Stoelting SCBA118-37 Installation Manual

513855

SCBA-SCBF

Owner’s Manual

SCBA & SCBF

ENGLISH

1 SAFETY PRECAUTIONS

1 Before connecting the dispenser to the power source,

check that the voltage shown on the rating plate matches your

electricity supply. Connect the dispenser to a single-phase

supply through a grounded outlet as required by current

regulations.

2 Do not use extension cables to connect the dispenser.

3 To avoid any risks, if the power cable is damaged, it must

be replaced by the manufacturer, by an authorized technician

or by a similarly qualified person.

4 The dispenser is not suitable for outdoor use.

5 The dispenser must be installed in the upright position.

2 TECHNICAL CHARACTERISTICS

SCBA128-37

SCBA118-37

Transparent removable bowls

Capacity of each bowl, approx. gal

Dimensions:

width in

depth in

height in

Net weight, approx. lb

Gross weight, approx. lb

Hermetic compressor

Air-cooled condenser

Overload protector

Noise level less than 70 dB (A)

1 2 3 1

1.5 1.5 1.5 2.5

7.8 15.623.67.8

18.918.918.918.9

24 24 24 27.9

55 90 125 55

25 44 60 27

SCBA168-37

SCBF118-37

2 3

2.5 2.5

15.6 23.6

18.9 18.9

27.9 27.9

99 134

48 64

SCBF128-37

SCBF168-37

6 Before cleaning, always disconnect the dispenser by

removing the plug from the outlet.

7 Always disconnect the dispenser before removing any of

the panels for cleaning or maintenance work.

8 Do not use a water jet to clean the dispenser.

9 This dispenser must not be operated by children.

10 Do not let children play with the dispenser.

11 This dispenser must not be used by persons unless they

have been trained regarding the safe use of the dispenser and

understand the risks involved.

12 Only persons who know and have practical experience of

the dispenser are permitted access to the inner components of

the dispenser, especially when dealing with issues regarding

safety and hygiene.

IMPORTANT

Electrical characteristics: read the data on the plate of

each individual dispenser. This is located at the bottom

of the front panel, behind the drip tray on the right. The

serial numbers of the devices (preceded by the symbol #)

are shown on the frame below. Always refer to the data

shown on the plate.

We reserve the right to amend this manual without notice.

3 INTRODUCTION

Read this instruction booklet carefully in order to familiarize

yourself with all aspects of the dispenser.

Like all mechanical products, this machine requires cleaning

and maintenance. Good operation can also be affected by any

errors made by the operator during disassembly and cleaning.

For this reason, in the case of daily operations such as disassembly, cleaning, sanitizing and reassembly, it is important that

the person using the dispenser is aware of the procedures and

can perform them without making errors.

The warranty for the SCBA and SCBF machines is as follows:

Five years on compressor; Three years on electrical board; Two

years on non-wear parts; One year labor

.

13 For the dispenser to operate correctly, ambient temperature

must be between +41° and +89°F.

14 Use the dispenser to cool the indicated liquids only.

15 Do not introduce dangerous or toxic liquids to the

dispenser.

Every machine includes White Glove

Service. One call does it all – customer

service, technical service, parts or

warranty information, installation,

startup, sales, on-site service dispatch

and much more. Available 24 hours a

day, seven days a week year-round.

Contact White Glove Service at 800319-9549

2

4 UNPACK THE MACHINE

1 Remove the dispenser from the packaging, which you

should keep in case it is needed in the future.

2 Check that the dispenser has not been damaged during

transport. If it has, make a report to the carrier immediately.

NOTICE: Do not lay the machine on its side or back.

NOTICE: Do not lift the machine by the tank, auger, or

handles. Only lift by grasping the bottom of the machine.

NOTICE: The machine must sit in the upright position for 24

hours before turning it on. This will allow the oil in the

compressor to settle into place following shipping.

3 Position the dispenser on a bench capable of supporting the

weight, even at full load.

4 Allow a minimum clearance of at least 6” all around the

dispenser so as not to impede the flow of cooling air.

5 Check the stability of the device, adjusting the height of the

legs if necessary. If the dispenser is provided with taller legs

(approximately 4”), these must replace the original ones.

ATTENTION

Make sure the device is properly grounded, otherwise

you may cause electric shocks to persons or damage to

the dispenser.

6 The dispenser does not leave the factory washed and

sanitized. Before use, it must be disassembled, washed and

sanitized, following the instructions in Chapter 7.4 CLEANING.

lemon juice, orange juice or coffee), dissolve 3.5 - 7 ounces of

sugar in each quart of product.

5 If using freeze-dried bases to be diluted with milk or water,

prepare the product in a separate bowl and only pour it into the

machine bowls after making sure that it is homogeneous and

that the powder is well dissolved.

MIX & RECIPE GUIDELINES

NOTICE: Amount of Sugar - The sugar level of the mix or

recipe must be between 10-17%. Mixes with sugar levels

outside of this range will not freeze properly. Less than

10%, the machine may over-freeze the mix.Greater than

17%, the machine will have difficulty freezing the mix.

NOTICE: Custom Recipes When using a custom recipe

instead of a commercial mix, Stoelting strongly recommends using a refractometer to measure the sugar content.

NOTICE: Using Alcohol - Alcohol is an anti-freeze.

Replace NO more than ¼ of the water required in the recipe with alcohol.

IMPORTANT

Use the dispenser with food products only.

6 The dispenser must operate without interruption: the

cooling system for each bowl automatically stops when the

product is ready to be dispensed, maintaining the set density.

The augers continue to operate.

IMPORTANT

Place the device in such a way that the power cable is

easily accessible.

7 If required by local regulations, it is possible to have the

dispenser permanently connected to electrical power supply,

ref. National Electrical Code (NEC) and NFPA 70. If this is the

case, remove the terminal block and, if necessary, enlarge the

hole on the sheet base, to allow the conduit entry.

5 TO OPERATE SAFELY

1 Do not operate the dispenser without reading this

operator’s manual.

2 Do not operate the dispenser unless it is properly

grounded.

3 Do not operate the dispenser unless all panels are secured

with screws.

4 Do not put objects or fingers in panel louvers or spigot

outlet.

5 Do not remove bowls, augers, or panels for cleaning or

routine maintenance unless the dispenser is disconnected from

its power source.

6 The cover must remain closed at all times.

6 OPERATING PROCEDURES

To remove the top cover from the bowl, press the lock button

and slide the cover towards the front of the bowl. If there is a

safety lock for the cover, turn the key in an counterclockwise to

unlock (see figure 2).

1 Wash and sanitize the dispenser before using it, following

the instructions in Chapter 7.3 WASHING.

2 Fill the bowl with the desired product. The maximum liquid

mix is as follows: SCBA machines 1.5 gallons, and SCBF

machines 2.5 gallons.

3 If using liquid or powder bases, specially prepared for

granita, follow the manufacturer's instructions carefully.

4 If using natural products to prepare granita (for example

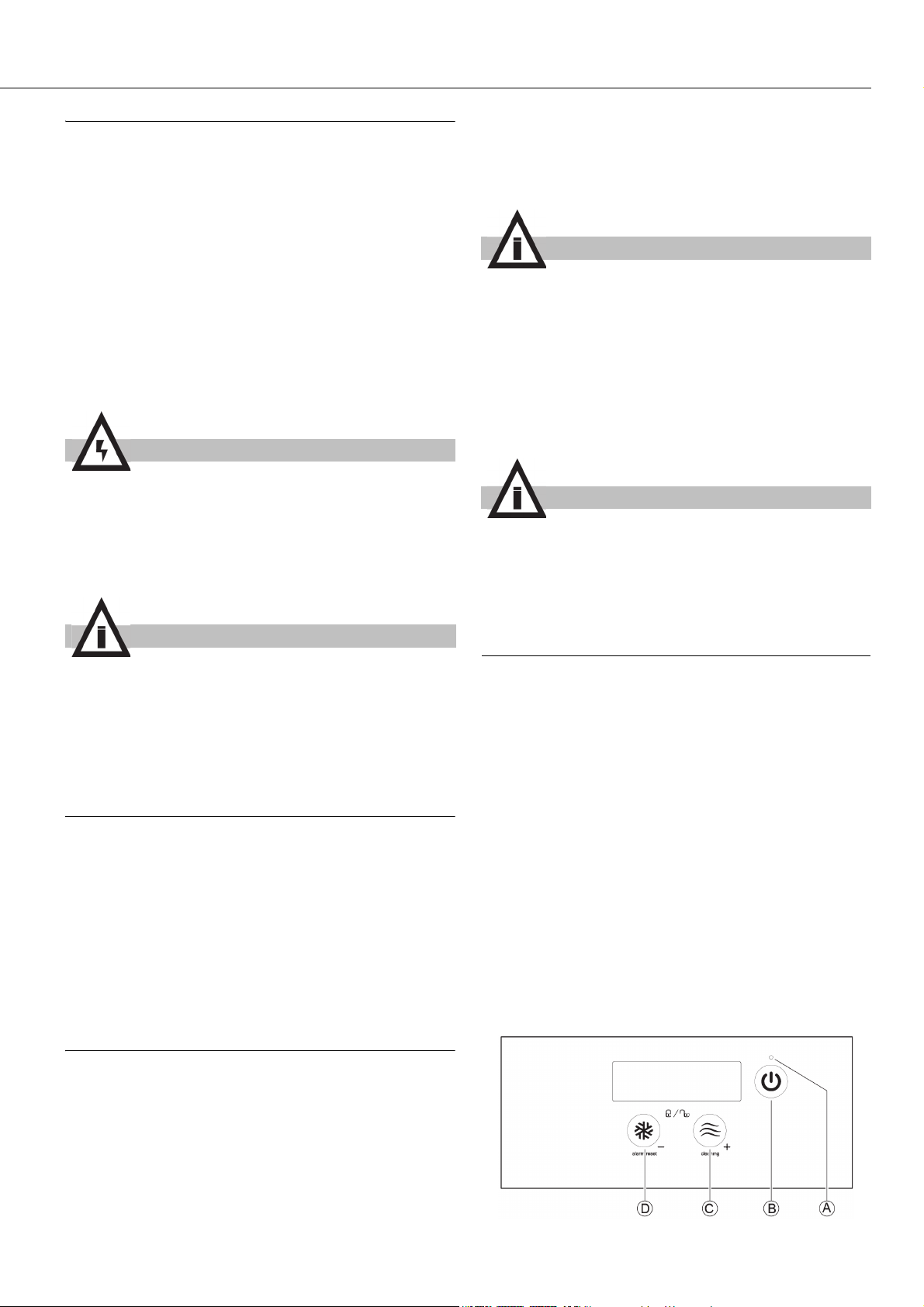

6. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with a main switch together with a

touchpad and a screen for each bowl. These devices allow setting the dispenser operation mode. The following modes are

available:

STANDBY: the dispenser is filled and it is ready to start.

GRANITA MAKING: the dispenser makes granitas according to

the product in the bowl.

PRODUCT PRESERVATION: the dispenser keeps the liquid

product at a suitable temperature for its preservation. This mode

can be selected during the night, since it allows maintaining the

product quality while reducing energy consumption.

WASHING: only the mixers work, the cooling system is stopped.

This mode can be selected during the dispenser washing.

MAIN SWITCH

The main switch is located under the dispenser, on the left side.

It has the following functions:

Position 0 : the dispenser is off.

Position I : the dispenser can work but it is in Standby

mode. Only pilot light (A) is on.

CONTROL KEYBOARD

figure 1

3

SCBA & SCBF

ENGLISH

The keys have the following functions:

Pilot light A On the right bowl: if it is on, it indicates that

the machine is in Standby mode; if it is off, it

indicates that the machine is working; if it

flashes, it indicates that the right bowl only is

off.

On the left bowl: if it is off, it indicates that

the bowl is working; if it flashes it indicates

that the bowl is off.

Standby

key (B)

Product

Preservation

Key (C)

Granita

Making key (D)

The display shows the following icons:

On the right bowl: if it is pressed for two seconds, it allows turning on and off the whole

machine; if it is pressed quickly while the

machine is working, it allows turning on and

off a single bowl (on machines with multiple

bowls only).

If it is pressed twice quickly: it allows turning

on and off the cover lights.

On the left bowl: if it is pressed quickly while

the machine is working, it allows turning on

and off a single bowl.

If it is pressed quickly, it allows increasing

density. If it is pressed one second while the

machine is running in the Granita making

mode, it allows switching to the Product

Preservation mode. If it is pressed one second while the machine is running in the

Product Preservation mode, it allows switching to the Washing mode.

If it is pressed quickly, it allows decreasing

density. If it is pressed one second while the

machine is running in the Product Preservation mode, it allows switching to the Granita

Making mode.

If it is pressed one second while the machine

is running in the Granita Making mode, it

allows resetting possible alarms.

The smart display (optional) shows the following icons, too:

Compressor icon

(E)

Product Preservation Icon (F)

Granita making

Icon (G)

Density bar (H) It shows the set density value and the

Current time (L) Displays the current time and/or product

°C/°F scale icon

(M)

Timer icon (N) when this symbol is lit, the timer is operat-

TIMER

DAY/NIGHT TIMER

This control board has a clock module which is used to automatically switch from day mode to night mode and vice versa at

preset times.

NOTE: On machines with multiple bowls, the timer is only present on the right control and its settings apply to all bowls.

When the machine is in Standby, the current time is displayed

with two flashing points separating the second and third digit to

indicate the seconds.

The current time and the mode switching times can only be set

when the machine is in Standby mode using the following keys:

Setting of current time and temperature scale (°C / °F)Key B +

Key C

Setting of mode switching time intervalsKey B + Key D

Timer ON/OFF Key D pressed for 5 seconds

It shows the condition of the cooling solenoid valve.

Icon off: solenoid valve closed

Icon flashing: delay timer on

Icon on: solenoid valve open

If it is on, it shows that the machine is in

the Product Preservation mode.

If it is on, it shows that the machine is in

the Granita Making mode.

alarms.

temperature.

temperature scale set (°C or °F).

ing.

Compressor icon

(E)

Product Preservation Icon (F)

Granita making

Icon (G)

Density bar (H) It shows the set density value and the

HOW TO START THE DISPENSER

Turn the main power switch to position I. Pilot light (A) hopper

be on showing that the dispenser is ready to work.

Keep button (B) pressed until the dispenser starts.

Select the operation mode and the desired product density by

means of keys (C) or (D).

It shows the condition of the cooling solenoid valve.

Icon off: solenoid valve closed

Icon flashing: delay timer on

Icon on: solenoid valve open

If it is on, it shows that the machine is in

the Product Preservation mode.

If it is on, it shows that the machine is in

the Granita Making mode.

alarms.

SETTING OF CURRENT TIME

Press keys B and C simultaneously to enter the current time

setting mode. Press keys C and D to make the individual settings and press key B to conform and move on to the next

selection. The following must be set in this order:

1 The number 24 or 12 are displayed and the second two

digits flash.

2 Setting of current time. The first two digits flash as well as

the third or fourth digit if the 12 hr mode is selected.

3 Setting of minutes. hopperThe second two digits flash.

SETTING OF MODE SWITCHING TIME INTERVALS

Press keys B and C simultaneously to enter the switching time

interval setting mode. The setting always starts from 00:00 and

the first time with the day mode, indicated by a lit G icon. Press

keys C and D to increase or decrease the time shown on the

display by intervals of 15 minutes and press key B to modify the

operating mode from day to night and vice versa. To adjust the

intervals, you must select whether the machine should be in

night or day mode at 00:00 by pressing key B and then press

key C until you reach the time you want to change mode. Now

press key B to switch mode and the icon comes on to indicate

that the mode has changed. Scroll backwards and forwards

using keys C and D to check the switching time intervals. You

can set mode switching for every 15 minutes. When you reach

23:45 press key C again to quit the switching time interval set-

4

ting.

If the 12 hr mode has been selected, A or P is indicated on the

third or fourth figure (denoting AM or PM).

TIMER ON/OFF

If you press key D for 5 seconds when the machine is in

Standby mode, the day/night timer is activated. The icon N indicates the state of the timer. The default value the first time the

machine is switched on is timer OFF.

NOTE: The keypad lock also has affects the Standby mode

and therefore the possibility of adjusting the clock.

TEMPORARY SUSPENSION OF TIMER

When the timer is activated and the machine is operating in Day

Mode, the timer can be temporarily suspended so that the operating mode can be manually adjusted. To do this, hold down the

night key for two seconds, when the timer icon flashes you can

select the Night Mode or Cleaning on any bowl. Press the day

key again to reactivate the timer.

6. 2 ADDITIONAL FUNCTIONS

6. 3 OPERATION HELPFUL HINTS

1 The time required to make servable product varies

depending on several factors such as the ambient temperature,

the initial temperature of the product, its sugar content (degrees

Brix) and fat content and the density adjustment.

2 Filling the bowls with product that is already pre-cooled

further increases the efficiency of the dispenser.

3 To further reduce recovery time, refill the bowls when the

level of product is below the halfway point of the evaporator.

4 To store the product correctly, the dispenser must also

operate at night, at least in the PRODUCT STORAGE position.

5 Night operation in the PRODUCT STORAGE position also

eliminates the possible formation of ice (due to condensation of

atmospheric moisture) on the outside of the bowls.

6 Never turn off the dispenser when there is product in the

bowls. If not cooled, the product may deteriorate. Furthermore,

unless it is mixed, it may stick together and form blocks of ice. If

the mixer is restarted in these conditions (without waiting for the

ice to melt), the dispenser may be damaged.

7 All dispensers of this kind emit heat. If, however, this

emission seems excessive, check that no source of heat is

located near the dispenser itself and, in particular, near the

louvered panels. Also make sure that the airflow is not impeded

by the proximity of walls, boxes or similar. Leave at least 6” free

space around the dispenser. Finally, check that the filter

located behind the rear panel is clean.

LIGHT SWITCHING ON/OFF

By pressing key standby (B) twice quickly, lights can be turned

on and off. When the machine is in the Granita Making mode,

lights are always on; when the machine is in the Product Preservation mode, lights are always off.

DENSITY ADJUSTMENT

When the machine is working in the Granita Making mode, it is

possible to adjust product density by pressing keys C or D briefly.

The factory set value is 8, which is recommended to make granitas.

WASHING MODE

When the dispenser is in the Product Preservation mode, by

pressing key C for two seconds, the Washing mode is enabled.

In such a case, the auger turns but cooling is disabled.

Use this mode during the machine washing and sterilization to

prevent the cleaning solution from cooling.

By pressing any key, the dispenser exits from the Washing

mode and returns to the Product Preservation mode.

ALARM DISPLAY

If a fault occurs during the dispenser operation, an alarm message is displayed. One of the elements on the density bar hopper flash showing the corresponding alarm number. To find a

detailed alarm list, please refer to the Service Manual.

COMPRESSOR CONDITION

The compressor condition is shown above the first density bar

of the right bowl:

- Off: compressor off

- Flashing: start delay timer on

- On: compressor on

TOUCHPAD LOCK

It is possible to lock the touchpad to prevent access to the dispenser controls by keeping keys C and D pressed together for

two seconds.

By pressing keys C and D at the same time again, the touchpad

is unlocked.

ATTENTION

The access to the service area is restricted to persons

having safety/hygiene knowledge and practical experience on the dispenser.

8 The product is for use with confectionery drinks only.

6. 4 CLEANING

1 Cleaning and washing are essential to guarantee the

perfect preservation of the taste of the product and the

maximum efficiency of your dispenser. The procedures

described below should be considered general in nature and

may vary due to local health regulations.

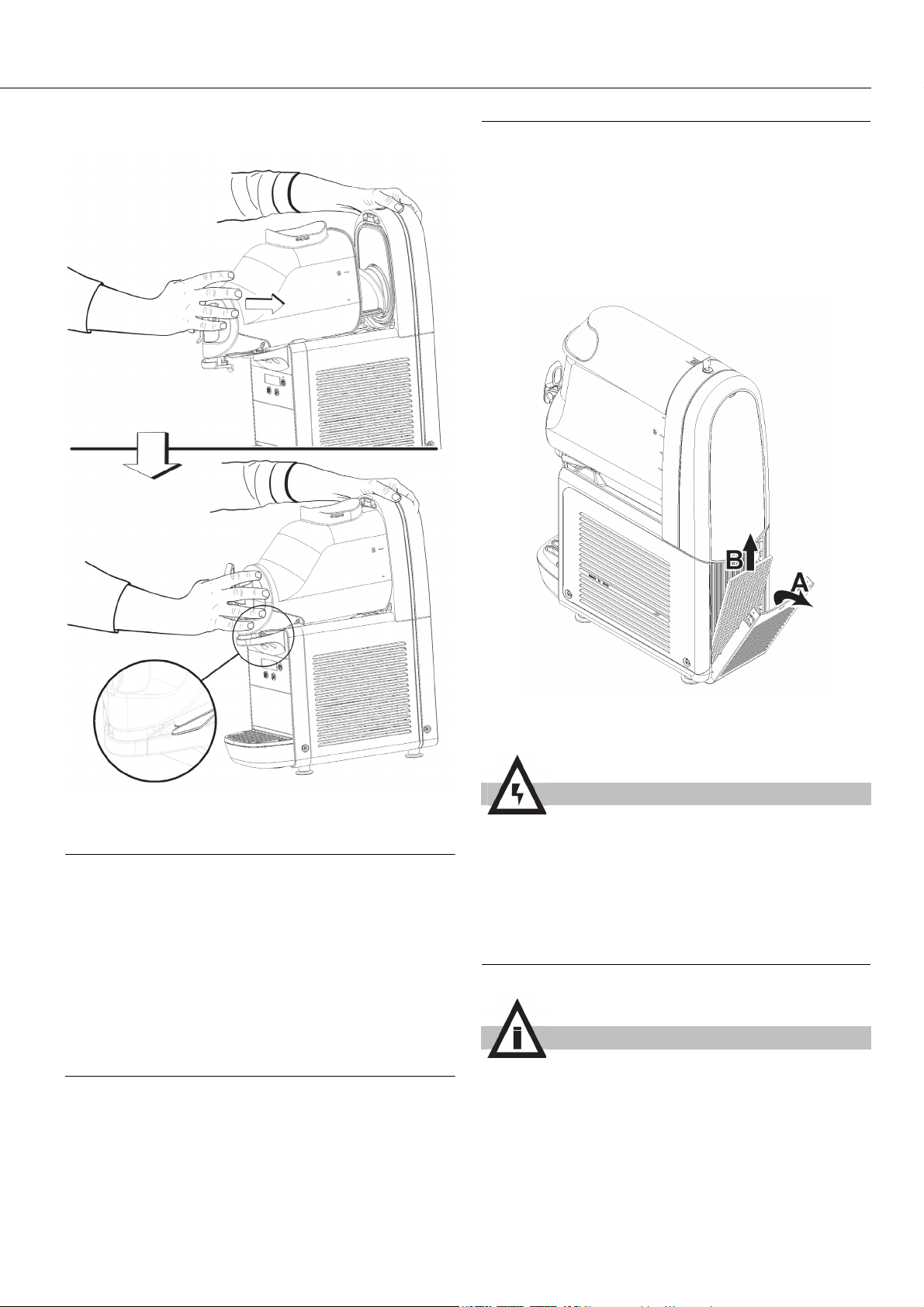

2 Before disassembly for washing, the dispenser must be

emptied. Proceed as follows:

- use the touchpad to select the CLEANING operating mode

- if necessary, wait until the product becomes liquid

- remove the flow restrictor from the bowl (see figure 8)

- place a bucket under each spigot and empty the bowls

- fill the bowls with water and allow the dispenser to operate

in CLEANING mode for a few minutes. Then empty the bowls.

- hold down key A to switch off the dispenser

- turn the main power switch OFF

6. 4. 1 DISASSEMBLY

ATTENTION

Before disassembling any component, always disconnect the dispenser from the power source.

1 To remove the cover of the bowl, press the lock button and

slide the lid towards the front of the bowl.

If there is a safety lock for the lid, turn the key counterclockwise

5

SCBA & SCBF

ENGLISH

to unlock (see figure 2).

and then remove the bowl (see figure 4).

figure 2

2 To remove the bowl, push the lever upwards (see figure 3)

figure 3

figure 4

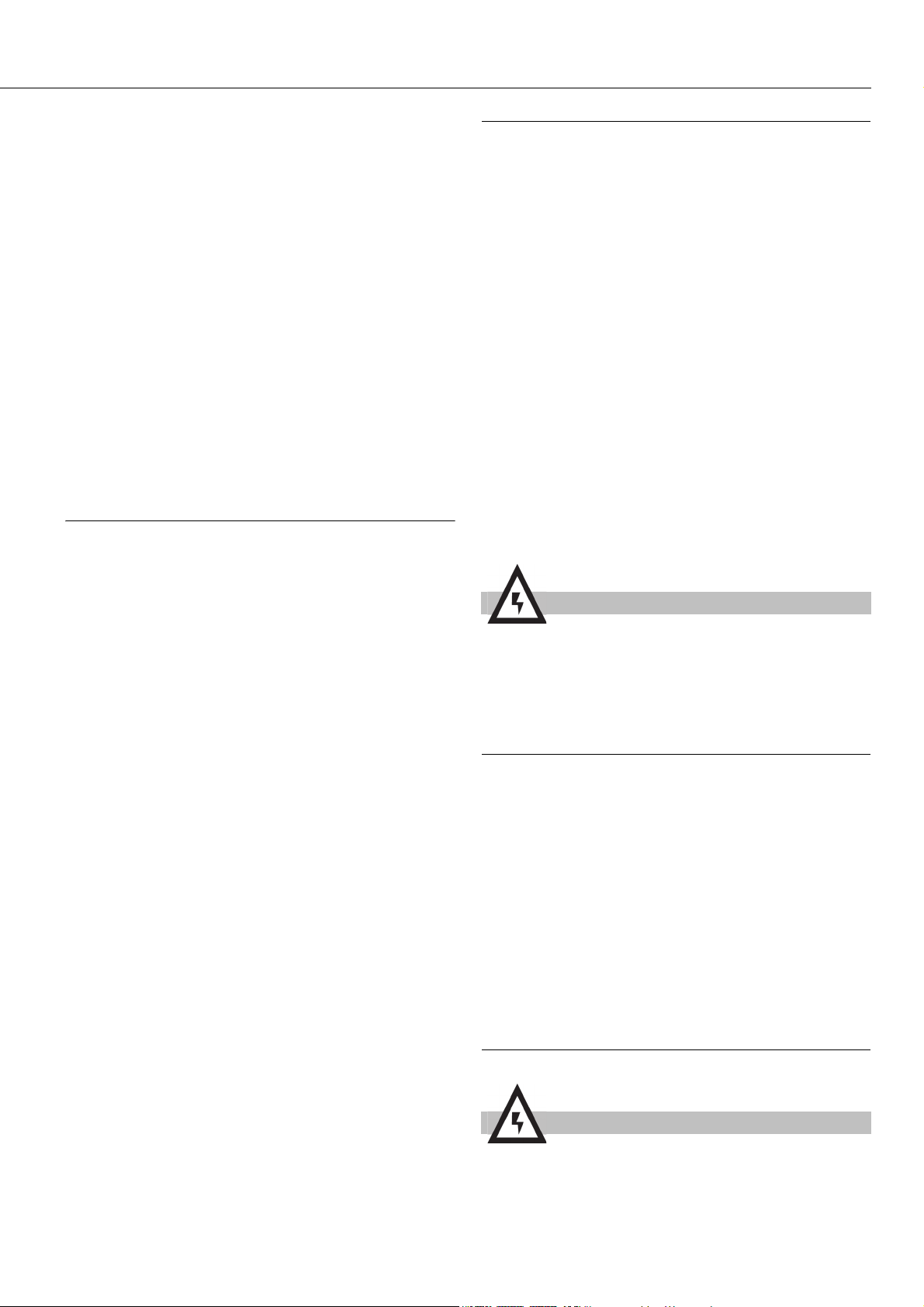

3 Remove the auger by sliding it out of the evaporator

6

cylinder. Then remove the hexagonal joint (see figure 5).

figure 5

4 Remove the gasket from its housing (see figure 6).

figure 7).

figure 7

6 Remove the drip tray and empty it.

7 Remove the flow restrictor from the bowl (see figure 8).

figure 6

5 Disassemble the spigot by following the order given (see

figure 8

6. 4. 2 CLEANING

IMPORTANT

Do not wash any part of the machine in a dishwasher.

ATTENTION

Before any cleaning operation, always disconnect the

dispenser from the power source.

1 Pour about one gallon of 90-110 °F water and mild

detergent into a bucket, following the manufacturer’s

instructions. A solution that is too strong can, in fact, damage

the parts to be washed, while a solution that is too diluted may

7

SCBA & SCBF

ENGLISH

not clean enough. Do not use abrasive detergents.

IMPORTANT

In order to prevent damage to the dispenser, use only

detergents that are compatible with the plastic parts.

2 Use a suitable brush and wash all the parts in contact with

the beverage thoroughly with the detergent solution.

ATTENTION

While washing the dispenser, do not use excessive

amounts of water around the electrical components. This

could cause electric shocks or damage to the dispenser.

3 Wash the evaporator cylinders using a soft brush.

4 Rinse all parts washed using tap water.

6. 4. 3 SANITIZING

Sanitizing must be done immediately before starting up the dispenser. Do not allow the dispenser to remain idle for a long time

after sanitation.

lubricant.

figure 9

figure 10

3 Reassemble the spigot on the bowl in reverse order

compared to that shown in figure 9.

4 Replace the bowl gasket.

NOTE: the rim with the greater diameter must be rested on the

rear wall (see figure 11).

1 Before starting the procedures described below, wash your

hands with antibacterial soap.

2 Prepare 2 gallons of Stera-Sheen sanitizing solution

according to the manufacturer's instructions.

3 Immerse all parts to be sanitized in the solution for the time

indicated by the product manufacturer.

4 Allow the sanitized parts to air dry on a clean surface.

5 Dry the external parts of the dispenser without using

abrasive cloths.

6. 4. 4 ASSEMBLY

NOTE: Total Blend sanitary lubricant, or equivalent must be

used when lubrication of parts is specified. Total Blend can

be used to lubricate parts and also as a spline lubricant. Do

not use more than one packet of Total Blend per freezing

cylinder.

NOTE: The United States Department of Agriculture and the

Food and Drug Administration require that lubricants used

on food processing equipment be certified for this use. Use

lubricants only in accordance with the manufacturer’s

instructions.

figure 11

5 Reassemble the hexagonal joint and then the auger (see

figure 12).

1 Slide the drip tray into place.

2 Lubricate the spigot piston, the hexagonal joint, and the

auger at the points indicated in figure 9 (SCBA) or figure 10

(SCBF), using only Total Blend or other food grade sanitary

figure 12

8

6 Replace the bowl by pushing it towards the back wall,

making sure it fits properly onto the gasket. The locking lever

will be lowered until it rests on the drip tray surface (see figure

13).

7 ROUTINE MAINTENANCE

1 Every day: inspect the dispenser and check for leaks of

product from the gaskets. If you notice leaks, first make sure

that the components of the dispenser are properly installed,

then check that the gaskets do not require lubrication and

finally that they are not worn or damaged. If they are, replace

them with original spare parts from the manufacturer.

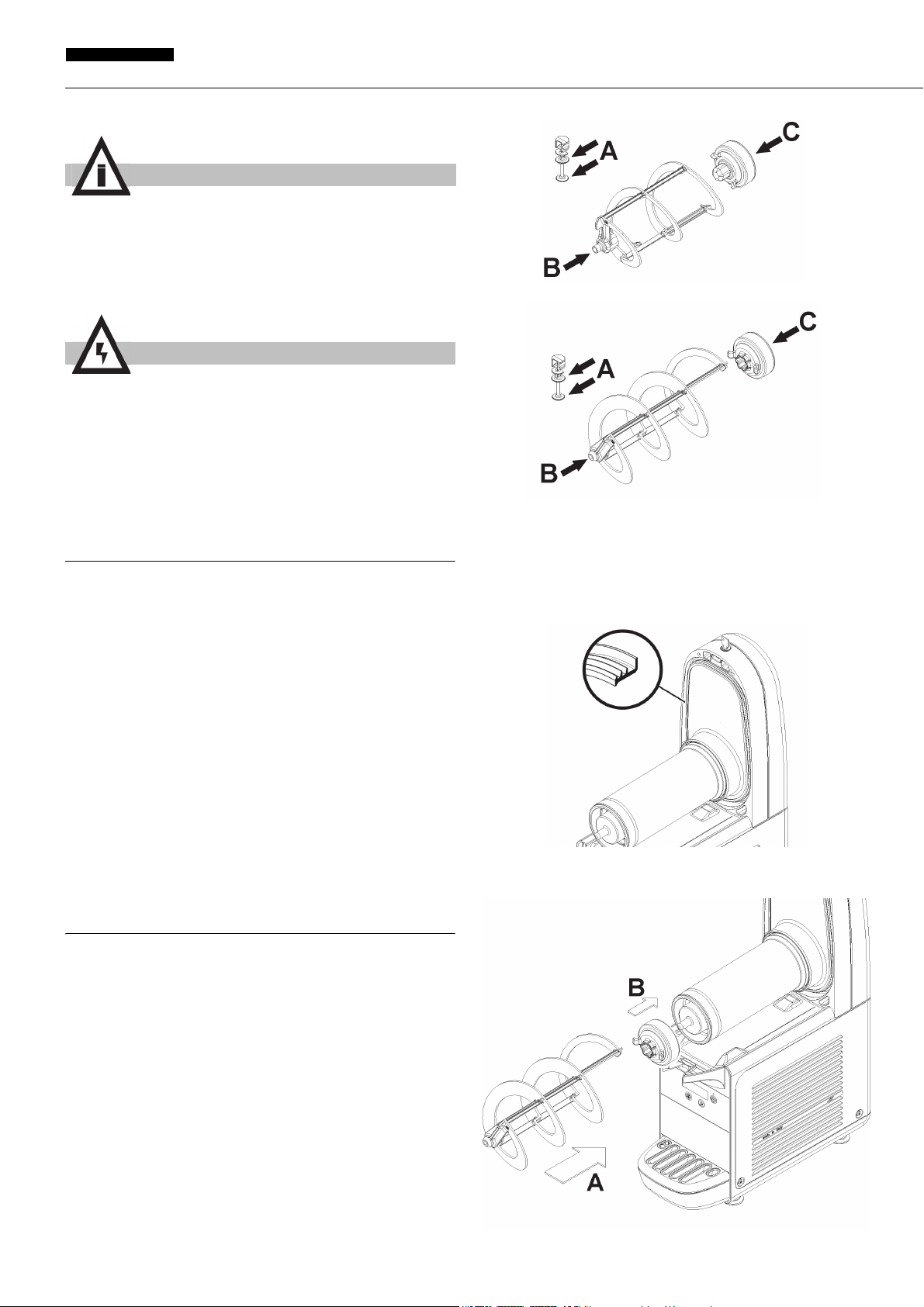

2 Every month: remove the dust from the condenser filter at

the back of the machine (see figure 14).

figure 13

6. 5 IN-PLACE SANITIZATION

1 Prepare 2 gallons of Stera-Sheen sanitizing solution

according to the manufacturer's instructions.

2 Pour the solution into the bowls.

3 Using a suitable brush, wipe the solution onto all parts

above the level of the solution and on the underside of the

cover.

4 Install the cover and operate the dispenser in order to allow

the solution to be stirred for about 2 minutes. Drain the

sanitizing solution from the bowls through the spigots and then

dispose of it.

5 Remove the flow restrictor from the bowl (see figure 8).

6. 6 FREEZE DOWN & OPERATION

1 Place a container under the spigot and rinse the bowl with

mix to flush out any remaining sanitizing solution.

2 Fill the bowls with chilled mix.

3 Turn on the main power.

4 Press the power/standby button then press and hold the

freeze button for 1 second to start freezing product.

5 Once freezing, the snowflake icon displays on the screen

and the density bars are displayed.

6 Momentarily press the freeze or clean button to increase or

decrease density.

figure 14

ATTENTION

Beware of the condenser fins as they are sharp.

3 In case of strange noise or failure, disconnect the dispenser

from the power source and call for service.

7. 1 MAINTENANCE (TO BE CARRIED OUT BY

QUALIFIED SERVICE PERSONNEL ONLY)

IMPORTANT

In order to prevent damage to the dispenser, the plastic

parts must only be lubricated with Total Blend or with

another food grade sanitary lubricant compatible with

plastic parts.

Annually: Remove all the panels and clean the inside of the dis-

penser including the base and the inside of the panels.

Never remove the anti-condensation material wrapped around

the evaporator outlet tube (the copper tube located to the right

of the geared motor). If said material is missing or lost, replace

with original spare parts from the manufacturer.

9

SCBA & SCBF

ESPAÑOL

8 INSTRUCCIONES DE SEGURIDAD

ELÉCTRICA

1 Antes de conectar la alimentación eléctrica del distribuidor,

verifique que la tensión de red sea la correcta, indicada en la

placa. Conecte el distribuidor a una red monofásica, utilizando

un enchufe con toma de tierra, en cumplimiento de las normas

vigentes. Si la desconexión del aparato de la red eléctrica se

realiza mediante un interruptor unipolar, este debe garantizar

una distancia de apertura de los contactos que permita la

desconexión completa, en las condiciones previstas para la

categoría de sobretensión III.

2 No utilice alargaderas para conectar el aparato a la

alimentación eléctrica.

3 En caso de deterioro del cable de alimentación, este debe

ser sustituido por el fabricante, por el servicio de asistencia

técnica o por una persona con cualificación similar, para

prevenir cualquier riesgo.

4 El aparato no es apto para ser utilizado ambientes

exteriores.

5 El aparato se debe instalar en posición vertical.

6 Antes de cualquier operación de limpieza, desconecte

siempre la alimentación eléctrica del distribuidor, extrayendo la

clavija de la toma.

7 No quite los paneles para realizar operaciones de limpieza

o mantenimiento, hasta verificar que el distribuidor está

desconectado de la alimentación eléctrica.

8 No utilice chorros de agua para la limpieza.

10 CARACTERISTICAS TECNICAS

SCBF118-37

SCBA128-37

SCBA118-37

Contenedores transparentes

desmontables

Capacidad de cada contenedor,

aproximada

Dimensiones:

ancho cm 20 40 60 20 40 60

largo cm 50 50 50 50 50 50

alto cm 62 62 62 70 70 70

Peso neto, aproximado kg 23 41 57 25 45 61

Peso bruto, aproximado kg 25 44 60 27 48 64

Motocompresor hermético

Condensador a ventilación forzada

Guardamotor

Nivel de ruido inferior a 70dB (A)

n 1 2 3 1 2 3

l 6 6 6 10 10 10

SCBA168-37

SCBF128-37

IMPORTANTE

Características eléctricas: leer los datos que aparecen

en la placa de cada distribuidor que se encuentra situada

en la parte inferior del panel frontal, detrás del cajón

recogedor de gotas de la derecha. Los números de serie

de los aparatos (precedidos del símbolo #) aparecen

debajo el bastidor. Los datos que aparecen en la placa

de características son los que se tienen que tomar siempre como punto de referencia.

Queda reservado el derecho de modificación del presente

manual sin aviso previo.

SCBF168-37

9 Este aparato no puede ser utilizado por niños.

10 Evite que los niños jueguen con el aparato.

11 Este aparato no puede ser utilizado por personas con

capacidades físicas, sensoriales o mentales reducidas, o sin

experiencia y conocimientos, a menos que hayan recibido

asistencia y capacitación para el uso seguro del aparato y

comprendan los peligros que este implica.

12 El acceso al interior del distribuidor está reservado a

personas con conocimiento y experiencia con el aparato,

especialmente si se trata de operaciones relacionadas con la

seguridad y la higiene.

9 INSTRUCCIONES DE SEGURIDAD

HIGIÉNICA

1 Este aparato está destinado al uso doméstico o similar.

2 Para su correcto funcionamiento, la temperatura ambiente

debe estar comprendida entre +5 y +32 °C.

3 Utilice el aparato exclusivamente para enfriar los líquidos

indicados.

4 No introduzca sustancias o líquidos peligrosos o tóxicos en

el aparato.

11 INTRODUCCION

Es necesario leer atentamente este manual de instrucciones

con el objetivo de conocer todas las características del

distribuidor.

Como todos los productos mecánicos, también este distribuidor

necesita limpieza y cuidados. Su buen funcionamiento se

podría ver comprometido, además, por eventuales errores

efectuados por el operador durante las fases de desmontaje y

limpieza. Esta es la razón por la que es importante que el

usuario del distribuidor conozca, sin posibilidad de cometer

errores, los procedimientos de desmontaje, lavado,

desinfección y reensamblado, puesto que se trata de

operaciones diarias.

12 INSTALACIÓN

1 Extraer el distribuidor del embalaje que se aconseja

conservar para futuras necesidades.

IMPORTANTE

Durante las operaciones de transporte o elevación, no se

puede sujetar nunca el distribuidor por los recipientes

transparentes o los cilindros evaporadores. El fabricante

no responde de los desperfectos provocados por este

tipo de maniobras erróneas.

2 Controlar si el distribuidor ha sufrido desperfectos durante

10

Loading...

Loading...