Page 1

• Two parallel refrigeration systems reduce energy and

water consumption.

• Vertically oriented freezing cylinder provides high

capacity, and maximum energy efficiency.

• Large diameter freezing cylinder facilitates extremely

fast freezing times, resulting in very small ice crystal

formation.

• Easy cleaning and simple assembly of beater parts.

• Low cost, long wearing, NSF approved plastic beater

blades minimize frequent and costly blade replacement.

• Heavy-duty stainless steel beater shaft built to

withstand years of use.

• Clear acrylic freezing cylinder cover allows

monitoring of product while freezing.

• Easy access to freezing cylinder when adding

variegates and particulates.

• Provides thorough mixing of variegates and

particulates unachievable with horizontal barrels.

• All controls and indicators conveniently grouped in

a single panel, on the front of the freezer.

• All buttons and indicators identified by easily

understood symbols relative to their function.

• Time/temperature controlled freezing achieves same

smooth texture and product consistency across full

and partial batches, a feature not possible with

consistency controlled freezers.

• Swing gate style, stainless steel extraction door design

provides rapid extraction of product.

• Two robust 5.0 horsepower, semi-hermetic compressors,

engineered for high quality and outstanding reliability.

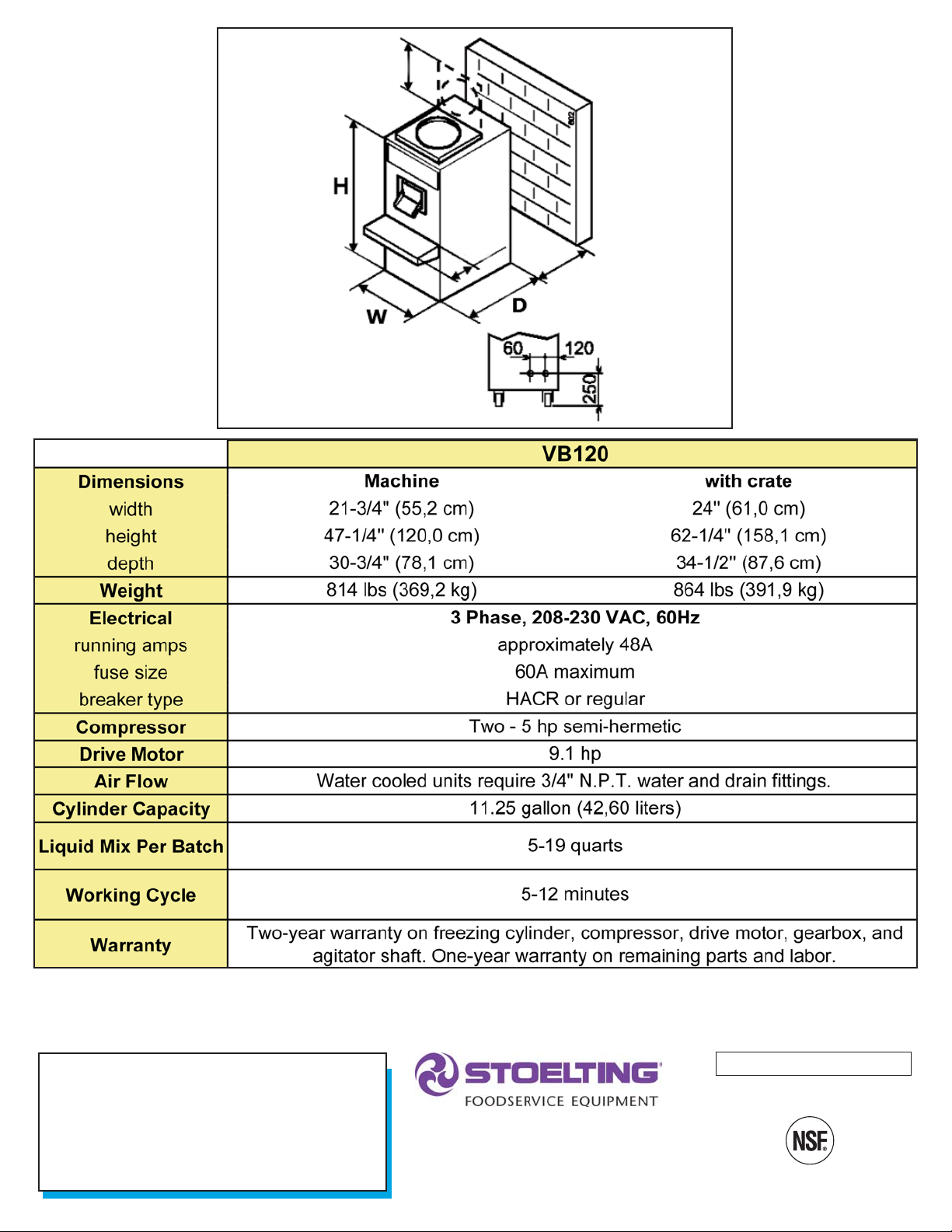

VB120

BATCH FREEZER

Page 2

Distributed by:

502 Highway 67 • Kiel, WI 53042-1600

920-894-2293 • 800-558-5807

Fax: 920-894-7029

E-mail: foodservice@stoelting.com

www.stoeltingfoodservice.com

Certified, Listed and/or Recognized by:

Continuous research leads to ongoing product improvements; therefore, these specifications are subject to change without notice.

0709

ISO 9001:2000 Registered

Loading...

Loading...