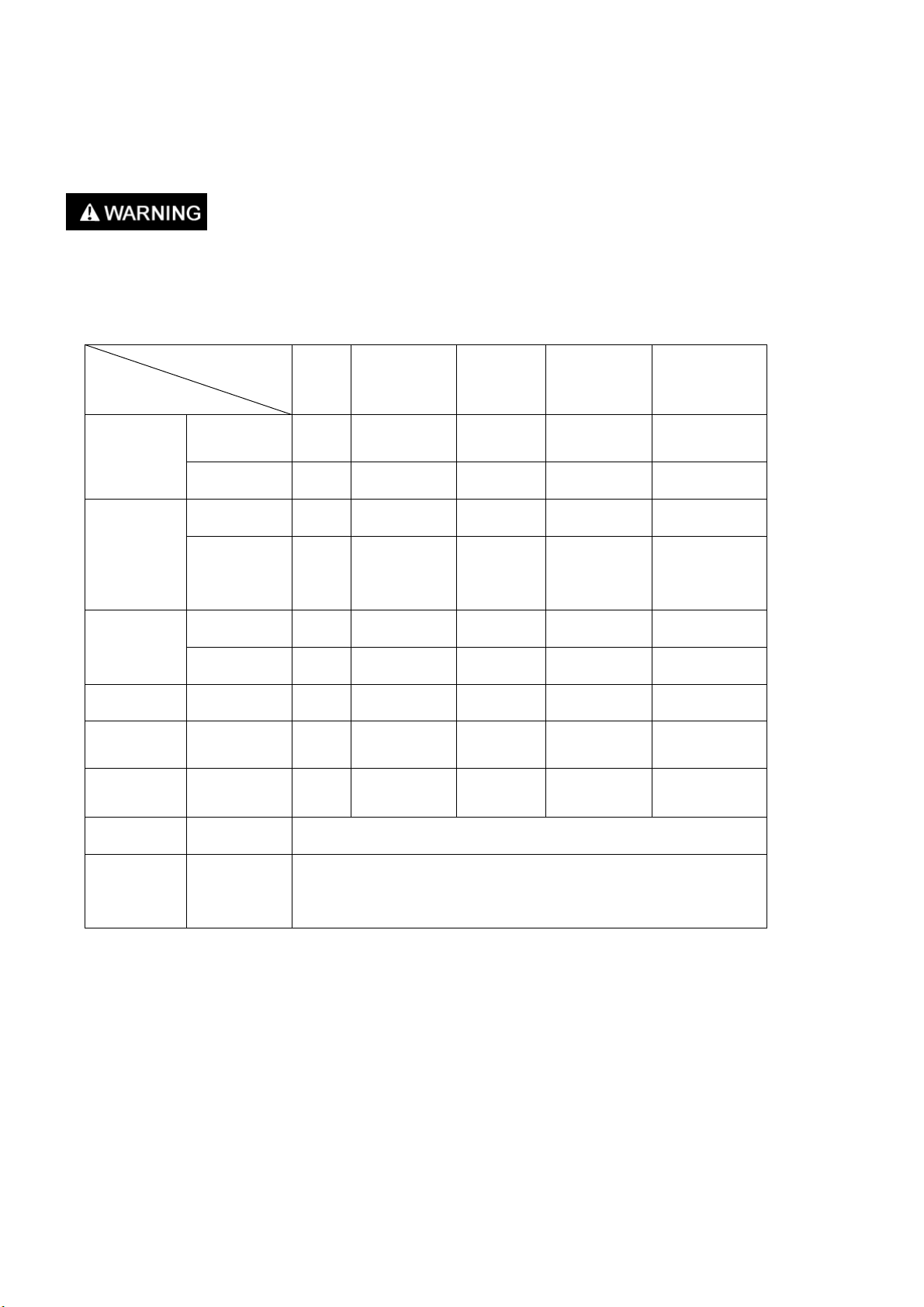

1-3 Service limit

UNIT:mm

Parts Item Standard Service limit

Engine

Cylinder head Sleeve I.D 68.00-68.02 68.160

Cylinder head Flatness 0-0.05 0.100

Piston

Piston rings

Connecting

rod

Crankshaft Crankshaft pin O.D 29.969-29.981 29.910

Valve

Camshaft

Camshaft Camshaft I.D. 9.00-9.04 9.19

Spark plug Gap 0.6-0.7 -

Maximum speed (No load)

Cylinder compression

Skirt O.D.

Piston – to cylinder clearance

Piston pin bore I.D.

Piston pin O.D

Piston pin-to-piston pin bore clearance

Ring side clearance: first/ second

Ring width: first/second

Ring end gap: first/second

Small end I.D

Big end I.D

Big oil clearance

Big end side clearance

Valve clearance

Stem O.D

Guide I.D

Stem clearance

Seat width

Spring free length

Cam height

Journal I.D

IN

EX

IN

EX

IN

EX

IN

EX

IN

EX

3800±100rpm

1.15Mpa at 1200rpm

67.971-67.989

0.011-0.049

16.006-16.012

15.994-16.00

0.006-0.018

0.04~0.08/0.04~0.08

2.60±0.10/2.80±0.10

0.13~0.28/0.20~0.40

16.005-16.021

30.000-30.018

0.019-0.049

0.3-0.7

0.10-0.15

0.15-0.20

5.440-5.455

5.430-5.445

5.500-5.520

5.500-5.520

0.045-0.080

0.055-0.090

0.85

30.50

23.98

27.88

9.00-9.04

3650/4000-

-

67.850

0.120

16.450

15.940

0.060

0.150

2.300

1.000

16.090

30.066

0.120

1.100

0.4

0.4

5.310

5.300

5.590

5.590

0.100

0.120

2.000

28.500

23.730

27.630

9.090

Ignition coil

Resistance

Air gap

Primary coil

Secondary coil

(at flywheel)

0.8-1.0 Ω

5.9-7.2 kΩ

0.35~0.45mm

-

-

-

3

II. DIMENSION AND TORQUE

2-1 Engine dimension

2-1-1 Appearance dimension

4

2-1-2 Installation hole position

2-1-3 P.T.O dimension figure

5

2-2 Torque value

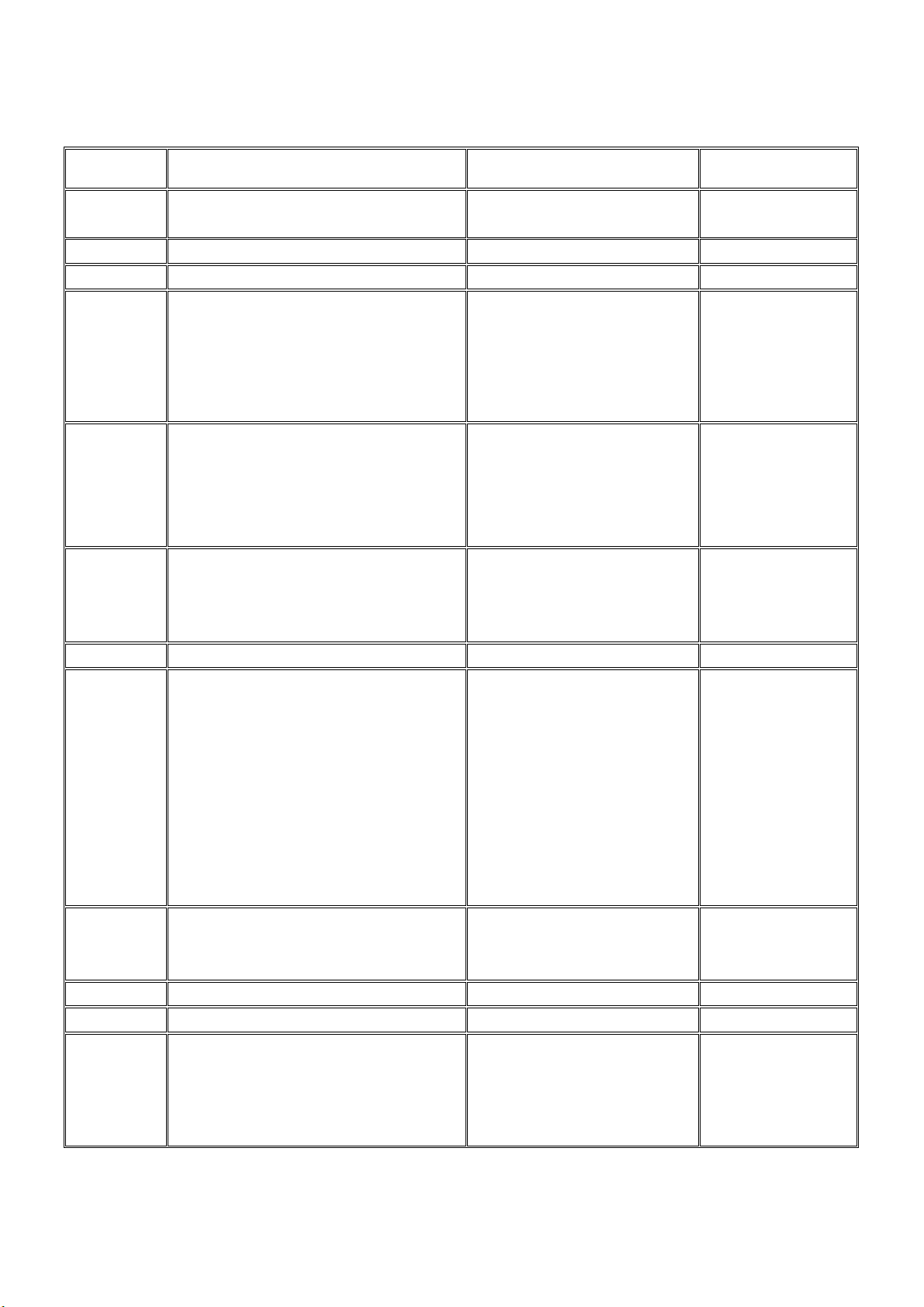

No. Item Specification Performance class

1 Cylinder head M8×65 10.9 28±2

2 Crankcase cover M6×30 8.8 10±1

3 Oil drain plug M10×15 8.8 22±2

4 Connecting rod M6×35 10.9 13±1

5 Valve locking nut M5 8 8±1

6 Governor gear M6×16 8.8 10±2

M14 (iron flywheel)

7 Flywheel

8 Spark plug M14×1.25 8.8 28±2

9 Valve cover

10 Breath groove covering plate M6×12 8.8 10±2

11 Brake

12 Ignition coil

13 Stud supporting bolt M6×83 8.8 10±2

M14 (aluminum

flywheel)

M6×12 8.8

M6×80 8.8

M6×12 8.8

M6×20 8.8

M6×20 8.8

M6×68 8.8

8 78±4

8 68±4

Torque value(N·m )

10±2

10±2

10±2

14 Lower shell M6×16 8.8 10±2

15 Muffler stud M8×109 8.8 25±2

16 Muffler nut M8 8 25±2

17 Air cleaner M6 8 8±2

18 Throttle control M6×12 8.8 10±2

19 Governor support lock nut M6 8 7±1

20 Recoil starter M6 8 8±2

M6×25 8.8 8±2

21 Fuel tank

M6 8 8±2

22 Engine housing M5×20 8.8 6±2

Notice: For unspecified bolt, screw and nut, refer to the standard torque value

6

2-3 Standard torque value

Fasteners Thread dia.(mm) Torque value(N·m)

5mm bolt, nut 4.5-6

10mm bolt, nut 29-34

12mm bolt, nut 49-59

6mm bolt, nut 8-12

8mm bolt, nut 18-25

4mm screw 1.5-2.6

5mm screw 3.5-5

Bolt and nut

6mm screw 7-11

5mm flange bolt 3.6-6.9

6mm screw 7-11

5mm flange bolt 3.6-6.9

6mm flange bolt 10-14

8mm flange bolt 20-26

10mm flange bolt

2-4 Important bolt torque value

Item

Connecting rod bolt M6×1.0

Cylinder head bolt M8×1.5 28 2.8

Flywheel nut M14×1.5 64 6.4

Crankcase cover bolt M6×1.0 10 1.0

Valve locking nut M5×0.5 8 0.8

Thread dia.(mm)

35-45

Torque value

N·m Kg·m

13

1.3

7

III. MAINTENANCE

3-1. Maintenance schedule

Good maintenance is essential for safe, economical, and trouble-free operation. It will also help reduce air pollution.

Exhaust gas contains poisonous carbon monoxide. Shut off the engine before performing any

maintenance. If the engine must be run, make sure the area is well ventilated.

Periodic maintenance and adjustment is necessary to keep the engine in good operating condition. Perform the service

and inspection at the intervals shown in the Maintenance schedule below:

Maintenance schedule

Frequency

Item

Oil level

Engine oil

Air cleaner

Spark plug

Fuel strainer

Valve

clearance

Cylinder

head

check

Replace √ √

–replace

Check, clean

Check-adjust

Each

time

√

Check √

Clean

Adjust √ Replace

Clean √

Clean

First month

or 20 hrs

√

√

Each

season or

50 hrs

Every 6

months or

100 hrs

Each year or

300 hrs

√*

√*

Fuel tank

Cylinder

head/piston

“*” This items should be serviced by company authorized dealer, unless you have the proper tools and

mechanically proficient.

NOTICE

Service more frequently when used in dusty areas.

Replace Every 3 years

Clean carbon

Each 150 hours*

deposit

8

3-2 Change oil

20

30

80

-

20

40

℃

°

30

10W 30

Oil dipstick

·change oil

NOTICE:

Drain the engine oil rapidly and completely out when the

engine is hot.

(1)Remove the drain plug and washer and tilt the engine to

drain engine oil thoroughly.

(2)Reinstall the drain plug and washer into securely by hand.

(3)Tighten the oil drain plug,EA190 torque value: 20-24N.m.

(4)Remove the dipstick and wipe up oil.

( 5 ) Refill the recommended clean oil ( EA190 engine

capacity:0.6L)and check oil level.

Lay the engine and place it on the level ground when checking.

Check as following:

a). Insert the dipstick into the filling hole without screwing

down and check the oil level.

b). If the oil level is too low, add the recommended engine oil

up to the oil upper limit.

c).Reinstall the dipstick and screw down.

NOTICE:

Use 4-stroke engine oil, API service classification SE class or

equivalent. Always check the API service label on the oil

container to assure it includes the letters SE or equivalent.

SAE10W-30 is recommended for general use. Other

viscosities shown in the chart may be used when the average temperature in your area is within the indicated range.

Recommend user to use SF class or equivalent.

WARNING: Engine oil is a major factor affecting engine performance and service life. Additive-free and 2-stroke

engine oil will damage the engine.

NOTICE: For environment protecting, please properly handle with the used oil. Running with insufficient engine oil

may damage the engine severely and it will not be covered the range of the warranty.

Used engine oil may cause skin cancer if repeatedly left in contact with the skin for prolonged

periods. Although this is unlikely unless you handle used oil on a daily basis, it is still advisable to

thoroughly wash your hands with soap and water as soon as possible after handling used oil.

9

Washer

5W 30

-

20

Drain plug

Upper limit

Figure

SAE VISCOSITY CLASS

-

-

40

20

0

-

10 0 10

ENVIRONMENT TEMPERATURE

60

Lower limit

100

F

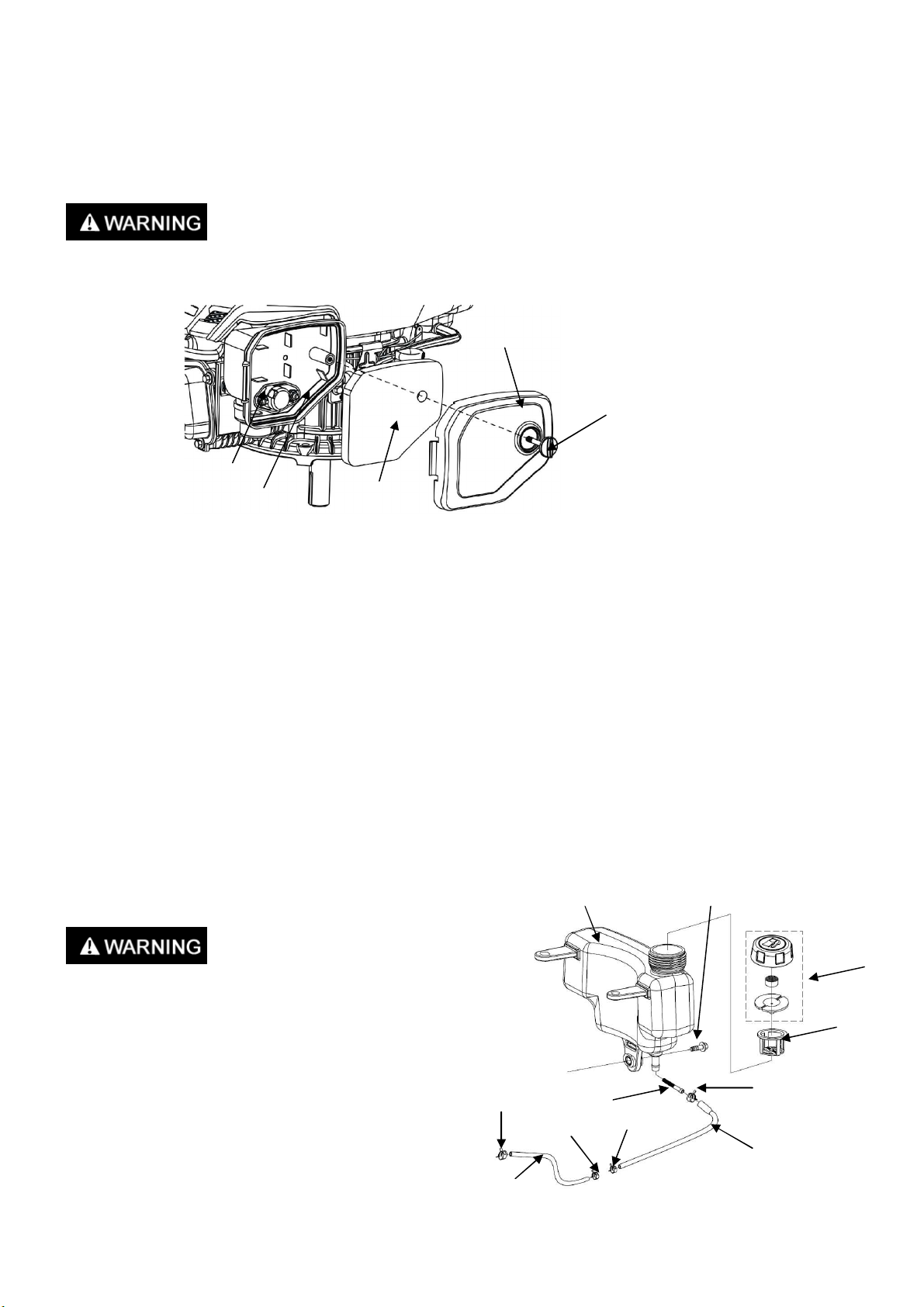

3-3 AIR CLEANER

Tank cap

Clip

NOTICE: A dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor malfunction, clean the air

cleaner each 50 hours (or three months) and service the air cleaner regularly. Service more frequently when operating the

engine in extremely dusty areas.

Using gasoline or flammable solvent to clean the filter element can cause a fire or explosion.

Use only soapy water or nonflammable solvent.

Never run the engine without the air cleaner. Rapid engine wear will result.

Nut M6

Air cleaner base

Air cleaner

element

① Screw off the connecting bolt and remove the air cleaner shell.

② Remove foam element or paper element. Be careful to prevent dirt and debris from falling into the air cleaner base

when opening,

③ Clean the element

Foam element: Clean the foam with detergent, and then blow it dry with compressed air or squeeze it dry. Dip the element

in clean oil, and then forcefully squeeze it dry and install it back.

Paper element: Tap the element lightly several times on hard surface to remove excess dirt or blow compressed air lightly

from the inside out. If dirty, replace in time.

CAUTION: Foam element containing too much oil will jam the foam element holes.

④ Check, clean or replace damaged air cleaner parts.

⑤ Reassemble the air cleaner element into the shell, install foam element or paper element back, cover the shell on and

screw in the connecting bolt.

Air cleaner shell

Connecting bolt

3-4 Fuel parts

Don’t smoke or use flame fires near

the flammable solvent.

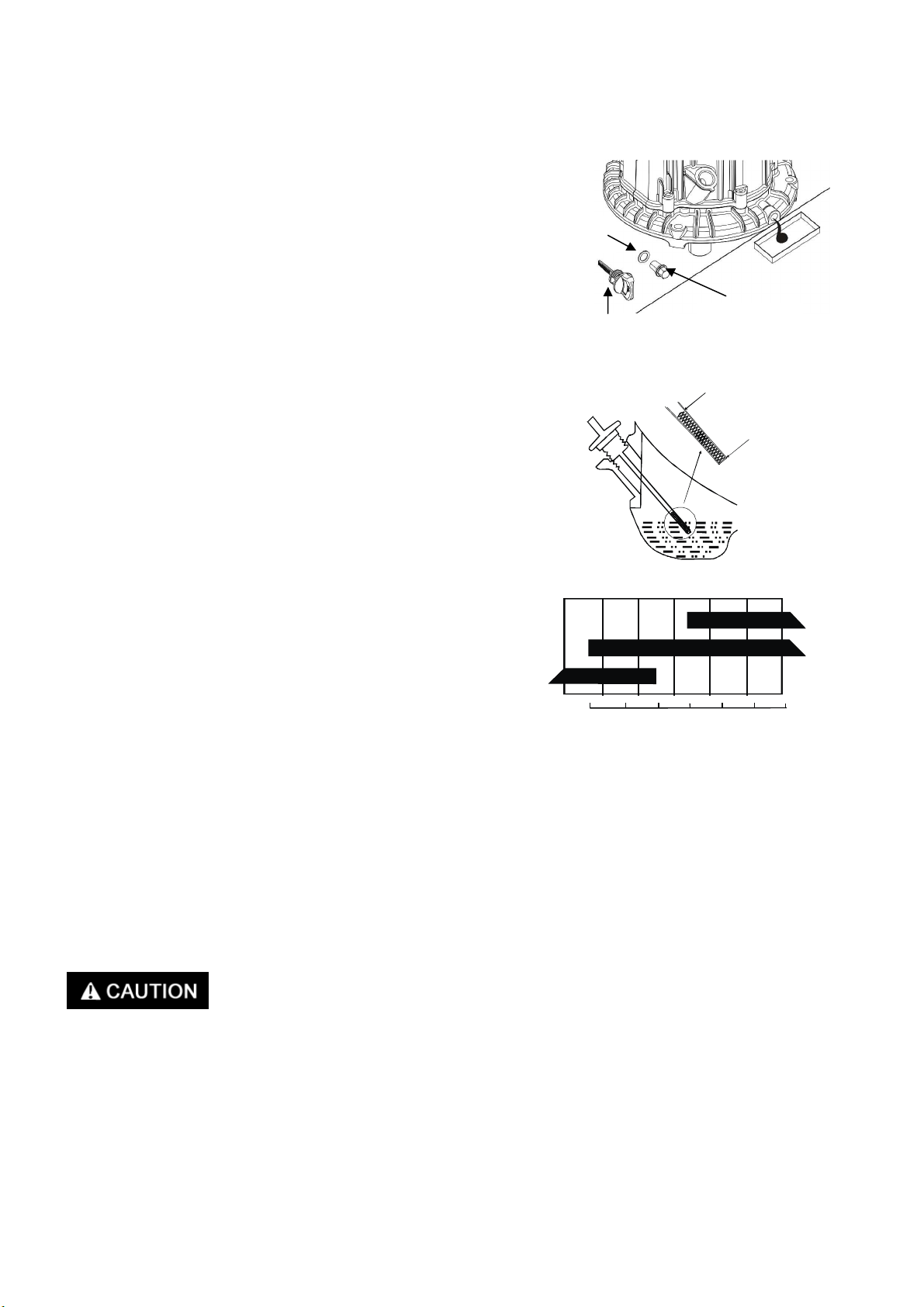

3-4-1 Strainer clean

(1) Drain the fuel into the container.

(2)Loose the clip, remove fuel tube and pull the strainer out.

(3) Check the strainer for damaged and clean the strainer in

the container.

(4) After cleaning, reinsert the strainer in the fuel tank,

connect fuel tube and tighten the clips.

NOTICE:

Check all connecting position for leaking.

10

Clip

Tube

Fuel tank

Strainer

Clip

Bolt M6×25

Fuel Gauge

Clip

Tube

3-4-2 Fuel check

Upper limit(850CC)

1. Remove the fuel tank cap and check fuel level.

2. If the level is too low, refuel the tank. Please don’t

refuel over the fuel gauge.

Fuel Gauge

WARNING:

Fuel tank

Fuel

1. Gasoline is extremely flammable and is explosive under certain conditions.

2. Refueling in a well-ventilation area with the engine stopped. Do not smoke or allow flames or sparks in

the area where gasoline is stored or where the fuel tank is refueled.

3. Do not overfill the fuel tank (The fuel will not exceed the fuel gauge). After refueling, make sure the

fuel tank cap is set back securely.

4. Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may ignite. If any fuel is spilled,

make sure the area is dry before starting the engine.

5. Avoid repeated or prolonged contact with skin or breathing of fuel vapor.

6. Keep out of reach of children.

RVC 190 fuel tank capacity:1.0L

Only use unleaded gasoline and recommend gasoline grade

90

#

over.

Unleaded gasoline can reduce gasoline engine carbon deposit and prolong the exhaust system service

life.

Never use contaminated gasoline or mixed gasoline with oil. Don’t allow the dust, foreign matter or

water entering into fuel tank.

CAUTION:

Fuel may damage the oil paint and plastic. Be careful not to spill fuel when refueling. Any damage due to

fuel spilling is not within valid warranty.

If " knocking" or "spark exploding" sound occur at a steady speed under normal load, change grade of

gasoline; if such phenomena still happen, consult your dealer for help, otherwise the engine may be

damaged.

CAUTION:

When the engine is running, continuously "knocking" or "spark exploding" sound occurring will damage

engine.

"Knocking" or "spark exploding" sound from misusing will not be within the valid warranty.

11

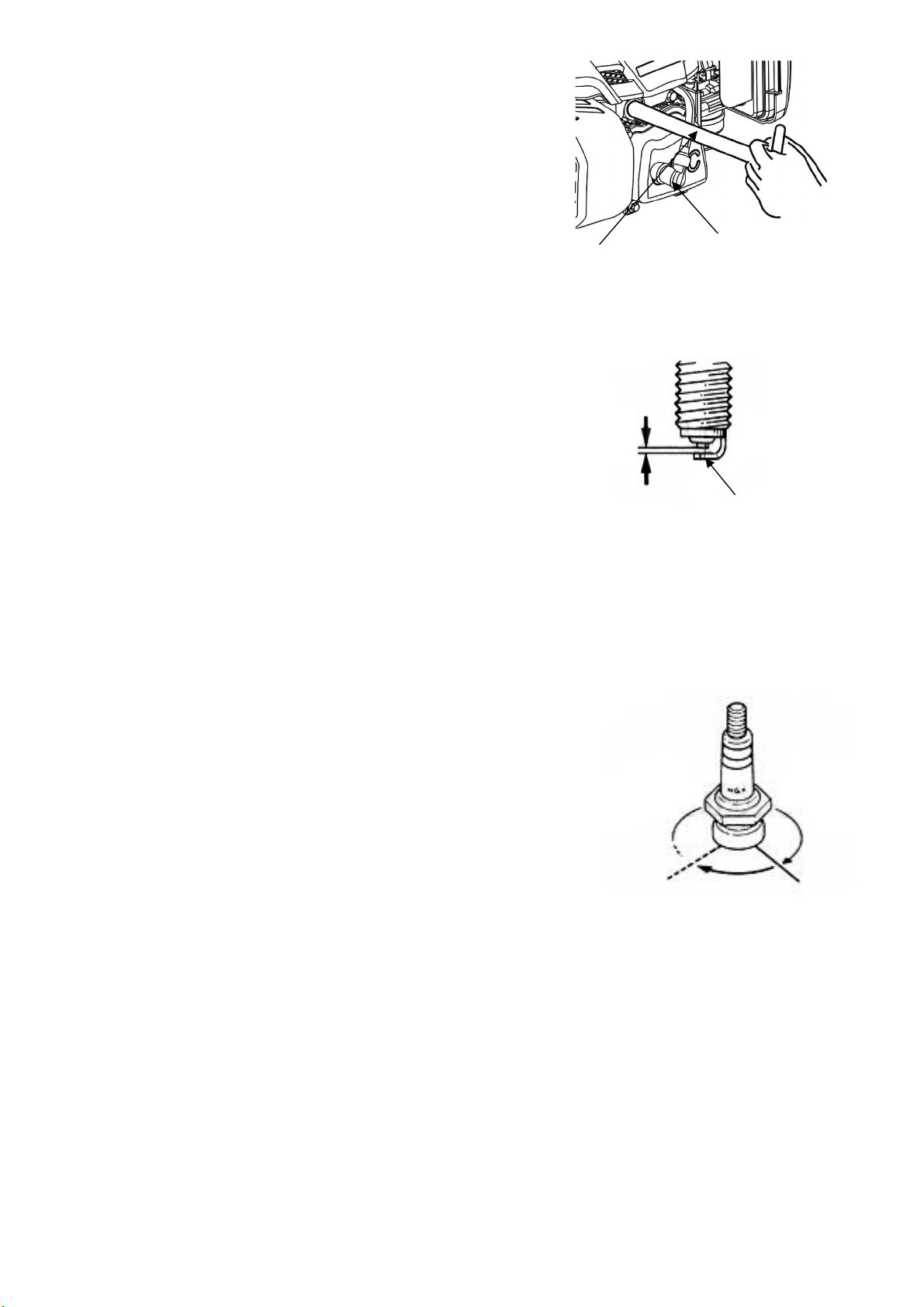

3-5 Spark Plug Service

(1) Remove the spark plug cap. Clear away dirt around the

spark plug base;

(2) Use the plug wrench to remove the spark plug;

(3) Visually inspect the spark plug, if the insulator is

cracked, replace with new the spark plug, if deposit

around the electrode, remove carbon or other deposits

with a stiff wire brush;

(4) Measure the spark plug clearance with a feeler. The

clearance should be 0.6~0.7mm.If need adjusting,

lightly tap (for gap too big) or pry up with flat

screwdriver (for gap too small) electrode.

(5) Check the spark plug washer if it is in good condition.

Plug wrench

0.60~0.70mm

Spark plug cap

Side electrode

(6) Install the spark plug on and screw down it with plug

wrench, compress the plug washer. Cover the spark

plug cap on.

NOTICE:

To avoid cross-threading, first, screw in spark plug by

hand, then tighten with a spark plug wrench to compress

the gasket.

If a new spark plug is used, more twist 1/2 turns after

compressing the gasket.

If reinstall the used spark plug, just more twist 1/8-1/4

turns.

Spark plug torque value: 22±2N·m

The spark plug must be tightened securely, or it may

become very hot to damage the engine.

When replaced, please pay attention to model of the spark plug to avoid damaging the engine or using

recommended spark plug or the equivalent. Incorrect heat range of the spark plug may damage the engine

·EA190 recommended spark plug model: NGK——BPR7HS

CHAMPION——RL87YC

TORCH——E7RTC

12

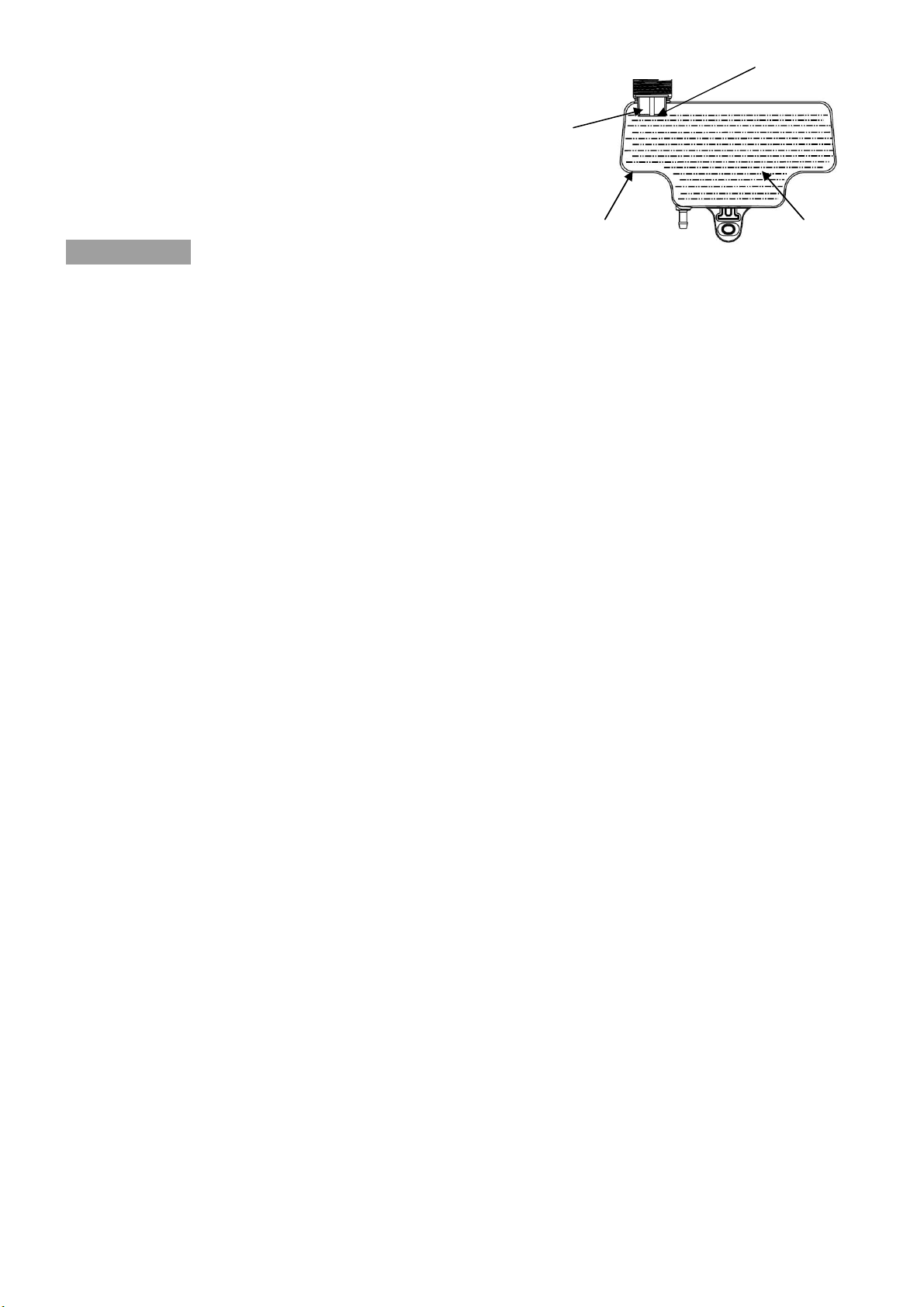

3-6 Valve clearance adjustment

Feeler

Gauge

Keep the clearance between engine valve rod end and driving parts for avoiding heat expanding and cold shrinking to

effect engine performance. If the valve clearance is too big, it can result in exhausting unsmooth, effecting engine

performance and increasing engine noise (valve abnormal); if the valve clearance is too small, the valve will close untight

to make the engine operating abnormal. After operating one year or 300hrs, check and adjust the valve.

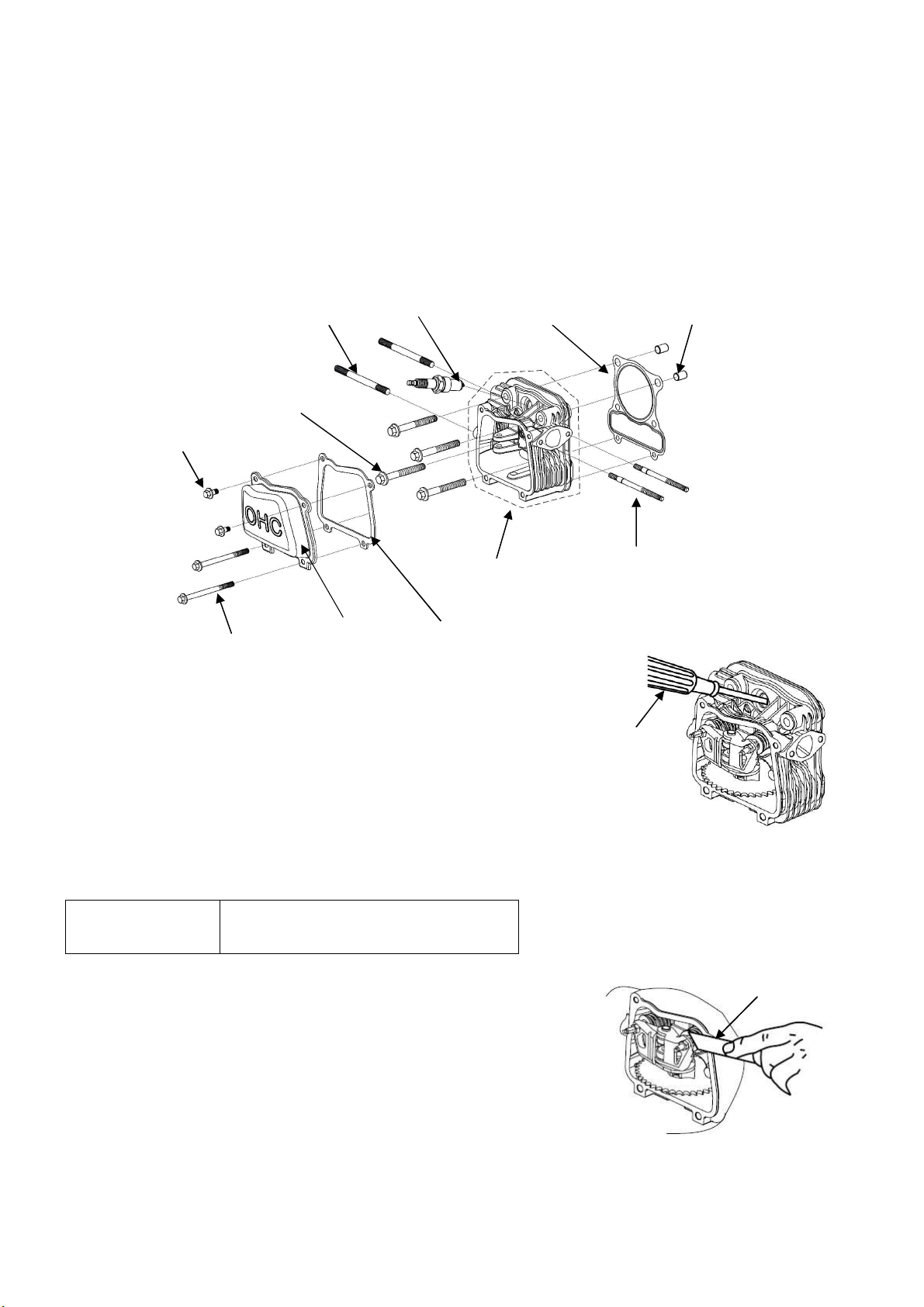

(1) Dismount the spark plug cap, spark plug, cylinder head cover bolt, cylinder head cover and gasket in order.

CAUTION: After the cylinder head cover is removed, engine oil may flow. Be sure to wipe up any flowed oil.

Stud M6×109

Spark plug

Cylinder head gasket

Bolt

Bolt M6×12

Cylinder head assy.

Bolt M6×80

Head cover

Cover gasket

(2) Lightly pull the starting rope and set the piston at top dead center

of the compression stroke (insert screwdriver into the hole of the

Dowel Φ10×14

Stud M6×102

Screwdriver

spark plug to check the height of piston.)

(3) Measure the valve clearance: Insert the feeler into the clearance

to measure clearance.

Valve clearance

IN:0.10-0.15mm

EX:0.15-0.20mm

Adjust if the valve clearance is out of

the service limit.

CAUTION:

Measure the valve clearance in the cold engine state.

(4)If adjustment is necessary, proceed as follows:

a. Hold valve adjusting bolt with tongs and loosen the valve lock nut.

b. Turn valve adjusting bolt to obtain the specified clearance.

c. Fix the valve adjusting bolt with tongs, and then fix the valve lock nut with spanner.

13

Loading...

Loading...