Page 1

Wide Transport

Stretcher

Model 738

Maintenance Manual

For Parts or Technical Assistance:

USA: 1-800-327-0770 (option 2)

Canada: 1-888-233-6888

2007/04 0738-009-002 REV B www.stryker.com

Page 2

Page 3

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning / Caution / Note Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Summary of Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Quick Reference Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Caster Cover Installation and Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Caster Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Brake Rod Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Release Pedal Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Foot End Release Pedal Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Foot End Release Pedal Rod Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fifth Wheel Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Litter Top Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Jack Descent Rate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removal of Excess Air (Vacuum) From The Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Foot End Hydraulic Jack Removal (Base With Dual Controls) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pneumatic Fowler Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fold Down Siderail Latch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Retractable 5th Wheel Base Assembly - 0853-006-110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fifth Wheel Assembly - 0853-006-130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Brake Assembly (Fifth Wheel Base) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Brake Rod Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Drive Link Assembly - 0853-003-010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Drive Link Assembly - 0853-006-135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8” Caster Assembly - 0753-010-220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Side Control Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Brake Rod / Side Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Side Control Brake Sub - Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Standard Brake Assembly, Colored Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Side Control Brake Assembly, Colored Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Dual Sided Hydraulics Assembly (Fifth Wheel Base) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Standard Hydraulics Assembly, Colored Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

End Control Hydraulics Assembly, Colored Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lowering Pedal Assembly - 0853-004-251 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Head End Pump Pedal Assembly - 0853-005-285 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Non-Constant Descent Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ww w.stryker.com 0738 -0 09 -002 RE V B 3

Page 4

Table of Contents

Assembly Drawings (Continued)

Non-Constant Jack Assembly - 0753-002-170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Jack Base Assembly, Variable Descent Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Base Labeling Assembly, Standard Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Base Labeling Assembly, 4-Sided Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Base Labeling, Colored Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Base Hood Department Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Litter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Fowler to Litter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Siderail Assembly, Right & Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pneumatic Fowler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Pneumatic Fowler Outer Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Optional Knee Gatch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Optional Knee Gatch Crankscrew Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Corner Cover, Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Corner Cover, Push Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Corner Cover, 2-Stage I.V. Pole Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Corner Cover, 2-Stage I.V. Pole, Push Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Corner Cover, 3-Stage I.V. Pole Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Corner Cover, 3-Stage I.V. Pole, Push Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Push Handle Assembly - 1211-351-010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Standard, Removable I.V. Pole Assembly - 0390-025-022 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Optional 2-Stage I.V. Pole Assembly - 1211-210-010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

I.V. Pole Latch Assembly - 1211-210-026. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Optional 3-Stage I.V. Pole Assembly - 1211-211-010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Optional 3-Stage I.V. Pole, 3rd Stage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Optional Defibrillator Tray Assembly - 0785-045-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Foot Extension/Defibrillator Tray Assembly - 0785-045-400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Foot Board/Chartholder Assembly - 0785-045-500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Upright Oxygen Bottle Holder Assembly - 1020-130-000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Optional Oxygen Bottle Retainer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Mattresses and Siderail Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

To Obtain Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Service Contract Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Service Contract Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Return Authorization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Damaged Merchandise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

International Warranty Clause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4 0738-0 09 -0 02 REV B www.stryker.com

Page 5

Introduction

INTENDED USE

This manual is designed to assist you with the maintenance of the Wide Transport Stretcher, Model 738. Carefully read

this manual thoroughly before using the equipment or beginning maintenance on it. To ensure safe operation of this

equipment, it is recommended that methods and procedures be established for educating and training staff on the safe

operation of this stretcher.

SPECIFICATIONS

Safe Working Load

Note: Safe Working Load indicates

the sum of the patient, mattress, and

accessory weight.

Overall Stretcher Length \ Width 83” / 34” 211.65 cm / 86.3 cm

Minimum \ Maximum Bed Height 21.5” / 36” 54.83 cm / 91.8 cm

Fowler Angle 0° to 90°

Knee Gatch Angle 0° to 30°

Trendelenburg \ Reverse Trendelenburg +18° to -18°

Minimum Under Stretcher Clearance 6” (15 cm) nominal

Stryker reserves the right to change specifications without notice.

Specifications listed are approximate and may vary slightly from unit to unit or by power supply fluctuations.

500 pounds 227 Kilograms

1.75” (4.5 cm) under the hydraulic cylinders and 5th wheel

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION, and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation, which if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation, which if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note

This provides special information to make maintenance easier or important instructions clearer.

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 5

Page 6

Symbols

~

Consult accompanying documentation

Alternating Current

Type B Equipment: equipment providing a particular degree of protection against electric shock,

particularly regarding allowable leakage current and reliability of the protective earth connection.

Class 1 Equipment: equipment in which protection against electric shock does not rely on basic insulation

only, but which includes an additional safety precaution in that means are provided for the connection of

the equipment to the protective earth conductor in the fixed wiring of the installation in such a way that

accessible metal parts cannot become live in the event of a failure of the basic insulation.

IPX4

Protection from liquid splash

Dangerous Voltage Symbol

Protective Earth Terminal

Potential Equalization Symbol

Medical Equipment Classified by Underwriters Laboratories Inc. with respect to Electric Shock, Fire,

Mechanical and Other Specified Hazards Only in Accordance with UL 60601-1, First Edition (2003) and

CAN/CSA C22.2 No. 601.1-M90 with updates 1 and 2.

Safe Working Load Symbol

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE), this symbol indicates that the product must not be disposed of as unsorted municipal waste,

but should be collected separately. Refer to your local distributor for return and/or collection systems

available in your country.

Return To Table of Contents

6 0738-0 09 -0 02 REV B www.stryker.com

Page 7

Summary of Safety Precautions

Before operating this stretcher, it is important to read and understand all information in this manual. Carefully read and

strictly follow the warnings and cautions listed on this page.

WARNINGS

Always apply the caster brakes when a patient is getting on or off the stretcher. Push on the stretcher to ensure the

•

brakes are securely locked. Always engage the brakes unless the stretcher is being moved. Injury could result if the

stretcher moves while a patient is getting on or off the stretcher.

Be sure the siderail latching mechanism is working properly at all times. If it is not, refer to your stretcher maintenance

•

manual for ”Siderail Latch Adjustment”.

When lowering the siderail to the collapsed position, keep extremities of patients and staff away from the siderail

•

spindles or injury could occur.

Keep fingers/hands clear of area around the Fowler release handle and the Fowler frame when lowering. Injury

•

could result if care is not taken when lowering the Fowler.

If the stretcher is equipped with the optional foot end I.V. pole, the I.V. pole must be in the raised position when the

•

foot extension/defibrillator tray is installed. If the I.V. pole is not raised, the foot extension will not function properly

and injury could occur.

CAUTIONS

To avoid damage, remove any equipment that may be in the way before raising or lowering the litter height.

•

To avoid injury or damage to the equipment, do not allow the siderail to lower on its own.

•

The push handles were designed for use while transporting the stretcher. Avoid using other parts of the stretcher as

•

push/pull devices because damage could occur.

If the Pneumatic Fowler is difficult to operate, refer to the stretcher maintenance manual for “Pneumatic Fowler

•

Adjustment”.

To avoid damage, the weight of the I.V. bags should not exceed 40 pounds.

•

To avoid damage while transporting the stretcher, verify the I.V. pole is at a low enough height to allow it to safely

•

pass through door openings and under light fixtures.

The unit cannot be raised (hydraulics on base) with a patient lift under the stretcher.

•

The hood may not be used for stepping.

•

Note

Clean hood storage area regularly.

•

The bottom of the brake rings should be cleaned regularly to prevent wax and/or floor remnant buildup.

•

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 7

Page 8

CHECKLIST

Preventative Maintenance

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

______

All fasteners secure.

Siderails move and latch properly.

Engage the brake pedal and push on the stretcher to ensure all casters lock securely.

All casters secure and swiveling properly.

Body restraints working properly.

I.V. pole intact and operating properly.

Oxygen bottle holder intact and operating properly.

Fowler operates and latches properly.

Trendelenburg/Reverse Trendelenburg operating properly.

No rips or cracks in mattress cover

Transfer boards intact and operating properly.

Ground chain intact.

No leaks at hydraulic connections.

Hydraulic jacks holding properly.

Hydraulic drop rate set properly.

Hydraulic oil level sufficient.

Lubricate where required.

Accessories and mounting hardware in good condition and working properly.

Note

Preventative maintenance should be performed at a minimum of annually. A preventative maintenance program should

be established for all Stryker Medical equipment. Preventative maintenance may need to be performed more frequently

based on the usage level of the product.

Stretcher Serial Number:

Completed by: _______________________________________ Date: _________________

Return To Table of Contents

8 0738-0 09 -0 02 REV B www.stryker.com

Page 9

Cleaning

Hand wash all surfaces of the stretcher with warm water and mild detergent. Dry thoroughly. Do not steam clean,

pressure wash, hose off or ultrasonically clean the stretcher. Using these methods of cleaning is not recommended and

may void this product’s warranty.

Suggested cleaners for stretcher surfaces:

Quaternary Cleaners (active ingredient - ammonium chloride).

•

Phenolic Cleaners (active ingredient - o-phenylphenol).

•

Chlorinated Bleach Solution (5.25% - less than 1 part bleach to 100 parts water).

•

Avoid over saturation and ensure the product does not stay wet longer than the chemical manufacturer’s guidelines for

proper disinfecting.

CAUTION

SOME CLEANING PRODUCTS ARE CORROSIVE IN NATURE AND MAY CAUSE DAMAGE TO THE PRODUCT IF USED

IMPROPERLY. If the products suggested above are used to clean Stryker patient care equipment, measures must be

taken to insure the stretcher is wiped with a damp cloth soaked in clean water and thoroughly dried following cleaning.

Failure to properly rinse and dry the stretcher will leave a corrosive residue on the surface of the stretcher, possibly

causing premature corrosion of critical components. Failure to follow the above directions when using these types of

cleaners may void this product’s warranty.

For mattress cleaning instructions, please see the tag on the mattress, or contact the mattress manufacturer.

Clean Velcro® after each use. Saturate Velcro® with disinfectant and allow disinfectant to evaporate. (Appropriate

disinfectant for nylon Velcro® should be determined by the hospital).

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 9

Page 10

Quick Reference Replacement Parts List

Note

The parts and accessories listed on this page are all currently available for purchase. Some of the parts identified on

the assembly drawing parts in this manual may not be individually available for purchase. Please call Stryker Customer

Service USA: 1-800-327-0770 (Option 2), Canada: 1-888-233-6888 for availability and pricing.

Part Name Part Number

Caster Assembly (1 complete)

Defibrillator Tray/Foot Extension

Foot Board/Chartholder Combination

Foot Board (2 per package)

Hydraulic Jack Assembly, Variable Descent

I.V. Pole, Standard Removable

Mattress, 3” x 30”, Enhanced Comfort

Mattress, 4” x 30”, Enhanced Comfort

Mattress, 4” x 30”, Ultra Comfort

Mattress, 5” x 30”, Ultra Comfort

Oxygen Bottle Holder, Upright

Paint, Touch-Up, Gloss Black, Bottle w/Brush

Paint, Touch-Up, Gloss Black, Spray Can

Paint, Touch-Up, Gray, Bottle w/Brush

Paint, Touch-Up, Gray, Spray Can

Pneumatic Cylinder

Restraint Strap, Ankle

Restraint Straps, Body

Restraint Strap, Wrist

Siderail Pad Set

0753-010-020

0785-045-400

0785-045-500

0946-029-100

0753-002-170

0390-025-000

0785-034-313

0785-034-323

0785-034-303

0785-034-333

1020-030-000

7000-001-322

7000-001-319

7000-001-320

7000-001-317

1010-031-078

0946-043-100

0390-019-000

0946-044-100

1010-052-000

Return To Table of Contents

10 0738 -0 09 -002 RE V B ww w.stryker.com

Page 11

1.

2.

3.

Service Information

CASTER COVER INSTALLATION AND REMOVAL

Double Prongs

Looking through the larger of the two side cut-outs, align the cover

with the axle nut or bolt head, as shown. Push down on the opposite

side of the cover until the single prong engages the caster horn.

Push on the cover with your palm until the double prongs engage.

Single Prong

Top View (Cut-Away)

Properly Attached

Cover

Top View (Cut-Away)

To remove the wheel cover, insert a large screwdriver into the

cut-out in the side of the wheel cover and into the space between

the double prongs. Pry up the cover to disengage the double prongs

and push sharply upward to disengage the single prong.

Top View (Cut-Away)

CASTER REMOVAL

Tools Required:

9/16” Open End Wrench

•

Procedure:

Remove the caster cover.

1.

While keeping pressure on the caster bolt with your index finger, use a 9/16” open end wrench to remove the nylock

2.

hex nut on top of the caster assembly.

Using the brake ring, lift up on the base assembly and pull the caster assembly down to remove it.

3.

Reverse steps 1-3 to install the new caster.

4.

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 11

Page 12

Service Information

BRAKE ROD REMOVAL

Tools Required:

Hammer

•

7/32” Punch

•

String or Bungee Cords

•

Procedure:

Pump the litter up to full height.

1.

Lift the base hood and support it from the litter using string or bungee cords.

2.

Remove the hex head cap screws connecting the brake rod supports to the base frame.

3.

Remove the bolt connecting the drive link assembly to the fifth wheel cam.

4.

Remove the rue ring cotter and clevis pin connecting the rod end link to the side control link.

5.

Remove the rue ring cotter connecting the drive link assembly to the bearing pivot support on the base frame (under

6.

the brake ring weldment).

Remove the three hex washer head screws holding the brake rod assembly to the base frame.

7.

Remove the slotted spring pins connecting the butterfly “V” pedals, drive link assemblies and side control link to the

8.

brake rod.

Reverse steps 1-8 to reinstall the brake rod. When reinstalling the brake rod supports, torque the hex head cap

9.

screws to 5-13 ft. - lbs.

CAUTION

When reattaching the brake rod assembly to the base frame, set the torque specs no higher than 13 ft. - lbs. or damage

could occur to the bolts.

Return To Table of Contents

12 0738 -0 09 -002 RE V B ww w.stryker.com

Page 13

Service information

SIDE CONTROL BRAKE ROD REMOVAL

Tools Required:

Hammer

•

7/32” Punch

•

Needle Nose Pliers

•

String or Bungee Cords

•

Procedure:

Pump the litter up to full height.

1.

Lift the base hood and support it from the litter using string or bungee cords.

2.

Remove the rue ring cotter and clevis pin connecting the rod end link to the side control link.

3.

Remove the four bolts holding the brake rod assembly to the base frame and remove the entire assembly.

4.

Using a hammer and 7/32” punch, drive the slotted spring pin out of the butterfly “V” pedal on the patient’s left side

5.

and remove the pedal,

Using a hammer and 7/32” punch, drive the slotted spring pin out of the hard stop in the center of the support

6.

weldment.

Using a hammer and 7/32” punch, drive out the slotted spring pin connecting the side control link to the side control

7.

brake rod on the patient’s right side.

Pull on the butterfly “V” pedal on the patient’s right side to remove the side control brake rod from the base.

8.

Reverse steps 1-8 to reinstall the brake rod. When reinstalling the assembly, torque the hex head cap screws to

9.

5-13 ft. - lbs.

CAUTION

When reattaching the brake rod assembly to the base frame, set the torque specs no higher than 13 ft. - lbs. or damage

could occur to the bolts.

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 13

Page 14

Service Information

RELEASE PEDAL ADJUSTMENT

Procedure:

1.

Manually disengage the release pedal swivel (item J on Dual Sided Hydraulics Assembly, Fifth Wheel Base section)

from the release pedal assembly.

2.

To increase the release rod engagement with the release valve, turn the release pedal swivel clockwise on the

threaded release rod.

3.

To decrease the release rod engagement with the release valve, turn the release pedal swivel counterclockwise on

the threaded release rod.

Note

If the pedal swivel assembly is threaded too far onto the release rod, the release valve will be partially activated and the

jack will drift.

FOOT END RELEASE PEDAL REPLACEMENT

Tools Required:

•

Needle Nose Pliers

Procedure:

1.

Apply the stretcher brakes.

2.

Disconnect the release pedal return springs from the foot end release pedals.

3.

Remove the rue ring cotters and the clevis pins connecting the foot end release pedals to the mounting bracket.

4.

Rotate the pedals upward.

5.

Remove the rue ring cotters connecting the head end and foot end release rods to the foot end release pedals and

remove the pedals.

6.

Reverse steps 2 - 5 to install the new pedals.

FOOT END RELEASE PEDAL ROD REMOVAL

Tools Required:

•

Needle Nose Pliers

Procedure:

1.

Remove the foot end release pedal (see procedure on Foot End Release Pedal Replacement section).

2.

Remove the snap in nyliners holding the foot end pedal release rods in the pedal mounting bracket.

3.

Unsnap the foot end pedal release rods from the white plastic release rod brackets.

4.

Dislodge the side control release pedal swivels from the studs on the side control release pedal weldment.

5.

Remove the foot end pedal release rods.

6.

Reverse steps 1 - 5 to reinstall the pedal rods.

Return To Table of Contents

14 0738 -0 09 -002 RE V B ww w.stryker.com

Page 15

Service information

BRAKE RING REMOVAL

Tools Required:

9/16” Socket With Extension

•

3/8” Drive Ratchet

•

Needle Nose Pliers

•

String or Bungee Cord

•

Procedure:

Pump the litter up to full height.

1.

Lift the base hood and support it from the litter using string or bungee cords.

2.

Using needle nose pliers, unhook the extension springs from the top of the base caster tubes.

3.

Remove the plastic caster covers.

4.

While putting pressure on the caster carriage bolt, use a 9/16” socket and a 3/8” drive ratchet to remove the caster

5.

nut on both sides of the stretcher.

Remove the casters.

6.

Remove the brake rod (see procedure).

7.

Remove the cotter pin from the clevis pin in the center of the brake ring weldment.

8.

Remove the cotter pin from the bearing pivot support.

9.

Remove the 3/4” nylock hex nut from the bearing pivot support.

10.

Remove the drive link assembly.

11.

Pull the brake ring down and out away from the stretcher base frame.

12.

Reverse steps 1 - 12 to reinstall the brake ring.

13.

FIFTH WHEEL ASSEMBLY REMOVAL

Tools Required:

1/2” Socket

•

3/8” Drive Ratchet

•

Procedure:

Using a 1/2” socket and 3/8” drive ratchet, remove the 1/2” bolt holding the fifth wheel cam drive link and fifth

1.

wheel drive link to the fifth wheel cam.

Remove the two 1/2” bolts holding the fifth wheel mounting bracket to the base frame weldment.

2.

Remove the fifth wheel assembly.

3.

Reverse steps 1 and 2 to reinstall the fifth wheel. When reinstalling the assembly, torque the hex head cap screws

4.

to 5 - 13 ft. - lbs.

CAUTION

When reattaching the fifth wheel assembly to the base frame, set the torque specs no higher than 13 ft. - lbs. or damage could occur to the bolts.

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 15

Page 16

Service Information

LITTER TOP REMOVAL

Tools Required:

1/2” Socket W/Extension

•

3/8” Drive Ratchet

•

Standard Screwdriver

•

Procedure:

Using the foot pedal, pump up the litter top to full height.

1.

Remove the stretcher mattress

2.

Remove the round, black hole plugs from the jack supports at each end of the litter to expose the jack support tube

3.

truss head screws.

Using a 1/2” socket, and a 3/8” drive ratchet, remove the truss head screws holding the jack support tubes to the

4.

jack shafts.

Thread a 7/16 - 20 fine thread bolt far enough into the top of the jack supports to separate the litter top from the

5.

jack shaft.

With the assistance of another person, lift the litter straight up to remove it from the jack shafts and set it aside.

6.

JACK DESCENT RATE ADJUSTMENT

Tools Required:

Screwdriver

•

Bungee Cords (or equivalent)

•

Procedure:

Pump the litter up to full height.

1.

Lift the base hood, separating the hood from the base frame. Support the hood from the litter using bungee cords

2.

so it is out of the way.

The descent rate needle valve is located on the base of the jack. Turning the needle valve clockwise, with a

3.

screwdriver, will decrease the rate of descent. Turning it counterclockwise will increase the rate of descent.

Note

The larger percentage of a patient’s weight is located in the torso area. Adjust descent rate accordingly.

Remove the bungee cords supporting the base hood and secure the hood to the base frame.

4.

Note

The jack descent rate is preset at the factory and adjustment is not recommended.

REMOVAL OF EXCESS AIR (VACUUM) FROM THE HYDRAULIC SYSTEM

Verify all hydraulic linkages are secure and operating properly.

1.

Using the pump pedal, actuate the system several times to force the air through the system. The jack should now

2.

raise properly.

Return To Table of Contents

16 0738 -0 09 -002 RE V B ww w.stryker.com

Page 17

Service information

HEAD END HYDRAULIC JACK REMOVAL

Tools Required:

•

1/2” Socket With Extension

•

3/8” Drive Ratchet

Procedure:

1.

Remove the litter top from the stretcher (see Litter Top Removal section).

2.

Using a 1/2” socket with extension and a 3/8” drive ratchet, remove the two hex head screws holding the jack base

to the stretcher base frame.

3.

Remove the two hex head screws holding the jack reservoir clamp to the base frame and remove the clamps.

4.

Lift straight up on the pump connecting rod and disconnect the pump piston from the connecting rod.

5.

Disconnect the pump pedal swivel from the release pedal mounting plate.

6.

Remove the head end release rod from the release valve assembly.

7.

Using a 1/2” socket with extension and a 3/8” drive ratchet, remove the two hex head screws holding the jack base

to the stretcher base frame.

Lift out the jack assembly.

8.

To reinstall the jack, install the bolts on the jack and reservoir clamp but do not tighten them fully.

9.

Reinstall the pump connecting rod and release rod.

10.

Depress the pump pedal fully (to the floor). This will properly locate the jack onto the base frame.

11.

Tighten the bolts on the jack and reservoir clamp.

12.

Pump up the litter and apply weight to verify the jacks hold and do not drift.

13.

Note

The jack descent rate is preset at the factory and adjustment is not recommended.

FOOT END HYDRAULIC JACK REMOVAL (BASE WITH DUAL CONTROLS)

Tools Required:

•

1/2” Socket

•

3/8” Drive Ratchet

•

Pliers

Procedure:

1.

Remove the litter top from the stretcher (see Litter Top Removal section).

2.

Lift the base hood off the base frame.

3.

Remove the two hex washer head screws and washers connecting the pump pedal link to the foot end pump pedal

assembly and pump connecting rod.

4.

Remove the foot end release rod from the release valve on the jack assembly by dislodging the release pedal swivel

from the pins on the release pedal weldment.

5.

Dislodge the jack pump piston from the pump connecting rod.

6.

Remove the two hex washer head screws holding the reservoir clamp.

7.

Remove the jack assembly.

8.

Reverse steps 1 - 7 to install the new jack.

Note

The jack descent rate is preset at the factory and adjustment is not recommended.

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 17

Page 18

Service Information

PNEUMATIC FOWLER ADJUSTMENT

Tools Required:

5/32” Hex Allen Wrench

•

1/2” Open End Wrench

•

Procedure:

Refer to the Pneumatic Fowler Assembly drawing for parts reference.

1.

For easier access, raise the Fowler to 75° or higher.

2.

Using a 1/2” open end wrench, loosen the hex nuts (item E) in the actuator arms on the end of the trip bar

3.

(item M).

To adjust the Fowler, use a 5/32” hex Allen wrench to turn the Allen screws (item J) 1 to 2 turns counterclockwise

4.

if the Fowler will not move or 1 to 2 turns clockwise if the Fowler will not hold its position.

Retighten the hex nuts. Be sure the Fowler travels from flat up to 90° and down again and holds its position when

5.

weight is applied before returning the stretcher to service.

FOLD DOWN SIDERAIL LATCH ADJUSTMENT

Tools Required:

1/8” Hex Allen Wrench

•

WARNING

The siderail latches are preset at the factory, and do not normally need adjustment. If adjustment must be done, it is

important to follow the procedure below. If adjustment is not done properly, injury to the patient or user could result.

Procedure:

Using a 1/8” hex Allen wrench, adjust the hex Allen screw located on the latch assembly opposite the latch. Turning

1.

the screw clockwise will decrease the amount of ”play” in the latching mechanism. Turning counterclockwise will

increase the amount.

Note

The amount of “play” in the siderail, when in full up engaged position, should be approximately 1/8 to 3/16 inches.

CAUTION

Too much “play” when the siderail is in the full up engaged position will give the siderail the appearance of being unstable

and could also cause premature wearing of the latch system.

Too little “play” will obstruct the latch and keep it from engaging completely in the full up position, which may result in

damage to the latch and/or injury to the patient or user

Return To Table of Contents

18 0738 -0 09 -002 RE V B ww w.stryker.com

Page 19

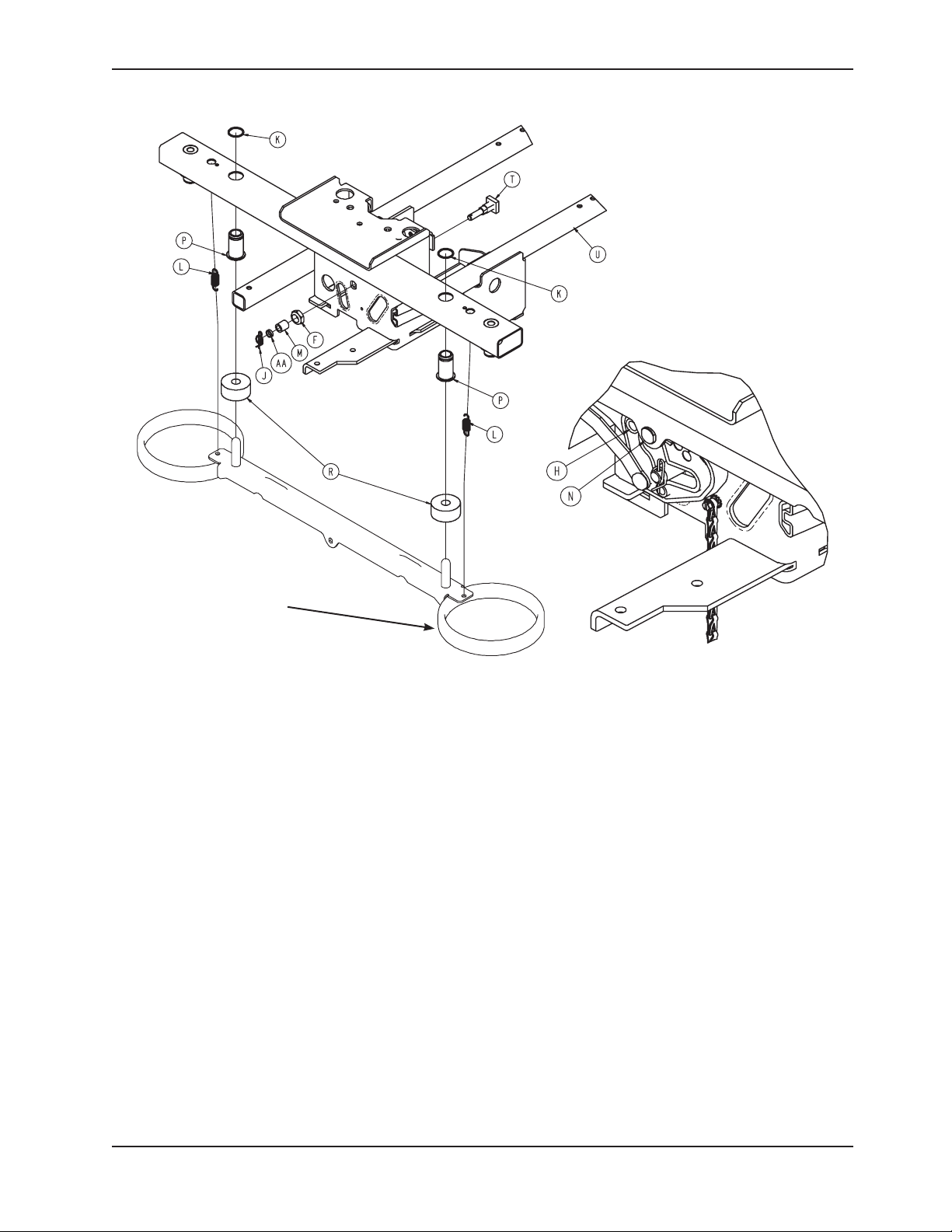

Retractable 5th Wheel Base Assembly - 0853-006-110

Item Part No. Part Name Qty.

A 0023-288-000 Hex Washer Head Screw 2

B 0023-305-000 Hex Head Cap Screw 1

C 0753-006-148 Cam Bearing 1

D 0853-006-130 Fifth Wheel Assembly 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 19

Page 20

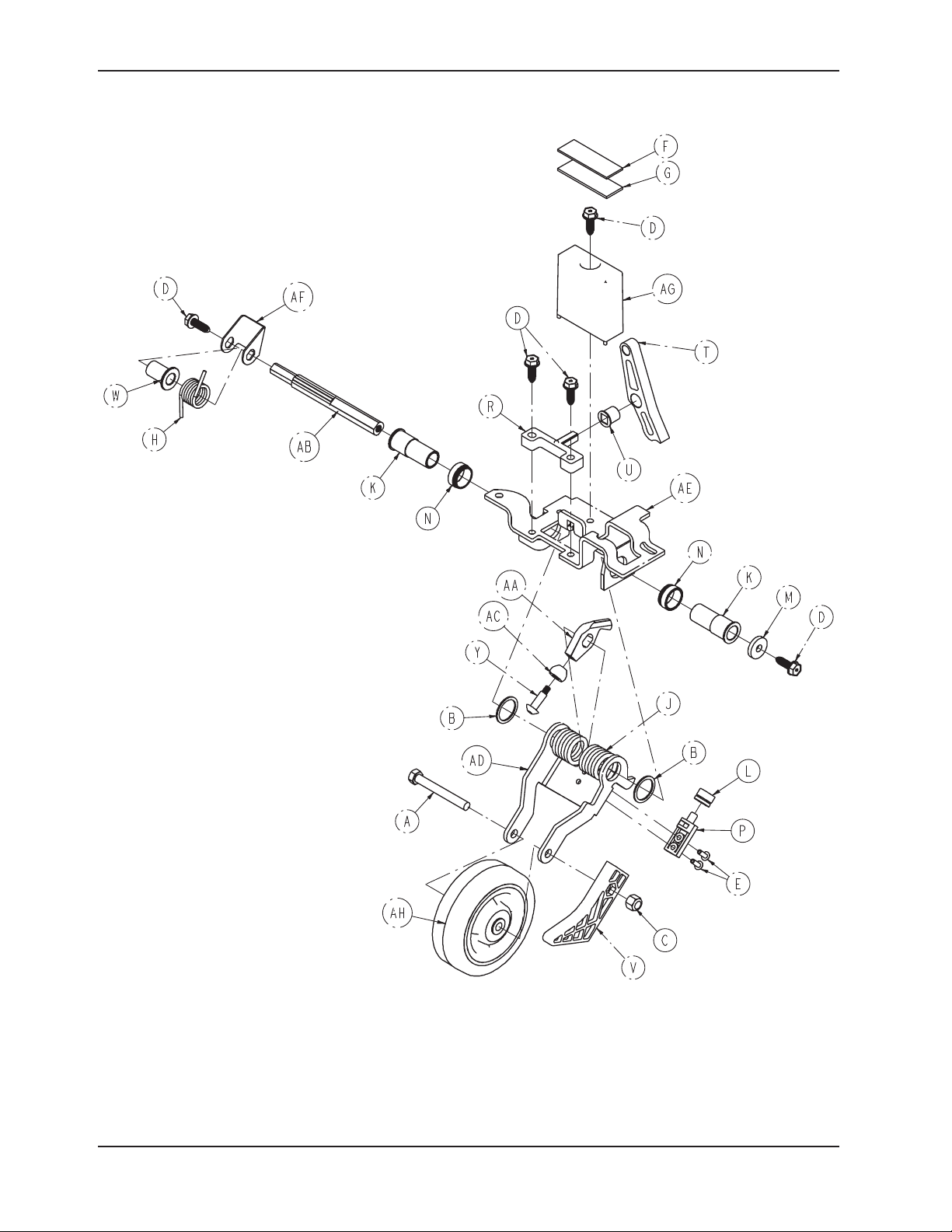

Fifth Wheel Assembly - 0853-006-130

Return To Table of Contents

20 0738 -0 09 -002 RE V B ww w.stryker.com

Page 21

Fifth Wheel Assembly - 0853-006-130

Fifth Wheel Assembly, Common Components - 0853-006-130 - (reference only)

Item Part No. Part Name Qty.

A 0003-083-000 Hex Head Cap Screw 1

B 0011-360-000 Washer 2

C 0016-035-000 Nylock Hexagonal Nut 1

D 0023-288-000 Hex Washer Head Screw 5

E 0025-050-000 Rivet 2

F 0029-007-000 Dual Lock 1

G 0029-009-000 Dual Lock 1

H 0753-006-074 Torsion Spring 1

J 0753-006-075 Torsion Spring 1

K 0753-006-097 Drive Shaft Bearing 2

L 0753-006-106 Dampener 1

M 0753-006-108 Thrust Washer 1

N 0753-006-115 Bearing 2

P 0753-006-120 Bumper Mounting Pin 1

R 0753-006-133 Cam Pivot Block 1

T 0753-006-142 Fifth Wheel Cam 1

U 0753-006-143 Cam Bearing 1

V 0753-006-149 5th Wheel Ramp 1

W 0753-006-152 Spring Spacer 1

Y 0753-006-153 Roller Stem 1

AA 0753-006-198 Drive Pin 1

AB 0753-006-223 Drive Shaft 1

AC 0753-006-277 Roller 1

AD 0853-006-126 5th Wheel Bracket 1

AE 0853-006-131 5th Wheel Weldment 1

AF 0853-006-227 Return Spring Hook 1

AG 0853-010-045 Hood Standoff 1

AH 1210-001-147 Wheel 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 21

Page 22

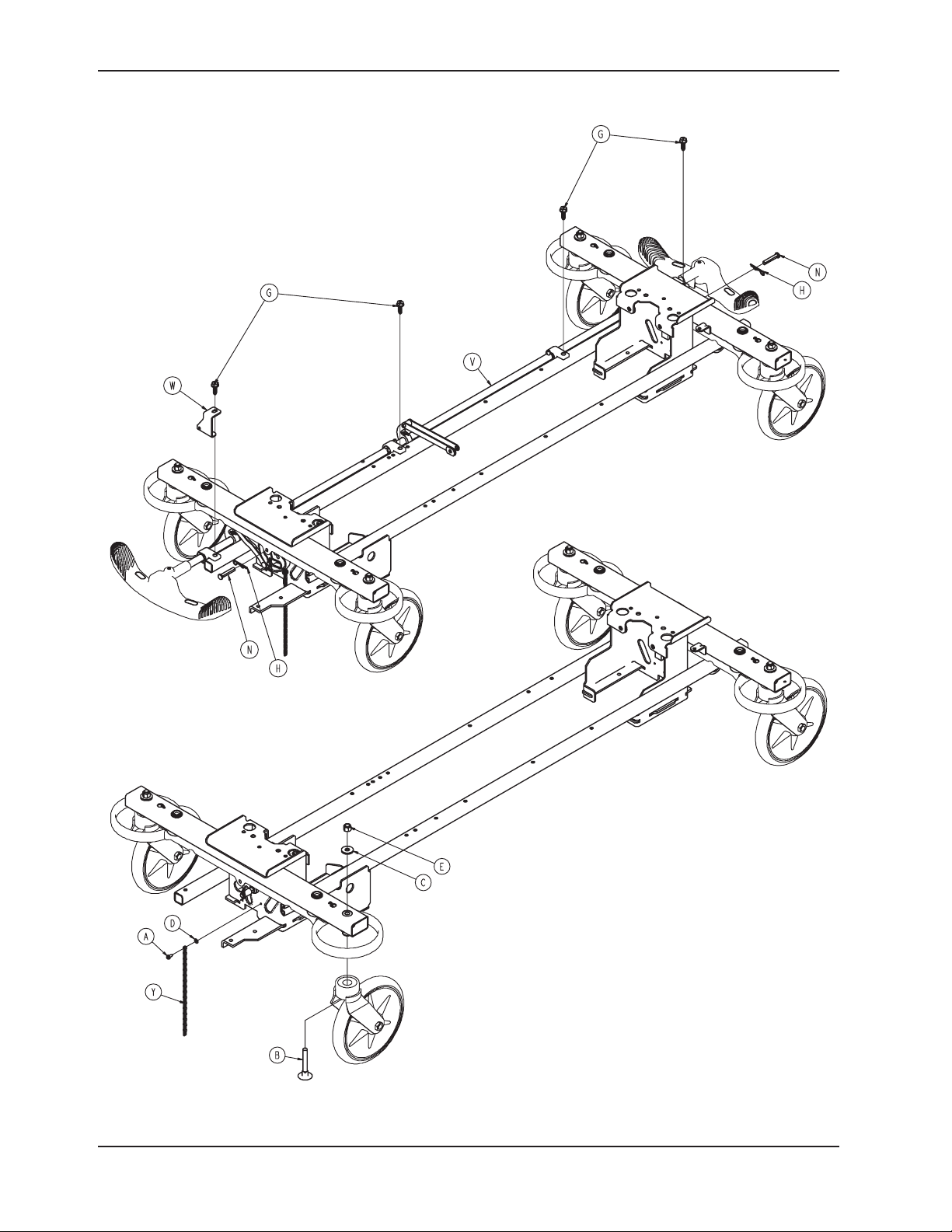

Standard Brake Assembly (Fifth Wheel Base)

For Reference Only: 0853-003-205

Return To Table of Contents

22 0738 -0 09 -002 RE V B ww w.stryker.com

Page 23

Standard Brake Assembly (Fifth Wheel Base)

(See Page 33)

Standard Brake Assembly,

Colored Components

Standard Brake Assembly, Common Components - 0853-003-205 - (reference only)

Item Part No. Part Name Qty.

A 0003-364-000 Hexagonal Screw 1

B 0005-044-000 Step Bolt 4

C 0011-262-000 Washer 4

D 0013-018-000 Tooth Lock Washer 1

E 0016-035-000 Nylock Hex Nut 4

F 0016-049-000 Nylock Hex Nut 2

G 0023-288-000 Hex Washer Head Screw 4

H 0027-012-000 Hitch Pin 2

J 0027-022-000 Rue Ring Cotter 2

K 0028-205-000 Spiral Retaining Ring 4

L 0038-439-000 Extension Spring 4

M 0081-272-000 Needle Bearing 2

N 0753-003-066 Clevis Pin 2

P 0753-003-079 Caster Tube Brake Pin Guide 4

R 0753-003-121 Brake Cushion 4

T 0853-003-230 Bearing Pivot Support 2

U 0853-001-001 Base Weldment 1

V 0853-003-201 Brake Rod Assembly 1

W 0853-005-087 Return Spring Hook 1

Y 3001-200-052 Ground Chain 1

AA 0753-003-131 Spacer 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 23

Page 24

For Reference Only: 0853-003-201

Brake Rod Assembly

Item Part No. Part Name Qty.

A 0026-014-000 Slotted Spring Pin 4

B 0026-273-000 Clevis Pin 3

C 0027-020-000 Rue Ring Cotter 3

D 0753-003-015 Brake Rod Nyliner 4

E 0853-003-004 Brake Rod Support 4

F 0853-003-010 Drive Link Assembly (pg. 25) 2

G 0853-003-014 Brake Rod 1

H 0853-006-135 Drive Link Assembly 1

J 1210-201-335 Red Brake Label 2

K 1210-201-336 Green Steer Label 2

Return To Table of Contents

24 0738 -0 09 -002 RE V B ww w.stryker.com

Page 25

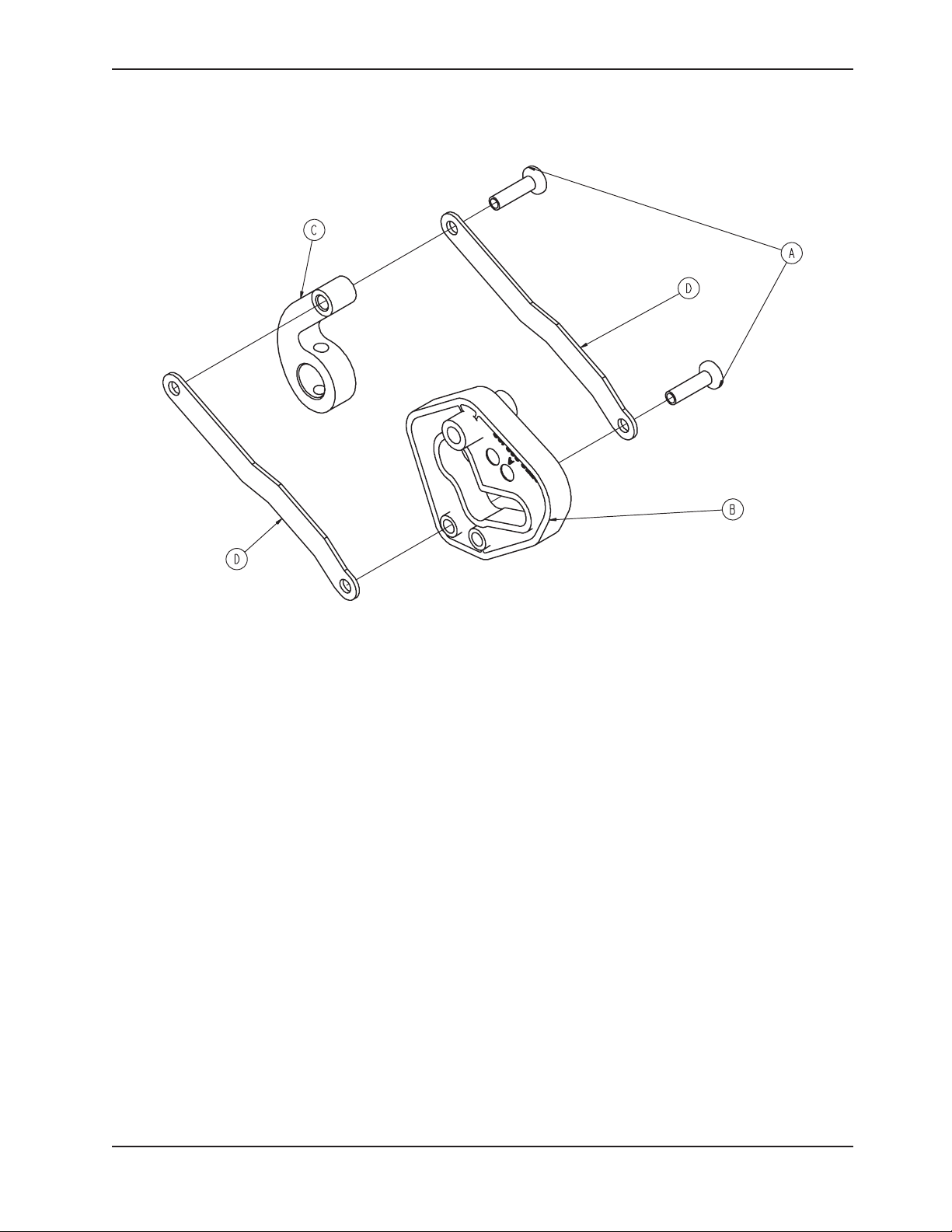

Drive Link Assembly - 0853-003-010

Item Part No. Part Name Qty.

A 0753-003-098 Flat Head Semi Tubular Rivet 2

B 0753-203-102 Brake Cam 1

C 0853-003-011 Brake Rod Drive Link 1

D 0853-003-061 Brake Cam Drive Link 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 25

Page 26

Drive Link Assembly - 0853-006-135

Item Part No. Part Name Qty.

A 0753-003-098 Semi Tubular Rivet 1

B 0853-003-011 Brake Rod Drive Link 1

C 0853-006-022 5th Wheel Cam Drive Link 1

D 0853-006-047 5th Wheel Cam Drive Link 1

Return To Table of Contents

26 0738 -0 09 -002 RE V B ww w.stryker.com

Page 27

8” Caster Assembly - 0753-010-220

Item Part No. Part Name Qty.

A 0003-099-000 Hexagonal Head Cap Screw 1

B 0016-060-000 Center lock Nut 1

C 0753-003-215 Wheel 1

D 0753-010-021 Caster Horn W/Bearing 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 27

Page 28

Side Control Brake Assembly

For Reference Only: 0853-003-220

Return To Table of Contents

28 0738 -0 09 -002 RE V B ww w.stryker.com

Page 29

Side Control Brake Assembly

See Detail A

Detail A

Typical Both Ends

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 29

Page 30

Side Control Brake Assembly

Typical Assembly Both Ends

Side Control Brake Assembly, Common Components - 0853-003-220 - (reference only)

Item Part No. Part Name Qty.

A 0003-364-000 Slotted Screw 1

B 0005-044-000 Step Bolt 4

C 0011-262-000 Washer 4

D 0013-018-000 Tooth Lock Washer 1

E 0016-035-000 Nylock Hex Nut 4

F 0016-049-000 Nylock Hex Nut 2

G 0023-233-000 Hex Washer Head Screw 8

H 0026-340-000 Clevis Pin 1

J 0027-012-000 Hitch Pin 2

K 0027-022-000 Rue Ring Cotter 1

L 0027-022-000 Rue Ring Cotter 2

M 0028-205-000 Spiral Retaining Ring 4

N 0038-439-000 Extension Spring 4

P 0081-272-000 Needle Bearing 2

R 0753-003-066 Clevis Pin 2

T 0753-003-079 Caster Tube Brake Pin Guide 4

U 0753-003-121 Brake Cushion 4

V 0853-003-230 Bearing Pivot Support 2

W 0853-001-001 Base Weldment 1

Y 0853-003-210 Side Control Brake Ass’y (pg. 32 1

AA 0853-003-225 Brake Rod/Side Cntrl Ass’y (pg.31) 1

AB 0853-005-087 Return Spring Hook 1

AC 3001-200-052 Ground Chain 1

AD 0753-003-131 Spacer 2

Return To Table of Contents

30 0738 -0 09 -002 RE V B ww w.stryker.com

Page 31

Brake Rod / Side Control Assembly

For Reference Only: 0853-003-225

Item Part No. Part Name Qty.

A 0026-014-000 Slotted Spring Pin 5

B 0026-273-000 Clevis Pin 3

C 0027-020-000 Rue Ring Cotter 3

D 0753-003-015 Brake Rod Nyliner 4

E 0753-003-112 Side Control Link 1

F 0753-003-004 Brake Rod Support 4

G 0853-003-010 Drive Link Assembly (pg. 25) 2

H 0853-003-014 Brake Rod 1

J 0853-006-135 Drive Link Assembly (pg. 26) 1

K 1210-201-335 Red Brake Label 2

L 1210-201-336 Green Steer Label 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 31

Page 32

Side Control Brake Sub - Assembly

For Reference Only: 0853-003-210

Item Part No. Part Name Qty.

A 0026-014-000 Slotted Spring Pin 4

B 0026-340-000 Clevis Pin 1

C 0027-020-000 Rue Ring Cotter 1

D 0753-003-112 Side Control Link 1

E 0753-003-117 Rod End Link 1

F 0853-003-214 Side Control Shaft Support 1

G 0853-003-319 Side Control Brake Rod 1

H 1210-201-335 Red Brake Label 2

J 1210-201-336 Green Steer Label 2

Return To Table of Contents

32 0738 -0 09 -002 RE V B ww w.stryker.com

Page 33

Standard Brake Assembly, Colored Components

For Reference Only: 0853-003-620

Part Number Part Description Quantity

0753-003-128 Brake Ring Weldment (Black) 2

0753-010-020 8” Caster Assembly (Black) 4

0753-201-126 Pump Pedal (Black) 2

0853-005-154 Butterfly “V” Pedal (Black) 2

1061-201-127 Short Uni-Pedal (Black) 2

Side Control Brake Assembly, Colored Components

For Reference Only: 0853-003-630

Part Number Part Description Quantity

0753-003-128 Brake Ring Weldment (Black) 2

0753-010-020 8” Caster Assembly (Black) 4

0753-201-126 Pump Pedal (Black) 2

0853-005-154 Butterfly “V” Pedal (Black) 2

1061-201-127 Short Uni-Pedal (Black) 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 33

Page 34

Dual Sided Hydraulics Assembly (Fifth Wheel Base)

For Reference Only: 0853-005-525

Return To Table of Contents

34 0738 -0 09 -002 RE V B ww w.stryker.com

Page 35

Dual Sided Hydraulics Assembly (Fifth Wheel Base)

See Detail A

Detail A

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 35

Page 36

Dual Sided Hydraulics Assembly (Fifth Wheel Base)

Insert Head End Release Rod

into Release Valve Assembly as

shown

Insert Foot End Release Rod into

Release Valve Assembly as shown

Dual Side Hydraulics Assembly, Common Components - 0853-005-525 - (reference only)

Item Part No. Part Name Qty.

A 0011-023-000 Washer 2

B 0014-071-000 Washer 2

C 0023-288-000 Hexagonal Washer Head Screw 7

D 0027-020-000 Rue Ring Cotter 2

E 0027-031-000 Hair Pin Cotter 1

F 0853-005-009 Return Spring 3

G 0753-005-044 Pump Pedal Bushing 2

H 0753-005-089 Pump Ram Plug 2

J 0052-909-000 Clevis Joint 2

K 0853-004-014 Head End Release Rod 1

L 0853-004-015 Foot End Release Rod 1

M 0853-004-251 Lowering Pedal Assembly (pg. 38) 1

N 0853-005-035 Pump Connecting Tube Weldment 1

P 0853-005-074 Pivot Pin 1

R 0853-005-075 Pump Pedal Link 1

T 0853-005-285 HE Pump Pedal Assembly (pg. 39) 1

U 0853-010-215 Release Rod Bracket 1

Return To Table of Contents

36 0738 -0 09 -002 RE V B ww w.stryker.com

Page 37

Standard Hydraulics Assembly, Colored Components

For Reference Only: 0853-005-650

Part Number Part Description Quantity

0753-201-126 Pump Pedal (Black) 2

0853-005-154 Butterfly “V” Pedal (Black) 1

1061-201-127 Short Unit - Pedal (Black) 2

End Control Hydraulics Assembly, Colored Components

For Reference Only: 0853-005-660

Part Number Part Description Quantity

0753-004-134 Left Foot End Release Pedal (Black) 1

0753-004-135 Right Foot End Release Pedal (Black) 1

0753-201-126 Pump Pedal (Black) 3

0853-003-099 Butterfly “V” Pedal (Black) 1

1061-201-127 Short Uni-Pedal (Black) 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 37

Page 38

Lowering Pedal Assembly - 0853-004-251

(See Page 37)

Standard Hydraulics Assembly,

Colored Components

Item Part No. Part Name Qty.

A 0025-133-000 Rivet 6

B 0753-004-029 Release Pedal Standoff 6

C 0853-004-004 Release Pedal Weldment 2

D 0853-004-320 Release Pedal Support 1

E 1069-004-320 Release Pedal Support 1

Return To Table of Contents

38 0738 -0 09 -002 RE V B ww w.stryker.com

Page 39

Head End Pump Pedal Assembly - 0853-005-285

(See Page 37)

Standard Hydraulics Assembly,

Colored Components

Item Part No. Part Name Qty.

A 0026-343-000 Groove Pin 2

B 0715-001-140 Vinyl Tube 1

C 0853-005-180 Head End Pump Pedal Weldment 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 39

Page 40

Non-Constant Descent Jack

For Reference Only: 0853-002-180

Item Part No. Part Name Qty.

A 0023-288-000 Hexagonal Washer Head Screw 8

B 0753-002-170 Jack Assembly,

Non-Constant Descent (pg. 41) 2

C 0853-010-007 Reservoir Clamp 2

Return To Table of Contents

40 0738 -0 09 -002 RE V B ww w.stryker.com

Page 41

Non-Constant Jack Assembly - 0753-002-170

Item Part No. Part Name Qty.

A 0045-273-000 O - Ring 1

B 0045-274-000 O - Ring 1

C 0048-190-000 U - Cup Seal 1

D 0753-002-017 Jack Cap 1

E 0753-002-075 Jack Base Assembly,

Non-Constant Descent (pg. 42) 1

F 0753-002-104 Actuator Rod Assembly 1

G 0753-002-106 Actuator Cylinder Assembly 1

H 0753-102-129 Reservoir Tube 1

J 0753-202-115 Jack Assembly Label 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 41

Page 42

Jack Base Assembly, Variable Descent Jack

For Reference Only: 0753-002-075

Item Part No. Part Name Qty.

A 0046-004-000 O - Ring 1

B 0048-021-000 CV Plug 2

C 0390-002-134 Conical Compression Spring 1

D 0715-001-341 Poppet 1

E 0753-002-003 Pump Ram Assembly 1

F 0753-002-010 Jack Base 1

G 0753-002-019 Valve Filter 1

H 0753-002-051 Plug Assembly 1

J 0753-002-052 Check Valve Assembly 1

K 0753-002-063 Standard Descent Valve Assembly 1

L 0753-002-065 Release Valve Assembly 1

Return To Table of Contents

42 0738 -0 09 -002 RE V B ww w.stryker.com

Page 43

Base Labeling Assembly, Standard Brakes

For Reference Only: 0853-010-062

Department Label see

Base Labeling, Colored

Components

Specification Label

(Serial Number Location)

Foot End

Head End

Item Part No. Part Name Qty.

A 0853-001-040 Base Hood 1

B 1040-010-134 Bellows 2

C 0946-201-060 Stryker Logo Label 4

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 43

Page 44

Base Labeling Assembly, 4-Sided Brakes

For Reference Only: 0853-010-063

Department Label see

Base Labeling, Colored

Components

Foot End

Specification Label

(Serial Number Location)

Head End

Item Part No. Part Name Qty.

A 0853-001-041 Base Hood 1

B 1040-010-134 Bellows 2

C 0946-201-060 Stryker Logo Label 4

D 0853-010-018 Brake/Steer Label, Right 1

E 0853-010-019 Brake/Steer Label, Left 1

Return To Table of Contents

44 0738 -0 09 -002 RE V B ww w.stryker.com

Page 45

Base Labeling, Colored Components

For Reference Only: 0853-010-062

Item D

Label Color Color P/N

RED 0853-010-120 0753-010-051 0853-010-055 0753-010-017 0853-010-054

PURPLE 0853-010-121 0753-010-151 0853-010-155 0753-010-170 0853-010-154

GREEN 0853-010-122 0753-010-251 0853-010-255 0753-010-270 0853-010-254

GREY 0853-010-123 0753-010-351 0853-010-355 0753-010-370 0853-010-354

TEAL 0853-010-124 0753-010-451 0853-010-455 0753-010-470 0853-010-454

PINK 0853-010-125 0753-010-551 0853-010-555 0753-010-570 0853-010-554

BLUE 0853-010-126 0753-010-651 0853-010-655 0753-010-670 0853-010-654

For Reference Only: 0853-010-063

Label Color Color P/N

RED 0853-010-120 0753-010-051 0853-010-055 0753-010-017 0853-010-054

PURPLE 0853-010-121 0753-010-151 0853-010-155 0753-010-170 0853-010-154

GREEN 0853-010-122 0753-010-251 0853-010-255 0753-010-270 0853-010-254

GREY 0853-010-123 0753-010-351 0853-010-355 0753-010-370 0853-010-354

TEAL 0853-010-124 0753-010-451 0853-010-455 0753-010-470 0853-010-454

PINK 0853-010-125 0753-010-551 0853-010-555 0753-010-570 0853-010-554

BLUE 0853-010-126 0753-010-651 0853-010-655 0753-010-670 0853-010-654

Brake/Steer,

Foot End

Item F

Brake/Steer,

Foot End

Item E

Lift/Lower, Left

Item G

Lift/Lower, Left

Item F

Brake/Steer,

Head End

Item H

Brake/Steer,

Head End

Item G

Lift/Lower,

Right

Item J

Lift/Lower,

Right

BASE HOOD DEPARTMENT LABELS

Department Label Part Number Department Label Part Number

Emergency 1010-900-215 Nuclear Medicine 1010-900-255

PACU 1010-900-220 Ambulatory Surgery 1010-900-260

Transport 1010-900-225 G.I. Lab 1010-900-265

Surgery 1010-900-230 Cath. Lab 1010-900-270

Extended Stay 1010-900-235 Same Day Surgery 1010-900-275

Maternity 1010-900-240 Cardiology 1010-900-280

Endoscopy 1010-900-245 Ultrasound 1010-900-285

Radiology 1010-900-250

Note

All base hood department labels are quantity of two.

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 45

Page 46

For Reference Only: 0738-010-010

Litter Assembly

Return To Table of Contents

46 0738 -0 09 -002 RE V B ww w.stryker.com

Page 47

Litter Assembly

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 47

Page 48

Litter Assembly

Return To Table of Contents

48 0738 -0 09 -002 RE V B ww w.stryker.com

Page 49

Litter Assembly

Litter Assembly, Common Components - 0738-010-010 - (reference only)

Item Part No. Part Name Qty.

A 0003-078-000 Hex Head Cap Screw 8

B 0004-135-000 Button Head Cap Screw 4

C 0004-201-000 Socket Head Cap Screw 4

D 0004-515-000 Button Head Cap Screw 14

E 0007-074-000 Truss Head Machine Screw 2

F 0011-002-000 Washer 4

G 0011-360-000 Washer 2

H 0014-021-000 Washer 8

J 0016-028-000 Fiberlock Hex Nut 10

K 0016-035-000 Nylock Hex Nut 4

L 0021-104-000 Set Screw 2

M 0025-038-000 Dome Head Rivet 20

N 0025-079-000 Dome Head Rivet 4

P 0025-171-000 Dome Head Rivet 24

R 0028-072-000 External Retaining Ring 2

T 0037-010-000 Hole Plug 2

U 0037-074-000 Hole Plug 2

V 0037-208-000 Hole Plug 1

W 0038-220-000 Compression Spring 2

Y 0059-100-000 Hole Plug 6

AA 0721-026-066 Pivot Screw 14

AB 0721-026-069 Upright Sleeve 10

AC 0721-026-074 Lock Handle 2

AD 0721-031-065 Hole Plug 22

AE 0753-010-026 Support Tube 1

AF 0753-010-030 Support Tube 1

AG 0926-400-142 Bumper 4

AH 0938-001-401 Collar 2

AJ 0946-001-060 Stryker Logo Label 1

AK 1001-001-037 Jack Support Tube, HE 2

AL 1001-040-012 Foot Board Receptacle 2

AM 1001-201-029 Nylon Insert 2

AN 1010-026-017 Siderail Assembly, Right (pg. 52) 1

AP 1010-026-019 Siderail Assembly, Left (pg. 52) 1

AR 1010-026-080 Lock Housing, Right 1

AT 1010-026-081 Lock Housing, Left 1

AU 1010-026-103 Spring Retainer 2

AV 1010-032-092 Foley Bag Rack 2

AW 1010-201-027 Bumper Channel 2

AY 1070-010-023 Trend Support 2

BA 1210-800-008 Patent Label 1

BB 1510-432-021 Foot Section Skin 1

BC 1550-030-005 Frame Weldment 1

BD 7900-001-102 Velcro Pile 17”

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 49

Page 50

For Reference Only: 0736-031-010

Fowler to Litter Assembly

Return To Table of Contents

50 0738 -0 09 -002 RE V B ww w.stryker.com

Page 51

Fowler to Litter Assembly

Fowler to Litter Assembly, Common Components - 0736-031-010 - (reference only)

Item Part No. Part Name Qty.

A 0004-182-000 Button Head Cap Screw 2

B 0004-183-000 Button Head Cap Screw 2

C 0014-020-000 Washer 2

D 0014-021-000 Washer 6

E 0015-060-000 Nylock Hex Nut 2

F 0016-036-000 Nylock Hex Nut 2

G 0016-117-000 Stover Hex Lock Nut 2

H 0023-256-000 Sheet Metal Screw 2

J 0025-050-000 Rivet 7

K 0721-031-065 Hole Plug 4

L 0736-031-120 Pneumatic Fowler Ass’y (pg. 53) 1

M 7900-001-102 Velcro Pile 9”

N 1010-031-078 Gas Cylinder 2

P 1211-031-031 Pneumatic Fowler Rest 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 51

Page 52

Siderail Assembly, Right & Left

J

F

For Reference Only: 1010-026-017 (Right)

1010-026-019 (Left)

(Left Side Shown)

Item Part No. Part Name Qty.

A 1010-026-015 Top Rail 1

B 1010-026-083 Upright 4

C 1010-026-084 Upright, Bent 1

D 1010-026-082 Spacer 6

E 0025-106-000 Semi-Tubular Rivet 6

F 1010-026-010 Round Hole Plug 4

H 1010-026-085 Upright, Latch 1

J 1010-026-012 Bent Spindle Stop 1

Return To Table of Contents

52 0738 -0 09 -002 RE V B ww w.stryker.com

Page 53

Pneumatic Fowler Assembly

For Reference Only: 0736-031-120

Item Part No. Part Name Qty.

A 0004-161-000 Button Head Cap Screw 2

B 0007-020-000 Truss Head Machine Screw 4

C 0015-037-000 Hex jam Nut 2

D 0015-050-000 Hex Nut 2

E 0016-028-000 Hex Nut 6

F 0021-125-000 Fiber Lock Nut 2

H 0025-120-000 Rivet 2

J 1001-001-036 Hole Plug 2

K 1210-031-106 Outer Housing Ass’y, Right (pg. 54) 1

L 1210-031-107 Outer Housing Ass’y, Left (pg. 54) 1

M 1501-031-013 Fowler Tube 1

N 1510-231-012 Fowler Skin 1

P 1710-031-118 Trip Bar Assembly 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 53

Page 54

Pneumatic Fowler Outer Housing Assembly

For Reference Only: 1210-031-106 (Right)

Item Part No. Part Name Qty.

A 0025-144-000 Semi - Tubular Rivet 1

B 1210-031-103 Pivot Tab 1

C 1210-031-104 Outer Housing, Right 1

For Reference Only: 1210-031-107 (Left)

Item Part No. Part Name Qty.

A 0025-144-000 Semi - Tubular Rivet 1

B 1210-031-103 Pivot Tab 1

C 1210-031-105 Outer Housing, Left 1

Return To Table of Contents

54 0738 -0 09 -002 RE V B ww w.stryker.com

Page 55

Optional Knee Gatch Assembly

For Reference Only: 0736-010-010

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 55

Page 56

Optional Knee Gatch Assembly

Return To Table of Contents

56 0738 -0 09 -002 RE V B ww w.stryker.com

Page 57

Optional Knee Gatch Assembly

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 57

Page 58

Optional Knee Gatch Assembly

Optional Knee Gatch Assembly, Common Components - 0736-010-010 - (reference only)

Item Part No. Part Name Qty.

A 0002-031-000 Machine Screw 2

B 0003-047-000 Hex Head Cap Screw 16

C 0003-078-000 Hex Head Cap Screw 12

G 0004-201-000 Socket Head Cap Screw 5

M 0025-038-000 Washer 12

P 0014-003-000 Washer 2

R 0016-014-000 Fiber Lock Hex Nut 2

T 0016-028-000 Fiber Lock Hex Nut 30

U 0016-035-000 Nylock Hex Nut 5

Y 0025-079-000 Dome Head Rivet 4

AA 0025-122-000 Dome Head Rivet 46

AC 0037-010-000 Hole Plug 2

AD 0037-074-000 Hole Plug 16

AF 0059-100-000 Hole Plug 6

AK 0721-031-065 Hole Plug 22

AL 0736-046-010 Knee Gatch Crankscrew Assembly

(pg. 59) 1

AV 1001-034-025 Hole Plug 4

AW 1001-034-029 Slider Support Assembly, Left 1

BH 1010-032-092 Foley Bag Rack 1

BK 1010-234-015 Mounting Bracket Assembly 2

BM 1070-014-009 Bumper 2

BN 1501-034-011 Thigh Frame Assembly 1

BP 1501-034-023 Mid Section Support Assembly 1

BR 1501-034-112 Calf Frame Weldment 1

BT 1510-034-090 Slider Pad 2

BU 1510-234-027 Mid Section Skin 1

BV 1510-234-028 Thigh Section Skin 1

BW 1510-234-126 Calf Section Skin 1

CB 1550-034-021 Thigh Support 2

CD 1550-090-034 Engage Gatch Label 1

Return To Table of Contents

58 0738 -0 09 -002 RE V B ww w.stryker.com

Page 59

Optional Knee Gatch Crankscrew Assembly

For Reference Only: 0736-046-010

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 59

Page 60

Optional Knee Gatch Crankscrew Assembly

Optional Knee Gatch Crankscrew Assembly - 0736-046-010 - (reference only)

Item Part No. Part Name Qty.

A 0004-007-000 Socket Head Cap Screw 1

B 0016-005-000 Cone Lock Nut 1

C 0026-010-000 Slotted Spring Pin 2

D 0026-014-000 Slotted Spring Pin 2

E 0026-045-000 Slotted Spring Pin 1

F 0081-174-000 Washer 2

G 0081-175-000 Washer 1

H 0081-176-000 Washer 1

J 0378-024-029 Shoulder Bolt 1

K 0938-001-175 Bearing Assembly 1

L 0938-001-177 Knob 1

M 0946-033-018 Crank Disc 1

N 1001-134-047 Knee Gatch Screw 1

P 1510-034-055 Gatch Drive Tube Assembly 1

R 1510-034-084 Screw Cover Assembly 1

T 1550-001-014 Magnet 1

U 1550-001-016 Crank Handle 1

60 0738 -0 09 -002 RE V B ww w.stryker.com

Page 61

For Reference Only: Part Number

Head End: 0736-035-010

Foot End: 0736-035-060

Corner Cover, Assembly

HEAD END SHOWN

Item Part No. Part Name Qty.

A 0023-104-000 Tapping Screw 4

B 0037-059-000 Heyco Hole Plug 1

C 1010-201-238 Corner Cover/Slot 1

D 1010-201-239 Corner Cover/Hole 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 61

Page 62

Corner Cover, Push Handle Assembly

For Reference Only: Part Number

For Reference Only: Part Number

Head End: 0736-035-015

Foot End: 0736-035-065

HEAD END SHOWN

Item Part No. Part Name Qty.

A 0023-104-000 Tapping Screw 4

B 0037-059-000 Heyco Hole Plug 1

C 1010-201-238 Corner Cover/Slot 1

D 1010-201-239 Corner Cover/Hole 1

E 0003-047-000 Hex Head Cap Screw 2

F 0003-050-000 Hex Head Cap Screw 4

G 0016-028-000 Fiberlock Hex Nut 6

H 0026-012-000 Slotted Spring Pin 2

J 1010-254-004 Push Handle Socket, LH 1

K 1010-254-006 Push Handle Socket, RH 1

L 1211-351-010 Push Handle Assembly (pg. 67) 2

Return To Table of Contents

62 0738 -0 09 -002 RE V B ww w.stryker.com

Page 63

Corner Cover, 2-Stage I.V. Pole Assembly

For Reference Only: Part Number

For Reference Only: Part Number

Head End: 0736-035-020

Foot End: 0736-035-070

HEAD END SHOWN

Item Part No. Part Name Qty.

A 0023-104-000 Tapping Screw 4

B 0037-059-000 Heyco Hole Plug 1

C 1010-201-238 Corner Cover/Slot 1

D 1010-201-239 Corner Cover/Hole 1

E 0003-047-000 Hex Head Cap Screw 2

F 0004-199-000 Button Head Cap Screw 1

G 0016-036-000 Nylock Hex Nut 1

H 1211-210-010 2-Stage IV Pole Assembly (pg. 69) 1

J 1509-110-001 IV Plug 1

K 1001-259-103 IV Pivot Weldment 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 63

Page 64

Corner Cover, 2-Stage I.V. Pole, Push Handle Assembly

For Reference Only: Part Number

For Reference Only: Part Number

Head End: 0736-035-025

Foot End: 0736-035-075

HEAD END SHOWN

Item Part No. Part Name Qty.

A 0023-104-000 Tapping Screw 4

B 1010-201-238 Corner Cover/Slot 1

C 1010-201-239 Corner Cover/Hole 1

D 0003-047-000 Hex Head Cap Screw 2

E 0003-050-000 Hex Head Cap Screw 5

F 0016-028-000 Fiberlock Hex Nut 8

G 0026-012-000 Slotted Sprin Pin 2

H 1010-254-004 Push Handle Socket, LH 1

J 1010-254-006 Push Handle Socket, RH 1

K 1211-351-010 Push Handle Assembly (pg.67) 2

L 0004-199-000 Button Head Cap Screw 1

M 0016-036-000 Nylock Hex Nut 1

N 1211-210-010 2-Stage IV Pole Assembly (pg. 69) 1

P 1509-110-001 IV Plug 1

R 1001-259-103 IV Pivot Weldment 1

T 0003-054-000 Hex Head Cap Screw 1

Return To Table of Contents

64 0738 -0 09 -002 RE V B ww w.stryker.com

Page 65

Corner Cover, 3-Stage I.V. Pole Assembly

For Reference Only: Part Number

Head End: 0736-035-030

Foot End: 0736-035-080

HEAD END SHOWN

Item Part No. Part Name Qty.

A 0023-104-000 Tapping Screw 4

B 1010-201-238 Corner Cover/Slot 1

C 1010-201-239 Corner Cover/Hole 1

D 0003-050-000 Hex Head Cap Screw 3

E 0016-028-000 Fiberlock Hex Nut 3

F 0004-199-000 Button Head Cap Screw 1

G 0016-036-000 Nylock Hex Nut 1

H 1211-210-010 2-Stage IV Pole Assembly (pg. 69) 1

J 1509-110-001 IV Plug 1

R 1001-259-103 IV Pivot Weldment 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 65

Page 66

Corner Cover, 3-Stage I.V. Pole, Push Handle Assembly

For Reference Only: Part Number

Head End: 0736-035-035

Foot End: 0736-035-085

HEAD END SHOWN

Item Part No. Part Name Qty.

A 0023-104-000 Tapping Screw 4

B 1010-201-238 Corner Cover/Slot 1

C 1010-201-239 Corner Cover/Hole 1

D 0003-047-000 Hex Head Cap Screw 2

E 0003-050-000 Hex Head Cap Screw 5

F 0016-028-000 Fiberlock Hex Nut 8

G 0026-012-000 Slotted Sprin Pin 2

H 1010-254-004 Push Handle Socket, LH 1

J 1010-254-006 Push Handle Socket, RH 1

K 1211-351-010 Push Handle Assembly (pg.67) 2

L 0004-199-000 Button Head Cap Screw 1

M 0016-036-000 Nylock Hex Nut 1

N 1211-211-010 3-Stage IV Pole Assembly (pg. 71) 1

P 1509-110-001 IV Plug 1

R 1001-259-103 IV Pivot Weldment 1

T 0003-054-000 Hex Head Cap Screw 1

Return To Table of Contents

66 0738 -0 09 -002 RE V B ww w.stryker.com

Page 67

Push Handle Assembly - 1211-351-010

Item Part No. Part Name Qty.

A 1010-354-024 Stop Link 1

B 1211-151-018 Sleeve Assembly 1

C 0026-118-000 Roll Pin 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 67

Page 68

Standard, Removable I.V. Pole Assembly - 0390-025-022

Item Part No. Part Name Qty.

A 0024-023-000 Plastic Knob 1

B 0390-003-053 Double I.V. Assembly 1

C 0393-003-043 Tube Assembly 1

D 0004-496-000 Socket Head Cap Screw 1

Return To Table of Contents

68 0738 -0 09 -002 RE V B ww w.stryker.com

Page 69

Optional 2-Stage I.V. Pole Assembly - 1211-210-010

I.V. Latch Wrench

1211-110-137

Item Part No. Part Name Qty.

A 0008-031-000 Socket Head Cap Screw 1

B 0052-017-000 Washer 2

C 0926-400-162 Spacer 1

D 1211-210-029 2nd Stage Assembly 1

E 1001-359-013 Dampener 1

F 1001-159-028 Base Tube 1

G 1010-059-016 I.V. Hook 2

H 1211-210-026 I.V. Pole Latch (pg. 70) 1

J 1001-359-112 Pivot 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 69

Page 70

I.V. Pole Latch Assembly - 1211-210-026

Item Part No. Part Name Qty.

A 0028-167-000 Retaining Ring 1

B 0031-004-000 Steel Ball 2

C 0038-392-000 Crest - to - Crest Spring 1

D 1211-091-034 Release Label 1

E 1211-110-018 I.V. Latch Seal 1

F 1211-110-020 Washer 2

G 1211-110-021 I.V. Latch Locking Pin 2

H 1211-110-022 I.V. Latch Guide 1

J 1211-110-024 I.V. Latch O.D. Housing 1

K 1211-110-035 Washer 1

L 1211-110-036 Self - Tapping Screw 2

M 1211-210-023 I.V. Latch I.D. Housing 1

Return To Table of Contents

70 0738 -0 09 -002 RE V B ww w.stryker.com

Page 71

Optional 3-Stage I.V. Pole Assembly - 1211-211-010

Item Part No. Part Name Qty.

A 0007-004-000 Truss Head Machine Screw 1

C 0026-076-000 Roll Pin 1

D 0052-017-000 Spacer 2

E 1211-210-031 2nd Stage Assembly 1

F 0926-400-162 Spacer 1

G 1211-110-032 3rd Stage Assembly (pg. 72) 1

H 1001-161-023 Base Tube 1

J 1010-059-016 I.V. Hook 2

K 1010-061-014 Collar 1

L 1211-210-026 I.V. Pole Latch 1

M 1211-110-016 Threaded Adaptor 1

N 1001-359-013 Dampener 1

P 1001-359-014 Dampener 1

R 1001-359-112 Pivot 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 71

Page 72

Optional 3-Stage I.V. Pole, 3rd Stage Assembly

For Reference Only: 1211-110-032

Note

Item F, part number 1010-061-018 is

left hand thread. When removing it,

turn clockwise to loosen it.

Item Part No. Part Name Qty.

A 0031-021-000 Ball 6

B 0038-303-000 Compression Spring 1

C 1010-061-013 Ball Retainer 1

D 1010-061-016 Retaining Shaft 1

E 1010-061-017 Thumb Knob 1

F 1010-061-018 Hand Guard 1

G 1211-110-117 Nut 1

H 1211-110-033 3rd Extension Rod 1

Return To Table of Contents

72 0738 -0 09 -002 RE V B ww w.stryker.com

Page 73

Optional Defibrillator Tray Assembly - 0785-045-200

Strap Securing Detail

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 73

Page 74

Optional Defibrillator Tray Assembly - 0785-045-200

Item Part No. Part Name Qty.

A 0002-0044-000 Machine Screw 2

B 0025-055-000 Rivet 4

C 0029-008-000 Dual Lock 6

D 0029-010-000 Dual Lock 6

E 0785-045-201 Defibrillator Tray Label 1

F 0785-045-402 Push/Pull Label 1

G 0785-045-403 Weight Capacity Label 1

H 0785-045-204 Tray Support 1

J 0785-045-207 Tray 1

K 0785-045-208 Bayonet 2

L 0785-045-210 Defibrillator Tray Frame Weldment 1

M 1010-050-021 Long Strap 1

Return To Table of Contents

74 0738 -0 09 -002 RE V B ww w.stryker.com

Page 75

Foot Extension/Defibrillator Tray Assembly - 0785-045-400

Item Part No. Part Name Qty.

A 0004-215-000 Button Head Cap Screw 4

B 0008-049-000 Shoulder Bolt 4

C 0014-020-000 Washer 4

D 0014-120-000 Washer 4

E 0016-028-000 Hex Nut 4

F 0037-052-000 Rubber Bumper 2

G 0038-133-000 Spring 2

H 0052-017-000 Spacer 4

J 0785-045-402 “Push/Pull” Label 2

K 0785-045-403 Weight Capacity Label 1

L 0785-045-401 Foot Extender/Defibrillator Tray Label 1

M 0785-045-405 Cushion 1

N 0785-045-410 Base Mtg. Weldment 1

P 0785-045-420 Frame Pivot Weldment 1

R 0785-045-430 Tray Assembly 1

T 0785-045-450 Knob 2

U 1010-050-021 Long Strap 1

V 1010-050-242 Pin Lock 1

W 1010-050-250 Lock Adjuster 1

X 1010-050-248 Lower Pin Lock 1

Y 0721-031-065 Hole Plug 2

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 75

Page 76

Foot Board/Chartholder Assembly - 0785-045-500

Item Part No. Part Name Qty.

A 0785-045-402 Push/Pull Label 1

B 0785-045-501 Footboard Label 1

C 0785-045-511 Chart Holder Thermoform 1

D 0785-045-512 Footboard Back 1

E 0785-045-513 Front Footboard 1

F 0785-045-514 Small Standoff 2

G 0785-045-515 Large Standoff 2

H 0946-029-010 Support 1

Return To Table of Contents

76 0738 -0 09 -002 RE V B ww w.stryker.com

Page 77

Upright Oxygen Bottle Holder Assembly - 1020-130-000

Item Part No. Part Name Qty.

A 0027-030-000 Hair Pin Cotter 1

B 1020-030-111 Upright Bottle Holder 1

C 1020-030-017 O2 Bottle Holder Label 1

Return To Table of Contents

ww w.stryker.com 0738 -0 09 -002 RE V B 77

Page 78

Optional Oxygen Bottle Retainer Assembly

For Reference Only: 1040-710-095

Base Hood

Item Part No. Part Name Qty.

A 1040-010-091 Bottle Retainer 1

B 1040-010-092 Scrulok Fastener 4

Return To Table of Contents

78 0738 -0 09 -002 RE V B ww w.stryker.com

Page 79

Mattresses and Siderail Pads

Mattress, 3” Thick x 30” Wide, Enhanced Comfort

Mattress, 4” Thick x 30” Wide, Enhanced Comfort

Mattress, 4” Thick x 30” Wide, Ultra Comfort

Mattress, 5” Thick x 30” Wide, Ultra Comfort

Mattress, 30” Pioneer

0785-03 4-313

0785-034-323

0785-034-303

0785-034-333

0850-030-000

Siderail Pad Set

ww w.stryker.com 0738 -0 09 -002 RE V B 79

1010-052-000

Return To Table of Contents

Page 80

Warranty

LIMITED WARRANTY

Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser the Wide Transport

Stretcher, Model 738 to be free from defects in material and workmanship for a period of One (1) years after date of

delivery. Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or

replacing, at its option, any product which is, in the sole discretion of Stryker, found to be defective. If requested by

Stryker, products or parts for which a warranty claim is made shall be returned prepaid to the factory. Any improper

use or any alteration or repair by others in such manner as in Stryker’s judgment affects the product materially and

adversely shall void this warranty. Any repair of Stryker products using parts not provided or authorized by Stryker shall

void this warranty. No employee or representative of Stryker is authorized to change this warranty in any way.

Stryker Medical Stretcher products are designed for a 10 year expected service life under normal use, conditions,

and with appropriate periodic maintenance as described in the maintenance manual for each device. Stryker warrants

to the original purchaser that the welds on its Stretcher products will be free from structural defects for the expected

10 year life of the Stretcher product as long as the original purchaser owns the product.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. Stryker makes no

other warranty or representation, either expressed or implied, except as set forth herein. There is no warranty

of merchantability and there are no warranties of fitness for any particular purpose. In no event shall Stryker be

liable here under for incidental or consequential damages arising from or in any manner related to sales or use of

any such equipment.

TO OBTAIN PARTS AND SERVICE

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives. These

representatives are factory trained, available locally, and carry a substantial spare parts inventory to minimize

repair time. Simply call your local representative, or call Stryker Customer Service USA at 1-800-327-0770,

Canada 1-888-233-6888.

SERVICE CONTRACT COVERAGE

Stryker has developed a comprehensive program of service contract options designed to keep your equipment

operating at peak performance at the same time it eliminates unexpected costs. We recommend that these programs