Page 1

Ambulance Cot Fastener

6393 6370

6371

6377

6378

6391

Operations Manual

International - EN | ES | FR

2018/06 C.0 6370-109-005 REV C

www.stryker.com

Page 2

sample text

Page 3

Ambulance Cot Fastener

6393 6370

6371

6377

6378

6391

Operations Manual

2018/06 C.0 6370-109-005 REV C

www.stryker.com

Page 4

sample text

Page 5

Symbols

Operating instructions/Consult instructions for use

General warning

Caution

Catalogue number

Lot (batch) code

Serial number

For US patents see www.stryker.com/patents

Manufacturer

Date of manufacturer

English

EN

Safe working load

www.stryker.com 6370-109-005 REV C

Page 6

sample text

Page 7

Table of Contents

Warning/Caution/Note Definition ............................................................................................................... 1-2

Summary of safety precautions................................................................................................................. 1-3

Introduction........................................................................................................................................... 1-4

Product description........................................................................................................................... 1-4

Indications for use ............................................................................................................................ 1-4

Expected service life......................................................................................................................... 1-4

Contraindications ............................................................................................................................. 1-4

Specifications.................................................................................................................................. 1-4

Product illustration............................................................................................................................ 1-5

Contact information .......................................................................................................................... 1-6

Serial number location ...................................................................................................................... 1-6

Date of manufacture......................................................................................................................... 1-6

Cot compatibility .............................................................................................................................. 1-6

Installation ............................................................................................................................................ 1-8

Installing the cot fastener................................................................................................................... 1-8

Selecting the vehicle safety hook ........................................................................................................ 1-8

Vehicle configuration ........................................................................................................................ 1-9

Positioning of the vehicle safety hook, front to back .............................................................................. 1-10

Positioning of the vehicle safety hook, side to side ................................................................................ 1-11

Installing the vehicle safety hook ....................................................................................................... 1-12

Installing the floor plate ................................................................................................................... 1-13

Installing the wall plate .................................................................................................................... 1-17

Installation checklist.............................................................................................................................. 1-22

Operation ........................................................................................................................................... 1-23

Mass casualty incident planning........................................................................................................ 1-23

Adjusting the rail assembly............................................................................................................... 1-23

Testing the cot fastener................................................................................................................... 1-25

Cleaning............................................................................................................................................. 1-26

Suggested cleaners........................................................................................................................ 1-26

Preventive maintenance ........................................................................................................................ 1-27

English

EN

www.stryker.com 6370-109-005 REV C 1-1

Page 8

Warning/Caution/Note Definition

English

EN

The words WARNING, CAUTION, and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

Note: Provides special information to make maintenance easier or important instructions clearer.

1-2 6370-109-005 REV C www.stryker.com

Page 9

Summary of safety precautions

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WARNING

• Always replace the cot fastener if it has been involved in an accident.

• A height limit kit is recommended for vehicle deck heights less than 30 in. (67 cm).

• Install the cot fastener by qualified personnel only. Improper installation could result in injury to the patient or

operator.

• Always make sure that all cots meet the installation specifications for the Stryker cot fastener system.

• Failure to install the vehicle safety hook may cause injury to the patient or operator.

• Always make sure that the safety bar connects with the vehicle safety hook before you remove the cot from the

vehicle patient compartment to avoid the risk of injury.

• Do not allow the rail clamp to overlap the red adjustment limit label on the rail tube. To prevent the rail jaws from

releasing the cot frame, the space between the rail clamp and the rail stationary jaw must never exceed 1 in. (2.5

cm).

• Do not use hand or fingers to press the release button when the rail jaws are open. The rail clamp fastener closes

with a strong spring action.

• Always test the fastener using AMD Standard 004 as a minimum. Improper testing can result in injury.

• Always wipe the product with clean water and dry after cleaning. Some cleaning products are corrosive in nature

and may cause damage to the product. Failure to properly rinse and dry the product leaves a corrosive residue on

the surface of the product and may cause premature corrosion of critical components.

English

EN

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

• Always set the cot load height to the proper stop height before operation.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the vehicle safety hook.

Consult the vehicle manufacturer before you install the vehicle safety hook. Make sure that the installation of the

vehicle safety hook does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank, or

electrical wiring of the vehicle.

• Do not use screws smaller than the 3/8 in. diameter specified to anchor the floor plates.

• Do not use a screw smaller than the 5/16 in. diameter specified to anchor the wall plate.

www.stryker.com 6370-109-005 REV C 1-3

Page 10

Introduction

English

EN

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating

or maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or

maintenance of this product.

CAUTION

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in

this manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable

operation resulting in injury to patient or operator. Modifying the product also voids its warranty.

Notes

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current

product information available at the time of printing. There may be minor discrepancies between your product and

this manual. If you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

Product description

The Stryker Ambulance Cot Fastener is designed to hold a compatible ambulance cot in an emergency vehicle for

patient transport purposes. The Ambulance Cot Fastener performs this function after the user manually loads the

compatible cot into the emergency vehicle and guides it into the fastener.

Indications for use

The Stryker Model 6370/6371/6377/6378/6391/6393 cot fasteners are not designed for any purpose other than to

restrict movement of an ambulance cot being transported in the patient compartment of an ambulance under normal

conditions.

Note: Usage of these products in any other way becomes the complete responsibility of the owner or user. The Model

6370/6371/6377/6378/6391/6393 cot fasteners comply to the Ambulance Manufacturers Division specification 004.

Caution must be used at all times during placement of the cot into the ambulance.

Expected service life

Cot fasteners have a seven year expected service life under normal use conditions and with appropriate periodic

maintenance.

Contraindications

None known.

Specifications

Model Type Part number

6371 Wall mounted 6371-000-000

6370 Floor mounted 6370-000-000

6377 Floor mounted 6377-000-000

1-4 6370-109-005 REV C www.stryker.com

Page 11

Introduction

A

B

C

D

Specifications (Continued)

Model Type Part number

6378 Floor mounted (reduced length) 6378-000-000

6391 Wall mounted mass casualty Power-

LOAD

6391 Floor mounted mass casualty Power-

LOAD

6393 Wall mounted mass casualty

Performance-LOAD

6393 Floor mounted mass casualty

Performance-LOAD

WARNING

• Always replace the cot fastener if it has been involved in an accident.

• A height limit kit is recommended for vehicle deck heights less than 30 in. (67 cm).

6391-001-001

6391-001-002

6393-001-001

6393-001-002

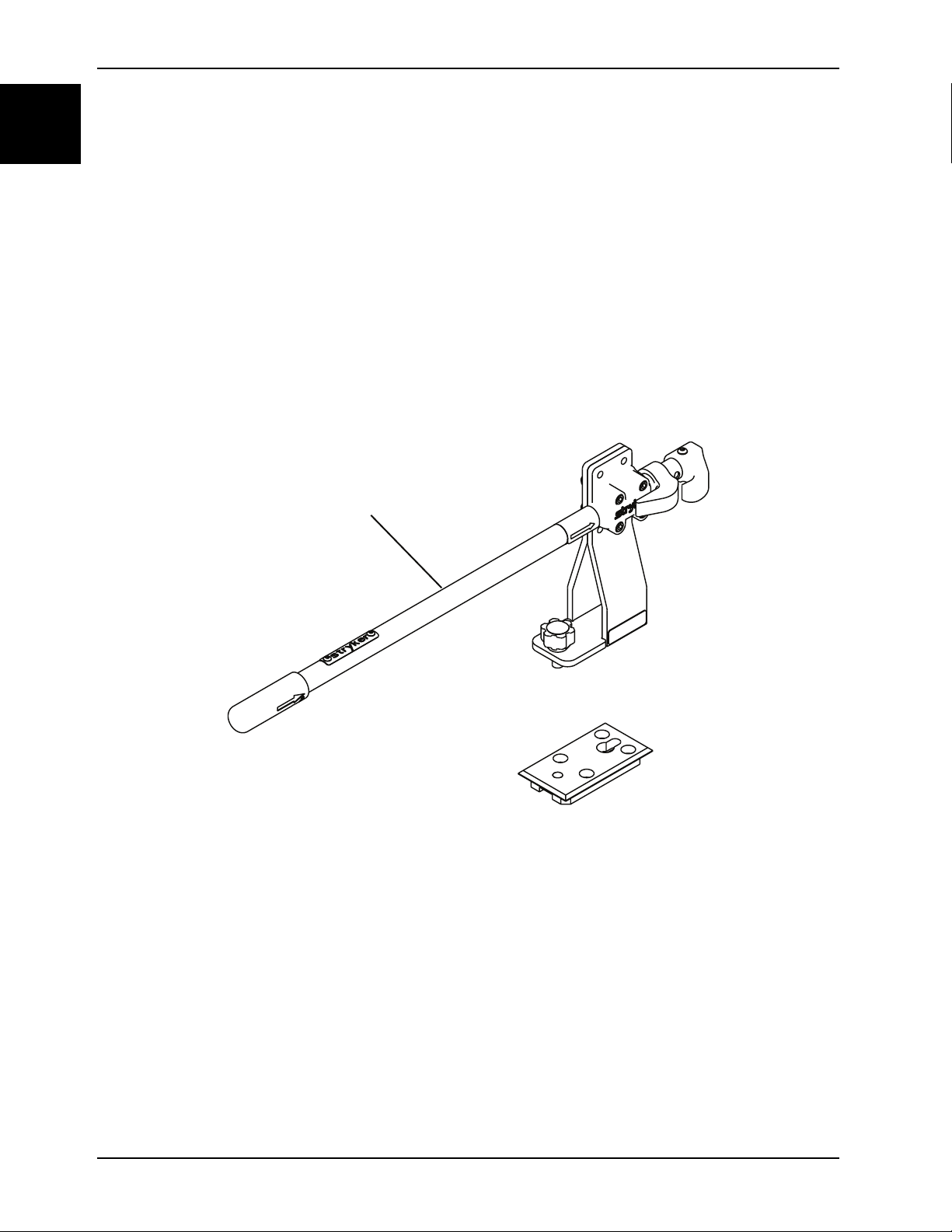

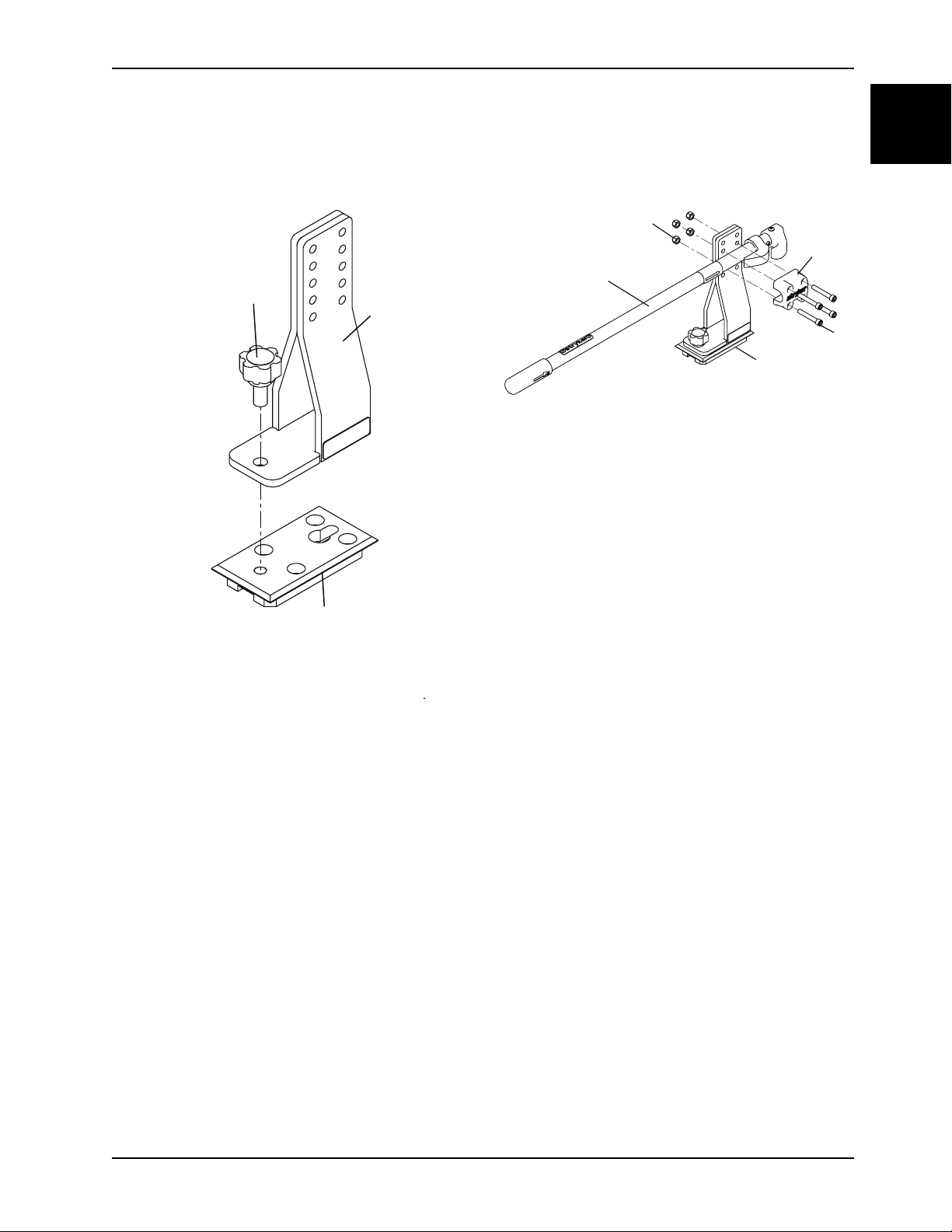

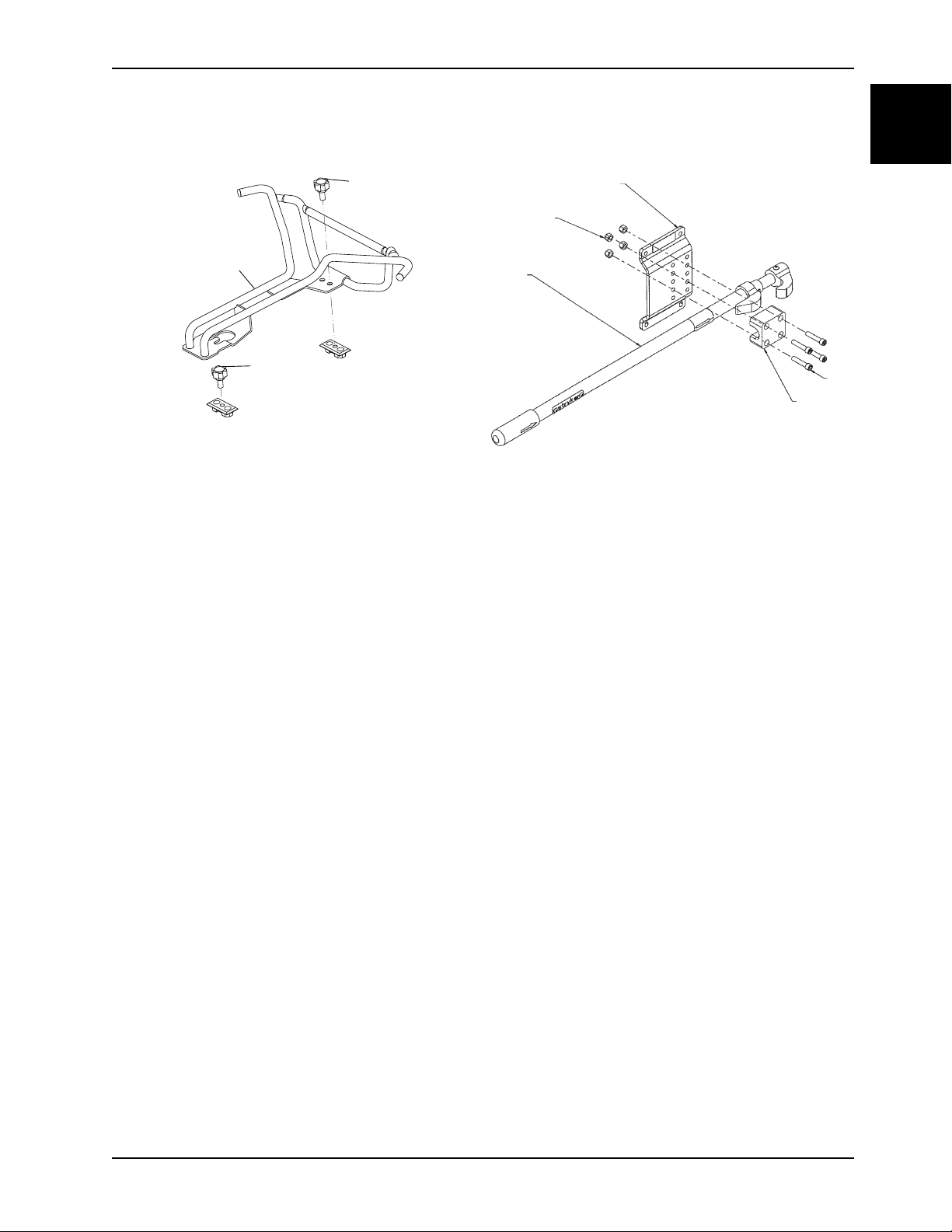

Product illustration

English

EN

Figure 1-1: Product illustration

A Rail assembly

B Floor plate

C

D Antler assembly

www.stryker.com 6370-109-005 REV C 1-5

Floor plates

Page 12

Introduction

A

English

EN

Contact information

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical

Support. Include the serial number in all written communication.

Serial number location

Figure 1-2: Serial number location

Date of manufacture

The year of manufacture is the first 2 digits of the serial number.

Cot compatibility

The Stryker 6370/6371/6377/6378/6391/6393 cot fastener systems are compatible only with cots that conform to the

installation specifications.

1-6 6370-109-005 REV C www.stryker.com

Page 13

Introduction

Cot compatibility (Continued)

WARNING

• Install the cot fastener by qualified personnel only. Improper installation could result in injury to the patient or

operator.

• Always make sure that all cots meet the installation specifications for the Stryker cot fastener system.

Ambulance cots which currently meet these specifications are:

Stryker

• Model 6060 DX Emergency Transport

• Model 6070 LX Emergency Transport

• Model 6080 MX-PRO

• Model 6081 MX-PRO Incubator Transporter

• Model 6082 MX-PRO

• Model 6083 MX-PRO Bariatric Transport

• Model 6085 Performance-PRO XT

• Model 6086 Performance-PRO XT

• Model 6090 EZ-PRO

• Model 6091 EZ-PRO 2

• Model 6092 EZ-PRO R3

• Model 6092 EZ-PRO R4

• Model 6500 Power-PRO XT

• Model 6506 Power-PRO XT

• Model 6510 Power-PRO IT

• Model 6516 Power-PRO IT

English

EN

Ferno-Washington

• Model 29-M Three Level Roll-In Cot*

• Model 93 ES Squadmate™*

• Model 93 EX Squadmate™*

• Model 35-A Mobile Transporter™*

• Model 35-A+ Mobile Transporter Plus™*

• Model 35-IT Incubator Transporter*

• Model 93P PROFlexx®

• Model 35X PROFlexx®

• Model 28Z PROFlexx®

• PowerFlexx®

Notes

• Adjustment of the rail clamp assembly may be required in order to compensate for any variation in cot retaining

post position depending on the ambulance cot manufacturer and model number.

• * 1999 model year or earlier. Styker is not responsible for changes in specifications to other manufacturer’s cots.

www.stryker.com 6370-109-005 REV C 1-7

Page 14

Installation

English

EN

Installing the cot fastener

The Stryker cot fastener systems are compatible only with cots that conform to the installation specifications.

WARNING

• Install the cot fastener by qualified personnel only. Improper installation could result in injury to the patient or

operator.

• Always make sure that all cots meet the installation specifications for the Stryker cot fastener system.

Note: You may need to adjust the rail clamp assembly to compensate for any variation in the cot retaining post position

depending on the cot manufacturer and model number.

These instructions are intended for cots with antler style cot fastener systems. For crash-rated cot fasteners, see the

appropriate operations manual for installation instructions.

Selecting the vehicle safety hook

The vehicle safety hook is a device that ships with the cot. The cot safety bar and vehicle safety hook keep the cot from

being accidentally removed from the vehicle and provide increased operator assurance and confidence when loading

and unloading.

Note: These instructions are intended for cots with antler style cot fastener systems. For crash-rated cot fasteners, see

the appropriate operations manual for installation instructions. Crash-rated cot fasteners are shipped and installed with

their own vehicle safety hook, thus no additional hook is needed.

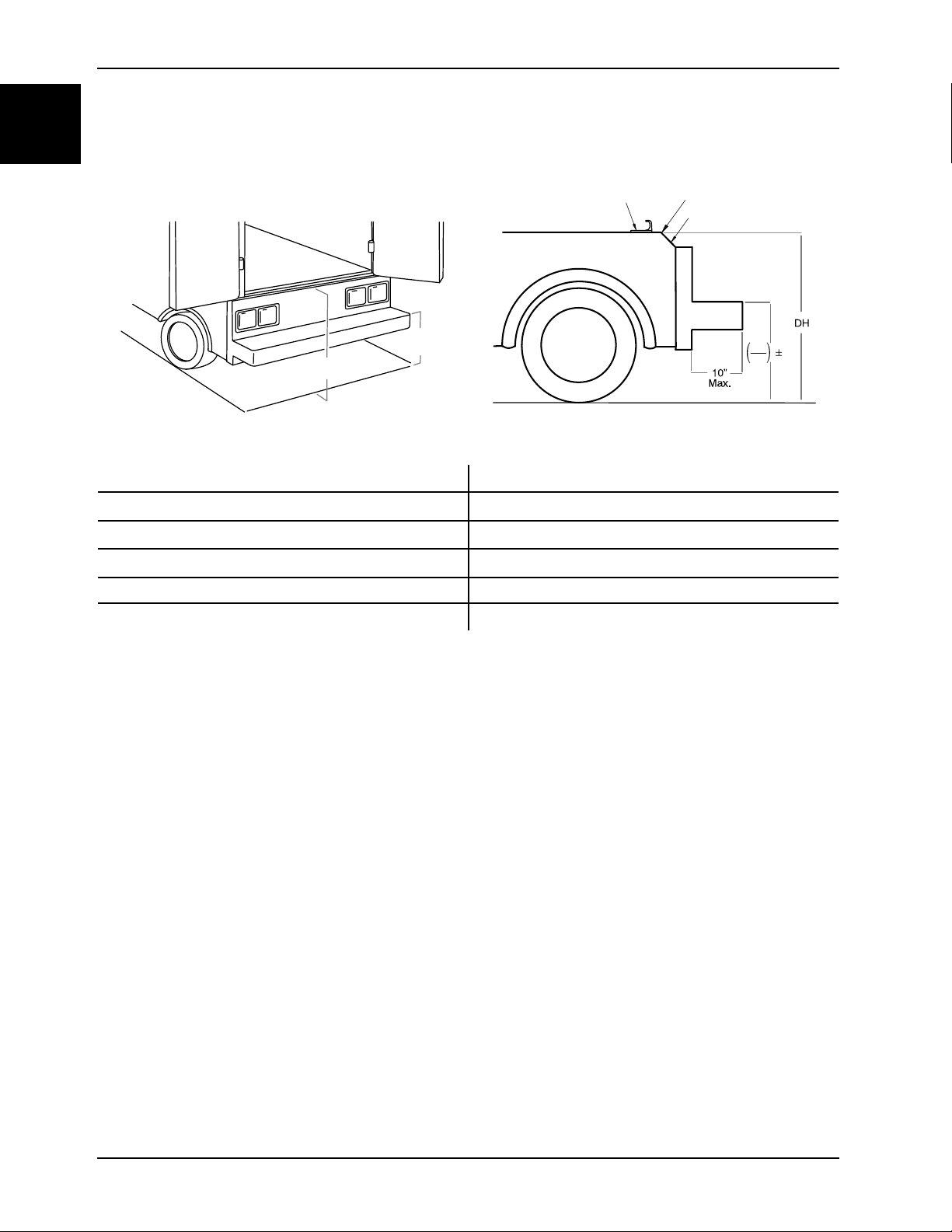

The vehicle safety hook was designed for compatibility and proper operation when loading and unloading the cot from a

vehicle that is compliant with Federal Regulation KKK-A-1822. Stryker offers three different types of vehicle safety

hooks that are ordered and shipped with your cot. These vehicle safety hook types meet the needs of various

emergency vehicle configurations, specifically the length and location of the floor structure support that is located in the

rear of the vehicle.

To select which vehicle safety hook is appropriate for your vehicle configuration:

• Consider the location of the floor structure support where there is adequate room to mount the vehicle safety hook.

• Mount the vehicle safety hook into the back of the vehicle. Provide bumper clearance to allow the operators to load

and unload the cot from the vehicle.

• Note the differences in vehicle design. Each vehicle safety hook provides a different mounting location option to

maintain the appropriate distance between the face of the vehicle safety hook and the edge of the door sill.

Due to the differences in vehicle dimensions and the floor structure support locations, each vehicle safety hook allows

for a different mounting location. Select the correct position for your vehicle safety hook installation.

• Positioning of the vehicle safety hook, front to back on page 1-10

• Positioning of the vehicle safety hook, side to side on page 1-11

Note: When you replace an existing vehicle safety hook with a new style, adjust the mounting location to maintain the

proper position of the vehicle safety hook face.

1-8 6370-109-005 REV C www.stryker.com

Page 15

Installation

Selecting the vehicle safety hook (Continued)

English

EN

Figure 1-3: Vehicle safety hook types

Vehicle configuration

CAUTION

• Always set the cot load height to the proper stop height before operation.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the vehicle safety hook.

Consult the vehicle manufacturer before you install the vehicle safety hook. Make sure that the installation of the

vehicle safety hook does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank, or

electrical wiring of the vehicle.

The cot is compatible with all vehicle deck heights that meet the Federal Specification for the Star-of-Life Ambulance

KKK-A-1822. See specifications for maximum load height.

According to Federal Specification for the Star-of-Life Ambulance KKK-A-1822:

• The rear of the ambulance shall be furnished with a sturdy, full-width, rear bumper, with step secured to the

vehicle’s chassis frame.

• The tread of the step shall have a minimum depth of 5 in. (13 cm) and a maximum depth of 10 in. (25 cm).

• If the step protrudes more than 7 in. (18 cm) from the rear of the vehicle, a fold-up step shall be furnished.

According to federal regulations (reference KKK-A-1822), the bumper height of the vehicle shall be installed equidistant

2 in. (± 5 cm) from the vehicle floor to the ground level, which is defined as the vehicle deck height. Installation of the

vehicle safety hook into any vehicle compliant with this federal specification provides adequate clearance for the cot

base to lower to its fully extended position.

www.stryker.com 6370-109-005 REV C 1-9

Page 16

Installation

DH

2

2

A

B

C D

E

F

A

B

English

EN

Vehicle configuration (Continued)

Figure 1-4: Deck and bumper height

A Deck height (DH)

B Bumper height

C Vehicle safety hook

D

Sill edge

E

F Bumper depth

Sill

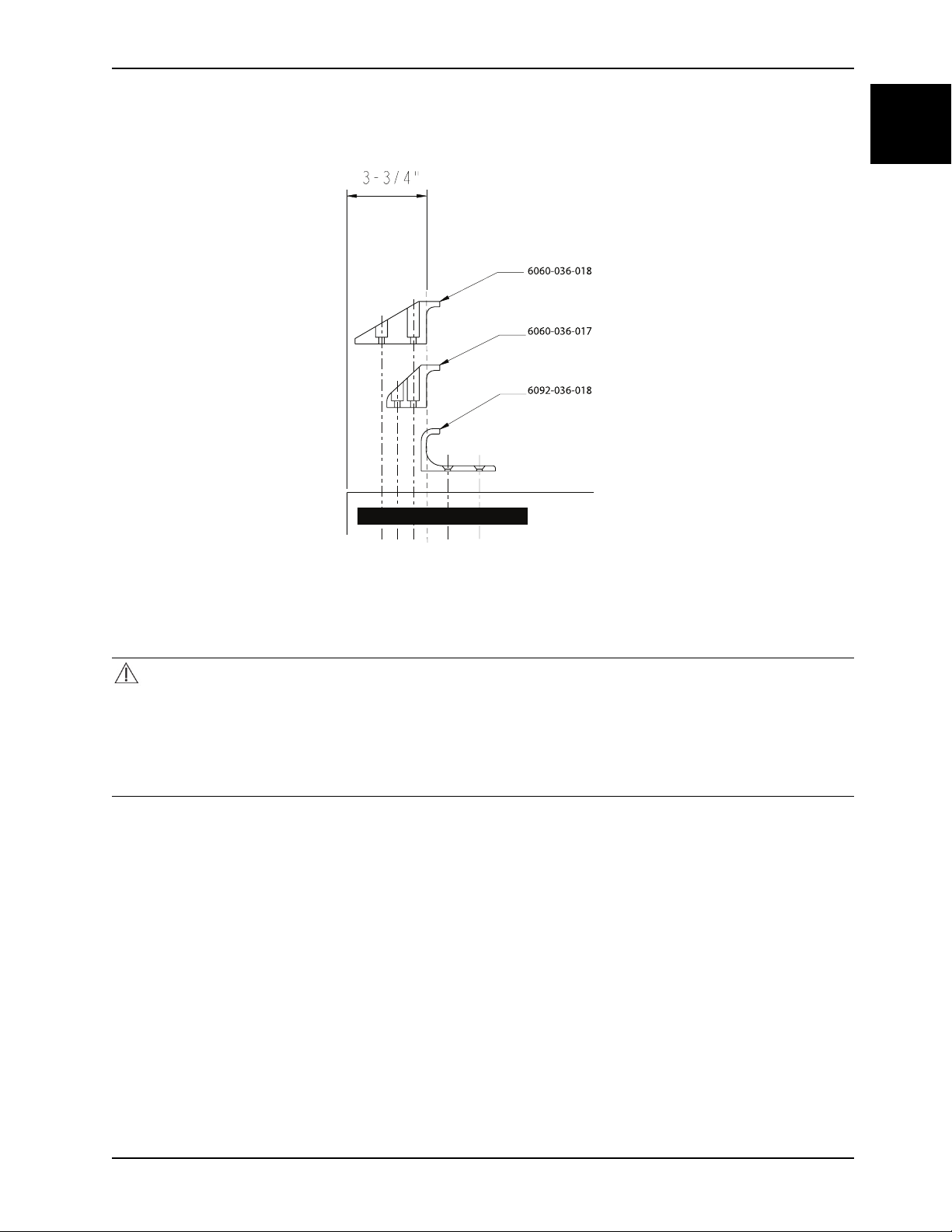

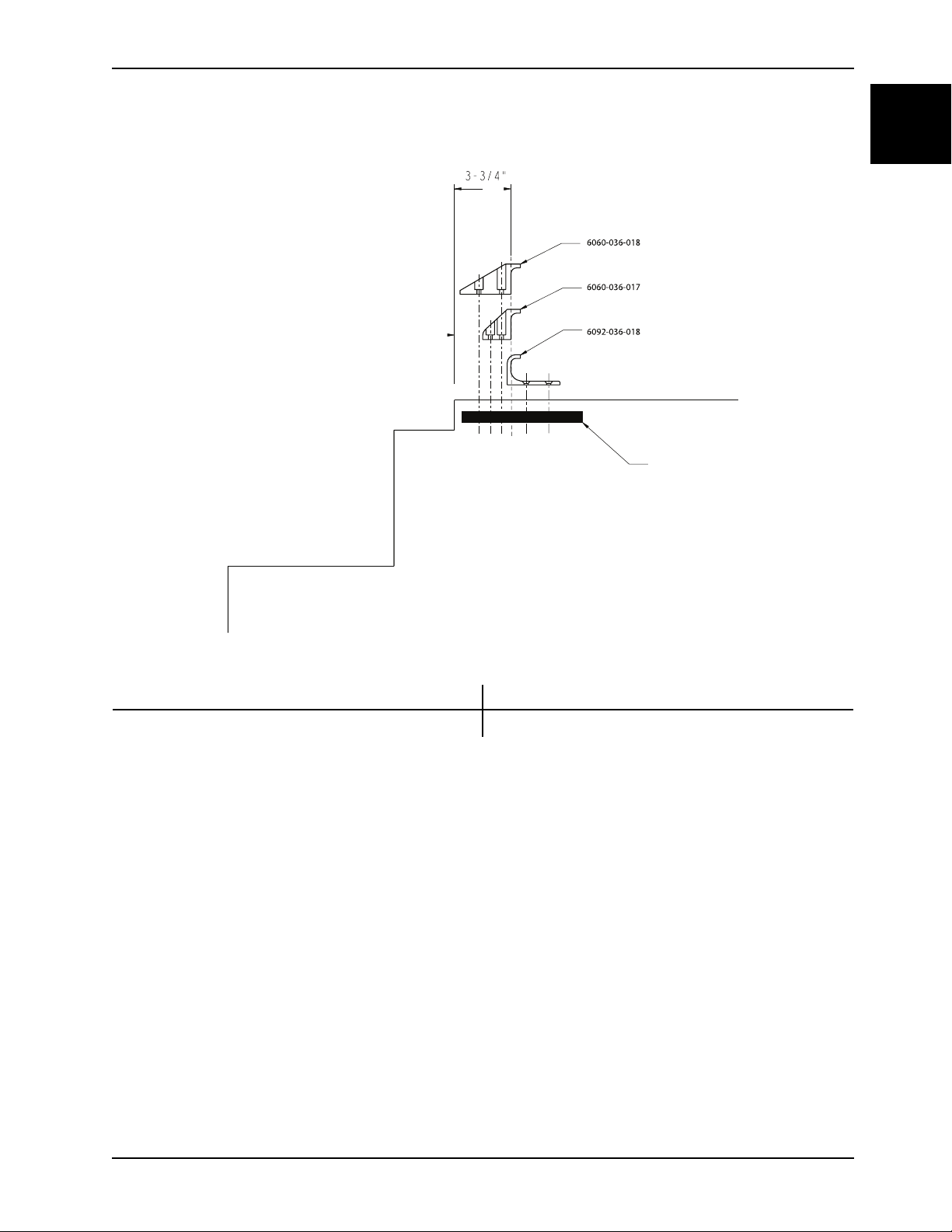

Positioning of the vehicle safety hook, front to back

Check the front to back and side to side positioning when unloading and loading the cot to make sure that you install the

vehicle safety hook correctly.

To check the front to back positioning:

1. Select the appropriate vehicle safety hook (Selecting the vehicle safety hook on page 1-8).

2. Position the vehicle safety hook at least 3-3/4 in. from the leading edge of the door sill (A). The recommended

distance from the face of the safety hook to be no less than 3-3/4 in.

3. Make sure that you can secure the vehicle safety hook to the mount in the back of the vehicle.

4. Make sure that you have adequate bumper clearance to allow the cot to be loaded and unloaded from the vehicle.

5. Confirm the side to side placement of the vehicle safety hook (Positioning of the vehicle safety hook, side to side on

page 1-11).

1-10 6370-109-005 REV C www.stryker.com

Page 17

Installation

A

B

Positioning of the vehicle safety hook, front to back (Continued)

English

EN

Figure 1-5: Vehicle safety hook placement

A

B Floor structure support

Sill

Positioning of the vehicle safety hook, side to side

Before you install the vehicle safety hook, check the front to back and side to side positioning, when you unload and

load the cot.

To check the side to side positioning:

1. Remove the cot from the cot fastener and unload it from the vehicle.

2. Note the position of the cot load wheels and the cot safety bar when you are remove the cot.

3. Mark the center of the cot safety bar on the vehicle floor.

4. Make sure that the position marked in step 3 is where the cot safety bar connects with the vehicle safety hook every

time when you unload the cot in a variety of positions (such as all the way to the left and all the way to the right).

www.stryker.com 6370-109-005 REV C 1-11

Page 18

Installation

English

EN

Positioning of the vehicle safety hook, side to side (Continued)

Notes

• If the cot safety bar does not connect with the vehicle safety hook in any of these positions (left, center, or

right), modify the vehicle. Do not modify the cot or the vehicle safety hook.

• If the cot safety bar connects with vehicle safety hook every time, install the vehicle safety hook.

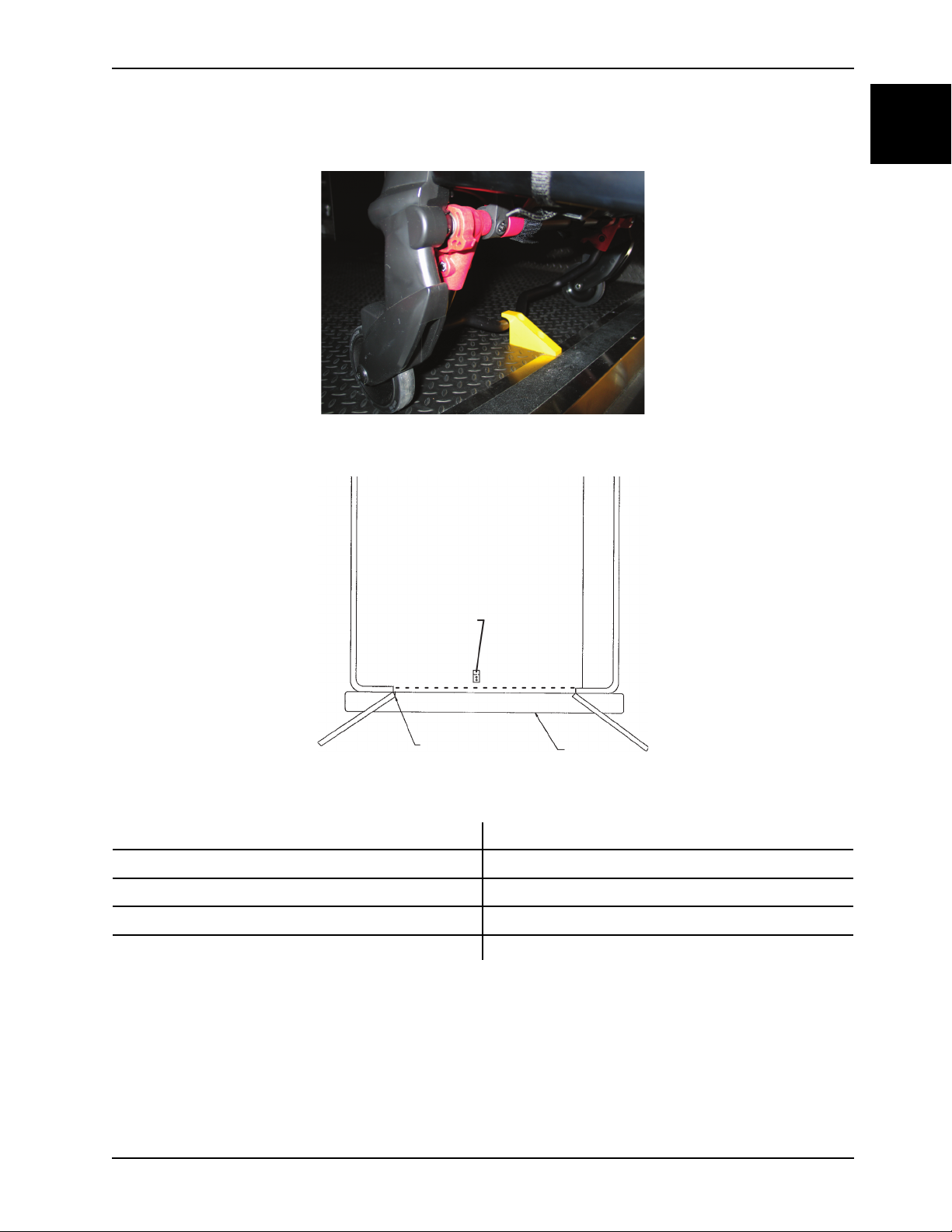

Installing the vehicle safety hook

Before installing the vehicle safety hook, the certified mechanic should plan for the placement of the vehicle safety

hook in the rear of the vehicle patient compartment.

WARNING

• Failure to install the vehicle safety hook may cause injury to the patient or operator.

• Always have a certified mechanic, familiar with ambulance vehicle construction, install the safety hook.

• Always make sure that the safety bar connects with the vehicle safety hook before you remove the cot from the

vehicle patient compartment to avoid the risk of injury.

Hardware required (not supplied):

• (2) Grade 5, minimum 1/4”-20 socket head cap screws * for the short vehicle safety hook or long vehicle safety

hook

• (2) Grade 5, minimum 1/4”-20 flat socket head cap screws * for the J vehicle safety hook

• (2) Flat washers

• (2) Lock washers

• (2) 1/4”-20 nuts

Note: The length of the socket head cap screws depend on the thickness of the vehicle floor. Use screws that are long

enough to go completely through the vehicle patient compartment floor, washer, and nut, with at least two full threads in

the nut.

1. Determine the correct vehicle safety hook front to back and side to side positioning, so the cot safety bar connects

to the vehicle safety hook every time.

• Positioning of the vehicle safety hook, front to back on page 1-10

• Positioning of the vehicle safety hook, side to side on page 1-11

2. Drill the holes for the screws.

3. Fasten the vehicle safety hook to the vehicle patient compartment floor.

4. Make sure that the cot safety bar connects with the vehicle safety hook before you remove the cot from the vehicle

patient compartment.

1-12 6370-109-005 REV C www.stryker.com

Page 19

Installation

A

B

C

DE

Installing the vehicle safety hook (Continued)

Figure 1-6: Safety bar secured in the vehicle safety hook

English

EN

Figure 1-7: Vehicle safety hook placement

A

B

C Squad bench

D Bumper

E

After installation, make sure that the cot legs lock into the load position without contacting the vehicle bumper.

Installing the floor plate

The Stryker cot fastener system for the floor plate mounting model is compatible only with cots that conform to the floor

plate mounting installation specifications.

www.stryker.com 6370-109-005 REV C 1-13

Top view of vehicle

Vehicle safety hook

Door frame

Page 20

Installation

12-5/8” (32 cm)

24.000

(Ref.)

(61 cm)

6-1/8”

(15,6

cm)

14-15/16”

(37,9 cm)

37-5/8”

(95,6 cm)

80.000 (Ref.)

(203 cm)

2-5/8”

(6,6 cm)

14-5/8” (Ref.)

(37,1 cm)

A

B

C

D

E

F

G

English

EN

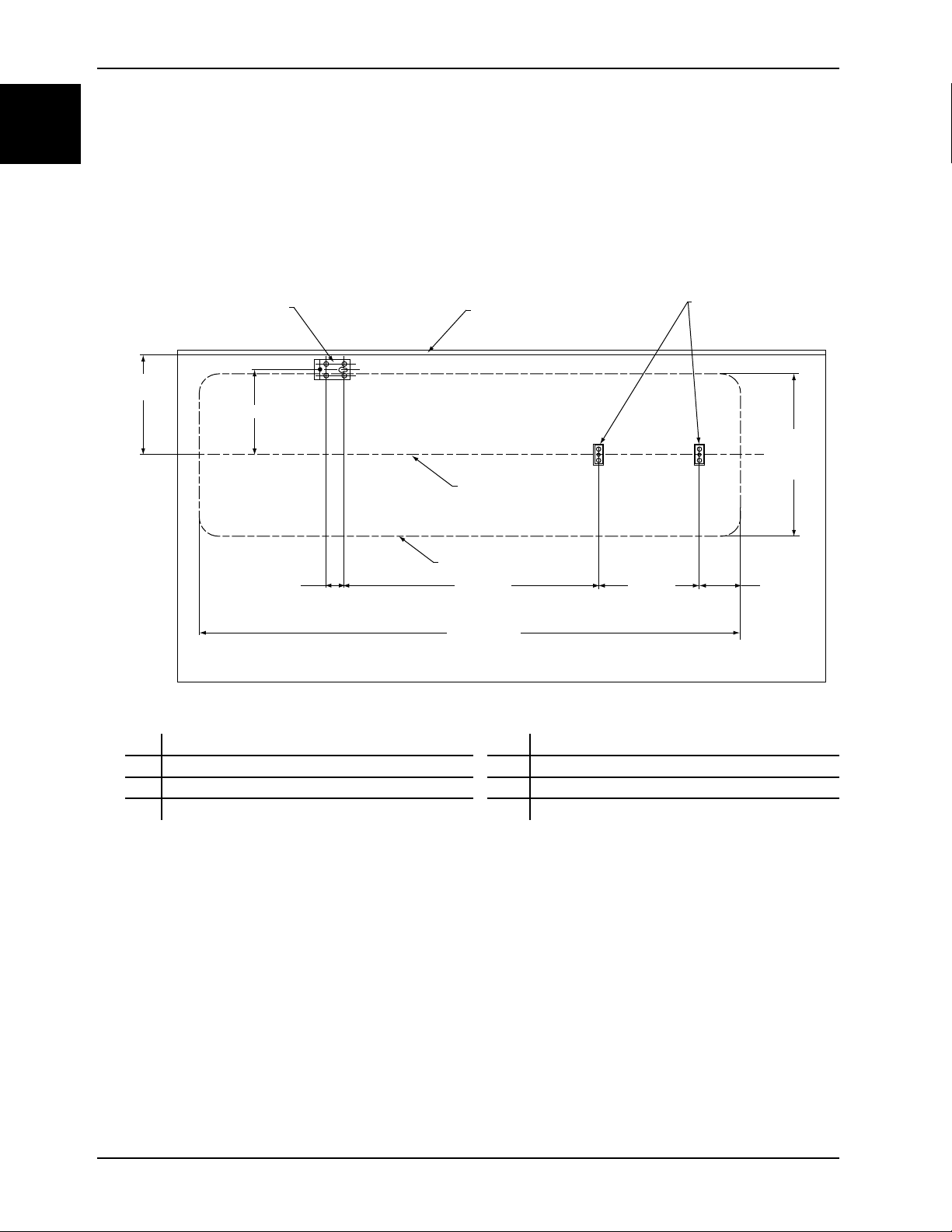

Installing the floor plate (Continued)

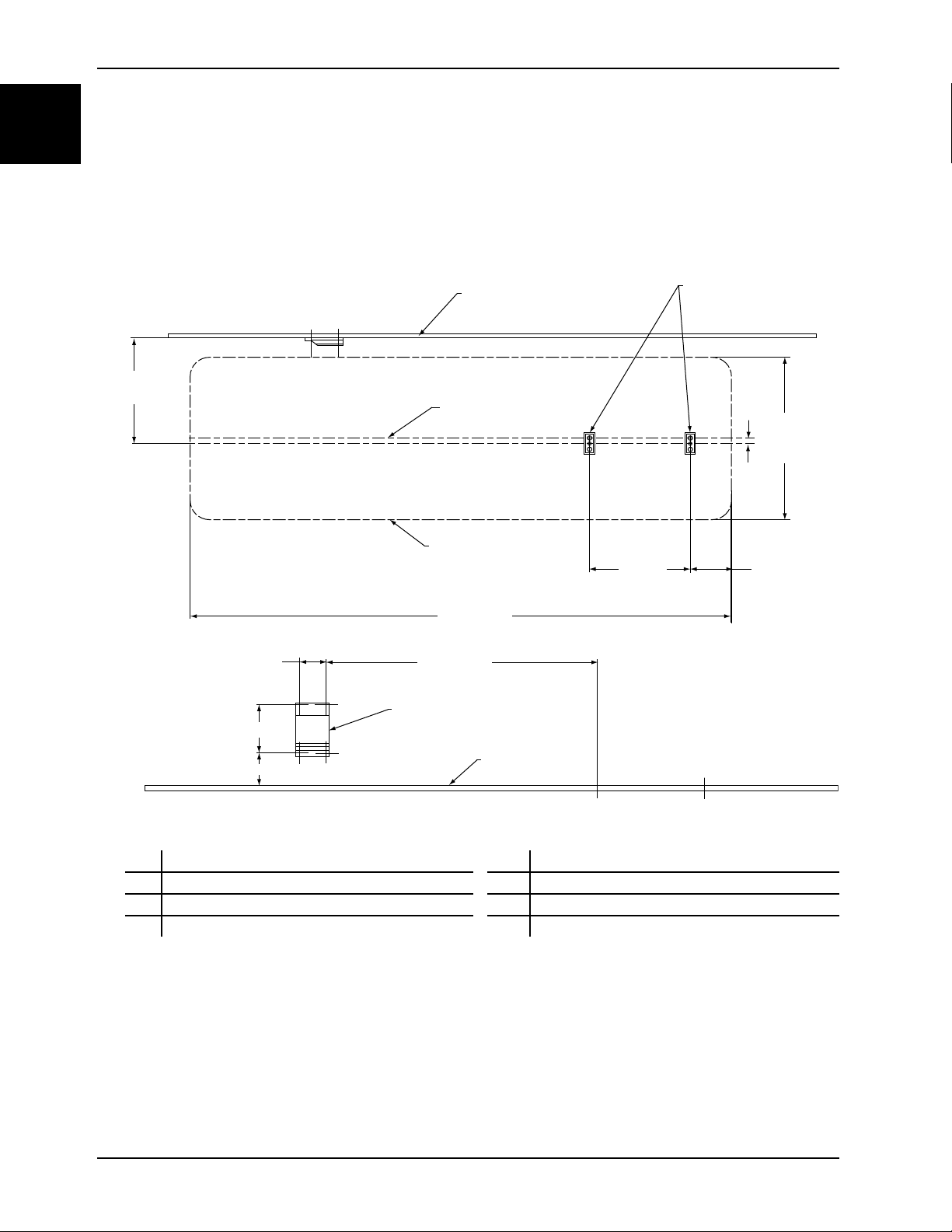

To position the antler floor mounting plates:

1. Determine the desired position of the cot inside the vehicle to allow for proper clearance around the cot.

Note: Federal ambulance specifications regarding aisle width and attendant seating may affect positioning of the

mounting brackets. If specifications do not apply, the installer should be certain that there is adequate clearance for

proper patient access, traction splint projection, rear door closure, and so on.

2. Using the dimensions shown in Figure 1-8 on page 1-14, locate and drill the points where the floor plates will attach.

Figure 1-8: Floor plate installation locations

Rail support bracket floor plate

A

B Wall of vehicle F

Antler floor plates

C

E Cot center line

Cot perimeter

G Cot head end

D Rear of ambulance

3. Cut 1 in. x 2-1/2 in. x 9/16 in. deep recessed openings (A) into the floor centered over the locating holes (Figure 1-9

on page 1-15).

1-14 6370-109-005 REV C www.stryker.com

Page 21

Installation

A

B

C

B

C

D

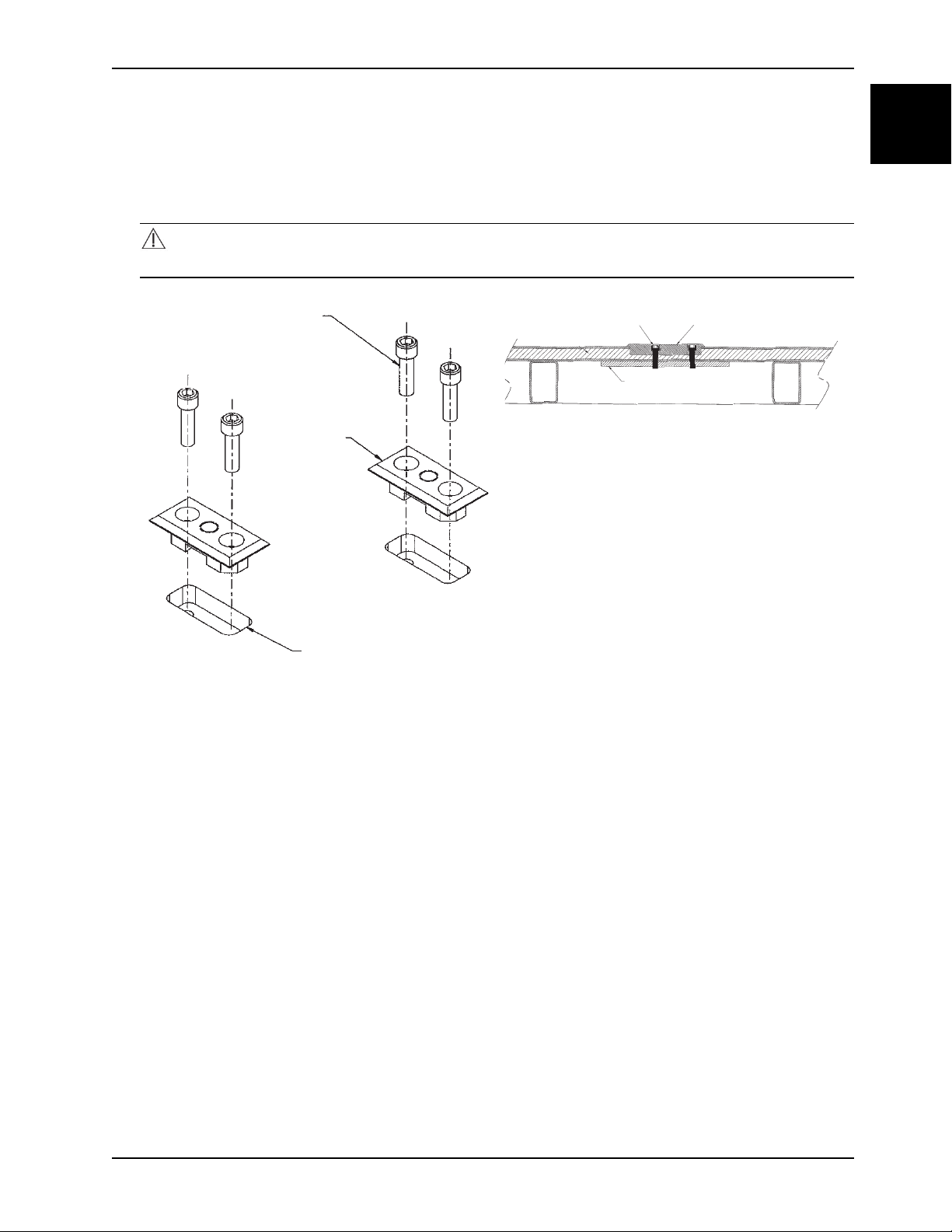

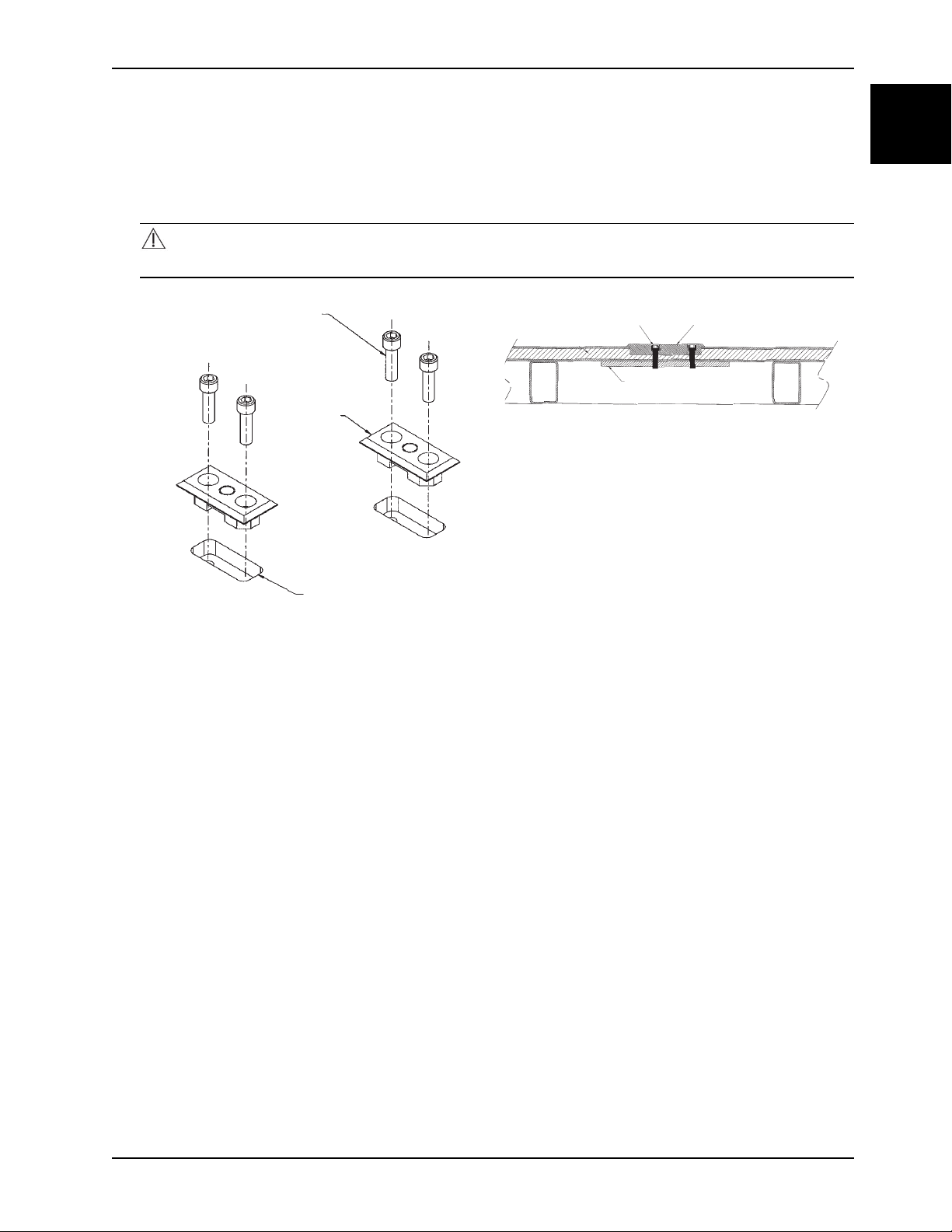

Installing the floor plate (Continued)

4. Using two 3/8 in. diameter socket head cap screws (B), preferably grade 8, anchor each floor plate (C) into the

recessed openings with the counter-bored holes facing up (Figure 1-10 on page 1-15).

Note: Steel backing plates (or equivalent) (D) (not supplied) are required for added support (Figure 1-10 on page 1-

15).

CAUTION

Do not use screws smaller than the 3/8 in. diameter specified to anchor the floor plates.

Figure 1-10: Anchor floor plate into recessed

openings

English

EN

Figure 1-9: Cut recessed openings over locating

holes

5. Using the dimensions shown in Figure 1-8 on page 1-14, locate and drill the four points where the rail support

bracket floor plate will attach. Cut one 2 1/2 in. x 5 in. x 9/16 in. deep opening (E) into the floor centered over the

locating points (Figure 1-11 on page 1-16).

www.stryker.com 6370-109-005 REV C 1-15

Page 22

Installation

E

F

G

A

B

B

English

EN

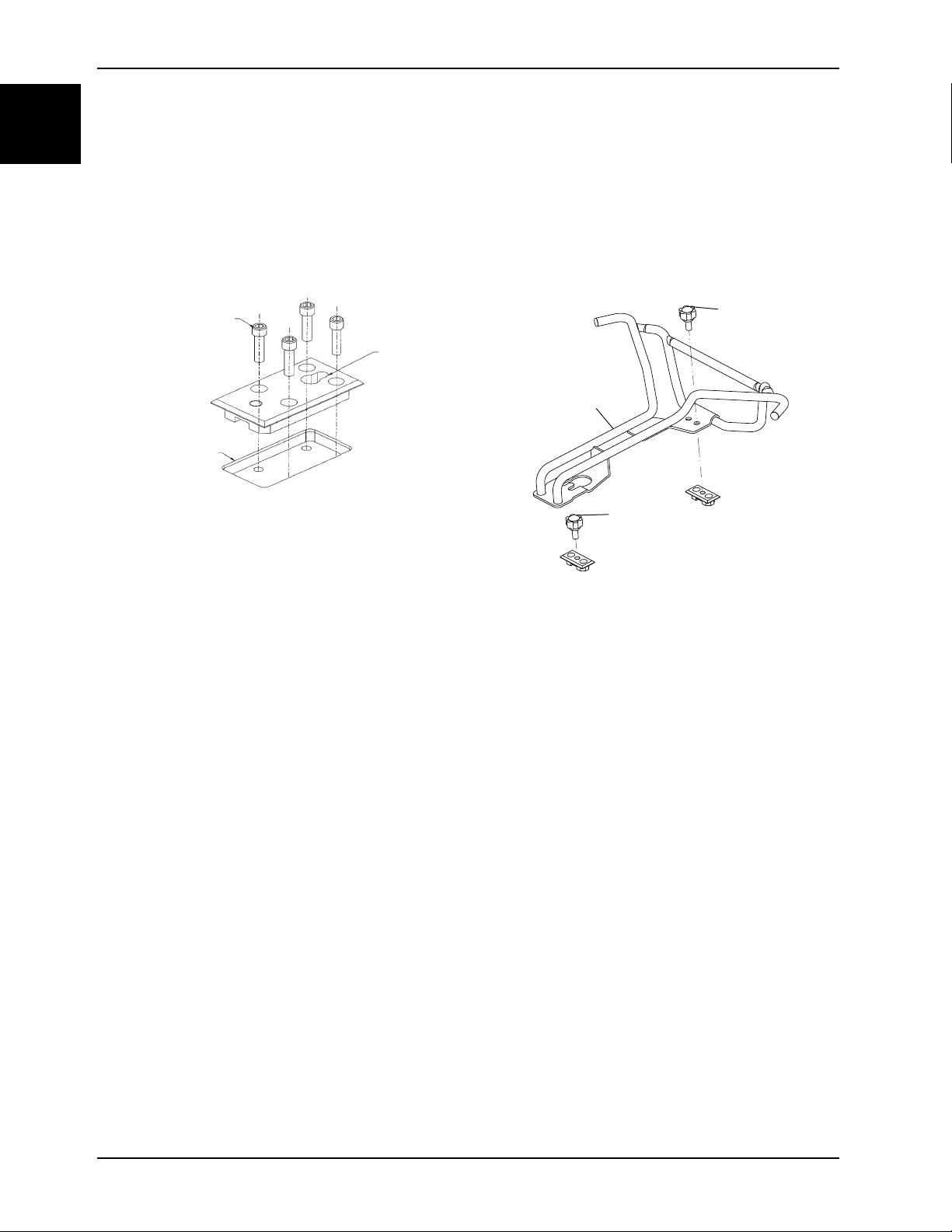

Installing the floor plate (Continued)

6. Using four 3/8 in. diameter socket head cap screws (F), anchor the floor plate into the recessed opening with the

counter-bored holes facing up (G) (Figure 1-11 on page 1-16). The keyhole should face toward the front of the

vehicle.

• A steel backing plate (or equivalent) is required for added support (not supplied).

• One set of additional floor plates is supplied with the Model 6377 fastener to allow alternate positioning

anywhere on the patient compartment floor. Cot space requirements are the same as shown in Figure 1-8 on

page 1-14. Repeat the above procedure to install the alternate position floor plates.

Figure 1-11: Floor plate anchor and locating points

Figure 1-12: Position and fasten antler over the floor

plates

7. Position the antler over the floor plates and fasten the antler (A) with the red knobs (B) (Figure 1-12 on page 1-16).

Notes

• Use the additional mounting holes in the antler bracket to position the antler for the Model 6371 wall mounted

cot fastener system.

• The red knobs that fasten the antler assembly to the patient compartment floor plate are not compatible with

the universal floor plate. See the Universal Floor Plate Installation Instructions for floor plate installation.

8. Position the rail support bracket (C) over the floor mounting plate (D) (Figure 1-13 on page 1-17).

9. Insert the socket head screw into the keyhole and slide the assembly forward until the hole in the bracket lines up

with the tapped hole in the floor plate.

10. Fasten securely by tightening one of the red knobs (E) (Figure 1-13 on page 1-17).

11. Position the rail assembly (F) on the support bracket (G) (Figure 1-14 on page 1-17).

1-16 6370-109-005 REV C www.stryker.com

Page 23

Installation

C

D

E

F

G

H

K

J

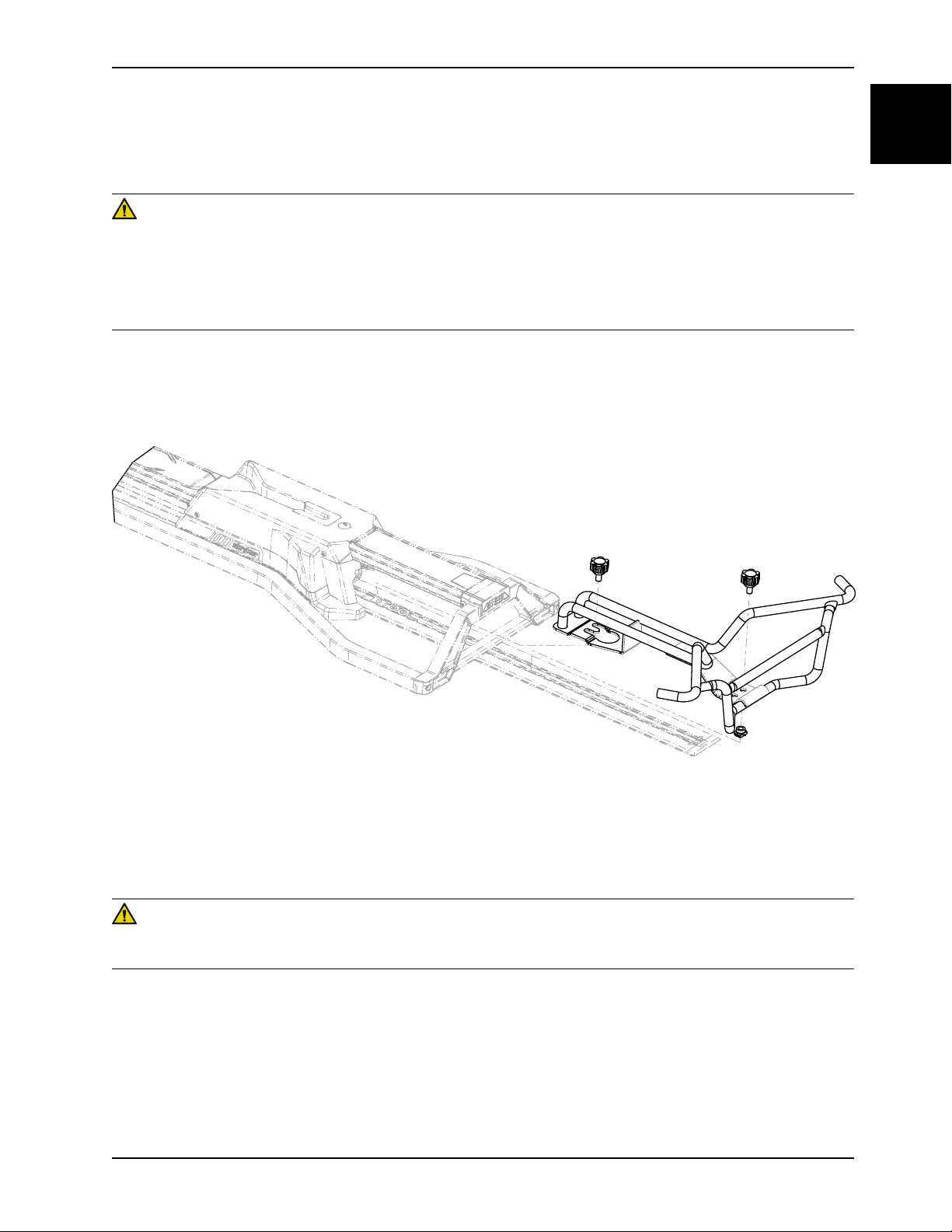

Installing the floor plate (Continued)

12. Install the four Nylock hex nuts (H) and four 5/16−18 x 2 in. socket head cap screws (J) to attach the rail clamp (K)

to the rail assembly (Figure 1-14 on page 1-17).

Figure 1-14: Attach rail clamp to rail assembly

English

EN

Figure 1-13: Fasten the rail support bracket

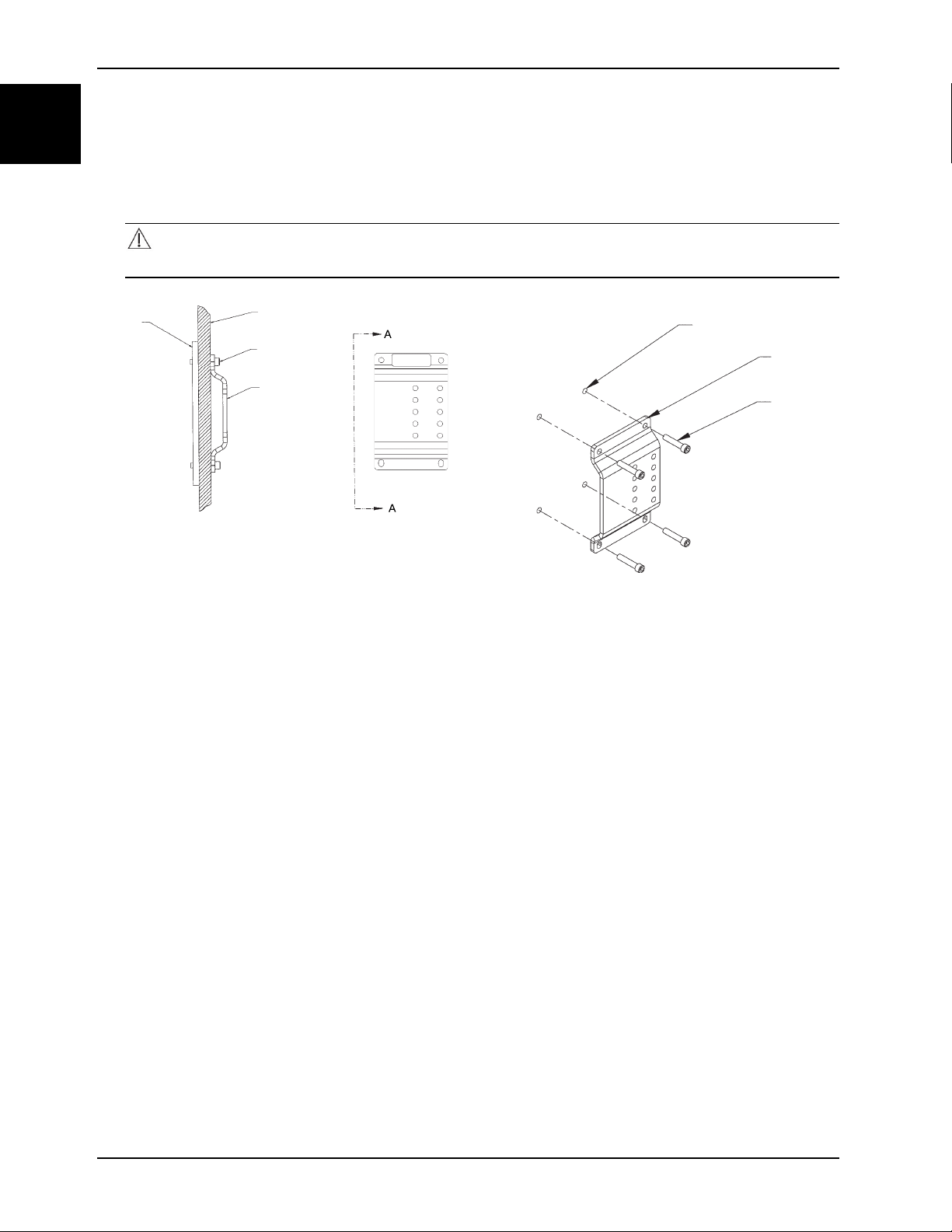

Installing the wall plate

The Stryker cot fastener system for the wall plate mounting model is compatible only with cots which conform to the wall

plate mounting installation specifications.

To position the antler floor mounting plates:

1. Determine the desired position of the cot inside the vehicle to allow for proper clearance around the cot.

Note: Federal ambulance specifications regarding that aisle width and attendant seating may affect positioning of

the mounting brackets. If specifications do not apply, the installer should be certain that there is adequate

clearance for proper patient access, traction splint projection, rear door closure, etc.

www.stryker.com 6370-109-005 REV C 1-17

Page 24

Installation

24.000

(Ref.)

(61 cm)

6-1/8”

(15,6

cm)

14-15/16”

(37,9 cm)

80.000 (Ref.)

(203 cm)

2-5/8”

(6,6 cm)

14-5/8”

(37,1 cm)

1-1/8”

(2,9 cm)

3-5/8””

(9,2 cm)

37-3/8”

(94,9 cm)

6-1/2” (16,5 cm)

4-5/16” (10,9 cm)

A

B

C

D

E

F

G

H

English

EN

Installing the wall plate (Continued)

2. Using the dimensions shown in (Figure 1-15 on page 1-18), locate and drill the points where the floor plates will

attach.

Note: When installing the wall plate for the Stryker Model 6371 cot fastener with the long rail assembly option

(6362-021-000), measure 33 in. for the horizontal dimension and 4 1/16 in. for the vertical dimension. The Stryker

Model 6371 cot fastener with the long rail assembly option is only compatible with the extended head section

assembly (9996-390-200).

Figure 1-15: Wall plate installation locations

A Wall of vehicle E

Antler floor plates

B

C Rear of ambulance G

Cot perimeter

F Cot head end

Wall mounting bracket

D Cot center line H Floor of vehicle

3. Cut two 1 in. x 2-1/2 in. x 9/16 in. deep recessed openings (A) into the floor centered over the locating holes

(Figure 1-16 on page 1-19).

1-18 6370-109-005 REV C www.stryker.com

Page 25

Installation

A

B

C

B

C

D

Installing the wall plate (Continued)

4. Using two 3/8 in. diameter socket head cap screws (B) (not supplied), preferably grade 8, anchor each floor plate

(C) into the recessed openings with the counter-bored holes facing up (Figure 1-17 on page 1-19).

Note: A steel backing plate (or equivalent) (D) (not supplied) is required for added support (Figure 1-17 on page 1-

19).

CAUTION

Do not use screws smaller than the 3/8 in. diameter specified to anchor the floor plates.

Figure 1-17: Anchor wall plate into recessed

openings

English

EN

Figure 1-16: Cut recessed openings over locating

holes

5. Using the dimensions shown in Figure 1-15 on page 1-18, locate and drill the four points where the rail wall

mounting bracket will attach.

www.stryker.com 6370-109-005 REV C 1-19

Page 26

Installation

E

F

G

J

H

F

E

English

EN

Installing the wall plate (Continued)

6. Using four 5/16 in. diameter socket head cap screws (E) (not supplied), anchor the wall bracket (F) through the 11/

32 in. diameter holes (G) to the wall (H) (Figure 1-18 on page 1-20)(Figure 1-19 on page 1-20).

Note: A steel backing plate (or equivalent) (J) (not supplied) is required for added support (Figure 1-18 on page 1-

20).

CAUTION

Do not use a screw smaller than the 5/16 in. diameter specified to anchor the wall plate.

Figure 1-18: Wall plate bracket and steel backing

Figure 1-19: Wall plate bracket and locating points

7. Position the antler over the floor plates and fasten the antler (A) with the red knobs (B) (Figure 1-20 on page 1-21).

Notes

• Use the additional mounting holes in the antler bracket to position the antler for the Model 6370/6377/6378

floor mounted cot fastener systems.

• The red knobs that fasten the antler assembly to the patient compartment floor plate are not compatible with

the universal floor plate. See the Universal Floor Plate Installation Instructions for floor plate installation.

8. Position the rail assembly (C) on the wall mounting bracket (D) (Figure 1-21 on page 1-21).

9. Install the four Nylock hex nuts (E) and four 5/16−18 x 2 in. socket head cap screws (F) to attach the rail clamp (G)

to the rail assembly (Figure 1-21 on page 1-21).

1-20 6370-109-005 REV C www.stryker.com

Page 27

Installation

A

B

B

C

D

E

F

G

Installing the wall plate (Continued)

Figure 1-20: Position and fasten antler over the floor

plates

English

EN

Figure 1-21: Attach the rail clamp to rail assembly

www.stryker.com 6370-109-005 REV C 1-21

Page 28

Installation checklist

English

EN

Follow this checklist with a Stryker Ambulance Cot Fastener Model 6370/6371/6377/6378/6391/6393 compatible cot.

Make sure that you do not have any unused components after installation. Your Stryker Ambulance Cot

Fastener does not ship with any extra components. If you have any unused components after installation, call

Stryker service.

Visually check that all bolts and screws are tightened with no signs of protruding or missing fasteners.

Lift the vehicle bumper to the raised position, if equipped.

Load the compatible cot into the cot fastener (see Cot compatibility on page 1-6).

Make sure that the cot is locked into the cot fastener by pulling in and out and side to side on the foot end of the

cot.

Pull to remove the cot from the vehicle patient compartment. Make sure that the cot safety bar connects with

the vehicle safety hook before you remove the cot from the vehicle patient compartment.

Test the fastener for proper operation (see Testing the cot fastener on page 1-25).

Product serial number:

Installed by: Date:

Inspected by: Date:

Note: Maintain a copy of this record for at least seven years.

1-22 6370-109-005 REV C www.stryker.com

Page 29

Operation

Mass casualty incident planning

You must use the Power-LOAD system, 6370 antler assembly (6370-230-038), or 6378 antler assembly (6378-030-038)

for mass casualty incidents.

WARNING

• Do not allow the rail clamp to overlap the red adjustment limit label on the rail tube. To prevent the rail jaws from

releasing the cot frame, the space between the rail clamp and the rail stationary jaw must never exceed 1 in. (2.5

cm).

• Do not use hand or fingers to press the release button when the rail jaws are open. The rail clamp fastener closes

with a strong spring action.

The mass casualty cot fasteners include a rail assembly for wall or floor mount. You should store this rail assembly in a

cabinet in case of emergency for quick attachment in the vehicle patient compartment.

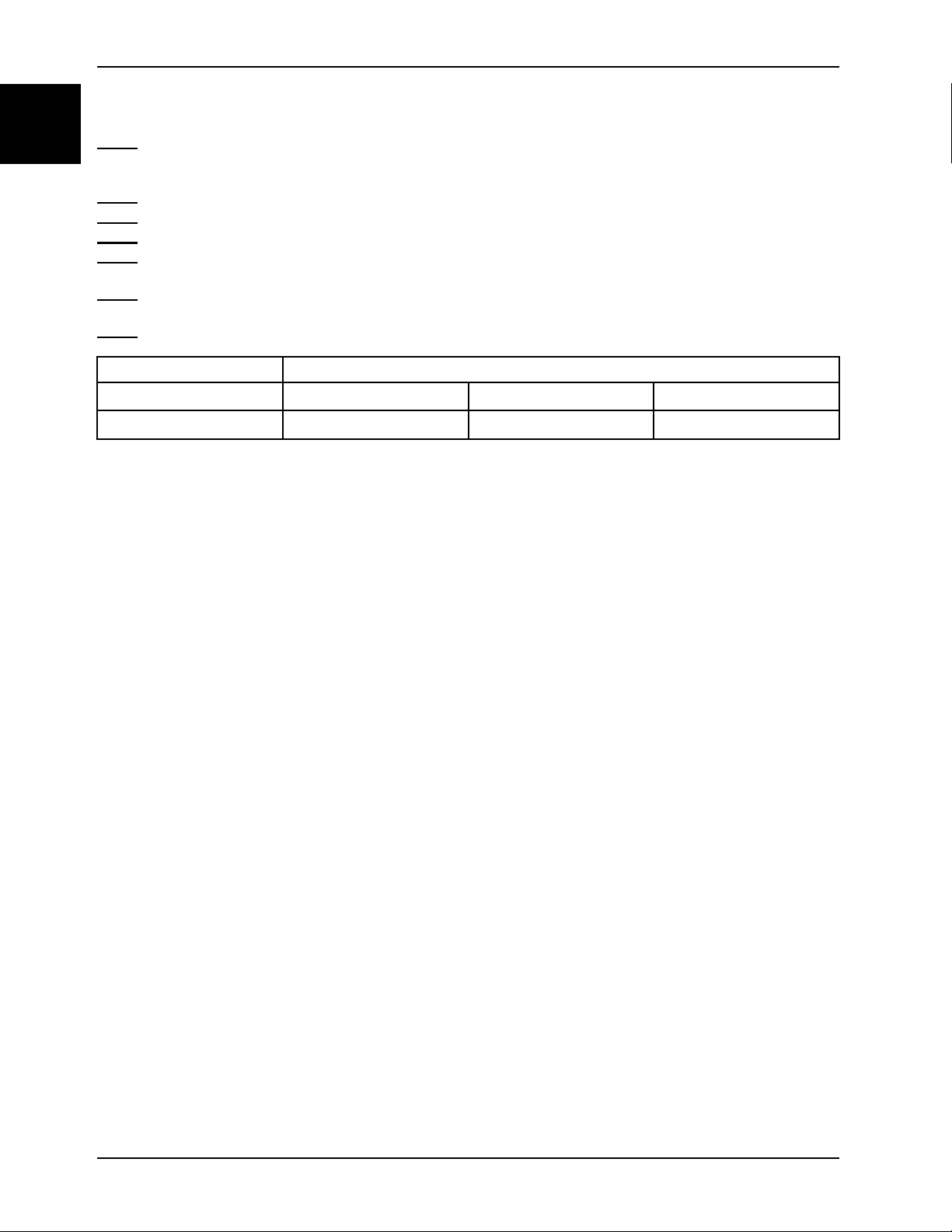

See Figure 1-22 on page 1-23.

English

EN

Figure 1-22: Performance-LOAD installation

Adjusting the rail assembly

Adjustment of the rail assembly may be required to compensate for slight variation in the position of the cot post.

WARNING

Do not allow the rail clamp to overlap the red adjustment limit label on the rail tube. To prevent the rail jaws from

releasing the cot frame, the space between the rail clamp and the rail stationary jaw must never exceed 1 in. (2.5 cm).

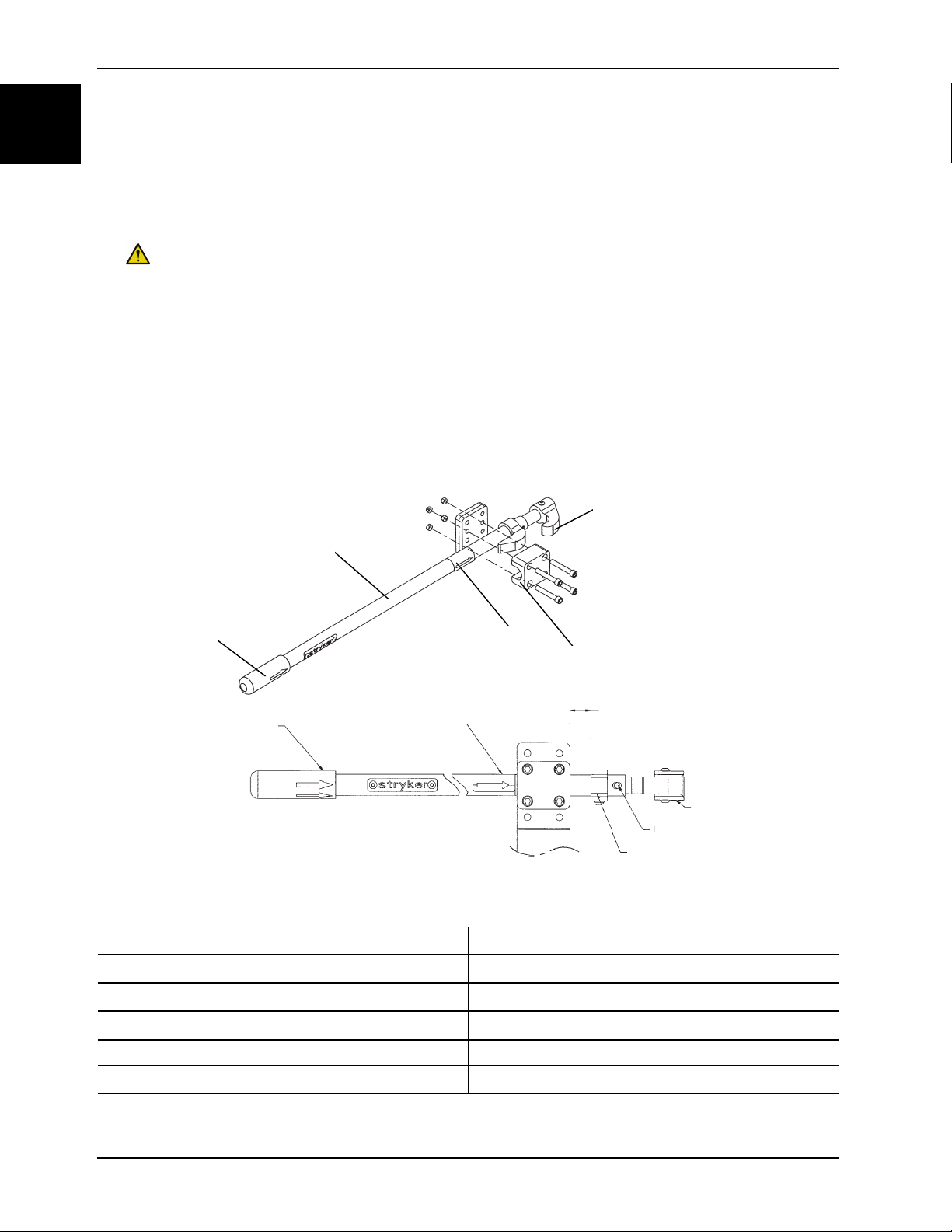

To vertically adjust the rail assembly (Figure 1-23 on page 1-24):

1. Remove the rail clamp (A) and rail assembly (B) from the existing mounting holes.

2. Move the rail clamp and rail assembly to the set of holes that align the clamp jaws (C) with the cot post.

3. Position the rail assembly front to back. Adjustment is limited to 1/2 in. front to back or 1 in. total movement.

Note: Do not overlap the adjustment limit label (D) on the rail assembly.

4. When adjustment is complete, rotate the rail assembly so the jaws are parallel with the floor.

www.stryker.com 6370-109-005 REV C 1-23

Page 30

Operation

A

B

D

E

C

Adjustment Limit Lab

el

A

B

C

D

E

D

E

F

G

H

I

English

EN

Adjusting the rail assembly (Continued)

5. Tighten the mounting screws until the rail clamp is drawn firmly against the support bracket.

6. Push the rail handle (E) forward until the release button engages and the jaws lock in the open position.

7. Guide the cot into the fastener at a slight angle by connecting the loading wheels with the antler one at a time

(Figure 1-24 on page 1-25).

WARNING

Do not use hand or fingers to press the release button when the rail jaws are open. The rail clamp fastener closes

with a strong spring action.

8. Move the foot end of the cot sideways until the cot post enters the rail jaws and presses the release button. The rail

jaws will close, locking the cot securely in position.

Note: Cot bedding may prevent attendants from seeing the rail jaws close around the cot post. Make sure that the

cot is locked into the fastener by firmly pulling side to side on the foot end of the cot.

9. Use one hand to push the rail handle forward far enough for the jaws to release the cot post. With the other hand,

grasp the cot and roll it away from the rail.

A Rail clamp

B Rail assembly

C Clamp jaws

D Adjustment limit label

E Rail handle

F 1” maximum adjustment

1-24 6370-109-005 REV C www.stryker.com

Figure 1-23: Adjusting the rail assembly

Page 31

Operation

Adjusting the rail assembly (Continued)

G

H Moveable jaw

I

Release button

Stationary jaw

English

EN

Figure 1-24: Guiding the cot into the fastener

Testing the cot fastener

WARNING

Always test the fastener using AMD Standard 004 as a minimum. Improper testing can result in injury.

To test the fastener:

1. Guide the cot into the cot fastener.

2. Make sure that the antler connects with the head end loading wheels of the cot.

3. Make sure that the rail clamp jaws are secure to the center of the cot post.

4. Test the fastener using AMD Standard 004 as a minimum.

Note: The fastener may be put into service after successfully passing steps two and three.

www.stryker.com 6370-109-005 REV C 1-25

Page 32

Cleaning

English

EN

Suggested cleaners

In general, when used in concentrations recommended by the manufacturer, either phenolic type or quaternary

(excluding Virex® TB) type disinfectants can be used. Iodophor type disinfectants are not recommended for use

because staining may occur.

WARNING

Always wipe the product with clean water and dry after cleaning. Some cleaning products are corrosive in nature and

may cause damage to the product. Failure to properly rinse and dry the product leaves a corrosive residue on the

surface of the product and may cause premature corrosion of critical components.

Suggested cleaners include:

• Quaternary cleaners (active ingredient - ammonium chloride)

• Phenolic cleaners (active ingredient - o-phenylphenol)

• Chlorinated bleach solution (5.25% - less than 1 part bleach to 100 parts water)

Avoid over saturation. Do not allow the product to stay wet longer than the chemical manufacturer's guidelines for

proper disinfecting.

Note: Failure to follow the above directions when using these types of cleaners may void this product’s warranty.

1-26 6370-109-005 REV C www.stryker.com

Page 33

Preventive maintenance

The following schedule is a general guide to maintenance. Factors such as weather, terrain, geographical location, and

individual usage will alter the required maintenance schedule. If you are unsure how to perform these checks, contact

your Stryker Service Technician. If you are in doubt as to what intervals to follow in maintaining your product, consult

your Stryker Service Technician. Check each routine and replace worn parts if necessary.

Routine Every

1 month 3 months 6 months 12 months

Cot and cot fastener

fit and function

All fasteners are

secure

X

X

English

EN

www.stryker.com 6370-109-005 REV C 1-27

Page 34

sample text

Page 35

Sujeción de camilla para ambulancias

6393 6370

6371

6377

6378

6391

Manual de uso

2018/06 C.0 6370-109-005 REV C

www.stryker.com

Page 36

sample text

Page 37

Símbolos

Instrucciones de utilización/consultar las instrucciones de uso.

Advertencias generales.

Precaución.

Número de catálogo.

Código de lote.

Número de serie.

Para patentes estadounidenses, visite www.stryker.com/patents.

Fabricante.

Fecha de fabricación

Español

ES

Carga de trabajo segura

www.stryker.com 6370-109-005 REV C

Page 38

sample text

Page 39

Índice

Definición de advertencia, precaución y nota ............................................................................................... 2-2

Resumen de las precauciones de seguridad................................................................................................2-3

Introducción ..........................................................................................................................................2-4

Descripción del producto ................................................................................................................... 2-4

Indicaciones de uso .......................................................................................................................... 2-4

Vida útil prevista ..............................................................................................................................2-4

Contraindicaciones........................................................................................................................... 2-4

Especificaciones.............................................................................................................................. 2-5

Ilustración del producto .....................................................................................................................2-5

Información de contacto .................................................................................................................... 2-6

Ubicación del número de serie............................................................................................................ 2-6

Fecha de fabricación ........................................................................................................................ 2-6

Compatibilidad de camillas................................................................................................................. 2-7

Instalación ............................................................................................................................................2-8

Instalación de la sujeción de camilla .................................................................................................... 2-8

Selección del gancho de seguridad del vehículo..................................................................................... 2-8

Configuración del vehículo................................................................................................................. 2-9

Colocación del gancho de seguridad del vehículo de la parte frontal a la posterior...................................... 2-10

Colocación del gancho de seguridad del vehículo de lado a lado ............................................................. 2-11

Instalación del gancho de seguridad del vehículo.................................................................................. 2-12

Instalación de la placa de suelo ........................................................................................................ 2-13

Instalación de la placa de pared........................................................................................................ 2-17

Lista de comprobación de la instalación.................................................................................................... 2-22

Uso ................................................................................................................................................... 2-23

Planificación de incidentes con múltiples víctimas................................................................................. 2-23

Ajuste del conjunto del raíl ............................................................................................................... 2-23

Prueba de la sujeción de camilla....................................................................................................... 2-25

Limpieza............................................................................................................................................. 2-26

Productos de limpieza propuestos ..................................................................................................... 2-26

Mantenimiento preventivo ...................................................................................................................... 2-27

Español

ES

www.stryker.com 6370-109-005 REV C 2-1

Page 40

Español

ES

Definición de advertencia, precaución y nota

Las palabras ADVERTENCIA, PRECAUCIÓN y NOTA tienen un significado especial y deberán revisarse detenidamente.

ADVERTENCIA

Advierte al lector sobre situaciones que, si no se evitan, podrían producir la muerte o lesiones graves. También puede

describir posibles reacciones adversas graves y peligros para la seguridad.

PRECAUCIÓN

Advierte al lector sobre situaciones potencialmente peligrosas que, si no se evitan, pueden producir lesiones leves o

moderadas al usuario o a la paciente, o daños al producto u otras propiedades. Incluye cuidados especiales necesarios

para el uso seguro y eficaz del dispositivo, y para evitar dañarlo con el uso o el mal uso.

Nota: Ofrece información especial que facilita el mantenimiento o aclara instrucciones importantes.

2-2 6370-109-005 REV C www.stryker.com

Page 41

Resumen de las precauciones de seguridad

Lea siempre las advertencias y precauciones indicadas en esta página y sígalas escrupulosamente. Las reparaciones

solo puede realizarlas personal cualificado.

ADVERTENCIA

• Sustituya siempre la sujeción de camilla si se ha utilizado en un accidente.

• Se recomienda un kit de límite de altura para las alturas de plataforma del vehículo de menos de 67 cm.

• La sujeción de camilla solo debe instalarla personal cualificado. Una instalación inadecuada puede provocar

lesiones al paciente o al operador.

• Asegúrese siempre de que todas las camillas cumplan las especificaciones de instalación del sistema de sujeción

de camilla de Stryker.

• No permita que la abrazadera de raíl se superponga a la etiqueta roja del límite de ajuste del tubo del raíl. Para

evitar que las mordazas del raíl liberen el bastidor de la camilla, el espacio situado entre la abrazadera de raíl y la

mordaza fija de este nunca podrá ser superior a 2,5 cm.

• No utilice las manos ni los dedos para pulsar el botón de liberación cuando las mordazas del raíl estén abiertas. La

sujeción de la abrazadera de raíl se cierra con un fuerte efecto de resorte.

• Pruebe siempre la sujeción usando el estándar AMD 004 como mínimo. Una prueba incorrecta puede derivar

lesiones.

• Limpie siempre el producto con agua limpia y séquelo después. Algunos productos de limpieza son corrosivos por

naturaleza y pueden provocar daños al producto. Si no se aclara y seca debidamente, en la superficie del producto

quedará un residuo corrosivo que podría provocar la corrosión prematura de componentes esenciales.

Español

ES

PRECAUCIÓN

• El uso inadecuado del producto puede provocar lesiones al paciente o al operador. Utilice el producto únicamente

como se describe en este manual.

• No modifique el producto ni ninguno de sus componentes. La modificación del producto puede provocar un

funcionamiento impredecible que a su vez cause lesiones al paciente o al operador. La modificación del producto

también anula su garantía.

• Disponga la altura de carga de la camilla siempre en la altura tope correcta antes de su uso.

• Solicite siempre que un mecánico certificado y familiarizado con la estructura de la ambulancia instale el gancho

de seguridad del vehículo. Consulte al fabricante del vehículo antes de instalar el gancho de seguridad. Asegúrese

de que la instalación del gancho de seguridad del vehículo no dañe las líneas de freno, de oxígeno o de

combustible, el tanque de combustible, o los cables eléctricos del vehículo ni interfiera con ellos.

• No utilice tornillos menores que los de 3/8 in de diámetro especificados para anclar las placas de suelo.

• No utilice un tornillo menor que el de 5/16 in de diámetro especificado para anclar la placa de pared.

www.stryker.com 6370-109-005 REV C 2-3

Page 42

Español

ES

Introducción

Este manual le ayudará a utilizar o mantener su producto de Stryker. Lea este manual antes de utilizar este producto o

de realizar su mantenimiento. Establezca métodos y procedimientos para formar a su personal en el uso o el

mantenimiento seguros de este producto.

PRECAUCIÓN

• El uso inadecuado del producto puede provocar lesiones al paciente o al operador. Utilice el producto únicamente

como se describe en este manual.

• No modifique el producto ni ninguno de sus componentes. La modificación del producto puede provocar un

funcionamiento impredecible que a su vez cause lesiones al paciente o al operador. La modificación del producto

también anula su garantía.

Notas

• Este manual es un componente permanente del producto y debe permanecer con él si se vende.

• Stryker busca continuamente el avance en el diseño y la calidad de sus productos. Este manual contiene la

información sobre el producto más actualizada disponible en el momento de la impresión. Puede haber ligeras

discrepancias entre su producto y este manual. Si tiene preguntas, póngase en contacto con el Servicio de

Atención al Cliente o con el Servicio de Asistencia Técnica de Stryker llamando al +1-800-327-0770.

Descripción del producto

La sujeción de la camilla de ambulancia de Stryker se ha diseñado para sujetar una camilla de ambulancia compatible

en un vehículo de urgencias con fines de transporte de pacientes. La sujeción de camilla de ambulancia realiza esta

función después de que el usuario cargue manualmente la camilla compatible en el vehículo de urgencias y la guíe

hacia la sujeción.

Indicaciones de uso

Las sujeciones de camilla de los modelos 6370/6371/6377/6378/6391/6393 de Stryker no se han diseñado para ningún

otro fin que no sea limitar el movimiento de una camilla de ambulancia que se transporta en el compartimento para

pacientes de una ambulancia bajo condiciones normales.

Nota: El uso de estos productos de un modo distinto al indicado pasa a ser total responsabilidad del propietario o

usuario. Las sujeciones de camilla de los modelos 6370/6371/6377/6378/6391/6393 cumplen la especificación de la

división de fabricantes de ambulancias 004. Se debe tener cuidado en todo momento durante la colocación de la

camilla en la ambulancia.

Vida útil prevista

Las sujeciones de camilla tienen una vida útil prevista de siete años en condiciones de uso normales y con el

mantenimiento periódico adecuado.

Contraindicaciones

Ninguna conocida.

2-4 6370-109-005 REV C www.stryker.com

Page 43

Especificaciones

A

B

C

D

Introducción

Modelo Tipo

6371 Montado en pared 6371-000-000

6370 Montado en suelo 6370-000-000

6377 Montado en suelo 6377-000-000

6378 Montado en suelo (longitud reducida) 6378-000-000

6391

6391

6393

6393

ADVERTENCIA

• Sustituya siempre la sujeción de camilla si se ha utilizado en un accidente.

• Se recomienda un kit de límite de altura para las alturas de plataforma del vehículo de menos de 67 cm.

Montado en pared para múltiples

víctimas Power-LOAD

Montado en suelo para múltiples

víctimas Power-LOAD

Montado en pared para múltiples

víctimas Performance-LOAD

Montado en suelo para múltiples

víctimas Performance-LOAD

Número de referencia

6391-001-001

6391-001-002

6393-001-001

6393-001-002

Español

ES

Ilustración del producto

Figura 2-1: Ilustración del producto

A

B Placa de suelo

Conjunto de raíl

www.stryker.com 6370-109-005 REV C 2-5

Page 44

Español

A

ES

Introducción

Ilustración del producto (Continuación)

C Placas de suelo

D

Información de contacto

Póngase en contacto con el Servicio de Atención al Cliente o con el Servicio de Asistencia Técnica de Stryker llamando

al: +1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

EE. UU.

Para ver en línea el manual de uso o de mantenimiento de su producto, visite https://techweb.stryker.com/.

Tenga a mano el número de serie (A) del producto de Stryker cuando llame al Servicio de Atención al Cliente o al

Servicio de Asistencia Técnica de Stryker. Incluya el número de serie en todas las comunicaciones escritas.

Conjunto de cuerno

Ubicación del número de serie

Figura 2-2: Ubicación del número de serie

Fecha de fabricación

El año de fabricación corresponde a los 2 primeros dígitos del número de serie.

2-6 6370-109-005 REV C www.stryker.com

Page 45

Introducción

Compatibilidad de camillas

Los sistemas de sujeción de camilla 6370/6371/6377/6378/6391/6393 de Stryker solo son compatibles con las

camillas que cumplan las especificaciones de instalación.

ADVERTENCIA

• La sujeción de camilla solo debe instalarla personal cualificado. Una instalación inadecuada puede provocar

lesiones al paciente o al operador.

• Asegúrese siempre de que todas las camillas cumplan las especificaciones de instalación del sistema de sujeción

de camilla de Stryker.

Las camillas de ambulancia que cumplen actualmente estas especificaciones son:

Stryker

• Modelo 6060 DX Transporte de urgencias

• Modelo 6070 LX Transporte de urgencias

• Modelo 6080 MX-PRO

• Modelo 6081 MX-PRO Transportador de incubadora

• Modelo 6082 MX-PRO

• Modelo 6083 MX-PRO transporte bariátrico

• Modelo 6085 Performance-PRO XT

• Modelo 6086 Performance-PRO XT

• Modelo 6090 EZ-PRO

• Modelo 6091 EZ-PRO 2

• Modelo 6092 EZ-PRO R3

• Modelo 6092 EZ-PRO R4

• Modelo 6500 Power-PRO XT

• Modelo 6506 Power-PRO XT

• Modelo 6510 Power-PRO IT

• Modelo 6516 Power-PRO IT

Español

ES

Ferno-Washington

• Modelo 29-M camilla sobre ruedas de tres niveles*

• Modelo 93 ES Squadmate™*

• Modelo 93 EX Squadmate™*

• Modelo 35-A Mobile Transporter™*

• Modelo 35-A+ Mobile Transporter Plus™*

• Modelo 35-IT transportador para incubadora*

• Modelo 93P PROFlexx®

• Modelo 35X PROFlexx®

• Modelo 28Z PROFlexx®®

• PowerFlexx®

Notas

• Podría ser necesario ajustar el conjunto de la abrazadera de raíl para compensar cualquier variación en la posición

del poste de retención de la camilla en función del fabricante de camilla de ambulancia y del número de modelo.

• * Modelo del año 1999 o anterior. Stryker no se responsabiliza de los cambios en la especificaciones en las

camillas de otros fabricantes.

www.stryker.com 6370-109-005 REV C 2-7

Page 46

Instalación

Instalación de la sujeción de camilla

Los sistemas de sujeción de camilla de Stryker solo son compatibles con las camillas que cumplan las especificaciones

de instalación.

Español

ES

ADVERTENCIA

• La sujeción de camilla solo debe instalarla personal cualificado. Una instalación inadecuada puede provocar

lesiones al paciente o al operador.

• Asegúrese siempre de que todas las camillas cumplan las especificaciones de instalación del sistema de sujeción

de camilla de Stryker.

Nota: Tal vez necesite ajustar el conjunto de abrazadera de raíl para compensar cualquier variación que se produzca

en la posición del poste de retención de la camilla dependiendo del fabricante y del número de modelo de esta.

Estas instrucciones son válidas para las camillas con sistemas de sujeción de estilo cuerno. Para conocer las

instrucciones de instalación de las sujeciones para la camilla a prueba de colisiones, consulte el Manual de uso

correspondiente.

Selección del gancho de seguridad del vehículo

El gancho de seguridad del vehículo es un dispositivo que se entrega junto con la camilla. La barra de seguridad de la

camilla y el gancho de seguridad del vehículo evitan que la camilla se salga accidentalmente del vehículo y

proporcionan al operador una mayor seguridad y confianza al cargarla y descargarla.

Nota: Estas instrucciones son válidas para las camillas con sistemas de sujeción de estilo cuerno. Para conocer las

instrucciones de instalación de las sujeciones para la camilla a prueba de colisiones, consulte el Manual de uso

correspondiente. Las sujeciones de camilla a prueba de colisiones se entregan e instalan junto con su propio gancho

de seguridad para el vehículo, por lo que no se necesita ningún gancho adicional.

El gancho de seguridad del vehículo está diseñado para ser compatible y funcionar correctamente al cargar y

descargar la camilla de un vehículo que cumpla el reglamento federal estadounidense KKK-A-1822. Stryker ofrece tres

tipos diferentes de ganchos de seguridad para vehículos que se solicitan y envían junto con la camilla. Estos tipos de

ganchos de seguridad para los vehículos satisfacen las necesidades de diversas configuraciones de vehículos de

urgencias, específicamente las relativos a la longitud y la ubicación del soporte del bastidor del suelo situado en la

parte trasera del vehículo.

Para seleccionar el gancho de seguridad adecuado para la configuración de su vehículo:

• Busque una ubicación del soporte del bastidor del suelo donde haya espacio suficiente para montar el gancho de

seguridad del vehículo.

• Monte el gancho de seguridad del vehículo en la parte trasera de este. Deje suficiente separación con el

parachoques para que los operadores puedan cargar y descargar la camilla del vehículo.

• Tenga en cuenta las diferencias de diseño entre los vehículos. Cada gancho de seguridad para los vehículos

ofrece una opción diferente de ubicación para el montaje con el fin de mantener una distancia adecuada entre la

cara del gancho de seguridad para el vehículo y el borde del umbral de la puerta.

Debido a las diferencias en cuanto a dimensiones y ubicación del soporte del bastidor del suelo de los vehículos, cada

gancho de seguridad permite elegir un lugar distinto de montaje. Elija la posición correcta para la instalación del

gancho de seguridad en su vehículo.

• Colocación del gancho de seguridad del vehículo de la parte frontal a la posterior de la página 2-10

• Colocación del gancho de seguridad del vehículo de lado a lado de la página 2-11

Nota: Al sustituir un gancho de seguridad de vehículo existente por otro de un estilo nuevo, ajuste el lugar de montaje

para mantener la posición adecuada de la cara del gancho de seguridad del vehículo.

2-8 6370-109-005 REV C www.stryker.com

Page 47

Instalación

Selección del gancho de seguridad del vehículo (Continuación)

Español

ES

Figura 2-3: Tipos de ganchos de seguridad del vehículo

Configuración del vehículo

PRECAUCIÓN

• Disponga la altura de carga de la camilla siempre en la altura tope correcta antes de su uso.

• Solicite siempre que un mecánico certificado y familiarizado con la estructura de la ambulancia instale el gancho

de seguridad del vehículo. Consulte al fabricante del vehículo antes de instalar el gancho de seguridad. Asegúrese

de que la instalación del gancho de seguridad del vehículo no dañe las líneas de freno, de oxígeno o de

combustible, el tanque de combustible, o los cables eléctricos del vehículo ni interfiera con ellos.

La camilla es compatible con todas las alturas de plataformas de vehículos que cumplan la especificación federal de

EE. UU. Star-of-Life Ambulance KKK-A-1822. Consulte las especificaciones para ver la altura de carga máxima.

Según la especificación federal de EE. UU. Star-of-Life Ambulance KKK-A-1822:

• La parte posterior de la ambulancia deberá llevar un parachoques posterior resistente en toda su anchura, con un

escalón fijado al chasis del vehículo.

• La almohadilla deberá tener una profundidad mínima de 13 cm y máxima de 25 cm.

• Si el escalón sobresale más de 18 cm de la parte posterior del vehículo, deberá incorporar un escalón plegado.

Según los reglamentos federales de EE. UU. (referencia KKK-A-1822), la altura del parachoques del vehículo deberá

instalarse equidistante a ±5 cm del suelo del vehículo y el nivel del suelo, definido como la altura de la plataforma del

vehículo. La instalación del gancho de seguridad del vehículo en un vehículo que cumpla con esta especificación

federal proporciona un espacio libre adecuado para que la base de la camilla baje a su posición totalmente extendida.

www.stryker.com 6370-109-005 REV C 2-9

Page 48

Español

DH

2

2

A

B

C D

E

F

A

B

ES

Instalación

Configuración del vehículo (Continuación)

Figura 2-4: Altura de la plataforma y del parachoques

A

B Altura del parachoques

C Gancho de seguridad del vehículo

D

E

F

Altura de la plataforma (AP)

Borde del alféizar

Alféizar

Profundidad del parachoques

Colocación del gancho de seguridad del vehículo de la parte frontal a la posterior

Compruebe la posición de la parte frontal a la posterior y de lado a lado al descargar y cargar la camilla para

asegurarse de que el gancho de seguridad del vehículo estará instalado correctamente.

Para comprobar la posición de la parte frontal a la posterior:

1. Seleccione el gancho de seguridad adecuado para el vehículo (Selección del gancho de seguridad del vehículo de

la página 2-8).

2. Sitúe el gancho de seguridad del vehículo a al menos a 9,53 cm del borde delantero del umbral de la puerta (A). La

distancia recomendada desde la cara del gancho de seguridad no debe ser inferior a 9,53 cm.

3. Asegúrese de que se puede fijar el gancho de seguridad del vehículo en el soporte de la parte posterior de este.

4. Asegúrese de que quede suficientemente separado del parachoques como para poder cargar y descargar la

camilla del vehículo.

5. Compruebe la colocación del gancho de seguridad del vehículo de lado a lado (Colocación del gancho de

seguridad del vehículo de lado a lado de la página 2-11).

2-10 6370-109-005 REV C www.stryker.com

Page 49

Instalación

A

B

Colocación del gancho de seguridad del vehículo de la parte frontal a la posterior

(Continuación)

Español

ES

Figura 2-5: Colocación del gancho de seguridad del vehículo

A

B

Alféizar

Soporte de la estructura del suelo

Colocación del gancho de seguridad del vehículo de lado a lado

Antes de instalar el gancho de seguridad del vehículo, compruebe la posición de la parte frontal a la posterior y de lado

a lado al descargar y cargar la camilla.

Para comprobar la posición de lado a lado:

1. Retire la camilla de su sujeción y descárguela del vehículo.

2. Tome nota de la posición de las ruedas de carga y de la barra de seguridad de la camilla al retirar esta.

3. Marque el centro de la barra de seguridad de la camilla sobre el suelo del vehículo.

4. Asegúrese de que la posición marcada en el paso 3 sea donde la barra de seguridad de la camilla se engrane en

el gancho de seguridad del vehículo cada vez que descargue la camilla en diversas posiciones (como por ejemplo,

totalmente a la izquierda y totalmente a la derecha).

www.stryker.com 6370-109-005 REV C 2-11

Page 50

Español

ES

Instalación

Colocación del gancho de seguridad del vehículo de lado a lado (Continuación)

Notas

• Si la barra de seguridad de la camilla no engrana en el gancho de seguridad del vehículo en ninguna de estas

posiciones (izquierda, centro o derecha), modifique el vehículo. No modifique la camilla ni el gancho de

seguridad del vehículo.

• Si la barra de seguridad de la camilla engrana en el gancho de seguridad del vehículo todas las veces, instale

el gancho de seguridad del vehículo.

Instalación del gancho de seguridad del vehículo

Antes de instalar el gancho de seguridad del vehículo, el mecánico certificado debe planificar la colocación del gancho

de seguridad del vehículo en la parte posterior del compartimento para pacientes del vehículo.

ADVERTENCIA

• Si no se instala el gancho de seguridad en el vehículo, el paciente o el operador podrían sufrir lesiones.

• Solicite siempre que un mecánico certificado y familiarizado con la estructura de la ambulancia instale el gancho

de seguridad del vehículo.

• Para evitar el riesgo de lesiones, asegúrese siempre de que la barra de seguridad esté conectada al gancho de

seguridad del vehículo antes de retirar la camilla del compartimento para pacientes del vehículo.

Equipamiento necesario (no suministrado):

• (2) tornillos de cabeza cilíndrica Allen de grado 5, mínimo 1/4” 20 * para el gancho de seguridad para vehículos

cortos o largos

• (2) tornillos de cabeza cilíndrica Allen de grado 5, mínimo 1/4” 20 * para el gancho de seguridad en J para

vehículos

• (2) arandelas planas

• (2) arandelas de presión

• (2) tuercas de 1/4”-20

Nota: La longitud de los tornillos de cabeza cilíndrica Allen dependerá del espesor del suelo del vehículo. Utilice

tornillos que sean lo suficientemente largos como para atravesar por completo el suelo del compartimento para

pacientes del vehículo, la arandela y la tuerca, con al menos dos roscas completas en la tuerca.

1. Determine la posición adecuada del gancho de seguridad del vehículo de la parte frontal a la posterior y de lado a

lado para que la barra de seguridad de la camilla engrane con el gancho de seguridad del vehículo cada vez.

• Colocación del gancho de seguridad del vehículo de la parte frontal a la posterior de la página 2-10

• Colocación del gancho de seguridad del vehículo de lado a lado de la página 2-11

2. Taladre los orificios para los tornillos.

3. Fije el gancho de seguridad al suelo del compartimento para pacientes del vehículo.

4. Asegúrese de que la barra de seguridad de la camilla esté engranada con el gancho de seguridad del vehículo

antes de retirar la camilla del compartimento para pacientes del vehículo.

2-12 6370-109-005 REV C www.stryker.com

Page 51

Instalación

A

B

C

DE

Instalación del gancho de seguridad del vehículo (Continuación)

Figura 2-6: Barra de seguridad fijada en el gancho de seguridad del vehículo

Español

ES

Figura 2-7: Colocación del gancho de seguridad del vehículo

A

B

C Banco para la tripulación

D Parachoques

E Marco de la puerta

Después de la instalación, asegúrese de que las patas de la camilla se fijen en la posición de carga sin entrar en

contacto con el parachoques del vehículo.

Instalación de la placa de suelo

El sistema de sujeción de camilla Stryker para el modelo de montaje con placa de suelo solo es compatible con

camillas que cumplen las especificaciones de instalación de montaje con placa de suelo.

www.stryker.com 6370-109-005 REV C 2-13

Vista del vehículo desde arriba

Gancho de seguridad del vehículo

Page 52

Español

12-5/8” (32 cm)

24.000

(Ref.)

(61 cm)

6-1/8”

(15,6

cm)

14-15/16”

(37,9 cm)

37-5/8”

(95,6 cm)

80.000 (Ref.)

(203 cm)

2-5/8”

(6,6 cm)

14-5/8” (Ref.)

(37,1 cm)

A

B

C

D

E

F

G

ES

Instalación

Instalación de la placa de suelo (Continuación)

Para colocar las placas de montaje en pared del cuerno:

1. Determine la posición deseada de la camilla dentro del vehículo para permitir el espacio adecuado alrededor de la

camilla.

Nota: Las especificaciones de las ambulancias federales relativas a la anchura del pasillo y del asiento del

asistente pueden afectar la colocación de los soportes de montaje. Si no se aplican las especificaciones, el

instalador debe asegurarse de que haya suficiente espacio para un acceso adecuado al paciente, la proyección de

la férula de tracción, el cierre de la puerta trasera, etc.

2. Mediante las dimensiones mostradas en Figura 2-8 de la página 2-14, localice y perfore los puntos donde se

fijarán las placas de suelo.

Figura 2-8: Ubicaciones de la instalación de la placa de suelo

Placa de suelo de la abrazadera de soporte del

A

raíl

E Línea central de la camilla

B Pared del vehículo F Perímetro de la camilla

C Placas de suelo del cuerno G Extremo de la cabeza de la camilla

Parte posterior de la ambulancia

D

3. Corte aberturas (A) empotradas de 2,54 x 6,35 x 1,43 cm de profundidad en el suelo centradas sobre los orificios

de posicionamiento (Figura 2-9 de la página 2-15).

2-14 6370-109-005 REV C www.stryker.com

Page 53

Instalación

A

B

C

B

C

D

Instalación de la placa de suelo (Continuación)

4. Con dos tornillos de cabeza cilíndrica Allen (B) de 3/8 in, preferentemente de grado 8, ancle cada placa de suelo

(C) en las aberturas empotradas con los orificios escariados mirando hacia arriba (Figura 2-10 de la página 2-15).

Nota: Se necesitan placas de apoyo de acero (o equivalentes) (D) (no suministradas) para tener un apoyo

adicional (Figura 2-10 de la página 2-15).

PRECAUCIÓN

No utilice tornillos menores que los de 3/8 in de diámetro especificados para anclar las placas de suelo.

Figura 2-10: Anclaje de la placa de suelo en las

aberturas empotradas

Español

ES

Figura 2-9: Corte de las aberturas empotradas sobre

los orificios de posicionamiento

5. Mediante las dimensiones mostradas en Figura 2-8 de la página 2-14, sitúe y perfore los cuatro puntos donde se

fijará la placa de suelo de la abrazadera de soporte del raíl. Corte una abertura (E) de 6,35 x 12,7 x 1,43 cm de

profundidad en el suelo centrada sobre los puntos de posicionamiento (Figura 2-11 de la página 2-16).

www.stryker.com 6370-109-005 REV C 2-15

Page 54

Español

E

F

G

A

B

B

ES

Instalación

Instalación de la placa de suelo (Continuación)

6. Con cuatro tornillos de cabeza cilíndrica Allen de 3/8 in de diámetro (F), ancle la placa de suelo en las aberturas

empotradas con los orificios escariados mirando hacia arriba (G) (Figura 2-11 de la página 2-16). El orificio en ojo

de cerradura debe mirar hacia la parte delantera del vehículo.

• Se necesita una placa de apoyo de acero (o equivalente) para tener un apoyo adicional (no suministrada).

• Se suministra un juego de placas de suelo adicionales con la sujeción modelo 6377 para permitir una

colocación alternativa en cualquier parte del suelo del compartimento para pacientes. Los requisitos de

espacio de la camilla son los mismos que se muestran en la Figura 2-8 de la página 2-14. Repita el

procedimiento anterior para instalar las placas de suelo en una posición alternativa.

Figura 2-11: Anclaje de la placa de suelo y puntos

de posicionamiento

Figura 2-12: Colocación y sujeción del cuerno sobre

las placas de suelo

7. Coloque el cuerno sobre las placas de suelo y sujételo (A) con las perillas rojas (B) (Figura 2-12 de la página 2-16).

Notas

• Utilice los orificios de montaje adicionales en el soporte del cuerno para colocar el cuerno para el sistema de

sujeción de camilla montada en la pared modelo 6371.

• Las perillas rojas que sujetan el conjunto del cuerno a la placa de suelo del compartimento para pacientes no

son compatibles con la placa de suelo universal. Consulte las instrucciones de instalación de la placa de suelo

universal para la instalación de la placa de suelo.

8. Coloque la abrazadera de soporte del raíl (C) sobre la placa de montaje en pared (D) (Figura 2-13 de la página 2-

17).

9. Introduzca el tornillo de cabeza Allen en el orificio de ojo de cerradura y deslice el conjunto hacia adelante hasta

que el orificio en el soporte se alinee con el agujero roscado en la placa de suelo.

10. Sujete con firmeza apretando una de las perillas rojas (E) (Figura 2-13 de la página 2-17).

11. Coloque el conjunto del raíl (F) en la abrazadera de soporte (G) (Figura 2-14 de la página 2-17).

2-16 6370-109-005 REV C www.stryker.com

Page 55

Instalación

C

D

E

F

G

H

K

J

Instalación de la placa de suelo (Continuación)

12. Instale las cuatro contratuercas hexagonales con seguro de nailon (H) y los cuatro tornillos de cabeza cilíndrica

Allen de 5/16-18 x 2 in (J) para fijar la abrazadera de raíl (K) al conjunto del raíl (Figura 2-14 de la página 2-17).

Figura 2-14: Fijación de la abrazadera de raíl al

conjunto del raíl

Español

ES

Figura 2-13: Sujeción de la abrazadera de soporte

del raíl

Instalación de la placa de pared

El sistema de sujeción de camilla de Stryker para el modelo de montaje de placa de pared solo es compatible con

camillas que cumplen las especificaciones de instalación de montaje de placa de pared.

Para colocar las placas de montaje en pared del cuerno:

1. Determine la posición deseada de la camilla dentro del vehículo para permitir el espacio adecuado alrededor de la

camilla.