Stoelting U431-109I2 Service Manual

Model U421 & U431

(Ser. #6374 Plus)

Operator’s Manual

513725 Rev.0

Section 1: Introduction

INTRODUCTION

This manual provides basic information about the machine. Instructions and suggestions are given covering its operation

and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make changes to the machine without

notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this manual are read completely

and are thoroughly understood. If problems develop or questions arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

MAINTENANCEPARTS TROUBLESHOOTING OPERATION

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

stoeltingfoodservice.com

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.319.9549

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2017 Stoelting

2 U421-I2 & U431-I2 OPERATOR’S MANUAL 513725 REV.0

This manual is divided into the following fi ve sections:

Section 1: Introduction

INTRODUCTION

INTRODUCTION

OPERATION

MAINTENANCE

A. Parts of the Machine

B. Specifi cations

A. Empty the Freezing Cylinders - Start here if cleaning a machine with mix in it

B. Disassemble Parts - Start here if cleaning an empty machine

C. Cleaning Disassembled Parts

D. Cleaning the Machine

E. Assembling the Machine

F. Sanitizing

G. Freeze Down

H. Brushes for Cleaning

I. Lubrication Points

J. Pump Hose Routing

A. Mix Pump Hose Replacement

B. Mix Pump Hose Cleaning

C. Fine Consistency Adjustment

D. Daily Procedures - Night

E. Daily Procedures Morning

MAINTENANCE PARTSTROUBLESHOOTINGOPERATION

TROUBLESHOOTING

PART S

513725 REV.0 U421-I2 & U431-I2 OPERATOR’S MANUAL 3

A. Troubleshooting Flow Charts

A. Auger Shaft & Front Door Parts

B. Cab Tubing

Section 1: Introduction

A. Parts of the U421-I2 Machine

INTRODUCTION

MAINTENANCEPARTS TROUBLESHOOTING OPERATION

IntelliTec2™

Spigot Handle

Front Door

Gate Handles

Freezing Cylinder

Cabinet

IntelliTec2™ Touchpad

The U421 has two types of spigot handles, gate and pull-down. The gate style is opened by moving the handle to the

left. The pull-down style is opened by pulling downwards.

This manual shows the pull-down handles which are self-closing. The gate style handles need to be closed when fi nished

dispensing.

4 U421-I2 & U431-I2 OPERATOR’S MANUAL 513725 REV.0

Section 1: Introduction

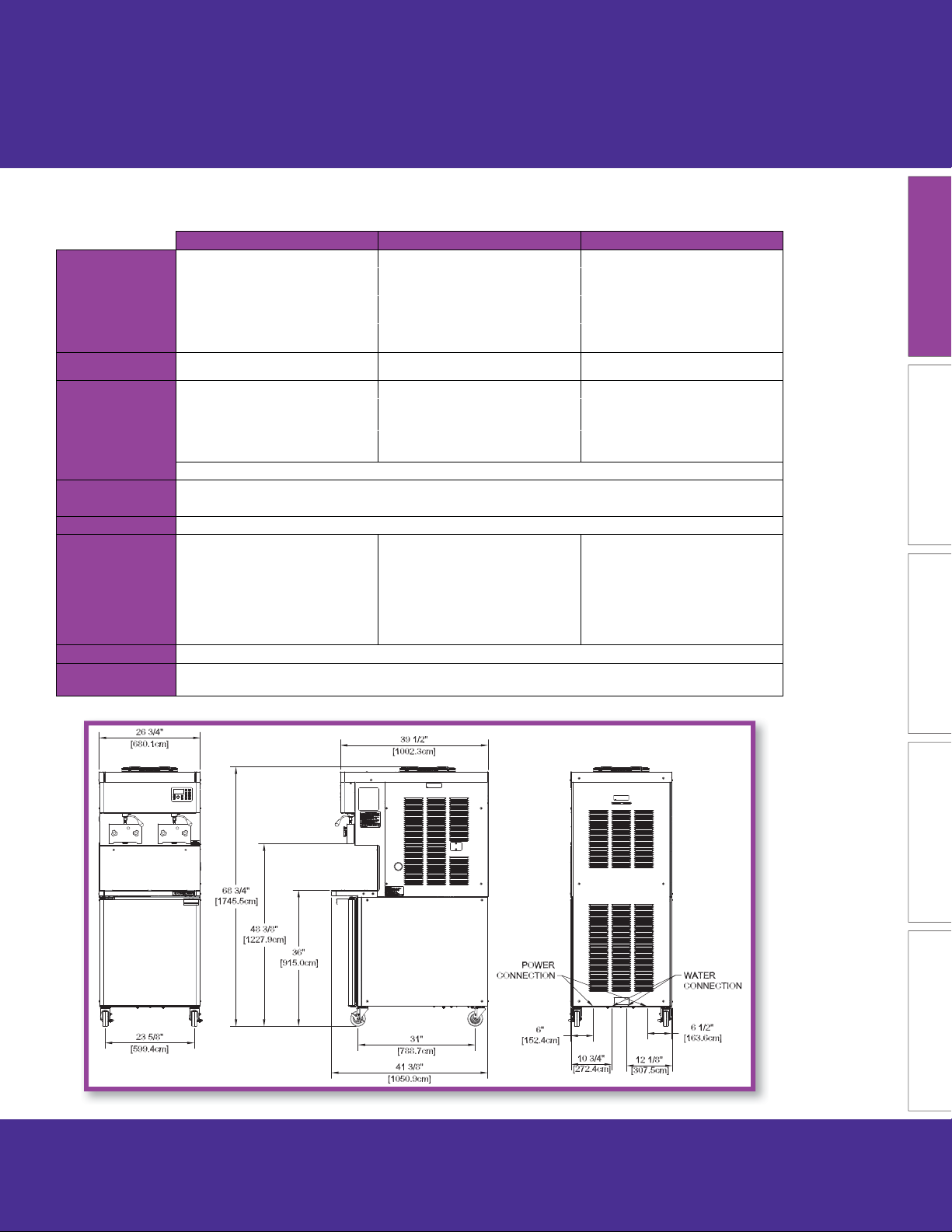

B. U421-I2 Specifi cations

U421-I2 A/C U421-I2 A/C Remote U421-I2 W/C

Dimensions

width

height

depth

Weight

Electrical

circuit ampacity

(per barrel)

overcurrent protection

device (per barrel)

Compressor

Drive Motor Two - 2 hp

Cooling

Cabinet Volume Two - 8 gallon (30,28 liters)

Freezing Cylinder

Volume

Machine with crate Machine with crate Machine with crate

26-3/4’’

(67,9 cm)

68-3/4’’

(174,6 cm)

39-1/2’’

(100,3 cm)

785 lbs

(356,0 kg)

1 PH 3 PH 1 PH 3 PH 1 PH 3 PH

32A 20A

50A 30A

34’’

(86,4 cm)

78’’

(198,1 cm)

48’’

(121,9 cm)

930 lbs

(421,8 kg)

26-3/4’’

(67,9 cm)

67-3/4’’

(172,1 cm)

39-3/4’’

(101,0 cm)

760 lbs

(344,7 kg)

36A Left /

31A Right

50A Left /

45A Right

(86,4 cm)

(198,1 cm)

(121,9 cm)

930 lbs

(421,8 kg)

The machine requires one dedicated electrical circuit per barrel.

Two - 19,000 Btu/hr

Cabinet - 1,300 Btu/hr Compressor (R-134a)

Air cooled units require 6” (15,2 cm) air

space on all sides and open at the top.

Remote air cooled requires two remote

condensers and two precharged line

sets.

Two - 1.33 gallon (5,03 liters)

34’’

78’’

48’’

26-3/4’’

(67,9 cm)

67-1/2’’

(171,5 cm)

39-1/2’’

(100,3 cm)

760 lbs

(344,7 kg)

34’’

(86,4 cm)

78’’

(198,1 cm)

48’’

(121,9 cm)

930 lbs

(421,8 kg)

20A 32A 20A

30A 50A 30A

Water cooled units require 1/2” N.P.T.

water and drain fi ttings. Maximum water

pressure of 130 psi. Minimum water fl ow

rate of 3 GPM per barrel. Ideal EWT of

50°-70°F. The machine requires 6” (15,2

cm) air space on all sides for the cabinet

refrigeration system.

INTRODUCTION

MAINTENANCE PARTSTROUBLESHOOTINGOPERATION

513725 REV.0 U421-I2 & U431-I2 OPERATOR’S MANUAL 5

Section 1: Introduction

C. Parts of the U431-I2 Machine

INTRODUCTION

MAINTENANCEPARTS TROUBLESHOOTING OPERATION

Spigot Handle

IntelliTec2™

Front Door

Gate Handles

Freezing Cylinder

Cabinet

IntelliTec2™ Touchpad

The U431 has two types of spigot handles, gate and pull-down. The gate style is opened by moving the handle to the

left. The pull-down style is opened by pulling downwards.

This manual shows the pull-down handles which are self-closing. The gate style handles need to be closed when fi nished

dispensing.

6 U421-I2 & U431-I2 OPERATOR’S MANUAL 513725 REV.0

Section 1: Introduction

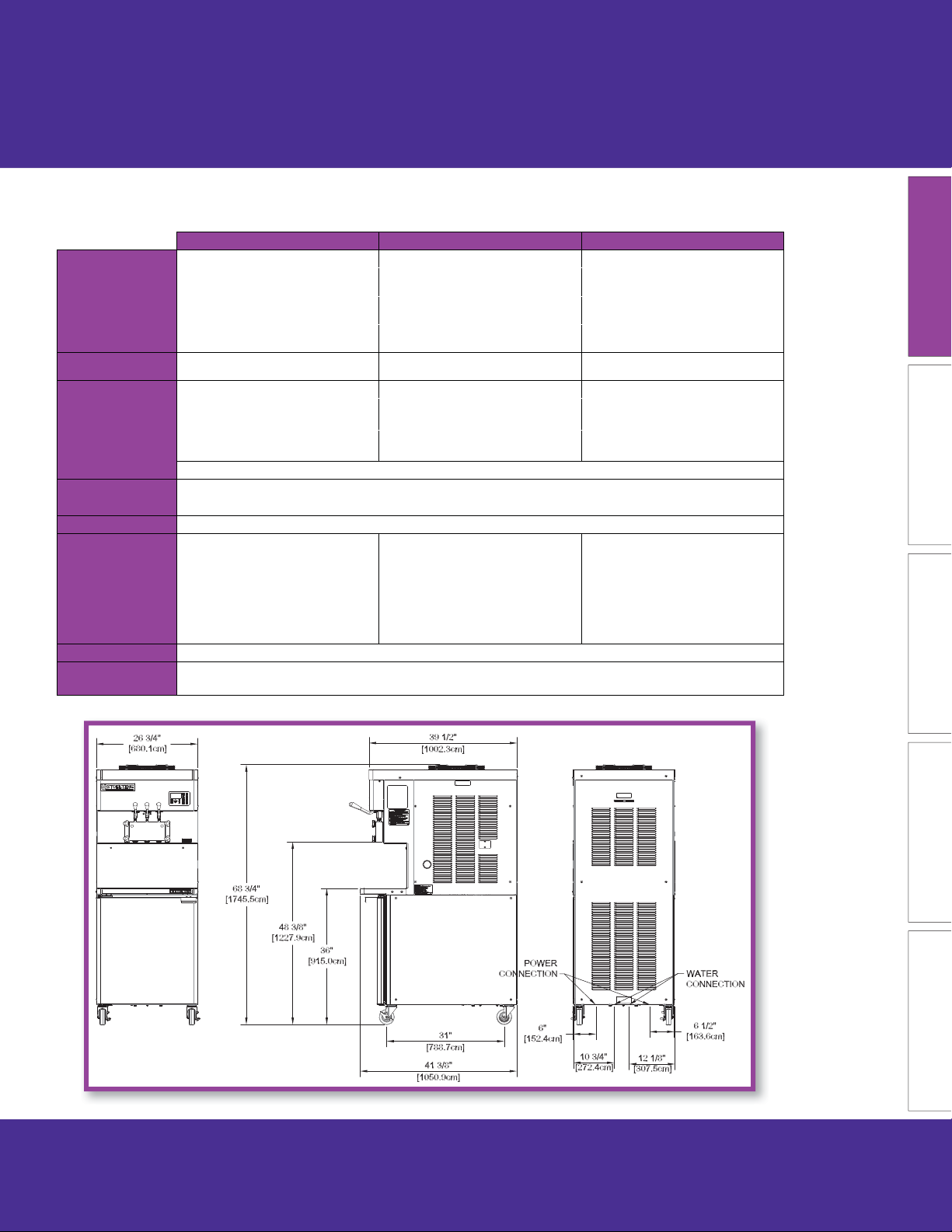

D. U431-I2 Specifi cations

U431-I2 A/C U431-I2 A/C Remote U431-I2 W/C

Dimensions

width

height

depth

Weight

Electrical

circuit ampacity

(per barrel)

overcurrent protection

device (per barrel)

Compressor

Drive Motor Two - 2 hp

Cooling

Cabinet Volume Two - 8 gallon (30,28 liters)

Freezing Cylinder

Volume

Machine with crate Machine with crate Machine with crate

26-3/4''

(67,9 cm)

68-3/4''

(174,6 cm)

39-1/2''

(100,3 cm)

785 lbs

(356,0 kg)

1 PH 3 PH 1 PH 3 PH 1 PH 3 PH

32A 20A

50A 30A

34''

(86,4 cm)

78''

(198,1 cm)

48''

(121,9 cm)

935 lbs

(424,1 kg)

26-3/4''

(67,9 cm)

67-3/4''

(172,1 cm)

39-3/4''

(101,0 cm)

760 lbs

(344,7 kg)

36A Left /

31A Right

50A Left /

45A Right

The machine requires one dedicated electrical circuit per barrel.

Two - 19,000 Btu/hr

Cabinet - 1,300 Btu/hr Compressor (R-134a)

Air cooled units require 6" (15,2 cm) air

space on all sides and open at the top.

Remote air cooled requires two remote

condensers and two precharged line

sets.

Two - 1.33 gallon (5,03 liters)

34''

(86,4 cm)

78''

(198,1 cm)

48''

(121,9 cm)

930 lbs

(421,8 kg)

26-3/4''

(67,9 cm)

67-1/2''

(171,5 cm)

39-1/2''

(100,3 cm)

760 lbs

(344,7 kg)

20A 32A 20A

30A 50A 30A

Water cooled units require 1/2" N.P.T.

water and drain fi ttings. Maximum water

pressure of 130 psi. Minimum water fl ow

rate of 3 GPM per barrel. Ideal EWT of

50°-70°F. The machine requires 6" (15,2

cm) air space on all sides for the cabinet

refrigeration system.

34''

(86,4 cm)

78''

(198,1 cm)

48''

(121,9 cm)

930 lbs

(421,8 kg)

INTRODUCTION

MAINTENANCE PARTSTROUBLESHOOTINGOPERATION

513725 REV.0 U421-I2 & U431-I2 OPERATOR’S MANUAL 7

Section 2: Operation

A. Empty the Freezing Cylinders

A.1

Turn off freezing cylinders.

A.2

OPERATION INTRODUCTION

MAINTENANCEPARTS TROUBLESHOOTING

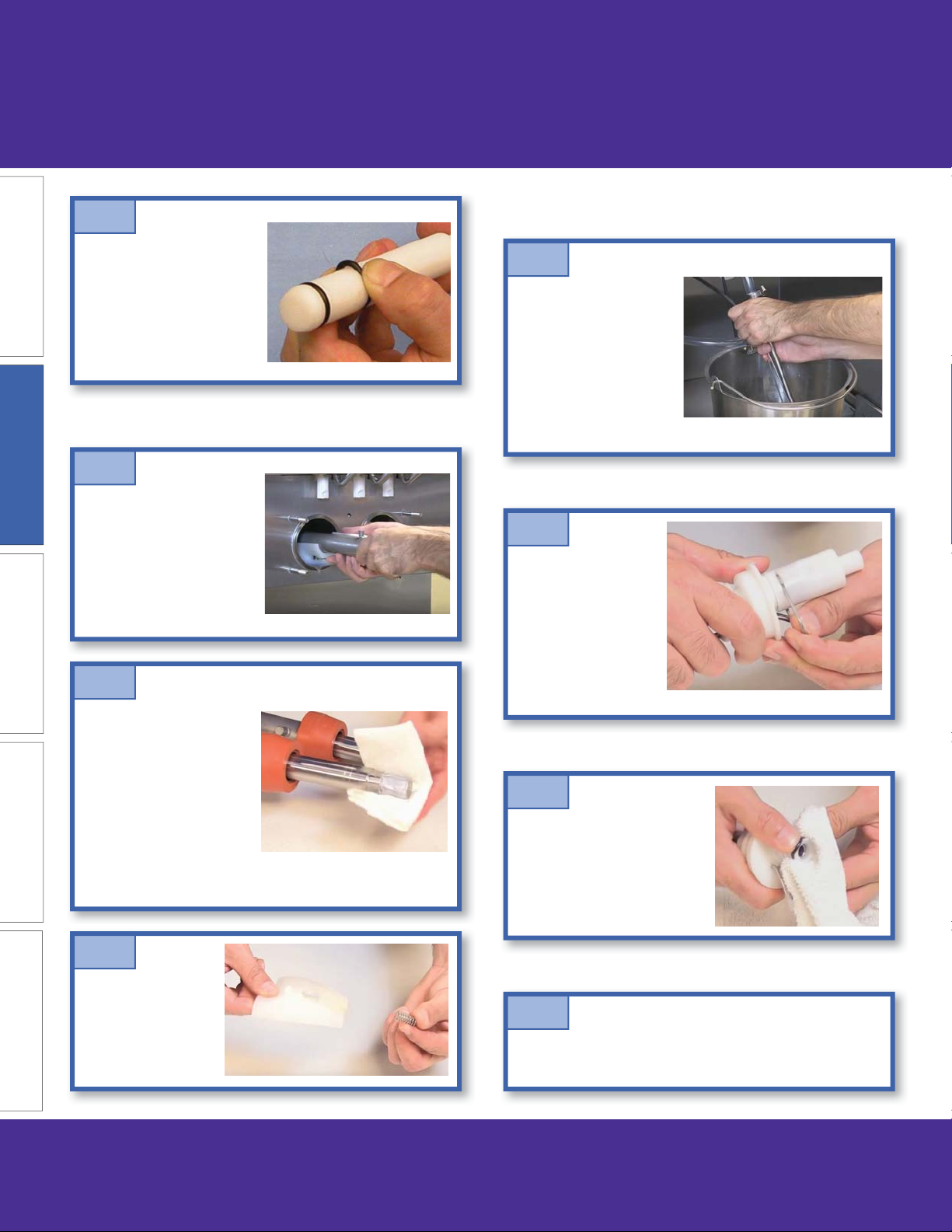

In the cab, remove the mix

pickup assemblies and place

them in a bucket fi lled with cool

tap water.

Remove the mix containers

and covers.

Optional: Fill the bucket with Stera Sheen

solution to make cleaning parts easier

after disassembly.

Clean mix containers on a regular basis.

Refer to State and local health codes for

frequency.

NOTE

NOTE

A.4

Open spigots to drain product

into a container until the

container is full. Empty the

container and repeat until

product has been drained from

the freezing cylinders.

A.5

Refi ll the bucket in the cab with cool tap water (or

Stera Sheen). Allow the freezing cylinders to fi ll then

drain the water into a container. Repeat until the water

draining from the freezing cylinders is clear.

NOTE

If the “Clean Time Exceeded” warning

is displayed on the IntelliTec2™, turn

the freezing cylinder on and off again

and press the Clean button to clear the

warning.

A.7

A.3

Press the Clean buttons.

8 U421-I2 & U431-I2 OPERATOR’S MANUAL 513725 REV.0

Remove any remaining

water from the bucket in the

cabinet.

Drain the water and press

the Clean buttons to stop

the augers.

A.8

Remove the buckets in the cab

and turn on the pumps to clear

any remaining liquid in the hoses.

Open the spigots to drain the

freezing cylinders.

A.9

Press and hold the Main

Freezer Power button for

three seconds to turn off

the power.

Section 2: Operation

Auger Flight Wear

1. Front Door Disassembly

B.1

Remove the spigot

extensions or rosette

caps if installed.

OPERATIONINTRODUCTION

MAINTENANCE PARTSTROUBLESHOOTING

B. Disassemble Parts

Before using the machine for the fi rst time, complete

machine disassembly, cleaning and sanitizing

procedures need to be followed. Routine cleaning

intervals and procedures must comply with the local

and state health regulations. Inspection for worn or

broken parts should be made at every disassembly

of the machine. All worn or broken parts should be

replaced to ensure safety to both the operator and the

customer and to maintain good machine performance

and a quality product. Check the wear line on the auger

fl ights on a regular basis and replace as needed.

Unscrew the knobs

on the front door and

remove the door.

B.2

Remove the front

door o-rings and

remove the spigots

from the front door.

B.3

Remove the air bleed

valve from the front

door.

513725 REV.0 U421-I2 & U431-I2 OPERATOR’S MANUAL 9

Section 2: Operation

B.4

Remove all o-rings from

parts by fi rst wiping off the

lubrication using a clean

towel. Then squeeze the

o-ring upward to form a

loop. Roll the o-ring out of

the groove.

2. Removing Auger

B.5

OPERATION INTRODUCTION

Remove front auger

supports and bushings

and remove the augers

from the freezing cylinders.

As the augers are being

pulled out, remove the

plastic fl ights with springs.

3. Disassemble Pump Hose

B.8

Disconnect the sensor

connectors from the

pickup assemblies

and unscrew the hose

clamps nearest the

assemblies.

Remove the mix pickup

assemblies.

B.9

Remove the lock

clips from the check

valves and remove

the check valves and

springs.

MAINTENANCEPARTS TROUBLESHOOTING

B.6

Wipe any remaining

lubricant off the hex end

of the auger and remove

the rear seal assembly

and o-ring. Wipe any

remaining lubricant off

the o-ring and auger.

Remove the rear seal

adapter from the rear seal.

B.7

Unscrew springs

from the auger

fl ights.

Detach the check

valve from the spring.

B.10

Remove the o-rings from the

assemblies.

B.11

If the pump hoses require cleaning and inspection,

follow the steps in Section 3.

10 U421-I2 & U431-I2 OPERATOR’S MANUAL 513725 REV.0

Section 2: Operation

C. Cleaning Disassembled Parts

Disassembled parts require complete cleaning,

sanitizing and air drying before assembling. Local

and state health codes will dictate the procedure

required. Some state health codes require a four sink

process (pre-wash, wash, rinse, sanitize, air dry), while

others require a three sink process (without the prewash step). The following procedures are a general

guideline only. Consult your local and state health

codes for the procedures required in your location.

C.1

Place all parts in 90° to 110°F

(32°C to 43°C) mild detergent

water and wash thoroughly. Use

the brushes that shipped with

the machine to clean all holes in

the front door, fl ights, mix pickup

assembly, etc.

D. Cleaning the Machine

D.1

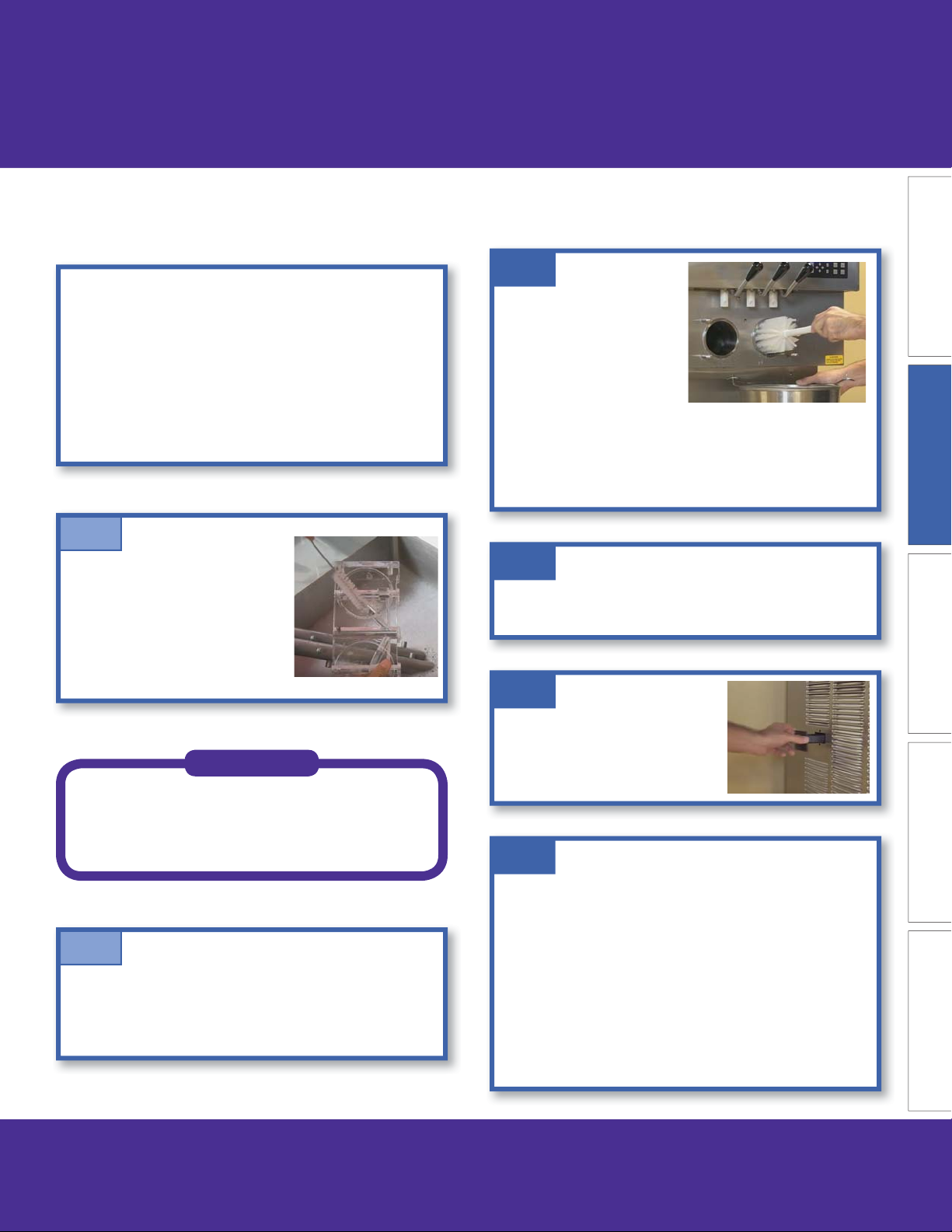

Using a detergent solution

and the large barrel

brush provided, clean

the freezing cylinders by

dipping the brush in the

solution and brushing

the inside of the freezing

cylinders.

Make sure to thoroughly clean the rear seal surfaces

on the inside of the freezing cylinders.

D.2

Wrap the brush in a clean cloth and thoroughly dry

the freezing cylinder.

D.3

OPERATIONINTRODUCTION

MAINTENANCE PARTSTROUBLESHOOTING

NOTE

Be sure to use the brushes that shipped

with the machine to properly clean the

parts.

C.2

Rinse all parts with clean 90° to 110°F (32°C to 43°C)

water. Then place all parts in a sanitizing solution for at

least 1 minute, then remove and let air dry completely

before assembling in machine.

Remove the drain tray from the

side of the machine. Remove the

drip tray from the front panel.

Clean and replace the trays.

D.4

The exterior of the machine should be kept clean at

all times to preserve the luster of the stainless steel.

A high grade of stainless steel has been used on the

machine to ease cleanup. To remove spilled or dried

mix, wash the exterior with 90° to 110°F (32°C to 43°C)

mild detergent water and wipe dry.

Do not use highly abrasive materials, as they will mar

the fi nish. A mild alkaline cleaner is recommended.

Use a soft cloth or sponge to apply the cleaner. For

best results, wipe with the grain of the steel.

513725 REV.0 U421-I2 & U431-I2 OPERATOR’S MANUAL 11

Section 2: Operation

E. Assembling Machine

NOTE

Total Blend or equivalent must be used

when lubrication of machine parts is

specifi ed.

The USDA and FDA require that lubricants

used on food processing equipment must

be certifi ed for this use. Use lubricants

only in accordance with the manufacturer’s

instructions.

OPERATION INTRODUCTION

NOTE

Stoelting recommends allowing the parts

to air dry before assembling.

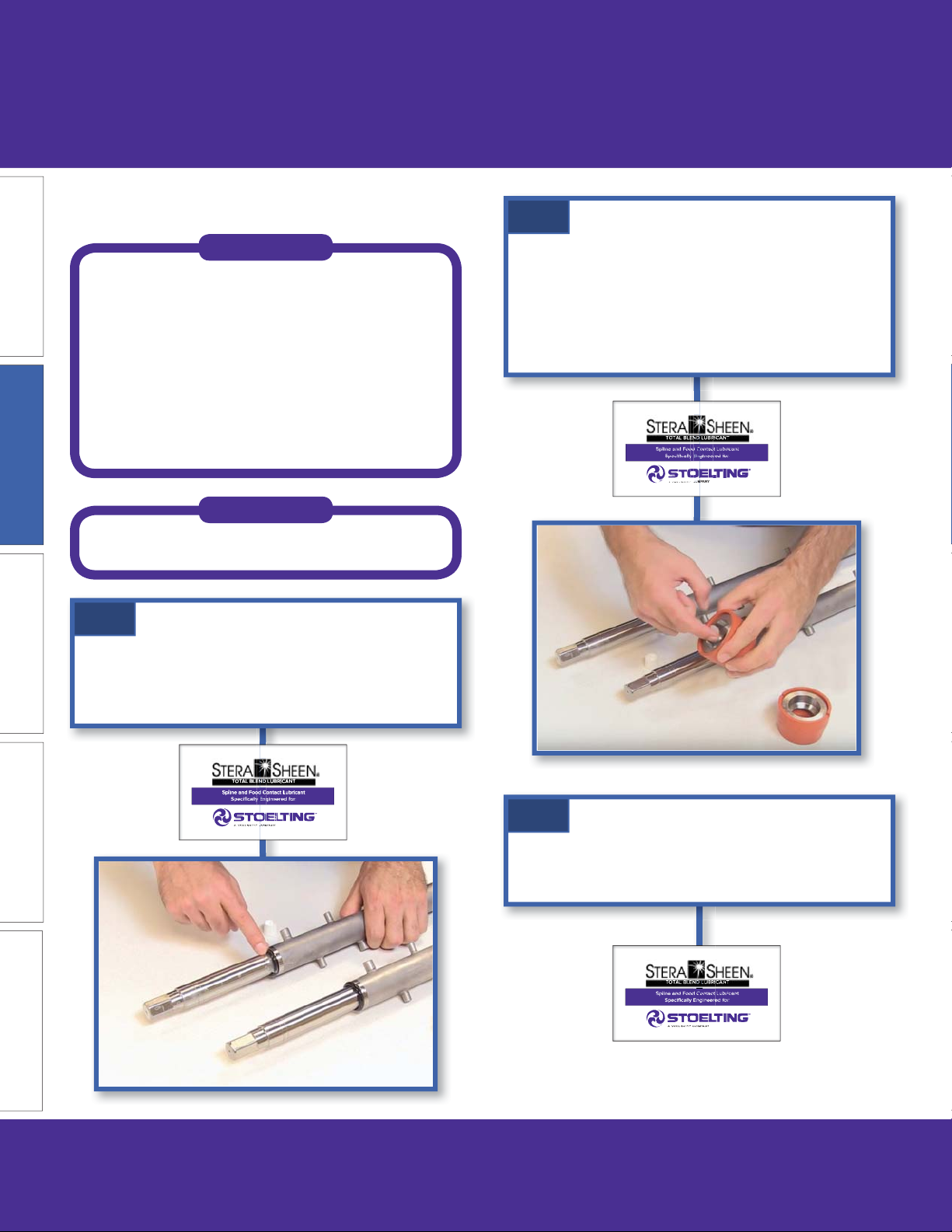

E.1

Install the rear seal o-rings onto the augers. Lubricate

the outside of the o-rings with a generous amount of

MAINTENANCEPARTS TROUBLESHOOTING

sanitary lubricant.

E.2

Install the stainless steel adapter into the rear seal

WITHOUT LUBRICANT. Then lubricate the inside of

the adapter and install it onto the auger.

DO NOT lubricate the outside of the rear seal.

E.3

Lubricate the hex end of the auger with Total Blend.

12 U421-I2 & U431-I2 OPERATOR’S MANUAL 513725 REV.0

Loading...

Loading...