Page 1

Model 5150

Video Generator Module

User Guide

Issue 5, March 2014

This User Guide is applicable for

Model 5150 modules with the following order codes:

M5150, M5150-01, M5150-02, M5150-03X, and M5150-04X

with serial numbers 00151 and later

and firmware versions

MCU 2.2 and later (m5150.s19) and FPGA 2.2 and later (m5150.bit)

Copyright © 2014 by Studio Technologies, Inc., all rights reserved

www.studio-tech.com

50184-0314, Issue 5

Page 2

This page intentionally left blank.

Page 3

Video Generator

Model 5150

Module

Table of Contents

Introduction ................................................................... 5

Installation .................................................................... 8

Configuration ................................................................ 12

Operation ...................................................................... 19

Technical Notes ............................................................ 23

Specifications ............................................................... 29

Appendix A—Model 5150 Versions .............................. 30

Appendix B—DC Input/Data and GPI/GPO

Interconnection Details ................................................. 31

Appendix C—Model 5150 Front Panel and

Printed Circuit Board (PCB) Dimensions ...................... 33

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 3

Page 4

Video Generator

Model 5150

Module

This page intentionally left blank.

Issue 5, March 2014 Model 5150 User Guide

Page 4 Studio Technologies, Inc.

Page 5

Video Generator

Model 5150

Introduction

The Model 5150 Video Generator Module

is a unique device suited for a variety of

custom broadcast, post-production, industrial, and corporate multimedia installations. As a member of the 5100-Series

of modules, the Model 5150’s compact

size belies its powerful video feature set.

Advanced circuitry within the Model 5150

supports the generation of a broadcaststandard high-definition SDI signal. And

rather than reproducing a fixed test pattern, the Model 5150 has the capability

to store and output two custom video images. The images, one for “720” and one

for “1080,” are based on bitmap (.bmp)

files that can be created using a personal

computer’s graphics program.

For convenience, the .bmp files are stored

in the module’s nonvolatile memory via a

standard USB flash drive. The appropriate

“720” or “1080” image is automatically connected to the SDI output whenever an SDI

input signal is not present. This ensures

that an SDI output signal is always sent to

equipment further along the signal chain.

The Model 5150’s video signal generation

capability can be extremely useful, serving as both a “keep-alive” signal as well as

allowing a detailed graphics image to be

displayed for identification purposes. When

Module

a valid HD- or 3G-SDI signal is connected

to the module’s input it will pass through,

unchanged, to the module’s SDI output.

Only when an input is not present will the

stored image be generated. The format

and rate of the stored image will match

that of the previously-connected SDI input

signal. This “learning” capability allows a

Model 5150 to automatically adapt to the

SDI format and rate utilized by a specific

facility or application.

An alternate operating mode can be selected, allowing the Model 5150 to serve

as a dedicated video signal generator. In

this mode an SDI signal connected to the

module will serve as an external timing

reference.

General Highlights

Applications for the Model 5150 include

sports broadcasting booth packages,

“POV” (point-of-view) remote-controlled

camera systems, stadium video interface

(I/O) locations, and government/corporate

facilities. The module’s performance is

completely “pro” with video quality, reliability, and installation flexibility matching that

of much larger-scale equipment.

For operation the Model 5150 only requires

connection of a few signals. These consist of SDI inputs and outputs, an external

Figure 1. Model 5150 Video Generator Module front and rear views

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 5

Page 6

Video Generator

Model 5150

Module

source of nominal 12 volts DC and, optionally, two wires associated with a local

RS-485 data bus. Some applications may

also utilize the general-purpose input (GPI)

and general-purpose output (GPO) functions (available only on modules with serial

numbers 00251 and later). Coaxial SDI in

put and output support is standard. Optical

input and output support is optional. The

acceptable DC input voltage range is 10 to

18, allowing a variety of power sources to

be utilized.

The Model 5150 uses standard connectors

for fast, convenient interfacing. Coaxial SDI

input and output signals use BNC connectors. An optional video SFP fiber optic

module can be installed at the factory. The

module supports interconnection of singlemode optical fibers using LC plugs. The

DC power input and data bus connections

use a 4-position, 0.1-inch header. The GPI

and GPO connections use a 3-position,

0.1-inch header. Low-cost IDC (insulationdisplacement connector) mating sockets

allow simple interconnection with a variety

of wire gauges. Four status LEDs offer

users both performance confidence and

troubleshooting assistance.

The Model 5150 is compatible with the

Studio Technologies’ Model 5190 Remote

Access Module. This will allow remote

configuration, monitoring and control, via

an Ethernet connection, of key module

operating and status parameters. A local

RS-485 data bus allows up to 16 of the

5100-Series modules to be connected to

a Model 5190.

A simple text file that reflects the desired

configuration is created and stored on the

USB flash drive. When inserted into the

appropriate socket on the Model 5150 the

file is read and stored. Updating the Model

5150’s firmware (embedded software) is

also possible using a USB flash drive loaded with factory-supplied files.

Model 5150 Video Generator Modules do

not include a mounting enclosure or chassis. They are intended for mounting in custom 19-inch rack panels, equipment boxes,

broadcast furniture, “NEMA” I/O boxes, or

other specialized enclosures. It is expected

that integration firms will create applications

that use Model 5150 modules as part of

complete broadcast, production, corporate,

and government solutions. Sophisticated

users will be able to easily create “one-off”

solutions to solve unique challenges.

SDI Inputs and SDI Outputs

High-definition SMPTE-compatible SDI signals with data rates of 1.485 Gb/s nominal

(HD-SDI) and 2.97 Gb/s nominal (3G-SDI)

can be connected. Virtually all of the commonly-utilized “720” and “1080” formats are

supported. Standard-definition SDI signals

with a data rate of 270 Mb/s nominal (SDSDI) are not supported. It was felt that users

looking for advanced solutions such as

those provided by the Model 5150 will not

typically be working with SD-SDI signals.

But be assured that many HD-SDI and

3G-SDI formats and rates are supported,

allowing the Model 5150 to be appropriate

for worldwide use.

Several Model 5150 operating parameters

can be configured to meet the needs of

specific applications. A USB flash drive

along with several DIP switches, are used

Coaxial (BNC) Support

Using standard BNC connectors, the Model

5150 supports one coaxial SDI input and

one coaxial SDI output.

to convey the configuration to the module.

Issue 5, March 2014 Model 5150 User Guide

Page 6 Studio Technologies, Inc.

Page 7

Video Generator

Model 5150

Module

Optical Fiber Support

Factory-implemented options allow the

Model 5150 to support SDI signals that

are transported using single-mode optical

fibers. Using video SFP modules a range

of optical input, output, and transceiver

capabilities can be supported. For a list

of available Model 5150 versions refer to

Appendix A.

The standard 1310 nanometer optical

transmit wavelength is available, as are

the more-esoteric CWDM wavelengths. A

module that includes an optical SDI output

will always have its optical output active,

transporting the same SDI data as that

present on the coaxial (BNC) output. When

a Model 5150 has been provided with an

optical SDI input a configuration choice

selects whether it, or the coaxial (BNC)

input, is active.

Video Generation Capability

During typical operation an HD- or 3G-SDI

signal is connected to the Model 5150’s

selected SDI input. It’s then “passed

through” to the module’s SDI output(s)

and on to the next part of the signal chain.

But what happens when the external SDI

signal is not present? That’s when the

Model 5150’s internal SDI generator becomes active. When a signal is not present

on the selected SDI input the module will

generate a high-definition (HD- or 3G-SDI)

image that will serve as a “slate,” ID, or

“SDI-active” signal.

From the factory two bitmap (.bmp) image

files are stored in nonvolatile memory. One

file is used for generating the image for

1280 x 720 pixel formats and the other for

1920 x 1080 pixel formats. But alternate

bitmap image files can be created and

stored in the Model 5150. These alternate

images can supply site- or applicationspecific information useful to “downstream”

users. Using a personal-computer graphics program, such as Microsoft® Paint® or

Adobe® Photoshop®, generating custom

images and storing them in the appropriate

bitmap format is a simple matter.

A USB port, located on the Model 5150’s

front panel, allows direct connection of

a standard USB flash drive. If the Model

5150’s firmware (embedded software)

recognizes compatible FAT32 bitmap (.bmp)

files on the USB flash drive they will be automatically loaded into nonvolatile memory.

The USB flash drive can then be removed

with the custom images safely stored within

the Model 5150.

One subtle but important configurable

feature has been included for broadcast

applications which use the Model 5150’s

SDI output(s) “on-air.” When an SDI signal

is removed from the module’s selected SDI

input, the Model 5150 can be configured to

output a few seconds of solid-gray color before the stored image appears. This will help

to ensure that technicians or operators will

be visually “warned” that the module’s input

signal has been lost and that the stored image will soon be taking its place. It’s hoped

that the solid-gray video image will be innocuous for on-air viewers yet different

enough to encourage operators to switch the

module’s output away from being “on air.”

A unique feature of the Model 5150 is its

ability to automatically adapt to the format and rate of a connected SDI signal.

This allows the stored image to be output

at the same format and rate as that used

by the associated network, local facility, or

event. If, for example, a connected input is

“1080i/59.94” then the Model 5150 will automatically detect and store that information.

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 7

Page 8

Video Generator

Model 5150

Module

From then on whenever an SDI input signal is not present the internal generator will

output the stored image at “1080i/59.94.”

Changing the format and rate of the generator only requires connection of an SDI

signal with the desired characteristics.

(A minimum required connection time

helps to ensure that an accidental format/

rate change won’t occur.) However, there

may be situations where maintaining the

format and rate of the internally-generated

signal is important. To support this condition one configuration choice allows the

automatic format/rate selection function

to be disabled.

Video Generation with External

Reference

Some applications may benefit from the

Model 5150 serving as a full-time stand

alone video generator. A configuration

choice helps to support such applications

by using the selected SDI input only as

a timing reference. Unlike typical operation, when selecting this operating mode a

signal connected to the selected SDI input

would not pass through to the SDI. Its rate,

format, and specific timing characteristics

would be used as a reference for the internally-generated video output. Note that

bi-level or tri-level analog timing reference

signals are not supported. Only a HD-SDI

or 3G-SDI signal can serve as a reference

signal for the Model 5150.

GPI and GPO

Model 5150 modules with serial numbers

00251 and later offer a general-purpose

input (GPI) and a general-purpose output (GPO) function. The GPI allows the

connection of a switch or relay contact to

control the on/off status of a Model 5150

function. As of the date of this User Guide,

no GPI operating function has been implemented in the module’s firmware (embedded software). Future versions of the

firmware may implement a GPI-controlled

action.

The GPO function provides an indication

of the status of the selected SDI input. It’s

intended that the GPO will be connected to

an LED indicator. A configuration choice selects whether the GPO is active (+3.3 volts)

when the selected SDI input is valid or active when the selected SDI input is invalid.

(This can also be described as active “high”

or active “low”). This allows, for example, a

green LED to light whenever a valid signal

is connected to the selected SDI input,

thus providing an “input good” indication.

Alternately, a red LED could light when the

selected SDI input is not active, providing

an “input fail” indication.

Installation

Integration of the Model 5150 into a selected application should prove quite simple,

only connecting SDI input and output signals as well as DC power is required. Some

applications will also require connection

to the module’s data bus, GPI, and GPO

functions. The coaxial (BNC) input and output connections are compatible with most

HD-SDI and 3G-SDI signals. If the specific

Model 5150 being installed also includes

optical support one or two single-mode fiber

interconnections will be made. The fiber

connections utilize miniature LC plugs.

The DC power source is nominal 12 volts

with an acceptable range of 10 to 18 volts.

It’s possible that the module will be part of

a local RS-485 data bus that’s associated

with a Studio Technologies’ Model 5190 Remote Access Module. If so, two additional

Issue 5, March 2014 Model 5150 User Guide

Page 8 Studio Technologies, Inc.

Page 9

Video Generator

Model 5150

Module

wires are required to connect the module

to the data bus. GPI and GPO connections

are made using a 3-pin header. After all the

connections have been completed the module can then be secured into the designated

mounting location.

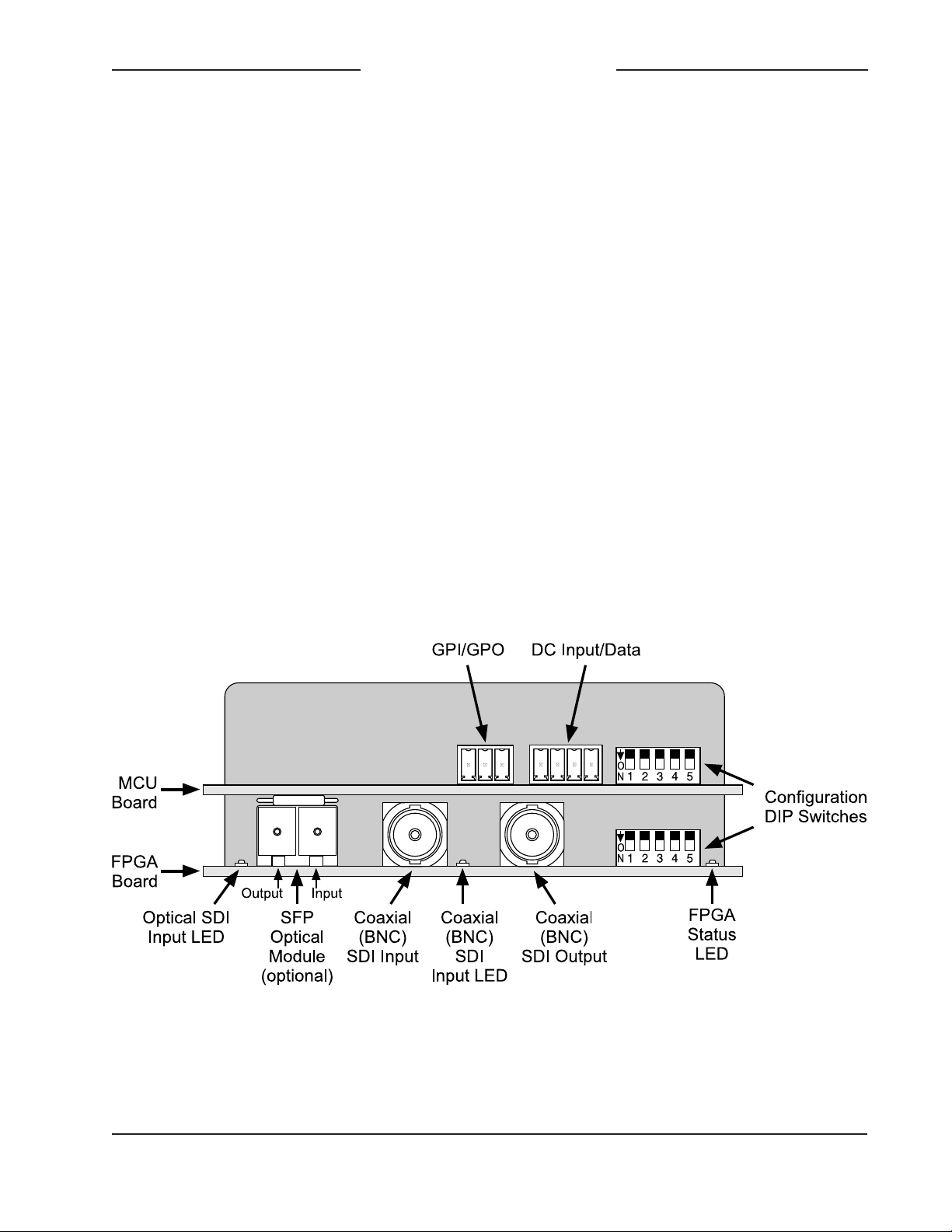

Coaxial (BNC) SDI Output

The Model 5150 provides an SDI output

that utilizes a broadcast-standard BNC

socket. This output is referred to as the

coaxial (BNC) SDI output. Refer to Figure 2

for a detailed view of the connector’s location on the rear of the module. The coaxial

(BNC) output, depending on operating

conditions, will be either a SMPTEcompliant HD-SDI (1.485 Gb/s nominal) or

a 3G-SDI (2.97 Gb/s nominal) signal. The

exact format/rate combinations supported

by the Model 5150 are listed in the Specifications section of this guide.

Coaxial (BNC) SDI Input

An SDI source can be connected to the

Model 5150 by way of a broadcast-standard BNC connector. This is referred to

as the coaxial (BNC) SDI input. Refer to

Figure 2 for a detailed view of the connec

tor’s location on the rear of the module.

The coaxial (BNC) input is compatible

with SMPTE-compliant HD (1.485 Gb/s

nominal) and 3G (2.97 Gb/s nominal) SDI

signals. It is not compatible with standard

definition SD-SDI (270 Mb/s nominal) signals. The exact format/rate combinations

supported by the Model 5150 are listed in

the Specifications section of this guide.

A configuration setting must be made for

the coaxial (BNC) SDI input to be active.

Refer to the Configuration section of this

guide for details.

-

Figure 2. Detailed rear view of the Model 5150 Video Generator Module showing the MCU

and FPGA boards

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 9

Page 10

Video Generator

Model 5150

Module

Optical SDI Output

This section applies only when the specific Model 5150 module being installed

was configured at the factory to provide an

optical output. A video SFP (small formfactor pluggable) optical module is used to

provide the optical SDI output. A range of

SFP modules can be installed in the “cage”

at the back of the Model 5150. These include transceiver modules that have both

an optical output (transmitter) and an optical input (receiver), as well as output-only

(transmitter) modules. The technical char

acteristics of the optical output will depend

on the specific module installed. The most

common transceiver or output-only SFP

module used in the Model 5150 will have

an FP (Fabry-Perot) laser emitting “light” at

a wavelength of 1310 nanometers. Other

modules can utilize a higher-performance

DFB (distributed feedback) laser that is

manufactured to produce light at one of the

18 CWDM wavelengths. (For broadcast

applications, the common first-utilized

CWDM wavelengths are often 1490 and

1550 nanometers.)

An LC plug terminated on a single-mode

optical fiber is used to mate with the SFP’s

optical output. When referenced to the

front of an SFP transceiver or output-only

SFP module the optical output is located

on the SFP module’s left side. To indicate

the optical output port a graphic arrow icon

pointing “out” may be present on the top of

the module. Refer to Figure 2 for a detailed

view. When terminating the LC plug with the

socket on the SFP module be certain that

the plastic plug’s locking tab is fully engaged into the slot of the SFP module. This

will help prevent the LC plug from becom

ing disconnected due to physical stress or

vibration on the fiber. Also ensure that the

-

-

end (“face”) of the plug’s ferrule has been

cleaned using appropriate methods.

Note that as of the time this user guide

was written the Model 5150 supports only

single-mode optical cable. Contact Studio

Technologies should support for multimode fiber be required.

The Model 5150 module should remain

without power whenever its optical output

has not been terminated. This ensures that

the optical energy will not project into free

space and possibly into the eyes of installation personnel. The optical output power

of video SFP modules selected by Studio

Technologies adheres to the class 1 laser

standard. As such, they do not emit sufficient power to be considered hazardous.

But best safety practices require that the

optical output port and all unconnected

fiber ends not be directly viewed.

No configuration setting is required to

activate the optical output. It is always active and will contain the same SDI data as

that found on the coaxial (BNC) output. As

such there is no problem in simultaneously

connecting to both the optical and coaxial

(BNC) outputs.

Optical SDI Input

If supported by the specific Model 5150

module being installed, an HD- or 3G-SDI

signal transported on a single-mode optical fiber can be connected. For an input to

be present a video SFP transceiver or a

receive-only SFP module must have been

installed in the SFP “cage” in the back of

the unit. The optical receiver circuitry in an

SFP module is “broadband” and doesn’t

need to receive a specific wavelength of

single-mode optical signal for correct operation. As long as the optical signal has

Issue 5, March 2014 Model 5150 User Guide

Page 10 Studio Technologies, Inc.

Page 11

Video Generator

Model 5150

Module

a wavelength between 1250 and 1650

nanometers and meets the applicable

SMPTE standards it will be recognized

correctly.

A single-mode optical fiber terminated

with an LC plug can be connected to the

receive port on the SFP module. This port

is on the right side when looking directly at

the back of the SFP module. Typically there

will be a graphic arrow icon pointing “in” on

the top of the module. Refer to Figure 2 for

details on the location of the SFP module.

Ensure that the LC plug fully “mates” with

the receive port and its tab is locked into

the slot of the SFP module.

A configuration setting must be appropriately made to enable the optical SDI input.

There is no automatic switching between

the optical and coaxial (BNC) SDI inputs.

Only one of the two SDI inputs can be

selected and active at a time. Refer to

the Configuration section of this guide

for details.

DC Input and Data Bus

A 4-position header is used to connect DC

power and a local RS-485 serial data bus

to the Model 5150. Two pins on the mating

connector are used to connect a source

of nominal 12 volts DC. The acceptable

range is 10 to 18 volts DC with a maximum

current of 400 milliamperes at 12 volts DC.

For remote control operation two pins on

the mating connector will implement the

data bus connection from a Studio Technologies’ Model 5190 Remote Access

Module.

The mating connector is compatible with

the AMP MTA-100 series of IDC receptacles. For 22 AWG wire the closed-end-style

receptacle is AMP 3-643813-4; the feedthrough-style receptacle, used for busing

1. – DC (Common)

2. + DC (10-18 volts)

+ Data (RS-485)

3.

4. – Data (RS-485)

Figure 3. DC Input and Data Bus Connections

connections, is AMP 3-644540-4. The body

color for both receptacles is red, following

the convention of the MTA-100 series for

compatibility with 22 AWG wire. Refer to

Appendix B of this guide for additional

connector details.

GPI and GPO

This section applies only to Model 5150

modules with serial numbers 00251 and

later.

A 3-position header is used to connect with

the Model 5150’s GPI (general-purpose

input) and GPO (general-purpose output)

functions. Pin 1 is used by both the GPI and

GPO, pin 2 is used by the GPI, and pin 3 by

the GPO. The mating connector is compatible with the AMP MTA-100 series of IDC

receptacles. For 22 AWG wire the closedend-style receptacle is AMP 3-643813-3;

the feed-through-style receptacle, used for

busing connections, is AMP 3-644540-3.

The body color for both receptacles is red,

following the convention of the MTA-100

series for compatibility with 22 AWG wire.

Refer to Appendix B of this guide for additional connector details.

Pins 1 and 2 should be connected to the

switch or relay contact designated to control

the GPI. Electrically the GPI (pin 2) is a logic input that is “pulled up” to 3.3 volts DC by

way of a 5 k (5000) ohm resistor. It operates

in a “logic low” manner requiring that the

switch or contact closure carry a little less

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 11

Page 12

Video Generator

Model 5150

Module

1. Common

2. GPI (general-purpose input)

GPO (general-purpose output)

3.

Figure 4. GPI and GPO Connections

than 1 milliamperes (0.66 mA) to activate

it. While the GPI circuitry is protected from

over-current and static (ESD) discharge,

care should be taken to prevent nasty

signals from reaching it. The input is active only when held in the low state; it can’t

be configured to change state (“latch”) in

response to a momentary closure.

Pins 1 and 3 are used by the GPO. Pin 1 is

common to the GPO, GPI, and the Model

5150’s circuitry. Pin 3 is 3.3 volts DC, current limited by a series resistance of 150

ohms. The GPO is intended to directly

power an LED indicator. Typical LEDs

have a drop of about 2 volts when active.

This will result in a GPO output current of

approximately 9 milliamperes. This LED

current will be perfectively satisfactory in

many applications but many contemporary

LEDs can function effectively with less

current. Adding additional series resistance can reduce the output current. For

example, adding 100 ohms in series with

the GPO will reduce the current through

a typical LED to about 5 milliamperes.

Note that shorting pin 3 to pin 1 when the

GPO is active will result in a current flow

of approximately 22 milliamperes. While

this situation is not recommended it won’t

lead to any damage to the Model 5150’s

circuitry.

Mounting

The Model 5150 is intended for mounting in an installation-specific enclosure or

rack panel. Refer to Appendix C at the end

of this guide for details on the required

mounting opening and screw locations.

Please contact the factory to discuss

mounting options.

Configuration

The manner in which a specific Model

5150 operates depends on how it has

been configured. One configuration parameter, RS-485 Address, is set in hardware

using four DIP switches. The other Model

5150 operating parameters can be set

either by way of menu pages associated

with a Model 5190 Remote Access Module

or by way of a simple text file that is stored

on a USB flash drive. (The file will auto

matically load when the USB flash drive is

inserted into the Model 5150.) To assist in

the configuration process an information

file, STATUS.TXT, is automatically created

by the model 5150 and stored on the same

USB flash drive.

Note that there are a number of unused

DIP switches. One is located on the MCU

board and five are located on the FPGA

board. These switches are reserved for

future use.

-

Figure 5. Rear view showing MCU and FPGA

board configuration DIP switches

Issue 5, March 2014 Model 5150 User Guide

Page 12 Studio Technologies, Inc.

Page 13

Video Generator

Model 5150

Module

RS-485 Address

A data bus address must be configured

for applications that implement remote

control of Model 5150 functions. While up

to 16 Model 5100-Series modules can

“share” the RS-485 data bus, each module

must have a unique address. Selecting the

device’s address involves setting four configuration switches on the MCU board. The

switches are a “piano key” type with their

up position being defined as off and their

down position defined as on.

An initial overview of the configuration choices is provided in the following paragraphs.

Following these paragraphs are details on

how to determine a module’s current configuration and how to revise parameters as

required.

SDI Input Select

The Model 5150 is capable of having its SDI

input in the form of a coaxial signal (BNC

connector) or an optical signal (SFP module). All versions of the Model 5150 support

the coaxial (BNC) input. The optical input is

an option and may or may not be present

on the specific module you are configuring.

Configuring this function can be performed

using the Model 5190 Remote Access Module or by way of a text file stored on a USB

flash drive.

SDI Output Image Format/Rate Mode

Figure 6. RS-485 Address Settings

Configuring Everything Else

Many other Model 5150 operating parameters can be configured using the Model

5190 Remote Access Module or by way of

a text file. Details on how to use the Model

5190’s menu pages are covered in other

documentation. Understanding how to create and use a configuration text file will be

covered in this guide.

One setting is used to configure how the

format and rate of the internal SDI genera

tor is selected. (The internal SDI generator

creates the short-duration solid-gray video

image and plays back the stored “720” and

“1080” images.) In the Auto mode the format

and rate will automatically “follow” that of a

connected SDI input. This allows the Model

5150 to automatically “learn” the specific

format and rate used by a broadcast facility

or live event. In the Locked mode the format

and rate of the internal SDI generator will be

“locked” so that it will not change. Configuring this mode can be performed using the

Model 5190 Remote Access Module or by

way of a text file stored on a USB flash drive.

Delay Before Stored Image

The Model 5150 can output a solid-gray

video image prior to the stored image being

generated. This is provided as an innocuous

indication to downstream equipment that a

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 13

Page 14

Video Generator

Model 5150

Module

loss of SDI has occurred. The solid-gray

image can be selected to be present for a

fixed duration of one to seven seconds. It

can also be disabled allowing the stored

image to be output as soon as a loss of

an input SDI signal is detected.

Moving Image Overlay

A “moving” graphic image can be overlaid

onto the stored “720” and “1080” images

when either one is being output by the Model

5150. The image is a red-colored box that

slowly moves around the screen. This simple

icon provides an indication to personnel

located downstream of the Model 5150 that

the SDI signal is active. This can be impor

tant to ensure that a distinction can be made

between an active image and an image that’s

the result of the last valid frame being held

and displayed by a piece of equipment even

though its SDI input is no longer present.

When the function is off the stored images

(“720” and “1080”) will be displayed without

the moving image being added. When the

function is on the moving image will be

added. Configuring this mode can be performed using the Model 5190 Remote

Access Module or by way of a text file

stored on a USB flash drive.

SDI Input as Timing Reference

In most applications it’s desired that a sig

nal connected to the selected SDI input will

automatically be routed to the SDI output(s).

But in special cases the Model 5150 may be

used as a full-time video generator. In this

latter case the ability to connect an external

timing reference would be desirable. This

would allow the SDI output(s) to be “locked”

to a master or “house” timing signal. An

operating mode selection allows an HD- or

3G-SDI signal to serve as a timing reference.

When the SDI Mode is set for Normal

a signal connected to the Model 5150’s

selected SDI input will pass through to the

SDI output(s). When SDI Mode is set for

RefOnly the timing, rate, and format of the

input SDI signal will impact the internallygenerated video image output. The video

information associated with the input signal

will not be routed to the SDI output(s).

Configuring this mode can be performed

using the Model 5190 Remote Access

Module or by way of a text file stored on

a USB flash drive.

GPI – General-Purpose Input

Depending on the hardware version of a

specific Model 5150 module there may be

a GPI function available. The GPI (generalpurpose input) will allow connection of an

external contact closure. The control will

then control a Model 5150 function. As of

the writing of this guide no function is available for control by way of the GPI. Configuring this function can be performed using

the Model 5190 Remote Access Module or

by way of a text file stored on a USB flash

drive.

GPO – General-Purpose Output

Depending on the hardware version of a

specific Model 5150 module there may

be a GPO function available. The GPO

(general-purpose output) provides a signal

corresponding to the status of the selected

SDI input. The GPO can be configured to

be active high when the selected SDI input

is correctly “locked” to the incoming SDI

signals. The GPO can also be configured

to be active low when the SDI input is

“locked.” Configuring this function can be

performed using the Model 5190 Remote

Access Module or by way of a text file

stored on a USB flash drive.

Issue 5, March 2014 Model 5150 User Guide

Page 14 Studio Technologies, Inc.

Page 15

Video Generator

Model 5150

Viewing Module Details

An associated Model 5190 Remote Access Module can be used to directly view

firmware (embedded software), hardware,

and configuration details about a Model

5150 module. In addition, the Model 5150

incorporates a unique standalone method

of providing these details. This is accomplished by the module creating a simple

text file which is stored on a USB flash

drive. This file can then be easily viewed

using a personal computer. Information

provided in the file includes firmware version numbers, hardware serial number,

and configuration settings. The information provided in the text file can provide

assistance when configuring, using, and

troubleshooting Model 5150 modules.

Each time a Model 5150 detects that a

USB flash drive has been connected a

text file will be created and stored. The

file, named STATUS.TXT, will be stored in

a folder named M5150 which is one level

below the root of the USB flash drive. If

the folder is not already present it will be

created. If a STATUS.TXT file is already

present a new one will automatically be

written over it.

The Model 5150 does not have a method

of accessing the current date or time, i.e.,

no real-time clock. This limitation requires

that a fixed file creation date be used and

12/31/1979 was selected. However, the

time stamp continues to advance in real

time until a power cycle occurs.

Module

[SYSTEM INFO]

PRODUCT=M5150

SERNUM=00262

MCUVER=2.2

FPGAVER=2.2

ADDRESS=4

[CONFIGURATION]

SDIINPUT=BNC

FORMAT=AUTO

IMGDELAY=1

MOTION=ON

SDIMODE=NORMAL

GPI=DISABLED

GPO=DISABLED

[OPTIONS]

SDIINPUT=BNC,SFP

FORMAT=AUTO,LOCKED

IMGDELAY=0,1,2,3,4,5,6,7

MOTION=OFF,ON

SDIMODE=NORMAL,REFONLY

GPI=DISABLED

GPO=DISABLED,SDIVALID,SDINOTVALID

Figure 7. Example of STATUS.TXT file

STATUS.TXT File – [SYSTEM INFO]

The [SYSTEM INFO] section of the

STATUS.TXT file provides general information about this specific Model 5150 module.

PRODUCT= identifies the module’s product type. For the Model 5150 it will be listed

as M5150. This information is provided as

a confirmation for situations where multiple

STATUS.TXT files are being examined.

The text contained in the STATUS.TXT file

is organized into three sections. The following paragraphs provide a detailed explanation. Refer to the Figure 7 for a sample file.

SERNUM= identifies the factory-assigned

serial number of this specific module. It will

typically be in the form of a 5-digit base-10

number. If for some reason a serial number

has not been factory assigned no number

will display and the field will be blank (empty).

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 15

Page 16

Video Generator

Model 5150

Module

MCUVER= identifies the version of the

microcontroller (MCU) firmware (embedded

software) that’s loaded into and operating

in this specific module’s MCU board. The

microcontroller is the overall “boss” of the

Model 5150, doing pretty much everything

but the SDI-related tasks.

FPGAVER= identifies the version of the

logic chip (FPGA) firmware (embedded software) that’s loaded into and operating in this

specific module’s FPGA board. The FPGA

creates the video images and processes the

SDI signals.

ADDRESS= identifies the RS-485 data bus

address of this specific module. The range

is 1 through 16. This address is configured

using four DIP switches located on the MCU

board.

STATUS.TXT File – [CONFIGURATION]

The [CONFIGURATION] section of the

STATUS.TXT file provides details on how

the module is actually functioning at the

time the file was created.

MOTION= identifies the status of the Moving Image Overlay function. OFF indicates

that the Moving Image Overlay function is

not active. ON indicates that the Moving

Image Overlay function is active.

SDIMODE= identifies which SDI Mode has

been selected. NORMAL indicates that a

valid SDI signal connected to the selected

SDI input will pass through to the module’s

SDI output(s). REFONLY indicates that

the selected SDI input will serve only as

a timing reference signal. The internallygenerated image will always be sent to

the SDI output(s).

GPI= identifies how the GPI (generalpurpose input) function has been selected.

NA indicates that the hardware version of

this specific Model 5150 module does not

support the GPI function (applies to modules with serial numbers 00250 or less).

DISABLED indicates that the function

is present in hardware but is not active.

Future versions of the MCU firmware may

implement other GPI actions.

SDIINPUT= identifies which physical SDI

input on the module has been selected.

BNC indicates that the Coaxial (BNC)

SDI Input has been selected. SFP indicates

that the optical SDI input has been selected.

FORMAT= identifies which SDI Output

Image Format/Rate Mode has been selected. AUTO indicates that the Auto Select

(Follows Input) mode has been selected.

LOCKED indicates that the Locked (Does

Not Follow Input) setting has been selected.

IMGDELAY= identifies the interval selected

for the delay before the stored image is

output. The range is 0 to 7 seconds. A setting of 0 indicates that there will be no delay.

During the delay period the Model 5150 will

GPO= identifies how the GPO (generalpurpose output) function has been selected. NA indicates that the hardware version

of this specific Model 5150 module does

not support the GPO function (applies to

modules with serial numbers 00250 or

less). DISABLED indicates that the function is present in hardware but is not active. SDIVALID indicates that the GPO will

be high when a valid SDI signal is connected to the selected SDI input (coaxial

(BNC) or optical). SDINOTVALID indicates

that the GPO will be high when a valid SDI

signal is not connected to the selected SDI

input (coaxial (BNC) or optical); the GPO

will be low when a valid SDI signal is connected.

output a video image with a solid-gray color.

Issue 5, March 2014 Model 5150 User Guide

Page 16 Studio Technologies, Inc.

Page 17

Video Generator

Model 5150

Module

STATUS.TXT File – [OPTIONS]

The [OPTIONS] section of the STATUS.

TXT file is provided as a guide when creating a CONFIG.TXT file which will set the

module’s configuration. This information is

provided in the STATUS.TXT file only as a

reference and doesn’t play an active part

in module configuration or operation.

SDIINPUT= selects which physical SDI

input on the module will be active. BNC

selects the coaxial (BNC) SDI input to be

active. SFP selects the optical SDI input

to be active.

FORMAT= selects the SDI Output Image

Format/Rate Mode. AUTO selects the Auto

Select (Follows Input) mode. LOCKED

selects the Locked (Does Not Follow Input)

mode.

IMGDELAY= selects the interval for the

delay before the stored image is output.

The range is 0 to 7 seconds. A setting of 0

selects no delay. During the delay period

the Model 5150 will output a video image

with a solid-gray color.

MOTION= selects the Moving Image

Overlay function. OFF disables the Moving

Image Overlay function. ON enables the

Moving Image Overlay function.

SDIMODE= selects the SDI Mode function. NORMAL selects that a valid SDI

signal connected to the selected SDI input

will pass through to the module’s SDI

output(s). REFONLY

selects that the selected SDI input will serve only as a timing

reference signal. In this latter mode, the

internally-generated image will always be

sent to the SDI output(s).

GPI= selects the GPI (general-purpose

input) function. DISABLED selects that the

function is not active. Future versions of the

MCU firmware may implement other GPI

actions. Note that if the hardware version

of this specific Model 5150 does not support the GPI function (modules with serial

numbers 00250 or less) this text line will not

appear.

GPO= selects the GPO (general-purpose

output) function. DISABLED selects that

the function is not active. SDIVALID selects

that the GPO will be high when a valid SDI

signal is connected to the selected SDI input

(coaxial (BNC) or optical). SDINOTVALID

selects that the GPO will be high when a

valid SDI signal is not connected to the selected SDI input (coaxial (BNC) or optical);

the GPO will be low when a valid SDI sig

nal is connected. Note that if the hardware

version of this specific Model 5150 does not

support the GPO function (modules with se

rial numbers 00250 or less) this text line will

not appear.

Configuration Text File

A text file can be created to specify how a

Model 5150 should be configured. Saved on

a USB flash drive, the file must have a name

of CONFIG.TXT and be stored in a folder di

rectly under the root with a name of M5150.

When the USB flash drive is plugged into

a Model 5150 the file will automatically be

read and the configuration stored. Immediately after the file is read the STATUS.TXT

file will be written to the M5150 folder. The

contents of this file will reflect the configuration that’s present after the contents of

the CONFIG.TXT have been read. This will

provide immediate feedback that the desired

configuration has be implemented.

-

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 17

Page 18

Video Generator

Model 5150

Module

[CONFIGURATION]

SDIINPUT=BNC

FORMAT=AUTO

IMGDELAY=1

MOTION=ON

SDIMODE=NORMAL

GPI=DISABLED

GPO=SDIVALID

Figure 8. Example of CONFIG.TXT file

The following paragraphs detail the configuration choices. This information is also

shown in the [OPTIONS] section of the

STATUS.TXT file, described previously

in this guide.

The text lines that follow the [CONFIGURATION] heading should remain in the

same order as shown in the example. (But

technically they are not required to do so.)

All configuration items are not required to

be present but for clarity it’s recommended

that they are. The text is case sensitive and

must follow the example.

SDIINPUT= selects which physical SDI

input on the module will be active. There

are two choices.

BNC selects the coaxial

(BNC) SDI input to be active. SFP selects

the optical SDI input to be active.

FORMAT= selects the SDI Output Image

Format/Rate Mode. There are two choices.

AUTO selects the Auto Select (Follows

Input) mode. LOCKED selects the Locked

(Does Not Follow Input) mode.

IMGDELAY= selects the interval for the

delay before the stored image is output.

The range is 0 to 7 seconds. A setting of

0 selects no delay. During the delay period

the Model 5150 will output a video image

with a solid-gray color.

MOTION= selects the status of the Moving Image Overlay function. There are two

choices. OFF disables the Moving Image

Overlay function. ON enables the Moving

Image Overlay function.

SDIMODE= selects the status of the SDI

Mode function. There are two choices.

NORMAL selects that a valid SDI signal

connected to the selected SDI input will

pass through to the module’s SDI output(s).

REFONLY selects that the SDI input will

serve only as a timing reference signal. The

internally-generated image will always be

sent to the SDI output(s).

GPI= selects the status of the GPI (generalpurpose input) function. DISABLED selects

that the function is not active. Future versions of the MCU firmware may implement

other GPI actions. Note that if the hardware

version of this specific Model 5150 does not

support the GPI function this text line can be

part of the file but will not be recognized.

GPO= selects the status of the GPO

(general-purpose output) function.

DISABLED selects the function to be not

active. SDIVALID selects the GPO to be

high when a valid SDI signal is connected

to the selected SDI input (coaxial (BNC) or

optical). SDINOTVALID selects the GPO to

be high when a valid SDI signal is not connected to the selected SDI input (coaxial

(BNC) or optical); the GPO will be low when

a valid SDI signal is connected. Note that if

the hardware version of this specific Model

5150 does not support the GPO function

this text line can be part of the file but will

not be recognized.

Issue 5, March 2014 Model 5150 User Guide

Page 18 Studio Technologies, Inc.

Page 19

Video Generator

Model 5150

Operation

Power Up

Upon 12 volt DC power being applied to

the Model 5150 the four front-panel LEDs

will perform a “walk-through” test, with

each LED lighting briefly in sequence.

Then the LEDs will light in patterns that

represent the version numbers of the

firmware (embedded software) files that

are loaded into the module. Upon completion, the Power LED will light continuously.

For normal operation to commence, prior

to powering up the module ensure that

a USB flash drive is not plugged into the

USB port on the front panel.

Module

The SDI Input LED lights whenever a valid

SDI signal is connected to the coaxial

(BNC) or optical SDI input. (A configuration

choice selects whether the coaxial (BNC)

SDI input or optical SDI input is active.)

The Data LED will light whenever data activity is taking place over the local RS-485

signal bus that is used to link the Model

5150 to a Studio Technologies’ Model 5190

Remote Access Module. The LED will flash

on and off each time data associated with

this specific Model 5150 is present. Not all

applications will include a connection to

the data bus so it’s certainly possible that

the Data LED may never flash except during module power up.

LED Indicators

A brief discussion of the Model 5150’s status LEDs will be covered in this section.

Front-Panel LEDs

As previously discussed, upon power up

the four front-panel LEDs will light in a

short sequence as an initialization test.

Afterwards they are used to display the

version number of the installed MCU and

FPGA firmware. Refer to the Technical

Notes section of this guide for details.

Following the power-up sequence, the

Power LED will light and remain lit.

The USB Activity LED will not light during

normal Model 5150 operation. It will be lit

continuously or in a pattern when a USB

flash drive is plugged into the USB port

on the front panel and file transfer activity is taking place. Details on how the LED

functions when the USB port is active are

covered in the Technical Notes section of

this guide.

FPGA Board LEDs

Three LEDs are located on the back edge

of the FPGA printed circuit board and

serve as factory- and field-diagnostic aids.

Upon Model 5150 power up each LED will

light for several brief durations with no spe

cific meaning associated with them. Then

the FPGA Status LED, located adjacent

to the DIP switches, will light and remain

lit. This indicates that the FPGA and MCU

boards are correctly communicating.

The LED located adjacent to the coaxial

SDI input’s BNC connector will light whenever that input has been configured to be

active and a valid SDI signal is connected.

It will not light if a valid SDI signal is connected but the SDI input configuration is

not set to activate the coaxial (BNC) input.

The LED located adjacent to the “cage”

that holds the SFP module will light if the

optical SDI input has been selected and a

valid SDI optical signal is connected. It will

not light if a valid optical signal is connected but the SDI input configuration is not

set to activate the optical input.

-

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 19

Page 20

Video Generator

Model 5150

Module

A fourth LED is located near the front of

the FPGA board. Called the FPGA Done

LED, it lights whenever the logic device

(FPGA) has loaded its firmware and is

operating normally. This LED is provided

only for factory troubleshooting use.

Initial SDI Output

After the power-up sequence has been

completed the module’s SDI output will

become active. (This will be both the coaxial (BNC) output and, if present, the optical

SDI output.) If a valid signal is connected

to the selected SDI input it will be routed to

the SDI output. If a signal is not connected

to the selected SDI input the internal SDI

generator will supply a signal to the SDI

output. In the latter case, what occurs after

the Model 5150’s power-up sequence has

taken place (taking about seven seconds)

depends on the module’s configuration.

A solid-gray image may be output for up

to seven seconds followed by the stored

“720” or “1080” image. Or, if the solid-gray

image has been disabled the stored image

will immediately be present.

SDI Input and SDI Output

Depending on the exact Model 5150 version that has been installed and how it was

configured an SDI signal can be connected

to the coaxial (BNC) input or the optical

input. When a signal that’s compatible with

the Model 5150 has been connected the

front-panel SDI Input LED will light. This

indicates that the signal is being routed

to the SDI output and the internal SDI

generator is not active. SDI signals that

comply with most HD (1.485 Gb/s nominal)

and 3G (2.97 Gb/s nominal) standards

are compatible. Refer to the Specifications

section of this guide for a list of the

supported standards.

The Model 5150 always provides an active SDI signal on the coaxial (BNC) output.

Some Model 5150 versions also provide an

optical output. This is accomplished at the

factory by installing one of a variety of available SFP optical modules in the back-panel

SFP “cage.” If an optical output is present it

will always be active and provide an identical copy to the signal present on the coaxial

(BNC) output.

If a valid SDI signal is not connected to the

selected SDI input the stored image will be

present on the coaxial (BNC) output and, if

present, optical output. Depending on the

stored format and rate values, the output

will be either a 1280 x 720 pixel (“720”) or

1920 x 1080 pixel (“1080”) fixed image.

Stored Images

When a valid signal is not connected to the

selected SDI input, the module generates

one of two fixed images. The two images,

one “720” and one “1080,” are stored

in nonvolatile memory within the Model

5150. From the factory two images are preloaded. The two are quite different from one

another with each having a unique photo

background and overlaid text. The overlaid

text provides support details on how alternate custom images can be created.

It’s expected that these pre-loaded images

will be replaced with application-specific

images. They can be easily created and

what they consist of is limited only by one’s

imagination. Refer to the Technical Notes

section of this guide for details.

Transitions between External

and Internal SDI Signals

This paragraph applies when the Model

5150 has been configured for normal SDI

Issue 5, March 2014 Model 5150 User Guide

Page 20 Studio Technologies, Inc.

Page 21

Video Generator

Model 5150

Module

input mode. Whenever a valid SDI signal is

connected to the selected Model 5150 input

it will immediately be routed to the coaxial

(BNC) and, if present, optical SDI outputs.

The situation is a little different when a valid

signal that’s been connected to the selected

SDI input is subsequently removed. When

the Model 5150 detects that an SDI input

signal is no longer present the SDI output

may switch to an image with a solid-gray

color. Depending on the module’s configuration this color may remain active for up

to seven seconds. This solid-gray image

provides a benign warning to users that the

normal SDI source is no longer present.

During this time period it’s expected that

any on-air use of the Model 5150’s output

can be terminated without alerting viewers

that anything is amiss. This solid-gray image can also be helpful as a marker when

editing recorded video. After the configured

interval has elapsed the internal generator

will output either the “720” or “1080” stored

image.

It’s also possible that the Model 5150 has

been configured to not output the solid-gray

video signal. In this case, when the module

detects that an SDI signal is no longer

present on the SDI input, the SDI output

will directly switch to the stored image.

It’s important to note that the Model 5150

does not perform a smooth transition when

switching between an external SDI source

and the internally-generated video signals.

The same holds true when the internal

color or image generator is active and then

a valid source is connected to the selected

SDI input. The SDI output does not stay

“locked” during the transition as the circuitry

in the Model 5150 was not designed to

that level of sophistication. This shouldn’t

cause an operational issue as the Model

5150 was not designed to be “on air”

during those transitions; the changeover

process is not seamless by design. One

can assume that up to two seconds of

interruption will occur during transitions but

typically it will be considerably shorter.

Full-Time Video Generation

A configuration selection allows the Model

5150 to act as a full-time video generator.

In this case the selected SDI input will only

be used as an external timing reference.

The front-panel SDI Input LED will light

whenever a valid signal is connected to

the selected SDI input. But the SDI input

source will only serve as a timing reference. Its video and related data (e.g., embedded audio) will not pass through to the

SDI output(s). The stored video image will

always be present on the SDI output(s).

Output Format and Rate

When a valid signal is connected to the

selected SDI input it will be routed to the

SDI output at the identical format and rate

of the source. When the SDI input is no

longer present the internally-generated

signal will become active and be routed to

the SDI output. The format and rate of the

internally-generated SDI signal will depend

on parameters that are stored within the

Model 5150. Whether these parameters

can change depends on the configuration

of the module’s SDI output image format/

rate mode. Typically, the mode will be set

for Auto Select which allows the Model

5150 to revise its parameters by following

the format and rate of the connected SDI

signal. This ensures that the Model 5150

can generate an SDI signal that matches

the requirements of a facility or event.

For the module to “learn” a new format

and rate simply requires the momentary

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 21

Page 22

Video Generator

Model 5150

Module

connection of an SDI signal that has the

desired format and rate. As long as the signal is present on the selected SDI input for

a minimum of five seconds the Model 5150

will store the “new” format and rate param

eters in nonvolatile memory. The module will

then use those parameters whenever the

internal generator is active. The only caveat

for the module to “learn” a new format/rate

combination is that it must be a compatible

combination. Refer to the Specifications

section of this guide for a complete list.

There are some applications that will benefit

from the internally-generated SDI output sig

nal always having a specific format and rate.

In this case the SDI output image format/

rate mode can be set for Locked. No mat

ter what the format and rate of a connected

SDI signal, the stored parameters will not

change. Changing the stored parameters

would require the format/rate mode to be

changed to Auto Select, an SDI signal with

the desired format and rate be connected

for a minimum of five seconds, and then the

format/rate mode changed back to Locked.

viewing is active. And, just to clarify, if

a signal is present on the Model 5150’s

selected SDI input it will be passed on to

the coaxial (BNC) and, if present, optical

SDI outputs. The moving image will never

overlay an input signal—it can only overlay

on top of the stored image.

GPI and GPO

Model 5150 modules with serial numbers

of 00251 and later include a GPI (generalpurpose input) and a GPO (generalpurpose output) function. Depending on

the application, connections may have

been made to the GPI and/or the GPO.

GPI

As of the date of this User Guide the

Model 5150’s firmware (embedded software) does not support the performance of

any action in response to the GPI function

changing state. Future firmware versions

may implement an action. (For now it’s just

something ready for the future.)

GPO

Moving Image Overlay

The Model 5150 has the ability to overlay a

moving image on top of the stored “720” and

“1080” images. A configuration setting selects whether the moving image overlay will

be active. The moving image, a box that’s

red in color, slowly moves around and on

top of whatever stored image is present on

the SDI output. The color, size, and rate of

motion of the “box” are fixed in the FPGA’s

firmware (embedded software) and can’t be

The GPO may be connected to an LED

indicator. A configuration choice allows the

GPO to be active “high” or active “low” in

response to a SDI signal connected to the

selected SDI input. If configured for active

high an associated LED would light whenever a valid SDI source is connected to the

selected SDI input. If configured for active

low the LED would light whenever a valid

SDI is not connected to the selected SDI

input.

altered.

The moving image is provided specifically

so that users who are “downstream” from

the Model 5150’s SDI output are assured

that the “720” or “1080” image they are

Issue 5, March 2014 Model 5150 User Guide

Page 22 Studio Technologies, Inc.

Page 23

Video Generator

Model 5150

Technical Notes

Bitmap Image File

Requirements

The Model 5150 allows two bitmap (.bmp)

images to be stored and output when an

SDI input signal is not present. One image

has a pixel size of 1280 x 720 while the

other has a pixel size of 1920 x 1080. To

be stored with the Model 5150 the files

must be FAT32-compatible and have

names of img720.bmp and img1080.bmp,

respectively.

The reason two files are required is simple:

the Model 5150 does not have the ability to

digitally “scale” a 1920 x 1080 image down

to 1280 x 720. But it does have the ability

to store two unique files. Most users will

create a single image using a personalcomputer graphics program and then save

it in the two required formats. So when the

Model 5150 generates either of the two im

ages (“720” or “1080”), a user will see what

appears to be an identical image. But there

is no reason why the two images (“720” and

“1080”) have to be based on the same original graphics. Studio Technologies chose to

create two different “720” and “1080” bitmap

files that are pre-loaded in the Model 5150

at the time of manufacture. They feature two

unique background images with text highlighting the main requirements for updating

them.

-

Module

Microsoft Paint and Adobe Photoshop applications will create .bmp files that meet this

requirement. But some other programs may

produce non-compatible files. For example,

the open-source GIMP graphics program

is very good but appears to save .bmp files

only as a BITMAPV4HEADER type. These

are not compatible with the Model 5150.

The possibility that various .bmp files will

have different header types doesn’t seem to

be an issue for displaying them successfully

with most personal-computer programs.

This is most likely due to the PC’s large

code space allowing essentially all the possible header types to be supported. But the

Model 5150, due to its target application,

has limitations in the file support area. (For

additional background information, please

refer to the Wikipedia online entry that discusses the structure of .bmp files.)

A compatible 1280 x 720 (“720”) .bmp

file created using Microsoft Paint or Adobe

Photoshop will have a size of approximately

2.63 MB; a 1920 x 1080 (“1080”) .bmp file

will have a size of approximately 5.63 MB.

The actual size of the files when created in

Microsoft Paint should be 2,764,854 bytes

and 6,220,854 bytes, respectively. When

created in Adobe Photoshop, the file sizes

should be 2,764,856 bytes and 6,220,856

bytes, respectively. (Why are they each

two bytes in size different? Who knows!

But both use the appropriate BITMAPINFOHEADER DIB type.)

While the two bitmap files (img720.bmp

and img1080.bmp) are “standard” in the

sense that they are FAT32-compatible and

have the extension .bmp, they must adhere

to one important requirement that not all

personal-computer graphics programs support. Their DIB (bitmap information header)

must be a BITMAPINFOHEADER type. The

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 23

Bitmap Image Update

Procedure

It’s expected that the Model 5150’s bitmap

(.bmp) files associated with the custom

“720” and “1080” images will always be

updated to best serve specific applications.

This will typically take place soon after a

Page 24

Video Generator

Model 5150

Module

Model 5150 has been installed. (While the

pre-loaded images are nice, they aren’t

really appropriate for actual active applications.) There’s no problem changing the files

whenever the application warrants alternate

images. The module has the ability to automatically load revised files by way of its

USB interface. The Model 5150 implements

a USB host function that directly supports

connection of a USB flash drive.

Updating the Model 5150’s “720” and “1080”

images is quite simple but requires some

care. The process begins by preparing a

USB flash drive. The flash drive doesn’t

have to be empty (blank) but must be in the

personal-computer-standard FAT32 format.

Save the new image (.bmp) files in the root

directory. Their names must be img720.

bmp and img1080.bmp. Typically both

.bmp files will be updated at the same time.

But there’s no requirement to do so. Individual files can be updated whenever desired.

Simply copy the desired file or files to the

root directly on the USB flash drive. Be certain that there are no Model 5150 firmware

files (m5150.s19 and m5150.bit) present

on the USB flash drive during this process.

As previously reviewed in this guide, the

1280 x 720 image must have a file name of

img720.bmp; the 1920 x 1080 image must

have a file name of img1080.bmp. Also

ensure that both have the DIB header type

BITMAPINFOHEADER so that they can be

recognized correctly by the Model 5150.

To install the new image files:

1. Power down the Model 5150 module.

2. Insert the prepared USB flash drive into

the module’s USB port.

3. Apply power to the module.

4. The module will go through its powerup LED sequence and normal operation will begin. At about the same time

that normal operation starts the new

.bmp files will begin to load, one after

the other. The USB Activity LED on the

module’s front panel will flash while the

loading process is taking place. Loading

both .bmp files will take approximately

6.5 minutes. (Loading only the

img720.

bmp file takes approximately 2 minutes;

loading only the img1080.bmp file takes

approximately 4.5 minutes.) Once the

loading process has been completed the

USB Activity LED will change from flashing to being lit continuously.

Note: If the module is currently output-

ting one of the stored images and a new

image of the same type (“720” or “1080”)

has just completed loading, the output

will automatically change to the new image. (It’s possible that a few seconds of

a solid color could be output during the

transition from the old image to the new

image.)

5. Power down the module.

6. Remove the USB flash drive from the

module’s USB port.

7. Power up the Model 5150 module. It will

go through its normal power-up LED

sequence and begin operation. It will use

the updated images whenever the internal SDI generator is active.

It’s possible that during the update process

any LEDs located on the USB flash drive

may light steadily or flash with varying patterns. These actions are not significant

to the Model 5150’s update procedure.

(The status LEDs on various USB flash

drives seem to behave in different ways

so there are no universal patterns that

can be identified.)

Issue 5, March 2014 Model 5150 User Guide

Page 24 Studio Technologies, Inc.

Page 25

Video Generator

Model 5150

Module

Firmware Update Procedure

It’s possible that updated versions of the

firmware (embedded software) that runs

the Model 5150 will be released to add features or correct issues. The module has the

ability to automatically load revised files by

way of its USB interface. The Model 5150

implements a USB host function that directly supports connection of a USB flash drive.

The Model 5150 uses two firmware files to

perform its functions. One file is used by the

microcontroller integrated circuit (MCU) and

has a file name of m5150.s19. The microcontroller is the overall “boss” of the Model

5150, doing pretty much everything but the

SDI-related tasks. The other firmware file

is used by the logic chip (FPGA) and has a

name of m5150.bit. This firmware, running

in the FPGA, creates the video images and

processes the SDI signals. The factory will

provide updates of these firmware files if

it’s warranted for your specific Model 5150

module.

To update the Model 5150’s firmware is

quite simple but requires careful execution.

The process begins by preparing a USB

flash drive. The flash drive doesn’t have to

be empty (blank) but must be in the personal-computer-standard FAT32 format.

Save the new firmware files in the root

directory. Their names must be m5150.s19

and m5150.bit. Be certain that any custom

image files (img720.bmp and img1080.

bmp) are not present on the USB flash

drive during this process.

the name of the zip file itself will include

the version number. For example, a file

named m5150v1r2MCU.zip would indicate that version 1.2 of the MCU firmware

(m5150.s19) is contained within this zip

file; a file named m5150v1r1FPGA.zip

would indicate that version 1.1 of the

FPGA (m5150.bit) is contained within

this zip file. The version numbers of the

files that are copied to the USB flash drive

should be noted for later reference. Once

the new files are loaded into a Model 5150

the module’s front-panel LEDs should be

used to confirm that the correct firmware

versions have been successfully installed.

Note: The firmware update procedure

itself will not erase or overwrite bitmap

image files that are already saved in the

Model 5150. However, this requires that

the custom image files (img720.bmp and

img1080.bmp) are not present on the

USB flash drive.

To install the firmware files:

1. Power down the Model 5150 module

you intend to upgrade.

2. Ensure nothing is inserted into the

USB port on the module. Power up

the module and “read” the version

numbers of the currently-installed

MCU (m5150.s19) and FPGA

(m5150.bit) files. Write these numbers

down for reference. The next section

of this guide details how to “read” the

installed firmware version levels.

Studio Technologies will supply the MCU

and FPGA files inside individual .zip

archive files. While the firmware file inside

of each zip file will adhere to the naming

3. Power down the Model 5150 module.

4. Insert the prepared USB flash drive into

the module’s USB port.

5. Apply power to the Model 5150 module.

convention required by the Model 5150,

Model 5150 User Guide Issue 5, March 2014

Studio Technologies, Inc. Page 25

Page 26

Video Generator

Model 5150

Module

6. The module will run a “boot loader”

program that will immediately load the

new MCU (m5150.s19) file. This takes

approximately eight seconds. Once the

file is loaded the module will perform

a normal power-up sequence with the

microcontroller using its newly-loaded

MCU firmware.

7. After the power-up sequence has been

completed the module will begin operation. It will process video as well as

checking for an FPGA (m5150.bit) file

on the USB flash drive. If it doesn’t find

this file normal operation will continue.

If it locates this file it will begin to load it

from the USB flash drive. In that case,

some Model 5150 functions will halt,

including reading changes to the configuration switches. As an indication that

the file transfer is under way, the USB

Activity LED will flash on and off.

8. The process of loading the FPGA

(m5150.bit) file will take approximately

90 seconds to complete. When the file

loading process is complete you will

see the module’s front-panel USB Activity LED change from flashing to being

continuously lit. At that time the Model

5150’s logic chip (FPGA) will reboot and

run under the newly-loaded firmware.

9. Power down the module.

10. Remove the USB flash drive from the

module’s USB port.

11. Power up the Model 5150 module and

it will begin operation using the updated

MCU and FPGA firmware. The version numbers of the installed MCU and

FPGA firmware should be “read” by way

of the front-panel LEDs. Compare and

confirm that these numbers match those

from the zip file names that were provided by the factory.

Note: It’s possible that during the update

process any LEDs located on the USB flash

drive may light steadily or flash with varying

patterns. These actions are not significant to

the Model 5150’s firmware update process.

(The status LEDs on various USB flash

drives seem to behave in different ways so

there are no universal patterns that can be

identified.)

Identifying the Installed

Firmware Versions

As previously discussed in the Configuration section of this guide, a file is automatically written to a USB flash drive whenever

it is plugged into the Model 5150. This file,

named STATUS.TXT, provides details of the

Model 5150’s firmware (embedded software), hardware, and configuration parameters. These parameters include the version

numbers of the MCU and FPGA firmware

that are stored in the module. This information is also available when using a Model

5190 Remote Access Module with the Model

5150. A third method is also available to determine the two firmware version numbers.

The Model 5150’s four status LEDs are used

during the power-up sequence to display

the numbers in a cryptic but effective manner. While the display method is a bit unique,

once a user gets accustomed to what’s

actually happening during power up it should

be fairly straightforward to “read” the version

numbers.

To identify the installed firmware versions:

1. Power up the Model 5150. The four LEDs

will perform a “walk-through” test, with

each LED briefly lighting in a sequence.

Issue 5, March 2014 Model 5150 User Guide

Page 26 Studio Technologies, Inc.

Page 27

Video Generator

Model 5150

Module

The USB Activity LED lights to represent the number 1

The SDI Input LED lights to represent the number 2

The Power LED lights to represent the number 3

The Data LED lights to represent the number 4

Figure 9. Detail of front panel showing how

the LEDs display the MCU and FPGA firmware

version numbers.

2. After a slight pause one of the four LEDs

will light briefly. This will indicate the

major number of the MCU’s firmware

version. The LED will stop lighting then

another one of the four LED will light

briefly to indicate the minor number of