Page 1

Model SO218 / SO318

SERVICE MANUAL

Manual No. 513573 Rev.3

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1. INTRODUCTION

1.1 Remote Possibilities ...................................................................................................................... 1

1.2 Features ........................................................................................................................................ 1

1.3 Dispenser Specifications................................................................................................................ 2

2. INSTALLATION INSTRUCTIONS

2.1 Safety Precautions........................................................................................................ ................. 3

2.2 Shipment and Transit ..................................................................................................................... 3

2.3 Freezer Installation...................................................................................................... ................... 3

2.4 Installing Permanent Wiring............................................................................................................ 4

3. INITIAL SET-UP AND OPERATION

3.1 Operator's Safety Precautions........................................................................................................ 5

3.2 Operating Controls and Indicators .................................................................................................. 5

3.3 Disassembly of Freezer Parts ........................................................................................................ 5

3.4 Cleaning the Freezer Parts............................................................................................................. 6

3.5 Sanitize Freezer and Freezer Parts................................................................................................ 6

3.6 Assembly of Freezer ...................................................................................................................... 6

3.7 Sanitizing ....................................................................................................................................... 7

3.8 Initial Freeze Down and Operation .................................................................................................. 8

3.9 Removing Product .......................................................................................................................... 8

3.10 General Operation Information ....................................................................................................... 9

4. PREVENTATIVE MAINTENANCE

4.1 Routine Cleaning ............................................................................................................................ 11

4.2 Preventative Maintenance............................................................................................................... 11

4.3 Extended Storage .......................................................................................................................... 11

4.4 Consistency Adjustment ................................................................................................................ 11

5. REFRIGERATION SYSTEM

5.1 Refrigeration System...................................................................................................................... 13

5.2 Compressor ................................................................................................................................... 13

5.3 Condenser...................................................................................................................................... 14

5.4 Evaporator...................................................................................................................................... 14

5.5 Hopper ........................................................................................................................................... 16

5.6 Capillary Tube ................................................................................................................................ 18

6. ELECTRICAL

6.1 Electrical........................................................................................................................................ 19

6.2 Front Electrical Box ....................................................................................................................... 19

6.3 Compressor Electrical Box............................................................................................................. 21

6.4 Major Component Replacement ..................................................................................................... 21

7. TROUBLESHOOTING .......................................................................................................................... 27

8. REPLACEMENT PARTS INFORMATION

8.1 Ordering Parts................................................................................................................................ 29

9. REFERENCE DRAWINGS .................................................................................................................... 31

10. ACCESSORIES

10.1 Fill-o-matic II ................................................................................................................................ 45

10.2 Fill-o-matic III................................................................................................................................ 49

11. ADDENDUM .......................................................................................................................................... 53

Page 6

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

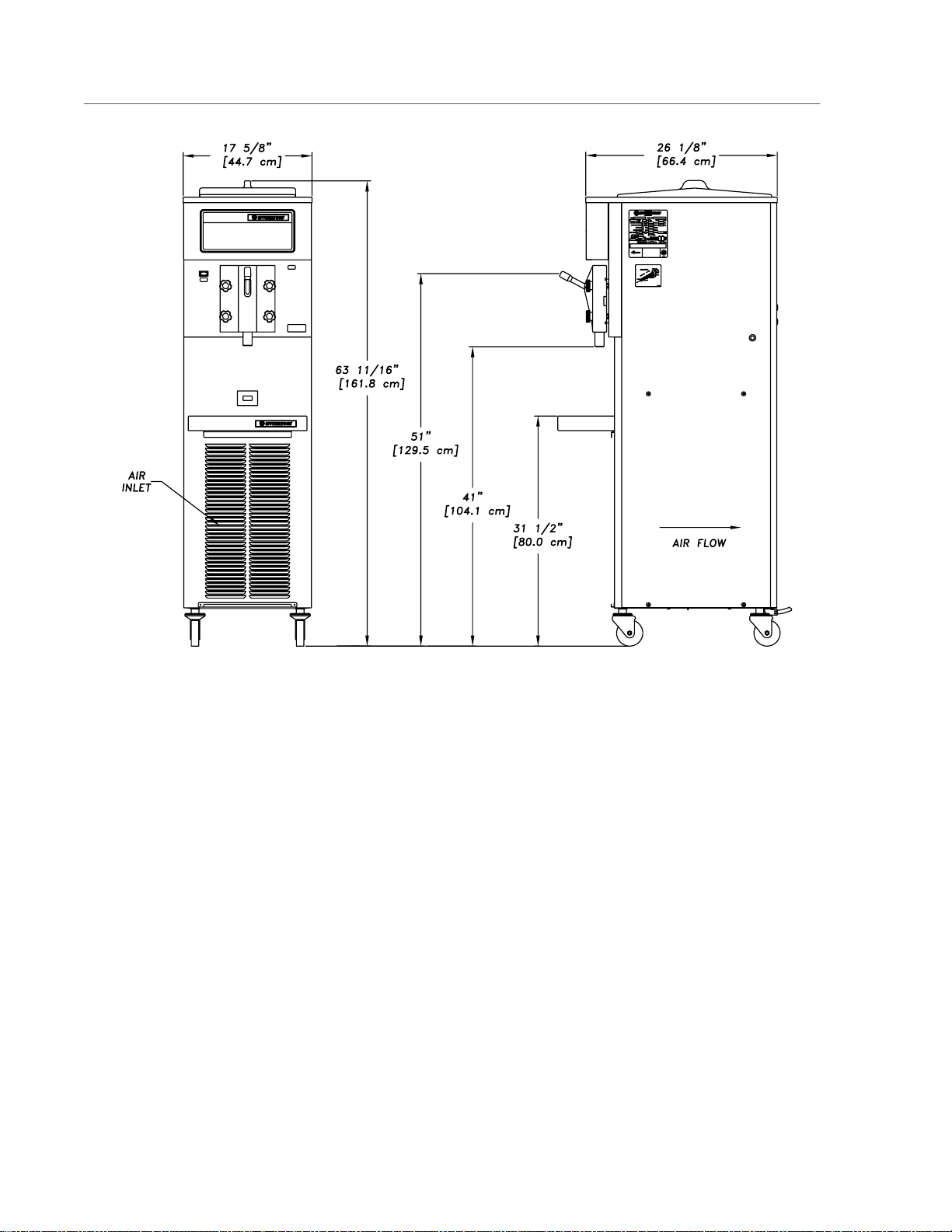

1 Model SO218/318.................................................................................................. 1

2 Dispenser Specifications ....................................................................................... 2

3 Leveling Unit .......................................................................................................... 3

4 Controls................................................................................................................. 5

5 Disassembling Freezer .......................................................................................... 6

6 Front Door and Auger Assembly............................................................................ 6

7 Rear Seal Assembly.............................................................................................. 6

8 Retainer Clip .......................................................................................................... 7

9 Consistency Control Knob ..................................................................................... 8

10 Nameplates ...........................................................................................................13

11 Compressor Terminal Cover Removal .....................................................................13

12 Compressor Connections.......................................................................................13

13 Ohm Meter Connection..........................................................................................14

14 Condenser .............................................................................................................14

15 Access Ports .........................................................................................................15

16 TXV........................................................................................................................15

17 Heat Sink ..............................................................................................................15

18 Drier.......................................................................................................................16

19 EPR & Access Port...............................................................................................16

20 EPR Valve Adjustment ..........................................................................................17

21 EPR Heat Sink ......................................................................................................17

22 Filter Drier..............................................................................................................18

23 Drier Cap. Tube Assembly.....................................................................................18

24 Electrical Panel .....................................................................................................19

25 Switch Removal ..................................................................................................... 19

26 Light Bulb Replacement.........................................................................................19

27 Safety Switch ........................................................................................................20

28 Liquid Level Control................................................................................................20

29 Pump Relay...........................................................................................................20

30 Torque Switch........................................................................................................21

31 Compressor Contactor...........................................................................................21

32 Fan Motor..............................................................................................................21

33 Condenser .............................................................................................................22

34 Electrical Wires .....................................................................................................22

35 Compressor ...........................................................................................................23

36 Torque Spring ........................................................................................................23

37 Torque Switch Bracket...........................................................................................24

38 Belt Tensioner........................................................................................................24

39 Bearing Assembly .................................................................................................24

Page 7

SECTION 1

INTRODUCTION

1.1 REMOTE POSSIBILITIES

The Stoelting Optima delivers frozen drink profits by the pitcher. The Model SO218/318 is a high-volume

producer of ready-to-serve frozen cocktails or frozen neutral base for those special drink recipes. From an

extra-small space, the Optima’s compact design and high capacity output will give you extra-large profits.

1.2 FEA TURES

High Capacity

- 15-18 gallons per hour output

- Thick, stackable slush for

post-mixing

- Or, ready-to-serve pre-mixed

products

High Efficiency Evaporator/

Auger

- Stainless steel construction

- Long life auger blades

- Quiet, smooth operation

- 8 qt. freezing cylinder capacity

Figure 1. Model SO218/318

Consistency Control

- Adjustable for thick or thin

products

- Sensitive to product demand

- 24 volt control circuits

1

Dispensing Head Door

- ”No-Freeze” design prevents

blockages

- Fast dispense for quick fill of

pitchers

- Controlled dispense for drinks

by the glass

- Convenient pull-type handle

- Attractive, clear, see-thru

design

- Visible, moving product for

merchandising appeal

Page 8

1.3 DISPENSER SPECIFICATIONS

Figure 2. Dispenser Specifications

Electrical Refrigeration Crated Dimensions Dimensions

208/230/60/1 HFC-404A environmentally- Width: 25" (63.5cm) Width: 17-5/8"(44.7cm)

20 amp circuit & plug friendly refrigerant Depth: 51" (129.5cm) Depth: 26-1/8"(66.4cm)

12 running amps SO318 Air-cooled or water- Height: 66" (167.6cm) Height: 63-1 1/16"(161.8cm)

cooled, self contained Weight: 410lbs.(186kg) w/casters

SO218 Air-cooled or water- Weight: 315lbs.(142.9kg)

cooled, self contained

2

Page 9

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the freezer. The

labels have been put there to help maintain a safe

working environment. The labels have been designed to

withstand washing and cleaning. All labels must remain

legible for the life of the freezer. Labels should be

checked periodically to be sure they can be recognized

as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, LLC

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

Figure 3. Leveling Unit

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and inspected at the factory. Upon arrival at the final destination, the complete freezer must be checked for any

damage which may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED. Do not pay the

freight bill until the freezer has been checked for damage. Have the carrier note any visible damage on the

freight bill. If concealed damage and/or shortage is found

later, advise the carrier within 10 days and request

inspection. The customer must place claim for damages

and/or shortages in shipment with the carrier. Stoelting,

Inc. cannot make any claims against the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

A. Uncrate the freezer.

B. The freezer must be placed in a solid level position. To

level adjust casters.

C. The freezer is equipped with an air cooled condenser

and requires correct ventilation; the front is the intake

and the back is the discharge. Both front and back

require 3" clearance for proper operation.

D. Place all switches in the OFF position.

3

Page 10

E. Connect the power cord. The plug is designed for 208/

230 volt/20 amp duty. The unit must be connected to

a properly grounded receptacle. The electrical cord

furnished as part of the freezer has a three prong

grounding type plug. The use of an extension cord is

not recommended. If one must be used, use one with

a size 12 gauge or heavier with a ground wire. Do not

use an adaptor to get around grounding requirements.

CAUTION

DO NOT ALTER OR DEFORM PLUG IN ANY WAY!

F. Install the drip tray, cover and other miscellaneous

parts on the freezer.

2.4 INSTALLING PERMANENT WIRING

If permanent wiring is required by local codes, the following procedure must be performed.

WARNING

DISCONNECT FREEZER FROM THE SOURCE

OF ELECTRICAL SUPPL Y BEFORE SERVICING.

A. Remove the right side panel and electrical box cover

to gain access to the power cord connection.

B. Disconnect the black and white wires from the termi-

nal block (L1 and L2). Disconnect the green ground

wire from the grounding screw.

C. Remove the strain relief connector from the bottom of

the freezer base.Remove the power cord.

D. Install permanent wiring according to local code.

E. Connect black wire to L1 on the terminal block.

Connect the white wire to L2 on the terminal block.

Connect the green or yellow and green striped

ground wire to the grounding screw.

F. Replace all panels.

4

Page 11

SECTION 3

INITIAL SETUP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

SAFE OPERA TION IS NO ACCIDENT; Observe these

rules:

A. Know the freezer. Read and understand the

Operating Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

F. Disconnect electrical cord for maintenance.

Never attempt to repair or perform maintenance on

the freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating condi

tions. Never operate the freezer if unusual or excessive noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the

operator know the function of each operating control.

Refer to Figure 4 for the location of the operating

controls on the freezer.

C. Mix Low Light

The Mix Low light will illuminate when you are low on

mix.

CAUTION

DO NOT OPERA TE FREEZER WHEN THE LOW

MIX LIGHT IS ILLUMINATED OR DAMAGE TO

THE FREEZER COULD RESULT.

D. Front Door Interlock Switch

When the front door is removed the freezer will not

run. When the front door is installed a stanless steel

peg will close the switch and the freeezer will run.

E. High Pressure Cutout Switch (water cooled only)

The high pressure cutout switch (high limit control) is

located on the lower left side. When the switch is

tripped nothing will run. Push to reset.

Pump Off/On

Switch

ËË

Ë

ËË

ÇÇ

Ç

ÇÇ

Mix Low

Light

Front Door Interlock Switch

ÇÇ

Ç

ÇÇ

ÇÇ

Ç

ÇÇ

Clean/Off/Serve

Switch

A. Pump OFF/ON Switch (Model SO318 only)

The pump OFF/ON Switch is a two position switch.

In the OFF position the pump will not run. In the ON

position the pump will run until the proper liquid level

is reached, then stop. If the hopper does not fill

completely , place the switch in the OFF position,

then back to ON to continue filling.

WARNING

THE CLEAN/OFF/SERVE SWITCH MUST BE PLACED

IN THE OFF POSITION WHEN DISASSEMBLING FOR

CLEANING OR SERVICING. THE FREEZER MUST BE

DISCONNECTED FROM ELECTRICAL SUPPLY BEFORE REMOVING ANY ACCESS P ANEL.

B. CLEAN/OFF/SERVE Switch

The CLEAN/OFF/SERVE switch is a three position

toggle and refrigeration switch used to control the

operation of the agitator. When the switch is placed

in the CLEAN position, the agitator will rotate.

When the switch is placed in the OFFposition,

nothing will operate. When the switch in placed in

the SERVE position, the agitator and refrigeration

system will run until proper consistency is reached

then stop.

Figure 4. Controls

3.3 DISASSEMBL Y OF FREEZER P ARTS

CAUTION

PLACE THE CLEAN/OFF/SERVE SWITCH IN THE

OFF POSITION BEFORE DISASSEMBLING FOR

CLEANING OR SERVICING.

Inspection for worn or broken parts should be made at

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced

to ensure safety to both the operator and the customer

and to maintain good freezer performance and a quality

product. Frequency of cleaning must comply with the

local health regulations.

T o disassemble the freezer , refer to the following steps:

A. Disconnect hose from hopper cover (Model SO318

only).

B. Remove hopper cover.

5

Page 12

C. Remove retaining clip and adaptor (Model SO318

only).

D. Remove the front door by turning off the knobs, and

then pull the front door off the studs.

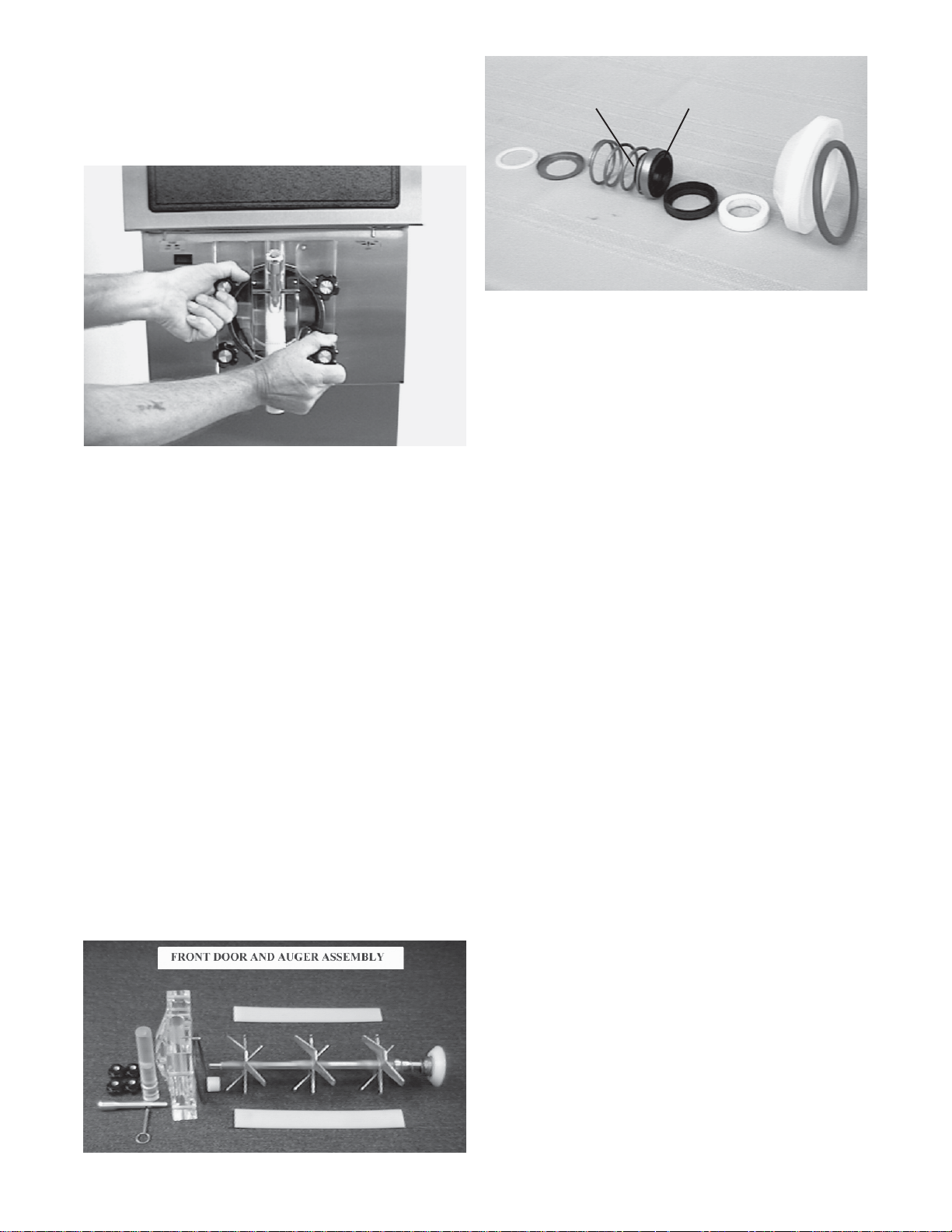

Figure 5. Disassembling Freezer

E. Remove the spigot body from the front door bypu lling

the retaining pin out of the spigot handle. Push the

spigot body thru the bottom of the front door.

SOFT RUBBER

SURFACE

Figure 7. Rear Seal Assembly

3.4 CLEANING THE FREEZER PARTS

Place all loose parts in a pan or container and take to

the wash sink for cleaning. To clean freezer parts refer

to the following steps:

A. Place all parts in warm mild detergent water and

clean with brushes provided. Rinse all parts with

clean hot water.

DO NOT DAMAGE PARTS BY DROPPING OR

ROUGH HANDLING.

HARD CARBON

SURFACE

CAUTION

F. Remove the agitator assembly from the freezer. Pull

the agitator assembly out of the freezer barrel.

G. Keep the rear of the agitator assembly tipped up

once it is clear of the freezer barrel to avoid dropping

rear seal.

H. Remove the front agitator support bearing and the

two agitator blades.

I. Remove the rear seal assembly .

J. Wipe socket lubricant from the drive end (rear) of the

agitator with a cloth or paper towel.

K. Remove all “O” Rings.

W ARNING

DO NOT USE ANY TYPE OF SHARP OBJECT TO

REMOVE THE “O” RINGS.

B. Wash the freezer barrel with warm detergent water

and brushes provided.

C. The exterior should be kept clean at all times to

perserve the lustre of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth or

sponge to apply the cleaner.

D. Remove the drip tray insert and drain tray. Clean with

a soap solution. Rinse with clean hot water.

3.5 SANITIZE FREEZER AND FREEZER P ARTS

A. Use a sanitizer mixed according to manufacturer’s

instructions to provide a 100 parts per million

strength solution. Mix sanitizer in quantities of no

less than 2 gallons (7.5 liters) of 120°F water. Allow

the sanitizer to contact the surfaces to be sanitized

for 5 minutes. Any sanitizer must be used only in

accordance with the manufacturer’s instructions.

B. Place all parts in the sanitizing solution, then remove

and let air dry .

Figure 6. Front Door and Auger Assembly

3.6 ASSEMBL Y OF FREEZER

T o assemble the freezer part s, refer to the following

steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

6

Page 13

NOTE

The United Sates Department of Agriculture and the

Food and Drug Administration require that lubricants

used on food processing equipment be certified for

this use. Use lubricants only in accordance with

the manufacturer’s instructions.

A. Assemble spigot “O” Rings onto parts dry , without

lubrication. Then apply a thin film of sanitary

lubrication to exposed surfaces of the “O” Rings.

K. Install hopper cover.

L. Connect mix hose to hopper cover (Model SO318

only).

3.7 SANITIZING

Sanitizing must be done after the freezer is clean and

just before filling with mix. Sanitizing the night before

is not effective. However, you should always clean the

freezer and parts after using it.

B. Assemble the rear seal assembly onto the agitator.

Be sure the “O” Ring is in place before installing

the rear seal. Do not lubricate.

C. Lubricate the agitator drive (rear) with a small

amount of white socket lubricant. A small container

of socket lubricant is shipped with the freezer.

D. Install the two plastic agitator blades onto the

agitator. Install front agit ator bearing to the door.

E. Push the auger into the freezer barrel and rotate

slowly until the agitator engages the drive socket.

F. Install the spigot body with “O” Rings into the front

door from the bottom. Push straight up until the

spigot is in place. Place the spigot handle into the

spigot and insert the retainer pin.

G. Install door “O” Ring after lubricating.

H. Install the front door on the freezer.

I. Install the knobs on the freezer studs.

CAUTION

FINGER TIGHTEN THE KNOBS EVENL Y . DO NOT

OVER-TIGHTEN KNOBS.

WARNING

THE UNITED ST ATES DEP ARTMENT OF AGRICUL TURE AND FOOD AND DRUG ADMINISTRATION REQUIRE THAT ALL CLEANING AND SANITIZING SOLUTIONS USED WITH FOOD PROCESSING EQUIPMENT BE CERTIFIED FOR THIS

USE. USE “STERA-SHEEN” OR EQUIVALENT.

When sanitizing the freezer, refer to local sanitary

regulations for applicable codes and recommended

sanitizing products and procedures. The frequency of

sanitizing must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions

to provide a 100 parts per million strength solution. Mix

sanitizer in quantities of no less than 2 gallons (7.5

liters) of 120°F water. Allow sanitizer to contact the

surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the

manufacturer’s instructions.

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning a

soft serve freezer. We therefore include a sample

with each new freezer. For further information read

the directions on the packet. Other products may

be as effective.

Look for the proper seal between the freezer barrel door,

“O” Ring, and front door.

J. Install hose adaptor onto hopper cover and secure

with retainer clip (SO318 only). Figure 8.

Figure 8. Retainer Clip

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MA Y CAUSE CORROSION OF ST AINLESS STEEL P ARTS.

In general, sanitizing may be conducted as follows:

A. Prepare 4 gallons (15 liters) of sanitizing solution

following manufacturer’s instructions, then pour into

hopper (pump thru auto fill, SO318 only).

B. Place the CLEAN/OFF/SERVE switch in the CLEAN

position. Check for leaks around the front door seal.

C. After five minutes, open spigot to drain sanitizing

solution. When solution has drained, place the

CLEAN/OFF/SERVE switch in the OFF position.

Allow the freezer barrel to drain completely .

7

Page 14

3.8 INITIAL FREEZE DOWN AND OPERA TION

This section covers the recommended operating

procedures to be followed for the safe operation of the

freezer.

A. Sanitize just prior to use.

B. Place the CLEAN/OFF/SERVE switch in the OFF

position.

D. Place the CLEAN/OFF/SERVE switch in the

SERVE position. The product will be ready to serve

in about 15 minutes.

3.9 REMOVING PRODUCT

Before disassembly, all product must be removed.

A. Open spigot and completely drain freezer.

C. With the spigot open, pour one cup of mix into the

hopper. Allow approximately 8 oz. of sanitizing

solution and mix to drain out. Close the spigot and

fill the hopper with mix.

B. Prepare not less than 3 gallons of warm detergent

water and pour into hopper (pump thru auto fill

SO318 only).

C. Use a brush to clean the hopper then completely

drain freezer.

ÊÊ

Ê

ÊÊ

Remove plug to

access consistency

adjustment screw

Figure 9. Consistency Control

8

Page 15

3.10 GENERAL OPERA TION INFORMA TION

The SO218/318 is a cocktail/slush freezer . It is available in 208-230 volt, either air-cooled or water-cooled.

The air-cooled version has front-to-back airflow requiring three inches of air space in the front and back for

proper refrigeration. This unit is not supplied with a pump, however, S toelting does offer the Fill-O-Matic II

(electric) and Fill-O-Matic III (gas) pumps FOR THE SO318. This freezer is intended for use with non-dairy

products only and will produce 15-18 GPH.

1. Filling

T o fill the freezer , pour mix into hopper until full. To fill freezers with the optional Fill-O-Matic pump, connect

the pump and turn the fill switch on. This will open the solenoid valve and the freezer will begin to fill. The

liquid level control circuit is designed with a fill timer. This timer is designed to shut the compressor off if

the top level probe is not satisfied before the timer expires. If the top level probe is not satisfied before the

timer times out, it locks the compressor out and freezing will not occur, if this happens, turn the fill switch

off and then back on, this will reset the timer .

2. Operation

Once the freezer is full of mix, turn the clean-off-serve switch to the “serve” position. The drive motor will

start immediately . The compressor utilizes a 10 second delay-on-make / delay-on-break timer therefore,

the compressor will start 10 seconds later. The compressor will continue to run until the drive motor torque

switch is satisfied, then after a 10 second delay stop. The drive motor runs continuously in the “serve” or

“clean” switch positions. There is no night mode or standby mode. If product is left in the freezer overnight

we recommend to simply turn the freezer off. Do not run the freezer in “clean” overnight. Freeze down time

will typically be 6-10 minutes depending on the type of product used and the starting product temperature.

3. Pump Operation

When the mix level in the hopper drops below the bottom level probe, the solenoid valve opens and the

pump begins to fill until the top level probe is satisfied. When satisfied, the solenoid valve closes, and

pump will continue to run until shut off pressure is reached. The electric pump will run until the pressure

reaches the cut-out pressure of the pump. A gas pump will continue to run until the pressure in the mix line

equals the gas pressure of the pump. If you wish to use the product in the hopper prior to cleaning, turn the

pump off and turn the freezer fill switch off. This will disable the fill timer and allow the compressor to

continue to run. Be cautioned that once the hopper is empty , the barrel could freeze up. Only run the

freezer until the hopper is empty or damage may occur.

4. Fill Timer Operation

The timer has ten dip switches, all switches placed in the “on” position are added together to make up the

total time delay. This freezer leaves the factory with 64, 128 and 256 in the “on” position, this is a total of

448 seconds. The preset time should be enough to fill the hopper up to the top level probe. Fill time may be

dependent on what style pump is employed. The purpose of the timer is to disable the compressorif the

mix supply runs out. When the timer expires, the mix low light will illuminate. If the mix low light is

illuminated, the compressor is locked out of the electrical circuit and will not run. It may be necessary to

change the timer settings to more closely match the pumping capacity of your pump.

9

Page 16

10

Page 17

SECTION 4

PREVENTIVE MAINTENANCE

4.1 ROUTINE CLEANING

T o remove spilled or dried mix from the freezer exterior ,

simply wash in the direction of the finish with warm

soapy water and wipe dry . Do not use highly abrasive

materials as they will mar the finish.

4.2PREVENT ATIVE MAINTENANCE

It is recommended that a maintenance schedule be

followed to keep the freezer clean and operating properly.

W ARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON FREEZER UNTIL THE MAIN

ELECTRICAL POWER HAS BEEN DISCONNECTED.

A. Daily

1. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth or

sponge to apply the cleaner.

B. Weekly

2. If the condenser is dirty, using compressed air or

CO2 tank, blow out the dirt from the fan side of the

condenser.

3. An alternative method of cleaning the condenser is to

use a condenser brush and vacuum.

NOTE

If the condenser is not kept clean, loss of refrigeration efficiency will result, causing extended run time

or soft product consistency .

4.3 EXTENDED STORAGE

Refer to the following steps for storage of the freezer

over any long period of shutdown time:

A. Turn CLEAN/OFF/SERVE switch to the OFF

position.

B. Disconnect (unplug) from the electrical supply

source.

C. Clean thoroughly with a warm detergent all parts that

come in contact with the mix. Rinse in clear water

and dry all parts. Do not sanitize.

1. Check “O” Rings and rear seal for excessive wear

and replace if necessary.

2. Remove the drip tray and insert. Clean the drip

tray and insert and front of the freezer with a soap

solution.

C. Monthly

CAUTION

THE FREEZER HAS AN AIR COOLED CONDENSER AND MUST HA VE PROPER AIR CIRCULA TION. FAILURE TO CLEAN THE CONDENSER

ON A REGULAR BASIS MAY RESULT IN SERIOUS FREEZER DAMAGE AND COULD VOID

FREEZER WARRANTY .

1. Visually inspect the condenser for dirt by shining a

light through the coil from the fan side of the condenser.

NOTE

Do not let the cleaning or sanitizing solution stand

in the hopper or in the freezer barrel during the shutdown period.

D. Remove, disassemble, and clean the front door, and

agitator parts. Place the agitator blades and the front

agitator support bearing in a plastic bag with a moist

paper towel to prevent them from becoming brittle.

4.4 CONSISTENCY ADJUSTMENT

The consistency adjustment knob is located behind the

right side panel near the back. Remove black plug to

access. T o adjust use a straight bladed screwdriver .

Turn clockwise for a thicker product and counterclockwise for a thinner product. Allow 15-30 minutes for the

product to change consistency .

11

Page 18

12

Page 19

SECTION 5

REFRIGERATION SYSTEM

5.1 REFRIGERATION SYSTEM

The refrigeration system is a dual purpose system. The

system is designed to operate the hopper and the evaporator simultaneously at different temperatures. The system is designed for efficient use with R404A as the

refrigerant. The proper charges are indicated on the nameplate. Figure 10.

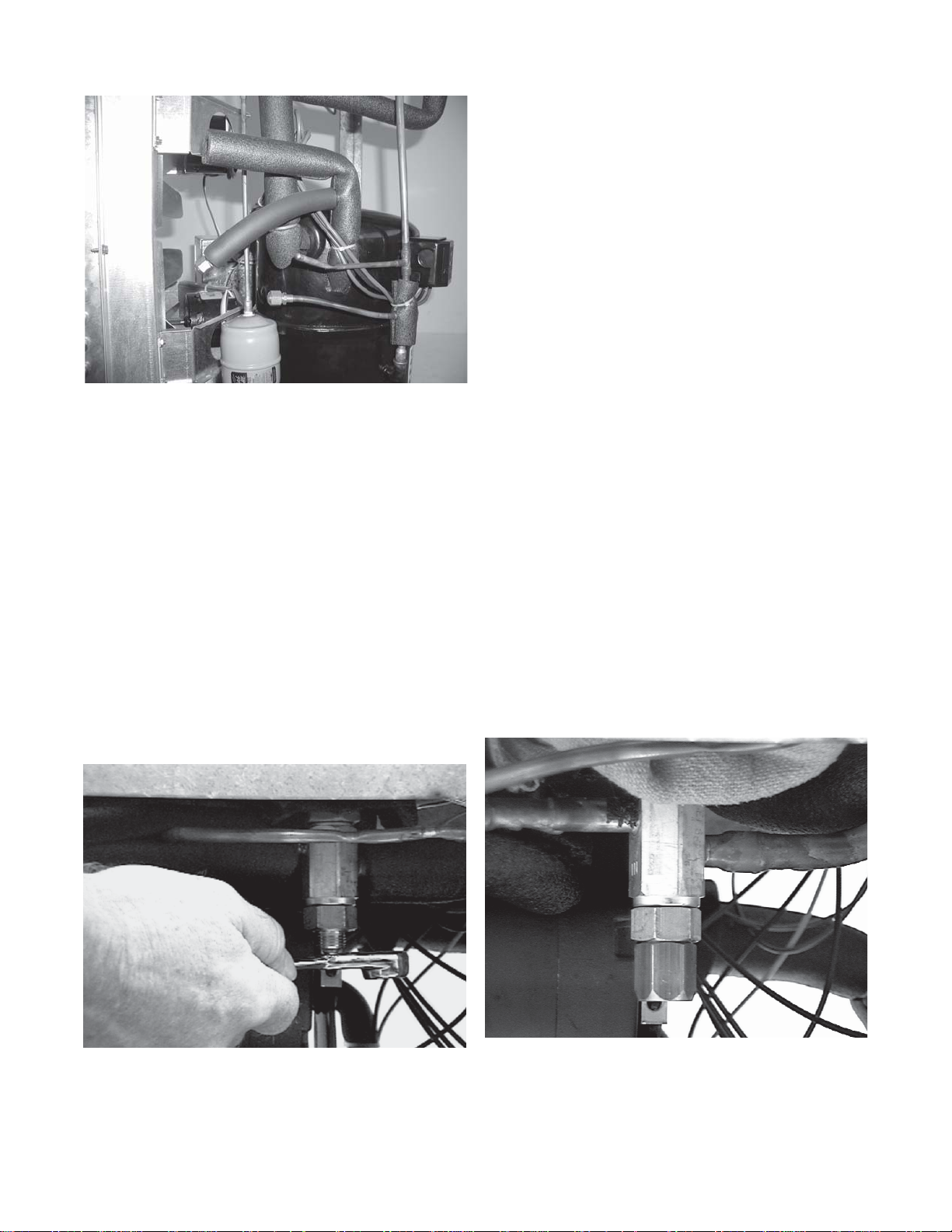

Figure 11. Compressor Terminal Cover Removal

Figure 10. Nameplate

5.2 COMPRESSOR

The compressor is designed specifically for use with

R404A.

A. Winding Test

T o test the compressor motor windings for possible

problems perform the following steps:

WARNING

DISCONNECT FREEZER FROM ELECTRICAL SUPPL Y

SOURCE BEFORE SERVICING.

1. Remove the retaining screws from the right side

panel and slide the side panel out and down.

2. Remove the compressor terminal cover by inserting a standard screw driver between the terminal

cover and retaining frame, pry out side then hold

with your hand while prying the other side then

remove cover. (Fig.11)

Figure 12. Compressor Connections

NOTE

The following values are for T ecumseh model

CS14K6E-PFV-235 with the compressor at or about

room temperature. For other models or brands consult the manufacturer's service data manual.

3. Connect ohmmeter to terminal C and R. Resistance through the run winding should be

1.10 ohms with the ohmmeter set at times one.

(Fig. 13)

13

Page 20

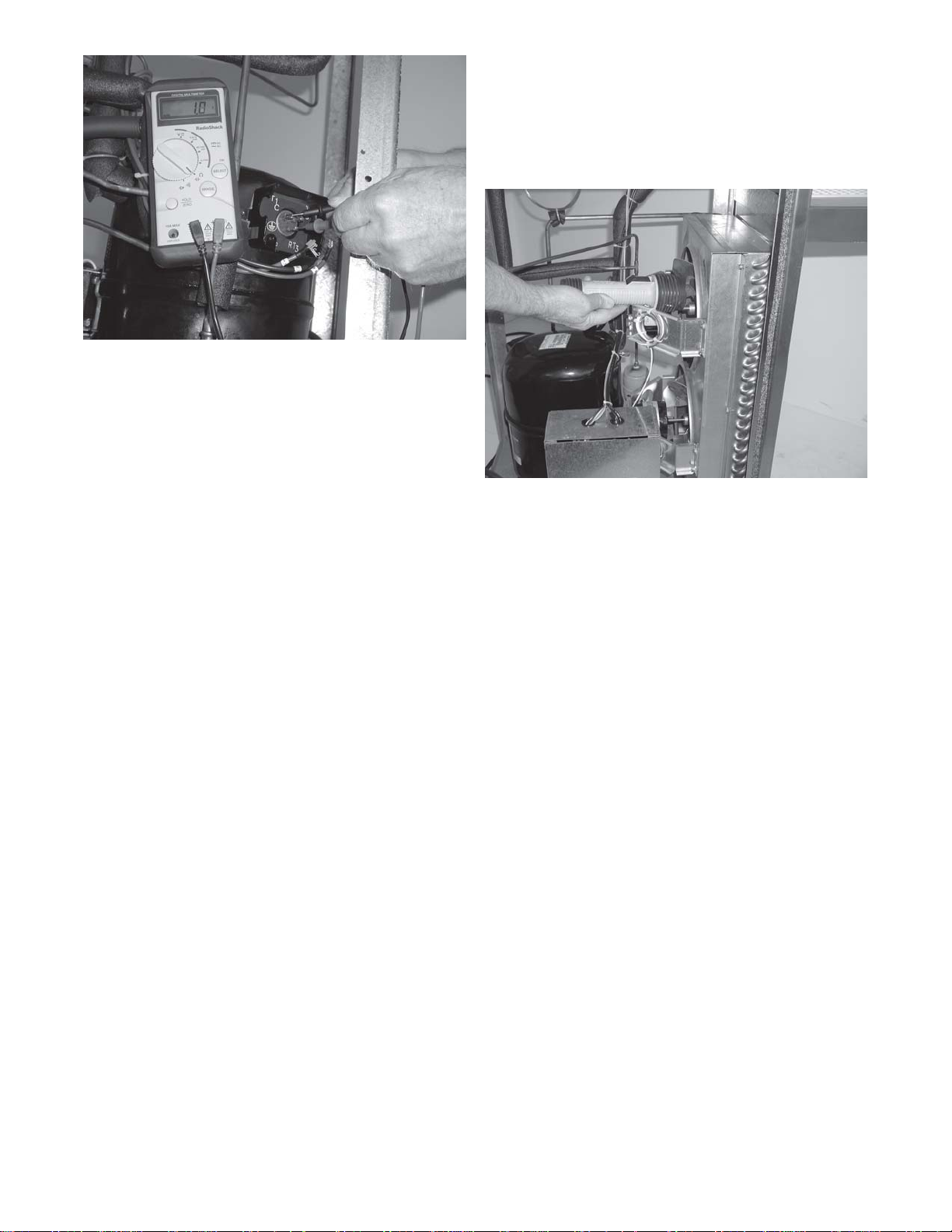

Figure 13. Ohm Meter Connection

4. Connect ohmmeter to terminal C and S. Resistance through the start winding should be 5.94

ohms with the ohmmeter set at times one.

5. To check if windings are shorted to ground connect one ohmmeter lead to a bare metal part on

the compressor such as any copper line leading

to or from the compressor and checking terminals

C, R, and S.

NOTE

The compressor is equipped with an internal overload protector. If the compressor trips the overload

check for high amperage draw.

2. Remove the retaining screws from the the right

side and back panel and slide the panels out

and down.

3. Visually inspect the condenser for dirt by shining

a light through the coil from the back (inside) of the

condenser. Figure 14.

Figure 14. Condenser

4. If the condenser is dirty, place a wet towel over the

front (outside) of the condenser.

5. Using compressed air or CO2 tank, blow out the

dirt from the back (inside) of the condenser. Most

of the dirt will cling to the wet towel.

5.3 CONDENSER

The air cooled condenser is a copper tube and aluminum

fin type. Condensing is totally dependent on air flow. A

plugged condenser or restrictions in the louvered grill will

restrict air flow. This will lower the capacity of the system

and damage the compressor.

The condenser must be kept clean from dirt and grease.

The freezer must have a minimum clearance of 6" at the

left and right side of the unit for free flow of air. Make sure

the freezer is not pulling over 100° F. of air in from other

equipment in the area.

The condenser filter and condenser require periodic cleaning. To clean refer to the following procedures:

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

1. Remove the condenser filter by pulling straight

out to the front. Then visually inspect for dirt. If the

filter is dirty, shake or brush excess dirt off the

filter and wash in warm soapy water. Once the

filter is clean rinse thoroughly in warm, clear water

and shake dry, taking care not to damage the

filter in any way.

An alternative method of cleaning the condenser is to use

a condenser brush and vacuum.

NOTE

If the condenser is not kept clean, loss of refrigeration efficiency will result, causing extended run time

or soft product consistency .

5.4 EVAPORATOR

An TXV (thermostatic expansion valve) is used to meter the

refrigerant to the evaporator. The self regulating TXV is

preset at the factory for approximately 28 PSIG at 75°F

ambient temperature.

A. TXV Adjustments

To determine whether or not the TXV is in need of adjustment, perform the following procedure:

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

1. Remove the retaining screws from the bottom of

the left and right side panels and slide the panels

out and down.

14

Page 21

2. Remove the cap from the low side access port

and install a 0 - 100 PSIG gauge. Figure 15

Figure 15. Access Ports

3. Plug the freezer in, start the refrigeration cycle and

read the pressure.

7. Once the 28 PSIG reading is obtained, replace the

cap on the TXV, remove the pressure gauge and

replace the low side schrader valve cap.

B. TXV Removal

CAUTION

IF THE TXV IS REPLACED THE HEA T SINK (WET

CLOTH) MUST BE USED TO PREVENT DAMAGE

TO THE V AL VE.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE OF SUPPL Y BEFORE SERVICING.

1. Assuming the left side, right side and back panels

are removed, perform the following procedures for

removing the TXV.

2. Remove the bulb from the suction line exiting from

the evaporator.

4. The proper gauge reading should be approximately 28 PSIG at 75°F. (21.1°C) Ambient temperature at the end of pull down. If the readings are

not within these parameters continue with the

following steps:

NOTE

Before performing the following procedures be absolutely certain it is necessary to adjust the TXV

and the freezer is full of cold mix.

5. Remove the cap on the TXV and using a service

wrench, turn the valve stem 1/4 (90°) turn counter

clockwise for more cooling or clockwise for less

cooling. Figure 16.

3. Recover refrigerant charge and leave a port open

to prevent pressure buildup during TXV removal.

4. Remove any insulation from the TXV and the

immediate surrounding lines.

5. Remove or push back any foam insulation from

surrounding lines.

6. Apply a heat sink (wet cloth) to the valve dome.

Figure 17.

7. Unsweat the suction line and liquid line from the

TXV and remove the TXV with heat sink.

Figure 16. TXV

6. Should the readings not reach 28 PSIG repeat

step #7 until the correct reading is obtained.

Figure 17. Heat Sink

15

Page 22

C. TXV Replacement

To replace the TXV perform the following procedures:

CAUTION

WHEN REPLACING THE TXV A HEAT SINK (WET

CLOTH) MUST BE USED TO PREVENT DAMAGE

TO THE V AL VE.

1. Position the TXV with the heat sink so the liquid

and suction line correspond with the proper valve

ports. Figure 17.

2. With an open port braze the liquid line and suction

line to the TXV using the appropriate brazing

material.

3. Remove the heat sink from the TXV.

10.Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to 500

microns of mercury.

11.Recharge the system to nameplate specifications

and leak test.

5.5 HOPPER

A parallel refrigeration circuit feeds the hopper. A capillary

tube is used to meter the refrigerant to the hopper. An

E.P.R. valve (Evaporator Pressure Regulating) is used to

control the refrigerant at the outlet. The E.P.R. controls the

hopper pressure so, during heavy dispensing periods,

hopper temperatures will not drop and freeze the mix in the

hopper. The adjustable E.P.R. valve is preset at the

factory. If the hopper temperature is too cold or too warm,

an E.P.R. valve adjustment may be necessary.

4. Replace foam insulation to the surrounding lines.

5. Replace any insulation to the TXV and immediate

surrounding areas.

6. Install bulb on suction line exiting the evaporator.

NOTE

The TXV bulb should always be mounted on the top

of the horizontal line with the capillary end facing

the flow of refrigerant. Good contact between the

bulb and suction line is necessary for proper operation of the valve. The bulb must also be well insulated.

7. Purge and evacuate the system.

8. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

9. Remove the dryer by unsweating the refrigeration

lines then with an open port sweat in the replacement dryer. Make certain the arrow points in the

direction of flow. Figure 18.

A. E.P.R. Valve Adjustment

To adjust the E.P.R. valve, refer to the following procedures:

1. Remove the phillips head screws from the bottom

of the right side panel and remove the side panel

by sliding out and down.

2. Remove the cap from the E.P.R. access port.

Figure 19.

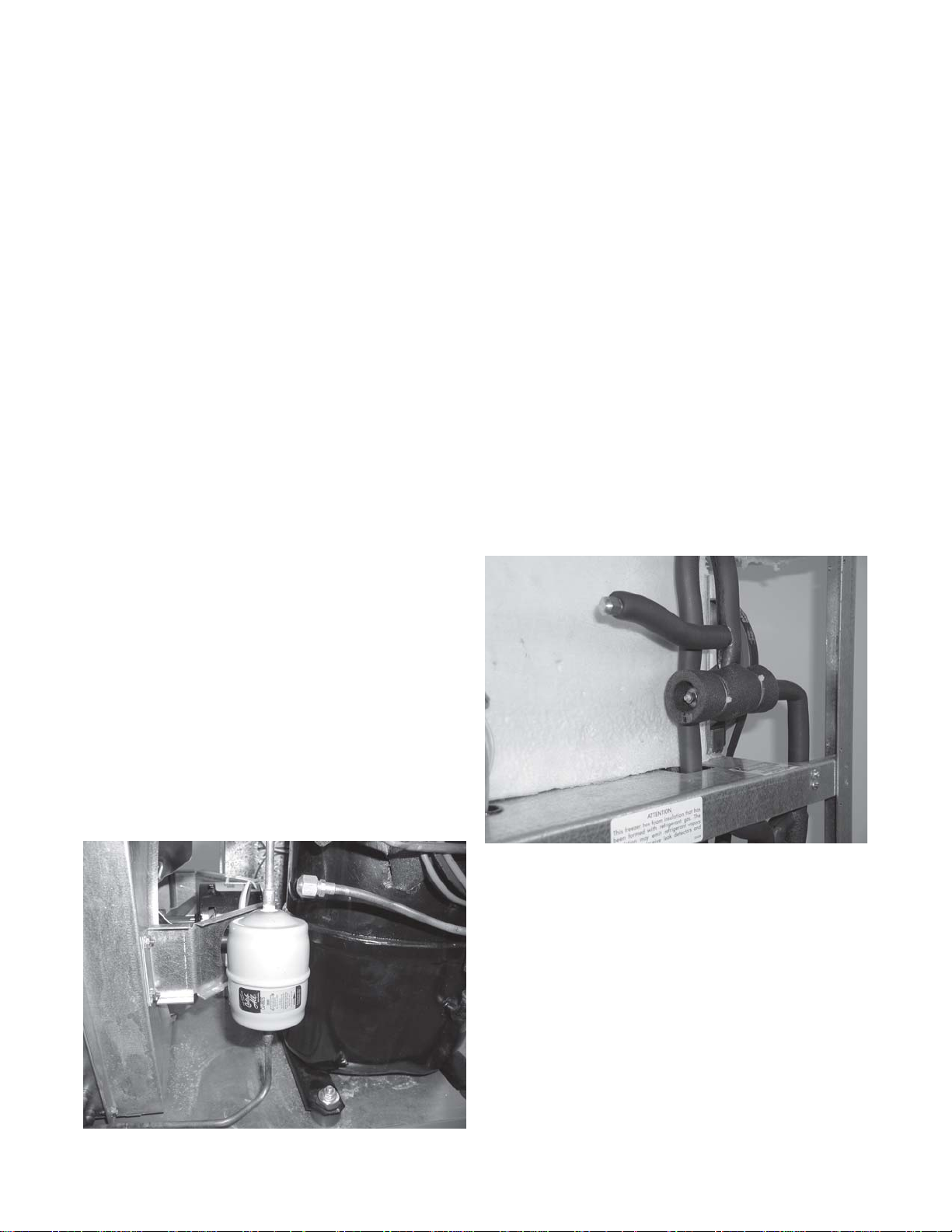

Figure 18. Drier

Figure 19. EPR and Access Port

3. Install a 0-100 P.S.I.G. gauge onto the E.P.R.

access port.

4. Start the refrigeration cycle and read the pressure.

NOTE

The ideal E.P .R. valve setting (69-71 PSIG) will not allow

mix to freeze to the walls of the hopper.

5. If the pressure gauge reading does not fall

between 69-71 PSIG parameters, proceed with

the following steps:

16

Page 23

6. Loosen the lock nut on the E.P .R. valve and

using a small screwdriver , turn the valve stem

1/4 (90°) turn counter clockwise for more cool

ing or clockwise for less cooling.Figure 20.

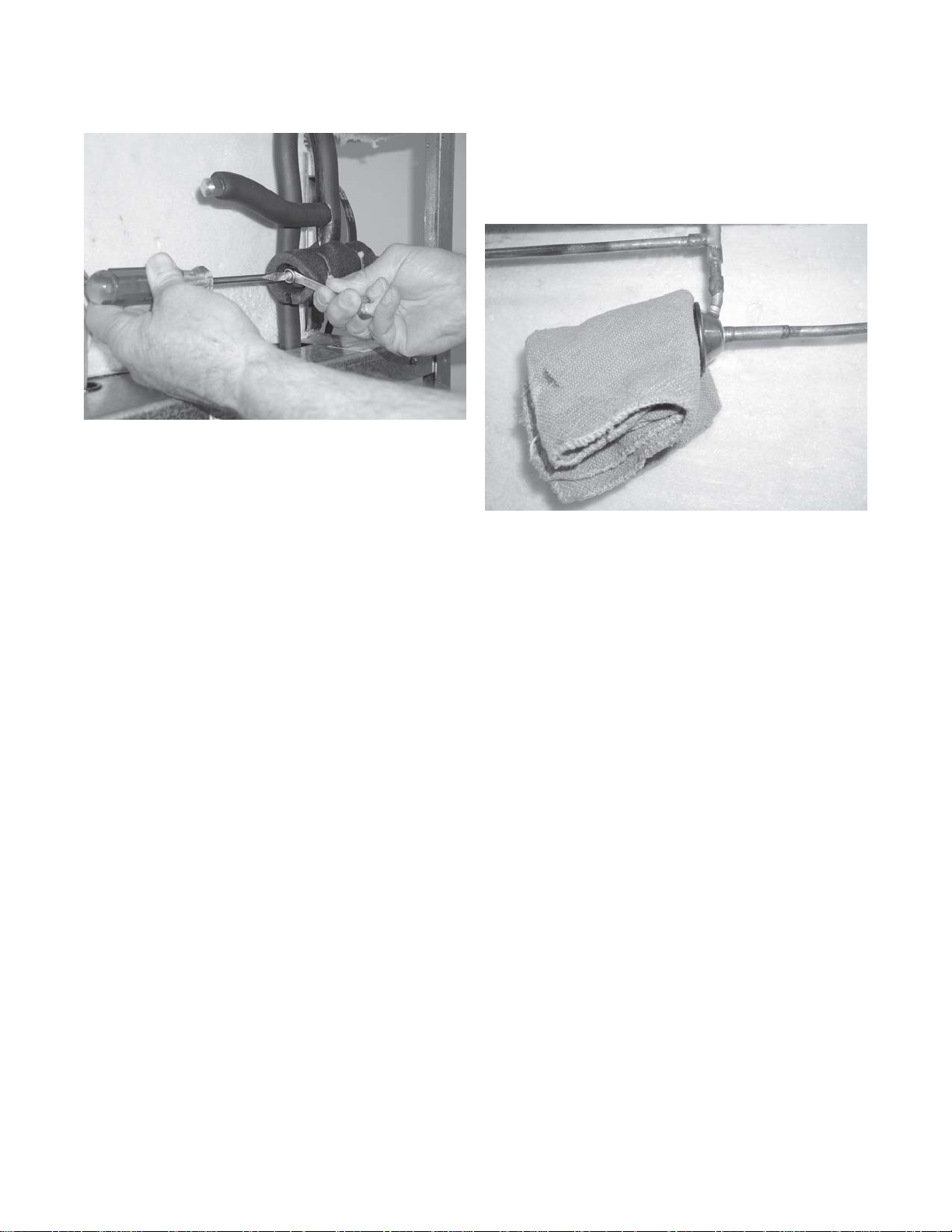

Figure 20. EPR Valve Adjustment

7. Allow the system to level out for 3 - 5 minutes

before taking another pressure reading.

2. Recover refrigerant charge and leave the port

open to prevent pressure build-up during

E.P .R. valve removal.

3. Remove foam rubber insulation from the surrounding lines.

4. Apply a heat sink (wet cloth) to the E.P.R.

valve. Figure 21.

8. Should the reading still not fall between 69-71

PSIG, repeat steps 6 and 7 until the correct

reading is obtained.

9. Once the 69-71 PSIG reading is obtained,

tighten the locknut snugly , remove the pressure

gauge and replace the E.P .R. access valve

cap.

10.Replace the side panel.

B. E.P.R. Removal

CAUTION

IF THE E.P.R. VALVE IS REPLACED THE HEA T

SINK (WET CLOTH) MUST BE USED TO PREVENT DAMAGE TO THE VA L VE.

1. Assuming the right side and back panelsare

removed, perform the following procedures for

removing the E.P .R. valve.

W ARNING

DISCONNECT THE FREEZER FROM ELECTRICAL SUPPL Y SOURCE BEFORE SERVICING.

Figure 21. EPR Heat Sink

5. Unsweat the hopper evaporator line and the line

leading to the low side of the main system from

the E.P.R. valve.

6. Remove the E.P .R. valve with the heat sink.

C. E.P.R. Replacement

CAUTION

IF THE E.P.R. VALVE IS REPLACED THE HEAT

SINK (WET CLOTH) MUST BE USED TO PREVENT DAMAGE TO THE V AL VE.

1. Position the E.P .R. valve with the heat sink, so

the hopper evaporator outlet line and the line

leading to the low side of the main system

correspond with the proper ports.

2. With an open port braze the lines to the E.P .R.

valve using the appropriate brazing material.

3. Remove the heat sink from the E.P .R. valve.

4. Replace any foam insulation to the surrounding

lines.

5. Purge and evacuate the system.

17

Page 24

6. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

7. Remove the dryer by unsweating the refrigeration

lines then with an open port sweat in the replacement dryer. Make certain the arrow points in the

direction of flow. Figure 22.

Figure 22. Filter Drier

Figure 23. Drier Cap. Tube Assembly

NOTE

Before unsweating the capillary tube at the hopper inlet it will be necessary to remove the foam insulation

from the capillary tube at that connection.

4. Remove the capillary tube dryer assembly.

B. Capillary Tube Replacement

8. Triple evacuate the system, evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen, then evacuate to 500

microns of mercury.

9. Recharge the system to the nameplate specifications and leak test.

5.6 CAPILLARY TUBE

Capillary tube replacement may be necessary if the

correct hopper cooling cannot be obtained.

A. Capillary Tube Removal

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL SUPPL Y SOURCE BEFORE SERVICING.

1. Remove the retaining screws from the right side

panel and pull the side panel out and down.

2. Recover refrigerant charge and leave a port open

to prevent pressure build-up during capillary tube

dryer assembly removal.

3. Unsweat capillary tube dryer assembly at the

dryer inlet and at the hopper inlet located at the

side of the hopper. Figure 23.

1. Position the capillary tube dryer assembly so

the large diameter tube is in position to be

brazed first using the appropriate brazing material.

2. Position the smaller diameter tube at the side

of the hopper and braze the tube to the hopper

inlet using the appropriate brazing material.

3. Replace the foam insulation to the hopper inlet

connections.

4. Purge and evacuate the system.

5. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

6. Remove the dryer by unsweating the refrigeration lines then with an open port sweat in the

replacement dryer. Make sure the arrow points

in the direction of flow.

7. Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to

500 microns of mercury.

8. Recharge the system to nameplate specifications and leak test.

18

Page 25

SECTION 6

ELECTRICAL

6.1 ELECTRICAL

The control system operates from drive motor torque.

When the product in the barrel freezes it puts a greater

load on the drive motor. As the resistance builds up the

drive motor body begins to rotate in the opposite direction of the motor shaft overcoming spring tension. When

the motor has rotated far enough it contacts a microswitch

shutting off the compressor. After time has passed or

some product has been drawn the resistance in the barrel decreases and the spring pulls the motor back. The

micro switch then closes and the compressor starts.

There is a 10 second time delay on the compressor start

and stop. The drive motor runs continuously .

6.2 FRONT ELECTRICAL BOX

The front electrical box contains the CLEAN-OFF-SERVE

switch, pump OFF/ON switch (SO318 only), safety switch

and mix low light. The box also contains the drive contactor,

24 volt transformer, liquid level control, ON/OFF time

delay timer and auto fill time delay relay (SO318 only).

Figure 24.

ÉÉ

É

ÊÊ

Ê

ÊÊ

Figure 25. Switch Removal

5. Replace the electrical panel and secure with the

four retaining screws.

B. Indicator

ÉÉ

Figure 24. Electrical Panel

To replace electrical components perform the following

procedures:

A. Switches

1. Remove the decorative panel by loosening the

two screws at the bottom of the panel, then pull

out and down.

1. Remove the decorative panel by loosening the

two screws at the bottom of the panel, then pull

out and down.

2. Identify and disconnect the wires from the

indicator.

3. Squeeze the four plastic retainers together and

push out through the hole. Figure 26.

4. Push the replacement through the hole and reconnect the wires.

ËË

Ë

ÌÌ

Ì

ÌÌ

ËË

2. Identify and disconnect the wires from the switch.

3. Remove the retaining nut and push out through

the hole. Figure 25.

4. Push the replacement switch through the hole

install and tighten the retaining nut, then

reconnect the wires.

19

ÊÊ

Ê

ÊÊ

Figure 26. Light Bulb Replacement

5. Replace the electrical panel and secure the two

retaining screws.

ÉÉ

É

ÉÉ

Page 26

C. Safety Switch

5. Reconnect the four wires.

1. Remove the two retaining screws from the switch

and lift out. Figure 27.

Figure 27. Safety Switch

2. Remove the two wires from the switch.

3. Connect the two wires to the replacement switch.

4. Locate and secure the replacement switch with

the two retaining screws.

D. Liquid Level Control (Low Mix Light)

1. Identify and remove the wires. Figure 28.

2. Remove the four retaining screws.

F. Drive Contactor

1. Identify and remove the wires.

2. Remove the two retaining screws and remove

the contactor.

3. Locate and secure the replacement contactor

with the two retaining screws.

4. Reconnect the wires.

G. Compressor ON/OFF Time Delay Relay

1. Identify and remove the wires.

2. Remove the retaining screw and remove the

relay.

3. Locate and secure the replacement relay with the

retaining screw.

4. Reconnect the two wires.

5. Adjust on and off times to 10 seconds.

WARNING

ALL REP AIRS MUST BE COMPLETED AND ALL

PANELS REPLACED BEFORE CONNECTING

THE FREEZER TO THE ELECTRICAL POWER.

THE REMAINING ELECTRICAL COMPONENTS

CAN BE REPLACED BY PERFORMING THE

FOLLOWING PROCEDURES:

Figure 28. Liquid Level Control

3. Remove the failed control.

4. Locate and secure the replacement control. Take

care to insure the wires are replaced properly or

the control will not work.

E. 24 Volt Transformer

1. Identify and remove the four wires.

2. Remove the two retaining screws, and remove

transformer.

H. Pump Time Delay Relay (SO318 only)

1. Release the two retainers by pushing to the side.

Figure 29.

Figure 29. Pump Relay

2. Unplug faulty relay.

3. Plug in replacement relay.

4. Push the two retainers onto the relay.

I. Torque Switch

3. Terminate the wires on the replacement transformer per the wiring diagram.

4. Locate and secure the replacement transformer

with the two retaining screws.

1. Remove the retaining screws from the right side

panel and slide out and down.

2. Identify and remove the wires and dummy

terminal from the switch.

20

Page 27

3. Remove the two retaining screws holding the

switch to the bracket. Fig. 30.

Figure 30. Torque Switch

4. Locate the replacement switch onto the bracket

and secure.

5. Connect the two wires and dummy terminal.

6.3 COMPRESSOR ELECTRICAL BOX

Remove the retaining screws from the right side panel

and pull the side panel out and down. Remove two

screws holding the electrical box cover and remove

cover.

A. Compressor Contactor

1. Identify and remove the wires. Fig. 31.

2. Remove the retaining screw and remove the

relay.

3. Locate and secure the replacement relay with

the two retaining screws.

4. Reconnect the wires.

C. Start and Run Capacitors

1. Identify and remove the wires.

2. Remove retaining bracket.

3. Install replacement capacitors and secure with

bracket.

4. Reconnect the wires.

WARNING

ALL REP AIRS MUST BE COMPLETED AND ALL

PANELS REPLACED BEFORE CONNECTING

THE FREEZER TO THE ELECTRICAL POWER.

THE REMAINING ELECTRICAL COMPONENTS

CAN BE REPLACED BY PERFORMING THE

FOLLOWING PROCEDURES:

6.4 MAJOR COMPONENT REPLACEMENT

Prepare for component removal. The procedures in this

section must be followed completely in the order in which

they appear. To remove any or all of the major components of the freezer, the following steps must be performed first.

Figure 31. Compressor Contactor

2. Remove the two retaining screws and remove

the contactor.

3. Locate and secure the replacement contactor

with the two retaining screws.

4. Reconnect the wires.

B. Relay

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

Remove the retaining screws from the side panels and

back panel, then remove panels.

A. Condenser Fan Motor Replacement

1. Identify the wires and disconnect. Fig. 32.

Ì

1. Identify and remove the wires.

Figure 32. Fan Motor

21

Page 28

2. Cut the necessary tie straps.

3. Remove the four retaining nuts and washers.

4. Remove the assembly from the freezer, and

remove the fan blade and fan bracket.

NOTE

Take a measurement of the fan blade position on

the shaft on the failed motor and position it in the

same place on the replacement motor shaft and

secure. Install the fan bracket onto the replacement

fan motor and secure.

5. Install the replacement condenser, and position

the condenser and shroud to align the holes.

Then secure with the 3/16" blind rivets or 3/16"

screws, nuts, and washers.

6. Braze the two refrigerant lines to the condenser

with an open access port to prevent pressure

build up.

7. Purge and evacuate the system.

8. Break the vacuum to 0 PSIG with dry nitrogen

then open an access port.

5. Locate the fan assembly into the freezer and

secure with the four retaining nuts and washers.

6. Properly terminate and reconnect all wires

and secure the wires with plastic tie straps.

B. Condenser Replacement

1. Recover the refrigerant charge and leave a port

open to prevent pressure build-up during condenser replacement.

2. Unsweat the two refrigerant lines. Then cover

exposed refrigerant lines to protect them from

debris while preparing the condenser for

removal.

3. To remove the condenser drill out the blind rivets

holding the condenser assembly to the frame.

Figure 33. Rivets can be accessed by removing

the lower front sheet metal . In addition to the

sheet metal retaining screws there are two acorn

nuts under the drip tray.

9. Remove the dryer by unsweating the refrigeration lines then with an open port sweat in the

replacement dryer. Make certain the arrow points

in the direction of flow.

10.Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to

500 microns of mercury.

11.Recharge the system to nameplate specifications and leak test.

C. Compressor Replacement

1. Remove the compressor terminal cover by

inserting a screwdriver between the terminal cover

and retaining frame, and pry out side, then hold

with your hand while prying the other side, then

remove cover.

2. ldentify and remove the three wires. Figure 34.

Figure 33. Condenser

NOTE

When replacing the front sheet metal re-seal the

seams with R.T.V.

4. Remove the condenser.

Figure 34. Electrical Wires

3. Remove the four nuts, washers, and bolts holding the compressor to the frame. Figure 35.

22

Page 29

Figure 35. Compressor

12.Remove the cap plugs from the replacement

compressor and with an open port braze the

suction and discharge lines to the compressor.

13.Connect the black wire to the overload and the

white wire to the relay. Then install the cover and

retaining clip.

14.Purge and evacuate the system.

15.Break the vacuum to 0 PSIG with dry nitrogen,

and open an access port.

16.Remove the dryer by unsweating the refrigeration lines and then with an open port sweat in the

replacement dryer. Make certain the arrow points

in the direction of the flow.

4. Recover the refrigerant charge and leave a port

open to prevent pressure build-up during

compressor replacement.

5. Remove and/or protect insulation that may be

contacted by flame or extreme heat, then unsweat

the discharge and suction line.

6. Remove the compressor through the right side of

the freezer.

7. Remove the four rubber compressor mounts

from the failed compressor.

NOTE

Rubber mounts are not always furnished with replacement compressors.

8. Check the compressor for a burn out condition

using an acid test kit. If acid is found, clean out the

system per the compressor manufacturers instructions.

9. Plug all open ports of the failed compressor.

17.Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to

500 microns of mercury.

18.Recharge the system to nameplate specifications.

19.Leak test and replace insulation.

D. Drive Motor Replacement

1. Remove the cover plate then identify and remove

the four wires.

2. Disconnect the ground wire.

3. Disconnect the torque spring by removing the nut

on the motor bracket and sliding off. Figure 36.

NOTE

A compressor returned to the company with any

open ports will void the warranty. Always plug any

open ports on a compressor that has been removed.

10.Install the four rubber mounts on the replacement compressor.

11.Install the replacement compressor into the

freezer and secure with the four bolts, washers

and nuts.

Figure 36. Torque Spring

4. Remove the two cap screws from the torque

switch bracket and move the bracket to the side.

Figure 37.

23

Page 30

Figure 37. Torque Switch Bracket

14.Locate torque switch bracket and secure with the

two screws.

15.Connect the electrical wires. Do not overlook the

ground wire, it must be connected.

If the belt tensioner needs adjustment perform the following procedures:

a. With idler loosely snug against mounting bracket,

rotate idler until belt is contacted.

b. With a wrench on large idler nut, rotate idler into

belt until indicator mark (single mark on idler half

against mounting bracket) aligns with first mark

closest to indicator mark (3 - 4.5 lbs. of tension).

5. Pull back belt tensioner and remove belt.

Figure 38.

Figure 38. Belt Tensioner

6. Remove the four retaining bolts, nuts and washers.

7. Slide the motor out through the back.

c. Tighten cap screw to lock idler into position.

E. Bearing Assembly Replacement

1. Remove the agitator assembly from the barrel.

2. Pull back the belt tensioner and remove the belt.

3. Measure the position of the pulley hub, then

remove by removing the three cap bolts and

turning two of the bolts in the threaded holes to

separate the hub from the pulley.

4. Remove the four retaining bolts and washers,

then remove the bearing and pulley assembly

through the back of the freezer. Figure 39.

8. Measure the position of the pulley before

removing.

9. Remove the pulley and bracket, then install on

the replacement motor in the same position.

10.Locate the replacement motor in the freezer with

the rubber pads in place over the mounting holes.

11.Secure the motor with the four bolts, nuts, and

washers.

12.Pull back the belt tensioner and install belt. Check

for proper alignment.

13.lnstall torque spring onto bracket and replace

nut.

Figure 39. Bearing Assembly

5. Install the bearing assembly on the barrel and

secure with the four retaining bolts and washers.

Pull back the belt tensioner and install the belt.

Check for proper alignment.

6. Locate the pulley on the replacement part and

securely tighten the three bolts.

24

Page 31

F. Axial Fan Replacement

1. Disconnect the two wires.

2. Remove the two 3/16" mounting screws, nuts and

washers.

3. Remove right side fan bracket, then remove fan

from right side. Figure 39.

4. Locate replacement motor in freezer.

5. Mount right side bracket to frame and motor, then

secure left side bracket to motor and tighten all

bolts, screws, nuts and washers.

6. Reconnect the two wires.

25

Page 32

26

Page 33

SECTION 7

TROUBLESHOOTING

:MELBORP ESUAC NOITCERROC

.spirtdaolrevorotomevirD

nehwnwodstuhsrezeerF(

)gninnur

.egatlovwoLylppusrewopkcehC

.yltcerrocnisesnepsidtcudorPniximwolrorednilyctcudorpn

.nihtootsitcudorPNAELCroFFOnihctiwselggoT

etatoRtoNseoDrotatigA.ffodeppirtdao

iximoN

.reppoh

.noitisop

.)C°7.73(

.gnidaerxirBreporpmI gnidaerxirBsahtahttcudorphtiwllifeR

.rotatigamorfgnissimedalbreparcS.edalbreparcsecalpeR

.nwa

rdrevogniebsirezeerF.wardfoetarnwodwolS

F°001tuobasierutarepmettneibmA

ogniebsirezeerF.wardfoetarehtnwodwolS

.ytridsiresnednoC.resnednocnaelC

lrevorotomevirD citamotuawolla,setunim5roffforezeerfnruT

.nwardrev

.nezorfrokcutsrotatigA .nezorffirezeerfni

.31dna11neewteb

.llufreppohdnarednilyctcudorppeeK

nihctiwselggotecalP

.teser

tcudorpwahT

.noitisopEVRES

.rezeerfmorfyawariatohtceridroevoM

.rotomevirdotrewopoN evirdnisehctiwsdnassenraheriwkcehC

.ecalperroriaperdnatiucric

sirotomevirD .yrassecenfiecalperdnakcehC

laitinInoslatsyrCecIoN

nwoDezeerF

.kcutSrognikaeLtogipS.gnissimroevitcefedsgnir"O"togipS evomeR.leveltogipswolebotximniarD

olB

.rezeerfot

.hcirootxiM deximylreporphtiwlliF.gnidaer"xirB"eka

.evitcefed

rewoptupnionrognidliubniesufnw

T

.rezeerfotwolfriadetcirtseR ehttuosegrahcsiddnatnorfehtnisretneriA

.tcudorpanihtootroftesycnetsisnoC .tcudorprekcihtaot

.ylbmessatogipsniximdeirD evomeR.leveltogipswo

otrewoptupniroesufnwolbrofkcehC

.rezeerf

.tcudorp

am,kcab

.wolfria

ycnetsisnocteS

.llatsnidnaetacirbul

lebotximniarD

tiwlliF.llatsnidnaelbmessa

.raelcerasaerahtobniatrecek

edisotedisdahsledomreilraewefA:ETON

,

dedeensasgnir"O"ecalper,naelc,togips

dnaelbmessasiD.togipsdnareniatertogips

-er,etacirbuL.hsurbdnaretawtohhtiwnaelc

.ximdiuqilh

27

Page 34

28

Page 35

SECTION 8

REPLACEMENT PARTS INFORMATION

8.1 ORDERING PARTS

To assure receipt of the proper replacement parts, supply your dealer or distributor with the following information:

A. MODEL NUMBER of equipment.

B. SERIAL NUMBER of model (stamped on nameplate).

DECALS AND TAGS

PART NUMBER DESCRIPTION

324105 DECAL - CAUTION: ELECT. SHOCK

324107 DECAL - CAUTION MOVING P ARTS

324141 DECAL - CAUTION: ROT A TING BLADES

324798 DECAL - CLEAN-OFF-SERVE SWITCH

324208 DECAL - REFRIG. LEAK CHECK

324393 DECAL - ST OEL TING SWIRL LOGO

324509 DECAL - CLEANING (SS & SHAKE)

324566 DECAL - WIRED ACCORDING TO . . .

324686 DECAL - DANGER ST ARTS AUT OMA TICALL Y

324689 DECAL - REAR SEAL ASSEMBLY

324799 DECAL - PUMP ON/OFF

324801 DECAL - MIX LOW

324825 DECAL - HEADER

C. PART NUMBER, PART NAME, AND QUANTITY

NEEDED. Many part names and numbers are listed

on drawings included in this manual.

NOTE

Minimum billing is $50.00.

D. WIRING DIAGRAMS reflect changes in effect with

the Serial Number which are also indicated by a

suffix.

29

Page 36

30

Page 37

SECTION 9

REFERENCE DRAWINGS

See Next Page.

31

Page 38

3233343536

Page 39

Page 40

Page 41

Page 42

Page 43

-SV

284104

37

-DS

Page 44

38

Page 45

-SV

-SV

39

Page 46

40

Page 47

744142

41

Page 48

42

Page 49

284104

-SV

-SV

43

Page 50

44

Page 51

SECTION 10

ACCESSORIES

Fill-O-Matic II

The Fill-O-Matic II is a self contained auto-fill system designed to be used with the Model SO318

and DQSO318 Freezer. The pump is built onto the cover of a 10 gallon mix vat. A draw tube

extends to the bottom of the container to supply the pump with mix, the mix then passes thru a

screen, thru the pump and discharges thru a hose to the freezer. The pump is controlled by a

pressure switch. The pump starts at 45 PSI and stops at 60 PSI.

Cleaning

1. Empty mix container completely.

2. Pour 2 gallons of quite warm detergent water into the mix container and pump thru the pump

and hoses.

NOTE

Do not allow the pump to run dry for more than a few minutes to prevent damage to the

pumps components.

3. Remove the strainer by turning counter clockwise, then thoroughly clean.

4. Apply a film of petro-gel to the male threads and "o" ring before reassembly. Do not over

tighten.

Sanitizing

1. Use a sanitizer mixed according to manufacturers instructions to provide a 100 parts per

million strength solution. Mix sanitizer in quantities of no less than 2 gallons (7.5 liters) of

120° water. Allow the sanitizer to contact the surfaces to be sanitized for 5 minutes. Any

sanitizer must be used only in accordance with the manufacturers instructions.

2. Pour the sanitizer into the mix container and pump thru the pump and hoses.

3. Make sure all the sanitizer has been pumped out and the container is completely empty,

then fill with mix and start the pump pushing out any sanitizer that may be remaining in the

hoses. The freezer barrel and hopper can now be filled.

45

Page 52

On/Off

Switch

Ç

115 Volt

15 Amp Plug

È

Strainer

Å

Fill-o-matic II

46

Page 53

474849

Page 54

Page 55

Fill-O-Matic III

The Fill-O-Matic III is a gas powered auto-fill system designed to be used with Slush and Cocktail

Freezers. The pump is built to hang on the side of a 10 gallon mix vat. The pump can be driven

by

either regulated CO2, nitrogen or filtered compressed air. A draw tube extends to the bottom of

the container to supply the pump with mix, the mix then passes thru the pump and discharges thru

a hose to the freezer. The pump is controlled by pressure in the mix line verses gas pressure to

the pump. Set the gas pressure to the pump between 20 to 40 PSIG.

Cleaning

1. Empty mix container completely.

2. Pour 2 gallons of quite warm detergent water into the mix container and pump thru the pump

and hoses.

NOTE

Do not allow the pump to run dry for more than a few minutes to prevent damage to the

pumps components.

Sanitizing

1. Use a sanitizer mixed according to manufacturers instructions to provide a 100 parts per

million strength solution. Mix sanitizer in quantities of no less than 2 gallons (7.5 liters) of

120° water. Allow the sanitizer to contact the surfaces to be sanitized for 5 minutes. Any

sanitizer must be used only in accordance with the manufacturers instructions.

2. Pour the sanitizer into the mix container and pump thru the pump and hoses.

3. Make sure all the sanitizer has been pumped out and the container is completely empty,

then fill with mix and start the pump pushing out any sanitizer that may be remaining in the

hoses. The freezer barrel and hopper can now be filled.

Page 56

Mix Outlet

Ë

Gas Inlet

Ë

É

Mix

Inlet

Ë

Gas

Outlet

Fill-o-matic III

50

Page 57

515253

Page 58

Page 59

SECTION 11

ADDENDUM

Dispenser Specifications

Electrical Refrigeration Crated Dimensions Dimensions

208/230/60/1 HFC-404A environmentally- Width: 22" (55.9cm) Width: 17.6"(44.7cm)

20amp circuit & plug friendly refrigerant Depth: 30" (76.2cm) Depth: 26.1"(66cm)

12 running amps 2 HP (14,800 BTUH) high- Height: 66" (167.7cm) Height: 61.2"(155cm) w/casters

1/2 HP Drive Motor efficiency compressor Weight: 400lbs.(182kg) Weight: 350lbs.(159kg)

Air cooled or Water cooled.

Page 60

54DS55565758596061626364656667

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

68

Loading...

Loading...