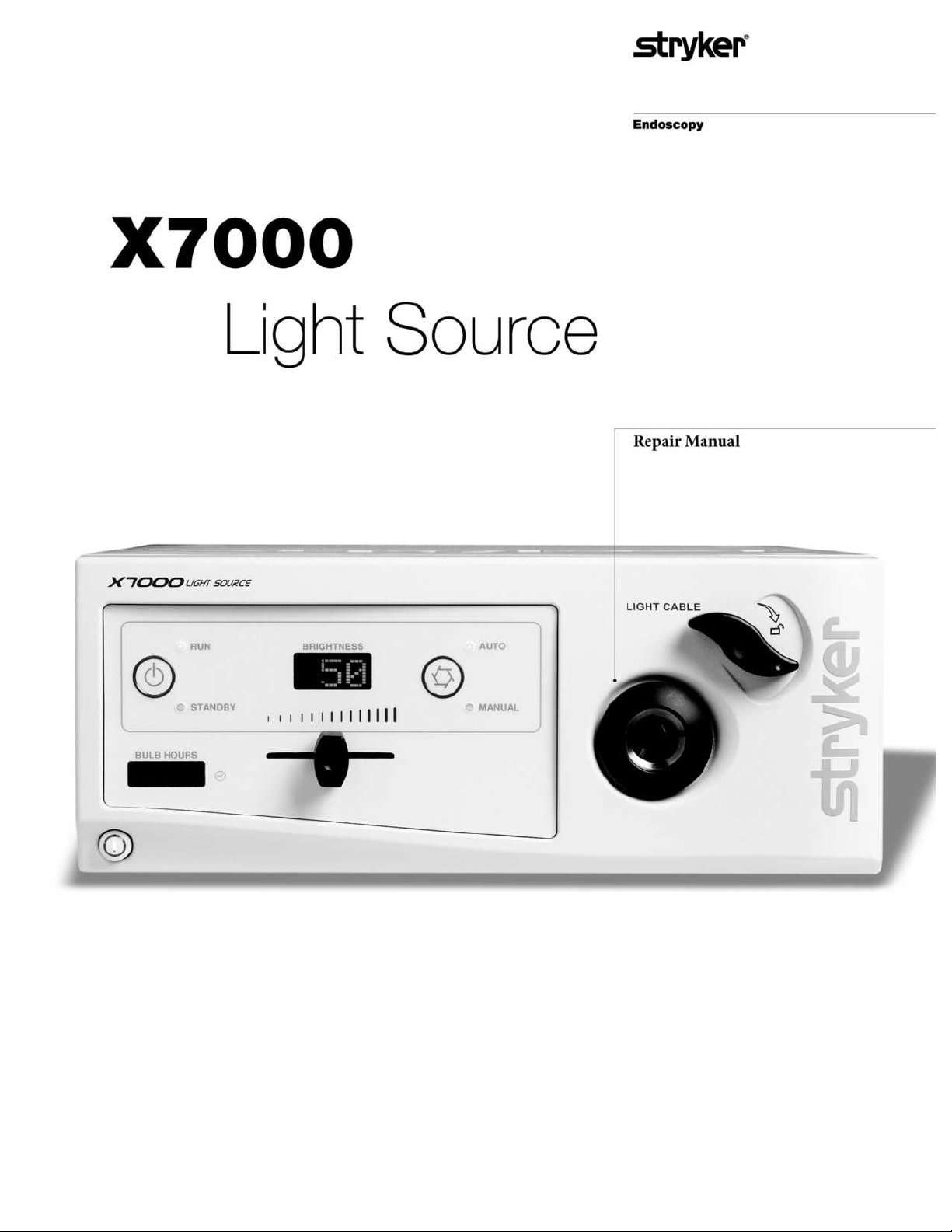

Page 1

Page 2

Warranty

Stryker Endoscopy warrants the X-7000 Light Source

against defects in both materials and workmanship to the

registered owner at the time of purchase. All components

are covered by the warranty for a period of one year from

the date of purchase.

This warranty does not apply to any unit which has been

the subject of misuse, abuse, neglect, improper installation

or operation or that which has been altered, adjusted, or

tampered with by any person other than Stryker Endos-

copy authorized service personnel.

The customer is responsible for returning the defective

equipment to the factory at his or her own expense.

Stryker Endoscopy or its representative will service the

unit, repair or replace any defective parts thereof, and

return the unit.

If, upon examination, it is determined that the fault has

been caused by misuse or abnormal conditions of opera-

tion, the repairs will be billed to the customer in the same

manner as out-of-warranty repairs.

shall Stryker Endoscopy be liable for any breach of war-

ranty in any amount exceeding the purchase price of the

product.

No agent, employee or representative of Stryker Endoscopy

has the authority to bind the Company to any other war-

ranty, affirmation, or representation concerning this

instrument.

This warranty is valid only to the original purchaser of

Stryker Endoscopy products directly from Stryker Endos-

copy or from a Stryker Endoscopy authorized agent. The

warranty cannot be transferred or assigned by the original

purchaser.

The X-7000 Light Source warranty is void if any WARN-

INGS, CAUTIONS, or NOTES are disregarded.

All Stryker products are warranted against defects in mate-

rials and workmanship.

Products repaired by Stryker Endoscopy will be issued a 30

day repair warranty against defects in both materials and

workmanship, provided the original warranty period has

expired. This warranty applies only to products that have

been repaired by Stryker. Instruments submitted due to

defects in materials and workmanship during the warranty

period will be repaired at no charge to the customer.

The warranty as set forth herein is exclusive and in lieu of

all other warranties, remedies, obligations, and liabilities of

Stryker Endoscopy Inc., expressed or implied, including

the implied warranties of merchantability and fitness for

use and of consequential damages. These products are

being sold only for the purpose described herein, and such

warranty only runs to the original purchaser. In no event

© Stryker and Stryker Endoscopy are registered trade-

marks of Stryker Corporation.

Page 3

Table of Contents

1.0 INTRODUCTION

1.1 Scope.........................................................................................................................................................................................1

1.2 Responsibility...........................................................................................................................................................................1

1.3 Upgrades...................................................................................................................................................................................1

1.4 Equipment Overview...............................................................................................................................................................1

1.5 Service Options........................................................................................................................................................................1

1.6 Maintenance Precautions........................................................................................................................................................1

1.7 Factory Service Instructions...................................................................................................................................................2

1.8 Required Equipment...............................................................................................................................................................2

1.9 Required Skills.........................................................................................................................................................................2

1.10 Required Replacement Components..................................................................................................................................2

2.0 DIAGNOSTICS AND CORRECTIVE MAINTENANCE

2.1 General Recommendations....................................................................................................................................................3

2.2 Power Requirements...............................................................................................................................................................3

2.3 Ambient Requirements...........................................................................................................................................................3

2.4 Connections and Wiring.........................................................................................................................................................3

2.5 Verify Operation......................................................................................................................................................................3

3.0 REPAIR CHECKLIST AND MATRIX

3.1 Diagnostic Analysis Checklist................................................................................................................................................5

3.2 Repair Matrix ..........................................................................................................................................................................6

4.0 COMPONENT REMOVAL AND REPAIR

4.1 Component Replacement Instructions.................................................................................................................................7

4.1.1 Component Removal Table.................................................................................................................................7

4.1.2 Individual Replacement Instructions.................................................................................................................8

4.2 Console Cover Removal ..........................................................................................................................................................8

4.3 Power Source Components...................................................................................................................................................9

4.3.1 Control Board Replacement...............................................................................................................................9

4.3.2 Lamp Ballast Replacement.................................................................................................................................10

4.3.3 AC Inlet Board Replacement.............................................................................................................................11

4.3.4 Ballast Fan Replacement....................................................................................................................................12

4.4 Light Source Components....................................................................................................................................................12

4.4.1 Bulb Fan Replacement........................................................................................................................................12

4.4.2 Bulb Board Replacement...................................................................................................................................13

4.4.3 Shutter Replacement..........................................................................................................................................13

4.4.4 Hot Mirror Replacement...................................................................................................................................13

4.4.5 Motor Mount Replacement..............................................................................................................................14

4.4.6.1 Motor Replacement.........................................................................................................................................15

4.4.6.2 Integrating Rod Replacement........................................................................................................................15

Page 4

4.5 Front Panel Components......................................................................................................................................................16

4.5.1 Jaw Handle Replacement...................................................................................................................................16

4.5.2 Potentiometer Knob Replacement....................................................................................................................16

4.5.3 Front Panel Replacement...................................................................................................................................17

4.5.4 Jaw Assembly Replacement...............................................................................................................................17

4.5.5 Power Switch Replacement................................................................................................................................18

4.5.6 Display Board Replacement..............................................................................................................................18

4.6 Fuse Replacement..................................................................................................................................................................19

4.6.1 Rear Panel Fuses..................................................................................................................................................19

5.0 ELECTRONIC PROCEDURES

5.1 Required Skills.......................................................................................................................................................................20

5.2 Alignment and Calibration..................................................................................................................................................20

6.0 FINAL ASSEMBLY AND TESTING

6.1 Required Skills.......................................................................................................................................................................21

6.2 Assembly.................................................................................................................................................................................21

6.3 Electrical Current Leakage Test...........................................................................................................................................21

6.4 Hi-Pot Test..............................................................................................................................................................................22

7.0 APPENDIX

7.1 Assembly Diagram................................................................................................................................................................23

7.2 Parts Listing............................................................................................................................................................................23

7.3 Reference Documents...........................................................................................................................................................23

8.0 WARRANTY

..................................................................................................................................................................................................................24

9.0 SERVICE

..................................................................................................................................................................................................................24

10.0 OTHER SERVICE

..................................................................................................................................................................................................................25

Page 5

1.0 Introduction

1.1 SCOPE

This manual is intended to be used as a reference guide for

electronics technicians and the Stryker Repair Team in the

analysis and repair procedures for the X-7000 Light

Source. It is meant to be used in conjuction with the

Stryker X-7000 Universal Light Source Operating and

Maintenance Manual (Stryker P/N 1000-400-651) and

does not replace existing documentation.

Stryker Endoscopy maintains a complete repair depart-

ment for the sole purpose of providing efficient and reli-

able service.

1.2 RESPONSIBILITY

Stryker Endoscopy accepts full responsibility for the effects

on safety, reliability, and performance of the equipment

only if readjustments, modifications and repairs have been

carried out exclusively by a person specifically authorized

by Stryker Endoscopy to do so.

In no event shall Stryker Endoscopy be liable for incidental

or consequential damages in connection with or arising

from the performance or use of its products after unautho-

rized modification or repair performed by individuals

other than Stryker Endoscopy perosnnel.

1.3 UPGRADES

The Stryker Endoscopy X-7000 Light Source is a high per-

formance device designed for use with Stryker Endoscopy

medical video cameras to provide outstanding illumina-

tion of the surgical site across all endoscopic applications.

With the proper light cable and adapters, it can be con-

nected to any flexible or rigid endoscope. Stryker Endos-

copy reserves the right to incorporate improvements

without notice. However, updated parts will be fully inter-

changeable with older versions and will offer at least the

same level of quality and performance.

tive for up-to-date information on available options and

upgrades to equipment as well as updates to this manual.

1.4 EQUIPMENT OVERVIEW

The Stryker Endoscopy X-7000 Light Source consists of

the light source, power cord, and Operation and Mainte-

nance Manual. Replacement or spare lamps can be pur-

chased separately.

1.5 SERVICE OPTIONS

The user is advised to return a malfunctioning unit to

Stryker Endoscopy for repair or replacement, where spe-

cialized equipment and technicians are available to per-

form repairs while maintaining full product quality and

safety.

In the event that the user decides to undertake repair pro-

cedures, Stryker Endoscopy recommends that these be car-

ried out only by qualified technicians with proper test

equipment listed in this manual, so that the safety of oper-

ators and patients may not be compromised.

1.6 MAINTENANCE PRECAUTIONS

WARNING: The incorrect use of any of the required tools

and techniques may risk damage to the

equipment or injury to the person carrying

out the procedure, subsequent operators, or

patient. Repairs should be made ONLY by

those that have been specificallytrained in

the use of all pertinent equipment andtech-

niques. Stryker Endoscopy cannot continue

to guarantee compliance to UL, CSA, TUV,

or other labeled safety standards if service is

performed by anyone other than Stryker

Endoscopy Personnel.

Stryker Endoscopy will inform customers of significant

upgrades to the product. Contact your Stryker representa-

1

Page 6

1.7 FACTORY SERVICE INSTRUCTIONS

1.9 REQUIRED SKILLS

If service is needed either during or after the warranty

period:

Contact Stryker Endoscopy at 1-800-624-4422 or contact

your local Stryker Endoscopy sales representative. If

needed, a loaner unit may be requested during the time of

your unit repair.

Package the X-7000 carefully in the original shipping container, if possible.

Ship the Stryker Endoscopy X-7000 Light Source, prepaid

and insured, to:

Stryker Endoscopy Customer Service

Attention: Repair Department

5900 Optical Court

San Jose, CA 95138

1.8 REQUIRED EQUIPMENT

Most of the procedures described in this manual require

the following basic tool kit:

Each diagnostic and repair procedure described in this

manual requires a technician qualified by training or experience in the following areas:

•Basic electronics techniques

•Multimeter operation

1.10 REQUIRED REPLACEMENT COMPONENTS

If a repair procedure necessitates replacements parts,

please refer to the Appendix (page 22).

• Small flat blade screwdriver

• Medium Philips screwdriver

• 8” adjustable wrench

• Needlenose pliers

• Small wire cutting pliers

• Wire stripper

• Soldering iron and solder

•Multimeter

• Stryker medical video camera

•Stryker Scope

•Fiber optic cable

• Glass fuse puller

•Shorting clip

• Bio Tek Model 170 Analyzer or equivalent current

leakage tester

• Nut drivers 11/32” and 5/16”

• Open end wrenches 7/16” and 1/2”

• Set of standard allen wrenches / hex keys

•Hi-Pot Tester

2

Page 7

2.0 Diagnostic and Corrective Maintenance

2.1 GENERAL RECOMMENDATIONS

The Stryker Endoscopy Model X-7000 Light Source is a

precision instrument which has been engineered and man-

ufactured with great care to ensure the safety of operators

and patients. In order to maintain the high level of safety

and reliability required of the X-7000, it is important to

fully understand and comply with all required procedures

set out herein.

If some part of a procedure is omitted or adequate equip-

ment is not used, the safety and performance of the device

may be unknowingly compromised. It is strongly recom-

mended that if any element in these procedures is beyond

the scope of the technician’s training, refer to section 1.7

for information on obtaining fully qualified professional

service at Stryker Endoscopy.

WA R N I N G : As is the case with all AC powered devices,

dangerous voltages are present. If adequate

safety precautions are not taken, results may

include damage to the equipment, injury, or

death. It is imperative that these procedures

be approached only by trained technicians

with proper equipment after fully reading

and understanding the steps involved.

2.2 POWER REQUIREMENTS

• There is one AC power cord for the X-7000 Light Source.

A separate AC power cord is normally required for any

other instrument being used.

• Each instrument is clearly marked for power require-

ments at the AC power cord connection.

• Testing the outlet for proper grounding and polarity is

highly recommended prior to connecting the X-7000

Light Source. If available, a ground-fault-interrupt type

outlet will provide an additional level of safety.

NOTE: A proper electrical installation procedure will

ensure that all associated signal cabling is cor-

rectly installed prior to applying AC power to the

system.

2.3 AMBIENT REQUIREMENTS

Ensure that:

• The distance between the X-7000 Light Source and the

associated devices does not exceed the available cable

length.

• Controls will be easily accessible to operator.

• Ventilation is not obstructed around the unit. Avoid

locations with excessive heat or temperature fluctua-

tions, such as direct sunlight.

2.4 CONNECTIONS AND WIRING

Please refer to the procedures detailed in the X-7000 Uni-

versal Light Source Operating and Maintenance Manual

(Stryker P/N #1000-400-651).

2.5 VERIFY OPERATION

After ensuring that both power and signal connections

have been correctly made, place the power switch in each

unit to the “ON” position. Check that an image is present

on the monitor.

3

Page 8

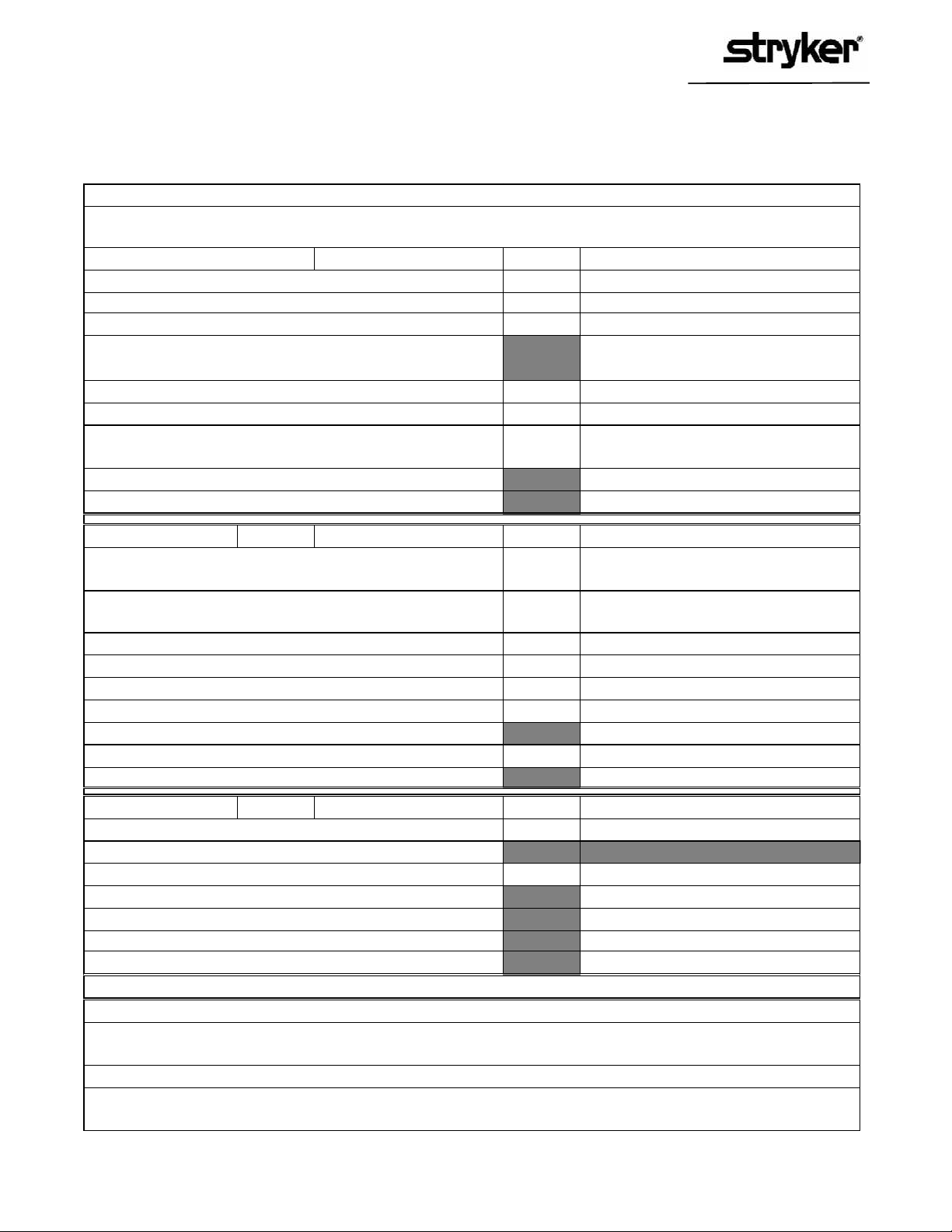

3.0 Repair Checklist and Matrix

3.1 INITIAL REPAIR CHECKLIST

The following page is intended for use by qualified Stryker

personnel only. Complete a copy of the checklist and file it

in the DHR.

3.2 REPAIR MATRIX #1

3.3 REPAIR MATRIX #2

The Repair Matrices are intended for use by qualified

Stryker personnel only, in conjuction with section 4.0

(Component Removal and Repair). See page 6 and 7 for

Repair Matrices.

4

Page 9

5900 Optical Court

San Jose, CA 95138

t: 408 754 2000 f: 408 754 2505

www .stryker.com

DIAGNOSTIC ANALYSIS CHECKLIST CHECK DATE: _______________NAME: _____________________

SERIAL #: ___________________

Endoscopy

What is the customer complaint?

General Assembly Check Points Yes/No Details

Is there any visual damage on the unit?

Are the door switches plastic or metal?

Are there screws on the door switches?

What is the Rev of the control board? (R ev. stamped on

control board)

Does the front display board backlight turn on when the device

Does warm message appear when the unit is powered on?

Does the unit turn on the front panel LEDs as expected after

message?

warm

What is the software version number?

How many hours are there on the bulb?

System Checks Yes/No Details

Does the unit have D53 and D54 chips? (Rev. F and prior

versions only)

Does the unit turn on the bulb when the interlocks are closed?

(door and light cable)

Does the unit show the brightness properly?

Does the unit switch between run/standby?

Does the unit switch between auto/manual?

When the cable is pulled out, does the bulb turn OFF?

If not, record the voltage between TP20 and GND.

Cable in: Cable out:

When the door is opened, does the bulb turn OFF?

If not, record the voltage between TP23 and GND.

Door open: Door closed:

Failure Diagnostics Yes/No Details

Is power button flashing when powered on?

Disconnect the ballast from the control board and

connect the jumper cable, Does the bulb turn ON?

If the bulb does not turn on,

Measure the boost voltage.

Measure the 5-V line voltage on the jumper.

Measure the 12-V line voltage on the jumper.

Boost voltage =

5-V line value =

12-V line value =

Other Observations:

Staff Recommendation:

Page 10

3.2 REPAIR MATRIX

Use the following matrix to identify failure and repair codes. Refer to section 4.0 for repair instructions.

REPAIR CODES

NLB

NCB

NLL

NMO

NPB

BBR

IRR

NSW

NFU

NFG

NSH

EPR

NDB

NJW

EBF

CHR

NC1

BUR

BAR

RCR

DFR

Replace Balla st

Replace Control Board

Replace Bulb Assem bly

Replace Motor

Replace AC Inlet Board

Replace Bulb Board

Replace Integrating Rod

Replace Power Switch

Replace Fuse

Replace Hot Mirror

Replace Shutter

Replace Eprom / Upgrade

Software (in-house)

Replace Display Board

Replace Jaw Assembly

Replace Ethernet Board

Replace Chassis

Replace Cover

Replace Bulb Fan

Replace Balla st Fan

Replace Ribbon Cable

Error Code Failures

E1F E-1 231

E2F E-2 3 1 4 2

E3F E-3 2 1

E5F E-5 4 3 2 1

E6F E-6 12

Power Failures

PSF Power Switch Fa ilure 4 3 2 1

LPF No Power 2 3 4 1

FBF Flashing Power Button 2 1 3

BUF "Bulb" in Bulb Hours 1 2 3

PFF Power only to Front Panel 1 2 3 4

Light Output Failure

NLF No Light Output 3 4 1 5 6 2

SBY Unit won't e xit Standb y Mode 4 2 3 6 7 1 5 8

LLF Low Light Output 5 1 4 3 2

BHF Bulb Hours not Displayed 3 1 2 4

DCF Delayed Ignition, Clicking 2 3 1

DPF Delayed Ignition, Popping 1 3 2

STR Strobing Light 321 54 6

LOF Light Stays On 2 3 1

Input/Output Ports

PSF Permanent Sidne Failure 1 2

ISF Intermittent Sidne Failure 2 1

ECF Ethernet Communication Failure 2 1

VIF Vide o Failure 1

Board/Component Failures

CBF Control Board Failure 1

FAILURE CODES

LBF Ballast Failure 1

DBF Display Board Failure 1

BJW Jaw Assembly Failure 1

BAF Bulb Assembly Failure 1

BBF Bulb Board Failure 1

EBR Ethe rnet B oar d F ailure 1

PBF AC Inlet Board Failure 1

FMO Motor Failure 1

IRF Integrating Rod Failure 1

BFG Hot Mirror Failure 1

BSH Shutter Failure 1

PSF Power Switch Fa ilure 1

BSP Slide Pot Knob Fa ilure 1

BHD Jaw Handle Failure 1

EPF Eprom Failure 1

FUF Fuse Failure 1

RBF Ribbon Cable Failue 1

FNF Fan Failure 12

Cosmetics

CHF Damaged Chassis 1

COF Damaged Cover 1

DFF Damaged/Missing Feet 1

FPF Damaged Front Panel 1

Replace Feet

NSP

NHL

NFP

Replace Slide Pot Knob

Replace Jaw Handle

Replace Front Panel

6

Page 11

4.0 Component Removal and Repair

4.1 COMPONENT REPLACEMENT INSTRUCTIONS

Required skills:

Basic electronics techniques.

WA R N I N G : The incorrect use of any of the required tools

and techniques may risk damage to the

equipment or injury to the person carrying

out the procedure, subsequent operators, or

patient. Repairs should be made ONLY by

those that have been specifically trained in

the use of all pertinent equipment andtech-

niques.

The following instructions apply to the removal of compo-

nents from the X-7000. To remove a component for

replacement or repair will require the removal of certain

other components. Components must be removed in the

order listed in the following procedures.

The table in section 4.1.1 shows the order in which compo-

nents must be removed according to the basic physical

assembly of the X-7000. To remove a component for

replacement, or repair, begin with section 4.2 and proceed

accordingly to the appropriate section.

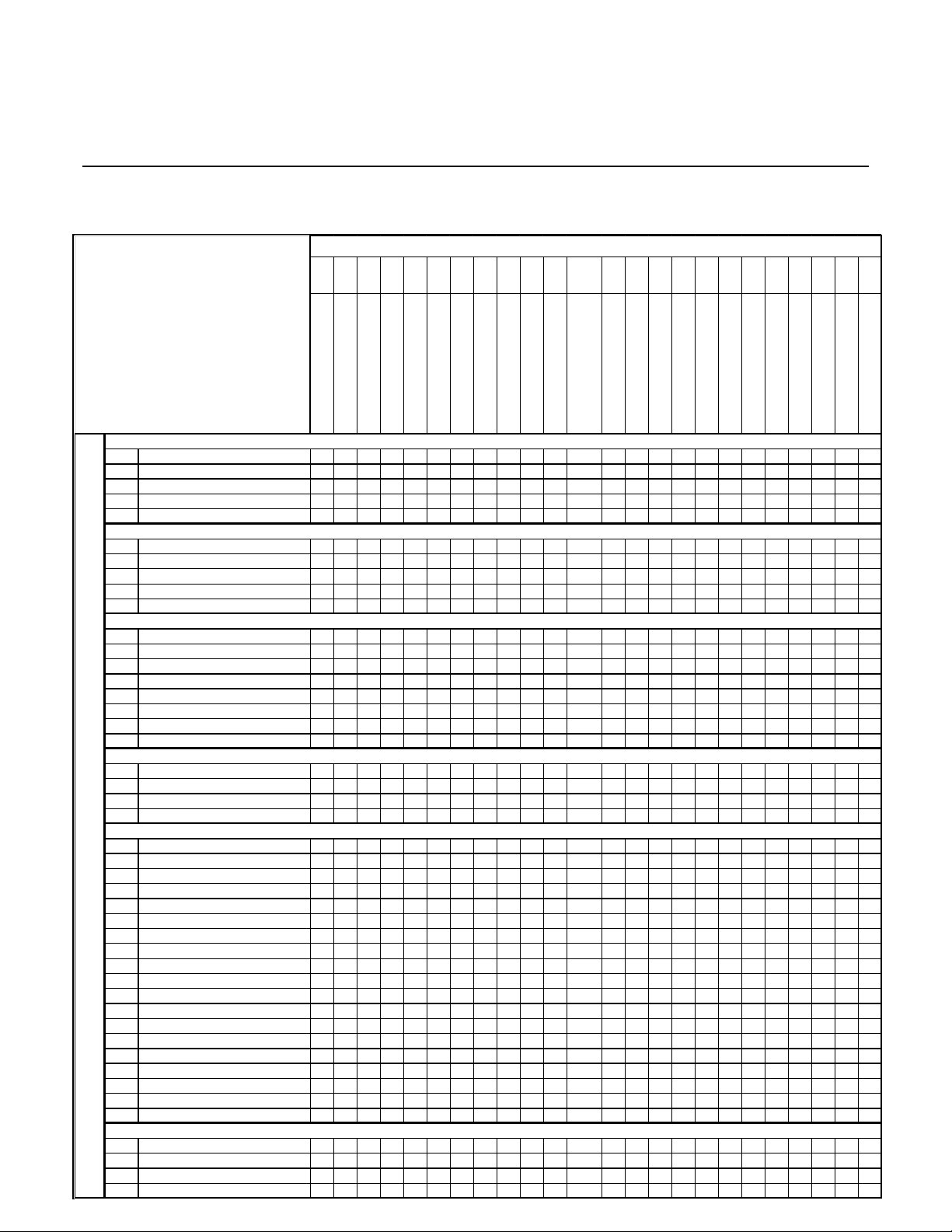

4.1.1 Component Removal Table

NOTE: All components in previous columns must be

removed before removing a component.

12 3 4 5

Control

Board

Bulb,

Bulb Fan

Slide

Button,

Jaw Knob

Ballast AC Inlet

Board

Ballast

Fan

Bulb

Board

Shutter Hot

Mirror

Front

Panel

Power

Switch

Display

Board

Motor

Mount

Assembly

Motor

Integrating Rod

Jaw

Assembly

7

Page 12

4.1.2 Individual Replacement Instructions

4.2 CONSOLE COVER REMOVAL

NOTE: Before removing any component in the X-7000,

the Console Cover must be removed (refer to sec-

tion 4.2).

To remove and repair any of the following components,

proceed to section 4.3 (Power Source Components):

• Control Board (4.3.1)

• Lamp Ballast (4.3.2)

• AC Inlet Board (4.3.3)

• Ballast Fan (4.3.4)

To remove and repair any of the following components,

proceed to section 4.4 (Light Source Components):

• Bulb (4.4.1)

• Bulb Fan (4.4.2)

• Shutter (4.4.3)

• Hot Mirror (4.4.4)

• Motor Mount (4.4.5)

• Motor (4.4.6.1)

• Integrating Rod (4.4.6.2)

Tools Required:

Basic Tool Kit

• Remove power cord.

• On the back of the unit, remove the two screws attaching

the console to the unit.

• Open the lamp door latch on the side of the unit and

open the door.

• Slide the cover back, then lift off.

To remove and repair any of the following components,

proceed to section 4.5 (Front Panel Components):

• Jaw Handle (4.5.1)

• Potentiometer Knob (4.5.2)

• Front Panel (4.5.3)

• Jaw Assembly (4.5.4)

• Power Switch (4.5.5)

• Display Board (4.5.6)

To remove and repair any of the following components,

proceed to section 4.6 (Rear Board Components):

• Fuses (4.6.1)

8

Page 13

4.3 POWER SOURCE COMPONENTS

4.3.1 Control Board Replacement

Tools Required:

Basic Tool Kit

• Remove power cord and console cover (procedure 4.2).

• Disconnect connectors and attached wires.

• Remove the 5 screws attaching the control board to the

ballast.

• Unscrew the nut and washer on the BNC connector.

• Remove the old control board.

• Install a new control board with 4 screws.

• Reattach the connectors to their original locations,

including attaching the ground for the ribbon cable with

the 5th screw.

• Screw washer and nut onto BNC.

• Perform calibration (procedure 5.2).

• Reinstall the console cover.

• Perform Electrical Current Leakage Test (procedure

6.3).

9

Page 14

4.3.2 Lamp Ballast Replacement

Tools Required:

Basic Tool Kit

• Remove power cord and console cover (procedure

4.2).

• Remove the control board (procedure 4.3.1).

• Label and disconnect the three power input cables

located at the rear of the ballast.

• Remove the bulb holder assembly.

• Using the X-Long Magnetic Phillips screwdriver, remove

the 4 screws attaching the lamp ballast to the chassis.

• Replace the lamp ballast assembly.

• Install new ballast assembly using an X-Long Magnetic

Phillips screwdriver.

• Reconnect all cables previously disconnected.

• Reattach the control board to the chassis.

• Reinstall the console cover.

• Perform Electrical Current Leakage Test (procedure 6.3).

• Perform Hi-Pot test (procedure 6.4).

10

Page 15

4.3.3 AC Inlet Board Replacement

Tools Required:

Basic Tool Kit

• Remove power cord and console cover (procedure

4.2).

• Remove the control board (procedure 4.3.1).

• Remove the lamp ballast (procedure 4.3.2).

• Remove the 2 bolts from the 2 nuts.

• Remove the 1-2 screws from the AC inlet board (number

of screws varies by revision).

• Remove the wiring harness from the J2 connector.

11

Page 16

4.3.4 Ballast Fan Replacement

4.4 LIGHT SOURCE COMPONENTS

Tools Required:

Basic Tool Kit

NOTE: BOTH fans must be replaced if one fan malfunc-

tions.

• Remove power cord and console cover (procedure

4.2).

• Remove the black ribbon cable.

• Remove the fan wire harness assembly.

• Note the fan orientation.

• Remove the 2 nuts attaching the fan to the Chassis and

remove the sub-assembly.

• Remove the 4 screws from the fan mounts.

4.4.1 Bulb Fan Replacement

Tools Required:

Basic Tool Kit

NOTE: BOTH fans must be replaced if one fan malfunc-

tions.

• Remove power cord and console cover (procedure

4.2).

• Remove the bulb module.

• Detach the wire harness from the control board.

• Remove the 2 nuts attaching the bulb fan housing assem-

bly to the chassis.

• Note the fan orientation.

• Remove the malfunctioning fan(s) and replace. Ensure

the correct orientation.

• Reinstall the 2 fan mounts with the 4 screws.

• Reinstall the 2 nuts.

• Reinstall the black ribbon cable, fan wire harness assem-

bly, and console cover.

• Perform Electrical Current Leakage Test (procedure 6.3).

• Remove the 4 nuts attaching the bulb fan to the fan

mounts/fan ducts.

• Reinstall the new fan onto the mounts/duct with 4 bolts,

ensuring the correct orientation.

• Reinstall the fan assembly onto the chassis with 2 nuts.

• Reconnect the wire harness.

• Replace the bulb module and cover.

12

Page 17

4.4.2 Bulb Board Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the bulb.

• Remove the bulb fan (procedure 4.4.1).

• Remove the 2 wire harnesses.

• Remove the bulb board and replace.

• Reinstall the 2 wire harnesses, bulb fan, bulb, and cover.

4.4.4 Hot Mirror Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the bulb (procedure 4.4.1).

• Remove the shutter (procedure 4.4.3).

• Remove the 2 Allen screws.

4.4.3 Shutter Replacement

• Remove the power cord and console cover (procedure

4.2).

• Remove the bulb (procedure 4.4.1).

• Remove the Allen screw from the shutter shaft.

• Remove the shutter and replace.

• Reinsert the Allen screw.

• Replace the bulb and cover.

• Remove the hot mirror mount and replace.

• Reinsert the 2 Allen screws.

• Replace the shutter, bulb, and cover.

13

Page 18

4.4.5 Motor Mount Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the bulb (procedure 4.4.1).

• Remove the hot mirror (procedure 4.4.4).

• Remove the 2 Phillips screws from beneath the hot mir-

ror.

• Remove the 2 nuts.

• Remove the motor wire harness from the control board.

• Remove the motor mount assembly with the motor

attached, and replace.

• Replace the wire harness.

• Reinsert the 2 nuts and 2 Phillips screws beneath the hot

mirror.

• Replace the hot mirror, bulb, and cover.

14

Page 19

4.4.6.1 Motor Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the motor mount (procedure 4.4.5).

• Remove the 4 Allen screws.

• Remove the motor and replace.

• Reinsert the 4 Allen screws.

• Replace the motor mount and cover.

4.4.6.2 Integrating Rod Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the motor mount (procedure 4.4.5).

• Remove the 2 screws and the cover.

• Slide the integrating rod out.

• Swab the rod holder with alcohol.

• Insert new integrating rod.

• Reinsert the 2 screws.

• Replace the cover and motor mount.

15

Page 20

4.5 FRONT PANEL COMPONENTS

4.5.2 Potentiometer Knob Replacement

4.5.1 Jaw Handle Replacement

• Remove power cord.

• Remove the set screw from the bottom of the jaw handle.

• Remove the jaw handle from the actuator shaft.

• Ensure that the jaw handle key (P/N 105-186-472) stays

in place on the actuator shaft.

• Replace the jaw handle onto the actuator shaft.

• Secure the jaw handle in place using the set screw.

• Reinsert the set screw and reinstall the cover.

• Remove power cord.

• If potentiometer knob is damaged or detaches from the

front panel, but the protruding metal tab is still con-

nected, perform the following repair steps:

• Remove the set screw from the bottom of the potentiom-

eter knob.

• Remove the knob from the slide pot of the front panel.

• Loosely screw the set screw into the bottom of the poten-

tiometer knob.

• With the screw hole facing down, insert the potentiome-

ter knob onto the slide pot.

• Secure the knob in place by screwing in the set screw.

• If the potentiometer knob is damaged or detaches from

the front panel, and the protruding metal tab is also

damaged or disconnected, replace the display board and

potentiometer knob.

16

Page 21

4.5.3 Front Panel Replacement

• Replace all removed components.

• Remove power cord and console cover (procedure 4.2).

• Remove the jaw knob and potentiometer knob (proce-

dures 4.5.1 and 4.5.2,).

CAUTION: DO NOT DAMAGE THE JAW INT ERLOCK

CABLE WHEN REMOVING THE FRONT

PAN EL .

• Disconnect the ribbon cable from the inside of the front

panel.

• Disengage the six tabs which hold the front panel onto

the chassis.

• Remove the jaw interlock cable from the display board.

• Remove the display board (procedure 4.5.6).

4.5.4 Jaw Assembly Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the front panel (procedure 4.5.3).

• Remove the motor mount (procedure 4.4.5).

• Remove the ESST wire harness from the display board.

• Remove the 4 Phillips screws.

• Remove the jaw assembly and replace.

• Reinsert the 4 Phillips screws.

• Replace the ESST wire harness, motor mount, front

panel, and cover.

• Remove the power switch (procedure 4.5.4).

• Remove the ESST ring.

• Remove the front panel and replace with new panel.

17

Page 22

4.5.5 Power Switch Replacement

4.5.6 Display Board Replacement

• Remove power cord and console cover (procedure 4.2).

• Remove the jaw knob and potentiometer

knob (procedures 4.5.1 and 4.5.2).

• Remove the front panel (procedure 4.5.3).

• Cut the zip tie over the cables.

• Disconnect wire harness from display board.

• Push in the two snap clips and push out the switch from

inside the console.

• Remove the LED and verify its operation.

• Replace the LED if necessary, inserting it to full depth

with the appropriate Allen wrench.

• Insert a new power switch.

• Remove power cord and console cover (procedure 4.2).

• Remove the front panel (procedure 4.5.3).

• Detach the flex cable from the display board (J1).

• Unclip the 6 front panel clips from the chassis.

• Remove the ESST ring cable from the display board.

• Remove the ribbon cable from the display board.

• Remove the power switch wire harness from the display

board.

• Remove the display board from the front panel clips.

• Replace the display board.

• Push the board onto the front panel clips.

• Reconnect the wire harness.

• Replace the zip tie, front panel, and console cover.

• Perform Electrical Current Leakage Test (procedure 6.3).

• Reattach the power switch wire harness.

• Reattach the ESST ring wire harness.

• Reattach the front panel ribbon cable.

• Reinsert the front panel onto the chassis.

• Reattach the jaw handle and potentiometer knob (proce-

dures 4.5.1 and 4.5.2).

• Reinstall the console cover.

• Perform Electrical Current Leakage Test (procedure 6.3).

18

Page 23

4.6 FUSE REPLACEMENT

4.6.1 Rear Panel Fuse Replacement

Too l s Re qu i re d :

Basic Tool Kit

• Remove power cord.

• Locate the fuse holder below the power cord inlet (see

Figure 1).

• Release the fuse holder clamps with a flat head screw

driver and remove the fuse holder with 2 attached fuses.

• Wipe the metallic ends of the new fuse(s) with a clean

tissue to remove any residue from fingers..

• Remove the old fuse(s) and install a new 5a fuse in the

fuse holder.

• Replace the fuse holder with 2 attached fuses.

• Reattach the fuse holder clamps.

19

Page 24

5.0 Electrical Procedures

5.1 REQUIRED SKILLS

• Basic electronics techniques.

• Experience in the operation of an oscilloscope.

WA R N I N G : The incorrect use of any of the required tools

and techniques may risk damage to the

equipment or injury to the person carrying

out the procedure, subsequent operators, or

patient. Repairs should be made ONLY by

those that have been specifically trained in

the use of all pertinent and techniques.

5.2 ALIGNMENT AND CALIBRATION

1. Align and calibrate the unit per the instructions in MAP

0337.

2. If the lamp ballast or the control board were replaced,

then perform a burn-in and hot strike, per the instruc-

tions in MAP 0337.

20

Page 25

6.0 Final Assembly and Testing

6.1 REQUIRED SKILLS

• Basic electronics techniques

• Experience in the operation of a Current Leakage Tester.

6.2 ASSEMBLY

• Reinstall all pertinent components.

• Verify that all connectors are firmly attached to their

proper locations.

• Ensure that there are no unattached or unsoldered leads.

• Check all physical mounting screws and nuts for tight-

ness.

• Install console cover.

• Apply power and check for proper operation.

• If unit is still malfunctioning after following this man-

ual’s instructions, follow procedure 1.7 to obtain factory

service at Stryker Endoscopy.

• If the unit appears to be operating correctly, proceed to

procedure 6.3.

• Disconnect the X-7000 power cord from the power

source.

• Disconnect the video cables from the console.

• Connect the X-7000 power cord to the power receptacle

on the safety analyzer front panel.

• Clip the safety analyzer test load to the X-7000 console

ground post.

• Set the main power switch on the X-7000 to “ON” and

plug in the light cable.

• Set the main power switch on the safety analyzer to the

“CHASSIS LEAKAGE µA” position.

• Read the leakage current in the following positions:

NORMAL POLARITY - NORMAL GROUND

NORMAL POLARITY - OPEN GROUND

REVERSE POLARITY - OPEN GROUND

REVERSE POLARITY - NORMAL GROUND

• If any leakage reading is over 500µA, send the unit to

Stryker Endoscopy for repair (refer to procedure 1.6 to

obtain factory service at Stryker Endoscopy).

6.3 ELECTRICAL CURRENT LEAKAGE TEST

Required Equipment:

Bio-Tek Current Leakage Tester

• ALWAYS perform this test after working on the unit and

prior to returning it to operation.

• Maximum leakage specification is 500µA for “open

ground” or single-fault condition.

• Set the X-7000 power and the safety analyzer power to

“OFF.”

• Disconnect the safety analyzer from the X-7000.

• This completes the repair procedure

21

Page 26

6.4 HI-POT TEST

• Energize the Hi-Pot tester and adjust the voltage by turn-

ing the adjusting knob until the meter reads 1.8KV.

• Ensure the Hi-Pot tester is operating properly by touch-

ing the positive and negative test leads and listening for

the sound emitted.

• If no sound is emitted, turn the equipment in for repair.

• If sound is emitted, reset the unit before proceeding.

• Connect an alligator clip to the neutral and positive ter-

minals of the power plug.

• Turn on the standby and power switches.

WARNING: HIGH VOLTAGE!

• Touch the positive test lead (red probe) to the alligator

clip and the negative lead (black probe) to the ground

post.

• Hold the leads there for one second. If sound is emitted

from the Hi-Pot tester, reject the unit.

22

Page 27

7.0 Appendix

7.1 ASSEMBLY DIAGRAM

7.2 PARTS LISTING

A 105-199-584 ASSY, X-7000 BOTTOM TRAY

B 105-199-581 ASSY, X-7000 ELLIPTICAL BULB MODULE

C 105-199-678 ASSY, COVER, X-7000

D 105-193-198 SCREW, 6-32 X 0.25 PH EXT. SEMS

7.3 REFERENCE DOCUMENTS

• MAP 0337

NOTE: NONE OF THE IN-HOUSE MAPs (Manufac-

turing Assembly Procedures), QIPs (Quality

Inspection Procedures), SPECIALTY TOOLS,

JIGS, OR FIXTURES LISTED IN THIS MAN-

UAL ARE AVAILABLE FOR PURCHASE.

23

Page 28

8.0 Warranty

This Stryker Endoscopy product is warranted to the original purchaser to be free from defects in material and workmanship for

the following times:

• One year following the date of delivery and an additional 30 days following repair

This warranty extends to all purchases and is limited to the repair or replacement of the product without charge when returned

in the original shipping case to:

Stryker Endoscopy

5900 Optical Court

San Jose, CA 95138

Stryker Endoscopy cannot accept responsibility for returns or replacements which have not been authorized. This warranty

does not cover damages caused by misuse or by failure to follow the procedures outlined in this manual or demonstrated by

Stryker Endoscopy representatives.

There are no other expressed warranties.

9.0 Service

The user is advised to return a malfunctioning unit to Stryker Endoscopy for repair or replacement, where specialized equip-

ment and technicians are available to perform repairs while maintaining full product quality and safety.

In the event that the user decides to undertake repair procedures, Stryker Endoscopy recommends that these be carried out

only by qualified technicians with proper test equipment listed in this manual, so that the safety of operators and patients may

not be compromised.

If service is needed either during or after the warranty period:

1. Contact Stryker Endoscopy at 1-800-624-4422, or call your local Stryker Endoscopy sales representative.

2. Clean and sterilize all parts that will be returned for service. Follow the instructions provided in the user manual.

3. Package all the components carefully in the original shipping container if possible.

4. Ship the product pre-paid and insured to:

Stryker Endoscopy Customer Service

Attention: Repair Department

5900 Optical Court

San Jose, CA 95138

The product described in this manual is continually being reviewed, and improvements may be made without notice.

Stryker and Stryker Endoscopy are registered trademarks of Stryker Corporation.

24

Page 29

10.0 Other Service

For service in the U.S.A., call your Stryker Endoscopy Representative. Outside of the U.S.A., please contact your Stryker

Endoscopy distributor at one of the following locations:

Stryker Corporation

2725 Fairfield Road

Kalamazoo, MI 49002

USA

Phone:1-269-385-2600

Telex:224464 STRYKER KMZ

Fax:1-269-385-1996

Stryker Canada

45 Innovation Drive

Hamilton, Ontario, Canada

L9H 7L8

Phone: (905) 690-5700

(800) 668-8323 (toll free)

Fax: +1(905) 690-5698

Stryker Deutschland GmbH

Gewerbeallee 18, D-45478

Mulheim an der Ruhr

GERMANY

Phone:49-208-999-060

Fax:49-208-999-0666

Stryker Latin America

15100 N.W. 67th Ave. Suite 210

Miami, Florida 33014

USA

Phone:1-305-821-1888

Fax:1-305-826-0067

Stryker European Rep - RA/QA Manager

ZAC Satolas Green Pusignan

Av. De Satolas Green

69881 MEYZIEU Cedex, France

Phone:33-1-48175000

Fax:33-1-48632175

Stryker India Private Limited

First Floor

C-5, SDA Commercial Complex

New Delhi 110 017

INDIA

Phone:91-11-686-6740

Fax:91-11-696-6020

Stryker Australia

Unit 58, 2a Herbert St.

St. Leonards NSW 2065

AUSTRA LIA

Phone: 02 9467 1000

Fax: 02 9467 1010

Stryker Singapore PTE/LTD

70 Bendemeer Road

#03-32 Hiap Huat House

SINGAPORE 339940

Phone:65-293-0119

Fax:65-293-7028

Stryker B.V.

Marinus van Meelweg 17

P.O. Box 8747

5657 En Eindhoven

THE NETHERLANDS

Phone:31-40-2922522

Fax:31-40-2922555

Stryker Osteonics, SA

5, Chemin des Aulx 5

1228 Plan-les-Ouates

Case Postale 725

1212 Grand-Lancy 1

Geneve, SWITZERLAND

Phone:41-22-884-0111

Fax:41-22-884-0199

Stryker Pacific Ltd.

Suite 2501, Citibank Tower

Citibank Plaza

3 Garden Road, Central

HONG KONG

Phone:61-2-9415-5100

Fax:61-29-4294127

Stryker Mexico, S.A. de C.V.

Calle Sacramento 410

Col. Insurgentes San Borja

C.P. 03100

Mexico, D.F.

MEXICO

Phone:525-488-0890

Fax:525-488-0891

25

Page 30

Stryker Finland

PL 80 (Makelankatuz)

FIN 00501 Helsinki

FINLAND

Phone:358 (0) 9 7744 680

Fax:358 (0) 9 7744 6820

Stryker Middle East / Africa

Via Della Posta

6934 Bioggio

Switzerland

Phone:(4021) 212-1122

Fax:(4021) 212-1133

Stryker Korea

11F Dong Sung Bldg.

154-24 Samsung-dong

Kangnam-ku

Seoul, KOREA 135-090

Phone:82-2-34517572

Fax:82-2-552-4156

Stryker China Limited

Room 903-905, Office Tower 2

Beijing Sun Dong An Plaza

138 Wang Fu Jing Da Jie

Beijing 100006, P.R. China

Phone:86-10-65136183

Fax:86-10-83913571

Stryker Japan

Dai Tokyo Kasai Shinjuku Bldg.

3-25-3, Yoyogi

Shibuya-ku, Tokyo 151-0053

Phone:813-535-29106

Fax:813-535-21789

Stryker Europe Headquarters

Cite-Centre, Grand Rue 92

CH-1820 Montreux

SWITZERLAND

Phone:41-21-966-1201

Fax:41-21-966-1200

NV Stryker SA (Belgium)

Ikaros Business Park Fase III

Ikaroslaan 12

1930 Zaventem

Brussels, BELGIUM

Phone:32-2-717-92-10

Fax:32-2-717-92-49

Stryker Chile

Avenida Nueva Tajamar 481

Oficina 805 Piso 8 Torre Norte Santiago,

CHILE

Phone:562-244-3600

Fax:562-244-3696

Stryker Spain

Manuel Tovar 35

28034 Madrid

SPAIN

Phone:34-91-7283500

Fax:34-91-3580748

Stryker AB Scandinavia

Krossverksgatan 3

S-216 10 Malmö

SWEDEN

Phone:46 40-69-18-100

Fax:46 40-69-18-190

26

Stryker Taiwan

5F-1,23 Pa Te Road

Section 1, Taipei, TAIWAN, R.O.C.

Phone:886-2-2322-2895

Fax:886-2-2357-8543

Stryker U.K. Ltd.

Hambridge Road

Newbury

Berkshire RG14 5 EG

United Kingdom

Phone:44-1635-262400

Fax:44-1635-262464

Stryker AB Denmark

Sankt Annae Plads 9

1021 Copenhagen, Denmark

Phone:45 33 9360 99

Fax:45 33 9320 69

MANUFACTURER

Stryker Endoscopy Inc.

5900 Optical Court

San Jose, CA 95138

USA

Phone:408-754-2000

Fax:408-754-2505

Page 31

5900 Optical Court

San Jose, CA 95138

408-754-2000

1-800-624-4422

1000-400-755 Rev. A

Loading...

Loading...