Page 1

Model U3-02

OPERATORS MANUAL

Manual No. 513557

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF CONTENTS

SECTION 1 — INTRODUCTION ............................................................................................................................ 1

1.1 Description ..................................................................................................................................................... 1

1.2 Specifications ................................................................................................................................................. 1

SECTION 2 — INST ALLATION INSTRUCTIONS................................................................................................... 3

2.1 Shipment and Transit ..................................................................................................................................... 3

2.2 National Sanitation Foundation Compliance Requirements............................................................................ 3

2.3 Installation ...................................................................................................................................................... 3

2.4 Mix Pump Check Out ..................................................................................................................................... 5

SECTION 3 — OPERA TION INSTRUCTIONS ....................................................................................................... 7

3.1 Safety Precautions ......................................................................................................................................... 7

3.2 Pump Motor Switch ........................................................................................................................................ 7

3.3 Operation Of U3 Mix Pump............................................................................................................................ 7

3.4 Cleaning......................................................................................................................................................... 8

3.5 Disassembly and Inspection of Removable Parts.......................................................................................... 8

3.6 Sanitizing and Startup.................................................................................................................................... 9

3.7 Cleaning Mix Lines ......................................................................................................................................... 9

SECTION 4 — MAINTENANCE INSTRUCTIONS ............................................................................................... 11

4.1 Overrun Adjustment .......................................................................................................................................11

4.2 Preventative Maintenance ..............................................................................................................................11

SECTION 5 — TROUBLESHOOTING ................................................................................................................ 13

SECTION 6 — REPLACEMENT P ARTS INFORMATION .................................................................................... 15

6.1 How to Order Replacement Parts................................................................................................................. 15

6.2 Parts List and Reference Drawings ............................................................................................................. 15

Page 6

LIST OF ILLUSTRATIONS

Figure Description Page

1 U3 Pump ................................................................................................................. 1

2 Mix Transfer Line .................................................................................................... 3

A Mix Pump Hose ...................................................................................................... 4

B Pickup Hose ........................................................................................................... 4

C Pickup Hose ........................................................................................................... 4

3 Mix Pump Installation.............................................................................................. 5

D 4-way Tee Connection ............................................................................................. 5

4 Pump Motor Switch................................................................................................. 7

5 Mix Pump Operation ............................................................................................... 8

6 Removing Parts ...................................................................................................... 8

7 Overrun Adjustment................................................................................................ 11

8 Reposition Mix Pump Hose..................................................................................... 12

9 Pump Roller Assembly............................................................................................ 12

10 Pump and Decal Assembly ..................................................................................... 15

Exploded Parts Illustrations..................................................................................... 17-21

Wiring Diagram........................................................................................................ 23

Page 7

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

The Model U3 Remote Mix Pump is specially designed for

use with Stoelting remote pressurized freezers. Used with

large capacity mix containers located in your bulk storage

cooler, the U3 Pump keeps mix handling to a minimum.

Stoelting’s Model U3 Remote Mix Pump performs three

important functions with precision and reliability. First, it

transfers a continuous supply of mix from your remote

storage container to the freezing cylinder of your freezer quickly, conveniently. Second, the U3 Pump precisely

injects a preset amount of air into the mix, maintaining

overrun to assure maximum profitability. Third, it pressurizes the freezing cylinder, forcing frozen product through

the spigot at the rapid dispense rates needed by high

volume locations.

1.2 SPECIFICATIONS

WEIGHT

24 lbs. (10.89 kg)

DIMENSIONS

Width: 9-3/4" (24.8 cm)

Height: 8-1/2" (21.6 cm)

Depth: 10-1/8" (25.7 cm)

ELECTRICAL

1 phase, 120 volts. Approximately 1.6 total running amps.

Cord and plug attached.

WARRANTY

One year parts.

UL, C-UL Approved, NSF Approved

Figure 1

U3 Pump

1

Page 8

2

Page 9

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SHIPMENT AND TRANSIT

The mix pump has been completely assembled, operated

and inspected at the factory. Upon arrival at the final

destination, the mix pump must be checked for any

damage that may have occurred during transit.

The mix pump should arrive in satisfactory condition. THE

CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN

TRANSIT, WHETHER VISIBLE OR CONCEALED. Do not

pay the freight bill until you have checked the equipment.

Have the carrier note any visible damage on the freight bill.

If concealed damage and/or shortage is found later, advise

the carrier inspector within 10 days and request inspection. The customer must place claim for damages and/or

shortages in shipment with the carrier. Stoelting, Inc.

cannot make any claims against the carrier.

2.2 NATIONAL SANITATION FOUNDATION

COMPLIANCE REQUIREMENTS

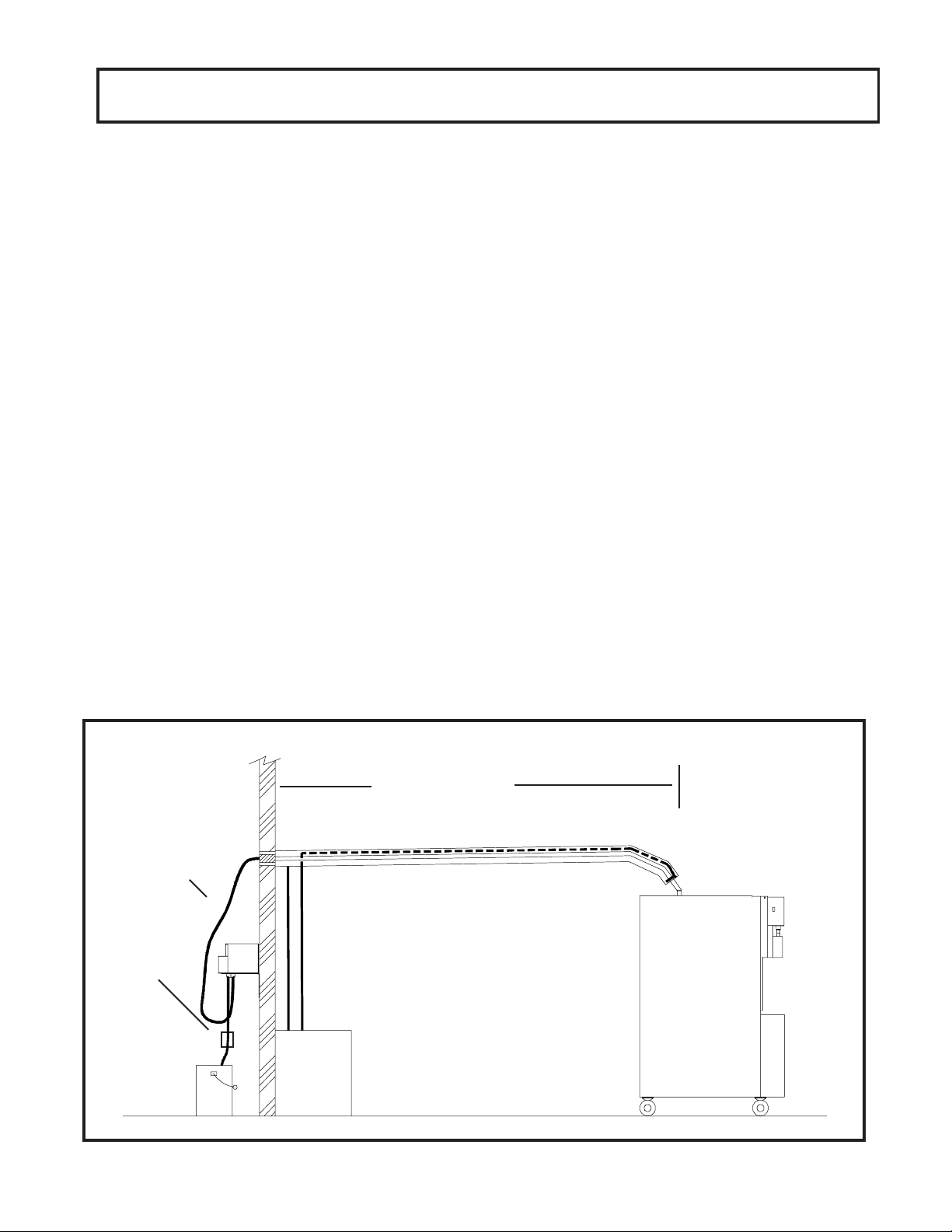

In order to comply with "NSF International" (NSF) code #6:

A. This unit (remote pump) must be installed with a

“NSF” listed refrigerated mix transfer line. The mix

transfer line must be pitched to cooler, with no sags

or low points, to allow complete drainage (Fig. 2).

B. The product at the mix pump and in transfer lines

must be maintained below 41°F (5°C.)

2.3 INSTALLATION

A. Follow the steps below to install the mix pump in an

upright position on the wall using optional pump

mounting kit. Allow clearance for a mix container

under pump. See Figure 2.

1.Mount by locating four (4) hole centers on cooler

wall using mounting bracket as template.

CAUTION

KNOW THE COOLER'S WALL DESIGN BEFORE

DRILLING TO PREVENT PERSONAL INJURY OR

PROPERTY DAMAGE.

2.Drill four (4) 1/2 inch diameter holes into cooler

wall 3/4 inch deep. See Figure 3.

3.Insert well-nut to flange and apply silicone sealant

around outside diameter of flange and cooler wall.

4.Repeat steps 2 & 3 for other located hole centers.

5.Mount bracket to cooler wall with supplied wing

screws. Hand tighten until secure.

6.Thread plastic standoffs (small parts bag) onto all

three pump mounting studs located under the

pump until bottomed.

7.Mount pump to bracket with wing nuts. Pump will

be held above the bracket by the standoffs.

COOLER WALL

10 FT. LIFT

MAXIMUM

PUMP

CHECK

VALVE

MIX

CONT AINER

20 FT. MAXIMUM

FREEZER

REFRIGERATION

UNIT FOR MIX LINE

Figure 2

Mix Transfer Line

3

Page 10

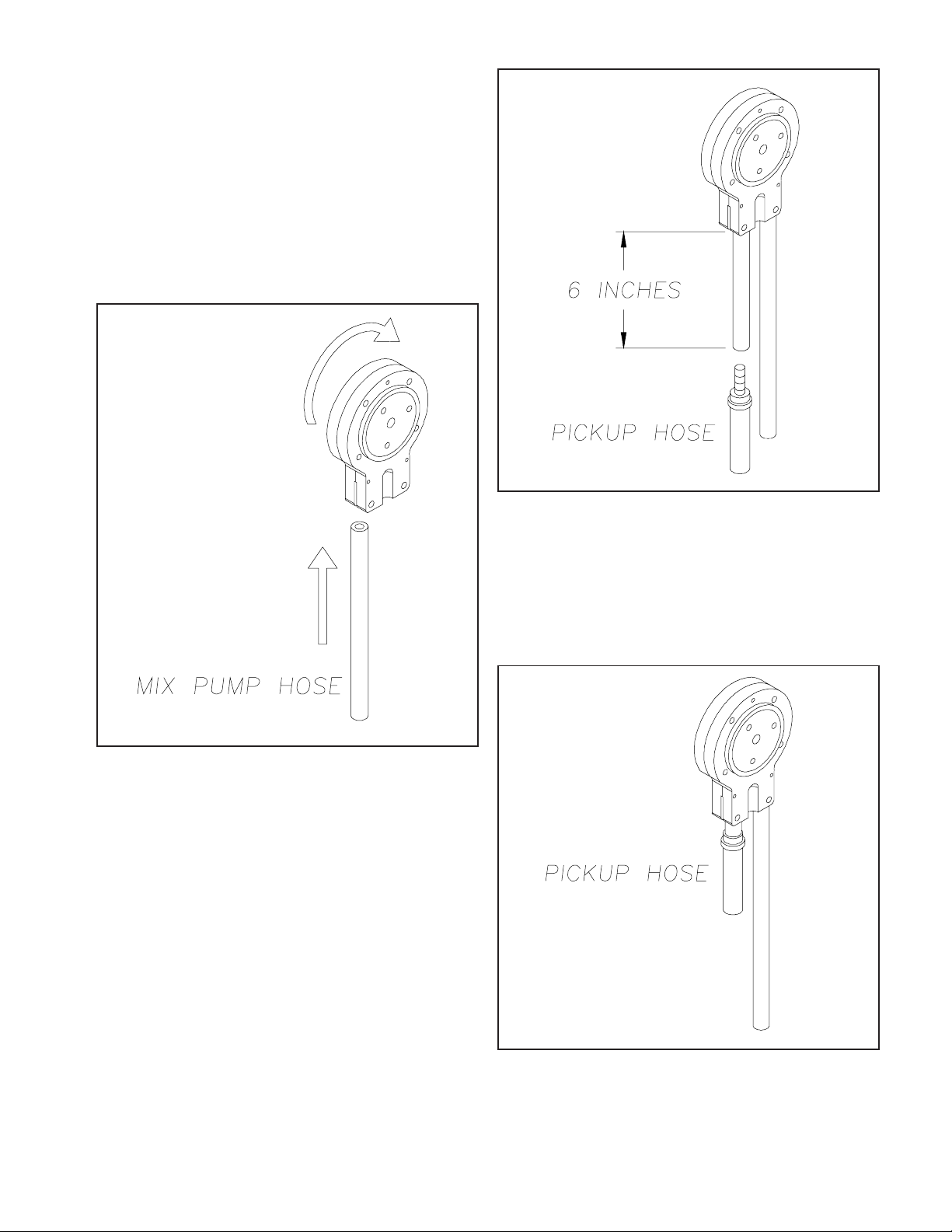

B. Mix Pump Hose Installation.

Follow the steps below to install the mix pump hose.

1. Turn pump on.

2. Feed one end of mix pump hose into the entering or

pick-up hose side (left) of black cover.

3. Gently push the hose into the black cover until it begins

to feed. See Figure A.

Figure B

7. Turn pump on.

Figure A

4. Allow the hose to feed itself thru the pump until 6"

remains on the entering side.

5. Turn pump off.

6. Connect mix pump hose to pickup hose adapter using

small hose clamp. See Figure B.

CAUTION: DO NOT TWIST MIX PUMP HOSE.

8. Gently pull on the discharge hose to help remaining 6"

of mix pump hose to feed thru pump until hose adapter

prevents further feeding.

9. Turn pump off. See Figure C.

Figure C

4

Page 11

OPTIONAL

MOUNTING

KIT

C.Connect 1/2 inch (1.27 cm) I.D. plastic food grade

tubing to the check valve and then to the mix container. Observe check valve flow arrow . Secure with

hose clamps.

D.Connect 1/2 inch (1.27 cm) ID plastic food grade

tubing between the large port of air/mix tee and

refrigerated mix transfer line. Secure with large hose

clamp or equivalent.

CAUTION

AIR/MIX TEE MUST REMAIN BELOW THE BLACK

COVER/CLAMP. IF THE TEE IS ABOVE THE PUMP MIX

WILL DRAIN TO THE AIR COMPRESSOR RESULTING

IN PUMP DAMAGE.

E. Plug mix pump into a 1 15 volt grounded receptacle.

Figure 3

Mix Pump Installation

10. Connect free end of mix pump hose to "4 way Tee"

as shown in Figure D. When all connections are

complete the "4 way Tee" must be lower than the

black pump housing.

Check

Valve

CHECK VAL VE

WARNING

TO MINIMIZE SHOCK HAZARD, THE REMOTE MIX

PUMP MUST BE PLUGGED INTO A PROPERLY

GROUNDED ELECTRICAL RECEPTACLE WITHOUT THE

USE OF A GROUND ADAPTER PLUG.

2.4 MIX PUMP CHECK OUT

Before using, the U3 Mix Pump should be thoroughly

cleaned. This is necessary to remove any foreign

materials that may be present.

A. The over-run adjustment is preset at the factory . If an

adjustment becomes necessary, refer to Section 4.1.

B. Check for air leaks by placing the suction line into

two gallons of cold water. Place the freezer switch in

the OFF position. Close the spigot and freezer air

vent. Place mix pump switch in the ON position and

allow the system pressure to build up and pump to

shut OFF automatically . Leave the pump on for ten

minutes.

During this time, do not open spigot or freezer air

vent. If pump does not automatically start again

during this period, the system is free of leaks. If the

pump does start, there is a leak in the system.

Locate leak by applying a liquid detergent or bubble

solution with a small brush to all tubing connections

and o-ring seals. Correct as required.

Figure D

5

Page 12

6

Page 13

SECTION 3

OPERATION INSTRUCTIONS

3.1 SAFETY PRECAUTIONS

Do not attempt to operate the U3 pump until the safety

precautions and operating instructions in the manual are

read completely and thoroughly understood.

Take notice of all warning labels on the U3 pump. The

labels have been put there to help in maintaining a safe

working environment. The labels are designed to withstand

washing and cleaning. All labels must remain legible for

the life of the mix pump. Warning labels should be checked

periodically to be sure they have not been removed,

painted over, rubbed off, and can be recognized as warning

labels.

If replacement labels are needed, indicate the part number,

type of label, location of label, and quantity required. Mail

your name and address to:

STOELTING, LLC

ATTENTION: Customer Service

502 Hwy 67

Kiel, Wisconsin 53042

Labels will be furnished and mailed at no charge.

The PUMP MOTOR switch (Fig. 4) is located on the mix

pump assembly. When the pump motor switch is placed

in the ON position, the mix pump motor will be actuated to

pump mix into the freezer cylinder. When the set pressure

is reached, the mix pump will shut off automatically. When

the pump motor switch is placed in the OFF position, the

mix pump will be inoperative.

NOTE

The mix pump motor is equipped with an internal

overload that will “kick-out” when the motor is overloaded. Consult the trouble shooting section for corrective information.The internal overload will automatically reset after cooling. If the condition continues, contact a qualified service person.

3.3 OPERATION OF U3 MIX PUMP

SAFE OPERATION IS NO ACCIDENT; Observe these

rules:

A. Know the U3 pump - read and understand the

Owner’s Manual.

B. Wear proper clothing - avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

C.Maintain a clean work area - avoid tripping or slipping

by cleaning up the area and keeping it clean.

D.Stay alert at all times - know which switch, push

button or control you are about to use and what effect

it is going to have.

E. Turn all switches to OFF prior to making any adjust-

ments.

F. Do not attempt to repair or perform maintenance on

the mix pump until the main electrical power has

been disconnected.

G.Do not operate the mix pump if unusual or

excessive noise or vibration occurs.

3.2 PUMP MOTOR SWITCH

Figure 4

Pump Motor Switch

This section describes the operation of the U3 mix pump.

NOTE

Mix pump hose must be repositioned every 1 2 weeks. Failure to comply will result in reduced

mix pump liquid capacity , dispense stoppage, popping, and possible mix pump hose leakage. Ref. to

Note from Section 4.2.

A. Refer to freezer owners manual for the operation of

the freezer.

B. Mix Operation: The peristaltic mix pump contains

one continuous mix pump hose. When looking at the

face of the peristaltic mix pump, the left side of this

hose is the suction or pickup. The right side of the

hose is the discharge. Mix is drawn up the suction

side of the hose and transferred thru the discharge

side to the freezer (Fig. 5).

C.Air Operation: The air compressor operates concur-

rently with the peristaltic mix pump. Air enters thru

an internal check valve on the piston downstroke.

The air is discharged thru a second internal check

valve, and an external check valve on the piston

upstroke. The air and mix join at the tee and then

travel to the freezer.

7

Page 14

ROLLER

MIX PILLOW

COVER/CLAMP

Mix Pump Operation

D.Overpressure Relief: Excess pressure is relieved

backwards through the peristaltic mix pump and out

the pickup side of the mix pump hose. This will occur

only if the pressure switch fails to shut off the pump

motor.

3.4 CLEANING

The mix pump must be cleaned when changing mix or

whenever the freezer is shut off for an extended period,

such as overnight or on nonbusiness days. For sanitary

reasons, mix must not be allowed to remain in the

freezer lines or mix pump when the freezer is not in

operation.

NOTE

T o clean the freezer , refer to the freezer owner’s manual

for complete cleaning procedures.

INLET SIDE

Figure 5

4 WAY TEE

3.5 DISASSEMBLY AND INSPECTION OF

REMOVABLE PARTS

Inspection of removable parts should be made whenever

maintenance is performed or pump requires disassembly.

WARNING

THE MIX PUMP SWITCH MUST BE IN THE OFF

POSITION WHEN SERVICING OR DISASSEMBLING PUMP .

CAUTION

NEVER DISCONNECT HOSES FROM FREEZER

OR PUMP WITHOUT FIRST OPENING SPIGOT

TO RELIEVE PRESSURE.

1. Place the CLEAN-OFF-ON switch in the clean

position and agitate 5-10 minutes maximum.

2. Remove suction tube from mix container. Draw of f

the mix remaining in freezer barrel.

3. Pump 2 gallons (7.5 liters) of cold potable water thru

freezer until water at spigot is free of mix.

4. Pump 2 gallons (7.5 liters) of warm detergent solution

water thru freezer. The use of sof t water is recommended, along with dishwashing detergents such as

“Joy,” “Dawn,” or equivalent.

5. Place mix pump switch in OFF position. Open spigot

to relieve remaining pressure.

6. Place the CLEAN-OFF-ON switch in the OFF posi-

tion.

Check

Valve

Figure 6

Removing Parts

8

Page 15

NOTE

If the mix lines or air lines are difficult to remove,

soften with a rag soaked in hot water. Hose connections may be sprayed with Haynes Sanitary Lubricant for ease of removal. Do not loosen or remove the mix pump cover wingnuts. Maintain the

mix pump hose in its operational condition.

1. Loosen clamp and remove air hose.

2. Remove the two wing nuts from the pressure control

manifold and pull out to remove.

3. Loosen clamp and disconnect mix pump hose.

Remove the pickup hose, check valve and pickup

hose adapter (and bag adapter if applicable) as an

assembly from mix container.

4. Completely disassemble both hose assemblies and

check valve. Place hoses, pressure control manifold

and o-ring, tee, check valve, and pickup hose adapter

in mild detergent water and wash thoroughly . Use soft

bristle brushes to clean inside of fittings. Rinse all

parts in clean hot water .

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning a

pump and soft serve freezer. W e therefore include

a sample with each new freezer. For further information read the directions on the packet. Other

products may be as effective.

CAUTION

PROLONGED CONTACT OF SANITIZER WITH FREEZER

MAY CAUSE CORROSION OF STAINLESS STEEL

PARTS.

In general, sanitizing may be conducted as follows:

1. Prepare two gallons (7.5 liters) of sanitizing solution

following manufacturer’s instruction, and place pump

suction (inlet) line into solution.

2. Place mix pump switch in ON position.

3. Check for leaks when freezer barrel is first pressur-

ized with sanitizing solution.

5. Carefully inspect each part for wear or damage.

Replace worn or damaged parts.

6. Prepare two gallons (7.5 liters) of sanitizing solution

using a USDA certified grade sanitizing solution.

Sanitize all removed parts, then air dry .

7. Check Hose Service Record decal to determine if

hose

reposition or replacement is required at this time

(Sec. 4.2).

8. Reassemble both hose assemblies per the diagram

(Fig.6). Lubricate the pressure control manifold oring

with sanitary lubricant before assembly . Reconnect

assemblies to the pump and discharge hose per the

diagram, using the clamps, locking plate washer and

wingnuts.

CAUTION

DO NOT FORCE P ARTS, THEY FIT TOGETHER

EASIL Y WHEN PROPERL Y INST ALLED.

3.6 SANITIZING AND STARTUP

For sanitizing to be effective, it must be performed after the

mix pump and freezer parts have been cleaned, and just

prior to filling the freezer with mix. Sanitizing the night

before is not effective.

To sanitize, refer to local sanitary regulations for applicable

codes and recommended disinfecting products and procedures. The frequency of cleaning must comply with local

health regulations. Use a solution containing 100 PPM of

free available chlorine. Use “Stera-Sheen Green Label

Sanitizer and Cleaner," or others in accordance with

Health Inspection Requirements.

9

4. Place freezer CLEAN-OFF-ON switch in CLEAN

mode (no refrigeration).

5. After five minutes in CLEAN mode, open spigot and

pump the remaining sanitizing solution thru the

freezer, close spigot and switch the freezer and pump

to OFF.

6. Place pickup tube into mix bag or container of mix

and start the pump.

7. Open spigot, allowing incoming mix to push remaining sanitizer out of hoses and freezing cylinder.

Close spigot as soon as pure mix begins to come out

(after about one pint).

8. Push in the air bleed valve located on the front door

(Challenger Series) and allow the mix to come within

1/2" of the air bleed valve, then close the valve.

9. Place freezer in the on or freezing position.

3.7 CLEANING MIX LINES

The mix lines must be cleaned and sanitized whenever

changing mix or whenever the freezer is off for an extended

period of time - such as overnight, or nonbusiness days.

The mix lines are sufficiently cleaned and sanitized when

cleaning and sanitizing the pump and freezer as an

assembly.

Once every 2 weeks, if required, perform the following

steps:

Page 16

A. Mix 2 gallons (7.5 liters) of milkstone remove solution

according to the directions on the container and pump

through the mix line.

B. Cut a piece of sponge slightly larger than the inside

diameter of the mix line. Place the sponge inside the

mix line and force through with tap water pressure. A

garden hose repair end clamped to the mix line works

well for this purpose.

10

Page 17

SECTION 4

MAINTENANCE INSTRUCTIONS

4.1 OVER-RUN ADJUSTMENT

The product when served is a combination of air and mix.

Over-run is a measure of the amount of air blended into the

mix.

Over-run can be expressed in terms of the amount of

weight loss for a given volume. For example, if a pint of

liquid mix weighs 18 ounces and a pint of frozen product

with air added weighs 12 ounces, the over-run is said to be

50 percent (18 oz. - 12 oz. = 6 oz., (6 /12) x 100 = 50%.

The over-run can be checked by placing a one pint

container on an ice cream scale and zeroing out the scale.

Then fill a one pint container with frozen product. The

container should be filled over the top and leveled with a

straightedge. The product should not contain any air

pockets. When weighed on an ice cream scale, one pint

of product should weigh 12 to 13 ounces.

The mix pump has been preset at the factory to produce a

product with approximately 40% overrun. Because of

differences in mix formulation, temperatures and barometric pressure, this figure may vary. It will be necessary for

approximately 2 gallons of mix to be pumped thru the

freezer before changes in the product are noticeable due

to adjustments in overrun.

Overrun is controlled by the length of the air compressor

piston stroke within the piston cylinder. Lengthening the

stroke within the cylinder will increase overrun. Conversely, shortening the stroke will decrease overrun. To

perform an overrun adjustment, refer to the following

procedure:

A. Turn the mix pump switch to the OFF position and

unplug the mix pump from its grounded 1 15V receptacle.

B. Remove the 2 electrical box cover screws and remove

the electrical box cover.

OVERRUN

ADJUSTMENT

Figure 7

Overrun Adjustment

F. Tighten the allen screw, then place the wrench back

in its clip. Replace the electrical box cover and

screws, plug the mix pump into its grounded 1 15V

receptacle and turn the mix pump power switch to the

ON position.

4.2 PREVENTATIVE MAINTENANCE

To assure trouble free operation and consistent over-run

when using the U3 mix pump, we must follow mix hose

repositioning and replacement procedures. The following

is the preventative maintenance schedule:

A. MIX PUMP HOSE REPOSITION (every one or two

weeks.)

NOTE

Mix pump hose must be repositioned every 1 - 2

weeks. Failure to comply will result in reduced mix

pump liquid capacity , dispense stoppage, popping,

and possible mix pump hose leakage.

C.

On air compressor side of pump, locate the long/

slender piston rocking arm. The rocking arm downward travel is limited by a stationery cam. On the

face of the cam there is an overrun setting indicator

plate numbered 3 thru 8 and an adjustment knob

(Fig. 7).

D.The overrun setting is indicated by a pointed pin.

E. T o adjust overrun, loosen the allenhead screw

(located within the center of the adjustment knob)

with the 5/32" allen wrench provided. Rotate the

adjustment knob counterclockwise to a higher

number for higher overrun, or clockwise to a lower

number for lower overrun. Each number multiplied by

10 represents the overrun percentage (ie: #4 = 40%

overrun).

1. Run cleaning solution through pump.

2. Turn pump off and if connected to freezer , relieve any

pressure by opening the spigot.

3. Grasp the pick-up hose end of the mix pump hose

with one hand and turn the pump on. Pull down on the

pick-up hose end until 12 to 14 inches of tubing has

reversed fed through the pump, then turn the pump

off.

4. Loosen small clamp at the pick-up hose adapter and

disconnect mix pump hose.

5. Cut 7-1/2 inches off the end of the mix pump hose.

The height of the pump can be used to measure. See

Figure 8.

11

Page 18

Pressures for Stoelting Freezers: Cut-out 24# ±3 PSIG

R

p

For Duke Freezers: Cut-out 30# ±3 PSIG

COVER/CLAMP

CUT LINE

MEASUREMENT

Figure 8. Reposition Mix Pump Hose

6. Reconnect mix pump hose to adapter .

7. Turn pump on.

8. Gently pull on the discharge hose to help remaining

6" of mix pump hose to feed thru pump until hose

adapter prevents further feeding.

9. Turn pump OFF and pump will be ready for normal

operation.

NOTE

Each hose is long enough for 3 repositions before

replacement is required. Record each event on Hose

Service Record decal.

MIX PILLOW

ROLLER

PICK UP

SIDE

19

DISCHARGE SIDE

20

4 WAY TEE

5. Turn pump roller assembly so one roller is at 6:00.

Roller

oller

Cover/Clam

Cover/Clamp

Inlet

Inlet

Side

Side

Discharge

Discharge Side

Side

B. MIX PUMP HOSE REPLACEMENT

NOTE

Mix pump hose must be replaced when tubing cannot be further repositioned (every four to eight

weeks). Failure to comply will result in hose failure

and possible pump damage.

1. Run cleaning solution through pump.

2. Turn pump off and if connected to freezer relieve any

pressure by opening the spigot.

WARNING

THE MIX PUMP SWITCH MUST BE IN THE "OFF"

POSITION WHEN SERVICING OR CLEANING PUMP.

CAUTION

NEVER DISCONNECT HOSES FROM FREEZER OR

6. Use a brush that fits in the opening and brush up and

down, first with detergent water and then clear water.

7. Connect mix pump hose to pick-up hose adapter,

using small clamp.

8. Insert free end of hose into the pick-up (suction side)

hose side of the black cover. Gently push the hose

into the black cover until it begins to self-feed. Allow

the hose to feed itself through the pump until the mix

pump hose comes out the discharge side. Then gently

pull on the discharge hose to help remaining mix

pump hose feed thru pump until hose adapter prevents

further feeding, then turn pump off.

PUMP WITHOUT FIRST OPENING SPIGOT TO RELIEVE PRESSURE.

3. Disconnect mix pump hose at each end.

4. Grasp the discharge hose end with one hand and turn

the pump on. Pull down on the hose until all of the

remaining hose is removed from the pump.

Remove cover clamp from pump on a monthly basis

to clean and check for wear. (Cover clamp & roller

bearings) Clean parts with soap and water and reassemble.

9. Reconnect mix pump hose to T using small clamp.

Pump is now ready to sanitize.

Figure 9. Pump Roller Assembly

NOTE

12

Page 19

SECTION 5

TROUBLESHOOTING

1. P UM P M OTO R DOES NOT RU N

Power to pump is off. Supply power to pump.

Low voltage. Check for low voltage.

Mix pump hose jammed insi de black cover/clamp. Dis connect pump from power source. Remove four

cover/clamp thumb screws. Separate co ver/clamp halves

and remove outer half. Remove jammed hose. Re-ins tall

cover/clamp and tighten four t humb screws securely.

Allow motor t hermal overload to reset. See Sec. 4.2 for

hose replacement. Do not use jammed portion of hose.

Pump motor overloaded. Allow internal thermal overload to reset; determine

overload cause and rep air.

Pressure switch on pump is defective. Check mechanic al oper at i on and co nt i nu i ty of pre ss ur e

switch .

Defective motor/capacitor Check motor amperage draw and/or capacitor. Replace

motor or capaci tor.

Defective toggle switch. Check continui ty; repair o r repl ace.

2. PUMP OPERATES BUT CYLINDER WILL NOT FILL

NOTE 1: A PROPERLY WORKING PUMP WILL FILL AN 8 OZ. CUP WITH MIX I N ABOUT 9 SECONDS.

NOTE 2: IMMEDIATELY AFTER A "BAG CHANGE" THE PUMP MAY BE UNABLE TO RE-ESTABLISH IT'S PRIME WITH

THE S YS TEM A T OPE RATI NG PRE SS URE. I N THI S CAS E , TURN THE PUMP O FF. DRAW 2 -3 PINTS TO RED UCE

SY STE M P RES S URE TO ZER O. TURN PUM P O N. P URGE RE MA I NI NG A I R I N M I X BA G A ND PI CK -UP HOS E.

IMPORTANT: Before connecting the pick-up hose to the mix bag, purge the mix bag of air to the extent

possible.

Out of Mix. Replenish mix supply.

MIx pu mp hose ki nke d i ns ide blac k cov e r/clamp. F ollow mix pump hose jammed re pair. (S ee #1 above.)

Hoses assembled incorrectly. Refer to diagram for correct hose connections .

Mix pump hose service life is exceeded. Reposition/replace mix pump hose. See Sec. 4.2.

Mix pump hose not connect ed to freezer. Connect mix pump hose to freezer.

Ice crystals in mix.

Mix bag drawn against adapter.

Forei g n objec ts i n mix.

Check valve is backwards.

3. OVE RRUN TOO LOW OR NO OVE RRUN

Overrun setting too low. Increase overrun setting.

Air leak. Tighten all hose clamps.

Air compressor not pumping air. Cont ac t loc al S t o elt ing Di stribut or .

4. OVERRUN TOO HI GH

Mix pump hose service life is exceeded. Reposition/replace mix pump hose.

Out of mix. Replenish mix supply.

Overrun setting too high.

Pick-up leg of mix pump hose is collapsing.

NOTE: ALSO SEE "2" ABOVE.

Completely thaw mix prior to use.

Assure bag is clear of pick-up tube.

Clear blockage. Use fresh mix .

Observe flow arrow for proper orientation.

Decrease overrun setting.

See Section 4.2.

13

Page 20

5. REPLACEMENT M I X PUMP HOSE WON'T FEED THROUGH PUMP

Feedi n g hos e i nto dis ch arg e hole of mix pump cover . Feed hose into pick-up side of cover.

Hose ends not cut s quarely. Carefully cut hose end off squarely (no tails).

Force feeding too quickly. Gently and slowly ass ist feedi ng of hose up into pick-up

hose side of cover.

Pump motor not runni ng. Turn on motor switch. Als o see Item 1 above.

6. AIR EXITING MIX PICK-UP HOSE

Pi ckup tube check valve missing.

7. DISPENSED PRODUCT AIR "POPS"

Overrun setting too high. Reposition/replace mix pump hose.

Mix pump hose service life is exceeded. Reposition/replace mix pump hose.

Overdrawing the freezer's capacity. Reduce di spense rate.

Recent "mix-out" condi tion. Open spigot fully and allow excess air to "belch" out.

NOTE: ALSO SEE 2 & 4 ABOVE.

8. MIX LEAKAGE FROM PUMP

CAUTION: To prevent mix pump damage from dried mix deposits, immediately disassemble and clean

pump.

Mix pump hose service life is exceeded. Remove mix pump hose. Disconnect pump from power

9. PUMP HAS POOR CAPACITY

Lift and run limits are exceeded. Pump is limited to 10' lift, 20' run.

NOTE: Also see 2, 4, 6 & 7.

10. PUMP IS NOI SY/SQUEAKI NG

NOTE: THE ACTION OF THE AIR COMPRESSOR ROCKING ARM CREATES A REPETITIVE CLICKING SOUND DURING

OPERATION. THIS IS NORMAL.

NOTE: THE PERISTALTIC MIX PUMP HAS THREE SQUEEZE ROLLERS WHICH USE SELF LUBRICATING BEA RINGS. I F

SQUEAKING EXI STS WITH THE MIX PUM P HOSE IN PLA CE, AND STOPS WITH THE HOSE REMOVED, THE SQUEEZE

ROLLER BEARINGS CAN BE LUBRICATED USING A SILICONE BASED SPRAY. REMOVE THE MIX PUMP HOSE.

DISCONNECT PUMP FROM E LECTRICAL POWER. REMOVE FOUR COVER/CLAM P THUMBSCREWS. REMOVE ENTIRE

COVER/CLAMP AS ONE UNIT. SPRAY SILI CONE BASED LUBRICANT ON EACH END OF EACH SQUEEZE ROLLER.

SPIN ROLLERS TO WORK LUBRICANT INTO BEARINGS. REPE AT AS NEEDED.

Cont ac t loc al S t o elt ing Di stribut or .

source. Remove mix pump cover/clamp. THOROUGHLY

rinse t hree squeeze rollers using a spray bottle filled with

hot water. Thoroughly clean all mix from pump. See Sec.

4.2 for hose replacement. Lubricate s queeze rol ler

bearings, s ee Item #10 below .

CAUTION: DO NOT USE CLEANING/DISSOLVING TYPE LUBRICANTS LIKE WD-40. THESE LUBRICANTS

ARE NOT BEARING FRIENDLY AND WILL ACCELE RAT E BEARING WEAR.

11. MIX IN AIR HOSES

Ai r/mix tee above black cover/clamp. Ai r/mix tee must be below black cover/ clamp.

Air leak. Tighten all hose clamps.

Mix hose on wrong air/mix tee fitting. Refer to diagram for correct hose connections.

Pressure control manifold o-ring leak. Check o-r i n g and mani fold ; rep lace as requi red.

14

Page 21

SECTION 6

REPLACEMENT PARTS INFORMATION

6.1 HOW TO ORDER REPLACEMENT P ARTS

To assure the receipt of the proper replacement parts,

supply your dealer, distributor or the company with the

following information:

A. Model number of equipment.

B. Serial number of Model. (Stamped on nameplate).

C.Part number, part name, and quantity needed. Many

part names and numbers are listed in this manual.

NOTE

Minimum Billing is $50.00 Net.

6.2 PARTS LIST AND REFERENCE DRAWINGS

The following lists and drawings will aid the user when

ordering parts or servicing the mix pump.

Figure 10

Pump and Decal Assembly

15

Page 22

Pump and Decal Assembly Parts List

ITEM STOELTING P/N QT Y. DESCRIPTION

1 130000 1 Bag, Envelope Front Loading

2 266018 1 Clip Adhesive Backed "J"

3 324105 1 Decal Caution - Elect. Shock

4 430022 1 Harness Cord 6.50 Ft.

5 538296 3 Nut Hex #10-24 x 3/8 SS

6 644116 3 Screw Cap 1/4-20 x 3/4 Hx Hd

7 647512 2 Screw Mach 8-32 x 3/8 Pan Hd

8 539419 3 Nut Wing 1/4-20

9 718532 1 Switch Toggle 10 Amp 250V

10 778027 1 Wrench Allen 5/32

11 1995611 1 Wiring Diagram U3 Pump

12 717917-SV 1 Switch Pressure (Stoelting)

12 717919-SV 1 Switch Pressure (Duke)

13 3170824 1 Mounting Bracket

14 3171850 1 Splash Guard

15 4177692 1 Pump Box Cover

16 4177691 1 Pump Box

17 647667 1 Screw Mach 10-24 x 1/2 Rd Hd

18 766950 1 Washer Shakeproof #10

19 223162 1 Bushing Strain Relief

20 766066 3 Washer Lock 1/4-20

21 208467 1 Brush (Not Shown)

22 324509 1 Cleaning Decal

23 2171853 1 Model ID Plate

24

25 1171960 1 Capacitor , Motor S t art

26 692225 3 Spacer , Nylon .5 OD, 1/4-20

27 1171958 1 Air Filter

28 4171953 1 Main Pump Assembly

29 324023 1 Decal NSF

16

Page 23

OPTIONAL MOUNTING KIT

SEE SERVICE REFERENCE, PAGE 19

17

Page 24

1819202122

Page 25

Page 26

Page 27

Page 28

Page 29

23

Page 30

Page 31

WARRANTY

SOFT SERVE / SHAKE FREEZERS

1. Scope:

Stoelting, LLC warrants to the first user (the “Buyer”) that the freezer cylinders, hoppers, compressors, drive motors,

speed reducers, auger and auger flights of Stoelting soft serve / shake freezers will be free from defects in materials

and workmanship under normal use and proper maintenance appearing within five (5) years, and that all other

components of such equipment manufactured by Stoelting will be free from defects in material and workmanship

under normal use and proper maintenance appearing within twelve (12) months after the date that such equipment is

originally installed.

2. Disclaimer of Other Warranties:

THIS W ARRANTY IS EXCLUSIVE; AND STOEL TING HEREBY DISCLAIMS ANY IMPLIED W ARRANTY OF MERCHANTABILITY OR FITNESS FOR PA RTICULAR PURPOSE.

3. Remedies:

Stoelting’s sole obligations, and Buyer’s sole remedies, for any breach of this warranty shall be the repair or (at

Stoelting’s option) replacement of the affected component at Stoelting’s plant in Kiel, Wisconsin, or (again, at

Stoelting’ s option) refund of the purchase price of the affected equipment, and, during the first twelve (12) months of

the warranty period, deinstallation/reinstallation of the affected component from/into the equipment. Those obligations/remedies are subject to the conditions that Buyer (a) signs and returns to Stoelting, upon installation, the

Checklist/Warranty Registration Card for the affected equipment, (b) gives Stoelting prompt written notice of any

claimed breach of warranty within the applicable warranty period, and (c) delivers the affected equipment to Stoelting

or its designated service location, in its original packaging/crating, also within that period. Buyer shall bear the cost

and risk of shipping to and from Stoelting’ s plant or designated service location.

4. Exclusions and Limitations:

This warranty does not extend to parts, sometimes called “wear parts”, which are generally expected to deteriorate

and to require replacement as equipment is used, including as examples but not intended to be limited to o-rings,

auger seals, auger support bushings and drive belts. All such parts are sold

AS IS.

Further, Stoelting shall not be responsible to provide any remedy under this warranty with respect to any component

that fails by reason of negligence, abnormal use, misuse or abuse, use with parts or equipment not manufactured or

supplied by Stoelting, or damage in transit.

THE REMEDIES SET FORTH IN THIS W ARRANTY SHALL BE THE SOLE LIABILITY STOEL TING

AND THE EXCLUSIVE REMEDY OF BUYER WITH RESPECT TO EQUIPMENT SUPPLIED BY

STOEL TING; AND IN NO EVENT SHALL STOEL TING BE LIABLE FOR ANY INCIDENT AL OR

CONSEQUENTIAL DAMAGES, WHETHER FOR BREACH OF W ARRANTY OR OTHER CONTRACT BREACH, NEGLIGENCE OR OTHER T ORT, OR ON ANY STRICT LIABILITY THEORY .

Loading...

Loading...