Stovax 8627 BS, P8627 MA, 8627 MA, P8627 BS User Manual

Riva Nemos

Balanced Flue Convector Fire

With upgradeable control valve

Instructions for Use,

Installation and Servicing

For use in GB, IE (Great Britain and Eire)

This appliance has been certified for use in countries other than those stated. To install this appliance in these countries, it is essential to

obtain the translated instructions and in some cases the appliance will require modification. Contact Gazco for further information.

IMPORTANT

Do not attempt to burn rubbish in this appliance. This appliance must only be operated with the glass door secured firmly in

position. The front casing of this appliance will become hot whilst in operation, it is therefore recommended that a suitable

guard should be used for the protection of young children, the elderly or infirm.

Please read these Instructions carefully before installation or use.

Keep them in a safe place for future reference and when servicing the fire.

The commissioning sheet found at the end of the Users Sections of these instructions should be completed by the Installer.

LPG Models: The appliance is factory set to be run on Butane G30.

If it is intended to be used on Propane G31 the aeration plate supplied must be fitted.

PR0728 Issue 3 (August 2008)

CONTENTS

COVERING THE FOLLOWING MODELS

8627 MA P8627 MA

8627 BS P8627 BS

PAGE

APPLIANCE COMMISSIONING CHECKLIST 3

USER INSTRUCTIONS 4

INSTALLATION INSTRUCTIONS 8

Technical Specifications 8

Site Requirements 9

Installation 12

Commissioning 18

SERVICING INSTRUCTIONS 19

Servicing Requirements 19

Fault Finding 19

How to replace parts 21

Basic spare parts list 25

Service Record 26

2

APPLIANCE COMMISSIONING CHECKLIST

IMPORTANT NOTICE

Explain the operation of the appliance to the end user, hand the completed instructions to them for safe keeping,

as the information will be required when making any guaranteed claims.

FLUE CHECK PASS FAIL

1. Flue is correct for appliance

2. Flue flow test N/A

3. Spillage test N/A

GAS CHECK

1. Gas soundness & let by test

2. Standing pressure test mb

3. Appliance working pressure (on High Setting) mb

NB All other gas appliances must be operating on full

4. Gas rate m3/h

5. Does ventilation meet appliance requirements N/A

6. Have controls been upgraded (Upgradeable models only) 8455 Standard YES NO

8456 Programmable Thermostatic and Timer YES NO

DEALER AND INSTALLER INFORMATION

Dealer .....................................................................

...............................................................................

...............................................................................

Gas Type ..................................................................

Installation Company ................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact No. ..............................................................

Date of Purchase .......................................................

Model No. ................................................................

Serial No. .................................................................

This product is guaranteed for 2 years from the date of installation, as set out in the terms and conditions of sale between Gazco and your

local Gazco dealer. This guarantee will be invalid, to the extent permitted by law, if the above Appliance Commissioning Checklist is not

fully completed by the installer and available for inspection by a Gazco engineer. The guarantee will only be valid during the second year,

to the extent permitted by law, if the annual service recommended in the Instructions for Use has been completed by a Corgi registered

engineer, and a copy of the service visit report is available for inspection by a Gazco engineer.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engineer ...................................................................

Contact No. ...............................................................

Corgi Reg No. ............................................................

Date of Installation ....................................................

3

USER INSTRUCTIONS

1. GENERAL

1.1 A competent person must carry out installation and

servicing.

1.2 In all correspondence, please quote the appliance type and

serial number, which can be found on the databadge

located on a plate under the control valve.

1.3 Ensure that curtains are not positioned above the appliance

and there is at least 300mm between the sides of the

appliance and any curtains.

1.4 If any cracks appear in the glass panel do not use the

appliance until the panel has been replaced.

1.5 If, for any reason, the flue has to be removed from the

appliance, the seals must be replaced in the inner spigot.

1.6 Do not obstruct the flue terminal in any way, i.e. by

planting flowers, trees, shrubs etc in the near vicinity, or by

leaning objects up against the terminal guard.

1.7 Do not use a garden sprinkler or hose near the terminal.

1.8 Do not stand or place objects on the terminal guard as this

will deform it.

This product is guaranteed for 2 years from the date of

installation, as set out in the terms and conditions of sale

between Gazco and your local Gazco dealer. Please consult

with your local Gazco dealer if you have any questions. In

all correspondence always quote the Model Number and

Serial Number.

2. LIGHTING THE NEMOS

2.6 Keep the control knob pressed for 10 seconds and then

release it, the pilot should stay alight. If the pilot goes out,

repeat the procedures until it does.

2.7 If the pilot will not light after repeated attempts, contact the

retailer or installer from whom the appliance was

purchased.

2.8 Turn the right hand control to point to main burner (

The appliance can now be controlled using the left

hand control knob.

2.9 Turn the left hand control knob to point to low fire (

the main burner will light on low. The burner can now

be controlled between low and high settings. Turn the

control knob anticlockwise to increase the flame height and

clockwise to decrease the flame height.

THE YELLOW FLAMES WILL APPEAR WHEN THE FIRE HAS

GAINED SUFFICIENT HEAT - TYPICALLY 10 TO 20 MINUTES.

).

),

3. TURNING THE NEMOS OFF

3.1 To turn the Riva off, locate the control valve, turn the left

hand control knob until it points to off (

will go out leaving the pilot burning.

3.2 To turn the pilot off, locate the control valve, turn the right

hand control knob until it points to off (

out.

IF THE FIRE IS EXTINGUISHED OR GOES OUT IN USE,

WAIT 3 MINUTES BEFORE ATTEMPTING TO RELIGHT

THE FIRE. THE CONTROL VALVE HAS AN INTERLOCK

DEVICE AND THEREFORE CANNOT BE LIT UNTIL THE 3

MINUTES HAVE ELAPSED.

). The main burner

), the pilot will go

2.1 Locate the control valve on the appliance. There are two

control knobs on the valve, the right hand knob controls the

pilot ignition and the left hand knob controls the main

burner.

2.2 If your appliance has already been upgraded to battery

remote control, please refer to the instructions provided

with the upgrade to operate the remote control. The

following instructions will work for either situation.

2.3 Ensure that the left hand control knob is pointing to off (

Ensure that the right hand control knob is pointing to off

2.4

2.5 Press in the right hand control knob and rotate it anticlockwise until a click is heard (keep pressing in) and the

knob is pointing to pilot (

the pilot has not lit, repeat the procedure until it does.

). The pilot should now light. If

( ).

4. UPGRADING YOUR NEMOS

4.1 Your Nemos is fitted with a control valve that can easily be

upgraded to battery powered remote control. This upgrade

can be fitted by anyone capable of simple DIY jobs and

requires no special training. There are two versions of this

control which can be obtained through your local Gazco

stockist.

4.2 STANDARD REMOTE CONTROL This remote control can

control the gas appliance after the pilot has been lit. It can

turn the main burner on and regulate it from low through to

high and back again. It can turn the main burner off leaving

the pilot burning. GAZCO PART NUMBER 8455.

4.3 PROGRAMMABLE THERMOSTATIC AND TIMER REMOTE

CONTROL This remote control can control the gas

appliance after the pilot has been lit. In ‘MANUAL MODE’

it can be used to turn the main burner on and manually

regulate it from low through to high and back again. It can

).

also be used to turn the main burner off leaving the pilot

burning. In ‘AUTO MODE’ it will automatically regulate the

room temperature to a pre-set temperature. In ‘TIMER

MODE’ it will turn the fire on and off according to a pre-set

programme and automatically regulate the room

temperature during the two on periods. GAZCO PART

NUMBER 8456.

4

USER INSTRUCTIONS

5. CLEANING THE NEMOS

ENSURE THE APPLIANCE IS COLD BEFORE PROCEEDING.

5.1 The outside casing of the Nemos should be cleaned using a

damp cloth. If you have a stainless steel door version, it

should be cleaned using a stainless steel cleaner.

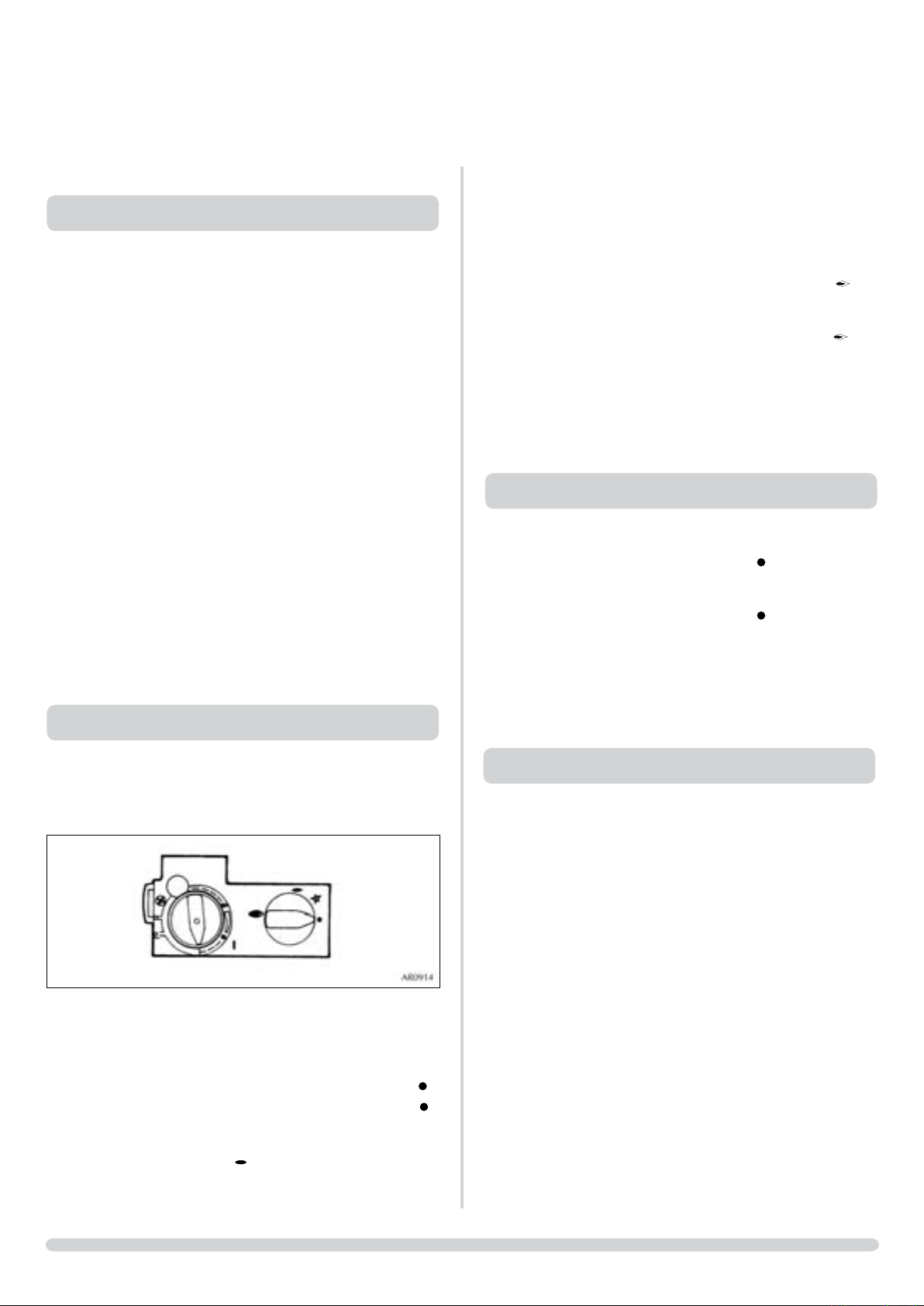

5.2 To clean the burner system, firstly depress the front door

centrally on the RH side and the door will release allowing

you to open fully. See diagram 1.

1

AR1287

5.3 Remove the glass panel by unscrewing the nine pozidriv

screws. See diagram 2.

5.8 To clean the glass surface, Gazco recommends you use a

ceramic glass product generally sold for cleaning ceramic

hobs.

6. ARRANGEMENT OF FUEL BED

COMPONENTS

ADVICE ON HANDLING AND DISPOSAL OF FIRE

CERAMICS

The fuel effect and side panels in this appliance are made

from Refractory Ceramic Fibre (RCF), a material which is

commonly used for this application.

Protective clothing is not required when handling these

articles, but we recommend you follow normal hygiene

rules of not smoking, eating or drinking in the work area

and always wash your hands before eating or drinking.

To ensure that the release of RCF fibres are kept to a

minimum, during installation and servicing a HEPA filtered

vacuum is recommended to remove any dust accumulated

in and around the appliance before and after working on it.

When servicing the appliance it is recommended that the

replaced items are not broken up, but are sealed within

heavy duty polythene bags and labelled as RCF waste.

RCF waste is classed as stable, non-reactive hazardous waste

and may be disposed of at a licensed landfill site.

Excessive exposure to these materials may cause temporary

irritation to eyes, skin and respiratory tract; wash hands

thoroughly after handling the material.

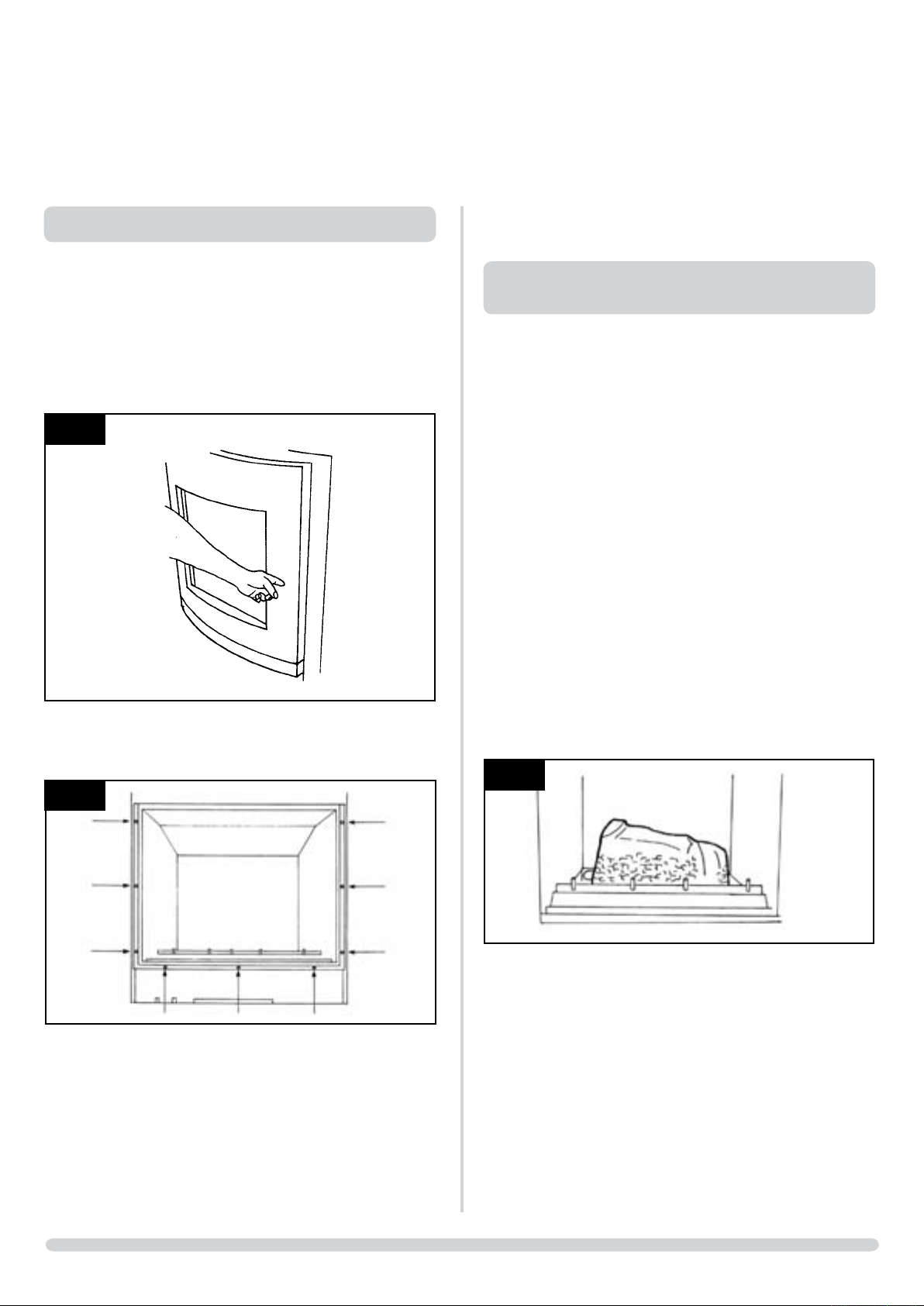

6.1 Place log A on to the burner. Ensure the rear of the log

touches the rear of the burner. See diagram 3.

2

AR0816

5.4 Remove the ceramic logs and place on a dry, clean surface.

It is not essential to remove the embers.

5.5 The logs should not require cleaning. Do not use a vacuum

cleaner or brush to clean the logs, any large pieces of debris

may be removed by hand.

5.6 Ensure any debris is removed from the burner ports.

5.7 Replace the ceramics and door by referring to section 6.

3

AR0816

CENTRALISE THE LOG BETWEEN THE BURNERPORTS AT

EITHER END

Four of the remaining logs have location holes on the

underside. These locate on the studs at the front of the fire.

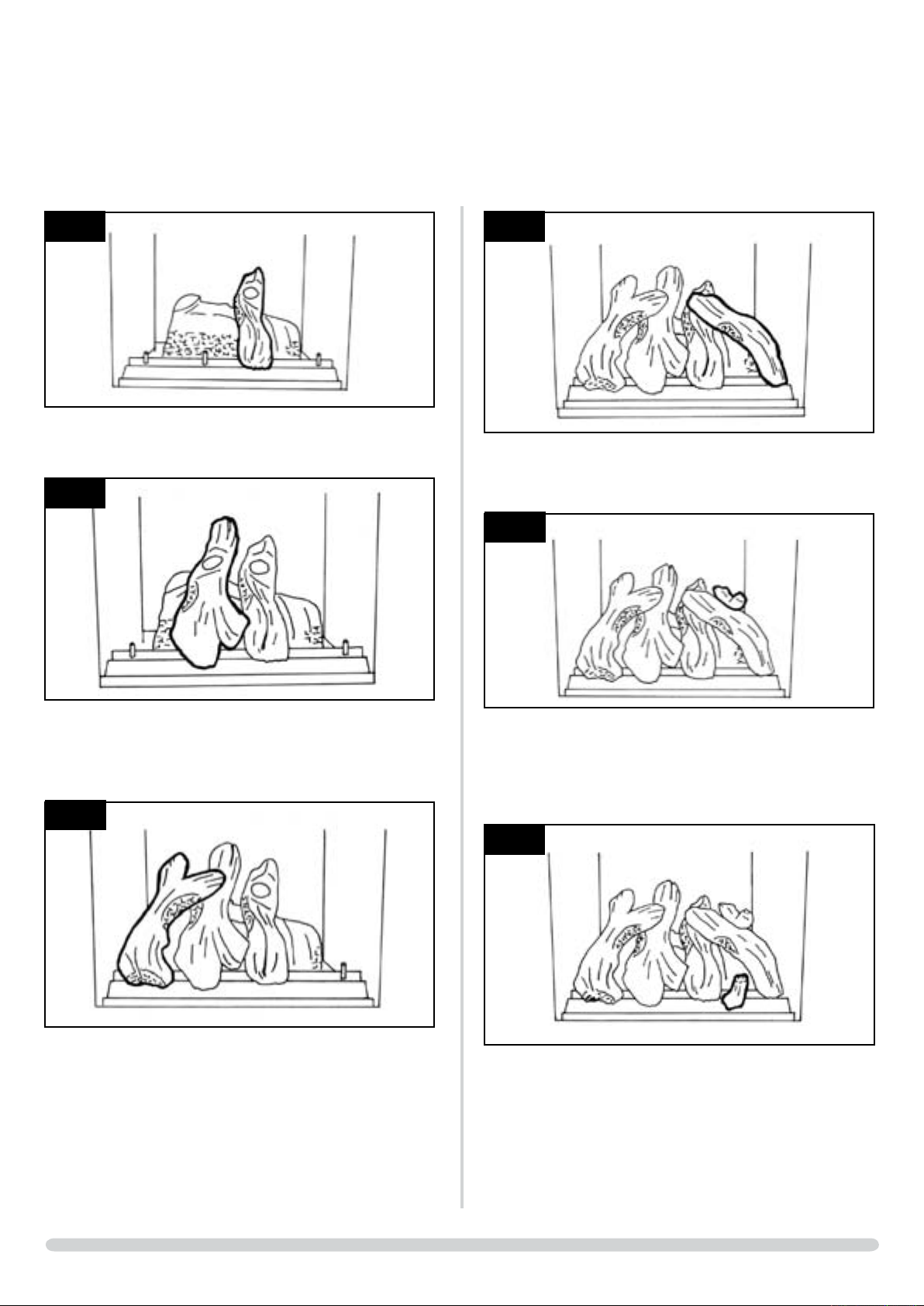

6.2 Place log D on the third stud from the left and resting at the

rear of log A. See diagram 4.

5

USER INSTRUCTIONS

4

AR1194

6.3 Place log C on the second stud and resting at the rear on

log A. See diagram 5.

5

7

AR1197

6.6 Place log F resting on the rear tray and leaning forward to

locate in the recess in log E. See diagram 8.

8

AR1195

6.4 Place log B on the first stud. The recess on the underside of

the log should locate on the top of log C. See diagram 6.

6

AR1196

6.5 Place log E on to the last stud. The recess on the underside

of the log should locate on to the top of log D. See diagram

7.

AR1198

6.7 Place log G at the front of the fire between logs D and E.

DO NOT PLACE THIS LOG ON THE BURNER. IT IS ONLY

TO FILL THE GAP BETWEEN LOGS D AND E. The charred

effect should face the rear of the fire. See diagram 9.

9

AR1199

6.8 With the granules fill the front compartment around the logs

evenly. ENSURE NO GRANULES FALL ON THE BURNER.

See diagram 10.

6

USER INSTRUCTIONS

10

AR1120

6.9 Ensure that the fibreglass seal on the back of the glass frame

is intact then hook the location tabs over the hooks on the

top of the firebox. Replace the nine screws working from

the top down. Tighten the screws evenly. DO NOT OVER

TIGHTEN. See diagram 2, section 5 "Cleaning the Nemos"

NEVER OPERATE THE APPLIANCE WHEN THE GLASS

PANEL IS REMOVED OR BROKEN.

6.10 Close the door by pushing shut centrally on the RH side.

NOTE: ENSURE THAT THE LOGS ARE POSITIONED AS

ABOVE. ONLY USE THE CORRECT AMOUNT OF LOGS

AS SPECIFIED IN THE DIAGRAMS.

11. INSTALLATION DETAILS

11.1 To assist in any future correspondence, your installer should

have completed the commissioning sheet at the front of this

book, this records the essential installation details of the

appliance. In all correspondence always quote the Model

number and Serial number.

12. HOT SURFACES

12.1 Parts of this appliance become hot during normal use. It is

therefore recommended that a suitable fire guard be used

for protection of young children and the infirm. Indeed, all

parts of the appliance should be treated as a 'working

surface' except for the control access panel.

7. FLAME FAILURE DEVICE

7.1 This is a safety feature incorporated on this appliance which

automatically switches off the gas supply if the pilot goes

out and fails to heat the thermocouple.

8. RUNNING IN

8.1 The surface coating on the logs used in your GAZCO fire

will "burn off" during the first few hours of use producing a

harmless and temporary odour. This will disappear after a

short period of use. If the odour persists, ask your installer

for advice.

9. SERVICING

9.1 The fire must be serviced every 12 months by a qualified

Gas Engineer. In all correspondence always quote the

Model number and the Serial number which may be found

on the databadge.

10. VENTILATION

10.1 This appliance requires no additional ventilation.

7

INSTALLATION INSTRUCTIONS

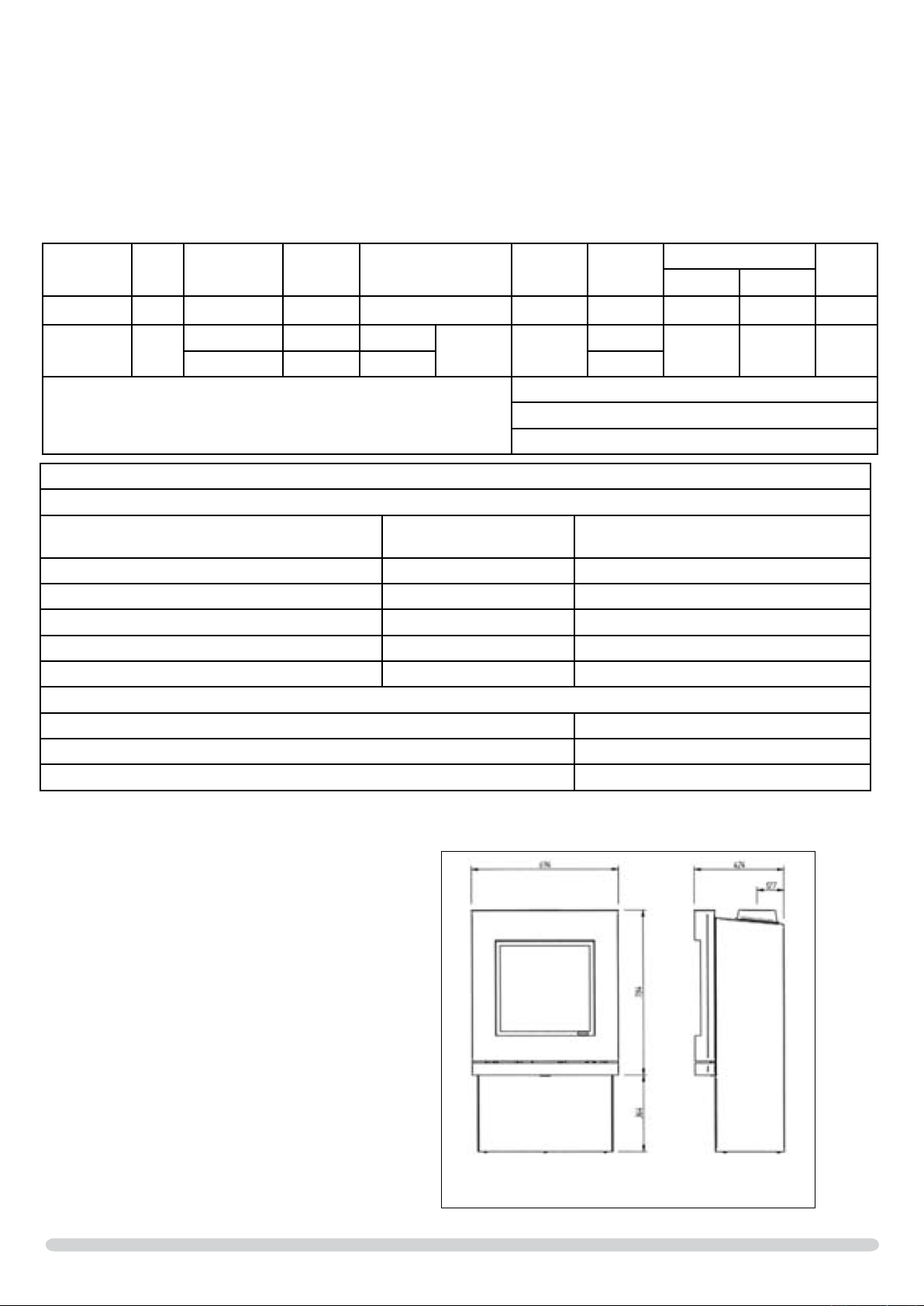

TECHNICAL SPECIFICATION

COVERING THE FOLLOWING MODELS:

8627 MA P8627 MA

8627 BS P8627 BS

Model Gas

CAT.

Nemos NG

Nemos LPG

Vertical flue height from top of appliance Horizontal length Restrictor Size

I

2H

I

3+

*LPG models. The appliance is factory set to run on butane G30.

If it is intended to be used on propane G31 the aeration plate

To change aeration plate refer to section replacing parts 9.

200mm to 500mm Up to 500mm No restrictor

500mm to 1000mm Up to 1000mm No restrictor

1000mm to 1490mm Up to 1000mm 70mm ø

1500mm to 1990m Up to 5000mm 70mm ø

2000mm to 3000mm Up to 5000mm 60mm ø

Gas

Type

Natural (G20) 20mbar 14 x 16 530 0.648 6.8 3.25 GB, IE

Butane (G20)

Propane (G31)

supplied must be fitted.

Vertical ue height from top of appliance Restrictor Size

3000mm to 4990mm 52mm ø

5000mm to 10000mm 47mm ø

Working

Pressure

29mbar

37mbar

VERTICAL & HORIZONTAL FLUE SPECIFICATION

TOP EXIT - VERTICAL ONLY INCLUDING OFFSET

Aeration Injector Gas Rate

15 x 17 OPEN

Blank 0.237

RESTRICTOR REQUIREMENT

1 SIDE

200 0.180

3/h

m

Efficiency Class II

Flue Outlet Size 100 Ø / 152mm Ø

Gas Inlet Connection Size 8mm Ø

Input kW (Gross) Country

High Low

6.3 3.25 GB, IE

PACKING CHECKLIST

Qty Description

1 Nemos stove assembly

1 Ceramic back panel *

1 Ceramic LH side panel *

1 Ceramic RH side panel *

1 Log set (7 logs)

1 Bag of Granules

1 Decorative Cast Collar

1 Fixing kit containing:

1 Instruction manual

3 Wood screws

3 Rawl plugs

* Fitted in appliance

AR1298

8

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

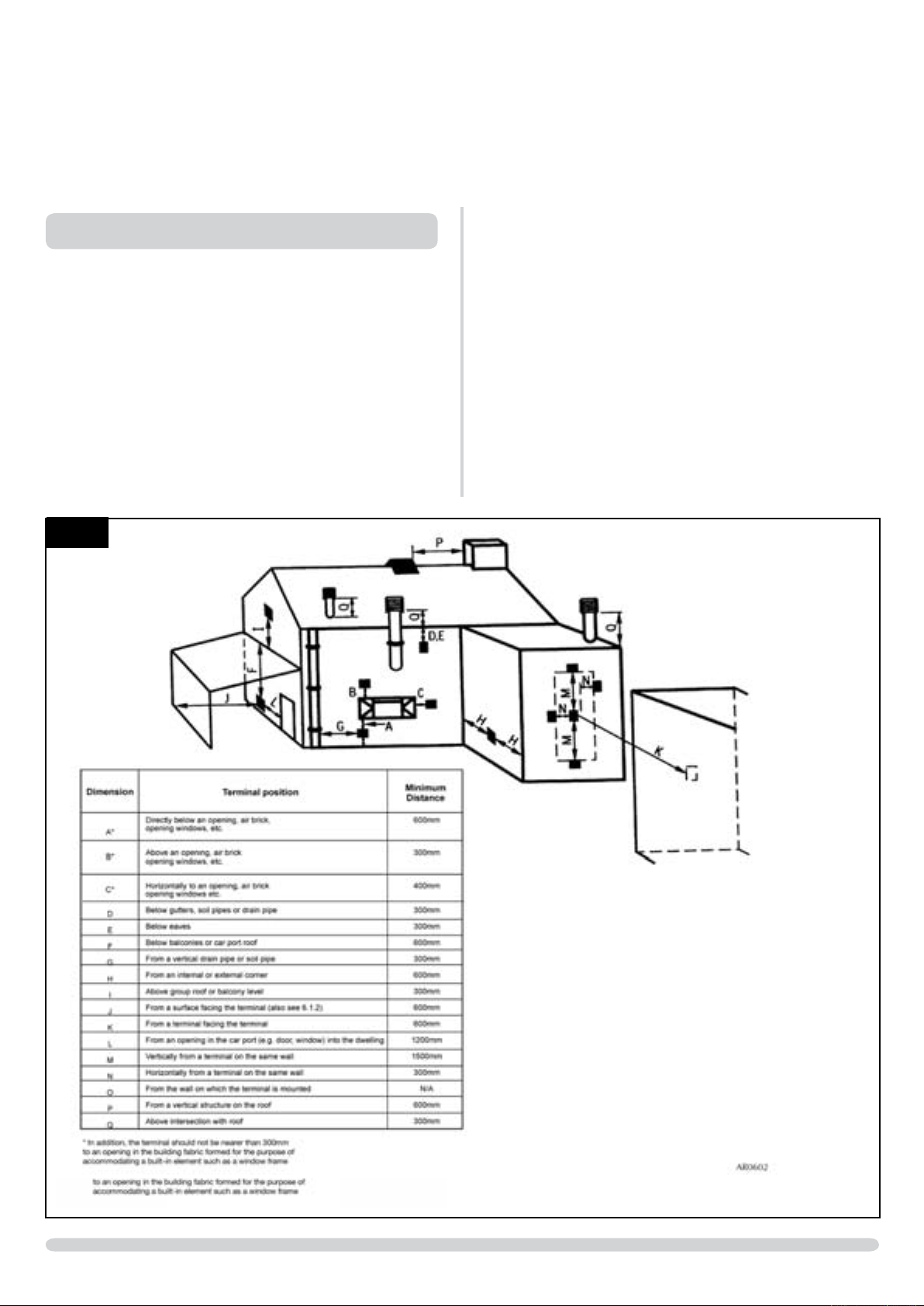

1. FLUE AND CHIMNEY REQUIREMENTS

NOTE: This appliance can only be installed in conjunction

with the flue supplied.

1.1 The flue must be sited in accordance with all local and

national regulations and current rules in force.

1.2 Any terminal which is less than 2 metres above any access

(level ground, balcony or above a flat roof to which people

have access) is to be fitted with a guard.

1.3 All vertical and horizontal flues must be securely fixed and

fire precautions followed in accordance with local and

national codes of practice.

1.4 A restrictor may be required. Refer to Technical

Specifications on page 8.

1

1.5 Two types of flue terminals are available, horizontal and

vertical. For a horizontal terminal, decide on the terminal

position and measure the height from the top of the

appliance to the centre of the required hole. For minimum

and maximum flue dimensions see Section 2.

1.6 Only the horizontal terminal section can be reduced in size.

TIMBER FRAMED BUILDINGS

1.7 It will be necessary to provide additional clearance when

the flue passes through a wall containing any combustible

materials so as to prevent a fire hazard.

1.8 The hole through which the flue will pass, must have a steel

sleeve which is positioned so that an air gap of at least

25mm is maintained between the outer surface of the flue,

and any part of the sleeve.

1.9 For further guidance on the installation of gas appliances in

timber framed buildings, contact your local buildings control

authority.

9

Loading...

Loading...