Page 1

Vertier™ Surgical Table

Service Manual

February 2010 1004-400-177 REV E www.stryker.com

Page 2

Page 3

Vertier™ Surgical Table

Service Manual

is manual contains con dential information that shall not be disclosed or duplicated for any reason

other than to use and maintain a Stryker Surgical Table. is restriction does not limit the right to use

information contained in this manual, if it is obtained from another source without restriction. e

information subject to this restriction is contained in all pages of this manual.

© February 2010 Stryker Communications. All rights reserved. Information in this document is subject to change without notice. Stryker, and Stryker logo are registered trademarks of Stryker.

All rights reserved.

Stryker Vertier™ Surgical Table Service Manual

1004-400-177 REV E

Page 4

Page 5

Contents

1. Warnings, Cautions, and Notes ...............................................................................................11

1.1 Warnings ............................................................................................................................11

1.2 Cautions .............................................................................................................................13

1.3 Notes ..................................................................................................................................14

1.4 Table Pinch Points ..............................................................................................................15

1.4.1 Pinch Point Zones ..................................................................................................... 16

2. Product Symbol Defi nition ...................................................................................................... 19

2.1 EMC Precautions ................................................................................................................21

3. Indications for Use .................................................................................................................. 23

3.1 Prior to Servicing Tables .....................................................................................................23

3.2 Following any Table Service ...............................................................................................24

3.3 Operating Characteristics ...................................................................................................24

4. Main Components Structure ................................................................................................... 25

4.1 Base and Column Casings .................................................................................................26

4.1.1 Base Cover Removal ................................................................................................27

4.1.2 Column Casings ........................................................................................................29

4.1.3 Bellows Frame Replacement ....................................................................................42

4.1.4 Castor Removal.........................................................................................................47

4.2 Inner Column ......................................................................................................................52

4.2.1 upper Energy Chain Assembly, 50mm (0788-200-038) ............................................52

4.2.2 Upper 50mm Energy Chain Replacement ................................................................54

4.3 Table Top & Sections ..........................................................................................................62

4.3.1 Lever Assembly (0788300067) Replacement/Preventive Maintenance ....................62

4.3.2 Threaded Lever Spring (0788400000) Replacement ................................................63

4.4 Seat Section and Assemblies .............................................................................................63

4.4.1 Center Rail Section ...................................................................................................67

4.4.2 Tilt Frame Assembly ..................................................................................................68

4.4.3 Tilt Frame Lower Parts Assembly (view from underside) ..........................................70

4.4.4 Slide Motor Assembly ...............................................................................................70

4.4.5 Right Sledge Assembly (0788-300-066) ...................................................................87

5

Page 6

4.4.6 Left Sledge Assembly (0788-300-065) ...................................................................... 88

4.4.7 Left Seat Section Tube - One Piece ..........................................................................89

4.4.8 Right Seat Section Tube - One Piece ........................................................................ 93

4.4.9 Left Back Section Cylinder ........................................................................................96

4.4.10 Left Leg Section Cylinder ..........................................................................................98

4.4.11 Right Back Section Cylinder .................................................................................... 100

4.4.12 Right Leg Section Cylinder ......................................................................................102

4.4.13 Left Joint Shields Assembly (0788300068) .............................................................104

4.4.14 Right Joint Shields Assembly (0788300069) ..........................................................105

4.4.15 Replacement of the Column Sealing Kit .................................................................108

5. Technical Data ...................................................................................................................... 124

5.1 Identifi cation Plate ............................................................................................................124

5.1.1 Illustrated Designations and Symbols .....................................................................125

5.2 Properties and Materials ..................................................................................................125

5.2.1 Surface Materials .................................................................................................... 125

5.3 Specifi cations ...................................................................................................................125

5.3.1 Environmental Specifi cations ..................................................................................125

5.3.2 Electrical Specifi cations ..........................................................................................126

5.3.3 Microcontroller .........................................................................................................126

5.3.4 Classifi cation Data ..................................................................................................126

5.3.5 Adjustment Ranges ................................................................................................. 127

5.3.6 Power Supply (0788-205-002) ................................................................................ 127

5.3.7 MPC - Motion Process Controller (0788-205-001) .................................................. 128

5.3.8 Hydraulic Unit Specifi cations (0788-203-000) ......................................................... 128

5.3.9 Weights and Dimensions ........................................................................................128

6. Electronics ............................................................................................................................ 130

6.1 Special User Attention ......................................................................................................130

6.1.1 Warnings .................................................................................................................130

6.2 Battery ..............................................................................................................................130

6.2.1 Replacing the Battery .............................................................................................. 131

6.2.2 Battery Charge ........................................................................................................132

6.2.3 Battery Indicators ......................................................................................................... 132

6.2.4 Storage of batteries .......................................................................................................132

6.3 Power Supply (0788205002) ............................................................................................133

6

Page 7

6.3.1 Specifi cations ..........................................................................................................133

6.3.2 Replacing the Power Supply ...................................................................................134

6.3.3 Setting the Secondary Voltage ................................................................................ 135

6.4 Main Switch Panel ............................................................................................................136

6.4.1 Replacing the fuses ................................................................................................. 137

6.4.2 Replacing the Power Entry Module Assembly (0788205011) .................................137

6.4.3 Replacing the Main Switch (0788305046) ..............................................................138

6.5 Remote Control ................................................................................................................139

6.5.1 Corded Hand Control (0788305001) ....................................................................... 139

6.5.2 IR-Controller (0788-305-002) ..................................................................................141

6.5.3 Device Address .......................................................................................................142

6.5.4 Programming ........................................................................................................... 143

6.5.5 IR Receiver Replacement Kit (0788205010) ...........................................................144

6.6 Override Panel Assembly (0788205000) ..........................................................................149

6.6.1 Override Panel Replacement .................................................................................. 149

6.7 Override Logic ..................................................................................................................159

6.8 Foot Switch (0788-305-005) .............................................................................................160

6.9 Hydraulic Pressure Sensor Assembly (0788203003) .......................................................160

6.9.1 Hydraulic Pressure Sensor (0788305016) .............................................................. 161

6.9.2 Hydraulic Pressure Sensor Replacement ...............................................................161

6.10 Tilt/Trend Sensors (0788305012) ....................................................................................165

6.10.1 Replacement of Tilt/Trend Sensor ...........................................................................166

6.11 Inductive Leg Sensor Assembly (0788205005) ................................................................175

6.11.1 Replacement of Inductive Leg Sensor .................................................................... 176

6.12 Seat Section Sensor Cable Harness Assembly (0788305025) ........................................184

6.12.1 Replacement of Seat Section Sensor Cable Harness Assembly ............................ 185

6.13 Potentiometers ..................................................................................................................196

6.13.1 Potentiometer Testing and Calibration ..................................................................... 196

6.13.2 Replacement of Potentiometers .............................................................................. 198

6.14 Safety Edge Sensors ........................................................................................................244

6.14.1 Replacement of Safety Edge Sensor ......................................................................244

6.14.2 Routing Lower Wire Harness of Safety Edge Sensor Assembly with Quick Connect ..

(0788205009) ......................................................................................................................251

6.15 Sensor Connections .........................................................................................................260

7

Page 8

6.16 MPC (Motion Process Controller, 0788-205-001) .............................................................261

6.16.1 General ...................................................................................................................261

6.16.2 Communication .......................................................................................................261

6.16.3 PC Connection ........................................................................................................ 262

6.16.4 Connectors ..............................................................................................................262

6.16.5 MPC Connections ...................................................................................................262

6.16.6 Replacement of the MPC ........................................................................................263

6.17 Vertier Wiring Diagram......................................................................................................265

6.18 Solenoid Pin Connector Confi guration .............................................................................267

6.19 MPC Motor Outputs and Power Inputs .............................................................................268

6.19.1 MPC Motor Output and Power Input Cable Replacement .......................................268

6.19.2 Slide Motor - MPC Cable Replacement (0788305024) .......................................... 271

6.20 Valve Block Control ...........................................................................................................279

6.20.1 Features .................................................................................................................. 279

6.21 Cables ..............................................................................................................................279

6.21.1 AC Voltage ...............................................................................................................279

6.21.2 DC Voltage .............................................................................................................. 279

6.21.3 Hook and Loop Fastener Placement ....................................................................... 279

7. Hydraulics ............................................................................................................................. 282

7.1 Safety Information.............................................................................................................282

7.1.1 Lift column ..............................................................................................................282

7.1.2 Warnings .................................................................................................................282

7.2 Hydraulic Unit (0788-203-000) .........................................................................................283

7.2.1 Removing the Hydraulic Unit ...................................................................................284

7.2.2 Hydraulic Oil (0788-303-008) .................................................................................. 285

7.3 Main Valve Block TLC3 (0788-203-001) ...........................................................................286

7.3.1 Hose Connections ................................................................................................... 287

7.3.2 Hydraulic Circuit Diagram .......................................................................................288

7.3.3 Valve Block TLC3 ....................................................................................................289

7.3.4 Replacement of TLC3 Manifold ............................................................................... 289

7.3.5 Exchange of TLC3 Valve .........................................................................................290

7.3.6 Changing the Solenoid Coil at SP1 (Valve Block Floor Lock) and TLC3 (Valve

System) ...............................................................................................................................292

7.4 Top Manifold .....................................................................................................................293

8

Page 9

7.4.1 Top Manifold ............................................................................................................295

7.4.2 Top Manifold Hose Repair and Replacement ..........................................................296

7.5 Cylinder Types ..................................................................................................................305

7.6 Floor Lock Cylinder Type LF16 .............................................................................................307

7.6.1 Connections ............................................................................................................ 307

7.6.2 Cylinder Type ...........................................................................................................308

7.6.3 Pressure Switch and Valve Block (0788203002) ..................................................... 316

7.7 5th Wheel Assembly .........................................................................................................316

8. Service Software .................................................................................................................. 318

8.1 General .............................................................................................................................318

8.2 Login .................................................................................................................................319

8.2.1 Password .................................................................................................................319

8.2.2 Table Confi guration Data .........................................................................................319

8.2.3 Update MPC SW ..................................................................................................... 320

8.2.4 Update Sidne™ IDAM SW ...................................................................................... 320

8.3 Identifi cation .....................................................................................................................321

8.3.1 Software Versions ...................................................................................................321

8.3.2 Serial Number ......................................................................................................... 321

8.3.3 IR Address .............................................................................................................. 321

8.3.4 Assembly Options ................................................................................................... 322

8.4 Motions .............................................................................................................................322

8.4.1 Motion Parameters ..................................................................................................322

8.4.2 Motions Limits ......................................................................................................... 322

8.5 Preset Positions ................................................................................................................324

8.5.1 Preset Position ........................................................................................................325

8.5.2 Cycle Drive Time ..................................................................................................... 325

8.6 Timings & Voltages ...........................................................................................................325

8.6.1 Battery Voltage ........................................................................................................326

8.6.2 Valve Timing ............................................................................................................326

8.6.3 Motion Maximum Duration ......................................................................................326

8.6.4 Automatic Shut off Time ..........................................................................................326

8.6.5 System Time ...........................................................................................................327

8.6.6 Total Motion Time ....................................................................................................327

8.7 Cycle Test .........................................................................................................................327

9

Page 10

8.7.1 Read From File ........................................................................................................328

8.8 Logged Data .....................................................................................................................329

8.8.1 Identifi ed Error Situations ........................................................................................330

9. Cleaning and Disinfecting ..................................................................................................... 332

9.1 Cleaning ...........................................................................................................................332

9.2 Disinfection .......................................................................................................................332

9.3 Mattresses and Pads ........................................................................................................332

10. Troubleshooting ................................................................................................................... 334

11. Maintenance ....................................................................................................................... 338

11.1 Safety During Maintenance Procedures ...........................................................................338

11.2 Daily Maintenance ............................................................................................................338

11.3 Monthly Maintenance .......................................................................................................338

11.4 Annual Maintenance .........................................................................................................339

11.5 Repair Maintenance .........................................................................................................340

12. Recycling ............................................................................................................................ 342

12.1 Metals and Plastics ...........................................................................................................342

12.2 Hydraulic Cylinders and Gas Springs ...............................................................................342

12.3 Oil .....................................................................................................................................342

12.4 Electronic Waste and Batteries .........................................................................................342

13. Replacement Part Numbers ............................................................................................... 344

14. Stryker Limited Warranty .................................................................................................... 352

15. Contact Information ............................................................................................................ 354

10

Page 11

1. Warnings, Cautions, and Notes

Please read this manual and follow its instructions carefully. The words WARNING, CAUTION, and

Note carry special meanings and should be carefully reviewed:

WARNING The personal safety of the patient or user may be involved. Disregarding

this information could result in injury to the patient.

Caution Special service procedures or precautions must be followed to avoid damag-

ing the instrument.

WARNING A lightening bolt within a triangle is intended to warn of the presence of

hazardous voltages. Refer all service to authorized personnel.

Note Special information to make maintenance easier or important information more

clear.

1.1 Warnings

To avoid potential serious injury to the user and the patient and/or damage to this device, the user

must:

Read this manual thoroughly, and be familiar with its contents prior to using this equipment.1.

Be qualifi ed medical personnel, having complete knowledge of the use of this equipment.2.

Always wear disposable gloves and a mask when working on used tables, due to risk of infec-3.

tion or disease. If the table appears to have an excess of biowaste, you may need to clean and

disinfect the table prior to service.

Test this equipment prior to a surgical procedure. This product was fully tested at the factory 4.

before shipment.

Disconnecting any of the hydraulic hoses can cause uncontrolled and dangerous movement 5.

of the table. Support the table parts before disconnecting any hoses. Only trained personnel

should maintain hydraulic components.

Avoid removing covers on the product to avoid electric shock.6.

Attempt no internal repairs or adjustments unless specifi cally instructed to do so in this oper-7.

ating manual.

The table weighs 600 lbs (300 kg), as such it is necessary to have two people to unpack/pack it. 8.

Use work gloves when handling the crate to avoid injury.

NEVER PLACE ITEMS ON THE TABLE BASE DURING ARTICULATION. THIS WILL 9.

CAUSE DAMAGE TO THE TABLE.

The Vertier™ Surgical Table should only be used in facilities made for medical purposes.10.

Connect the Mains Cord only to a grounded power supply.11.

The Vertier™ shall be operated from its internal battery if the integrity of the protective 12.

grounding conductor arrangement is in doubt.

Place the patient in the longitudinal center line of the table top. 13.

11

Page 12

In NORMAL mode maximum patient weight is 275 kg (600 lbs).14.

In REVERSE mode maximum patient weight is 180 kg (400 lbs).15.

DO NOT attempt to clear errors and troubleshooting during surgery. Use the Override Panel.16.

Adjust the table top to the horizontal position (0-position) with the Hand Control Unit before 17.

transporting a patient on the surgical table.

Transporting of patients weighing up to 180 kg (400 lbs) is only allowed when table top is in 18.

horizontal position (0-position) and the height of the table is max 900mm (3 ft).

Transporting of patients weighing 180-225 kg (400-500 lbs) is only allowed when the table is in 19.

NORMAL mode, in horizontal position (0-position), and in the lowest position.

Transporting of patients weighing 225-275 kg (500-600 lbs) is not allowed.20.

Use extreme caution when transporting the table with a patient. Transporting of the table with 21.

a patient requires two persons. To maximize patient safety utilize proper restraint methods

during transport.

To avoid endangering the patient’s respiratory system, nerve pathways, and circulatory system, 22.

the patient should be positioned properly and kept under observation!

Check that table top sections catches lock correctly. Incorrect attachment of table sections is 23.

dangerous and can cause personal injury or equipment damage!

Use only accessories recommended by the table manufacturer.24.

To avoid injury to the patient or user, do not attach large accessories to the rails of the head 25.

rest.

Do not use worn or damaged accessories. When using the table, ensure that all accessories are 26.

properly mounted and check the function of accessory locking and adjustments.

Do not attempt to remove or attach more than one section at a time.27.

When adjusting the surgical table, take care that fi ngers, hands, or other parts of the patient’s 28.

body are not placed between edges of back, leg, or seat section frames and pivoting points.

Always handle sections by the rains on the side, especially the head rest.29.

Use care when attaching sections, fi ngers or appendages can be trapped between two sections, 30.

causing harm to the patient or user.

The head rest utilizes pressurized gas springs to assist in movement of the head. Use extreme 31.

caution while articulating to avoid patient or user injury. Never press the release bar while the

head rest is not connected to the table. Always keep fi ngers away from articulating pins.

To avoid injury to the patient and user, keep fi ngers, hands and body parts clear of the pinch 32.

points.

Use only permitted table top confi gurations illustrated in the user manual.33.

Before adjusting the surgical table ensure that table top will not hit external obstacles.34.

Before adjusting the surgical table ensure that NORMAL/REVERSE mode has been chosen 35.

correctly and is the same as patient’s orientation on the table top. After use of Main Switch, the

NORMAL mode is set by default.

Always follow manufacturer instructions when using diathermy or defi brillation equipment.36.

When using high frequency surgical equipment take care to prevent the patient coming into 37.

contact with metal parts of the surgical table or accessories. Do not place the patient on wet or

damp surfaces or electrically conductive pads due to hazard of burn injuries!

Combustible anaesthetic gases must not be used with the Vertier™ Surgical Table.38.

Use potential equalization conductor with patient monitoring equipment. Connector placed at 39.

12

Page 13

the table base.

When recharging the battery, plug the Mains Cord to table receptacle, and then to the wall 40.

socket.

When recharging is completed, disconnect the Mains Cord fi rst from the wall socket, and then 41.

from the table receptacle.

The Main Switch can be used as an emergency stopping device (demanded by the standards). 42.

Normally the switch lever is in up position. When the lever is turned down (in the STOP position) all table functions are cancelled and table movement stops immediately.

Disconnect the Mains Cord from the table and turn the Main Switch to STOP position before 43.

cleaning the table.

Disconnect the Mains Cord from the table before any service procedures. 100-240 V~ is used in 44.

power unit placed in the table base. Hazard of electric shock!

The Vertier™ Surgical Table has been tested to IEC601-1-2 to ensure proper electromagnetic 45.

compatibility. Other products used in the vicinity of the Vertier™ Surgical Table should also

comply with this standard. If they do not comply, interference between products in unintended

responses may occur. Please contact the appropriate manufacturer if any problems arise.

Portable and mobile RF-communications equipment can affect the Vertier™ Surgical Table.46.

Do not attempt to remove or attach more than one section at a time.47.

Always handle sections by the rails on the side, especially the head rest.48.

To avoid injury to the patient or user, do not attach large accessories to the rails of the head

rest.

1.2 Cautions

If the surgical table has been in the cold, allow it to warm up at room temperature for at least 1.

6 hours before recharging the battery or switching on, to allow any condensation formed to

evaporate.

Recharge the battery prior to use. See the starting instructions attached to table base panel.2.

Take care to not catch the edges of the table or contents while packing/unpacking the crate.3.

If the table is not plugged in when a solid red light is illuminated, the batteries may be damaged 4.

by a complete discharge.

When adjusting the surgical table, take care to avoid collision between accessories and the sur-5.

gical table.

Take precautions while using the Override Panel. None of the software limitations are active 6.

during manipulations.

Always remember to disconnect the power cord prior to moving the table.7.

Static charges can harm sensitive electronic components. Ground yourself to metallic parts of 8.

the table before touching components.

The Override panel is only for returning the table top to the horizontal position in the case of 9.

electronic malfunction. Override makes it possible to adjust the table without the controlling

processor if any of the programmed restrictions are not functioning.

If the surgical table surface is not raised high enough when trendelenburg and side tilt are in 10.

their extreme positions, the back section may impact the table base casing, damaging the surgical table and creating pinching hazard.

The best place to store the Hand Control Unit, especially during transport, is the lever under 11.

the head section. Be careful not to smash the hand controls on doors or walls during transport.

13

Page 14

The surgical table has been classifi ed as splash proof equipment. Use of pressurized water to 12.

clean the table is not allowed.

Cleaning and disinfecting should be performed according to the user manual.13.

Do not pull or push the shields of back and leg section joints. Check during adjustment that 14.

there are no foreign obstacles between shields.

It is possible to adjust the Slide adjustment only when back or leg section are in horizontal or 15.

above horizontal position. Slide adjustment will stop automatically before collision if back or

leg section is under the horizontal position.

Slide adjustment is only possible when table top is in horizontal position. Use of Slide adjust-16.

ment is restricted with tilted table top.

Mattresses should be cleaned only with neutral detergent (pH 7-8).17.

The antistatic properties of the surgical table require the use of original brand mattresses and 18.

antistatic fl ooring.

1.3 Notes

It is recommended to recharge the battery overnight after one day’s use to ensure the table will 1.

be always ready for use, and to maintain the battery life.

If the Main Switch is turned to STOP position (downward), all table functions are blocked, in-2.

cluding the battery recharging ability. Check that the green LED above the charging inlet lights

up when the Mains Cord is connected to the table.

When Mains Cord is connected to the surgical table, the cooling fan of the power unit is ac-3.

tivated causing a humming sound. After disconnecting the Mains Cord, the cooling fan will

continue to run for a few seconds.

Turn the Main Switch to the STOP position (downward) when the table is not in use or stored 4.

for a long period of time. This eliminates the possibility of unintended use and also saves the

battery capacity.

Activate the fl oor lock before adjusting the table. Only the trendelenburg and back rest adjust-5.

ments will function if fl oor lock is not activated. A red LED will blink on the Hand Control

Unit if another button is pressed. Press the ON/OFF button to stop the blinking.

Cardboard packing material should be recycled. Wood and plastics are energy waste.6.

Batteries contain lead and need to be recycled in accordance with local environmental regula-7.

tions if replaced.

Hook and loop tapes on table top plates can be cleaned with pressurized air. Hook and loop 8.

tape can also be replaced; spare parts and instructions are available from Stryker Technical

Support.

Floor lock can be deactivated with a release lever placed at the table base if normal deactivating 9.

with Hand Control Unit or Override Panel can’t be done. Turn the lever or knob located at the

front side of the base 90° clockwise and the table will descend on to its castors. Turn the lever

back to its original position after releasing.

Only trendelenburg and back rest adjustments are possible when the fl oor locks are deacti-10.

vated.

To articulate the legs down a full -105°, press Slide Reverse until the table reaches a preset stop 11.

about half way through the full range of slide motion. Once past this position, a full -105° can

be reached.

The individual leg manipulation is only possible when the optional separate leg sections are at-12.

14

Page 15

tached to the foot end of the seat section, or when no section is attached.

Memory buttons are dependant on orientation. The buttons can be programmed in both the 13.

normal and reverse orientation and pertain to the particular orientation mode, respectively.

Simultaneous maximum angles of trendelenburg/reverse trendelenburg and side tilt are limited 14.

with software.

Head section gas spring can be disposed of as metal waste after nitrogen gas and oil have been 15.

removed.

Instructions for gas releasing are available from your sales representative.16.

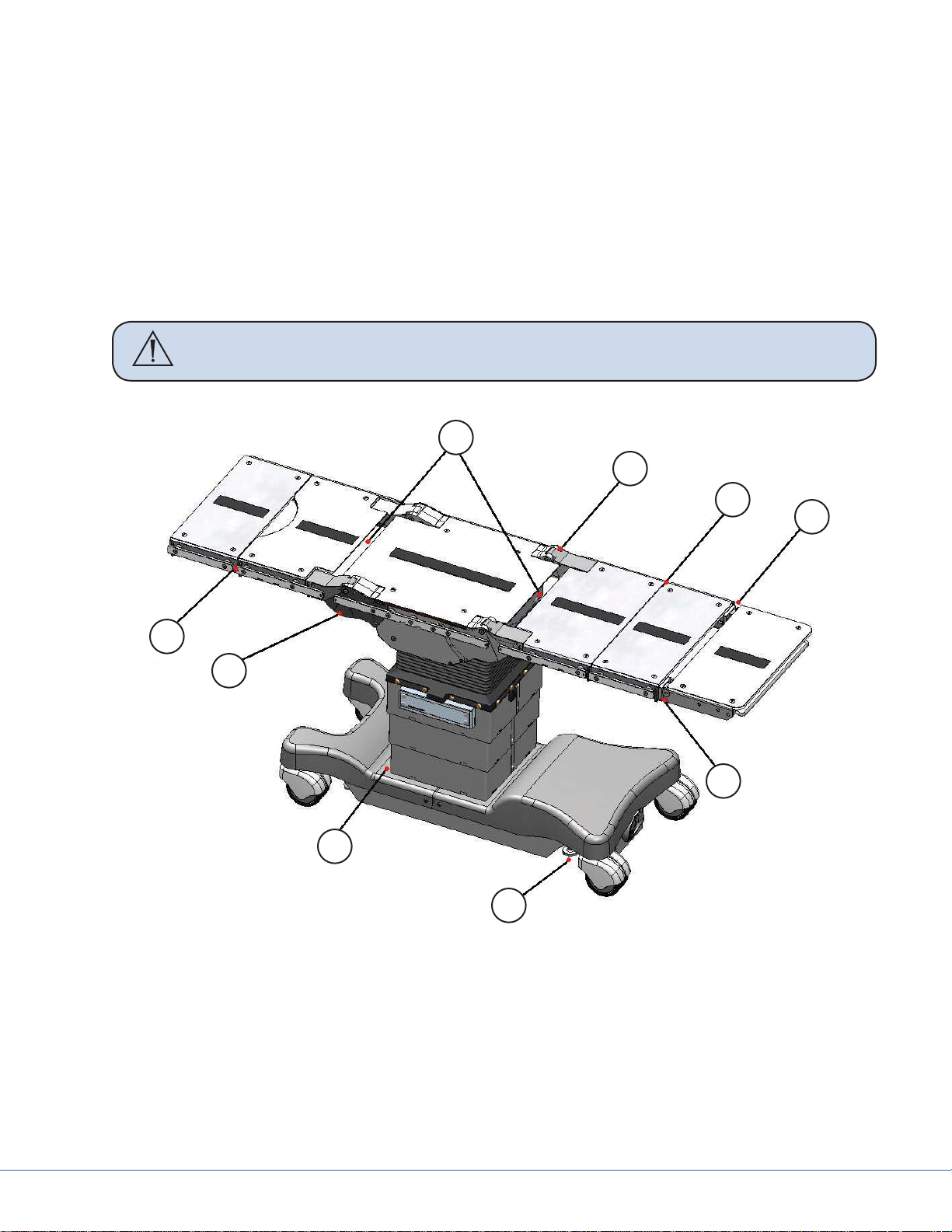

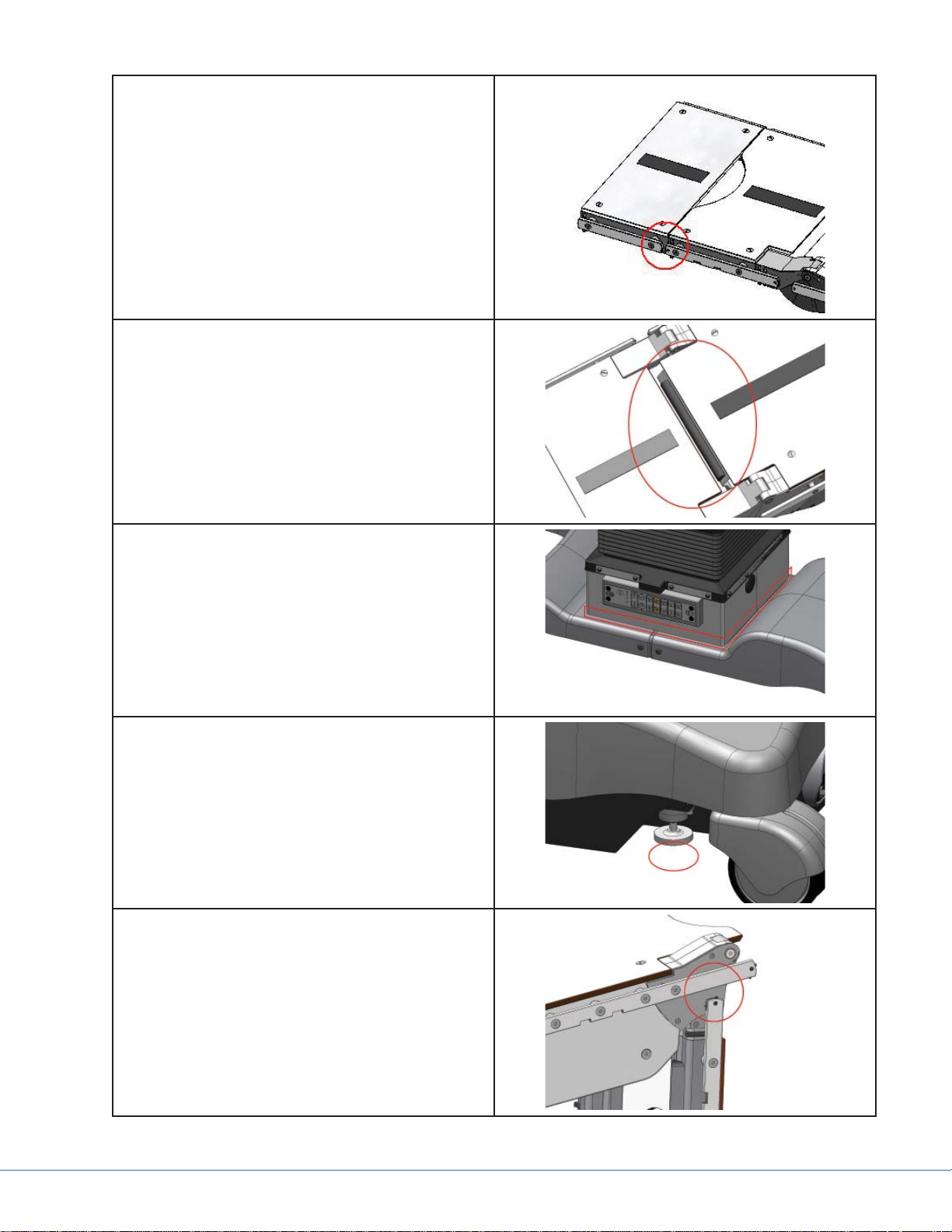

1.4 Table Pinch Points

WARNING To avoid injury to the patient and user, keep fi ngers, hands, and body parts

clear of pinch points.

7

5

1

2

6

4

3

8

9

Figure 1.1 - Pinch Point Locations

15

Page 16

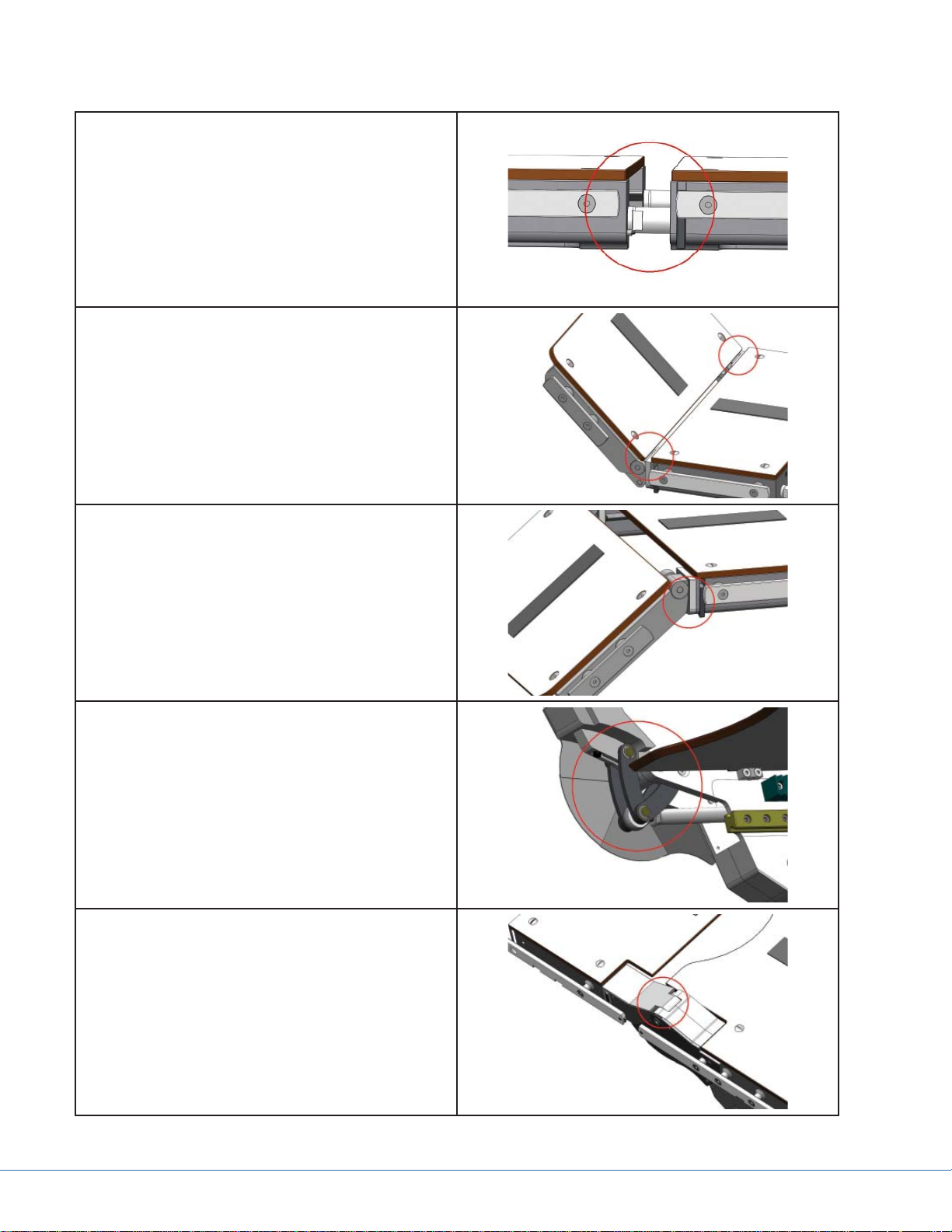

1.4.1 Pinch Point Zones

A pinch point exists at the connection interface

of all modular sections when the sections are attached to each other or to the table.

A pinch point exists on the top edge of both head

rest joints when the head rest is articulated upward. This pinch point also exists when the head

rest is disconnected from the table. Keep fi ngers

and hands clear of this zone at all times. Do not

press the release bar when the head rest is disconnected from the table.

A pinch point exists on the bottom edge of both

head rest joints when the head rest is articulated

downward.

Pinch Points exist under the four articulating

joints of the table behind the joint shields. Do

not put fi ngers or hands underneath the joints of

the table.

A pinch point exists at all four articulating joints

of the table as a gap between the joint and the

main body of the table. Keep fi ngers away from

the articulating joints of the table during movement.

16

Page 17

Pinch points exist between all accessory rails of

a 25cm section and a 40cm section. Keep fi ngers

and hands clear when connecting a 25cm section

to a 40cm section.

Pinch points exist between the sections and the

column of the table while the table is sliding.

Keep hands and body parts out of this area during articulation of the table.

Pinch points exist under all column casing edges

when it is articulated downward toward the base

of the table.

A crush zone exists beneath all four fl oor locks.

Do not position fi ngers, feet, or hands underneath the fl oor locks.

Pinch points exist on both sides of the table at

the accessory rails when the leg section is articulated downward to the maximum 105°.

17

Page 18

Pinch points exist at any zone where the table top

collides with the base of the table or the fl oor.

Keep all body parts out of these zones when articulating the table.

Pinch points exist inside the fl exible bellows of

the table column. Keep fi ngers and hands away

from the bellows during table articulation.

18

Page 19

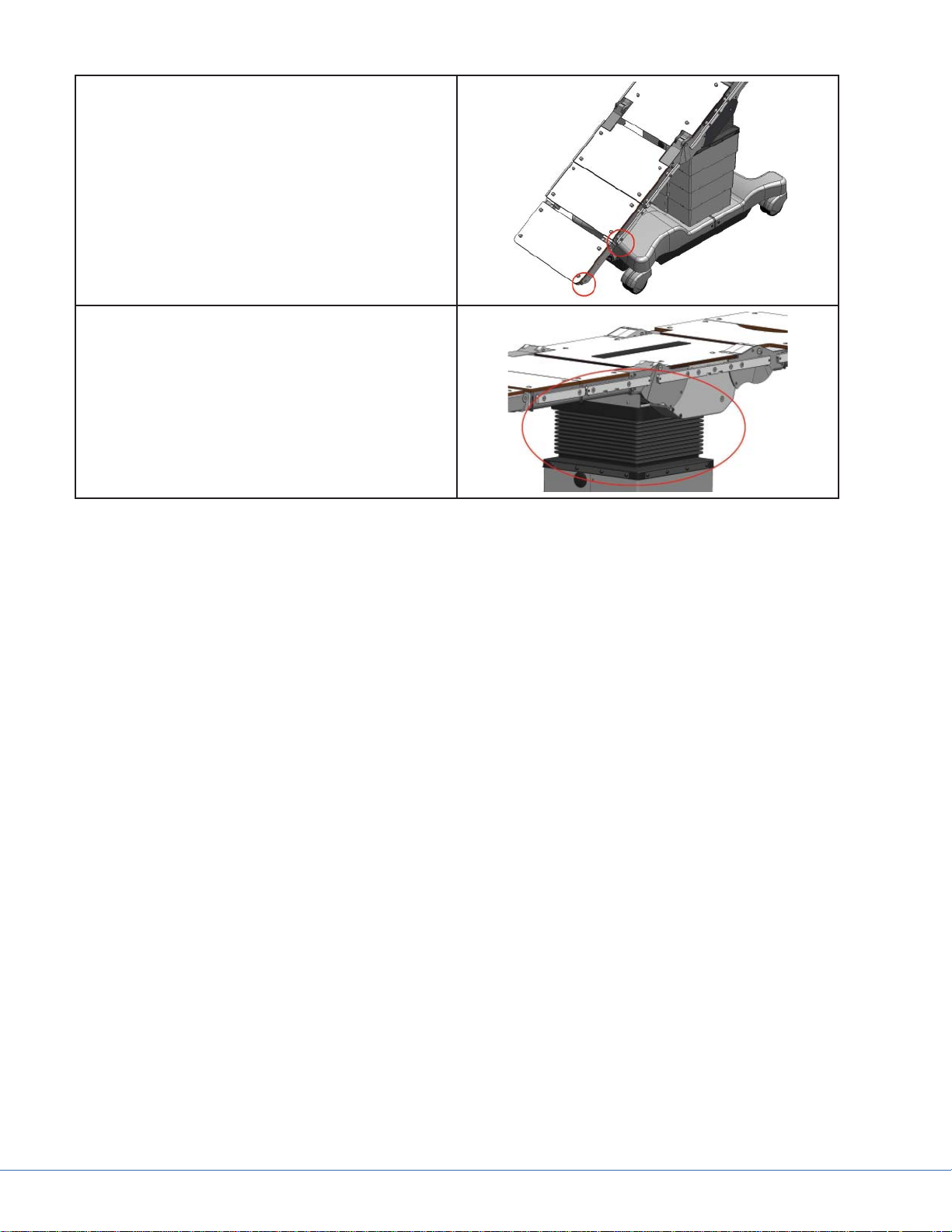

2. Product Symbol Defi nition

The following symbols may be found on the Vertier related equipment:

An exclamation mark within a triangle is intended to alert the user to the presence

of important operating and maintenance (service) instructions in the literature accompanying the product.

Denotes the presence of a pinch point.

A lightning bolt within a triangle indicates the presence of hazardous voltage. Refer

all service to authorized personnel.

Denotes earth ground.

Denotes equipotentiality.

Denotes temperature limits.

EDS

(29AZ)

Denotes humidity limits.

Denotes pressure limits.

Denotes a load limitation.

Denote electrical shock hazard.

Denotes oxygen explosion hazard.

Denotes potential electromagnetic interference (EMI).

Denotes usage tips and useful information.

Denotes compliance to European Community Directive 93-42-EEC.

Indicates the product is compliant “Medical Electrical Equipment with Respect to

Electrical Shock, Fire, and Mechanical Hazard only in accordance with UL60601-1.

19

Page 20

(13PZ)

Indicates the product is compliant “Medical Electrical Equipment with Respect to

Electrical Shock, Fire, and Mechanical Hazard only in accordance with UL60601-1,

CAN/CSA C22.2 No601.1.

Indicates hot surfaces.

Denotes compliance to CSA Standard C22.2, 60601.1 - M90, AS 3200, IEC 60601,

IEC 60601-2-46, UL 60601, EN 60601

Denotes the date the equipment was manufactured.

Denotes the manufacturer of the device.

A yellow box with a hand within a triangle is intended to warn the user of the presence of an electrostatic sensitive device. Follow ESD prevention procedures.

Denotes product/part number.

Denotes product/serial number.

Denotes lot or batch number.

Denotes European Representative.

For U.S. audience only - Caution: Federal Law (USA) restricts this device to sale by

or on the order of a physician.

Denotes quantity.

Denotes Class 1 and Type B Equipment.

Class 1 Equipment: equipment in which the protection against electric shock does

not rely on Basic Insulation only, but includes an additional safety precaution in

such a way that means are provided for the connection of Accessible Conductive

Parts to Protective (ground) Conductor in the fi xed wiring of the installation in

such a way that Accessible Conductive Parts cannot become Live in the event of a

failure of the Basic Insulation.

Type B Equipment: equipment is suitable for international external and internal application to the patient excluding Direct Cardiac Application.

20

Page 21

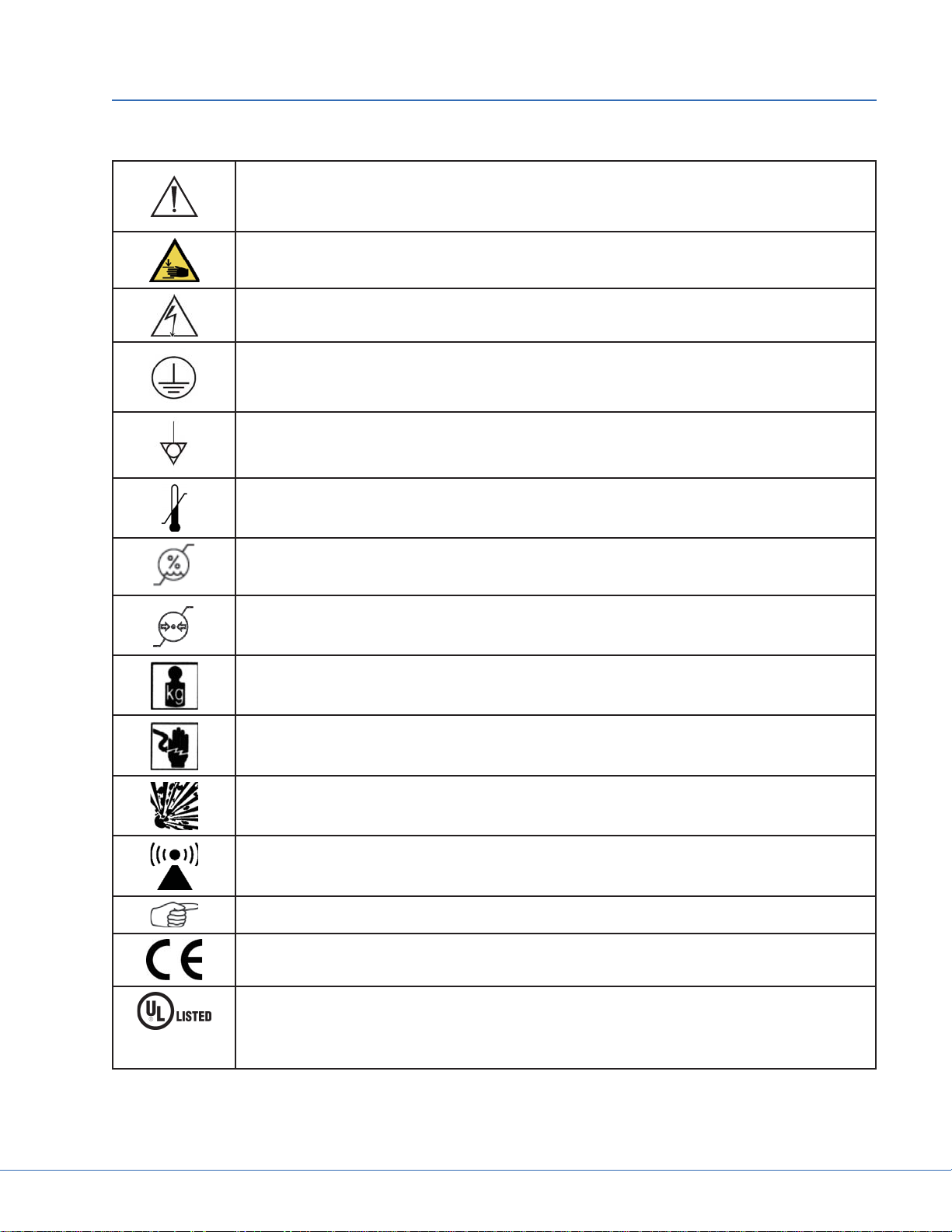

In accordance with European Community Directive 2002/96/EC on Waste Electrical and Electronic Equipment, this symbol indicates that the product must not be

disposed of as unsorted municipal waste but should be collected separately.

Note: The device does not contain any hazardous materials.

Legal regulations may include specifi cations regarding the disposal of this product. We request that you contact Stryker when planning to withdraw this device

from service for discard.

Denotes the device contains more than .002% cadmium.

Denotes the device contains more than .0005% mercury.

Denotes the device contains more than .004% lead.

2.1 EMC Precautions

This device is considered medical electrical equipment and requires special precautions regarding

EMC and needs to be installed and put into service according to the information provided.

Portable and mobile RF communications equipment can affect the performance of this device and

must be used in accordance with the information in this manual.

21

Page 22

Page 23

3. Indications for Use

Stryker conforms to the quality certi cation ISO13485. In addition, the Vertier™ Surgical Table meets

the requirements of UL 60601-1, IEC 601-1-2, and IEC 601-2-46, as certi ed by Intertek ETL Semko.

e Vertier™ Surgical Table is intended for general surgical use. It is also well suited for:

Day surgery•

ENT surgery•

Plastic surgery•

Orthopedics•

Arthroscopy•

Gynecology•

Urology•

Pediatrics•

Neurosurgery•

3.1 Prior to Servicing Tables

WARNING Always wear disposable gloves and a mask when working on used tables

due to a risk of infection or disease. If the table appears to have an excess

of biomaterial, it may need to be cleaned and disinfected the table prior to

service.

Connect to the table via the USB-B service port located at the bottom of the Override Panel. •

See Section 8 for details.

Launch the PC Service software and log into the program; see Section 8 Service Software on •

how to login to the service software.

Verify the Software version. To ensure usage of the most up-to-date version, log on to Agile •

and view Document Number 0100223109. For instructions on how to identify the software/

fi rmware revisions on the table, see Section 8.3 Service Software Identifi cation.

Save the table confi guration data as a safety step in the event that the MPC becomes corrupted •

during service. For instructions on saving the table confi guration data, see Section 8 Service

Software.

View and capture the error data.•

- Go to the Logged Data tab and click on “Read from MPC” and then “Write to File.”

Note The error log can be opened in Notepad or WordPad. Notice the Serial Number

is captured and included at the top of the error log; this will only appear if data

has been read from the MPC as outlined in the above step. This step is very important when error data is sent and analyzed later.

Verify the table functionality before taking any actions; click on the Cycle Test tab. Click on the •

‘Read from File key’ and load the fi le “Test_Cycle_Field”. Remove all sections, pads, and accessories from the table except for the 40CM pelvic extension and the 40CM lower back sections. If the column casings are damaged, remove them and the base covers prior to executing

the cycle test. Ensure the table is free from obstruction and then click on the “Play” button to

execute the cycle test.

23

Page 24

Note If any malfunctions are encountered during this cycle test, investigate and at-

tempt to resolve the issue before proceeding.

Update the MPC software if necessary by going to Agile as specifi ed above and view Document •

Number 0100223108 for the most up-to-date version. For detailed instructions see Section 8.

3.2 Following any Table Service

Verify the Vertier Table Default MPC Settings are correct. Updating software, changing MPC, •

or updating to Sidne™ compatibility can corrupt settings if a problem is encountered during

update. To ensure the settings are correct, go to Agile (For instructions on how to get to Agile

see Section 3.1), retrieve document number 0788307000, compare the default settings to the

actual settings, and make changes as necessary. To make changes, see Section 8 Service Software.

Run the “Test_Cycle_Field” cycle test program on the table again to verify there are no errors or •

malfunctions. See Section 8.7 for details on how to execute this program.

Complete the fi eld service form per SOP1902•

3.3 Operating Characteristics

Vertier™ is a transportable, electrohydraulic battery and Mains operated surgical table. It is •

microprocessor controlled and its function parameters are reprogrammable with a special

PC-operated service program. The table can be connected to 100–240 VAC Mains power, and

its secondary voltage is 24 VDC. The table electronics are safely grounded and it has an equipotential connection.

The table top consists of sliding Seat Section and detachable 25 and 40-sections. The sections •

can be rearranged depending on the surgical concept and operation. The width of the table top

is 540mm, (21 1/4 inches) without rails, and the length is 2100mm (82 inches). The table-top

plate is radiotranslucent material.

Vertier™ can be adjusted with a cable connected Hand Control Unit, an IR Hand Control Unit, •

the foot switch, or through Sidne™. The surgical table can also be adjusted with the Override

Panel in case of electronic malfunction (i.e., if the Hand Control Unit or table microprocessor

becomes defective).

Safe and fault-free use and maintenance of the equipment requires careful adherence to these •

instructions. When mounting accessories to the equipment, the instructions provided with

them must be followed closely. Always keep the instructions for accessories together with this

manual.

24

Page 25

25cm Section

0788300011

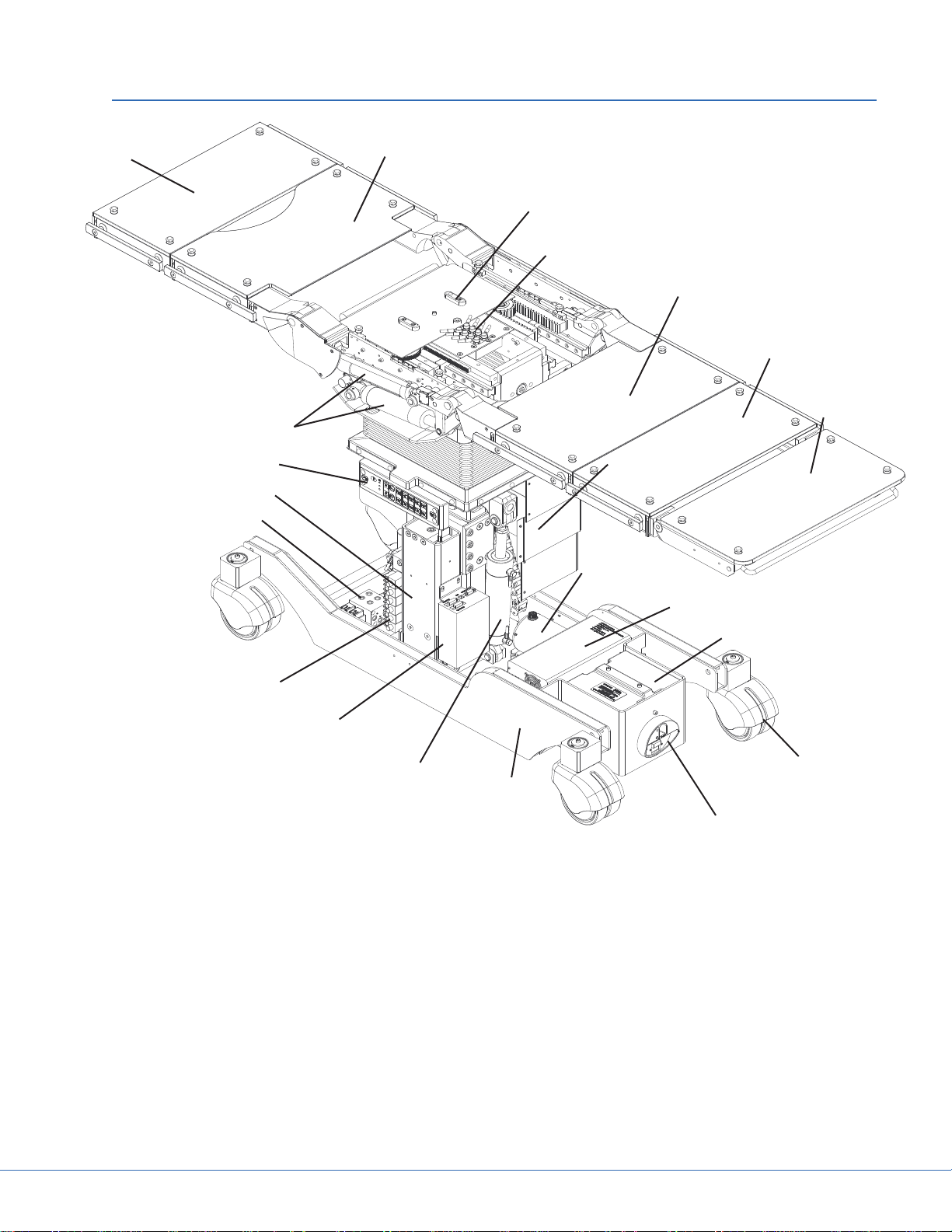

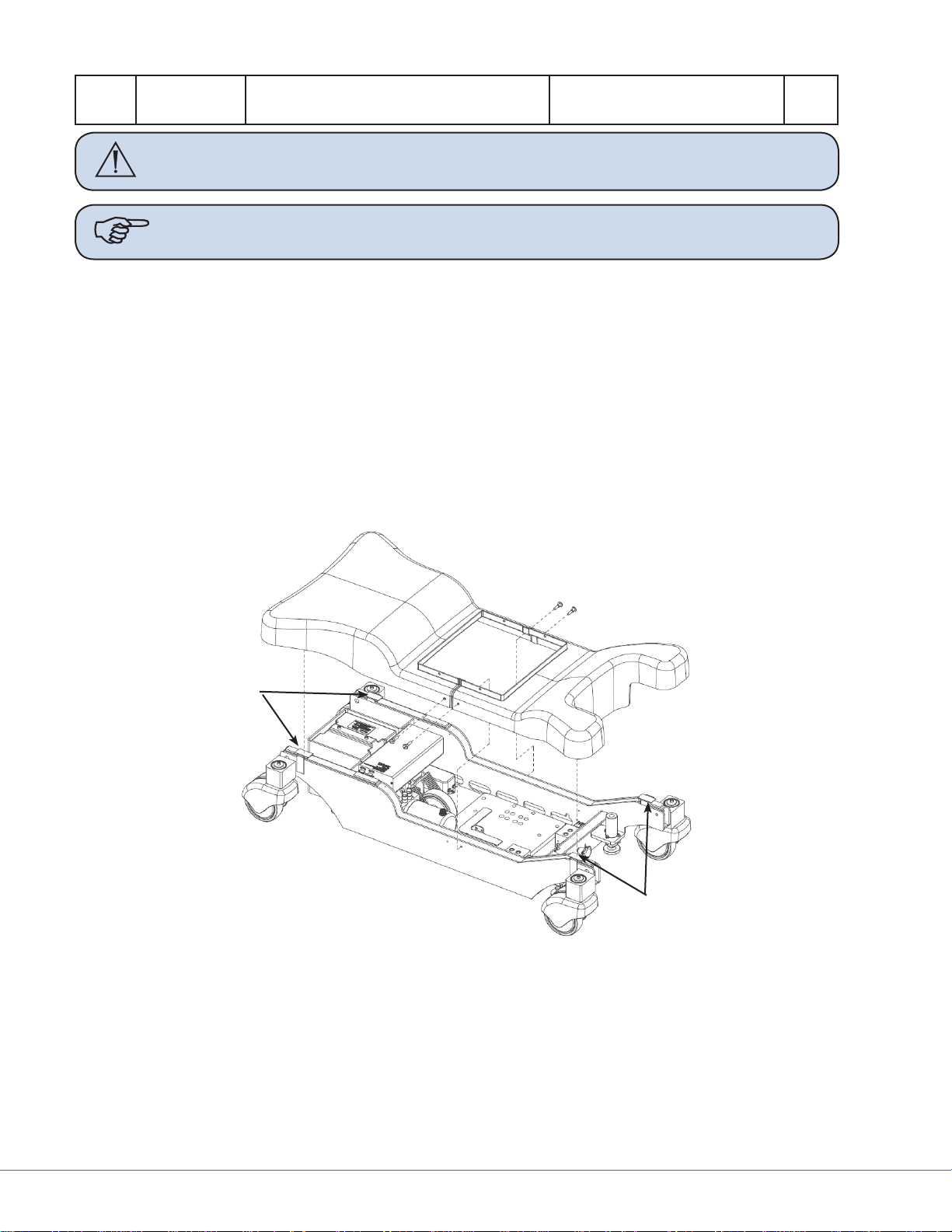

4. Main Components Structure

40cm Pelvic Extension Section

0788300004

Seat and Sliding Section

V alve Top Manifold

40cm Lower Back section

0788300008

25cm Section

0788300011

Back and Leg Section

Cylinders

Override Panel

Lifting Column

Floor Lock Valve Block

TLC3 Valve Block

MPC

Cylinder for

Trendelenburg

Head Basic Rest

0788300012

Casing Column

Hydraulic Unit

Power Supply

Battery

Castor

Base Frame

Main Switch, Fuses

and Charging Socket

Figure 4.1 - Main Components Structure

25

Page 26

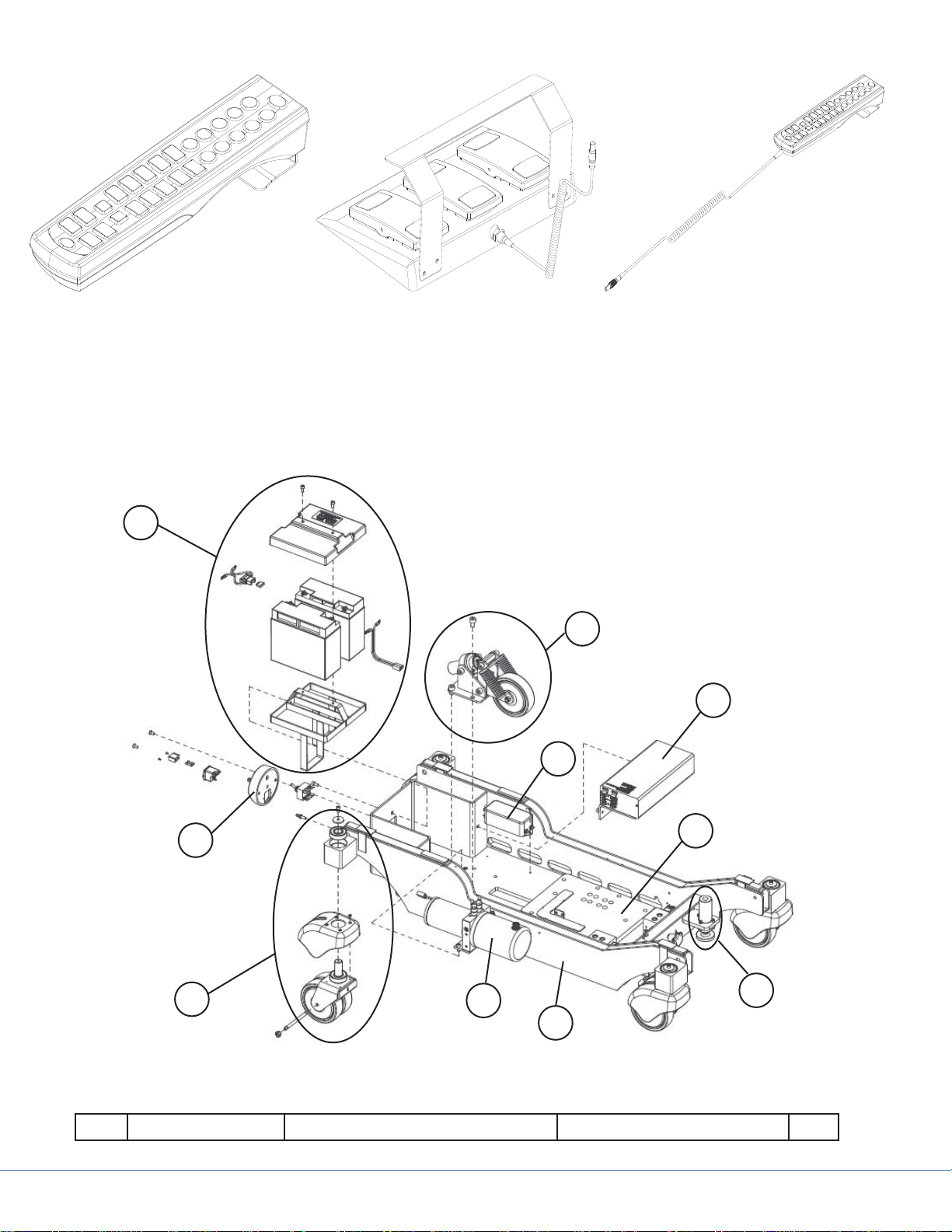

IR-Remote Control

0788305002

Figure 4.2 - Control Devices

4.1 Base and Column Casings

9

Foot Switch Control

0788305005

Sidne™

Remote Control

0788305001

8

6

7

4

5

2

10

3

1

Figure 4.3 - Base

Part Code Part Name Additional Information Qty.

26

Page 27

1 A11533000 Base Frame 1

2 0788300064 Castor Assembly 4

3 0788203000 Hydraulic Unit Assembly 1

4 A11521700 Column Offset Plate 1

5 A1152900 Floor Lock Assembly 1

6 0788205002 Power Charger Assembly 1

7 0788505016 EMI, Filter Unit Medical B-type 1

8 A41763300 5th Wheel Assembly 1

A41767000 5th Wheel Mechanical Parts 1

A41766700 5th Wheel Hydraulic Components 1

9 0788205007 Battery Assembly 1

10 A21549400 Main Switch Panel 1

4.1.1 Base Cover Removal

1b

1a

3

2

1c

Figure 4.4 - Table Base Casings

Part Code Part Name Additional Information Qty.

1 0788200000 Base Cover Set Includes items a, b, c, d, and e 1

1a 0788300045 Vertier, Base Cover Leg 1

1b 0788300046 Vertier, Base Cover Back 1

1c 0788300044 Vertier, Base Cover Screw, Plastic Head 4

1d 0788400006 Base Cover Clip Not shown 4

1e 0788400076 Base Cover Hook and Loop Tape Not shown 1

2 0788400004 Column Case-to-Base Screw M4.2X13 A2 F-H DIN 7982 4

27

Page 28

3 0788400025 Machined Column Case-to-Base

Washer

Caution Disconnect the Mains Cord from the table and turn the Main Switch to the

OFF position before removing any base covers.

Note If replacing either base cover, order Base Cover Set 0788200000.

Articulate the table to the highest position.1.

Turn Main Switch to the OFF position and disconnect the Mains Cord.2.

Remove the M4.2X13 column case-to-base screws (Item 2, Figure 4.4) and the machined col-3.

umn case-to-base washers (Item 3, Figure 4.4) from the lowest protective casing shroud.

Remove plastic head screws (Item 1c, Figure 4.4) from both sides of the base covers.4.

Li up the lower column casing shroud slightly and then pull up on the base covers (Items 1a 5.

and 1b, Figure 4.4) to disconnect the hook and loop tape (Item 1e, Figure 4.4).

Pull the base covers toward the end of the table to remove. See Figure 4.5 for the location of the 6.

base cover hook and loop tape.

Repeat steps 1-6 in reverse order to reinstall the base covers.7.

4

Hook and

Loop Tape

Figure 4.5 - Base Cover Removal and Hook and Loop Tape Location

Hook and

Loop Tape

28

Page 29

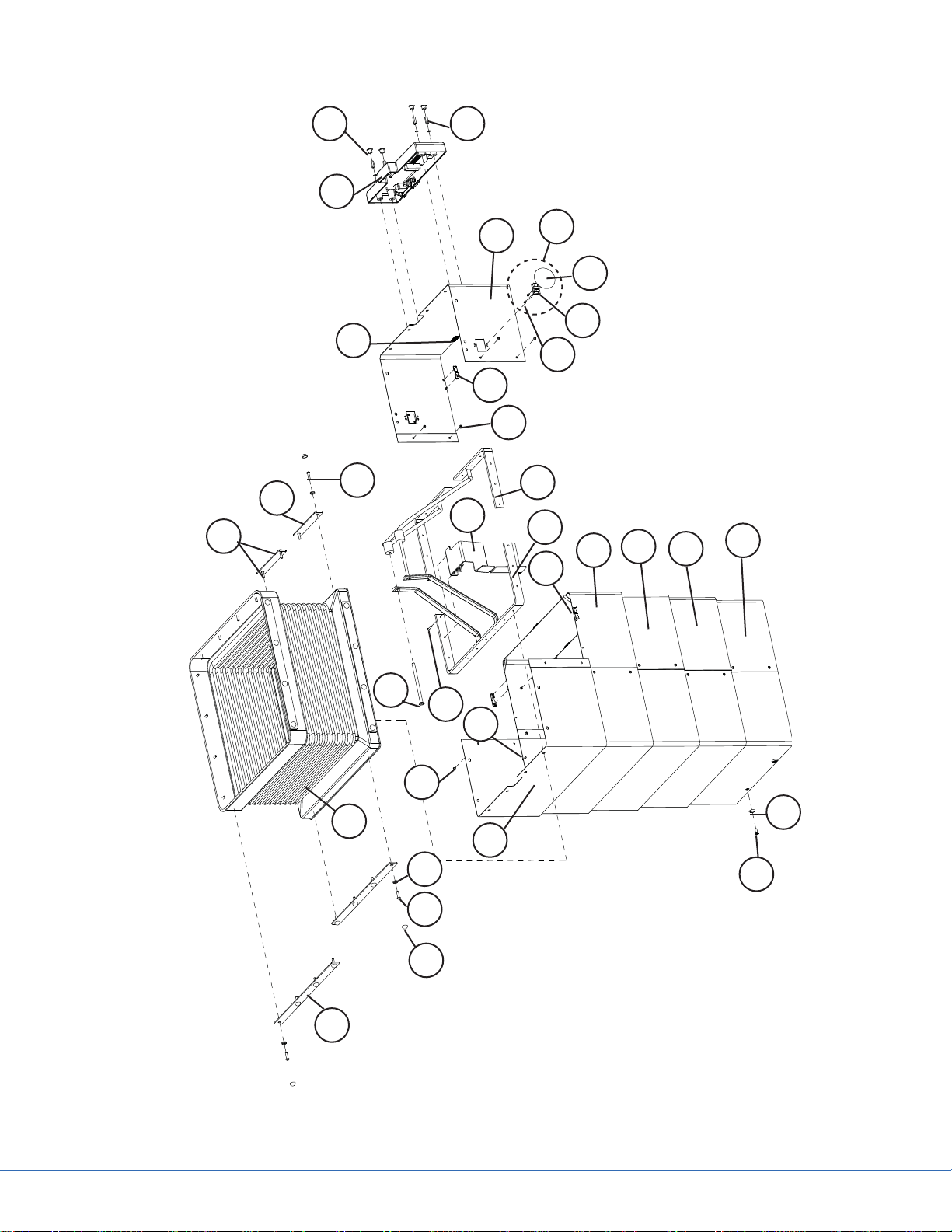

4.1.2 Column Casings

30

28

27

14

4

6

29

25

13

16

12

11

10

9

17

17c

17a

17b

19

20

21

22

7

26

8

18

5

15

3

4

2

1

Figure 4.6 - Column Casing Reference

23

24

29

Page 30

Part Code Part Name Additional Information Qty.

1 0788399014 Bellows Fixing Plate Long 7

2 0788400008 Screw Protecting Cap Black 32

3 0788400032 Plastic Washer 32

4 0788400007 Screw M4X16 ISO 7380 27

5 0788300049 Column Bellows 1

6 0788399013 Bellows Fixing Plate Short 2

7 0788400012 Screw M6X100 DIN 7991 2

8 7105801 Strap 20

9 3761800 Column Casing Spacer 19

10 0788300078 Lower Bellows Frame Right 1

11 0788300079 Lower Bellows Frame Left 1

12 A00767 Compression Nut M3 20

13 3761800 Column Casing Spacer 1

14 A41609500 Hook and loop tape 28

15 A21543500 Casing Half Right 1

16 A41617700 Casing Half Left 1

17 0788205010 IR-Receiver Assembly Includes a, b, and c 2

17a 0788305052 IR ABS Cover 2

17b A41921000 IR PCB 2

17c 0788400084 Fixing Screws M2.5X5 4

18 0788400011 Screw M3X4 Column casing screw 20

19 A21543100 Protective Casing IV 1

20 A21542900 Protective Casing III 1

21 A21542600 Protective Casing II 1

22 A21542300 Protective Casing I 1

23 0788400005 Machined Column Case-to-Base

Washer

24 0788400004 Screw 4,2X13 A2 F-H DIN 7982 4

25 0788399007 Cable Chain Guidance Bracket 1

26 0788400014 Bracket-to-Column Case Screw M3X16 1

27 0788205000 Override Panel Assembly Includes cables 1

28 0788400028 OR Panel Nut Cover 4

29 0788400027 OR Panel Nut M3X15 (5.5MS/NI) 4

4

30 0788400037 Screw M4X6 (located where the

Override Panel wires are

routed)

30

4

Page 31

4.1.2.1 Column Casing Lifted for Base Access

Articulate the table to the highest position.1.

Turn Main Switch to the OFF position and disconnect the Mains Cord.2.

Using a Phillips screw driver, remove the four M4.2X13 column case-to-base screws (Item 24, 3.

Figure 4.6) and machined washers (Item 23, Figure 4.6) that secure the column casings to the

base covers (Figure 4.7).

Gently lift upward on the lower column casing until all of the column casings collapse into the 4.

upper column casing (Figure 4.8).

Figure 4.7

Lift Upward

Figure 4.8

Use bungee cords to secure the column casing in the collapsed position (Figure 4.9).5.

31

Page 32

Figure 4.9

If more access to the lower base frame is needed, the base covers will need to be removed ac-6.

cording to the following steps.

Ensure the Main Switch is in the OFF position and the Mains Cord is disconnected.7.

Remove the plastic head screws from both sides of the base covers (Figure 4.10).8.

32

Figure 4.10

Page 33

Pull up on the base covers to disconnect the hook and loop tape.9.

Pull the base covers toward the ends of the table to remove.10.

Repeat steps 1-10 in reverse order to reattach the base covers and column casings.11.

4.1.2.2 Partial Removal of Column Casings for Access

Note The back side of the table is the side with the Main Switch, and the leg side is the

side with the cutout in the base.

Articulate the table to the highest position.1.

Turn Main Switch to the OFF position and disconnect the Mains Cord.2.

Use a small fl athead screw driver to remove the screw protecting caps (Item 2, Figure 4.6) from 3.

the right casing (Item 8, Figure 4.6).

Using a 2.5mm hex Allen wrench, remove the seven M4X16 screws (Item 6, Figure 4.11) con-4.

necting the right casing half (Item 8, Figure 4.11) to the Bellows Frame.

Using a 2mm hex Allen wrench, remove the M3X16 screw (Item 4, Figure 4.11 and Item 26, 5.

Figure 4.6) that runs through the right casing half (Item 8, Figure 4.11 and Item 15, Figure 4.6)

holding the bracket (Item 25, Figure 4.6) to the right Bellows Frame (Item 10, Figure 4.6). It is

important that this screw be separated for later reinstallation.

Using a 2mm hex Allen wrench, remove the four M3X4 screws (Item 7, Figure 4.11) that join 6.

the right and left casings. The right casing (Item 8, Figure 4.11) can be removed at this point.

Using a 2.5mm hex Allen wrench, remove the two M4X16 screws (Item 5, Figure 4.11) that 7.

secure the leg side of the left casing half (Item 10, Figure 4.11) to the left Bellows Frame (Item

11, Figure 4.6). Using a 2.5mm hex Allen wrench, remove the two M4X16 screws (Item 1, Figure

4.11) that secure the back side of the left casing half (Item 10, Figure 4.11) to the left Bellows

Frame (Item 11, Figure 4.6). Do not remove the two M4X6 screws (Item 3, Figure 4.11) and

the two M4X6 screws (Item 2, Figure 4.11) on the front of the left casing half that are above the

Override Panel.

Flex the left casing half outward in order to lift up on the lower casing sets to disengage the col-8.

umn spacers (Figure 4.12).

Collapse the column casing sets I-IV (Items 19-22, Figure 4.6) all of the way down, until they 9.

are resting on the base covers (Figure 4.13). This allows partial access to all of the column components without fully removing the column casings. For full removal and replacement of the

casings, see Section 4.1.2.3.

To put the column casings back together, repeat steps 1-9 in reverse order.10.

33

Page 34

6

4

8

3

2

10

Figure 4.11 (a) - Screw Locations

6

1

2

3

7

8

7

Figure 4.11 (b) - Screw Locations

5

10

34

Page 35

6

8

7

Figure 4.11 (c) - Screw Locations

5

10

Figure 4.12 - Flex Casing Outward

35

Page 36

Column Casings

I-IV Collapsed

Figure 4.13

36

Page 37

4.1.2.3 Full Removal and Replacement of Column Casings

13

12

10

11

14

6

8

7

5

4

2

1

6

9

3

Figure 4.14 - Column Casing Replacement Set

Part Code Part Name Additional Information Qty.

- 0788200001 Vertier, Column Casings Set Includes items 1-14 below 1

1 A41981500 Column Casing Pair I 1

2 A41981600 Column Casing Pair II 1

3 A41981700 Column Casing Pair III 1

4 A41981800 Column Casing Pair IV 1

5 A41981900 Column Casing Pair V 1

6 A41839800 Spacer with lip 16

7 A41978800 Column Spacer 8

8 A41978900 Column Spacer 8

9 A41784000 Grounding Strip 4

10 0788400011 Column Casing Screw M3X4 20

11 0788400013 Bracket to Bellows Frame Screw M4X8 1

12 0788400014 Bracket to Column Case Screw M3X16 1

13 0788399007 Cable Chain Guidance Bracket 1

14 0788400026 IR Wire Protection Tape 2

Caution Disconnect the Mains Cord from the table and turn the Main Switch to the

OFF position before removing any base covers.

37

Page 38

4.1.2.4 Full Removal and Replacement of Column Casing

Articulate the table to the highest position.1.

Turn the Main Switch to the OFF position and disconnect the Mains Cord.2.

Using a Phillips drive, remove the four M4.2X13 column case-to-base screws (Item 24, Figure 3.

4.6) and machined washers (Item 23, Figure 4.6) that secure the column casings to the base covers (Figure 4.7).

Using a 2.5mm hex Allen wrench, remove the seven M4X16 screws (Item 4, Figure 4.6) connect-4.

ing the right casing half (Item 15, Figure 4.6) to the Bellows Frame.

Using a 2mm hex Allen wrench, remove the M3X16 screw (Item 26, Figure 4.6 and Item 12, Fig-5.

ure 4.14) that runs through the right casing half (Item 15, Figure 4.6) holding the bracket (Item

13, Figure 4.14) to the right Bellows Frame (Item 10, Figure 4.6). It is important that this screw

be separated for later reinstallation.

Using a 2mm hex Allen wrench, remove the four M3X4 screws (Item 10, Figure 4.14) that join 6.

the right and left casings. The right casing (Item 15, Figure 4.6) can be removed at this point.

Using a 2.5mm hex Allen wrench, remove the two M4X16 screws (Item 5, Figure 4.11) that 7.

secure the leg side of the left casing half (Item 15, Figure 4.6) to the left Bellows Frame (Item

11, Figure 4.6). Using a 2.5mm hex Allen wrench, remove the two M4X6 screws (Item 1, Figure

4.11) that secure the back side of the left casing half (Item 16, Figure 4.6) to the left Bellows

Frame (Item 11, Figure 4.6). Do not remove the two M4X16 screws (Item 3, Figure 4.11) and

the two M4X6 screws (Item 2, Figure 4.11) on the front of the left casing half that are above the

Override Panel.

Flex the left casing half outward and lift up on the lower casing sets (Figure 1.12) to disengage 8.

the column spacers (Item 9, Figure 4.6).

Collapse the column casing sets I-IV (Items 1-4, Figure 4.14) all of the way down until they are 9.

resting on the base covers (Figure 4.13).

Starting with casing set IV (Item 4, Figure 4.14), use a 2mm hex Allen wrench and remove the 10.

four M3X4 screws (Item 10, Figure 4.14) that join the right and left casings. The casings can be

rotated 90° to allow better access to the screws. Separate the right and left casing halves of set IV

and remove. The casing sets can now be “peeled” away from the other casing set. Continue this

action to separate and remove the casing sets III-I (Items 1-3, Figure 4.14).

In step 5 the M3X16 screw (Item 12, Figure 4.14) that held the casing, bellows, and bracket 11.

together was removed. Now remove the M4X8 screw (Item 11, Figure 4.14) with a 2.5mm hex

Allen wrench. In order to access this screw, cut the zip tie (Item 1, Figures 4.14 and 4.15) that

secures the OR Panel cables to the white cable clip. Once this screw is removed, cut the zip ties

(Items 2 and 3, Figure 4.16) that secure the guidance bracket (Item 13, Figure 4.14) to the upper

Energy Chain Bracket and the upper Energy Chain, then remove the guidance bracket.

Note This process requires the use of a special 5.5mm thin nut driver tool (Figure

4.18).

38

Page 39

Figure 4.15

1

1

2

3

Figure 4.16

Remove the four grey plastic plugs on the Override Panel (Item 28, Figure 4.17).12.

Using a thin 5.5mm nut driver (Figure 4.18), remove the four nuts (Item 29, Figure 4.17) at-13.

taching the Override Panel to the left upper column casing (Item 16, Figure 4.17) and pull the

Override Panel off of the column casing free from the threaded studs. The Override Panel will

remain suspended by the control cables.

39

Page 40

29

28

16

17b

17c

Figure 4.17 - Override Panel and Column Casing

Figure 4.18 - 5.5mm Nut Driver

Peel back and remove the adhesive covers (Item 14, Figure 4.14) on the back side of the IR sen-14.

sors inside the remaining column casing (Item 16, Figure 4.17). These will be replaced by new

adhesive covers included with the column casing replacement kit (Figure 4.14).

Starting on the inside of the remaining left casing half (Item 16, Figure 4.17), remove the two 15.

small Phillips screws (Item 17c, Figure 4.17) attaching the IR PCB (Item 17b, Figure 4.17) to the

IR plastic lens (Item 17a, Figure 4.17). Do the same for the opposite side.

17a

40

Page 41

1

Figure 4.19

3

2

Use a #1 Phillips drive to remove the M3X6 screw (Item 3, Figure 4.19 [back side is shown]) that 16.

secures the cable clip above the IR Receiver. Be careful not to lose the nut on the inside of the

column casing. Do this for both sides of the column casing.

Use a 2.5mm Allen wrench to remove the cable clip screws (Item 1, Figure 4.20) that secure the 17.

IR cable to the inside of the Bellows Frame. Cut the zip ties (Item 2, Figure 4.20) that secure the

IR cable to the corners of the Bellows Frame. Do this for both sides of the column casing.

2

1

Figure 4.20

Remove the two M4X16 and two M4X6 screws (Items 2 and 3, Figure 4.11) that are located 18.

above the Override Panel, allowing the ability to remove the left half of the column casing pair V

(Item 16, Figure 4.17) from the Bellows Frame.

41

Page 42

The left half of the column casing pair V (Item 16, Figure 4.17) should come free with the plas-19.

tic IR lenses (Item 17a, Figure 4.17) still attached to the casing.

Remove the Phillips screws (Item 2, Figure 4.19) holding the IR lenses to the column casing for 20.

reinstallation on the new column casing set.

To install a new column casing set (Figure 4.14), work in reverse order through the above listed 21.

steps. When installing new zip ties, check that all zip ties are secure and do not pinch the control wires. When installing the new grounding clips (Item 9, Figure 4.14), the corner of the clips

must be bent to allow better seating between the column casing pairs I-IV (Figure 4.21). Install

clips facing outward from column casing pairs I-IV (Figure 4.22). When cycling the column up

and down, the guidance bracket should not noticeably deform, and the Energy Chain should

move freely without stretching or kinking wires. DO NOT crash the upper column casing into

the lower ones if they are partially disassembled.

Figure 4.21

Figure 4.22

Note When replacing damaged column casing sets, examine the Bellows Frames (Items

10 and 11, Figure 4.6 and Items 1b and 1c, Figure 4.23) to ensure there is no

permanent deformation. If these frames are not square, as shown in Section 4.1.3,

they must be replaced. If the Bellows Frames are to be replaced, be sure to transfer

the cable clips onto the new frames from the old frames. Properly secure all cables

prior to reassembly of the new column casings.

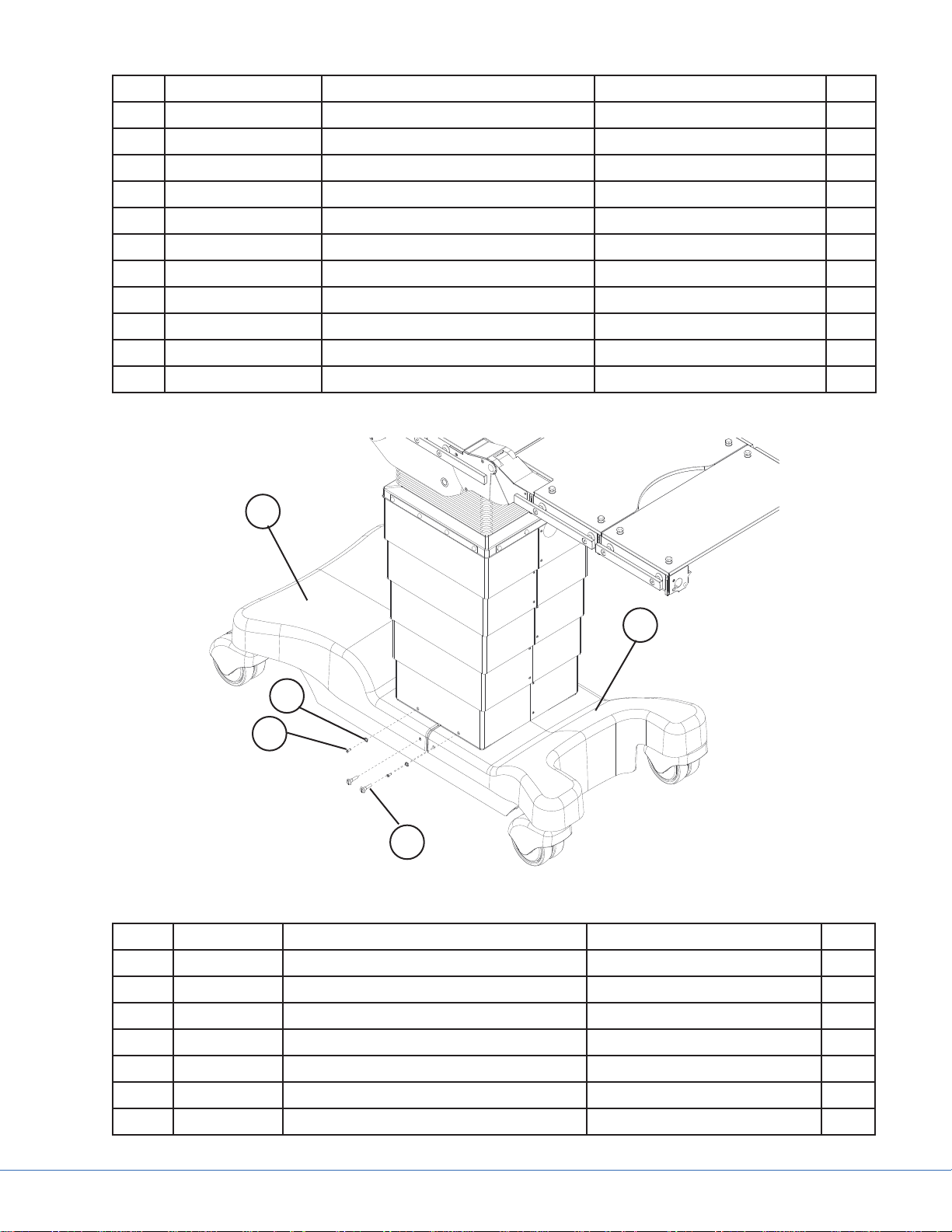

4.1.3 Bellows Frame Replacement

42

Page 43

Route hydraulic hoses

through here

4

1c

1b

2

3

1a

Figure 4.23 - Bellows Frame Assembly

Note Bellows frame assembly only includes items 1a, 1b, and 1c.

Part Code Part Name Additional Information Qty.

1 0788200040 Bellows Frame Assembly Includes items 1a, 1b, and 1c 1

1a 0788400012 Bellows Frame Mounting Bolt M6X100 DIN 7991 2

1b 0788300079 Lower Bellows Frame Right 1

1c 0788300078 Lower Bellows Frame Left 1

2 - Hose Retaining Bracket 1

3 - Main Column Spacer 1

4 0788399009 Upper 50mm Energy Chain Guid-

1

ance Bracket

If the Bellows Frames needs to be replaced, fi rst follow the Full Removal and Replacement of the 1.

Column Casings in Section 4.1.2.3.

Unhook the sensor extension wire from the extension wire bracket shown in Figure 4.24. Late 2.

model tables will have the short bracket shown on the right side in Figure 4.23, where older

tables have the long bracket on the left side of the fi gure.

43

Page 44

Tilt the table to the patient left and use bungee cord to secure the Column Bellows (Item 5, Fig-3.

ure 4.6) out of the way to allow for easier access to the two M6 screws (Item 1a, Figure 4.23).

Using a 2.5mm hex Allen wrench, remove the grounding screw (Item 1, Figure 4.25) located 4.

along the right Bellows Frame (Item 1b, Figure 4.23).

Figure 4.24

1

Figure 4.25

Carefully cut away the zip ties that secure the two yellow and green ground wires to the Bellows 5.

Frame (Items 1, 2, and 3, Figure 4.26). New zip ties will need to be placed in these locations

upon installation of the new Bellows Frame.

44

Page 45

1

2

Figure 4.26

Using a 2.5mm hex Allen wrench, carefully remove the cable clip screws (Item 1, Figure 4.27) to 6.

allow for removal of the IR Receiver cables. Cut away any zip ties (Item 2, Figure 4.27) securing

cables to the Bellows Frame. New zip ties will need to be placed in these locations upon installation of the new Bellows Frame.

1

3

2

3

Figure 4.27

Cut the zip ties for OR Panel cables (Items 1 and 2, Figure 4.28). New zip ties will need to be 7.

placed in these locations upon installation of the new bellow frame.

45

Page 46

1

2

Figure 4.28

Note Carefully examine how the hydraulic hoses are routed between the hose retaining

bracket (Item 2, Figure 4.23) and the main column spacer (Item 3, Figure 4.23)

Using a 4mm hex Allen wrench, carefully remove the two M6X100 mounting bolts (Item 1a, 8.

Figure 4.23) that connect the Bellows Frames (Items 1b and 1c, Figure 4.23) and hold the

brackets (Items 2, 3, and 4, Figure 4.23) together to the main column support. Be very careful

to not strip the 4mm hex head key of the M6X100 mounting bolts (Item 1a, Figure 4.23) upon

removal. These screws torque tightly, making them easy to strip and round out. If this happens,

use a screw extractor bit (Figure 4.29) to remove the M6X100 mounting bolt.

Figure 4.29 - Extractor Bit

While the unit is disassembled, refer to Section 12.5 to perform any repairs or maintenance 9.

needed.

To install new Bellows Frame assembly (Item 1, Figure 4.23), work in reverse order through 10.

steps 1-9. Use new zip ties to secure wires and cables as shown in Figures 4.25, 4.26, and 4.27.

46

Page 47

WARNING Ensure that items 2, 3, and 4 in Figure 4.23 are installed in the proper

sequence. Ensure that the lip of the hose retaining bracket (Item 2, Figure

4.23) is pointing up and outward. Failure to do this will cause a hazardous

situation for the patient and user.

4.1.4 Castor Removal

Fixing bolt

M6X12

Figure 4.30

47

Page 48

7

3

11

2

6

5

8

1

4

9

Figure 4.31 - Castor Assembly

Part Code Part Name Additional Information Qty.

- 0788300064 Castor Assembly Includes items 1-11 below 1

1 A31619700 Castor Frame 1

2 71565 Shaft Bearing 2

3 A4445101 Metal Washer 1

4 A41667100 Castor Axel 1

5 0788300047 Castor Cover 1

6 706531 Screw M4X8 DIN 7991 A2 4

10

7 0788400036 Screw M6X12 SFS 2219 1

8 71249 Castor Wheel 2

9 A00873 Wheel Bearing Housing 4

10 707422 Nut M8 A2 DIN 985 2

11 - Plastic Washer 1

48

Page 49

Note THIS IS AN IN-HOUSE FACTORY REPAIR ONLY. Please contact customer ser-

vice for factory repair.

WARNING Before gaining access to remove castors, use the factory table winch to lift

up the surgical table from the ground. Do not attempt without appropriate

factory support equipment for the table.

WARNING Use extreme caution when performing the following sequence of events.

The table is very heavy and can cause serious harm if dropped on the body.

Caution Bearings sit tightly in the base frame—if it is necessary to change them, the

bearing puller may be needed to get them out.

Note Bearings must also be replaced if the castor needs replacement.

Raise the table with the support crane and position it on the high lift pallet jack to gain access to 1.

the castor.

Remove base covers, see Section 4.1.1.2.

Remove the M6 screw (Item 7, Figure 4.31) using a 5mm Allen wrench.3.

The bearings are press fi t into the base frame and cannot be changed without special tools. The 4.

castor frame (Item 1, Figure 4.31) should drop free from the bottom of the base once the M6

screw (Item 7, Figure 4.31) is removed. If this is not the case, a light tapping force can be applied

to the top of the shaft using a brass rod or other soft metal.

Once the castor is free, the four M4 screws (Item 6, Figure 4.31) can be removed with a 2.5mm 5.

Allen wrench such that the castor cover can be replaced.

For bearing removal, use the bearing remover tool (Figure 4.32).6.

Figure 4.32 - Bearing Puller

Once the castor shaft is free and the bearings are still pressed in the base frame, insert the prongs 7.

of the bearing remover along the inside surface of the bearings (Item 2, Figure 4.31 and Figure

4.33).

49

Page 50

Tighten the head of the bearing remover to allow the prongs to expand and grip the bearing 8.

from the inside (Item 1, Figure 4.34).

2

1

Figure 4.33

1

1

Figure 4.34

Pull repeatedly on the handle to dislodge the bearing (Item 2, Figure 4.31 and 4.32) until it is 9.

free (see Figure 4.35).

Caution To avoid damage to the bearing races, ensure that you are pulling the bear-

ing straight out.

50

Figure 4.35

Page 51

To install a new bearing (Item 2, Figure 4.31) use the bearing installer tool shown in Figure 4.36 10.

below.

Figure 4.36 - Bearing Installer

Unscrew the two halves of the bearing installer and place the bearings (Item 2, Figure 4.37) con-11.

centric within the two shafts. The upper half of the bearing installer (Item 1, Figure 4.37) will

have a ½” drive for a socket attachment.

2

2

Figure 4.37

Take the upper half of the bearing installer (Item 1, Figure 4.38) and place it through the top 12.

side of the base frame bearing outlet (not shown).

1

2

3

1

4

Figure 4.38

Take the lower half of the bearing installer (Item 3, Figure 4.38) and place it through the bottom 13.

side of the base frame bearing outlet (not shown).

Align properly so the two halves of the bearing installer are threaded together (Figure 4.38). En-14.

sure that the two bearings (Item 2, Figure 4.38) are concentric to the base frame bearing outlet

(not shown) and to the bearing installer shafts.

51

Page 52

Caution To avoid damage to the bearings and base frame, continually check that the

bearings are straight while tightening the bearing installer.

Attach a ½” drive socket wrench (Item 4, Figure 4.38) and tighten the bearing installer to press 15.

fi t the bearings into the base frame bearing outlet until both the bearings are fl ush.

Once the new bearings are installed, repeat steps 1-4 in reverse order to install a new castor.16.

4.2 Inner Column

upper Energy Chain

Lower Energy Chain

Figure 4.39 - Column

The column includes the bulk of the hydraulic system. Once the column casings are removed, the column is revealed. The main hydraulic valve block with solenoid valves is attached to the column. There

are two Energy Chains to allow for constrained motion of hoses and cables. The tilt, trend and height

cylinders are located here. The height cylinders can not be replaced. The wiring harness is located

directly above the main hydraulic valve block (not shown in Figure 4.39). The wiring diagram can be

found in Section 6. The large metal structure on the top is the tilt frame.

4.2.1 upper Energy Chain Assembly, 50mm (0788-200-038)

52

Page 53

2

6

5

1

3

4

5

Figure 4.40 - upper Energy Chain

Part Code Part Name Additional Information Qty.

- 0788200038 Vertier, upper Energy Chain Assembly, 50mm

1 0788300100 Vertier, upper Energy Chain

(50mm)

2 0788399009 Vertier, Upper 50mm Energy

Chain Guidance Bracket

3 0788399010 Vertier, Lower 50mm Energy

Chain Guidance Bracket

Includes items 1-6 below 1

1

1

1

4 0788400029 M4X6 Socket Cap Screw 2

5 0788400010 M3X8 Socket Cap screw 4

6 0788400030 M3X24 Hex Nut 4

Note Tables with a 40mm Energy Chain can be retrofi tted with the 50mm Energy

Chain Assembly. The 40mm Energy Chain only measures 40mm across and has

the Override Panel cables routed on the outside edge (Figure 4.41).

53

Page 54

1

3

40mm

2

Figure 4.41 - 40mm Energy Chain

4.2.2 Upper 50mm Energy Chain Replacement