Stoelting SU444 Installation Manual

Model SU444

OWNERS MANUAL

Manual No. 513639 Oct., 2009 Rev.2

Owner's Manual

For SU444 & U444A Series

Combination Soft Serve/Shake

Pressure Machine

This manual provides basic information about the machine. Instructions and suggestions are given

covering its operation and care.

The illustrations and specifications are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide

new parts for machines built prior to date of change.

DO NOT A TTEMPT to operate the machine until instructions and safety precautions in this manual

are read completely and are thoroughly understood. If problems develop or questions arise in

connection with installation, operation, or servicing of the machine, contact the company at the

following location:

STOELTING Ph: 800-558-5807

502 Hwy. 67

Kiel, WI 53042 Fax: 920-894-7029

© 2009 Stoelting, LLC, All Rights Reserved

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This Owner's Manual provides the operator with

information for the safe operation and maintenance of

Stoelting equipment. There are hazards associated

with the operation of this machine. For this reason

safety is emphasized throughout the manual. To

highlight specific safety information, the following

safety definitions are provided to assist the reader.

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine S toelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality .

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury . The message that follows the symbol

contains important information about safety .

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTICE

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety or personnel or equipment/property .

TABLE OF

CONTENTS

Section Description Page

1 Description and Specifications

1.1 Description .................................................................................................1

1.2 Specifications.............................................................................................2

2 Installation Instructions

2.1 Safety Precautions.....................................................................................3

2.2 Shipment and Transit .................................................................................3

2.3 Machine Installation.................................................................................... 3

2.4 Installing Permanent Wiring........................................................................3

2.5 Check Check Compressor for Proper Power...............................................4

2.6 Check Blender Rotation..............................................................................4

2.7 Mix Pump...................................................................................................4

A. Mix Pump Hose Installation ................................................................................ 4

B. Mix Pickup Hose Installation............................................................................... 5

C. Mix Low Level Indicator Adjustment....................................................................6

3 Initial Set-Up and Operation

3.1 Operator’s Safety Precautions ...................................................................7

3.2 Operating Controls and Indicators .............................................................7

3.3 Important Information Regarding Cleaning and Sanitizing .........................9

3.4 Disassembly of Left Side............................................................................10

A. Remove Front Door and Auger ...........................................................................1 1

3.5 Disassembly of Right Side .........................................................................11

A. Remove Blender (SU444 Only) ..........................................................................1 1

B. Remove Front Door and Auger ...........................................................................1 1

3.6 Cleaning Disassembled Parts.....................................................................12

3.7 Sanitizing Parts..........................................................................................12

3.8 Cleaning the Machine.................................................................................12

3.9 Assembling the Left Side............................................................................12

3.10 Assembling the Right Side .........................................................................13

3.11 Sanitizing ...................................................................................................14

3.12 Initial Freeze Down and Operation ..............................................................15

A . Adding Mix ...........................................................................................................15

B. Preparing the IntelliTec Control .......................................................................... 15

C. Initial Freeze Down .............................................................................................1 5

D. Adjusting the IntelliTec Control...........................................................................15

E. Serving Product ...................................................................................................1 6

3.13 Normal Freeze Down and Operation ...........................................................16

3.14 Mix Information...........................................................................................17

3.15 Operation of Mix Pump...............................................................................17

3.16 Mix Pump Cleaning ....................................................................................17

3.17 Disassembly and Inspection of Removable Parts........................................18

Section Description Page

4 Maintenance and Adjustments

4.1 Machine Adjustment...................................................................................19

4.2 Product Temperature Adjustment (Left Side) ..............................................19

4.3 Product Consistency Adjustment (Right Side)............................................19

4.4 Locking the Control Panel (Right Side) .......................................................19

4.5 Obtaining Readings and Modifying Settings

(Service Personnel Only) (Right Side).........................................................19

4.6 Readings (Service Personnel Only) (Right Side) .........................................20

4.7 Adjustments (Service Personnel Only) (Right Side) ....................................21

4.8 Other Settings (Service Personnel Only) (Right Side) .................................21

4.9 Overrun Adjustment ....................................................................................22

4.10 Mix Pump Hose Reposition ........................................................................23

4.11 Mix Pump Hose Replacement ....................................................................24

4.12 Cab Temperature Adjustment .....................................................................24

4.13 Drive Belt Tension Adjustment....................................................................25

4.14 Condenser Cleaning (Air-Cooled Machines) ................................................25

4.15 Preventative Maintenance ...........................................................................25

4.16 Extended Storage.......................................................................................25

5 Troubleshooting

5.1 Error Codes (Right Side).............................................................................27

5.2 Troubleshooting - Error Codes (Right Side) .................................................27

5.3 Troubleshooting - Machine..........................................................................29

5.4 Troubleshooting - Mix Pump .......................................................................31

6 Replacement Parts

6.1 Brushes, Decals and Lubrication ................................................................33

6.2 Left Side Auger Shaft and Front Door Parts................................................34

6.3 Right Side Auger Shaft and Front Door Parts..............................................35

6.4 Blender Parts and Drip Tray........................................................................36

6.5 Cab Tubing .................................................................................................37

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1.1 DESCRIPTION

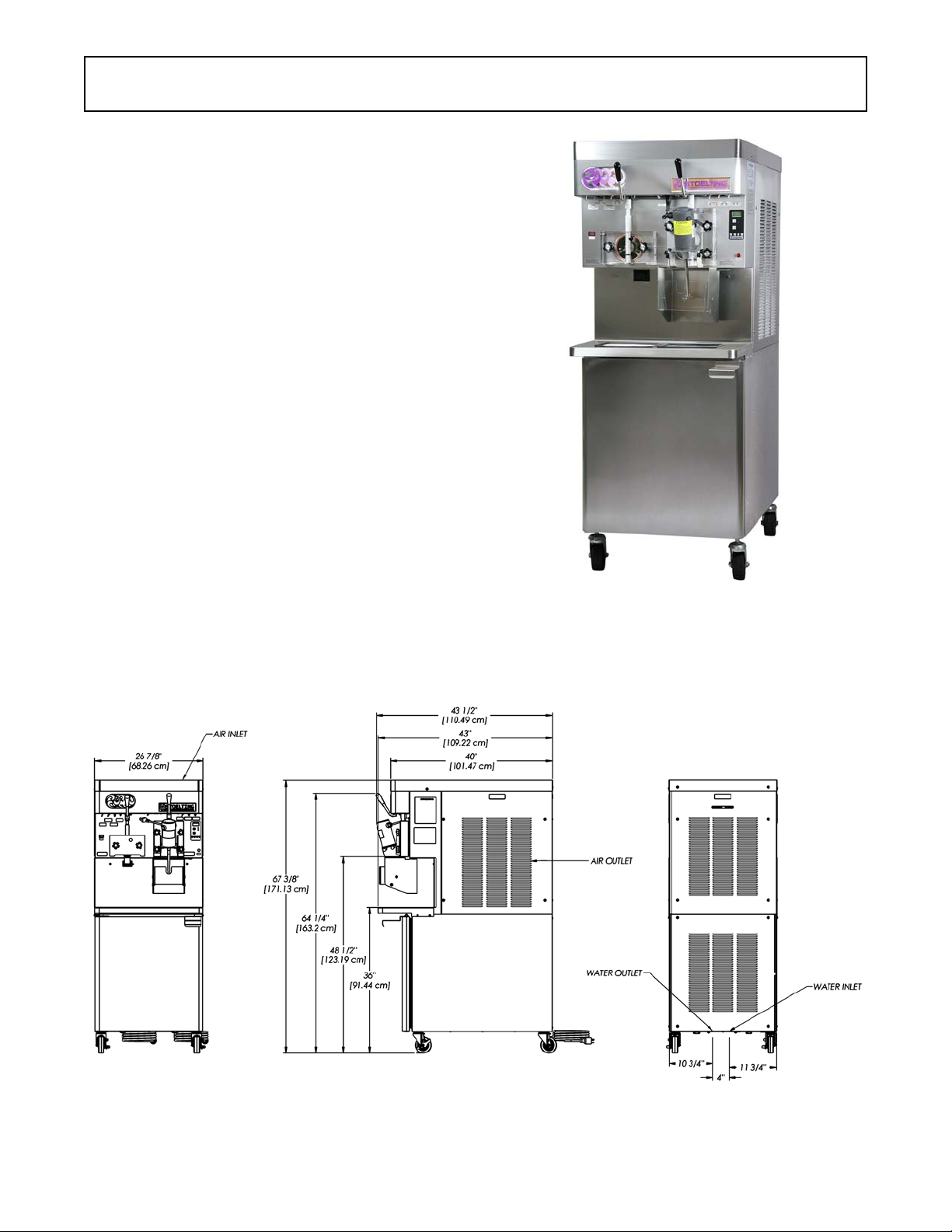

The Stoelting SU444 and U444A floor model machines are

pressure fed. They are equipped with fully automatic

controls to provide a uniform product. The SU444 and

U444A are designed to dispense soft serve product from the

left side and shake product from the right side. The SU444

has a blender attached to the front door of the shake side.

This manual is designed to assist qualified service personnel and operators with installation, operation and maintenance of the SU444 and U444A.

Figure 1-1 Model SU444 Machine

Figure 1-2 Dimensions

1

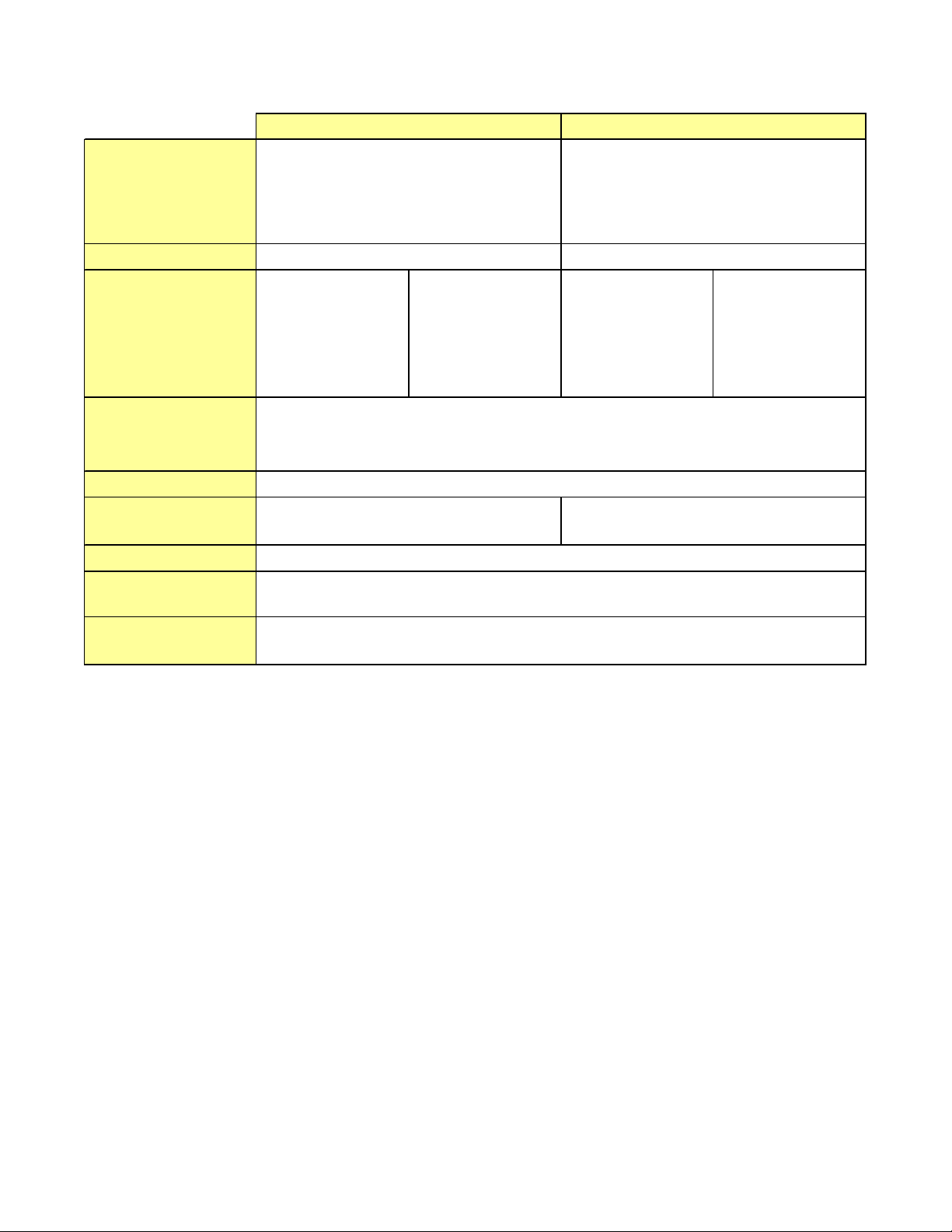

1.2 SPECIFICATIONS

Dimensions

width

height

depth

Weight

Electrical

minimum circuit

ampacity

maximum overcurrent

protection device

Compressor

Drive Motor

Cooling

Hopper Volum e

Freezing Cylinder

Volume

Production

Capacity

SU444 Water Cooled

Machine

26-7/8'' (68,3 cm)

67-3/8'' (171,1 cm)

40'' (101,6 cm ) 48'' (121,9 cm )

760 lbs (344, 7 kg)

1 PH

left right left right left right left right

wi th c r a te

34'' (86,4 cm )

78'' ( 1 98,1 cm )

908 lb s ( 411,8 kg)

3 PH

26-7/8'' (68, 3 cm)

67-3/8'' (171,1 cm)

40'' (101,6 cm)

760 lbs (344, 7 kg)

SU444 Air Co oled

Machine

1 PH

wi t h c rate

34'' (86,4 cm)

78'' (198,1 cm)

48'' (121,9 cm)

908 lbs (411, 8 kg)

3 PH

30A 22A 19A 15A 31A 23A 19A 15A

45A 35A 30A 25A 45A 35A 30A 25A

Soft Serve - 19,000 Btu/h r Scroll™ Compressor (R-404A)

Shake - 15,000 Btu/hr Scroll™ Compressor (R-404A)

Cabinet - 1,300 Btu/hr Compressor (R-134a)

Soft Ser ve - 2 hp , Shake - 3/ 4 hp

Water cool ed u nits r equ ire 1/ 2" N. P.T.

wat er and drain f ittings.

Air cool ed units re quire 6" ( 15,2 cm) air

space on both sides and back.

T w o - 8 ga l lon ( 30,28 liters )

Soft Serve - 1. 33 gallon (5.32 quart), 5, 4 liters

Sha ke - 2.1 gal l o n (8. 4 quart) , 7,95 liter s

Soft Serve - 19 GPH (71,92 liters)

Shake - 32 G PH ( 121,13 l iter s)

2

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The labels

have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the machine. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate the

part number, type of label, location of label, and quantity

required along with your address and mail to:

STOELTING

A TTENTION: Customer Service

502 Hwy . 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

The machine has been assembled, operated and inspected

at the factory. Upon arrival at the final destination, the

entire machine must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the machine should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill until

the machine has been checked for damage. Have the

carrier note any visible damage on the freight bill. If

concealed damage and/or shortage is found later, advise

the carrier within 10 days and request inspection. The

customer must place a claim for damages and/or shortages in shipment with the carrier. Stoelting, Inc. cannot

make any claims against the carrier.

2.3 MACHINE INSTALLATION

WARNING

Installation must be completed by a qualified

electrician/refrigeration specialist.

Incorrect installation may cause personal injury,

severe damage to the machine and will void factory

warranty.

Installation of the machine involves moving the machine

close to its permanent location, removing all crating,

setting in place, assembling parts, and cleaning.

A. Uncrate the machine.

B. Install the four casters. Turn the threaded end into

the machine until no threads are showing. To level,

turn out casters no more than 1/4" maximum, then

tighten all jam nuts.

C. The machine must be placed in a solid level

position.

NOTE

Accurate leveling is necessary for correct drainage

of freezing cylinder and to insure correct overrun.

D. Machines with air cooled condensers require a

minimum of 6" (15,2cm) space on all sides and

back for proper circulation.

NOTE

In order for the condenser fan motor to work the left

side needs to be connected to a power source.

E. Machines that have a water cooled condenser

require 1/2" NPT supply and drain fittings.

2.4 INSTALLING WIRING

A. Refer to the nameplate on the side panel of the

machine for specific electrical requirements. Make

sure the power source in the building matches the

nameplate requirements. Bring the wires into the

junction boxes through the access holes in the

bottom rear of the freezer.

NOTE

Three phase freezers in areas of unbalanced electrical loads require special attention when connecting input electrical power. The unbalanced leg of

power (called wild or high) must be connected to L2

in the junction box.

B. Remove the back panel and the junction box cover

located at the bottom of the machine.

C. Install permanent wiring according to local code.

D. If the line voltage is less than 215V, the fan motor

needs to be rewired. Refer to the wiring diagram for

details.

NOTE

Low incoming voltage affects the fan motor speed

and could cause high head pressure errors from the

reduced air flow. Rewiring the fan motor prevent s the

fan speed from decreasing to an unsuitable rate.

3

6" (15cm)

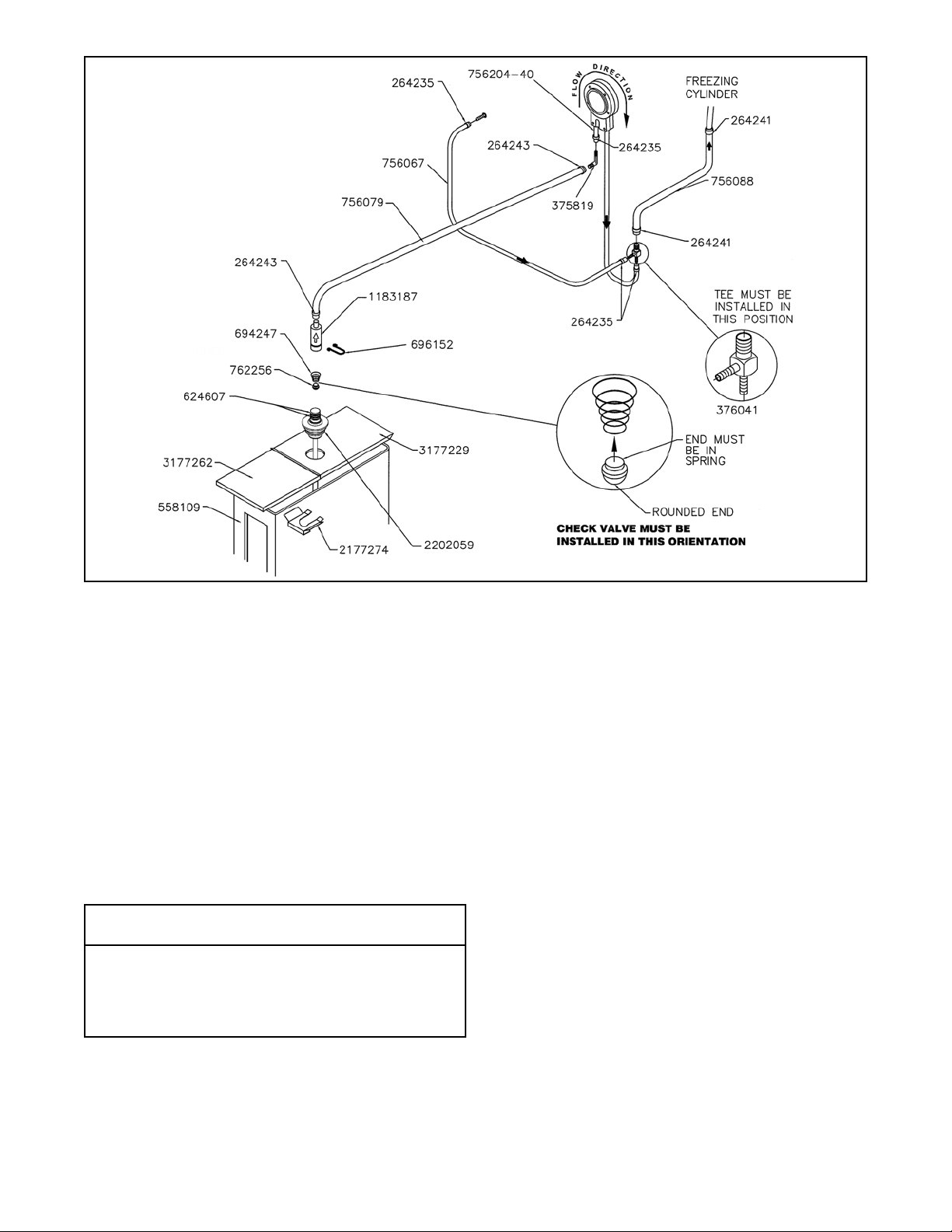

Figure 2-2 Mix Hose Installation

2.5 CHECK COMPRESSOR FOR PROPER

POWER (3 PHASE ONLY)

After connecting the electrical, check that the compressor

is operating in the proper direction.

A. Start a freezing cycle.

On the right side, place the Main Freezer Power

switch and Freezing Cylinder OFF/ON switch to

the ON position. Press the PUSH TO FREEZE

button.

On the left side, place the Clean/Off/Serve and the

Standby/Serve switches in the Serve position.

B. The suction line will be cold to the touch within 1

minute.

C. If it is not, disconnect power to the machine and

reverse L1 and L3 lines in the junction box.

D. After reversing the electrical lines, recheck the

suction line.

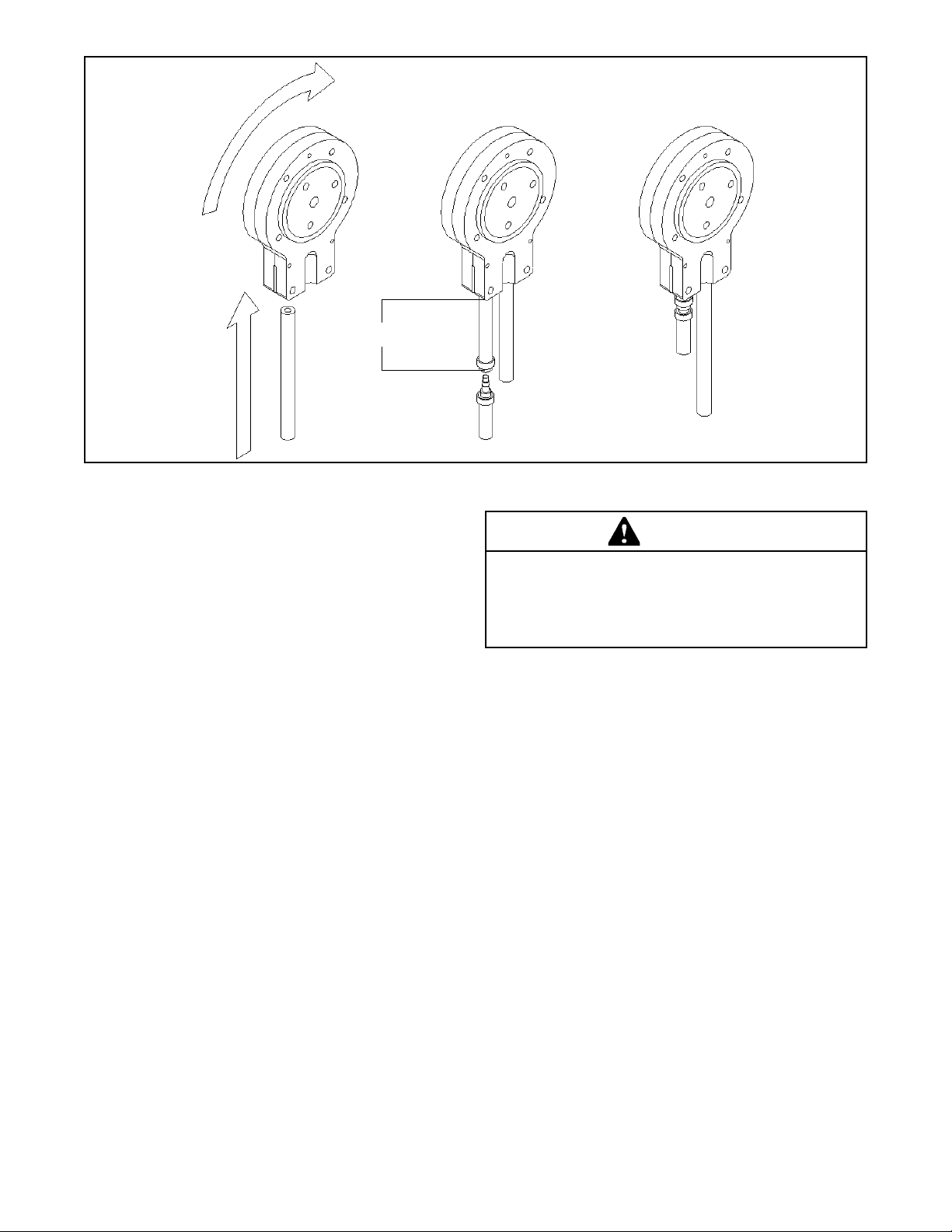

2.6 CHECK BLENDER ROTATION

After connecting the electrical, check the blender on the

right side for proper rotation.

A. Place the Blender Power Off/On switch to the ON

position.

B. With the clear swing sheild in place, move the

spigot handle to the right.

WARNING

Hazardous Moving Parts

Blender shaft and agitator can grab and cause injury . Do not operate blender without protective shield

or swing splash shield.

C. The blender should rotate clockwise looking from

the top of the blender.

D. If the rotation is counterclockwise, refer to the

wiring diagram located behind the header panel

and check the diode direction. Reverse the diode

polarity if needed.

2.7 MIX PUMP

A. MIX PUMP HOSE INSTALLATION

Follow the steps below to install the mix pump hose in the

cabinet part of the machine.

1. Turn the mix pump on. The switch is located on the

header panel.

2. Feed one end of the mix pump hose into the

entering or pickup hose side (left) of black cover

(Fig 2-2).

NOTE

Feed the tube into the clamp so the natural curve of

the tube is towards the outside of the black cover.

This prevents the hose from looping around the

black cover twice.

3. Gently push the hose into the black cover until it

begins to feed.

4

Figure 2-3 Mix Pump Connections for Standard Mix Container

4. Allow the hose to feed itself through the pump until

about 6" (15cm) remains on the entering side.

5. Turn the pump off.

6. Connect the mix pump hose to the elbow fitting

(located on the left side of the mix line manifold)

using a small hose clamp. Be careful not to twist

the mix hose.

7. Turn the pump on.

8. Allow the remaining 6" (15cm) of tubing to feed

through pump until the hose adapter prevents

further feeding.

9. Turn the pump off.

CAUTION

Risk of Product Damage

Air/Mix T ee must remain below the black cover clamp.

If the Tee is above the pump, mix may drain into the

air compressor resulting in pump damage.

10. Connect the free end of the mix pump hose to the

3-way Tee (Fig. 2-3). When all connections are

complete, the 3-way Tee must be lower than the

black pump housing.

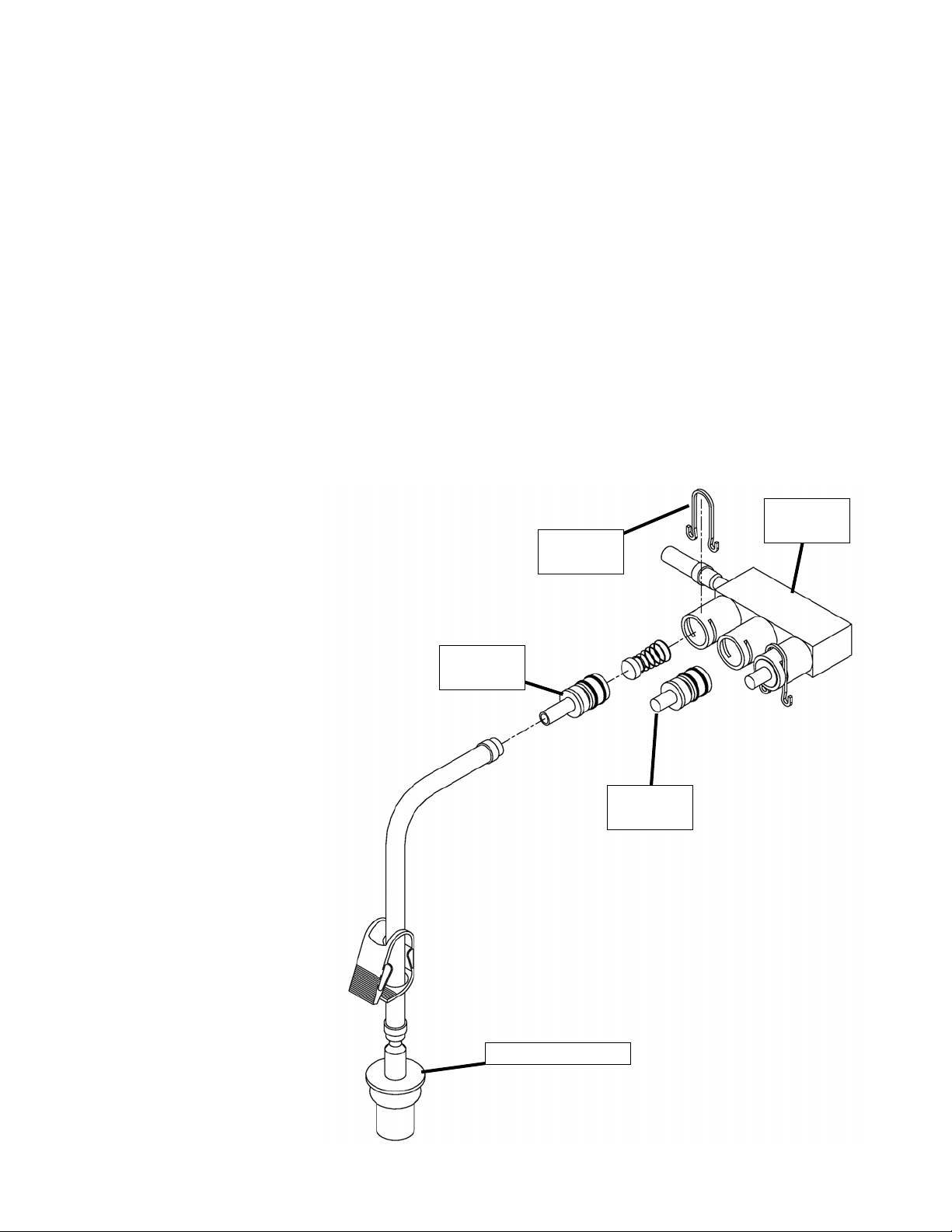

B. MIX PICKUP HOSE INSTALLATION

The machine may be connected to the standard mix

container or up to three prepacked mix bags. Follow the

instructions below that match your configuration.

Standard Connection:

1. Place the mix pickup assembly through the hole in

the cover and install the retaining clip.

2. Connect a 24" (61cm) length of 3/8" (9,5mm) ID

plastic food grade tubing to the mix pickup

assembly. Secure with a hose clamp.

3. Connect the elbow fitting to the free end of the

tubing. Connect the opposite end of the elbow to 1/

4" ID tan tubing on the left side of the pump head.

Secure with hose clamps (Fig. 2-3).

When Using Bag Connection System (BCS) with Three

Bags (optional kit):

The position of the three bags in the mix container is

important. The bag that is connected nearest the outlet of

the manifold will drain last and should be placed at the back

of the mix container. The mix low level indicator relies on

proper bag placement.

1. Connect 3/8" (9,5mm) ID plastic food grade tubing

to a bag adapter. Secure with hose clamps.

5

2. Slide the hose clip over free end of 3/8" (9,5mm) ID

plastic food grade tubing. Attach the free end of the

tubing to a manifold adapter. Secure with a large

hose clamp or equivalent.

3. Push the manifold adapter with spring and valve

into the left port (nearest the manifold outlet) of the

mix inlet manifold and secure with a retaining clip.

4. Repeat steps 1 to 3 for the middle port and for the

right port of the mix inlet manifold.

5. Place three mix bags into the mix container.

6. Connect the bag adapter attached to the left side

of the manifold (closest to the mix outlet) to the mix

bag in the back of the mix container.

7. Connect the bag adapter attached to the middle of

the manifold to the mix bag in the middle of the mix

container.

8. Connect the bag adapter attached to the right side

of the manifold (farthest from the mix outlet) to the

mix bag in the front of the mix container.

When Using Bag Connection

System (BCS) with One or Two

Bags (optional kit):

When connecting one or two bags,

the manifold adapters must be

installed closest to the manifold

outlet and the manifold plug(s)

must be placed farthest from the

manifold outlet.

1. Connect 3/8" (9,5mm) ID

plastic food grade tubing

to a bag adapter. Secure

with hose clamps.

2. Slide the hose clip over

the free end of the tubing.

Attach the free end of the

tubing to a manifold

adapter. Secure with a

large hose clamp.

3. Push the manifold

adapter with spring and

valve into the left port

(nearest the manifold

outlet) of the mix inlet

manifold and secure with

retaining clip. (See Figure

2-4).

4. If using two mix bags,

repeat steps 1 to 3 for the

middle port.

5. Install a manifold plug into

each empty inlet and

secure with a retaining

clip.

Manifold

Adapter

6. Place the mix bag(s) into the mix container.

7. Connect the bag adapter attached to the left side

of the manifold (closest to the mix outlet) to the mix

bag in the back of the mix container.

C. MIX LOW LEVEL INDICATOR ADJUSTMENT

The sensitivity of the “Mix Low” indication can be adjusted

to operator preference. If more advanced notice of low mix

is required, loosen the black adjustment knobs located on

the sensor brackets at the back of the machine cabinet and

slide the bracket upwards. If the “Mix Low” message (right

side) or flashing light (left side) appears while there is still

sufficient mix in the container, slide the bracket downward.

Be sure to tighten the adjustment knobs after properly

positioning the sensor.

Mix Inlet

Retaining

Clip

Manifold

Plug

Bag Adapter

Manifold

Figure 2-4 Bag Connection System (Optional)

6

SECTION 3

INITIAL SET-UP AND OPERATION

3.1 OPERATOR’S SAFETY PRECAUTIONS

SAFE OPERATION IS NO ACCIDENT; observe these

rules:

A. Know the machine. Read and understand the

Operating Instructions.

B. Notice all warning labels on the machine.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry that could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect power for maintenance. Never attempt

to repair or perform maintenance on the machine

until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the machine if unusual or excessive

noise or vibration occurs.

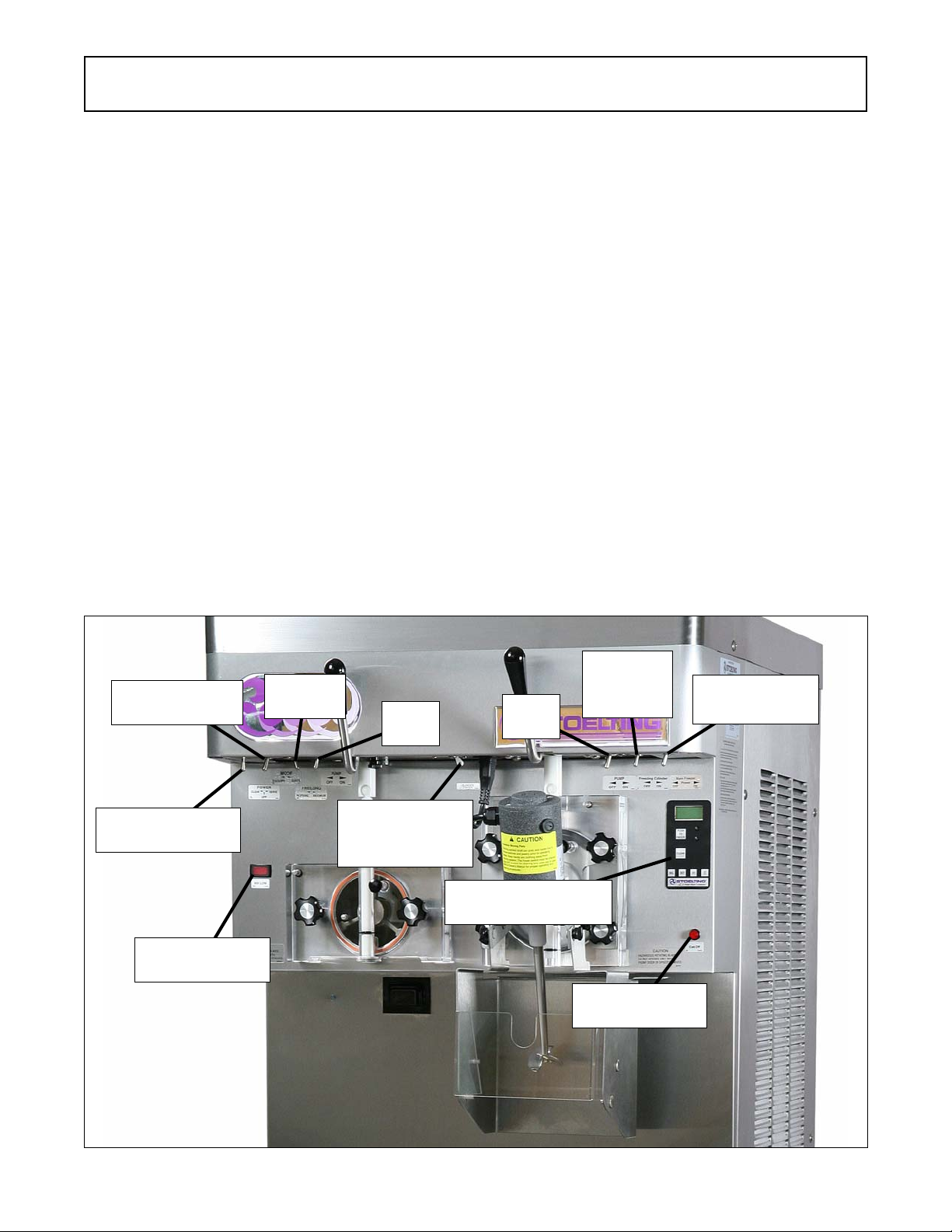

3.2 OPERATING CONTROLS AND

INDICATORS

Before operating the machine, it is required that the

operator know the function of each operating control. Refer

to Figure 3-1 for the location of the operating controls on the

machine. For the information regarding error codes displayed on the control panel, refer to the troubleshooting

section of this manual.

A. Pump Switch (Both Sides)

The pump motor switch is the toggle switch located under

the header panel. When the switch is placed in the OFF

position, the pump will not run. When the switch is placed

in the ON position, the pump will run until the preset

pressure is reached. It then cycles on and off as product is

drawn to maintain that pressure.

B. Spigot Switch (Both Sides)

The spigot switch is mounted to the spigot cam assembly

behind the header panel. When the spigot is opened to

dispense product, the spigot switch opens and the "Serve

Mode" begins.

Standby/Serve

Switch

Clean/Off/Serve

Switch

Mix Low

Indicator Light

Freezing

Switch

Pump

Off/On

Blender Power

Off/On Circuit

Breaker

Pump

Off/On

IntelliTec Control

(See Figure 3-2)

Freezing

Cylinder

Off/On

Cab Off

Indicator Light

Main Freezer

Power Off/On

Figure 3-1 SU444 Freezer Controls

7

Loading...

Loading...