Stoelting U421 series, U431-I2 W/C, U431 series, U431-I2 A/C, U431-I2 A/C Remote Operator's Manual

Page 1

Model U421 & U431

Operator’s Manual

513713 Rev.0

Page 2

Section 1: Introduction

This manual provides basic information about the machine. Instructions and suggestions are given covering its operation

and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make changes to the machine without

notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this manual are read completely

and are thoroughly understood. If problems develop or questions arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

stoeltingfoodservice.com

White Glove Service Network

Phone: 888.319.9549

© 2017 Stoelting

2 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 3

This manual is divided into the following fi ve sections:

Section 1: Introduction

INTRODUCTION

OPERATION

MAINTENANCE

A. Parts of the Machine

B. Specifi cations

A. Empty the Freezing Cylinders - Start here if cleaning a machine with mix in it

B. Disassemble Parts - Start here if cleaning an empty machine

C. Cleaning Disassembled Parts

D. Cleaning the Machine

E. Assembling the Machine

F. Sanitizing

G. Freeze Down

H. Brushes for Cleaning

I. Lubrication Points

J. Pump Hose Routing

A. Mix Pump Hose Replacement

B. Mix Pump Hose Cleaning

C. Fine Consistency Adjustment

D. Daily Procedures - Night

E. Daily Procedures Morning

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

TROUBLESHOOTING

PART S

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 3

A. Troubleshooting Flow Charts

A. Auger Shaft & Front Door Parts

B. Cab Tubing

Page 4

Section 1: Introduction

A. Parts of the U421-I2A Machine

IntelliTec2™

Spigot Handle

Front Door

Swing Gate Style Handles

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

Freezing Cylinder

Cabinet

IntelliTec2™ Touchpad

The U421 has two types of spigot handles, swing gate and pull-down. The swing gate style is opened by moving the

handle to the left. The pull-down style is opened by pulling downwards.

This manual shows the pull-down handles which are self-closing. The swing gate style handles need to be closed when

fi nished dispensing.

4 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 5

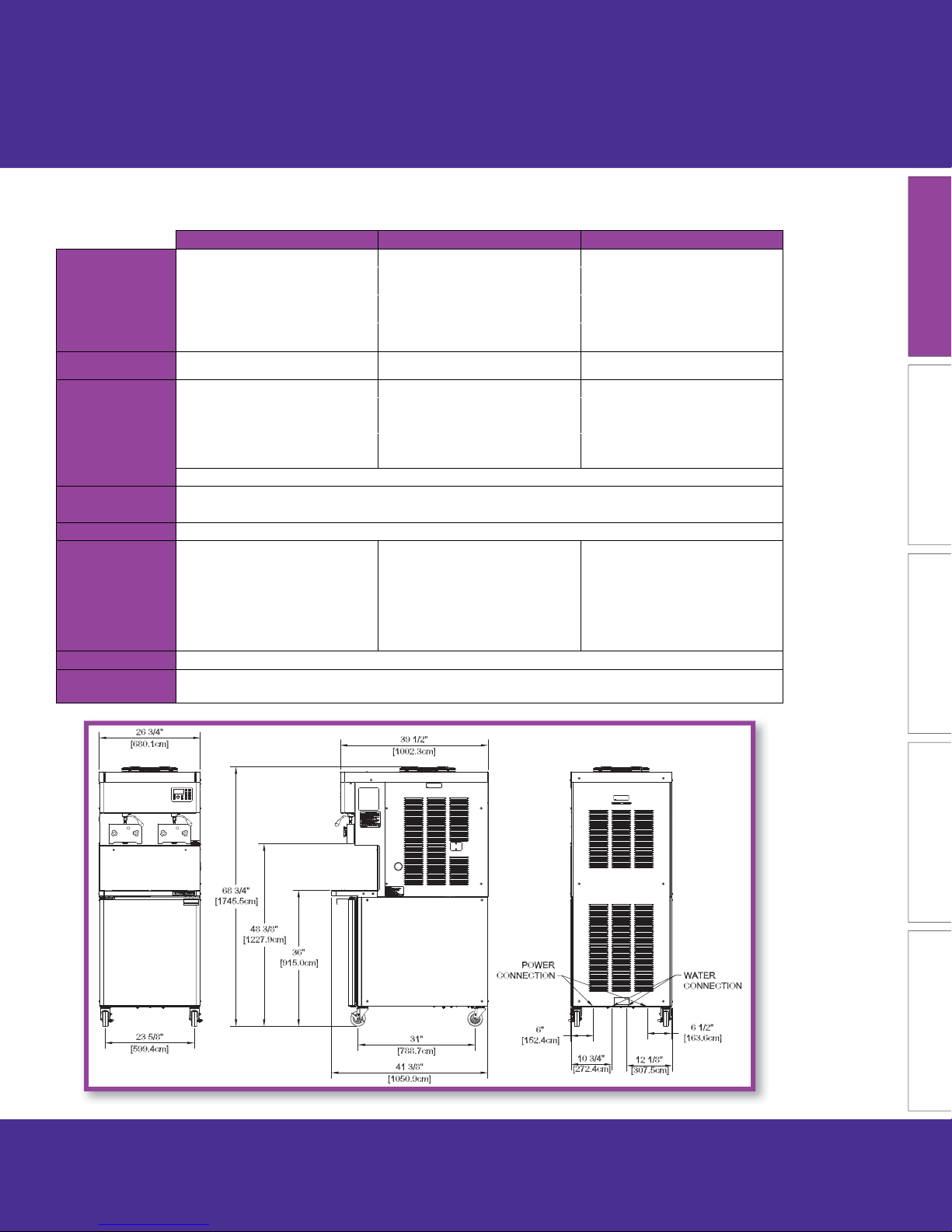

B. U421-I2A Specifi cations

U41-I2A A/C U421-I2A A/C Remote U421-I2A W/C

Dimensions

width

height

depth

Weight

Electrical

circuit ampacity

(per barrel)

overcurrent protection

device (per barrel)

Compressor

Drive Motor Two - 2 hp

Cooling

Hopper Volume Two - 8 gallon (30,28 liters)

Freezing Cylinder

Volume

Machine with crate Machine with crate Machine with crate

26-3/4’’

(67,9 cm)

68-3/4’’

(174,6 cm)

39-1/2’’

(100,3 cm)

785 lbs

(356,0 kg)

1 PH 3 PH 1 PH 3 PH 1 PH 3 PH

32A 20A

50A 30A

34’’

(86,4 cm)

78’’

(198,1 cm)

48’’

(121,9 cm)

935 lbs

(424,1 kg)

26-3/4’’

(67,9 cm)

67-3/4’’

(172,1 cm)

39-3/4’’

(101,0 cm)

760 lbs

(344,7 kg)

36A Left /

31A Right

50A Left /

45A Right

(86,4 cm)

(198,1 cm)

(121,9 cm)

908 lbs

(411,8 kg)

The machine requires one dedicated electrical circuit per barrel.

Two - 19,000 Btu/hr

Cabinet - 1,300 Btu/hr Compressor (R-134a)

Air cooled units require 6” (15,2 cm) air

space on all sides and open at the top.

Remote air cooled requires two remote

condensers and two precharged line

sets.

Two - 1.33 gallon (5,03 liters)

Section 1: Introduction

34’’

78’’

48’’

20A 32A 20A

30A 50A 30A

26-3/4’’

(67,9 cm)

67-1/2’’

(171,5 cm)

39-1/2’’

(100,3 cm)

760 lbs

(344,7 kg)

Water cooled units require 1/2” N.P.T.

water and drain fi ttings. Maximum water

pressure of 130 psi. Minimum water fl ow

rate of 3 GPM per barrel. Ideal EWT of

50°-70°F. The machine requires 6” (15,2

cm) air space on all sides for the cabinet

refrigeration system.

34’’

(86,4 cm)

78’’

(198,1 cm)

48’’

(121,9 cm)

908 lbs

(411,8 kg)

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 5

Page 6

Section 1: Introduction

C. Parts of the U431-I2A Machine

Spigot Handle

IntelliTec2™

Front Door

Swing Gate Style Handles

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

The U431 has two types of spigot handles, swing gate and pull-down. The swing gate style is opened by moving the

handle to the left. The pull-down style is opened by pulling downwards.

Freezing Cylinder

Cabinet

IntelliTec2™ Touchpad

This manual shows the pull-down handles which are self-closing. The swing gate style handles need to be closed when

fi nished dispensing.

6 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 7

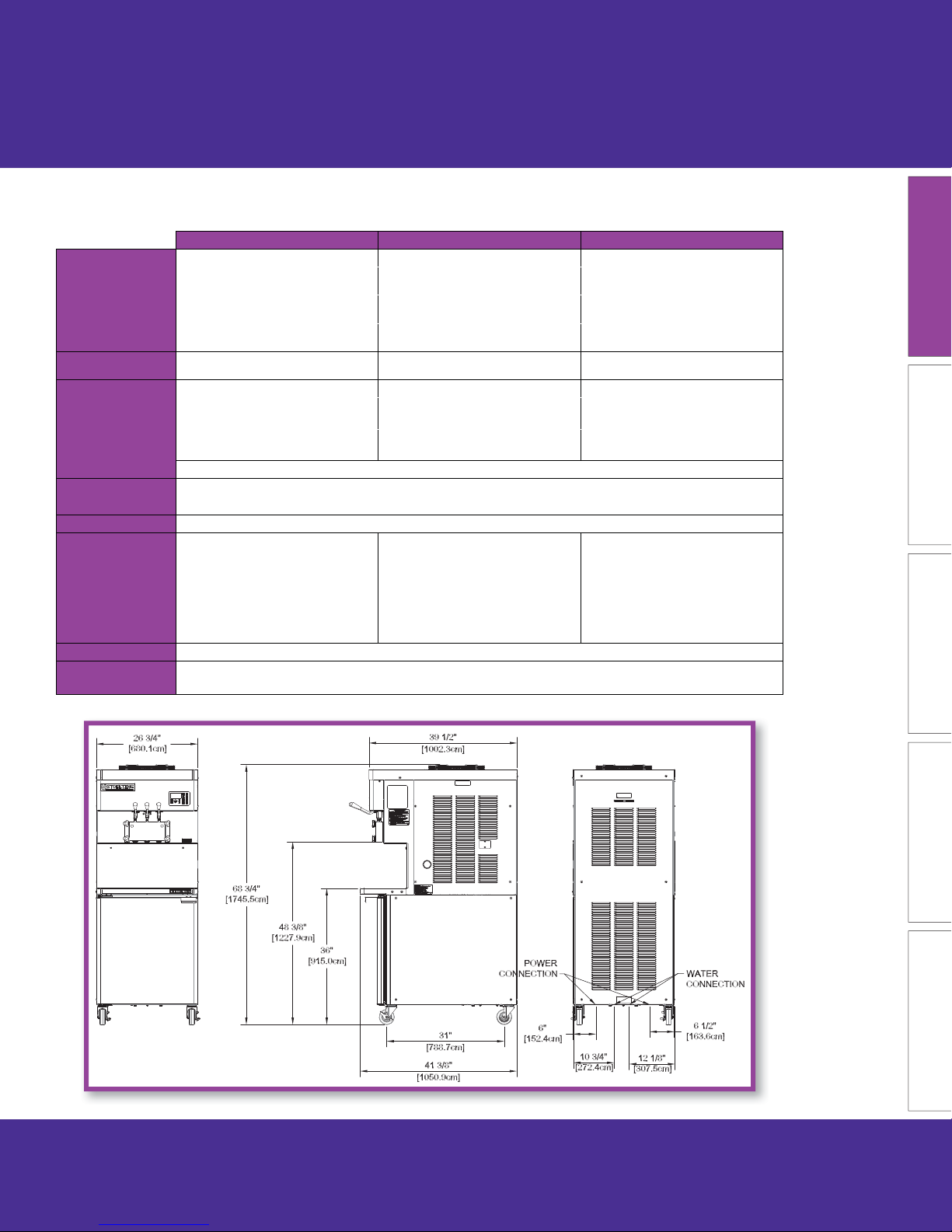

D. U431-I2A Specifi cations

U431-I2 A/C U431-I2 A/C Remote U431-I2 W/C

Dimensions

width

height

depth

Weight

Electrical

circuit ampacity

(per barrel)

overcurrent protection

device (per barrel)

Compressor

Drive Motor Two - 2 hp

Cooling

Hopper Volume Two - 8 gallon (30,28 liters)

Freezing Cylinder

Volume

Machine with crate Machine with crate Machine with crate

26-3/4''

(67,9 cm)

68-3/4''

(174,6 cm)

39-1/2''

(100,3 cm)

785 lbs

(356,0 kg)

1 PH 3 PH 1 PH 3 PH 1 PH 3 PH

32A 20A

50A 30A

34''

(86,4 cm)

78''

(198,1 cm)

48''

(121,9 cm)

935 lbs

(424,1 kg)

26-3/4''

(67,9 cm)

67-3/4''

(172,1 cm)

39-3/4''

(101,0 cm)

760 lbs

(344,7 kg)

36A Left /

31A Right

50A Left /

45A Right

The machine requires one dedicated electrical circuit per barrel.

Two - 19,000 Btu/hr

Cabinet - 1,300 Btu/hr Compressor (R-134a)

Air cooled units require 6" (15,2 cm) air

space on all sides and open at the top.

Remote air cooled requires two remote

condensers and two precharged line

sets.

Two - 1.33 gallon (5,03 liters)

Section 1: Introduction

34''

(86,4 cm)

78''

(198,1 cm)

48''

(121,9 cm)

908 lbs

(411,8 kg)

20A 32A 20A

30A 50A 30A

26-3/4''

(67,9 cm)

67-1/2''

(171,5 cm)

39-1/2''

(100,3 cm)

760 lbs

(344,7 kg)

Water cooled units require 1/2" N.P.T.

water and drain fi ttings. Maximum water

pressure of 130 psi. Minimum water fl ow

rate of 3 GPM per barrel. Ideal EWT of

50°-70°F. The machine requires 6" (15,2

cm) air space on all sides for the cabinet

refrigeration system.

34''

(86,4 cm)

78''

(198,1 cm)

48''

(121,9 cm)

908 lbs

(411,8 kg)

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 7

Page 8

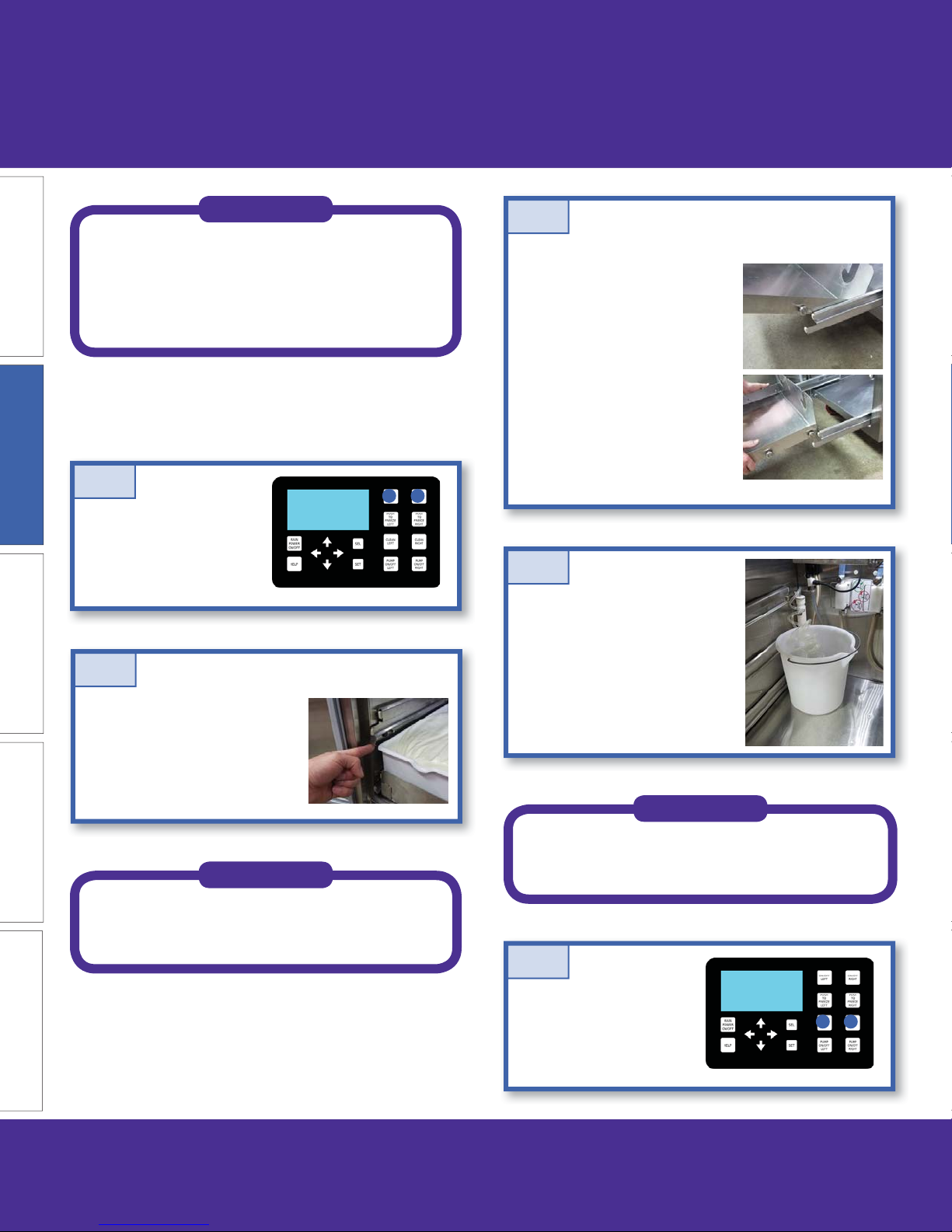

Section 2: Operation

NOTE

The machine must be emptied,

disassembled, cleaned and sanitized

every 3 days or per local health code

requirements (whichever is sooner).

A. Empty the Freezing Cylinders

A.1

Turn off freezing cylinders.

A.2

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

In the cab, lift the drawer latches

and pull out the drawers.

A.3

Set up cab and hoses for rinse procedure.

1. Remove the bags from the cab

and store them in a cooler.

2. Remove the three plastic bins

from the cab.

3. Remove the drawers. To

remove a drawer, pull it

out. Tilt the drawer up to

disengage the front rollers.

Pull it further out then up to

disengage the rear rollers.

A.4

Fill a bucket with 2 gallons of cool

tap water and place the coiled

hoses with bag adapters into

the bucket.

Disconnect the bag adapters

from the bags and place caps

on the bags

NOTE

Optional: Fill the bucket with Stera Sheen

solution to make cleaning parts easier after

NOTE

disassembly.

Wire trays are located at the upper left and

right corners of the cab to store bag caps.

A.5

Press the Clean buttons.

Make sure the display

shows that the mix pumps

are on

8 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 9

Section 2: Operation

A.6

Open spigots to drain product

until no product is visible through

the front door. Refi ll the bucket

with water as necessary.

NOTE

If the “Clean Time Exceeded” warning

is displayed on the IntelliTec2™, turn the

freezing cylinder on and off again to clear

the warning. Press the Clean button to

resume cleaning.

A.7

Remove the buckets to help

clear any remaining liquid in

the hoses.

A.9

Press and hold the Main

Freezer Power button for

three seconds to turn off

the power.

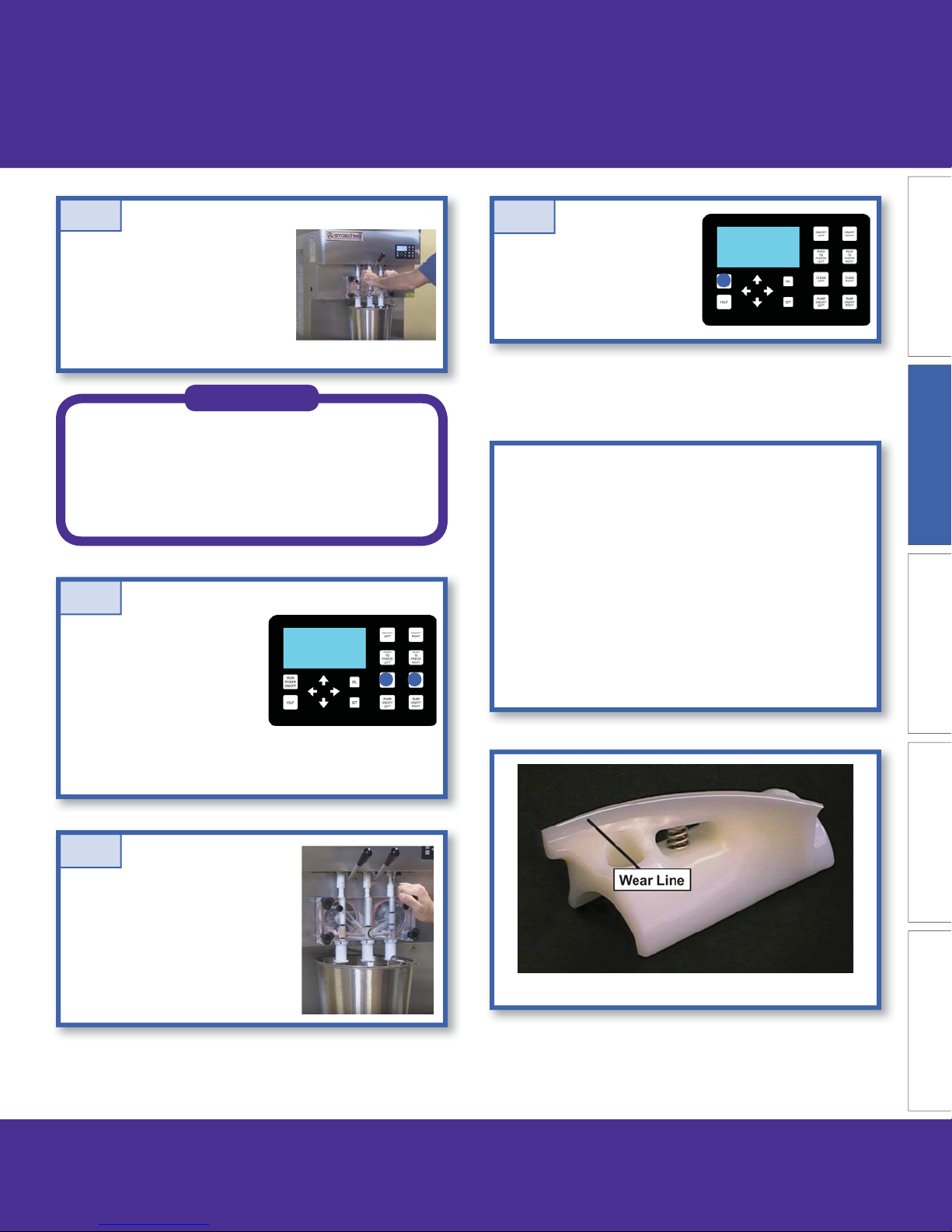

B. Disassemble Parts

Before using the machine for the fi rst time, complete

machine disassembly, cleaning and sanitizing

procedures need to be followed. Routine cleaning

intervals and procedures must comply with the local

and state health regulations. Inspection for worn or

broken parts should be made at every disassembly

of the machine. All worn or broken parts should be

replaced to ensure safety to both the operator and the

customer and to maintain good machine performance

and a quality product. Check the wear line on the auger

fl ights on a regular basis and replace as needed.

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

Drain the water from the

freezing cylinders and press

the Clean and Pump buttons

to stop the augers.

A.8

Open the spigots to release

any pressure in the freezing

cylinders (machines with gate

style handles).

Auger Flight Wear

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 9

Page 10

Section 2: Operation

1. Front Door Disassembly

B.1

Remove the spigot

extensions or rosette

caps if installed.

Unscrew the knobs

on the front door and

remove the door.

B.2

Remove the front

door o-rings and

remove the spigots

from the front door.

2. Removing Auger

B.5

Remove front auger

supports and bushings

and remove the augers

from the freezing cylinders.

As the augers are being

pulled out, remove the

plastic fl ights with springs.

B.6

Wipe any remaining

lubricant off the hex end

of the auger and remove

the rear seal assembly

and o-ring. Wipe any

remaining lubricant off

the o-ring and auger.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

B.3

Remove the air bleed

valve from the front

door.

B.4

Remove all o-rings from

parts by fi rst wiping off the

lubrication using a clean

towel. Then squeeze the

o-ring upward to form a

loop. Roll the o-ring out of

the groove.

Remove the rear seal

adapter from the rear seal.

B.7

Unscrew springs

from the auger

fl ights.

NOTE

The pump hose must be replaced every

800 gallons or every two weeks, whichever

occurs fi rst. Go to Section 3 A for pump

hose replacement instructions.

10 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 11

Section 2: Operation

C. Cleaning Disassembled Parts

Disassembled parts require complete cleaning,

sanitizing and air drying before assembling. Local

and state health codes will dictate the procedure

required. Some state health codes require a four sink

process (pre-wash, wash, rinse, sanitize, air dry), while

others require a three sink process (without the prewash step). The following procedures are a general

guideline only. Consult your local and state health

codes for the procedures required in your location.

C.1

Place all parts in 90° to 110°F

(32°C to 43°C) mild detergent

water and wash thoroughly. Use

the brushes that shipped with

the machine to clean all holes in

the front door, fl ights, mix pickup

assembly, etc.

D. Cleaning the Machine

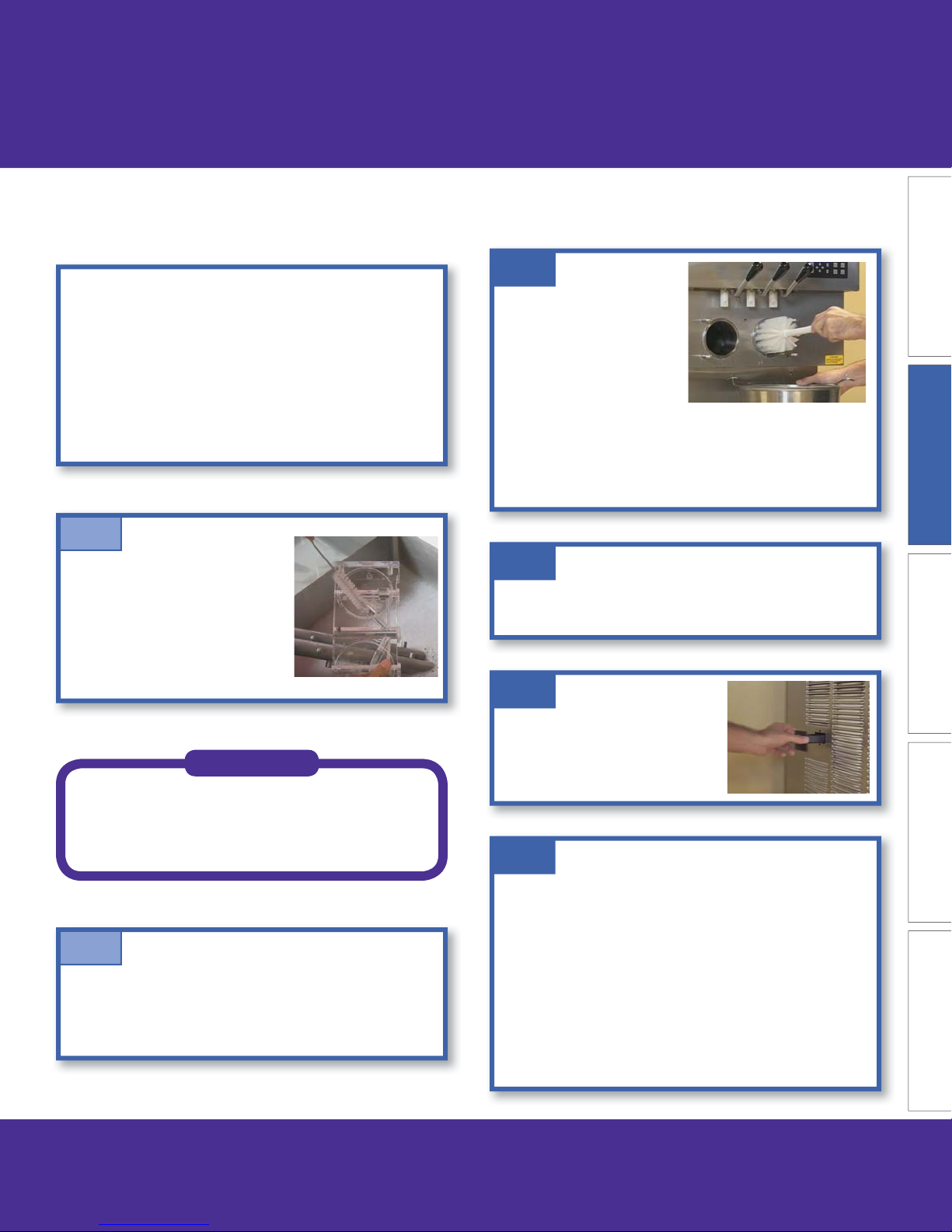

D.1

Using a detergent solution

and the large barrel

brush provided, clean

the freezing cylinders by

dipping the brush in the

solution and brushing

the inside of the freezing

cylinders.

Make sure to thoroughly clean the rear seal surfaces

on the inside of the freezing cylinders.

D.2

Wrap the brush in a clean cloth and thoroughly dry

the freezing cylinder.

D.3

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

NOTE

Be sure to use the brushes that shipped

with the machine to properly clean the

parts.

C.2

Rinse all parts with clean 90° to 110°F (32°C to 43°C)

water. Then place all parts in a sanitizing solution for at

least 1 minute, then remove and let air dry completely

before assembling in machine.

Remove the drain tray from the

side of the machine. Remove the

drip tray from the front panel.

Clean and replace the trays.

D.4

The exterior of the machine should be kept clean at

all times to preserve the luster of the stainless steel.

A high grade of stainless steel has been used on the

machine to ease cleanup. To remove spilled or dried

mix, wash the exterior with 90° to 110°F (32°C to 43°C)

mild detergent water and wipe dry.

Do not use highly abrasive materials, as they will mar

the fi nish. A mild alkaline cleaner is recommended.

Use a soft cloth or sponge to apply the cleaner. For

best results, wipe with the grain of the steel.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 11

Page 12

Section 2: Operation

E. Assembling Machine

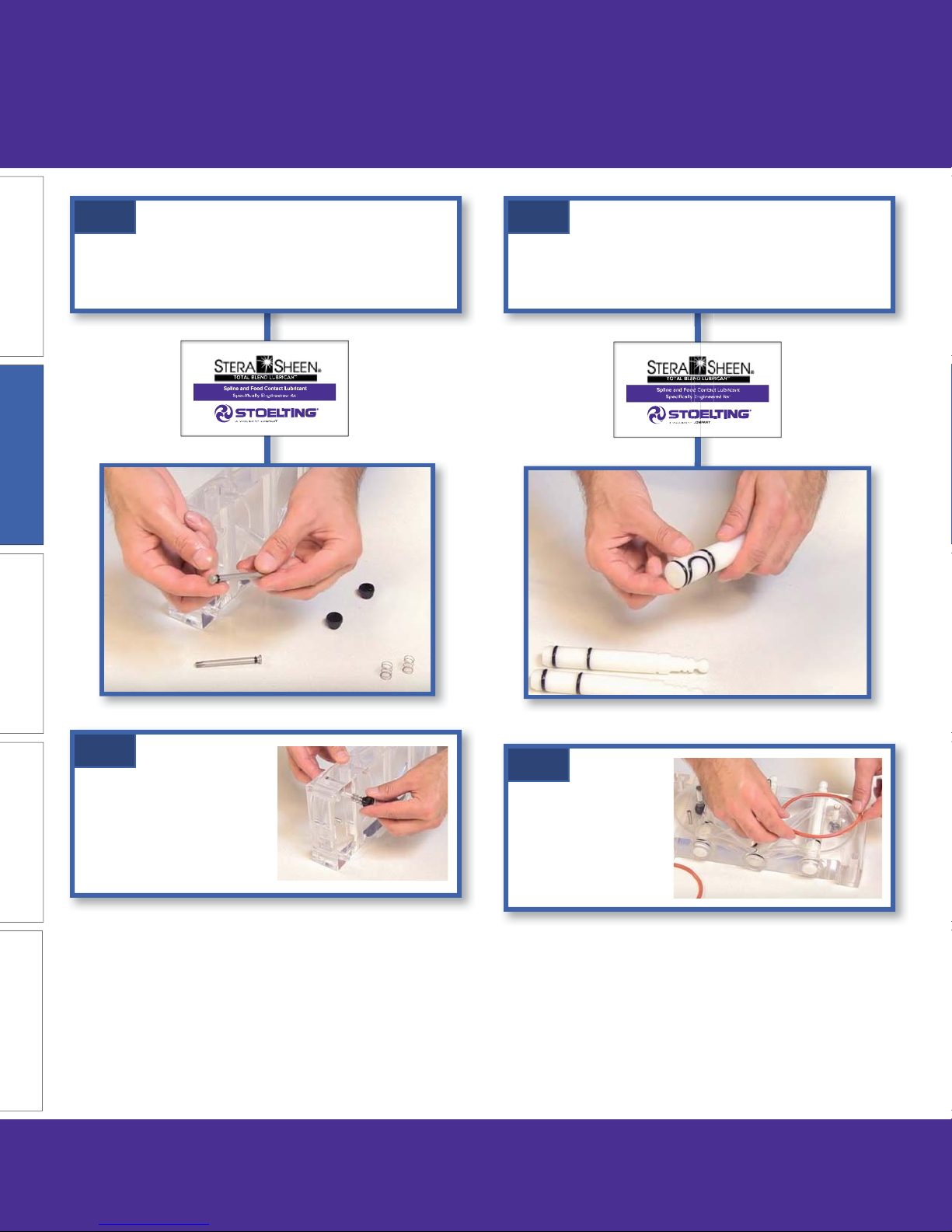

NOTE

Total Blend lubricant or equivalent must be

used when lubrication of machine parts is

specifi ed.

The USDA and FDA require that lubricants

used on food processing equipment must

be certifi ed for this use. Use lubricants

only in accordance with the manufacturer’s

instructions.

NOTE

Stoelting recommends allowing the parts

to air dry before assembling.

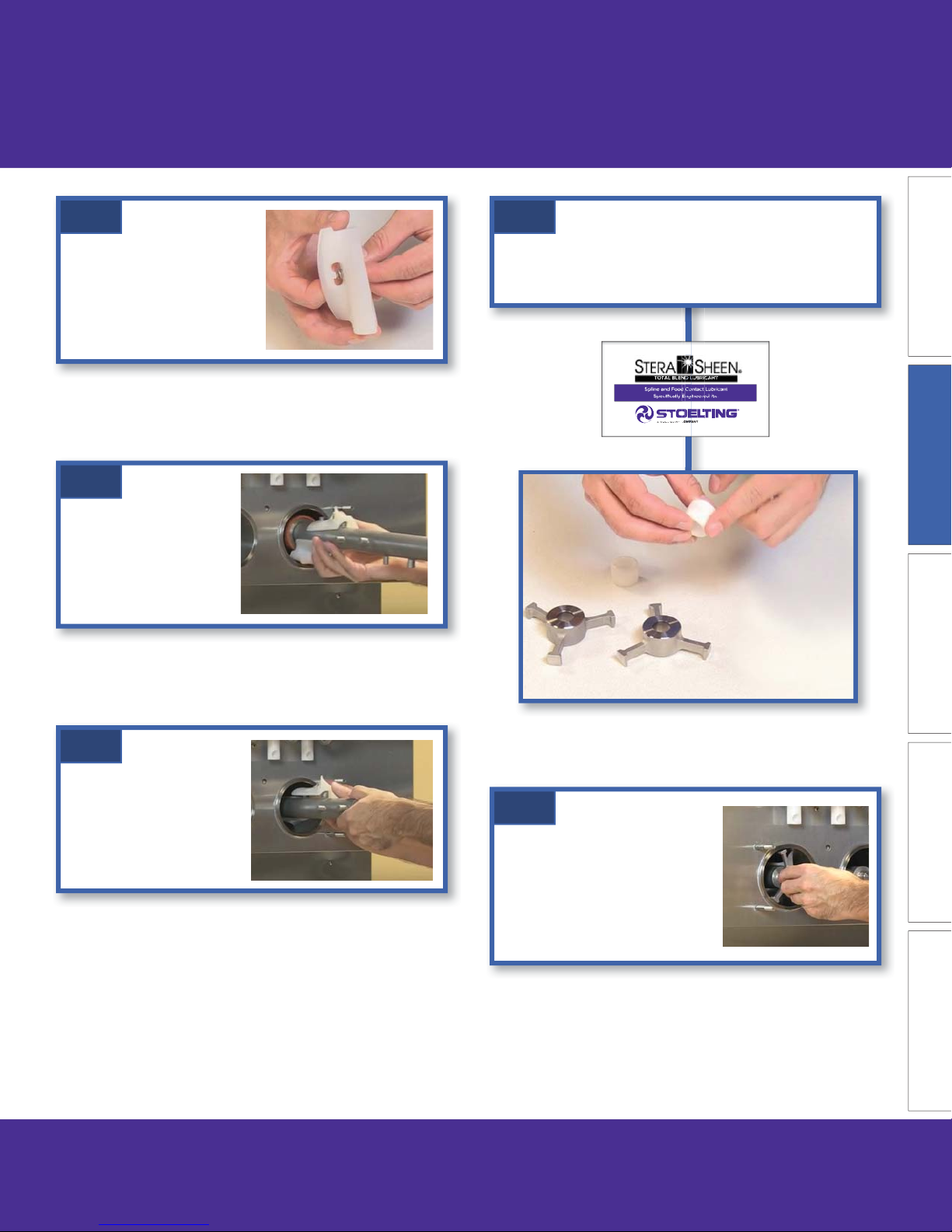

E.1

Install the rear seal o-rings onto the augers. Lubricate

the outside of the o-rings with a generous amount of

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

sanitary lubricant.

E.2

Install the stainless steel adapter into the rear seal

WITHOUT LUBRICANT. Then lubricate the inside of

the adapter and install it onto the auger.

DO NOT lubricate the outside of the rear seal.

12 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

E.3

Lubricate the hex end of the auger with Total Blend

lubricant.

Page 13

Section 2: Operation

E.4

Screw the springs onto

the studs in the plastic

fl ights. The springs must

be screwed into the

fl ights completely to provide

proper compression.

E.5

Install the two plastic

fl ights onto the rear of

the auger and insert

it part way into the

freezing cylinder.

E.7

Apply a thin layer of Total Blend lubricant to the inside

and outside of the auger support bushing.

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

E.6

Install the remaining

plastic fl ights, push the

auger into the freezing

cylinder and rotate slowly

until the auger engages

the drive shaft.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 13

E.8

Install the bushing onto the

auger support and install the

auger support into the front

of the auger. Rotate the auger

support so that one leg of the

support points straight up.

Page 14

Section 2: Operation

E.9

Assemble the air bleed valve o-ring onto the air bleed

valve. Position the o-ring into the groove. Apply a thin

fi lm of Total Blend lubricant to the o-ring.

E.11

Install the o-rings onto the spigot bodies and apply a

thin layer of Total Blend lubricant to the o-rings . Install

the spigot bodies through the bottom of the front door.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

E.10

Insert the air bleed valve into

the back of the front door.

Install the compression

spring onto the air bleed

valve then screw the knob

on fi nger tight.

E.12

Fit the front door

o-rings into the groove

on the rear of the front

door.

14 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 15

Section 2: Operation

E.13

Place the front door

assembly on the

mounting studs and the

push front door against

the machine carefully.

NOTE

Make sure the pins on the front door do

not touch the legs of the auger supports.

E.14

Secure the front door to

the machine by placing

the knobs on the studs

and tightening until

fi nger tight. Tighten in

a crisscross pattern.

Do not overtighten.

Proper o-ring seal can

be observed through the

transparent front door.

F. Sanitizing

Sanitizing must be done after the machine is clean and

just before the machine is fi lled with mix. Sanitizing

the night before does not ensure sanitization the next

day. However, you should always clean the machine

and parts after using it.

NOTE

The United States Department of

Agriculture and the Food and Drug

Administration require that all cleaning

and sanitizing solutions used with food

processing equipment be certifi ed for this

use

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

When sanitizing the machine, refer to local sanitary

regulations for applicable codes and recommended

sanitizing products and procedures. The frequency of

sanitizing must comply with local health regulations.

Mix sanitizer in quantities of no less than 2 gallons

of 90°F to 110°F (32°C to 43°C) water. Allow sanitizer

to contact the surfaces to be sanitized for 5 minutes.

Any sanitizer must be used only in accordance with

the manufacturer’s instructions and to provide a 100

parts per million strength solution.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 15

Page 16

Section 2: Operation

F. 1

Prepare 2 gallons of sanitizing

solution for each freezing

cylinder. Following the sanitizer

manufacturer’s instructions for

preparing the sanitizing solution.

Place the coiled hoses with bag

adapters into the buckets of

sanitizer.

F. 4

After you hear the pump

shut off, press the air

bleed valves to release

the air pressure. Allow

water to fi ll the freezing

cylinders.

F. 2

Press the Main Power

button. Then press the

Pump buttons to turn the

pumps ON.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

F. 3

Check for leaks when the freezing cylinder is fi rst

pressurized with sanitizing solution.

1. Check for leaks at the front door seals.

2. Check the drain tray located in the side panel for

leaks coming from the rear of the rear auger seal.

3. Check the inside of the cab unit for leaks at the

hose connections.

F. 5

Press the CLEAN buttons to

start the augers rotating. The

IntelliTec2™ display shows a

5-minute timer.

F. 6

While the cylinders are being sanitized complete the

following:

1. Remove the buckets containing sanitizer.

2. Install spigot extensions and rosette caps (if

applicable).

16 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 17

Section 2: Operation

F. 7

After the fi ve minute timer expires,

open the spigots to drain the

sanitizing solution into a container.

When the solution has drained,

press the Pump and Clean buttons

to stop the pump and auger. Allow

the freezing cylinder to drain

completely.

F. 8

Install the three drawers. Start

with the bottom drawer.

1. Pull the drawer guides out so

they are fully extended.

2. Insert the rear rollers into the

guides.

3. Push the drawer in and insert

the front rollers into the

guides.

G. Freeze Down

Make sure the display shows the freezing cylinders

are off . If they are not, press the On/Off Left or On/Off

Right button to turn them off .

G.1

Place a bag of mix into one of the bottom drawer

sections.

NOTE

Make sure the bag opening is facing up

and towards the back of the drawer. Align

the bag corners with the corners of the

drawer so the bag is not twisted and drains

evenly.

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

4. Place the plastic bins into the

drawers.

5. Insert the bag adapters

(connected to the coiled

hoses) into the cutouts at the

back of the drawers.

The machine is now sanitized and ready for adding mix.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 17

G.2

Remove the cap on the bag and

place it in the cap tray.

Page 18

Section 2: Operation

G.3

Push as much air out of

the bag as possible and

connect the bag adapter

to the bag. Make sure the

adapter is fully inserted

into the bag.

IMPORTANT TIP

Purge excess air from the bags before fully

inserting the adapters.

Excess air in the bags and hoses will

negatively aff ect product overrun and

machine operation.

G.4

G.6

Place a container under the

spigot and open the spigot

to allow the mix to fl ush out

about 8 ounces (0.23 liters) of

sanitizing solution and liquid

mix.

G.7

Allow cylinders to fi ll until

the pumps shut off . Press the

valves to release pressure

in the cylinders.

The cylinders will be fi lled

to the proper level after the

pumps shut off the second

time.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

Insert the bag adapter

into the cutout at the back

of the drawers.

Make sure the adapter is

fully inserted into the bag.

G.5

Repeat for each of the

drawer sections.

Then press the Pump buttons

to turn the pumps on.

G.8

Press the On/Off buttons

to turn on the freezing

cylinders then press the

Push to Freeze buttons.

When the product is ready,

the display will read “SERVE” or “SERVE 2”. Open the

spigot to dispense product.

G.9

If the control fl ashes and displays “Check Mix”, open

the cabinet and check the mix bags. This message is

generally displayed when air gets into the mix lines.

Operate normally to clear the error.

If “Mix Out” is displayed, check the mix levels in the

bags and replace as necessary.

18 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 19

H. Brushes for Cleaning

Section 2: Operation

208387

208467

208465

208135

208380

Part Number Where Used

208135 Freezing cylinder

208465 Front door, check valve block, pump hose

208380 Front door, pump hose, mix sensor

208467 Front door, manifold, check valve block

208485 Coiled hose

208387 Front door, pump hose, manifold, mix sensor, mix tube

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

208485

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 19

Page 20

Section 2: Operation

I. Lubrication Points

O-Ring

O-Ring & Hex

End of Auger

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

Inside & Outside

of Bushing

ONLY Inside

Metal Adapter

All O-Rings*

* U431 spigot bodies shown, U421 has only one spigot

20 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 21

J. Pump Hose Routing

Black Cover Clamp

Black Cover Clamp

Coiled Hose

Coiled Hose

Bag Adapter

Bag Adapter

Mix Sensor

Mix Sensor

1/2" Clear Tube

1/2" Clear Tube

Section 2: Operation

Bag Adapter Cap

Bag Adapter Cap

Collection Manifold

Collection Manifold

Manifold Cap

Manifold Cap

Tan Pump Hose

Tan Pump Hose

3/8" Clear Tube

3/8" Clear Tube

Check Valve Block

Check Valve Block

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 21

Page 22

Section 3: Maintenance

A. Mix Pump Hose Replacement

NOTE

Replace pump hose every 800 gallons or

every 2 weeks, whichever occurs fi rst.

Replace the hose during the cleaning

process.

A.1

Remove the three drawers from the cab. To remove a

drawer, pull it out. Tilt the drawer up to disengage the

front rollers. Pull it further out then up to disengage

the rear rollers.

A.3

Loosen the clamps on the tan

hose at the mix sensor and check

valve block.

Disconnect the hose at both

ends.

A.4

Turn the pump on and pull the hose out of the black

cover.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

A.2

Turn the pump on and pull down

on the pickup end of the tan

hose until a few inches of tubing

is visible. The pickup end is on

the left side.

Then turn the pump off .

Then turn the pump off .

A.5

Rotate the pump rollers so one of the

rollers is at the 6:00 position.

With a brush, clean the roller

assembly with detergent water, then

with clear water.

22 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 23

Section 3: Maintenance

A.6

Connect a new length of tan hose

to the mix sensor using a clamp.

A.7

Turn the pump on and feed the other

end of the tan hose into the left side

of the black cover.

Face the natural curve of the tan hose

towards the outside of the cover to

prevent the hose from looping around

twice.

A.9

Press and hold the Pump

buttons until the pump hose

reset message appears on

the screen.

A.10

Continue normal cleaning and sanitizing procedures.

MAINTENANCE PART STROUBLESHOOTINGOPERATIONINTRODUCTION

A.8

As the hose feeds through the cover, orient the sensor

at an angle so the sensor wire does not interfere with

the drawer closing and is not obstructed by the other

hoses.

Then turn the pump off .

Connect the hose to the check valve block.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 23

Page 24

Section 3: Maintenance

B. Mix Pump Hose Cleaning

NOTE

Any cleaning procedure must always be

followed by sanitizing before fi lling the

machine with mix.

The mix pump is approved for CIP (clean-in-place). It

is thoroughly cleaned when the cleaning solution is

pumped through the machine. To ensure CIP has been

properly performed, the pump should be completely

disassembled and cleaned every 7 days.

WARNING

1. Disassembly and Coiled Hose

Cleaning

B.1

Remove the three drawers from the cab. To remove a

drawer, pull it out. Tilt the drawer up to disengage the

front rollers. Pull it further out then up to disengage

the rear rollers.

B.2

Disconnect the bag adapters from

the coiled hoses.

Pull the coiled hoses so they are

straight. Then use detergent water

with the long brush to clean the hoses.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

Hazardous Moving Parts

Revolving pump head can grab, mangle, and cause

serious crushing injury. Make sure the display shows

the freezing cylinders and pump are off . If they are

not, press the On/Off button and Pump button to turn

them off .

System Under Pressure

Never disconnect hoses from the machine or the pump

without fi rst opening the spigot to relieve pressure.

CAUTION

NOTE

Rotate the coiled hose as it is stretched to

help straighten it out.

B.3

Lift the collection manifold upwards

then tilt it back to detach it from the

bracket.

The manifold may need to be

rotated so the metal stem clears

the bracket.

24 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 25

Section 3: Maintenance

B.4

Disconnect the wires from the

low mix sensor.

B.5

Turn the pump on and pull down

on the pickup end of the tan

hose until a few inches of tubing

is visible. The pickup end is on

the left side.

Then turn the pump off .

Loosen the clamp on the tan hose

and disconnect the hose at the

low mix sensor.

B.6

B.8

Loosen the clamp on the mix tube at the top of the

cab and remove the hose from the tube.

B.9

Remove the two o-rings from the

base of the check valve block.

B.10

Remove the hose assemblies from the cab.

Loosen all clamps and disconnect all hoses including

the following:

• Bag adapters

• Mix collection manifold

• Low mix sensor

• Check valve block

MAINTENANCE PART STROUBLESHOOTINGOPERATIONINTRODUCTION

Turn the mix pump on and pull the tan house out of

the black cover clamp then turn the mix pump off .

B.7

Unfasten the wire clamp on the

check valve block by swinging

the clamp to the right. Remove

the check valve.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 25

2. Inspect and Cleaning

B.11

Inspect all the parts for wear and replace as necessary.

B.12

Thoroughly clean the parts with 90° to 110°F detergent

water and brushes provided. Rinse with clean, 90° to

110°F water.

Page 26

Section 3: Maintenance

y

B.13

Wash the mix tube and the check

valve base in the cabinet with the

detergent water and brushes.

Rinse with clean, 90° to 110°F

water.

3. Reassembly

3. Reassembl

3. Reassembly

B.14

Connect the coiled hoses to

the bag adapters and to the mix

collection manifold.

Connect the clear hose to the

bottom of the manifold.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

B.17

Turn the pump on and feed the

tan hose into the left side of the

black cover clamp.

NOTE

Face the natural curve of the tan hose

towards the outside of the cover to prevent

the hose from looping around twice.

B.18

As the hose feeds through the cover, orient the sensor

at an angle so the sensor wire does not interfere with

the drawer closing and is not obstructed by the other

hoses.

B.15

Install the manifolds into the

bracket.

B.16

Connect the tan hose to the low mix sensor.

26 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Then turn the pump off .

B.19

Connect the hose from the

bottom of the manifold to the

low mix sensor.

Page 27

Section 3: Maintenance

B.20

Connect the tan hose to the bottom of the check

valve block. The bottom of the block has the smaller

hose connector.

B.21

Install the o-rings onto the base of the check valve

block. Apply a thin layer of sanitary lubricant to the

o-rings.

B.22

Connect the clear hose to the top of the check valve

block and tighten the clamp.

Insert the other end of the clear hose onto the mix

tube at the top of the cabinet. Do not tighten the clamp

until the check valve block is installed.

B.23

Install the check valve into the

block and secure the block with

the wire clamp. Make sure the

rubber check valve is installed in

the bottom seat of the assembly.

MAINTENANCE PART STROUBLESHOOTINGOPERATIONINTRODUCTION

B.24

Adjust the clear hose so that it is not kinked and tighten

the clamp holding the hose to the mix tube.

B.25

Connect the low mix sensor wires

to the sensor

B.26

Sanitize assembled machine as per instructions

outlined in Section 2 F.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 27

Page 28

Section 3: Maintenance

C. Fine Consistency Adjustment

Product consistency can be adjusted on the Fine

Consistency Adjustment Screen.

C.1

From the Current

Status screen, press

the left arrow button to

access the password

screen.

Press the right arrow

then the SEL button.

C.2

C.3

Press the SET button to save the changes.

Press the SEL button to toggle between freezing

cylinders.

C.4

Press the left arrow button when done to return to the

Current Status screen.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION INTRODUCTION

Press the SET

button on the

Fine Consistency

Adjustment screen.

And use the arrows

to change the value.

Increase the value for higher consistency (thicker).

Change the +/- symbol to “-” and adjust the value for

lower consistency (thinner) product.

Make adjustments in increments of 5 for best results.

Allow 3-4 draws or 30 minutes for the changes to

take eff ect.

28 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 29

Section 3: Maintenance

Daily Procedures

D. Daily Procedures - Night E. Daily Procedures - Morning

D.1

Remove the drip tray from

the front panel. Clean the

tray and reinstall it.

D.2

Remove the spigot extensions. Clean and sanitize

them and let them air dry.

D.3

Clean the underside of the clear front door and the

exposed portion of the spigots with mild detergent

water and then with sanitizing solution.

E.1

Clean the underside of the clear front door and the

exposed portion of the spigots with brushes and a

mild detergent water and then with sanitizing solution.

E.2

Install the spigot extensions.

E.3

MAINTENANCE PART STROUBLESHOOTINGOPERATIONINTRODUCTION

Check the mix level of the mix bags in the cab.

Add new mix bags as necessary.

D.4

Wipe the exterior clean with a mild detergent water to

remove spilled or dried mix and wipe dry.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 29

E.4

Press the Push To Freeze

button to start freezing the

product.

When the product is ready,

the display will read “SERVE”

or “SERVE 2”. Open the

spigot to dispense product.

Page 30

Section 4: Troubleshooting

Product is Too

Increase the fine

consistency.

Is the product still

MAINTENANCEPART S TROUBLESHOOTING OPERATION INTRODUCTION

too Soft?

Soft

Yes

Is there an air flow

restriction around

the machine?

Product is Too

Firm

Decrease the fine

consistency.

Is the product still

too firm?

No

Continue normal

operation.

No

Yes

Contact your authorized

Stoelting distributor for

further assistance

No

Yes

Move anything blocking

the louvered panels and

make sure there is

enough air clearance

around the machine.

Continue normal

operation.

30 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Yes

Is the problem

fixed?

No

Contact your authorized

Stoelting distributor for

further assistance

Page 31

Section 4: Troubleshooting

If an error code appears on the machine complete the steps on the following pages before calling your authorized

Stoelting distributor. Oftentimes the issues can be resolved using new/fresh product in a clean and sanitized machine.

Any Error Code

on IntelliTec2™

Go to the flow chart

for the error code

Make sure there is no excess air in

the mix bags.

Error Code (E2)

High Torque

Make sure the bags of mix are

supplying the freezing cylinder, fully

thawed and connected properly.

Error Code (E3) Run Time

Air-Cooled Machines

Turn the power off using the Main Freezer

Power button. Make sure the electrical plug is

secure in the outlet. Turn the power back on.

Error Code (E3) Run Time

Water-Cooled Machines

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

Freeze the product and test.

Error Code (E9) High

Pressure Cutout

Air-Cooled Machines

Is there still an

error code?

No

Continue normal operation.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 31

Yes

Error Code (E9) High

Pressure Cutout

Water-Cooled Machines

Contact your authorized

Stoelting distributor for further

assistance for all other codes.

Page 32

Section 4: Troubleshooting

E2 Common Causes

• Excess air in the freezing cylinder

due to air in the mix bags.

• Improper adjustments to the

IntelliTec2™ control.

No

Error Code (E2)

High Torque

Is there liquid

product in the

freezing cylinder?

Yes

MAINTENANCEPART S TROUBLESHOOTING OPERATION INTRODUCTION

Allow product to thaw, then

disassemble and check

condition of the parts.

Replace as necessary

Continue normal operation.

Contact your authorized Stoelting

distributor for further assistance

Is the problem

fixed?

Yes No

Contact your authorized Stoelting

distributor for further assistance

32 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 33

Error Code (E3)

Run Time

Air-Cooled Machines

Is there an air flow

restriction around

the machine?

Yes

Section 4: Troubleshooting

Move anything blocking

the louvered panels and

make sure there is

enough air clearance

around the machine.

E3 Common Causes

• Blocked airfl ow around machine or

dirty air fi lter.

• Excess air in the freezing cylinder

due to air in the mix bags.

• Pump turned off or not operating

• Improper adjustments to the

IntelliTec2™ control.

Is the problem

fixed?

Yes

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

No

Does the error

occur after the first

freezing cycle?

No

Contact your authorized

Stoelting distributor for

further assistance

Yes

Disassemble machine

and reassemble

following the steps in the

operators manual.

No

Is the problem

fixed?

No

Continue normal operation.

Yes

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 33

Page 34

Section 4: Troubleshooting

Error Code (E3)

Run Time

Water-Cooled Machines

Is the water or

glycol system

turned off?

No

Are the water or

glycol lines kinked

or damaged?

Yes Turn the system on.

No

Repair or replace the

lines.

Is the problem

fixed?

E3 Common Causes

• Lack of water/glycol fl ow.

• Excess air in the freezing cylinder

due to air in the mix bags.

• Pump turned off or not operating

• Improper adjustments to the

IntelliTec2™ control.

Yes

Is the problem

fixed?

YesYes

MAINTENANCEPART S TROUBLESHOOTING OPERATION INTRODUCTION

Does the error

occur after the first

freezing cycle?

Contact your authorized

Stoelting distributor for

further assistance

No

No

Yes

Disassemble machine

and reassemble

following the steps in the

operators manual.

No

Is the problem

fixed?

No

Yes

Continue normal operation.

34 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 35

Error Code (E9)

High Pressure Cutout

Air-Cooled Machines

Is there an air flow

restriction around

the machine?

Yes

Section 4: Troubleshooting

Move anything blocking

the louvered panels and

make sure there is

enough air clearance

around the machine.

E9 Common Causes

• Blocked airfl ow around machine or

dirty air fi lter.

• External heat source

Is the problem

fixed?

Yes

No

Check for an exterior heat source

from equipment. Examples include:

• Ice Machine

• Grill

• Hot Dog Steamer

Is there an

exterior heat

source?

No

Contact your authorized

Stoelting distributor for

further assistance

Yes

Move equipment that

increases the ambient

temperature away from

the machine.

No

Is the problem

fixed?

No

Continue normal operation.

MAINTENANCE PARTSTROUBLESHOOTINGOPERATIONINTRODUCTION

Yes

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 35

Page 36

Section 4: Troubleshooting

Error Code (E9)

High Pressure Cutout

Water-Cooled Machines

E9 Common Causes

• Lack of water/glycol fl ow.

MAINTENANCEPART S TROUBLESHOOTING OPERATION INTRODUCTION

Are the water or

glycol lines kinked

Is the water or

glycol system

turned off?

No

or damaged?

No

Repair or replace the

lines.

Is the problem

fixed?

No

Is the problem

fixed?

No

YesYes Turn the system on.

YesYes

Contact your authorized

Stoelting distributor for

further assistance

36 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Continue normal operation.

Page 37

Section 5: Replacement Parts

A.1

2208137

2208137

2208193

2208193

232025

232025

Cab Tubing

756236

756236

264235

264235

2208043

2208043

234235

234235

2208169

2208169

264241

264241

264235

264235

232024

232024

756088

756088

756079

756079

264241

264241

264235

264235

756204

756204

694247

694247

2206611

2206611

762256

762256

624644

624644

624619

624619

MAINTENANCE PART STROUBLESHOOTINGOPERATIONINTRODUCTION

Part Number Description Quantity

232024 Cap - Manifold 4

232025 Cap - Bag Adapter 4

264235 Clamp - Metal (1/4” ID Tubing) 264241 Clamp - Metal (1/2” ID Tubing) 624616-5 O-Ring - Check Valve Block - Lower - Black (5 Pack) 2

624644-5 O-Ring - Check Valve Block - Upper - Black (5 Pack) 2

694247 Spring - Check Valve 2

756079 Tubing - 3/8” ID - Clear 2

756088 Tubing - 1/2” ID - Clear 2

756204 Tubing - 1/4” ID - Pump (50’ Box Only) (Per Inch) 756204-24 Tubing - 1/4” ID - Pump (Pre-Cut 24” Piece) 2

756236 Tubing - 1/4” I.D. - Coiled - Blue 6

762256 Check Valve 2

2206611 Check Valve Block 2

2208137 Mix Bag Adapter (Stainless Steel) 6

2208169 Manifold - Mix Collection (Manifold Only) 2

2208043 Sensor - Mix 2

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 37

Page 38

Section 5: Replacement Parts

A.2

694200

694200

482004

482004

2204252

2204252

624598

624598

MAINTENANCEPART S TROUBLESHOOTING OPERATION INTRODUCTION

U421-I2A Auger Shaft & Front Door Parts

667868

381804

381804

2183106

2183106

2187696

2187696

Part Number Description Quantity

149003 Bushing - Front Auger Support 2

381804 Auger Flight 12

482004 Knob (Air Bleed Valve) 2

482019 Knob - Front Door (Black) 4

624520 O-Ring - Air Bleed Valve - Black 2

624598 O-Ring - Spigot - Black 4

624678 O-Ring - Rear Seal - Black 2

625133 O-Ring - Front Door - Black 2

667868 Seal - Rear Auger (Orange) 2

694200 Spring - Air Bleed Valve 2

694255 Spring - Auger Flight 12

1151859 Adapter - Rear Seal (Code 1) 2

2183106 Valve - Air Bleed 2

2104552 Support - Front Auger 2

2187696 Front Door 2

2204252 Spigot Body 2

4151178 Auger Shaft 2

624520

624520

482019

482019

2104552

2104552

625133

625133

149003

149003

4151178

4151178

694255

694255

624678

624678

667868

1151859

1151859

38 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 39

Section 5: Replacement Parts

A.3

482004

482004

694200

694200

624664

624664

624614

624614

U431-I2A Auger Shaft & Front Door Parts

381804

381804

2110116

2110116

694255

624520

624520

2187811

2187811

Part Number Description Quantity

149003 Bushing - Front Auger Support 2

381804 Auger Flight 12

482004 Knob (Air Bleed Valve) 2

482019 Knob - Front Door (Black) 4

624520 O-Ring - Air Bleed Valve - Black 2

624598 O-Ring - Outside Spigot - Black 4

624614 O-Ring - Top & Bottom Center Spigot - Black 2

624664 O-Ring - Middle Center Spigot - Black 1

624678 O-Ring - Rear Seal - Black 2

625133 O-Ring - Front Door - Black 2

667868 Seal - Rear Auger (Orange) 2

694200 Spring - Air Bleed Valve 2

694255 Spring - Auger Flight 12

1151859 Adapter - Rear Seal (Code 1) 2

2104552 Support - Front Auger 2

2110116 Valve - Air Bleed 2

2177427 Front Door 1

2187811 Spigot Body - Center 1

2187812 Spigot Body - Outer 2

4151178 Auger Shaft 2

482019

482019

2104552

2104552

2187812

2187812

624598

624598

625133

625133

149003

149003

2177427

2177427

694255

4151178

4151178

624678

624678

1151859

1151859

667868

667868

MAINTENANCE PART STROUBLESHOOTINGOPERATIONINTRODUCTION

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 39

Page 40

40 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 41

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 41

Page 42

42 U421-I2A & U431-I2A OPERATOR’S MANUAL 513713 REV.0

Page 43

DOMESTIC WARRANTY

(Including Mexico)

SOFT SERVE / SHAKE EQUIPMENT

1. Scope:

PW Stoelting, L.L.C. (“Stoelting”) warrants to the first user (the “Buyer”) that the freezing cylinders,

hoppers, compressors, drive motors, speed reducers, and augers of Stoelting soft serve / shake

equipment will be free from defects in materials and workmanship under normal use and proper

maintenance appearing within five (5) years, and that all other components of such equipment

manufactured by Stoelting will be free from defects in material and workmanship under normal use

and proper maintenance appearing within twelve (12) months after the date that such equipment is

originally installed.

2. Disclaimer of Other Warranties:

THIS WARRANTY IS EXCLUSIVE; AND STOELTING HEREBY DISCLAIMS ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE.

3. Remedies:

Stoelting’s sole obligations, and Buyer’s sole remedies, for any breach of this warranty shall be the

repair or (at Stoelting’s option) replacement of the affected component at Stoelting’s plant in Kiel,

Wisconsin, or (again, at Stoelting’s option) refund of the purchase price of the affected equipment,

and, during the first twelve (12) months of the warranty period, deinstallation/reinstallation of the

affected component from/into the equipment. Those obligations/remedies are subject to the

conditions that Buyer (a) signs and returns to Stoelting, upon installation, the Start-Up and Training

Checklist for the affected equipment, (b) gives Stoelting prompt written notice of any claimed breach

of warranty within the applicable warranty period, and (c) delivers the affected equipment to Stoelting

or its designated service location, in its original packaging/crating, also within that period. Buyer shall

bear the cost and risk of shipping to and from Stoelting’s plant or designated service location.

4. Exclusions and Limitations:

This warranty does not extend to parts, sometimes called “wear parts”, which are generally expected

to deteriorate and to require replacement as equipment is used, including as examples but not

intended to be limited to o-rings, auger flights, auger seals, auger support bushings, and drive belts.

All such parts are sold

AS IS.

Further, Stoelting shall not be responsible to provide any remedy under this warranty with respect to

any component that fails by reason of negligence, abnormal use, misuse or abuse, faulty repair made

by others, use with parts or equipment not manufactured or supplied by Stoelting, any modification or

alteration of any parts or equipment, or damage in transit.

The use of this equipment as a rental asset will negate all warranties associated with the equipment.

THE REMEDIES SET FORTH IN THIS WARRANTY SHALL BE THE SOLE LIABILITY

STOELTING AND THE EXCLUSIVE REMEDY OF BUYER WITH RESPECT TO

EQUIPMENT SUPPLIED BY STOELTING; AND IN NO EVENT SHALL STOELTING

BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING

AS EXAMPLES BUT NOT INTENDED TO BE LIMITED TO DOWNTIME, OVERHEAD,

MATERIALS, AND PERFORMANCE PENALTIES, WHETHER FOR BREACH OF

WARRANTY OR OTHER CONTRACT BREACH, NEGLIGENCE OR OTHER TORT,

OR ON ANY STRICT LIABILITY THEORY.

513713 REV.0 U421-I2A & U431-I2A OPERATOR’S MANUAL 43

SFWARR-013

Revision 05

Page 1 of 1

Page 44

Loading...

Loading...