Page 1

APPROVALS DATE TITLE

DRAWN BY:

A. Infanger

ORIGINATOR

02/28/07

Stryker Endoscopy

5900 Optical Court, San Jose, CA 95138

X8000 Light Source

Service Guide

A. Infanger

SIZE REV. DOCUMENT NO. SHEET OF

02/28/07

A A 1000-400-933 1 71

REVISIONS REVISIONS

LTR ECN NO. DATE APPROVED LTR ECN NO. DATE APPROVED

A ECO 104650 02/28/07 A. Infanger

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

Printing Instructions:

1. 8.5 × 11” portrait

2. Front and back

3. Color printing

4. Select binding and paper weight based on cost

Global Source:

Archive this document as a service/repair guide.

Page 2

X8000 Light Source

220-200-000

Service Guide

2007/02 www.stryker.com 1000400933 A

Page 3

Page 4

Contents

Warnings and Cautions ..................................................................................................................4

Introduction ..........................................................................................................................................5

Service Options ....................................................................................................................................5

Required Skills, Tools, and Components .............................................................................................5

Reference Documents .........................................................................................................................5

Device Description ...........................................................................................................................6

Technical Specications .......................................................................................................................6

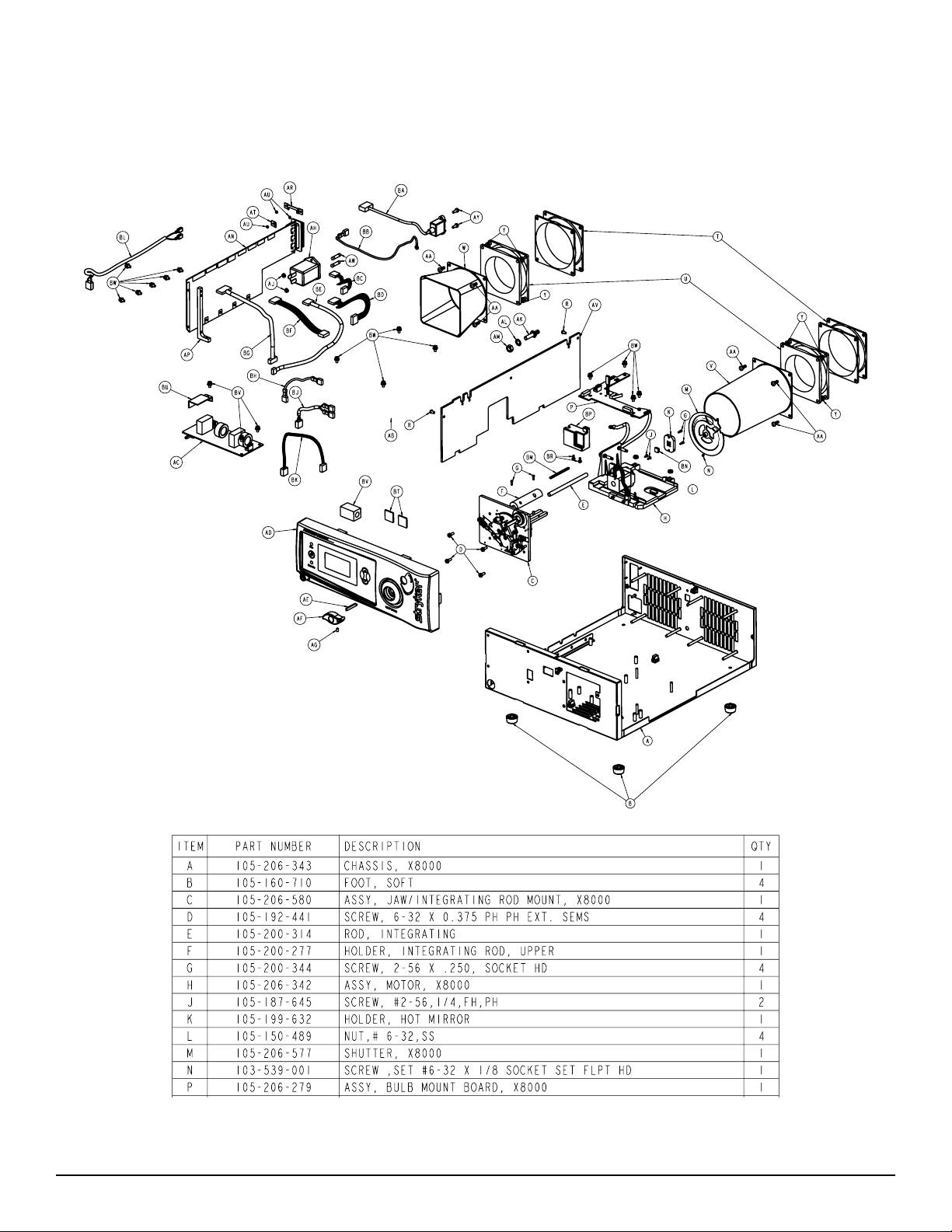

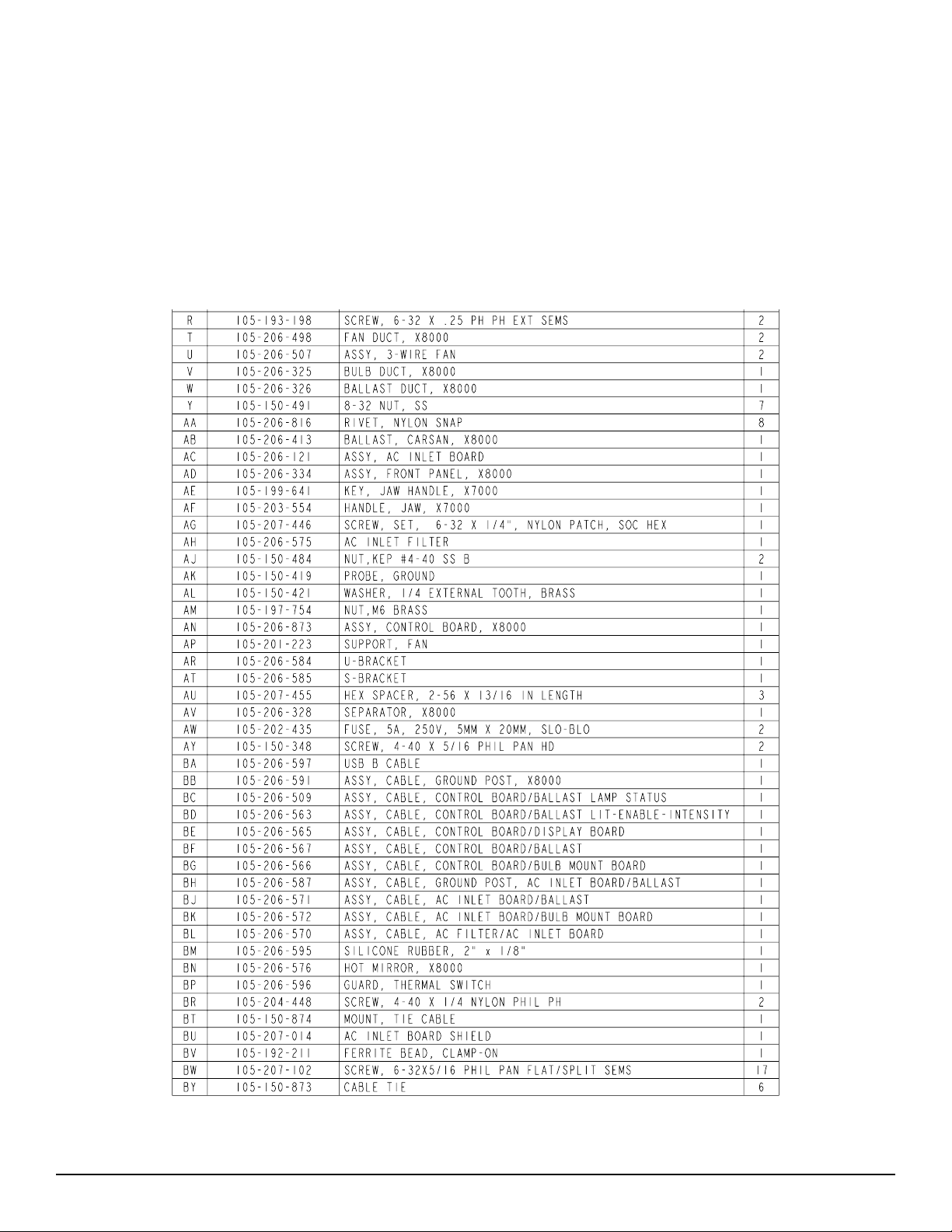

Device Diagrams ..................................................................................................................................7

Basic Maintenance .........................................................................................................................10

Cleaning the X8000 ............................................................................................................................10

Caring for the Bulb Module ................................................................................................................10

Replacing the Bulb Module ................................................................................................................10

Replacing the Fuses ...........................................................................................................................11

Disposing of the X8000 ......................................................................................................................11

Troubleshooting ................................................................................................................................12

Error Code Denitions ........................................................................................................................13

Diagnosis ..............................................................................................................................................14

Control Board Diagrams ....................................................................................................................18

Repair/Replacement ......................................................................................................................19

1.0 Chassis Cover ..............................................................................................................................20

2.0 Control Board ...............................................................................................................................21

3.0 Ballast ..........................................................................................................................................25

4.0 Bulb Mount Board .......................................................................................................................32

5.0 AC Inlet Board .............................................................................................................................35

6.0 Jaw Handle ..................................................................................................................................38

7.0 LED power switch .......................................................................................................................39

8.0 Display Board ..............................................................................................................................43

9.0 Front Panel Membrane .................................................................................................................45

10.0 Shutter ........................................................................................................................................47

11.0 Hot Mirror ...................................................................................................................................49

12.0 Motor ..........................................................................................................................................51

13.0 Jaw Assembly ............................................................................................................................53

14.0 Integrating Rod .........................................................................................................................55

15.0 AC Inlet Filter ..............................................................................................................................57

16.0 Ballast Fan .................................................................................................................................60

17.0 Bulb Fan .....................................................................................................................................62

Final Testing and Inspection .....................................................................................................65

Tools Needed .....................................................................................................................................65

Hi-Pot/Di-Electric Breakdown Test ....................................................................................................67

Warranty ................................................................................................................................................67

3

Page 5

Warnings and Cautions

Please read this manual and follow its instructions carefully.

e words warning, caution, and note carry special

meanings and should be carefully reviewed:

Warning Warnings indicate risks to the safety

of the patient or user. Failure to follow

warnings may result in injury to the

patient or user.

4. Ensure that readjustments, modications, and/

or repairs are carried out exclusively by Stryker

Endoscopy or other authorized personnel.

5. Ensure that the electrical installation of the relevant

operating room complies with the applicable IEC,

CEC, and NEC requirements.

Federal law (United States of America) restricts this device

to use by, or on order of, a physician.

Caution Cautions indicate risks to the

equipment. Failure to follow cautions

may result in product damage.

Note Notes provide special information to

clarify instructions or present additional

useful information.

An exclamation mark within a triangle

is intended to alert the user of special

warnings or important operating and

maintenance instructions in the manual.

A lightning bolt within a triangle is

intended to warn of the presence of

hazardous voltage. Refer all service to

authorized personnel.

e incorrect use of any of the required tools and/or

techniques may risk damage to the equipment or injury to

the person carrying out the procedure, subsequent operators,

or patient. Perform the repair ONLY if you have been

specically trained in the use of all pertinent equipment

and techniques. Stryker Endoscopy cannot continue to

guarantee compliance to UL, CSA, TUV, or other labeled

safety standards if service is performed by anyone other than

Stryker Endoscopy personnel.

To help avoid potential serious injury to the user and the

patient and/or damage to this device:

1. Read this manual thoroughly, especially the

warnings, and be familiar with its contents prior to

using this equipment.

2. Never sterilize any part of the X8000 console.

3. Disconnect the X8000 from the electrical outlet

when inspecting the fuses.

IMPORTANT SAFETY NOTICE

Before operating or performing any maintenance or

repairs on the X8000 Light Source, read the user guide

and service guide thoroughly and carefully. When using

any light source, such as the X8000, re and/or severe

injury may result to the patient, user or inanimate

objects, if the instructions in this manual are not

followed.

All light sources, including the X8000, can generate

signicant amounts of heat at the scope tip, the scope

light post, the light cable tip, and/or near the light cable

adapter. Higher levels of brightness from the light source

result in higher levels of heat.

To avoid the risk of burns and/or re:

• Always adjust the brightness level of the camera

and the monitor before adjusting the brightness

level of the light source.

• Adjust the brightness level of the light source to

the minimum brightness necessary to adequately

illuminate the surgical site.

• Adjust the internal shutter of the camera higher

in order to run the light source at a lower

intensity.

• Avoid touching the scope tip or the light cable

tip to the patient, and never place them on top

of the patient, as doing so may result in burns to

the patient or user.

• Never place the scope tip, the scope light post,

the light cable adapter, or the light cable tip on

the surgical drapes or other ammable material,

as doing so may result in re.

• Always place the light source in Standby mode

whenever the scope is removed from the light

cable or the device is unattended. e scope

tip, scope light post, light cable adapter, and

light cable tip will take several minutes to cool

o aer being placed in Standby mode, and

therefore may still result in re or burns to the

patient, user, or inanimate objects.

4

Page 6

Introduction

Required Skills, Tools, and Components

is manual is intended to be used as a service guide for

Stryker repair technicians in the installation, maintenance,

and repair of the Stryker X8000 Light Source. It is meant

to be used in conjunction with the X8000 Light Source

User Manual (1000-400-885) and does not replace existing

documentation.

Service Options

Factory Service

Due to the complexity of the X8000 Light Source, Stryker

recommends that any malfunctioning system be returned

to Stryker Endoscopy for repair or replacement, where

specialized equipment and technicians are available to

perform repairs while maintaining full product quality and

safety. If service is needed either during or aer the warranty

period:

1. Contact Stryker Endoscopy at 1-800-624-4422,

or contact your local Stryker Endoscopy sales

representative.

2. Package all the components carefully in the original

shipping container, if possible.

3.

Ship the X8000 Light Source, prepaid and insured, to:

Stryker Endoscopy Customer Service

Attention: Repair Department

5900 Optical Court

San Jose, California 95138

You may request a loaner unit during the repair period.

On-Site Service

Stryker Endoscopy accepts responsibility for the eects on

safety, reliability, and performance of the equipment only if

readjustments, modications, and repairs have been carried

out exclusively by a person specically authorized by Stryker

Endoscopy to do so.

On-site repair should be carried out only by qualied

technicians with the proper test equipment listed in this

manual, so that the safety of operators and patients is not

compromised.

In no event shall Stryker Endoscopy be liable for incidental

or consequential damages in connection with or arising from

the performance or use of its products aer unauthorized

modication or repair.

e repair procedures described in this manual require a

basic set of skills, tools, and replacement components.

Skills

Stryker recommends diagnostic and repair procedures be

performed by authorized, qualied technicians with training

or experience in the following:

• Basic electronics

techniques

• Multimeter operation

• Oscilloscope operation

• Vectorscope operation

• BioTek Safety Analyzer

operation

To o l s

Most of the procedures described in this manual can be

performed using a basic tool kit that includes the items listed

below.

Basic tools Advanced tools

• Phillips screwdriver

• Flathead screwdriver

• 8˝ adjustable wrench

• Needlenose pliers

• Color video monitor

• Glass fuse puller

• Multimeter

• Oscilloscope

(20 Mhz or higher)

• NTSC/Pal Vectorscope

• BioTek Model 601

PRO Safety Analyzer

or equivalent current

leakage tester

Components

Replacement parts are identied in the “Device Diagrams”

section of this manual. Certain components are for in-house

use only and will not be available to any non-Stryker entity.

Before any parts are purchased, an Indemnication Letter

must be signed and submitted to Stryker Endoscopy,

available from Customer Service at 1-800-624-4422.

Stryker reserves the right to incorporate improvements

to the X8000 without notice and will inform customers of

any signicant upgrades. All updated parts will be fully

interchangeable with older versions and will oer at least the

same level of quality and performance.

For up-to-date information on upgrades to the product or to

this manual, contact your Stryker representative.

Reference Documents

None of the in-house Manufacturing Assembly Procedures

(MAPs), Quality Inspection Procedures (QIPs), specialty

tools, jigs, or xtures listed in this manual are available for

purchase.

5

Page 7

Device Description

Technical Specifications

e Stryker X8000 Light Source is a light-generating unit

designed to illuminate surgical sites during endoscopic

applications. e X8000 uses a 300-watt xenon bulb to

generate light, which it delivers to the surgical site via a

beroptic light cable.

e X8000 is compatible with all Stryker light cables, and,

with the proper light cable and adapters, can connect to any

exible or rigid endoscope.

e X8000 is equipped with Electronic Scope Sensing

Technology (ESST), a special safety feature that helps

prevent accidental burns caused by a light cable that is

not connected to the scope. When operated with an ESST

light cable, the X8000 senses when the scope and the light

cable are separated and places the light source in Standby

mode. In Standby mode, the X8000 will reduce light output

to a minimum, preventing the light cable from generating

excessive heat.

Electrical

Primary: 100 – 120 VAC, 50/60 Hz, 450 W

220 – 240VAC, 50/60 Hz, 450 W

Fuses (2): 5.0A, 250V

Dimensions

Height: 4.75˝ (12.1 cm)

Width: 12.5˝ (31.8 cm)

Depth: 16.8˝ (42.7 cm)

Weight: 16.0 lbs (7.3 kg)

Fiberoptic Cable Range

2 – 6.5 mm diameter

Bulb

Type: 300 Watt Xenon (Elliptical)

Life: Approximately 500 hours

Operating Conditions

10 – 40°C

30 – 75% Relative Humidity

Transportation and Storage

-20 – 50°C

10 – 75% Relative Humidity

700 – 1060 hPa

Classications and Approvals

Complies with medical safety standards:

• IEC 60601-1:2005

• CAN/CSA C22.2 No.601.1-M90

• UL 60601-1: 2003

Complies with medical EMC standard:

• IEC 60601-1-2:2001

Class 1 Equipment

Type CF applied parts

Water Ingress Protection, IPX0 — Ordinary

Equipment

Continuous Operation

Patent Protection

U.S. #5,850,496; 6,110,107; and 6,689,050.

Other patents pending.

6

Page 8

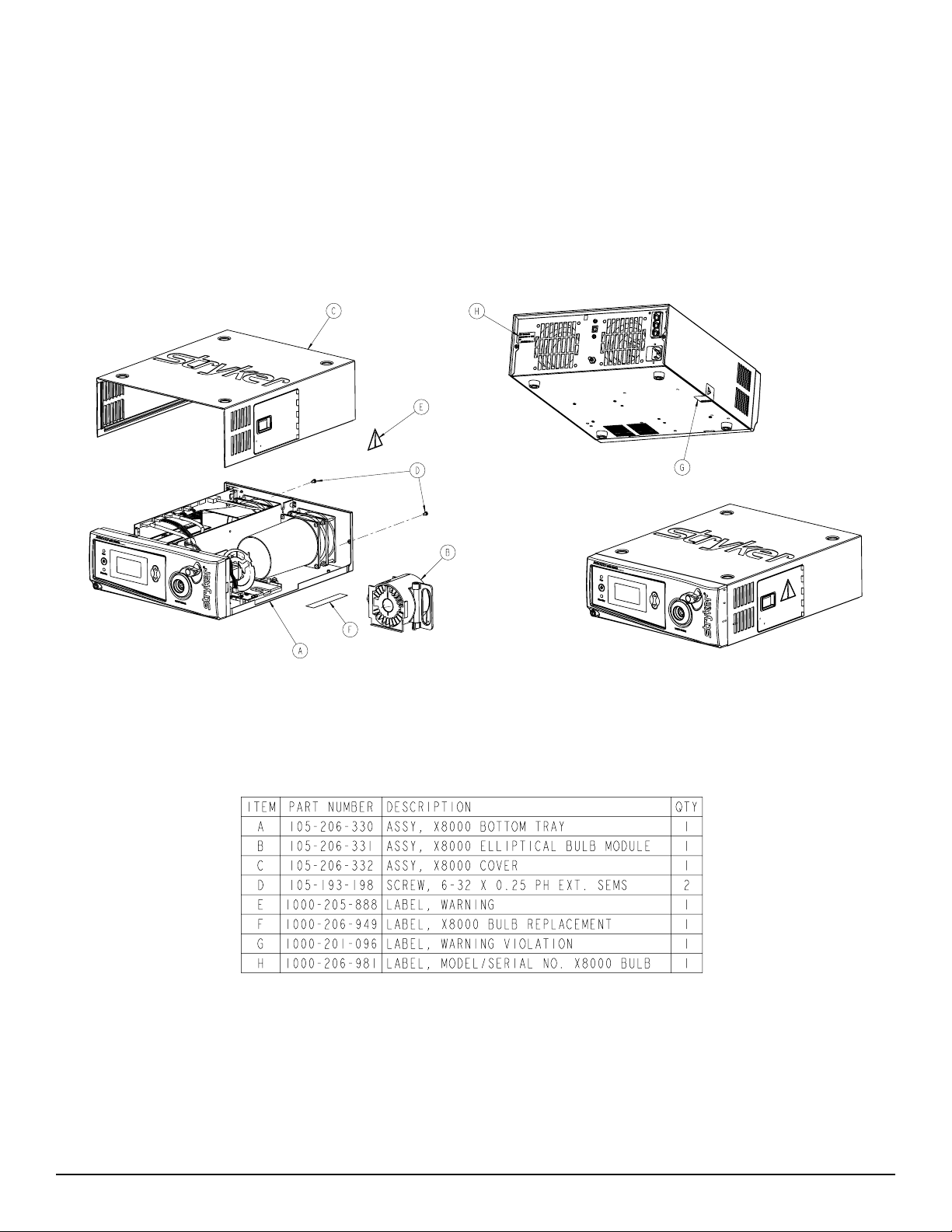

Device Diagrams

e individual components of the X8000, which are referred to throughout this manual, are identied in the

following diagrams.

To p Chassis Assembly

7

Page 9

Bottom Chassis Assembly

8

Page 10

9

Page 11

Basic Maintenance

Replacing the Bulb Module

Cleaning the X8000

Caution Unplug the X8000 before cleaning the

unit.

1. As needed, clean the external surfaces of the X8000

using a cloth or sponge dampened with a mild

detergent or disinfectant.

2. Clean and maintain the light cable according to the

manufacturer’s instructions.

Caution Do not use any abrasive cleaners. Do not

allow any liquid to drip into the unit.

Caution Do not sterilize or immerse the X8000.

Caring for the Bulb Module

e X8000 uses a Xenon bulb, which has a guaranteed

life of 500 hours when used properly. Always follow these

guidelines to ensure maximum bulb life:

1. If the bulb is touched, clean the bulb face with

alcohol and a cotton swab. Dirt or oil on the bulb

face will cause the bulb to heat unevenly and fail.

2. Do not power on and o the bulb in rapid

succession. Allow the bulb to run for at least ve

minutes once it has been powered on. Failure to do

so can cause the bulb to rapidly darken and fail.

Replace the bulb module when the LCD indicates 500 hours

or when the bulb no longer suciently illuminates the

surgical site. If possible, replace the bulb module between

surgical procedures.

Warning During operation, the bulb and the

housing around the bulb may be hot.

Wa it at least three minutes for the bulb

to cool before handling it.

To replace the bulb module,

1. Power down the X8000 and wait at least three

minutes for the bulb to cool.

2. Open the bulb door.

3. Rotate the bulb module handle to the right, grasp it,

and withdraw the bulb.

Warning Do not reach inside the bulb door for

any reason other than replacing the bulb

module. Touching parts other than the

bulb module may cause burns or product

damage.

Warning Do not touch any part of the bulb module

except for the handle. e module may be

very hot and cause burns.

Caution e X8000 has been designed to start the

bulb under most conditions, even when

it is hot. However, if the bulb does not

start within 10 seconds aer the X8000

has powered on, turn the unit o and

wait at least ve minutes for the bulb to

cool before restarting. Further attempts

to start the bulb can damage the bulb and

possibly the internal circuitry.

10

4. Insert the new bulb module (Stryker part number

220-201-000) along the guide rails until it is fully

seated on the mating connectors.

5. Rotate the handle to the le to secure the bulb

module within the light source.

6. Close and latch the bulb door.

7. Power on the unit.

8. Power on the bulb (if not already on) and verify that

the LCD displays the bulb hours as “0.”

Note Using a non-Stryker replacement bulb

module will result in no light output.

Caution Do not operate the X8000 with a burned-

out bulb or with no bulb installed.

Page 12

Replacing the Fuses

1. Unplug the light source from the AC outlet and

remove the power cord from the rear of the unit.

2. Unlatch the fuse holder and remove the fuse(s).

3. Replace the fuse(s) with fuse(s) of the same

value and rating.

Warning To help avoid the risk of re, use only

5.0A 250V fuses.

4. Reinstall the fuse holder.

Disposing of the X8000

is product is considered electronic

equipment. It must not be disposed of

as unsorted municipal waste and must

be collected separately. Please contact

the manufacturer or other authorized

disposal company to decommission

your equipment.

11

Page 13

Troubleshooting

Problem Possible Solution

No light output

• Ensure the AC power cord is properly connected to a hospital-grade power outlet and

the inlet on the rear console panel.

• Ensure the power switch on the front panel is powered on. (It will illuminate when

powered on.)

• Ensure all fuses are operating.

• Ensure the bulb is properly seated in the bulb housing. e bulb handle should be

turned all the way to the le within the light source.

• Ensure the bulb is in operating condition. Replace the bulb if necessary.

• Ensure the light cable is correctly engaged with the cable port. As a safety feature, the

X8000 will provide no light output unless a beroptic light cable is properly seated in

the cable port.

• Ensure the bulb access door is completely shut.

• Check for error codes E-1, E-2, E-3, E-4 or E-5. See the Error Code Denitions section

of this manual for details.

• Check that vents are not obstructed.

• If the safety shuto has been activated, please return the X8000 for service. Please see

the Component Replacement section of this manual for additional information.

To o much or too little

light output

Excessive glare in the

video

• Ensure the light cable is correctly engaged with the cable port.

• Ensure the bulb has adequate bulb life remaining. e bulb has a warranty of 500 hours.

• Ensure the X8000 is in Run mode. (e Run LED should be illuminated.) If necessary,

press the Mode button to switch from Standby to Run. If the unit remains in Standby:

1. Ensure the light cable is correctly engaged with the cable port.

2. If an ESST cable is connected to the X8000, ensure the cable is attached to the scope

using an ESST scope adapter.

• Use the up/down buttons to adjust the brightness.

• Ensure the beroptic cable is transmitting light properly. Hold the light-source end of

the cable to an overhead room light and look into the scope end of the light cable. If

the pattern contains any black spots, the light cable may be worn out and may require

replacement.

• Ensure the light cable is of an adequate size for the application. e cable diameter may

be too small to provide adequate light transmission for the medical video camera in the

endoscopic application.

• Ensure the electronic shutter on the camera is operating properly to control the video

signal brightness. If further light reduction is required, decrease the light source

brightness with the down button.

12

Page 14

Error Code Definitions

e X8000 displays error codes when one of the following conditions occurs. Follow the recommended action to correct the

error.

Code Definition Recommended Action

E-1

E-2

E-3

E-4

E-5

Blinking

500

All conditions are met for the bulb to illuminate, yet it

remains o.

All conditions are not met for the bulb to illuminate, yet it

remains on.

e bulb has higher than expected current or voltage

applied to it.

e bulb is kept o because the ballast fan is not working

properly.

e bulb is kept o because the bulb fan is not working

properly.

e bulb has exceeded its recommended lifetime of 500

hours.

Consult the Diagnosis section of this manual.

Consult the Diagnosis section of this manual.

Consult the Diagnosis section of this manual.

Consult the Diagnosis section of this manual.

Consult the Diagnosis section of this manual.

Install a new Stryker bulb.

Replace

Bulb

e bulb has reached 1000 hours and has exceeded its

recommended lifetime of 500 hours.

Install a new Stryker bulb.

13

Page 15

Diagnosis

To diagnose system errors, follow the strategies provided

below. For steps that involve test points on the control

board, refer to the control board diagram at the end of the

Diagnosis section.

Diagnosis strategies are grouped by symptom:

A. Bulb does not turn on

B. Bulb does not turn o

C. Bulb ignites immediately upon system startup

D. LCD display is blue or completely dark

E. Fan does not run

F. Light source does not switch from STANDBY to

RUN mode

G. Brightness cannot be adjusted

H. E-1 error appears on the LCD display

I. E-2 error appears on the LCD display

J. E-3 error appears on the LCD display

K. E-4 error appears on the LCD display

L. E-5 error appears on the LCD display

M. Bulb hours value does not display

N. Shutter makes noise or does not move properly.

A. Bulb does not turn on

1. Check the voltages on the control board test points

TP22 and TP23.

• If the test points read 12V and 0V respectively,

then the ballast is faulty. Replace the ballast.

• If the voltages are in the vicinity of 5.5V and

7V respectively, proceed to step 2.

2. Visually check if the bulb door is properly

closed with the cover or a stand-alone magnet. If

necessary, close the door.

3. Visually check if the light cable is properly inserted

into the jaw. If necessary, reinsert the cable.

4. Visually check if the bulb has the one-wire memory

chip. If it does, ensure the chip makes contact with

the bulb mount board connector. If necessary,

adjust contact between the chip and the connector.

5. Using a multimeter, electronically check the

following test points on the control board. Each test

point should read 3.3 volts.

• PD1—reads 3.3 volts if the one wire chip is

detected by the control board. If PD1 reads 0

volts (and PD2 reads 3.3 volts), try a dierent

bulb. Push the bulb rmly towards the plastic

separator panel to ensure contact.

• PD2—reads 3.3 volts if the door reed switches

are closed. If PD2 reads 0 volts,

- Check if the reed switches on the bulb

mount boards are soldered properly. If

necessary, repair the soldering.

- Check for shorts using the magnet on the

reed switch. Repair/replace as necessary.

- Check if the cable wire colors are

correctly oriented. Adjust as necessary.

• PD3—reads 3.3 volts if the fans are functioning

properly

• PD4—reads 3.3 volts if a regular light cable is

inserted. If PD4 reads 0 volts, remove the front

panel and check if the beam sensor is properly

positioned and connected to the display board.

Adjust as necessary.

• PD5—reads 3.3 volts if an ESST light cable is

inserted. If PD5 reads 0 volts, remove the front

panel and check if the beam sensor is properly

positioned and connected to the display board.

Adjust as necessary.

6. If none of these help, contact Technical Support at

+1.800.624.4422.

B. Bulb does not turn o

If the bulb turns on immediately aer AC power is applied

to the light source, proceed to diagnosis strategy C, “Bulb

ignites immediately upon system startup.”

If the bulb ignites aer the regular startup sequence but then

will not turn o, perform the following steps until the source

of the problem is identied.

1. Remove the light cable from the jaw.

2. Open the bulb door or remove the magnet from the

reed switches.

3. Using a multimeter, check the following test points

on the control board:

• PD2—If PD2 reads 3.3 volts, the reed switches

are faulty. Replace the reed switches.

• PD4 and PD5—If either PD4 or PD5 reads 3.3

volts, the light cable sensor (beam sensor) is

faulty. Replace the light cable sensor.

4. If PD4 or PD5 reads 0 volts, measure the voltage

dierence between TP22 and TP23.

• If the voltage dierence is around -1.3 volts,

replace the ballast.

• If the voltage dierence is around 12 volts,

proceed to step 5.

5. Measure the voltage level for TP32.

• If TP32 reads 0 volts, replace the control board.

(See the Repair/Replacement Procedures

section of this manual.)

• If TP32 reads 3.3 volts, proceed to step 6.

14

Page 16

6. Measure the voltage for TP34.

• If TP34 reads 0 or 1.6 volts, replace the control board.

(See the Repair/Replacement section of this

manual.)

• If TP34 reads otherwise, contact Technical

Support at +1.800.624.4422.

C. Bulb ignites immediately upon system

startup

1. Check if the jumpers on the ballast (JP300) are

properly installed. When the ballast is viewed from

the bulb side, the jumpers should read 0 I I 0 I 0 0.

Adjust as necessary.

2. Check the voltage dierence between TP22 and

TP23 on the control board:

• Turn o system power

• Connect the positive multimeter probe to TP22

and the negative probe to TP23

• Turn on system power

• If the voltage dierence is around 12V, proceed

to step 3

• If the voltage dierence is around -1.3 volts,

replace the ballast (See the Repair/Replacement

section of this manual.).

3. Check the voltage of TP32. If it does not read 3.3

volts, replace the control board (See the Repair/

Replacement section of this manual.).

4. Make sure that the 6-pin power cable from the

ballast to the control board is connected.

• If the power button lights up, perform steps

1 – 3.

• If the power button still does not light up,

replace the control board (See the Repair/

Replacement section of this manual.).

E. Fan does not run

1. If one or both fans are not working, an E-4 (ballast)

or E-5 (bulb) error should display on the LCD

screen. Conrm this.

2. If both fans do not work, measure the voltage on the

10.2V test point on the control board (underneath

lamp status connector).

• If it does not read around 10.2 volts, replace

the control board (See the Repair/Replacement

section of this manual.).

3. If only one fan works, switch the fan connectors

between the working and non-working fans.

• If non-working fan still fails to run, then it is

faulty. Replace it. (See the Repair/Replacement

section of this manual.)

• If the non-working fan begins to run, but the

working fan stops running, then the control

board is faulty. Replace it. (See the Repair/

Replacement section of this manual.).

D. LCD display is blue or completely dark

Power on the light source:

• If you hear the fans running, or if the power

button is lighted, perform steps 1 – 3.

• If you don’t hear the fans running, and the

power button is not lighted, perform step 4.

1. Check if the cable between the control board and

front display board is connected properly. Adjust as

necessary.

2. Insert the bulb, close the bulb door, and measure the

voltages of PD1 and PD2 on the control board.

• If they do not read 3.3 volts, replace the control

board. (See the Repair/Replacement section of

this manual.)

• If they do read 3.3 volts, proceed to step 3.

3. Measure the voltage across the C47 and C48

capacitors (directly beneath the display board cable

on the control board side).

• If they read 3.3 volts and 12.3 volts respectively,

replace the display board (See the Repair/

Replacement section of this manual.).

• If not, replace the control board (See the

Repair/Replacement section of this manual.).

F. Light source does not switch from

STANDBY to RUN mode

1. Check if the bulb is lit. If it is lit, go to step 2. If it is

not lit, then go to diagnosis strategy A.

2. Press the brightness up and brightness down buttons

on the membrane. Check if the mini brightness

meter in the top right corner of the display increases

or not.

• If the meter does not change, remove the front

panel and check if the front panel membrane

connector is fully connected to the display

board. Adjust as necessary.

• If the meter does change and the membrane

is properly connected, cycle the light source

power.

- As the LCD powers up, check the soware

version numbers. ey should read at

least SW REV P 1. 2 and SW REV P.1.2

consecutively. (e revision numbers may

be higher if newer soware versions are

installed.)

- If the version numbers are not at least

1.2, contact Technical Support at

+1.800.624.4422 for soware updates.

- If the version numbers are adequate,

contact Technical Support.

15

Page 17

G. Brightness cannot be adjusted

1. Switch the light source between STANDBY and

RUN modes by pressing on the membrane switch.

(Make sure to use a non-ESST cable, or an ESST

cable that has the ESST adaptor at the tip.)

• If the light source does not switch between

modes, replace the control board (See the

Repair/Replacement section of this manual.)

• If the light source switches between modes, but

brightness cannot be increased or decreased,

proceed to step 2.

2. Remove the jaw handle and the plastic front panel.

Ensure that the front panel membrane is properly

connected to the front LCD display board. Adjust as

necessary.

3. If the membrane is properly connected, but

brightness still cannot be adjusted, replace the

membrane.

4. If the new membrane does not work, check for

proper connection between the control board and

the display board. Adjust as necessary.

5. If the membrane works aer checking the

connections, replace the front LCD display board

(See the Repair/Replacement section of this

manual.)

H. E-1 error appears on the LCD display

1. Make sure that the light cable is inserted, the bulb

door is closed with a bulb inside, and the lamp is

not lit.

2. Check the voltages on TP22 and TP23.

• If the voltage dierence between TP22 and

TP23 is not 12V, replace the control board.

• If the voltage dierence between these two test

points is 12V, ensure the J3 cable is connected

properly to the ballast and that the individual

wires are not crossed.

- Ensure that L3 and L4 ferrites, located

underneath the J3 connector, are

soldered properly to the control board.

- If these ferrites are missing, broken, or

not soldered properly, repair or replace

the control board.

3. If none of the above steps resolves the problem,

replace the ballast.

I. E-2 error appears on the LCD display

1. Make sure that the bulb is lit and the light is on.

2. Repeat diagnosis strategies B and C, respectively.

J. E-3 error appears on the LCD display

1. Probe TP13 with a multimeter.

• If it reads 3.3 volts, and E-3 still appears on the

display, replace the control board.

• If the voltage on TP13 is low, replace the

ballast.

K. E-4 error appears on the LCD display

1. Verify that the ballast fan is not running.

2. Ensure the ballast fan is connected to the control

board.

3. If the fan seems to be working, visually compare the

speed of the ballast fan to the bulb fan.

• If the ballast fan seems to be running slower,

replace the fan and verify that the E-4 error

disappears.

• If the E-4 error does not disappear with the

new fan, replace the control board.

L. E-5 error appears on the LCD display

1. Check to verify that the bulb fan is not running.

2. Ensure the ballast fan is connected to the control

board.

3. If the fan seems to be working, visually compare the

speed of the bulb fan to the ballast fan.

• If the ballast fan seems to be running slower,

replace the fan and verify that the E-5 error

disappears.

• If the E-5 error does not disappear with the

new fan, replace the control board.

M. Bulb Hours value does not display

1. Connect a regular light cable to the light source.

2. Make sure there is a bulb in the light source, close

the door, and verify that it is lit.

3. Verify that there is a one-wire memory properly

attached.

4. Verify that the one-wire memory is making contact

with the connectors on the bulb mount board.

5. If the bulb does not light, perform diagnosis

strategy A.

6. If you are unsure about the proper contact, insert a

new bulb to see if the hours will display.

7. If the hours still do not display, verify that the cable

between the bulb mount board and the control

board is properly connected.

8. If the cables are properly connected, but the hours

still do not display, replace the control board.

16

Page 18

N. Shutter makes noise or does not move

properly.

1. Check the pinouts of the motor cable and the bulb

mount board/control board cable. Make sure the

wire colors match the drawing.

2. Make sure the connectors J1 and J2 on the bulb

mount board are not soldered in the wrong

direction.

3. Make sure the minimum shutter switch is soldered

properly. Make sure the switch lever is properly

connected to the switch itself.

4. Make sure the shutter wheel is properly connected

to the motor sha.

5. Make sure the shutter wheel is not rubbing against

the hot mirror holder.

6. If the motor is rotating the shutter in the reverse

direction when power is applied to the light source,

replace the motor.

7. If the motor is hesitantly rotating the shutter back

and forward, then replace the motor.

8. If the shutter’s mini tab is catching the bottom

of the minimum shutter switch, replace the bulb

mount board.

9. If none of the steps above solves the problem,

contact Technical Support at +1.800.624.4422.

17

Page 19

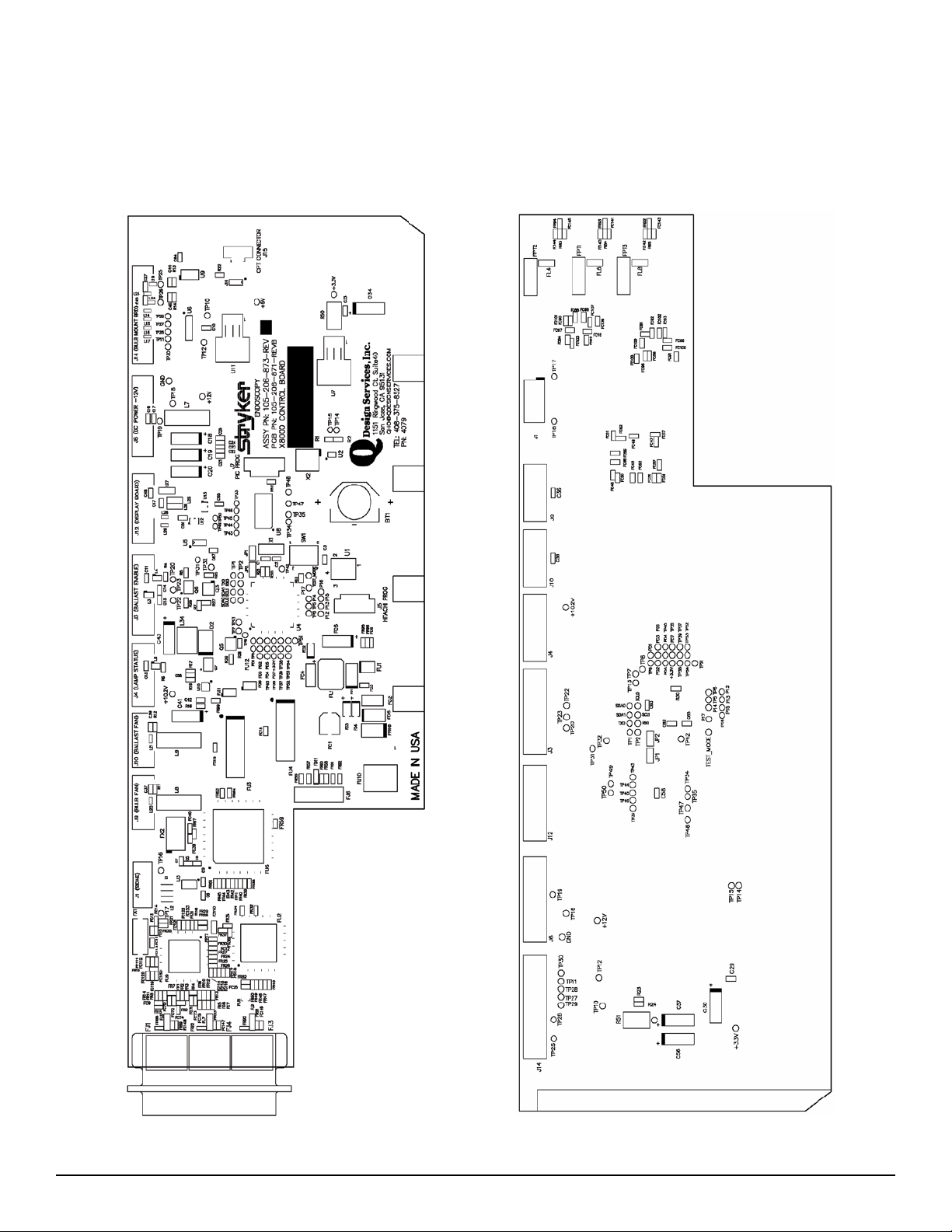

Control Board Diagrams

18

Page 20

Repair/Replacement

e X8000 Light Source is a precision instrument that has

been engineered and manufactured with great care to ensure

the safety of operators and patients. In order to maintain the

high level of safety and reliability required in devices of this

nature, it is important to fully understand and comply with

all required procedures set forth herein.

If some part of a procedure is omitted or adequate equipment

is not used, the safety and performance of the devices may

be unknowingly compromised. If any of the procedures

described in this manual are beyond the scope of the

technician’s training, consult the “Service Options” section of

this manual for information on how to obtain service from

Stryker Endoscopy.

As is the case with all AC powered

devices, dangerous voltages are present.

If adequate safety precautions are not

taken, results may include damage to the

equipment, personal injury, or death. It

is imperative that these procedures are

approached only by trained technicians

with proper equipment aer fully reading

and understanding the steps involved.

Note For all steps that involve the application of

Loctite, apply Loctite to the threaded holes

rather than to the threads on the screws

unless otherwise specied.

Note When using a power screwdriver, set

torque setting to 3 high unless otherwise

specied.

Each of the following tables provides repair/replacement

instructions for specic components of the X8000. For each

instruction, the required tools, equipment, and replacement

part numbers are provided.

Caution ESD Protection is required to perform

this assembly. Failure to follow this

procedure can cause undetectable

damage to electrical components.

19

Page 21

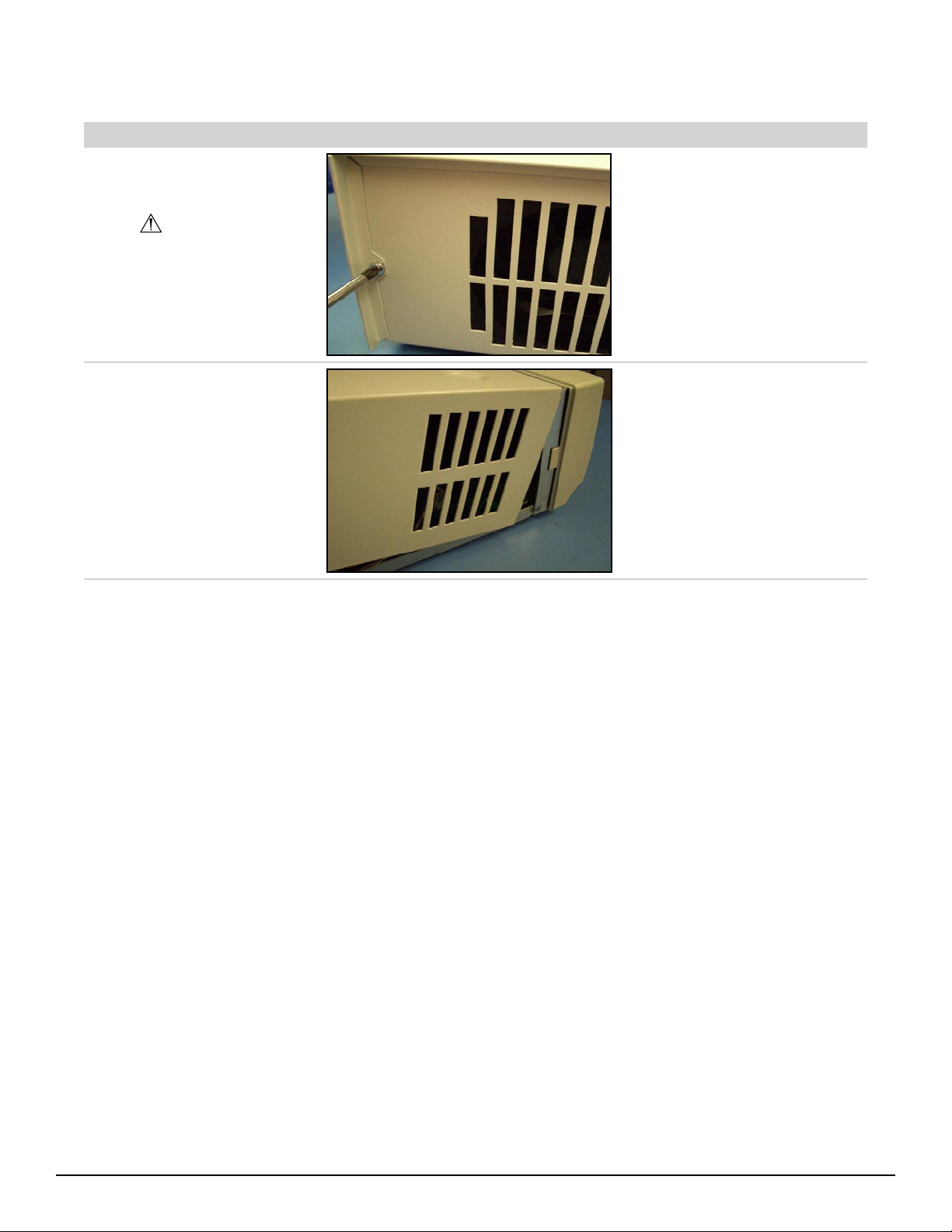

1.0 Chassis Cover

Seq. Ta s k Description Figure To o l s Needed Parts

10 Unscrew Chassis Cover

from Chassis.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

• X8000 Cover

• X8000 Chassis

Ext. Sems. (2)

(198)

(407)

(343)

20 Remove Chassis Cover

from Chassis.

• X8000 Cover

(407)

• X8000 Chassis

(343)

20

Page 22

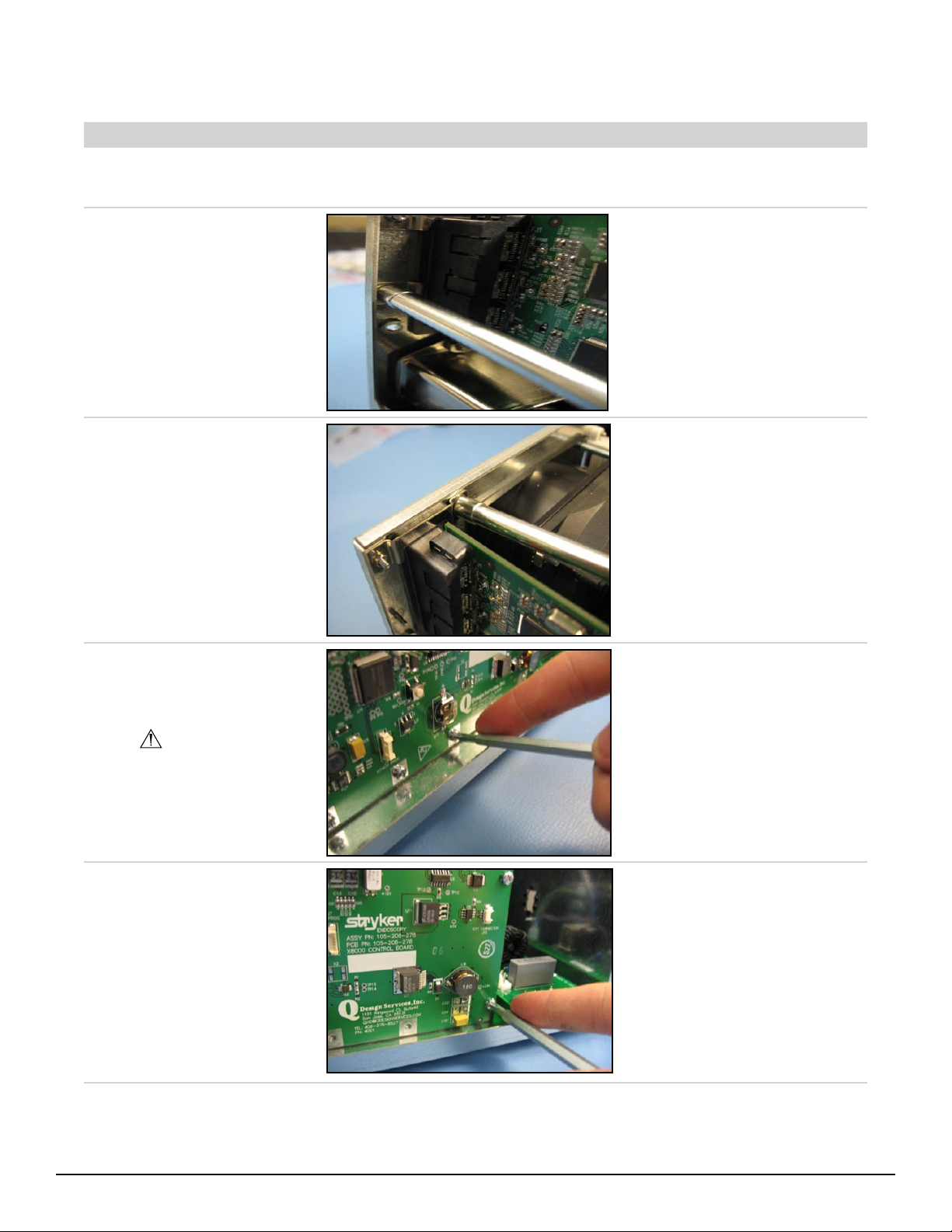

2.0 Control Board

Seq. Ta s k Description Figure To o l s Needed Parts

30 Remove Chassis Cover

from Chassis (procedure

1.0).

40 Remove all Cables

connected to the Control

Board. Unscrew S-Bracket

from Chassis as shown.

• 4mm Nut

Driver

• 2-56 Hex Nut

• S-Bracket

• X8000 Chassis

(866)

(585)

(343)

50 Unscrew U-Bracket from

Chassis as shown.

60 Unscrew Control Board

from lower Control Board

mounts as shown.

Do not bend Control

Board!

70 Unscrew Control Board

from Fan Support. Remove

Control Board from Unit.

• 4mm Nut

Driver

• Power

Screwdriver

(Phillips)

• Power

Screwdriver

(Phillips)

• 2-56 Hex Nut

(2) (866)

• U-Bracket

(584)

• X8000 Chassis

(343)

• 6-32 x 5/16

PH Screw (4)

(102)

• X8000 Control

Board (873)

• X8000 Chassis

(343)

• 6-32 x 5/16

PH Screw (2)

(102)

• Fan Support

(223)

• X8000 Control

Board (873)

21

Page 23

80 Get New Control Board.

Remove Control Board

from metal-shielded bag

and place on ESD-safe Mat.

• X8000 Control

Board (873)

90 Loosen the Fan Support

from the Chassis. is will

allow for easier reassembly.

100 Place new Control Board

into Chassis and align with

screw mounts on Chassis

ange.

Be careful not to hit the

A/C Inlet Board!

• 5/16” Nut

Driver

• 6-32 SS Nut

(489)

• Fan Support

(223)

• X8000 Chassis

(343)

• X8000 Control

Board (873)

• X8000 Chassis

(343)

110 Connect 3-Wire Fan cable

from Bulb Fan to Control

Board connector J9 (BULB

FAN).

Do not bend Control

Board!

22

• 3-Wire Fan

Cable from

Bulb Fan (3Pin 3-Wire)

• X8000 Control

Board (873)

Page 24

120 Connect 3-Wire Fan from

Ballast Fan to Control

Board connector J10

(BALLAST FAN).

Do not bend Control

Board!

• 3-Wire Fan

Cable from

Ballast Fan (3Pin 3-Wire)

• X8000 Control

Board (873)

130 Connect 4-Pin 4-Wire

Control Board/Ballast

Lamp Status Cable to

Control Board connector J4

(BALLAST FAN).

Do not bend Control

Board!

140 Connect 6-Pin 4-Wire

Control Board/Ballast LitEnable-Intensity Cable to

Control Board connector J3

(BALLAST ENABLE).

Do not bend Control

Board!

• Control

Board/Ballast

Lamp Status

Cable (4-Pin

4-Wire) (509)

• X8000 Control

Board (873)

• Control

Board/Ballast

Lit-EnableIntensity Cable

(6-Pin 4-Wire)

(563)

• X8000 Control

Board (873)

150 Connect 5-Pin 5-Wire

Control Board/Display

Board Cable from Display

Board to Control Board

connector J12 (DISPLAY

BOARD).

Do not bend Control

Board!

• Control

Board/Display

Board Cable

(5-Pin 5-Wire)

(565)

• X8000 Control

Board (873)

23

Page 25

160 Connect 6-Pin 6-Wire

Control Board/Ballast

Cable from Ballast to

Control Board connector J6

(DC POWER – 12V).

Do not bend Control

Board!

• Control

Board/Ballast

Cable (6-Pin

6-Wire) (567)

• X8000 Control

Board (873)

170 Connect 8-Pin 8-Wire

Control Board/Bulb Mount

Board Cable from Bulb

Mount Board to Control

Board connector J14 (BULB

MOUNT BRD).

Do not bend Control

Board!

180 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure

190 Screw Chassis Cover to

Chassis.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• Control

Board/Bulb

Mount Board

Cable (8-Pin

8-Wire) (566)

• X8000 Control

Board (873)

• X8000 Cover

(407)

• X8000 Chassis

(343)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

24

Page 26

3.0 Ballast

Seq. Ta s k Description Figure To o l s Needed Parts

200 Remove Chassis Cover

from Chassis (procedure

1.0).

210 Disconnect all cables on the

Control Board side.

Do not bend Control

Board!

• X8000 Control

Board (873)

220 Remove green Ground Post

A/C Inlet Board/Ballast

Cable from bottom Ballast

connector GND J103.

230 Unscrew black Ballast/

Bulb Cathode Cable from

Ballast.

240 Unscrew red Ballast/Bulb

Anode Cable from Ballast.

• Needlenose

Pliers

• Power

Screwdriver

(Phillips)

• Power

Screwdriver

(Phillips)

• Ground Post

AC Inlet

Board/Ballast

Cable (587)

• X8000 Ballast

(413)

• Ballast/Bulb

Anode Cable

Assembly

(568)

• X8000 Ballast

(413)

• Ballast/Bulb

Anode Cable

Assembly

(569)

• X8000 Ballast

(413)

25

Page 27

250 Unscrew Ballast from front-

le Chassis PEM as shown.

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(313)

260 Unscrew Ballast from

front-right Chassis PEM as

shown.

270 Unscrew Ballast from rear-

le Chassis PEM as shown.

280 Unscrew Ballast from

rear-right Chassis PEM as

shown

Remove the ballast from

the unit.

• Power

Screwdriver

(Phillips)

• Power

Screwdriver

(Phillips)

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(313)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(313)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(343)

26

Page 28

290 Remove Brown and Blue

lead of AC Inlet Board/

Ballast Cable from original

Ballast.

• Needlenose

Pliers

• X8000 Ballast

(413)

• A/C Inlet

Board/

Ballast Cable

Assembly

(571)

300 Remove Control Board/

Ballast Lamp Status Cable

from original Ballast.

310 Remove Control Board/

Ballast Lit-Enable-Intensity

Cable from original Ballast.

320 Get New Ballast. Remove

the Ballast from metalshielded bag and place on

ESD safe mat.

• X8000 Ballast

(413)

• Control

Board/

Ballast Lamp

Status Cable

Assembly (4Pin) (509)

• X8000 Ballast

(413)

• Control

Board/Ballast

Lit-EnableIntensity Cable

(6-Pin 4-Wire)

(563)

• X8000 Ballast

(413)

27

Page 29

330 Attach Control Board/

Ballast Cable -567 to Ballast

Connector J422.

• X8000 Ballast

(413)

• Control

Board/

Ballast Cable

Assembly

(6-Pin 6-Wire)

(567)

340 Attach Control Board/

Ballast Lit-Enable-Intensity

Cable -563 to Ballast

Connector J500.

350 Attach Control Board/

Ballast Lamp Status Cable

-509 to Ballast Connector

J504.

360 Attach Blue lead of AC Inlet

Board/Ballast Cable -571 to

top Ballast connector HOT

J101.

Flat end of connector

should face in towards

Ballast.

• Needlenose

Pliers

• X8000 Ballast

(413)

• Control

Board/Ballast

Lit-EnableIntensity Cable

(6-Pin 4-Wire)

(563)

• X8000 Ballast

(413)

• Control

Board/

Ballast Lamp

Status Cable

Assembly (4Pin) (509)

• X8000 Ballast

(413)

• A/C Inlet

Board/

Ballast Cable

Assembly

(571)

28

Page 30

370 Attach Brown lead of AC

Inlet Board/Ballast Cable

-571 to middle Ballast

connector NEUT J102 on

Ballast.

Flat end of connector

should face in towards

Ballast.

• Needlenose

Pliers

• X8000 Ballast

(413)

• A/C Inlet

Board/

Ballast Cable

Assembly

(571)

380 Place and align Ballast onto

Chassis PEM’s with Heat

Sink towards outside of

Chassis.

390 Screw Ballast to rear-right

Chassis PEM as shown.

• Power

Screwdriver

(Phillips)

• X8000 Ballast

(413)

• X8000 Chassis

(343)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(343)

400 Screw Ballast to rear-le

Chassis PEM as shown.

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(313)

29

Page 31

410 Screw Ballast to front-right

Chassis PEM as shown.

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(313)

420 Screw Ballast to front-le

Chassis PEM as shown.

430 Attach green Ground Post

A/C Inlet Board/Ballast

Cable to bottom Ballast

connector GND J103.

Flat end of connector

should face in towards

Ballast.

440 Screw red Ballast/Bulb

Anode Cable from forward

Banana Plug to Ballast

connector J602 LAMP +

Screw Cable at side

down.

• Power

Screwdriver

(Phillips)

• Needlenose

Pliers

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (1)

(102)

• X8000 Ballast

(413)

• X8000 Chassis

(313)

• Ground Post

AC Inlet

Board/Ballast

Cable (587)

• X8000 Ballast

(413)

• Ballast/Bulb

Anode Cable

Assembly

(569)

• X8000 Ballast

(413)

30

Torque setting of 3!

Page 32

450 Screw black Ballast/Bulb

Cathode Cable from rear

Banana Plug to Ballast

connector J604 LAMP –

Screw Cable at side

down.Torque setting of 3!

460 Reconnect all the cables

to the Control Board

(procedure 2.0, seq 120

- 170).

470 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

• Power

Screwdriver

(Phillips)

• Ballast/Bulb

Anode Cable

Assembly

(568)

• X8000 Ballast

(413)

• X8000 Cover

(407)

• X8000 Chassis

(343)

480 Screw Chassis Cover to

Chassis.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

31

Page 33

4.0 Bulb Mount Board

Seq. Ta s k Description Figure To o l s Needed Parts

490 Remove Chassis Cover

from Chassis (procedure

1.0). Remove the Bulb

Assembly. Unplug A/C

Inlet Board/Bulb Mount

Board Cable from A/C Inlet

Board.

500 Unplug Stepper Motor

connector from Bulb

Mount Board connector J2

as shown. Also unplug A/C

Inlet Board/Bulb Mount

Board Cable from Bulb

Mount Board.

510 Unscrew Bulb Mount Board

Assembly from Chassis

PEM’s. Remove old Bulb

Mount Board from unit.

520 Remove ermal Switch

Guard from Bulb Mount

Board.

Use a manual

screwdriver!

• Power

Screwdriver

(Phillips)

• Screwdriver

(Phillips)

• X8000 Stepper

Motor (341)

• X8000

Horizontal

Bulb Mount

Board

Assembly

(279)

• A/C Inlet

Board/Bulb

Mount Board

Cable (572

• 6-32 x 5/16

PH Screw (4)

(102)

• X8000

Horizontal

Bulb Mount

Board

Assembly

(279)

• X8000 Rail

Plate (329)

• 4-40 x ¼

Nylon Phil.

PH Screws (2)

(448)

• ermal

Switch Guard

(596)

32

Page 34

530 Get New Bulb Mount

Board. Place ermal

Switch Guide over ermal

Switch and A/C Inlet

Board/Bulb Mount Board

Cable as shown.

Pass ermal Switch

through opening in

ermal Switch Guard as

shown!

540 Screw ermal Switch

Guard onto Bulb Mount

Board.

Use a manual

screwdriver!

• Screwdriver

(Phillips)

• ermal

Switch Guard

(596)

• Bulb Mount

Board (279)

• 4-40 x ¼

Nylon Phil.

PH Screws (2)

(448)

• ermal

Switch Guard

(596)

550 Get new Bulb Mount

Board. Screw Bulb Mount

Board Assembly to Chassis

PEM’s above Rail Plate until

secure.

560 Plug Stepper Motor

connector into Bulb Mount

Board connector J2 as

shown. Also, plug in A/C

Inlet Board/Bulb Mount

Board Cable -572 into Bulb

Mount Board and A/C Inlet

Board.

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (4)

(102)

• X8000

Horizontal

Bulb Mount

Board

Assembly

(279)

• X8000 Rail

Plate (329)

• X8000 Stepper

Motor (341)

• A/C Inlet

Board/Bulb

Mount Board

Cable (572)

• X8000

Horizontal

Bulb Mount

Board

Assembly

(279)

33

Page 35

570 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

• X8000 Cover

(407)

• X8000 Chassis

(343)

580 Screw Chassis Cover to

Chassis. Insert Bulb back

in unit.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

34

Page 36

5.0 AC Inlet Board

Seq. Ta s k Description Figure To o l s Needed Parts

590 Remove Chassis Cover

from Chassis (procedure

1.0). Remove the Bulb

Assembly.

600 Disconnect all cables from

A/C Inlet Board.

610 Unscrew A/C Inlet Board

from Chassis PEM’s.

Remove AC Inlet board and

AC Inlet Shield from unit.

620 Get new A/C Inlet Board.

Remove A/C Inlet Board

from metal-shielded bag

and place on ESD-safe mat.

• Power

Screwdriver

(Phillips)

• A/C Inlet

Board (121)

• 6-32 x 5/16

PH Screw (3)

(102)

• A/C Inlet

Board (121)

• X8000 Chassis

(343)

• AC Inlet

Shield (014)

• A/C Inlet

Board (121)

35

Page 37

630 Screw A/C Inlet Board

to Chassis PEM’s with

connector GND J4 to front

of Chassis. Attach AC Inlet

Shield to single screw on

le side of board.

• Power

Screwdriver

(Phillips)

• 6-32 x 5/16

PH Screw (3)

(102)

• A/C Inlet

Board (121)

• X8000 Chassis

(343)

• AC Inlet

Shield (014)

640 Connect 3-Pin 2-Wire

A/C Inlet Board/Ballast

Cable from Ballast to A/C

Inlet Board connector J3

BALLAST.

650 Connect green A/C Inlet

Board/Ballast Ground Post

Cable from Ballast to A/C

Inlet Board connector J4

GND.

• A/C Inlet

Board/Ballast

Cable (3-Pin 2

–Wire) (571)

• A/C Inlet

Board (121)

• A/C Inlet

Board/Ballast

Ground Post

Cable (1-Wire)

(571)

• A/C Inlet

Board (121)

660 Connect 3-Pin 2-Wire

A/C Inlet Board/Bulb

Mount Board Cable to A/C

Inlet Board connector J2

B.MOUNT.

36

• A/C Inlet

Board/Bulb

Mount Board

Cable (3-Pin

2-Wire) (572)

• A/C Inlet

Board (121)

Page 38

670 Connect 8-Pin 8-Wire

Control Board/Bulb Mount

Board Cable to Bulb Mount

Board connector J1.

• Control

Board/Bulb

Mount Board

Cable (8-Pin

8-Wire) (566)

• Bulb Mount

Board (279)

680 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

690 Screw Chassis Cover to

Chassis. Insert Bulb back

in unit.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• X8000 Cover

(407)

• X8000 Chassis

(343)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

37

Page 39

6.0 Jaw Handle

Seq. Ta s k Description Figure To o l s Needed Parts

700 Remove Jaw Handle from

Jaw Handle Key and Pinion

Sha as shown.

Make sure the Jaw

Handle Key remains in the

Pinion Sha groove

• 1/16” Hex

Wre nc h

• #6 x ¼ FLPT

• Jaw Handle

• Jaw Handle

• X8000 Pinion

SS BLK Set

Screw (002)

(554)

Key (641)

Sha (298)

710 Place small amount of

Loctite 222 onto threaded

sha of new Jaw Handle,

then place Jaw Handle onto

Jaw Handle Key and Pinion

Sha as shown and screw

into place until secure.

Make sure that Loctite

does not get on the plastic

of Jaw Handle or damage

can occur.

• 1/16” Hex

Wre nc h

• Loctite 222

• #6 x ¼ FLPT

SS BLK Set

Screw (002)

• Jaw Handle

(554)

• Jaw Handle

Key (641)

• X8000 Pinion

Sha (298)

38

Page 40

7.0 LED power switch

Seq. Ta s k Description Figure To o l s Needed Parts

720 Remove Chassis Cover

from Chassis (procedure

1.0).

730 Remove Jaw Handle from

Jaw Handle Key and Pinion

Sha (procedure 6.0, seq

700).

740 Remove Jaw Handle Key

from Pinion Sha groove.

750 Unsnap Front Panel from

Chassis as shown.

• Jaw Handle

Key, X7000

(641)

• X8000 Pinion

Sha (298)

• X8000 Front

Panel (337)

• X8000 Chassis

(343)

760 Unplug Control Board/

Display Board Cable

-565 from Display Board

connector J20.

• Control

Board/Display

Board Cable

Assembly

(5-Pin 5-Wire)

(565)

• X8000 Display

Board (336)

39

Page 41

770 Unplug 3mm LED

connector from Display

Board connector as shown.

• X8000 3mm

LED (594)

• Display Board

(336)

780 Pull 3mm LED from rear of

Power Button.

790 Get new 3mm LED. Insert

3mm LED into rear of

Power Button and push

forward until it stops.

800 Plug 3mm LED connector

into Display Board

connector as shown.

• X8000 3mm

LED (594)

• Power Button

(226)

• X8000 3mm

LED (594)

• Power Button

(226)

• X8000 3mm

LED (594)

• Display Board

(336)

40

Dress LED wires neatly

against Front Panel.

Connect LED

connector with metal pins

facing up.

Page 42

810 Plug Control Board/Display

Board Cable -565 into

Display Board connector

J20 and pass through front

of Chassis as shown.

Dress LED Cable under

Display Board!

• Control

Board/Display

Board Cable

Assembly

(5-Pin 5-Wire)

(565)

• X8000 Display

Board (336)

820 Snap Front Panel to Chassis

as shown.

830 Insert Jaw Handle Key into

Pinion Sha groove.

840 Attach Jaw Handle onto

Jaw Handle Key and Pinion

Sha (procedure 6.0, seq

710).

850 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

• X8000 Front

Panel (337)

• X8000 Chassis

(343)

• Jaw Handle

Key, X7000

(641)

• X8000 Pinion

Sha (298)

• X8000 Cover

(407)

• X8000 Chassis

(343)

41

Page 43

860 Screw Chassis Cover to

Chassis.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

42

Page 44

8.0 Display Board

Seq. Ta s k Description Figure To o l s Needed Parts

870 Remove Chassis Cover

from Chassis (procedure

1.0).

880 Disconnect front panel

from unit (procedure 7.0,

seq 730 - 770).

890 Unplug Front Panel Overlay

Cable from Display Board

connector J20.

• Front Panel

• Display Board

Overlay Cable

(336)

900 Unplug Beam Sensor-ESST/

Display Board Cable from

Display Board connector

J17 as shown.

910 Unsnap Display Board

from Front Panel as shown.

Remove Display Board

from unit.

920 Peel o LCD Cover and

snap on new Display Board

to Front Panel with LCD

facing out of Front Panel as

shown.

• Beam SensorESST/Display

Board Cable

(573)

• Display Board

(336)

• Display Board

(336)

• Front Panel

Assembly

• Display Board

(336)

• Front Panel

Assembly

43

Page 45

930 Plug Beam Sensor-ESST/

Display Board Cable into

Display Board connector

J17 as shown.

• Beam SensorESST/Display

Board Cable

(573)

• Display Board

(336)

940 Plug Front Panel Overlay

Cable into Display Board

connector J20.

Tuck ribbon under

Display Board to protect

from abrasion from Jaw

Assembly.

950 Complete the reassemble of

the unit (procedure 7.0, seq

800-860).

• Front Panel

Overlay Cable

• Display Board

(336)

44

Page 46

9.0 Front Panel Membrane

Seq. Ta s k Description Figure To o l s Needed Parts

960 Remove Chassis Cover

from Chassis (procedure

1.0).

970 Disconnect Front Panel

from unit (procedure 7.0,

seq 730 - 770).

980 Remove Display Board

from front panel

(procedure 8.0, seq 890

- 910).

990 Unpeel the Front Panel

Membrane from Front

Panel.

• Front Panel

• X8000 Front

Membrane

(292)

Panel (337)

1000 Pull Front Panel Membrane

cable through Front Panel

as shown.

1010 Get new Front Panel

Membrane. Peel adhesive

backing o Front Panel

Membrane.

Ensure 2nd Backing

Piece behind ex cable is

removed

1020 Pass Front Panel Membrane

cable through Front Panel

as shown.

Leave lm on outside of

display to protect it from

scratching.

• Front Panel

Membrane

(292)

• X8000 Front

Panel (337)

• Front Panel

Membrane

(292)

• Front Panel

Membrane

(292)

• X8000 Front

Panel (337)

45

Page 47

1030 Press Front Panel

Membrane ush against

Front Panel until adhesive

backing is secure.

Check alignment before

securing. Once it is on the

front panel it cannot be

adjusted.

1040 Reinstall Display Board and

cables (procedure 8.0, seq

920 - 940).

1050 Complete the assemble of

the unit (procedure 7.0, seq

800 – 860).

• Front Panel

Membrane

(292)

• X8000 Front

Panel (337)

46

Page 48

10.0 Shutter

Seq. Ta s k Description Figure To o l s Needed Parts

1060 Remove Chassis Cover

from Chassis (procedure

1.0). Remove Bulb

Assembly.

• X8000 Bulb

Assembly

(331)

1070 Unscrew set screw from

Shutter and motor sha.

1080 Slide Shutter o sha with

cutout passing over the rail

plate protrusion.

1090 Place new Shutter onto

Stepper Motor and screw

into burr hole on Motor

sha until secure.

Start screw in Shutter

before mounting to Motor.

• 1/16” Hex

Wre nc h

• 1/16” Hex

Wre nc h

• Loctite 290

• 6-32 x 1/8

Socket HD Set

Screw (001)

• X8000 Shutter

(577)

• X8000 Stepper

Motor (341)

• 6-32 x 1/8

Socket HD Set

Screw (001)

• X8000 Shutter

(577)

• X8000 Stepper

Motor (341)

Slide Shutter on sha

with cutout passing over

the rail plate protrusion.

1100 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

• X8000 Cover

(407)

• X8000 Chassis

(343)

47

Page 49

1110 Screw Chassis Cover to

Chassis. Insert Bulb back

in unit.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

48

Page 50

11.0 Hot Mirror

Seq. Ta s k Description Figure To o l s Needed Parts

1120 Remove Chassis Cover

from Chassis (procedure

1.0). Remove the Bulb

Assembly.

1130 Remove Shutter (procedure

10.0, seq 1070 - 1080).

1140 Unscrew Hot Mirror

Holder from Motor Mount

as shown.

Unscrew bottom screw

rst and then top screw.

• 5/64” Hex

Wre nc h

• 2-56 x 0.250

• Hot Mirror

• X8000 Motor

Socket HD

Screw (2)

(344)

Holder (632)

Mount (339)

1150 Remove Hot Mirror from

Hot Mirror Holder.

1160 Place new Hot Mirror in

Hot Mirror Holder.

Handle Hot Mirror

with Adept Wipes.

1170 Screw Hot Mirror Holder

to Motor Mount as shown.

Screw in top screw rst

and then bottom screw.

• 5/64” Hex

Wre nc h

• X8000 Hot

Mirror (576)

• Hot Mirror

Holder (632)

• X8000 Hot

Mirror (576)

• Hot Mirror

Holder (632)

• 2-56 x 0.250

Socket HD

Screw (2)

(344)

• Hot Mirror

Holder (632)

• X8000 Motor

Mount (339)

49

Page 51

1180 Reinstall the Shutter

(procedure 10.0, seq 1080

– 1090).

1190 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

• X8000 Cover

(407)

• X8000 Chassis

(343)

1200 Screw Chassis Cover to

Chassis. Insert Bulb back

in unit.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

50

Page 52

12.0 Motor

Seq. Ta s k Description Figure To o l s Needed Parts

1210 Remove Chassis Cover

from Chassis (procedure

1.0). Remove the Bulb

Assembly.

1220 Remove Shutter (procedure

10.0, seq 1070 - 1080).

1230 Unplug Stepper Motor

connector from Bulb

Mount Board connector J2

as shown.

• X8000 Stepper

• X8000

Motor (341)

Horizontal

Bulb Mount

Board

Assembly

(279)

1240 Unscrew Stepper Motor

from Motor Mount.

1250 Get new Stepper Motor.

Screw in new Stepper

Motor to Motor Mount.

Make sure the Motor

wire pointed towards

outside of Chassis.

1260 Plug Stepper Motor

connector into Bulb Mount

Board connector J2 as

shown.

• Power

Screwdriver

(Phillips)

• Power

Screwdriver

(Phillips)

• M2.5 x 8 mm

PH Head

Screw (4)

(071)

• X8000 Stepper

Motor (341)

• X8000 Motor

Mount (339)

• M2.5 x 8 mm

PH Head

Screw (4)

(071)

• X8000 Stepper

Motor (341)

• X8000 Motor

Mount (339)

• X8000 Stepper

Motor (341)

• X8000

Horizontal

Bulb Mount

Board

Assembly

(279)

51

Page 53

1270 Reinstall the Shutter

(procedure 10.0, seq 1080

– 1090).

1280 Slide Chassis Cover onto

Chassis until ush with

Chassis and secure.

• X8000 Cover

(407)

• X8000 Chassis

(343)

1290 Screw Chassis Cover to

Chassis. Insert Bulb back

in unit.

Torque setting of 5.

• Power

Screwdriver

(Phillips)

• 6-32 x 0.25 PH

Ext. Sems. (2)

(198)

• X8000 Cover

(407)

• X8000 Chassis

(343)

52

Page 54

13.0 Jaw Assembly

Seq. Ta s k Description Figure To o l s Needed Parts Needed

1300 Remove Chassis Cover

from Chassis (procedure

1.0). Remove the Bulb

Assembly.

1310 Remove Shutter (procedure

10.0, seq 1070-1080).

1320 Remove Hot Mirror Holder

(procedure 11.0, seq 1140).

! Make sure the Hot Mirror

remains in the Hot Mirror

Holder.

1330 Disconnect Front Panel

from unit (procedure 7.0,

seq 730 - 770).

1340 Unscrew Lower Integrating

Rod Holder from Motor

Mount.

• Screwdriver

(Phillips)

• 2-56 x ¼ FH

PH Screw (2)

(645)

• X8000 Motor

Mount (339)

• Lower

Integrating

Rod Holder

(276)

1350 Unscrew Jaw Assembly

from front of Chassis.

Remove Jaw Assembly.

1360 Get new Jaw Assembly.

Screw Lower Integrating

Rod Holder to Motor

Mount until secure.

• Power

Screwdriver

(Phillips)

• Screwdriver

(Phillips)

• 6-32 x 3/8

PH Screw (4)

(441)

• Completed

X8000 Jaw

Assembly

• X8000 Chassis

(343)

• 2-56 x ¼ FH

PH Screw (2)

(645)

• X8000 Motor

Mount (339)

• Lower

Integrating

Rod Holder

(276)

53

Page 55

1370 Screw Jaw Assembly to

front of Chassis until

secure.

Torque setting of 5!

Apply enough Loctite

290 so that it is visible on

Chassis threads.

1380 Reinstall Hot Mirror

Holder (procedure 11.0, seq

1170).

1390 Reinstall the Shutter

(procedure 10.0, seq 1080

– 1090).

1400 Complete the assembly of

the unit (procedure 7.0, 810

– 860).

• Q-Tips

• Loctite 290

• Power

Screwdriver

(Phillips)

• 6-32 x 3/8

PH Screw (4)

(441)

• Completed

X8000 Jaw

Assembly

• X8000 Chassis

(343)

54

Page 56

14.0 Integrating Rod

Seq. Ta s k Description Figure To o l s Needed Parts

1410 Remove Chassis Cover

from Chassis (procedure

1.0)

1420 Remove Shutter, Hot

Mirror Holder, Front

Panel and Jaw Assembly

(procedure 13.0, seq 1310

– 1350).

1430 Unscrew Upper Integrating

Rod Holder from Lower

Integrating Rod Holder and

remove rod.

1440 Slide new Integrating Rod

into Lower Integrating Rod

Holder and push forward

until ush with end of

Holder.

Do Not Touch Ends.

• 5/64” Hex

Wre nc h

• 2-56 x 0.250

• Upper

• X8000

• Lower

Socket HD

Screw (2)

(344)

Integrating

Rod Holder

(277)

Integrating

Rod (314)

Integrating

Rod Holder

(276)

Make sure new Rod has

no chips.

1450 Salvage silicone strip

from original assembly

unless adhesive on strip is

longer aective. Replace if

necessary. Press Silicone

Strip into Upper Integrating

Holder.

• Silicone Strip

2in x 1/8 in

(595)

• Upper

Integrating

Rod Holder

(277)

55

Page 57

1460 Screw Upper Integrating

Rod Holder to Lower

Integrating Rod Holder.

Ensure Integrating Rod

is ush with end of Lower

Integrating Rod Holder.

1470 Complete assembly of the

unit (procedure 13.0, seq

1360 – 1400).

• 5/64” Hex

Wre nc h

• 2-56 x 0.250

Socket HD

Screw (2)

(344)

• Upper

Integrating

Rod Holder

(277)

56

Page 58

15.0 AC Inlet Filter

Seq. Ta s k Description Figure To o l s Needed Parts

1480 Remove Chassis Cover

from Chassis (procedure

1.0).

1490 Remove Control Board

(procedure 2.0, seq 50

– 80).

1500 Remove Ballast

(procedure 3.0, seq 230

– 280).

1510 Remove Ground Post Cable

from outermost single

ange of A/C Inlet Filter.

• X8000 Ground

• A/C Inlet

Post Cable

(591)

Filter (575)

1520 Remove A/C Filter/AC

Inlet Board Cables from

A/C Inlet Filter.

1530 Unscrew A/C Inlet Filter

from Chassis.

• A/C Inlet

Filter

Tightening

To o l

• ¼” Nut Driver

• A/C Filter/AC

Inlet Board

Cable (570)

• A/C Inlet

Filter (575)

• 4-40 SS B KEP

Nuts (2) (484)

• A/C Inlet

Filter (575)

• X8000 Chassis

(343)

57

Page 59

1540 Remove fuse holder from

A/C Inlet Filter.

• Twe ezers • 5A SLO-BLO

Fuse (2) (435)

• A/C Inlet

Filter (575)

1550 Take out original 5A SLO-

BLO fuses from A/C Inlet

Filter fuse holder. Put fuses

in fuse holder a new AC

Inlet Filter.

Open holder using a

Screwdriver (Flathead).

1560 Screw new A/C Inlet Filter

to Chassis with single prong

facing out of Chassis as

shown.

Attach lower nut rst!

1570 Attach A/C Filter/AC Inlet

Board Cable to A/C Inlet

Filter with Blue Wire on top

ange and Brown Wire on

bottom ange.

• Screwdriver

(Flathead)

• A/C Inlet

Filter

Tightening

To o l

• ¼” Nut Driver

• 5A SLO-BLO

Fuse (2) (435)

• A/C Inlet

Filter (575)

• 4-40 SS B KEP

Nuts (2) (484)

• A/C Inlet

Filter (575)

• X8000 Chassis

(343)

• A/C Filter/AC

Inlet Board

Cable (570)

• A/C Inlet

Filter (575)

58

Flat side of Cable

should face out of Chassis.

Page 60

1580 Attach Ground Post

Cable to outermost single

ange of A/C Inlet Filter

by running Cable under

Ballast Duct.

Flat side of Green Cable

should face out of Chassis

1590 Reinstall Ballast (procedure

3.0, seq 380 – 450).

1600 Reinstall Control Board and

Chassis Cover (procedure

2.0, seq 100 – 190).

• X8000 Ground

Post Cable

(591)

• A/C Inlet

Filter (575)

59

Page 61

16.0 Ballast Fan

Seq. Ta s k Description Figure To o l s Needed Parts