Page 1

Model SC118

SERVICE MANUAL

Manual No. 513567

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1. Introduction............................................................................................................................................. 1

2. Installation Instruction

2.1 Safety Precautions ............................................................................................................................ 3

2.2 Shipment and Transit ........................................................................................................................ 3

2.3 Freezer Installation ............................................................................................................................ 3

2.4 Installing Permanent Wiring............................................................................................................... 4

3. Initial Set-Up and Operation

3.1 Operator's Safety Precautions ........................................................................................................... 5

3.2 Operating Controls and Indicators...................................................................................................... 5

3.3 Disassembly of Freezer Parts ........................................................................................................... 5

3.4 Cleaning the Freezer Parts................................................................................................................ 7

3.5 Sanitize Freezer and Freezer Parts ................................................................................................... 7

3.6 Assembly of Freezer ....................................................................................................... .................. 7

3.7 Sanitizing .......................................................................................................................................... 7

3.8 Initial Freeze Down and Operation ..................................................................................................... 8

3.9 Consistency Adjustment ................................................................................................................... 8

4. Maintenance

4.1 Bulb Replacement ............................................................................................................................. 9

5. Refrigeration System

5.1 Refrigeration System ......................................................................................................................... 11

5.2 Compressor....................................................................................................................................... 11

5.3 Condensers ....................................................................................................................................... 12

5.4 Evaporators ....................................................................................................................................... 13

5.5 Hopper .............................................................................................................................................. 14

5.6 Capillary Tube ................................................................................................................................... 16

5.7 High Pressure Cutout Switch............................................................................................................. 17

6. Sequence of Operations

6.1 Lights ................................................................................................................................................ 19

6.2 Switches ........................................................................................................................................... 19

6.3 Safety Switch .................................................................................................................................... 19

7. Electrical

7.1 Electrical ........................................................................................................................................... 21

7.2 Front Electrical Panel ........................................................................................................................ 21

7.3 Rear Electrical Panel......................................................................................................................... 22

7.4 Major Component Replacement......................................................................................................... 24

8. Troubleshooting...................................................................................................................................... 29

9. Parts List & Drawings ............................................................................................................................. 31

Page 6

Page 7

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

1 Model SC118..............................................................................................................................1

2 Specifications.............................................................................................................................2

3 Leveling Unit ...............................................................................................................................3

4 Power Cord ................................................................................................................................4

5 Controls......................................................................................................................................5

6 Disassembling Freezer...............................................................................................................5

7 Front Door and Auger Assembly.................................................................................................6

8 Rear Seal Assembly...................................................................................................................6

9 Consistency Control Knob ..........................................................................................................8

10 Light Bulb ...................................................................................................................................9

11 Nameplate ..................................................................................................................................11

12 High Pressure Cut Out ...............................................................................................................11

13 Compressor Terminal Cover Removal..........................................................................................11

14 Compressor Connections ...........................................................................................................11

15 Ohm Meter Connection...............................................................................................................12

16 Clearance For Air Flow ...............................................................................................................12

17 Condenser ..................................................................................................................................12

18 Access Ports .............................................................................................................................13

19 TXV ............................................................................................................................................13

20 Heat Sink ...................................................................................................................................14

21 Drier ...........................................................................................................................................14

22 EPR & Schrader Valve ...............................................................................................................14

23 EPR Valve Adjustment ...............................................................................................................15

24 EPR Heat Sink ...........................................................................................................................15

25 Filter Drier ..................................................................................................................................16

Page 8

LIST OF ILLUSTRATIONS

26 Drier Cap. Tube Assembly................................................................................................... 16

27 Pressure Switch "T" ............................................................................................................ 17

28 Pressure Switch .................................................................................................................. 17

29 Electrical Panel ................................................................................................................... 21

30 Switch/Indicator Removal..................................................................................................... 21

31 Light Bulb Replacement ...................................................................................................... 21

32 Rear Electrical Panel........................................................................................................... 22

33 Temperature Control ............................................................................................................ 23

34 Transformer ......................................................................................................................... 23

35 Safety Switch...................................................................................................................... 23

36 Torque Switch ..................................................................................................................... 23

37 Liquid Level Control ............................................................................................................. 24

38 Condenser Fan Motor .......................................................................................................... 24

39 Condenser ........................................................................................................................... 25

40 Electrical Wires ................................................................................................................... 25

41 Compressor ......................................................................................................................... 25

42 Torque Spring ...................................................................................................................... 26

43 Drive Motor/Siffener Bracket ................................................................................................ 26

44 Belt Tensioner ..................................................................................................................... 26

45 Bearing Assembly ............................................................................................................... 27

Page 9

SECTION 1

INTRODUCTION

The Stowaway is a countertop profit machine. This compact unit fits onto any crowded bar, yet its high

capacity means it will turn out more than seven gallons every hour. And the Stowaway is as versatile

as it is fast, dispensing frozen, pre-mixed or ready-to-serve blends all with the same smooth

consistency.

Figure 1. Model SC118

Stowaway Features

[ Easy plug-in installation.

[ Lighted, moving product and front-mounted flavor label attract attention and merchandise

product.

[ Large 5.5 quart freezing cylinder serves cups, glasses or pitchers.

[ Mix-low warning light notifies when to refill.

[ Night-mode thermostat allows you to schedule cleaning frequency.

[ Front air intake requires less counter space.

[ Belt-drive system means quiet, dependable operation.

[ Torque control ensures consistent quality product.

1

Page 10

Figure 2. Specifications

Specifications

12 running amps 1 15/60/1

15-amp fuse

2.5 gallon (9.5 liter) hopper capacity

5.5 quart (5.2 liter) barrel capacity

1/3 horsepower drive motor

UL & C-UL approved, NSF approval pending

2

Page 11

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the freezer. The labels

have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the freezer. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, INC.

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

Figure 3. Leveling Unit

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and inspected

at the factory. Upon arrival at the final destination, the

complete freezer must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill until

the freezer has been checked for damage. Have the carrier

note any visible damage on the freight bill. If concealed

damage and/or shortage is found later, advise the carrier

within 10 days and request inspection. The customer must

place claim for damages and/or shortages in shipment

with the carrier. Stoelting, Inc. cannot make any claims

against the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

WARNING

DO NOT USE SPIGOT SPOUT AS A HANDLE TO

LIFT OR MOVE THE FREEZER.

A. Uncrate the freezer.

B. The freezer must be placed in a solid level position. To

level adjust bottom portion of leg.

C. Place all switches in the OFF position.

3

Page 12

Figure 4. Power Cord

D. Connect the power cord. The plug is designed for 115

volt/15 amp duty. The unit must be connected to a

properly grounded receptacle. The electrical cord furnished as part of the freezer has a three prong grounding type plug. The use of an extension cord is not

recommended. If one must be used, use one with a

size 12 gauge or heavier with a ground wire. Do not use

an adaptor to get around grounding requirements.

CAUTION

DO NOT AL TER OR DEFORM PLUG IN ANY WA Y!

E. Install the drip tray, cover and other miscellaneous

parts on the freezer.

2.4 INSTALLING PERMANENT WIRING

If permanent wiring is required by local codes, the following

procedure must be performed.

W ARNING

DISCONNECT FREEZER FROM THE SOURCE OF

ELECTRICAL SUPPL Y BEFORE SER VICING .

A. Remove the necessary panels to gain access to the

power cord connection.

B. Disconnect the black and white wires from the terminal

block (L1 and common). Disconnect the green ground

wire from the grounding screw.

C. Remove the strain relief connector from the bottom of

the freezer base.Remove the power cord.

D. Install permanent wiring according to local code.

E. Connect black wire to L1 on the terminal block. Con-

nect the white wire to the common on the terminal

block. Connect the green or yellow and green striped

ground wire to the grounding screw.

F. Replace all panels.

4

Page 13

SECTION 3

INITIAL SETUP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

SAFE OPERA TION IS NO ACCIDENT; Observe these

rules:

A. Know the freezer. Read and understand the

Operating Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

Figure 5. Controls

F. Disconnect electrical cord for maintenance.

Never attempt to repair or perform maintenance on

the freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating condi

tions. Never operate the freezer if unusual or excessive noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the

operator know the function of each operating control.

Refer to Figure 8 for the location of the operating

controls on the freezer.

A. Clean OFF ON Switch

The clean off on switch is a three position switch. In

the clean position only the drive and condenser fan

will run. In the ON position the drive and condenser

fan and compressor will run until the proper consistency is reached, then the compressor will stop and

the drive and condenser fan will continue to run.

B. Mix Low Light

The mix low light will illuminate when the liquid level

in the hopper is less than 2".

C. Standby Serve Switch

The standby switch is a two position switch. In the

standby position mix temperature will be maintained

between 32° and 40°F . In the serve position the

product temperature in the barrel will be determined

by product consistency .

D. Lights Off On Switch

The lights Off On Switch is a two position switch.

When the switch is in the ON position the lights will

illuminate, when the switch is in the off position the

lights will be OFF.

E. High Pressure Cut Out Switch

The high pressure cut out switch is located under the

right side frame about halfway back. Push up to reset.

Figure 6. Disassembling Freezer

3.3. DISASSEMBLY OF FREEZER PARTS

CAUTION

PLACE THE CLEAN OFF ON SWITCH IN THE OFF

POSITION BEFORE DISASSEMBLING FOR

CLEANING OR SERVICING.

Inspection for worn or broken parts should be made at

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced to

ensure safety to both the operator and the customer and

to maintain good freezer performance and a quality product. Frequency of cleaning must comply with the local

health regulations.

5

Page 14

Figure 7. Front Door and Auger Assembly

T o disassemble the freezer , refer to the following steps:

A. Remove the front door by removing the upper and lower

plastic shrouds then turn off the knobs, and pull the

front door off the studs.

B. Remove the spigot body from the spout by pulling the

horse shoe clip up and out. Then pull the spigot body

out of the spout. Disassemble by turning off the black

plastic knob and removing all loose pieces.

C. Pull the agitator assembly out of the freezer barrel.

D. Keep the rear of the agitator assembly tipped up once

it is clear of the freezer barrel to avoid dropping rear

seal.

E. Remove the front agitator support bearing and the two

agitator blades.

F. Remove the rear seal assembly and disassemble.

G. Wipe socket lubricant from the drive end (rear) of the

agitator with a cloth or paper towel.

H. Remove all "O" Rings.

WARNING

DO NOT USE ANY TYPE OF SHARP OBJECT TO

REMOVE THE "O" RINGS.

Figure 8. Rear Seal Assembly

6

Page 15

3.4 CLEANING THE FREEZER PARTS

Place all loose parts in a pan or container and take to the

wash sink for cleaning. To clean freezer parts refer to the

following steps:

C. Lubricate the drive end of the agitator (rear) shaft with

a small amout of white socket lubricant. A small

container of socket lubrication is shipped with the

freezer.

A. Place all parts in warm mild detergent water and clean

with brushes provided. Rinse all parts with clean hot

water.

CAUTION

DO NOT DAMAGE PARTS BY DROPPING OR

ROUGH HANDLING.

B. Wash the freezer barrel and spout with warm detergent

water and brushes provided.

C. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild alkaline

cleaner is recommended. Use a soft cloth or sponge to

apply the cleaner.

D. Remove the drip tray and insert. Clean with a soap

solution. Rinse with clean hot water.

3.5 SANITIZE FREEZER AND FREEZER PARTS

A. Use a sanitizer mixed according to manufacturer's

instructions to provide a 100 parts per million strength

solution. Mix sanitizer in quantities of no less than 2

gallons (7.5 liters) of 120°F water. Allow the sanitizer to

contact the surfaces to be sanitized for 5 minutes. Any

sanitizer must be used only in accordance with the

manufacturer's instructions.

D. Install the two plastic agitator blades onto the agitator.

Install front agitator bearing.

E. Push the auger into the freezer barrel and rotate slowly

until the agitator engages the drive.

F. Assemble and install the spigot body with "O" Rings

into the spout. Push straight in until the spigot is in

place. Then install the horse shoe clip.

G. Install door "O" Ring.

H. Install the front door on the freezer.

I. Install the knobs on the freezer studs and tighten.

CAUTION

FINGER TIGHTEN THE KNOBS EVENL Y . DO NOT

OVER-TIGHTEN KNOBS.

Look for the poper seal between the freezer barrel door, "O"

Ring, and front door.

3.7 SANITIZING

Sanitizing must be done after the freezer is clean and just

before filling with mix. Sanitizing the night before is not

effective. However, you should always clean the freezer

and parts after using it.

B. Place all parts in the sanitizing solution, then remove

and let air dry.

3.6 ASSEMBLY OF FREEZER

To assemble the freezer parts, refer to the following steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubricants used on food processing equipment be certified for this use. Use lubricants only in accordance

with the manufacturer's instructions.

A. Assemble all "O" Rings onto parts dry, without lubrica

tion. Then apply a thin film of sanitary lubrication to

exposed surfaces of the "O" Rings. Apply a thin film of

sanitary lubricant on the fron tof the agitator shaft.

B. Assembly the rear seal assembly onto the agitator. Be

sure the "O" Rings and gaskets are in place before

installing the rear seal.

WARNING

THE UNITED ST ATES DEP ARTMENT OF AGRICUL TURE AND FOOD AND DRUG ADMINISTRATION REQUIRE THAT ALL CLEANING AND SANITIZING SOLUTIONS USED WITH FOOD PROCESSING EQUIPMENT BE CERTIFIED FOR THIS

USE. USE "STERA-SHEEN" OR EQUIVALENT.

When sanitizing the freezer, refer to local sanitary regulations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations. Mix sanitizer

according to manufacturer's instructions to provide a 100

parts per million strength solution. Mix sanitizer in quantities of no less than 2 gallons (7.5 liters) of 120°F water.

Allow sanitizer to contact the surfaces to be sanitized for

5 minutes. Any sanitizer must be used only in accordance

with the manufacturer's instructions.

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning a

soft serve freezer. We therefore include a sample

with each new freezer. For further information read

the directions on the packet. Other products may

be as effective.

7

Page 16

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MA Y CAUSE CORROSION OF ST AINLESS STEEL P ARTS.

In general, sanitizing may be conducted as follows:

A. Prepare 2 gallons (7.5 liters) of sanitizing solution

following manufacturer's instructions.

B. Pour sanitizer into hopper.

C. Place the CLEAN OFF ON switch in the CLEAN

position. Check for leaks around the front door seal.

D. After five mintues, open spigot to drain sanitizing

solution. When solution has drained, place the CLEAN

OFF ON switch in the OFF position. Allow the freezer

barrel to drain completely.

3.8 INITIAL FREEZE DOWN AND OPERATION

This section covers the recommended operating procedures to be followed for the safe operation of the freezer.

A. Sanitize just prior to use.

B. Place the CLEAN OFF ON switch in the OFF position.

C. Fill the hopper with mix.

D. Place the CLEAN OFF ON switch in the ON position.

The product will be ready to serve in about 20-30

minutes.

3.9 CONSISTENCY ADJUSTMENT

The consistency adjustment knob is located next to the

right front leg. Turn clockwise for a thicker product and

counterclockwise for a thinner product. Allow 15-30 minutes for the product to change consistency.

Figure 9. Consistency Control Knob

8

Page 17

SECTION 4

BULB REPLACEMENT

4.1 LIGHT BULB REPLACEMENT

1. Remove the upper plastic shroud.

2. Remove the four retaining screws from the electrical

panel and tip forward.

3. Grasp faulty bulb and pull out.

4. Push in replacement bulb until it snaps into place.

5. Replace the electrical panel and secure with the four

retaining screws.

6. Replace the plastic shroud.

Figure 10. Light Bulb

9

Page 18

10

Page 19

SECTION 5

REFRIGERATION SYSTEM

5.1 REFRIGERATION SYSTEM

The refrigeration system is a dual purpose system. The

system is designed to operate the hopper and the evaporator simultaneously at different temperatures. The system is designed for efficient use with R404A as the

refrigerant. The proper charges are indicated on the nameplate. Figure 11.

Figure 11. Nameplate

The system has a high pressure cutout set to trip at 470

P.S.I.G. The reset can be accessed from under the right

side frame about half way back.

2. Remove the compressor terminal cover by inserting a standard screw driver under the terminal

cover retaining clip and gently pry off. (Fig.13)

Figure 13. Compressor Terminal Cover Removal

3. Remove the retaining clip and cover.

4. Remove the relay by pulling straight off. Remove

the wire from terminal C. (Fig. 14)

É

É

Reset

Reset

Figure 12. High Pressure Cut Out

5.2 Compressor

The compressor is designed specifically for use with

R404A.

A. Winding Test

T o test the compressor motor windings for possible

problems perform the following steps:

WARNING

DISCONNECT FREEZER FROM ELECTRICAL SUPPL Y

SOURCE BEFORE SERVICING.

1. Remove the retaining screws from the bottom of

the left side panel and slide the side panel out and

down.

Figure 14. Compressor Connections

NOTE

The following values are for T ecumseh model

AE9422ZXA with the compressor at or about room

temperature. For other models or brands consult

the manufacturer's service data manual.

5. Connect ohmmeter to terminal C and R. Resistance through the run winding should be

1.10 ohms with the ohmmeter set at times one.

(Fig. 15)

11

Page 20

The condenser filter and condenser require periodic cleaning. To clean refer to the following procedures:

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

1. To remove the condenser filter, remove the lower

front plastic shroud by pulling straight out. Then

remove the filter. Visually inspect for dirt. If the

filter is dirty, shake or brush excess dirt off the

filter and wash in warm soapy water. Once the

filter is clean rinse thoroughly in warm, clear water

and squeeze dry, taking care not to damage the

filter in any way.

Figure 15. Ohm Meter Connection

6. Connect ohmmeter to terminal C and S. Resistance through the start winding should be 5.94

ohms with the ohmmeter set at times one.

7. To check if windings are shorted to ground connect one ohmmeter lead to a bare metal part on

the compressor such as any copper line leading

to or from the compressor and checking terminals

C, R, and S.

NOTE

The compressor is equipped with an external overload protector. If the compressor trips the overload

check for high amperage draw.

5.3 CONDENSERS

The air cooled condenser is a copper tube and aluminum

fin type. Condensing is totally dependent on air flow. A

plugged condenser or restrictions in the louvered grill will

restrict air flow. This will lower the capacity of the system

and damage the compressor.

The condenser must be kept clean from dirt and grease.

The freezer must have a minimum clearance of 2 - 3" at the

rear of the unit for free flow of air. Make sure the freezer is

not pulling over 100° F. of air in from other equipment in the

area. Figure 16.

2. Remove the retaining screws from the bottom of

the right or left side panel and slide the panel out

and down. Remove the phillips head screws from

the back panel and pull down and out.

3. Visually inspect the condenser for dirt by shining

a light through the coil from the back (inside) of the

condenser. Figure 17.

Figure 17. Condenser

4. If the condenser is dirty, place a wet towel over the

front inside of the condenser.

Lower sides

must be

free of

obstructions

for proper

air flow

Figure 16. Clearance for Air Flow

5. Using compressed air or CO2 tank, blow out the

ÅÅ

Å

ÅÅ

3" Of

Clearance

Required

for Air Flow

- Rear

ÌÌ

Ì

ÌÌ

An alternative method of cleaning the condenser is to use

a condenser brush and vacuum.

12

dirt from the back (outside) of the condenser. Most

of the dirt will cling to the wet towel.

NOTE

If the condenser is not kept clean, loss of refrigeration efficiency will result, causing extended run time

or soft product consistency .

Page 21

5.4 EVAPORATOR

An TXV (thermostatic expansion valve) is used to meter the

refrigerant to the evaporator. The self regulating TXV is

preset at the factory for approximately 45 PSIG at 75°F

ambient temperature.

A. TXV Adjustments

To determine whether or not the TXV is in need of adjustment, perform the following procedure:

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

1. Remove the retaining screws from the bottom of

the left and right side panels and slide the panels

out and down.

Figure 19. TXV

2. Remove the cap from the low side schrader valve

and install a 0 - 100 PSIG gauge. Figure 18.

ÊÊ

Ê

ÊÊ

High Side

ÉÉ

É

ÉÉ

Low Side

Figure 18. Access Ports

3. Plug the freezer in, start the refrigeration cycle and

read the pressure.

4. The proper gauge reading should be approximately 45 PSIG at 75°F. (21.1°C) Ambient temperature at the end of pull down. If the readings are

not within these parameters continue with the

following steps:

NOTE

Before performing the following procedures be absolutely certain it is necessary to adjust the TX V.

6. Should the readings not reach 45 PSIG repeat

step #7 until the correct reading is obtained.

7. Once the 45 PSIG reading is obtained, replace the

cap on the TXV, remove the pressure gauge and

replace the low side schrader valve cap.

B. TXV Removal

CAUTION

IF THE TXV IS REPLACED THE HEA T SINK (WET

CLOTH) MUST BE USED TO PREVENT DAMAGE

TO THE V AL VE.

WARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE OF SUPPL Y BEFORE SERVICING.

1. Assuming the left and right side panels are removed, perform the following procedures for removing the TXV.

2. Remove the bulb from the suction line exiting from

the evaporator.

3. Recover refrigerant charge and leave a port open

to prevent pressure buildup during TXV removal.

4. Remove any insulation from the TXV and the

immediate surrounding lines.

5. Remove or push back any foam insulation from

surrounding lines.

5. Remove the cap on the TXV and using a service

wrench, turn the valve stem 1/4 (90°) turn counter

clockwise for more cooling or clockwise for less

cooling. Figure 19.

6. Apply a heat sink (wet cloth) to the valve dome.

Figure 20.

7. Unsweat the suction line and liquid line from the

TXV and remove the TXV with heat sink.

13

Page 22

Figure 20. Heat Sink

Figure 21. Drier

C. TXV Replacement

To replace the TXV perform the following procedures:

CAUTION

WHEN REPLACING THE TXV A HEAT SINK (WET

CLOTH) MUST BE USED TO PREVENT DAMAGE

TO THE V AL VE.

1. Position the TXV with the heat sink so the liquid

and suction line correspond with the proper valve

ports.

2. With an open port braze the liquid line and suction

line to the TXV using the appropriate brazing

material.

3. Remove the heat sink from the TXV.

4. Replace foam insulation to the surrounding lines.

5. Replace any insulation to the TXV and immediate

surrounding areas.

6. Install bulb on suction line exiting the evaporator.

10.Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to 500

microns of mercury.

11.Recharge the system to nameplate specifications

and leak test.

5.5 HOPPER

A parallel refrigeration circuit feeds the hopper. A capillary

tube is used to meter the refrigerant to the hopper. An

E.P.R. valve (Evaporator Pressure Regulating) is used to

control the refrigerant at the outlet. The E.P.R. controls the

hopper pressure so, during heavy dispensing periods,

hopper temperatures will not drop and freeze the mix in the

hopper. The adjustable E.P.R. valve is preset at the

factory. If the hopper temperature is too cold or too warm,

an E.P.R. valve adjustment may be necessary.

A. E.P.R. Valve Adjustment

To adjust the E.P.R. valve, refer to the following procedures:

1. Remove the phillips head screws from the bottom

of the right side panel and remove the side panel

by sliding out and down.

NOTE

The TXV bulb should always be mounted on the top

of the horizontal line with the capillary end facing

the flow of refrigerant. Good contact between the

bulb and suction line is necessary for proper operation of the valve. The bulb must also be well insulated.

7. Purge and evacuate the system.

8. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

9. Remove the dryer by unsweating the refrigeration

lines then with an open port sweat in the replacement dryer. Make certain the arrow points in the

direction of flow. Figure 21.

14

2. Remove the cap from the E.P.R. schrader valve.

Figure 22.

EPR

ÌÌ

Ì

ÌÌ

ÌÌ

Ì

ÌÌ

ÅÅ

Å

ÅÅ

Figure 22. EPR and Schrader Valve

Schrader Valve

Schrad

Page 23

3. Install a 0-100 P.S.I.G. gauge onto the E.P.R.

schrader valve.

4. Start the refrigeration cycle and read the pressure.

WARNING

DISCONNECT THE FREEZER FROM ELECTRICAL SUPPL Y SOURCE BEFORE SERVICING.

NOTE

The ideal E.P.R. valve setting (69-71 PSIG) will not allow

mix to freeze to the walls of the hopper.

5. If the pressure gauge reading does not fall

between 69-71 PSIG parameters, proceed with

the following steps:

6. Loosen the lock nut on the E.P .R. valve and

using a small screwdriver , turn the valve stem

1/4 (90°) turn counter clockwise for more

cooling or clockwise for less cooling.

Figure 23.

2. Recover refrigerant charge and leave the port

open to prevent pressure build-up during

E.P .R. valve removal.

3. Remove foam rubber insulation from the surrounding lines.

4. Apply a heat sink (wet cloth) to the E.P.R.

valve.

Figure 23. EPR Valve Adjustment

7. Allow the system to level out for 3 - 5 minutes

before taking another pressure reading.

8. Should the reading still not fall between 69-71

PSIG, repeat steps 6 and 7 until the correct

reading is obtained.

9. Once the 69-71 PSIG reading is obtained,

tighten the locknut snugly , remove the pressure

gauge and replace the E.P.R. shcrader valve

cap.

10.Replace the side panel.

B. E.P.R. Removal

CAUTION

IF THE E.P.R. VALVE IS REPLACED THE HEAT

SINK (WET CLOTH) MUST BE USED TO PREVENT DAMAGE TO THE VA L VE.

1. Assuming the right side panel is removed for

adjusting the E.P .R. valve, perform the following

procedures for removing the E.P .R. valve.

Figure 24. EPR Heat Sink

5. Unsweat the hopper evaporator line and the line

leading to the low side of the main system from

the E.P.R. valve.

6. Remove the E.P .R. valve with the heat sink.

C. E.P.R. Replacement

CAUTION

IF THE E.P.R. VALVE IS REPLACED THE HEAT

SINK (WET CLOTH) MUST BE USED TO PREVENT DAMAGE TO THE V AL VE.

1. Position the E.P.R. valve with the heat sink, so

the hopper evaporator outlet line and the line

leading to the low side of the main system

correspond with the proper ports.

2. With an open port braze the lines to the E.P.R.

valve using the appropriate brazing material.

3. Remove the heat sink from the E.P .R. valve.

4. Replace any foam insulation to the surrounding

lines.

5. Purge and evacuate the system.

15

Page 24

6. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

7. Remove the dryer by unsweating the refrigeration

lines then with an open port sweat in the replacement dryer. Make certain the arrow points in the

direction of flow. Figure 25.

Figure 26. Drier Cap. Tube Assembly

NOTE

Before unsweating the capillary tube at the hopper inlet it will be necessary to remove the foam insulation

from the capillary tube at that connection.

Figure 25. Filter Drier

8. Triple evacuate the system, evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen, then evacuate to 500

microns of mercury.

9. Recharge the system to the nameplate specifications and leak test.

5.6 CAPILLARY TUBE

Capillary tube replacement may be necessary if the

correct hopper cooling cannot be obtained.

A. Capillary Tube Removal

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL SUPPL Y SOURCE BEFORE SERVICING.

1. Remove the retaining screws from the bottom of

the right side panel and pull the side panel out and

down.

2. Recover refrigerant charge and leave a port open

to prevent pressure build-up during capillary tube

dryer assembly removal.

3. Unsweat capillary tube dryer assembly at the

dryer inlet and at the hopper inlet located at the

side of the hopper. Figure 26.

4. Remove the capillary tube dryer assembly.

B. Capillary Tube Replacement

1. Position the capillary tube dryer assembly so

the large diameter tube is in position to be

brazed first using the appropriate brazing material.

2. Position the smaller diameter tube at the side

of the hopper and braze the tube to the hopper

inlet using the appropriate brazing material.

3. Replace the foam insulation to the hopper inlet

connections.

4. Purge and evacuate the system.

5. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

6. Remove the dryer by unsweating the refrigeration lines then with an open port sweat in the

replacement dryer. Make sure the arrow points

in the direction of flow.

7. Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to

500 microns of mercury.

8. Recharge the system to nameplate specifications and leak test.

16

Page 25

5.7 HIGH PRESSURE CUTOUT SWITCH

A. Pressure Switch Removal

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL SUPPL Y SOURCE BEFORE SERVICING.

6. Remove the two retaining screws holding the

switch to the bracket and remove the switch.

B. Pressure Switch Replacement

1. Position the replacement switch on the bracket

and secure with the two retaining screws.

1. Remove the retaining screws from the bottom

of the right side panel and pull the side panel

out and down.

2. Recover the refrigeration charge and leave a

port open to prevent pressure build-up during

pressure switch removal.

3. Remove foam rubber insulation from the area

where the capillary tube is sweated into the “T”.

4. Cut the plastic tie straps holding the capillary

tube. Then unsweat the capillary tube from the

“T”. Figure 27.

2. Install the two electrical wires.

3. Position the capillary tube in the “T” and braze

using the appropriate brazing material.

4. Position and tie the capillary tube to the 1/4"

line with plastic tie straps.

5. Replace the foam rubber insulation.

6. Purge and evacuate the system.

7. Break the vacuum to 0 PSIG with dry nitrogen,

then open an access port.

8. Remove the dryer by unsweating the refrigeration lines then with an open port sweat in the

replacement dryer. Make sure the arrow points

in the direction of flow.

9. Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to

500 microns of mercury.

Figure 27. Pressure Switch "T"

5. Remove the two electrical wires from the switch.

Figure 28.

10.Recharge the system to nameplate specifications and leak test.

Figure 28. Pressure Switch

17

Page 26

18

Page 27

SECTION 6

SEQUENCE OF OPERATIONS

6.1 LIGHTS

On/Off light switch is independent of all other switches.

When on, the light transformer is operational and the

lights illuminate.

6.2 SWITCHES

On/Off/Clean Mode

Switch Switch

Position Position Sequence of Operations

Clean Serve -Drive Motor and Condenser Fan Motor start and run together,

or No time limit exists.

Standby -Power Transformer, torque switch, compressor, liquid level

control, and mix low light are non-operational.

On Serve -Drive Motor and Condenser Fan start and run together

continuously.

-Power Transformer is on.

-Liquid level control and mix low light are operational.

-With liquid mix or loose slush in the freezing cylinder, the torque

switch is closed. The delay-on-make timer starts the compressor

after a 10-30 second delay.

-When the slush reaches consistency, the torque switch opens

and the compressor immediately shuts off. The drive motor and

condenser fan motor continue to run.

On Standby -Power transformer, liquid level control and mix low light are

operational only when the temperature control is closed.

-Drive motor, condenser fan motor, and compressor cycle on and

off with the temperature control (compressor start delays 10-30

seconds).

NOTE

If the temperature control is set too cold, control will default to the torque switch to prevent freeze-up.

6.3 SAFETY SWITCH

Door Switch - If the front door is removed, the freezer will not function.

Motor Internal Thermostat - If the motor overheats, the freezer will not function.

Warning - The motor internal thermostat automatically resets as the motor cools. The freezer will automatically

restart. Disconnect freezer from power source for servicing.

High Pressure Cutout Switch - If the compressor discharge pressure exceeds 470 PSIG, the freezer will not

function.

19

Page 28

20

Page 29

SECTION 7

ELECTRICAL

7.1 ELECTRICAL

The control system operates from drive motor torque.

When the product in the barrel freezes it puts a greater

load on the drive motor. As the resistance builds up the

drive motor body begins to rotate in the opposite direction

of the motor shaft overcoming spring tension. When the

motor has rotated far enough it contacts a microswitch

shutting off the compressor . After time has p assed or some

product has been drawn the resistance in the barrel decreases and the spring pulls the motor back. The micro

switch then closes and the compressor starts. There is a

10-30 second time delay on the compressor start. The

drive motor and condenser fan runs continuously .

7.2 FRONT ELECTRICAL PANEL

The front electrical panel contains the CLEAN-OFF-ON

switch, mode switch, light switch, and mix low light. The

panel also covers the lights that illuminate the sign and

front door.

ËË

Ë

ÌÌ

Ì

ÌÌ

ÊÊ

Ê

ÊÊ

Figure 30. Switch/Indicator Removal

5. Push the replacement switch through the hole

and reconnect the wires.

6. Replace the electrical panel and secure with the

four retaining screws.

ËË

ÉÉ

É

ÉÉ

Figure 29. Electrical Panel

To replace electrical components perform the following

procedures:

A. Switch and Indicator

1. Remove the upper plastic shroud by lifting up and

out.

2. Remove the four retaining screws from the electrical panel and tip forward. Figure 29.

7. Replace the plastic shroud.

B. Light Bulb

1. Remove the upper plastic shroud.

2. Remove the four retaining screws from the electrical panel and tip forward.

3. Grasp faulty bulb and pull out. Figure 31.

3. Identify and disconnect the wires from the switch

or indicator.

4. Squeeze the four plastic retainers together and

push out through the hole. Figure 30.

Figure 31. Light Bulb Replacment

4. Push in replacement bulb until it snaps into place.

5. Replace the electrical panel and secure with the

four retaining screws.

6. Replace the plastic shroud.

21

Page 30

7.3 REAR ELECTRICAL PANEL

The rear electrical panel contains a 24 volt transformer,

contactor, and time delay. To replace the electrical components perform the following procedures:

A. Electrical Panel

C. Contactor

1. Identify and remove the six wires.

2. Remove the two retaining screws and remove the

contactor.

1. Remove the retaining screws from the bottom of

the left and right side panel and slide the panels

out and down.

2. Remove the retaining screws from the top and

bottom of the back panel and pull the panel out and

down.

3. Remove the two retaining screws from the electrical panel and remove the panel. Figure 32.

Figure 32. Rear Electrical Panel

4. Replace faulty component.

3. Remove the four dummy insulated space type

connectors and install on the replacement

contactor.

4. Locate and secure the replacement contactor

with the two retaining screws.

5. Reconnect the four wires.

D. Time Delay Relay

1. Identify and remove the two wires.

2. Remove the retaining screw and remove the relay.

3. Program the replacement relay with the first four

dip switches closed.

4. Locate and secure the replacement relay with the

retaining screw.

5. Reconnect the two wires.

WARNING

ALL REP AIRS MUST BE COMPLETED AND ALL P ANELS REPLACED BEFORE CONNECTING THE FREEZER

TO THE ELECTRICAL POWER. THE REMAINING ELECTRICAL COMPONENTS CAN BE REPLACED BY PERFORMING THE FOLLOWING PROCEDURES:

5. Relocate electrical panel and secure with the two

retaining screws.

6. Replace the rear and side panels and secure with

the retaining screws.

Assuming the electrical panel is removed perform the

following procedures, to replace the electrical components:

B. 24 Volt Transformer

1. Disconnect the four wires.

2. Remove the two retaining screws, and remove

transformer.

3. Terminate the wires on the replacement transformer per the wiring diagram.

4. Locate and secure the replacement transformer

with the two retaining screws.

5. Reconnect the four wires.

E. Temperature Control

1. Remove the retaining screws from the bottom of

the left side panel and slide the panel out and

down.

2. Remove the temperature sensing probe by pulling

straight out. Figure 33.

3. Remove the two retaining screws from the temperature control and remove the two wires.

4. Connect the two wires to the replacement control.

5. Locate the control and secure with the two retaining screws.

6. Form the replacement temperature sensing probe

to match the one removed and push into the well.

7. Adjust temperature control to 11 o'clock (midrange).

22

Page 31

Figure 33. Temperature Control

Figure 35. Safety Switch

F. Transformer

1. Remove the retaining screws from the bottom of

the right side panel and slide out and down.

2. Remove the two retaining screws from the transformer. Figure 34.

3. Identify and disconnect the four wires.

4. Locate and secure the replacement switch to the

bracket.

5. Connect the two wires.

6. Locate switch assembly in the freezer and secure

with the two retaining screws.

NOTE

On earlier models the front sheet metal may have to be

removed to access the safety switch.

H. Torque Switch

1. Remove the retaining screws from the bottom of

the right side panel and slide out and down.

2. Identify and remove the three wires from the

switch.

3. Remove the two retaining screws holding the

switch bracket to the floor pan. The screws can be

accessed from under the floor pan. Figure 36.

Figure 34. Transformer

4. Connect the four wires to the replacement transformer.

5. Secure with the two retaining screws.

G. Safety Switch

1. Remove the retaining screws from the bottom of

the right side panel and slide out and down.

2. Remove the two retaining screws from the switch

bracket and lift the assembly out. Figure 35.

3. Remove the two wires from the switch and remove

the switch from the bracket.

Switch

Ì

Figure 36. Torque Switch

4. Remove the failed switch from the bracket.

23

Page 32

5. Locate the replacement switch onto the bracket

and secure.

6. Locate the switch and bracket assembly in the

freezer and secure with the two retaining screws.

7. Connect the three wires.

1. Remove the retaining screws from the side panels, back panel, and rear top panel then remove

panels.

2. To replace the drive motor you must also remove

the lower front plastic panel and the two inner

slotted panels.

I. Liquid Level Control (Low Mix Light)

1. Remove the lower front plastic panel by pulling

straight out.

2. Remove the retaining screws from the bottom and

top of the slotted lower left innerfront panel and

remove the panel.

3. Idenfiy and remove the five wires from the front row

of spade connectors then remove the blue wire

from the back row of spade connectors. Figure 37.

A. Condenser Fan Motor Replacement

1. Identify the three wires and disconnect.

2. Cut the necessary tie straps.

3. Remove the four retaining nuts and washers.

Figure 38. Condenser Fan Motor

Figure 37. Liquid Level Control

4. Remove the four retaining screws and ground

wires.

5. Remove the failed control and transfer the remaining wires to the replacement control.

6. Locate and secure the replacement control in the

freezer. Take care to insure the ground wires are

replaced properly or the control will not work.

7. Replace the remaining wires.

7.4 MAJOR COMPONENT REPLACEMENT

Prepare for component removal. The procedures in this

section must be followed completely in the order in which

they appear. To remove any or all of the major components

of the freezer, the following steps must be performed first.

W ARNING

DISCONNECT FREEZER FROM ELECTRICAL

SOURCE BEFORE SERVICING.

4. Remove the assembly from the freezer, and

remove the fan blade and fan bracket.

NOTE

Take a measurement of the fan blade position on

the shaft on the failed motor and position it in the

same place on the replacement motor shaft and

secure. Install the fan bracket onto the replacement

fan motor and secure.

5. Locate the fan assembly into the freezer and

secure with the four retaining nuts and washers.

6. Properly terminate and reconnect the three wires

and secure the wires with plastic tie straps.

B. Condenser Replacement

1. Recover the refrigerant charge and leave a port

open to prevent pressure build-up during condenser replacement.

2. Unsweat the two refrigerant lines. Then cover

exposed refrigerant lines to protect them from

debris while preparing the condenser for removal.

24

Page 33

3. Remove the two retaining screws from the electrical panel below the condenser and remove the

panel.

4. Drill out the four blind rivets holding the condenser

to the freezer frame and the two rivets holding the

shroud to the condenser frame. Figure 39.

Figure 39. Condenser

C. Compressor Replacement

1. Remove the compressor terminal cover by inserting a screwdriver under the terminal cover retaining clip and gently pry off, then remove clip and

cover.

2. ldentify and remove the white and black supply

wires. Figure 40.

5. Remove the condenser.

6. Install the replacement condenser, and position

the condenser and shroud to align the four holes.

Then secure with the 3/16" blind rivets or 3/16"

screws, nuts, and washers. It is not necessary to

replace the rivet holding the shroud to the condenser.

7. Braze the two refrigerant lines to the condenser.

8. Purge and evacuate the system.

9. Break the vacuum to 0 PSIG with dry nitrogen then

open an access port.

10.Remove the dryer by unsweating the refrigeration

lines then with an open port sweat in the replacement dryer. Make certain the arrow points in the

direction of flow.

11.Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to 500

microns of mercury.

Figure 40. Electrical Wires

3. Remove the four nuts, washers, and bolts holding

the compressor to the frame. Figure 41.

Figure 41. Compressor

4. Recover the refrigerant charge and leave a port

open to prevent pressure build-up during compressor replacement.

12.Recharge the system to nameplate specifications

and leak test.

13.Locate and secure the rear electrical panel with

the two screws.

5. Remove and/or protect insulation that may be

contacted by flame or extreme heat, then unsweat

the discharge and suction line.

6. Remove the compressor through the left side of

the freezer.

7. Remove the four rubber compressor mounts from

the failed compressor.

25

Page 34

NOTE

Rubber mounts are not always furnished with replacement compressors.

8. Check the compressor for a burn out condition

using an acid test kit. If acid is found, clean out the

system per the compressor manufacturers instructions.

9. Plug all open ports of the failed compressor.

NOTE

A compressor returned to the company with any

open ports will void the warranty. Always plug any

open ports on a compressor that has been removed.

10.Install the four rubber mounts on the replacement

compressor.

11.Install the replacement compressor into the freezer

and secure with the four bolts, washers and nuts.

12.Remove the cap plugs from the replacement

compressor and with an open port braze the

suction and discharge lines to the compressor.

13.Connect the black wire to the overload and the

white wire to the relay. Then install the cover and

retaining clip.

14.Purge and evacuate the system.

15.Break the vacuum to 0 PSIG with dry nitrogen, and

open an access port.

16.Remove the dryer by unsweating the refrigeration

lines and then with an open port sweat in the

replacement dryer. Make certain the arrow points

in the direction of the flow.

Figure 42. Torque Spring

4. Remove the three cap screws from the stiffener

bracket and remove the bracket. Figure 43.

ÉÉ

É

ÉÉ

Bracket

Figure 43. Drive Motor/Stiffener Bracket

5. Pull back belt tensioner and remove belt.

Figure 44.

17.Triple evacuate the system. Evacuate twice to

1500 microns of mercury, break in the vacuum

each time with dry nitrogen. Then evacuate to 500

microns of mercury.

18.Recharge the system to nameplate specifications.

19.Leak test and replace insulation.

D. Drive Motor Replacement

1. Follow the electrical wires from the motor and

disconnect at the spade connectors.

2. Disconnect the ground wire.

3. Disconnect the torque spring by removing the nut

on the motor bracket and sliding off. Figure 42.

Figure 44. Belt Tensioner

6. Remove the four retaining bolts, nuts and washers.

26

Page 35

7. Slide the motor out through the front.

8. Measure the position of the pulley and fans before removing.

9. Remove the pulley, fans, and bracket, then

install on the replacement motor in the same

position.

10.Locate the replacement motor in the freezer with

the rubber pads in place over the mounting holes.

1 1.Secure the motor with the four bolts, nut s, and

washers.

12.Pull back the belt tensioner and install belt. Check

for proper alignment.

13.Install torque spring onto bracket and replace nut.

14.Locate stiffener bracket and secure with the four

cap screws.

15.Connect the electrical wires. Do not overlook the

ground wire, it must be connected.

If the belt tensioner needs adjustment perform the following procedures:

a. With idler loosely snug against mounting

bracket, rotate idler until belt is contacted.

b. With a wrench on large idler nut, rotate idler

into belt until indicator mark (single mark on

idler half against mounting bracket) aligns with

first mark closest to indicator mark (3 - 4.5

lbs. of tension).

c. Tighten cap screw to lock idler into position.

Figure 45. Bearing Assembly

4. Measure the position of the pulley hub, then remove by removing the three cap bolts and turning

two of the bolts in the threaded holes to separate

the hub from the pulley.

5. Install the pulley on the replacement part and

securely tighten the three bolts.

6. Locate the pulley bearing assembly on the barrel

and secure with the four retaining bolts and washers. Pull back the belt tensioner and install the

belt. Check for proper alignment.

E. Bearing Assembly Replacement

1. Remove the agitator assembly from the barrel.

2. Pull back the belt tensioner and remove the belt.

3. Remove the four retaining bolts and washers, then

remove the bearing and pulley assembly through

the left side of the freezer. Figure 45.

27

Page 36

28

Page 37

SECTION 8

TROUBLESHOOTING

PROBLEM: CAUSE CORRECTION

High Pressure Cutout Switch Tripped. Restricted air flow to condenser. Remove restriction.

Condenser fan not running. Check for obstruction or damage.

Dirty condenser. Clean condenser

Drive motor overload trips. (Freezer

shuts down when running)

Product dispenses incorrectly. No mix in product cylinder or low mix in hopper. Keep product cylinder and hopper full.

Product is too thin. Toggel switch in OFF or CLEAN position. Place toggel switch in ON position.

Agitator Does Not Rotate Drive motor overload tripped off. Turn freezer off for 5 minutes, allow automatic reset.

No Ice Crystals on Initial Freeze Down Blown fuse in building or no input power to

Spigot Leaking or Stuck. Spigot "O" rings defective or missing. Drain mix to below spigot level. Remove spigot, clean,

Improper Brix reading. Refill with product that has Brix reading between 11

and 13.

Low voltage. Check power supply

Scraper blade missing from agitator. Replace scraper blade.

Freezer is being overdrawn. Slow down rate of draw.

Ambient temperature is about 100°F (37.7°C). Move or direct hot air away from freezer.

Freezer is being overdrawn. Slow down the rate of draw.

Condenser is dirty. Clean condenser.

Agitator stuck or frozen. Thaw product in freezer if frozen.

No power to drive motor. Check wire harness and switches in drive circuit and

repair or replace.

Drive motor is defective. Check and replace if necessary.

Check for blown fuse or input power to freezer.

freezer.

Mix too rich. Take "Brix" reading. Fill with properly mixed product.

Restricted air flow to freezer. Air enters lower front and discharges out the top back,

make certain both areas are clear.

Consistency set for too thin a product. Set consistency to a thicker product.

replace "O" rings as needed, lubricate and install.

Dried mix in spigot assembly. Drain mix to below spigot level. Remove spigot retainer

and spigot. Disassemble and clean with hot water and

brush. Lubricate, re-assemble and install. Fill with liquid

mix.

29

Page 38

30

Page 39

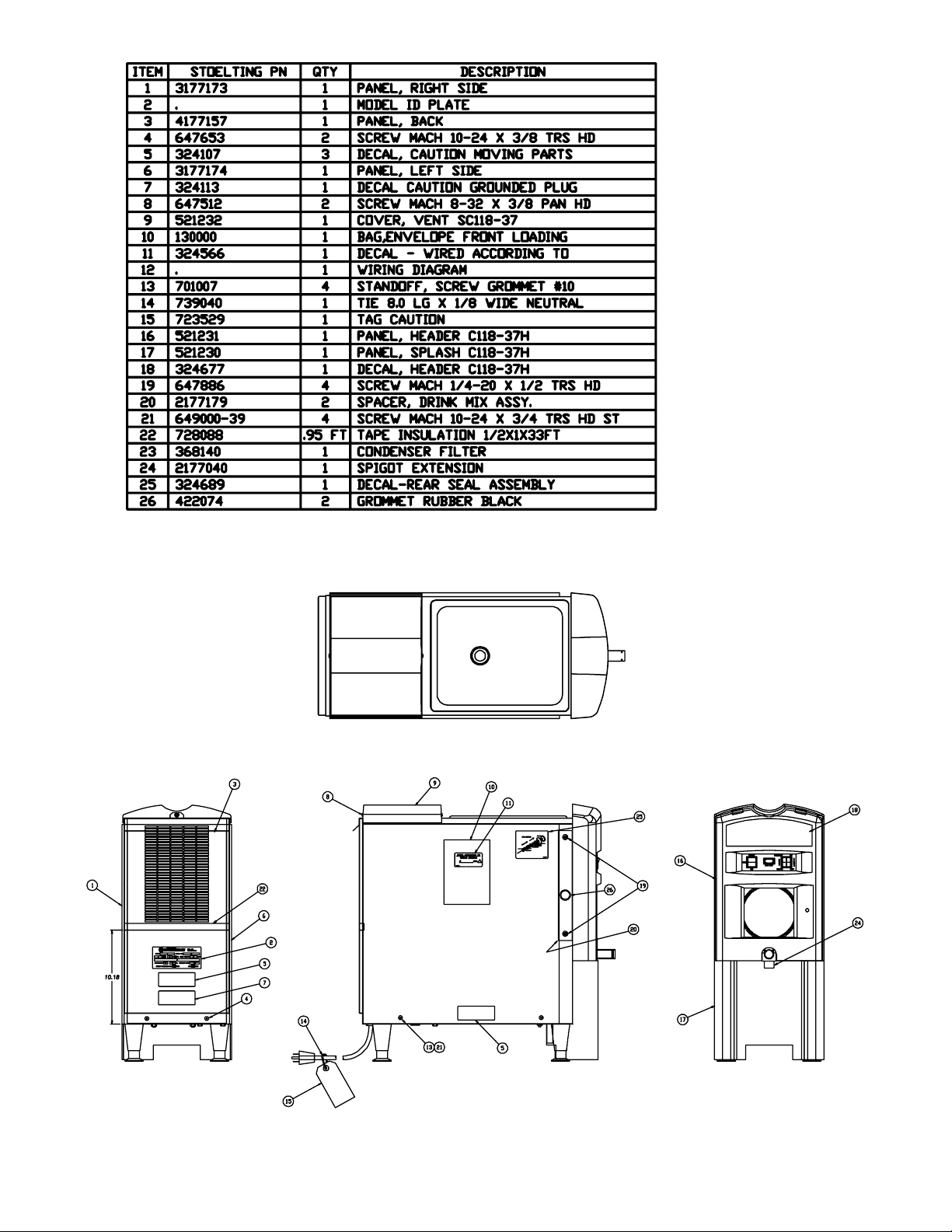

SECTION 9

PARTS LIST & DRAWINGS

4171820-SV Hopper & Evap. Assy . (Ser . #0-9994)

4172889 Back Panel (Ser . #0-9994)

4172948 Auger

4177157 Back Panel (Ser . #10,005 Plus)

4177158-SV Hopper & Evap. Assy. (Ser . #10,005 Plus)

3170878 Bearing Housing Assy.

3172953 R.H. - Side Panel

3172954 L.H. - Side Panel

31771 14 Front Panel

3177121-SV Front Door w/Pin (Ser . #10,005 Plus)

3172964-SV Front Door w/Pin (Ser. #0-9994)

2171834 Spigot Assy.

2172898 Front Lower Slotted Panel

2177040 Spigot Extension

2177123-SV Light Strip (Top) (Ser. #10,005 Plus)

2177160 Air Blockoff Panel

2172939 Probe Assy.

2172966-02SV 2 Light S trip (Sides) (Ser. #0-9994)

2172966-03SV 3 Light S trip (T op) (Ser . #0-9994)

1 106373 Spline Lubricant

1 120918 Splash Defelctor - Spigot Body

1 170836-SV Limit Switch - Door Safety

1 170836-TC Limit Switch - Torque Consistency

1 170882 Auger Bushing

1 172926 Drip Tray Grid

718768 Hi Pressure Limit Control Switch

718886 Rocker Switch - Clean/Off/On

718887 Rocker Switch - Serve/Standby , Lights On/Of f

739543 Timer Delay

744142 Transformer

744269 Drain Tray

756085 1/2" I.D. Tubing - Drain Tube (Per Foot)

762410 Expansion Valve

762978 EPR Valve

771004 Window - Front

771005 Window - Lower

618488 Relay Overload - Comp.

618530 Relay - Comp.

624607 O-Ring - Spigot Body

624857 O-Ring - Rear Seal

62531 1 Quad Ring - Front Door

647512 Screw - Vent Cover

647653 Panel Screw - Back Panel/Front Slotted Panels

649000-39 Panel Screw - Side Panels

667830 V-Ring Seal - Brg. Hsg. Assy.

667860 Shaft Seal - Brg. Hsg. Assy.

667892 Rear Seal

694400 Spring - Spigot Body

695763 Spring - T orque Consistency Adjustment

696130 Lock Clip - Spigot Body

31

Page 40

508135 Petro-Gel 4 oz. tube

513556 Owner's Manual

521227 Vent Cover (Ser. #0-9994)

521228 Hopper Cover

521229 Drip Tray

521230 Splash Panel

521231 Header Panel

521232 Vent Cover (Ser.#10,005 Plus)

522418 Motor - 1/3 HP

522833 Fan Motor - Condenser

598012 Pulley - Motor

598331 Pulley - Bearing Assy.

430168 Power Cord - 15 Amp.

454016 Idler

458104 Indicator Light - Mix Out

482004 Knob - T orque Consistency Adjustment

482024 Knob - Spigot Body

482043 Knob - Front Door

490725 Leg

490730 Non-Skid Pad - Leg

493063 Incandescent Light Bulb - 24V/5 Watt (Ser. #0-9994)

493064 Incandescent Light Bult - 24V/10 Watt (Ser. #10,005 Plus)

324014 Decal - Black Arrow on White

324105 Decal - Caution Elec. Shock

324107 Decal - Caution Moving Parts

3241 13 Decal - Caution Grounded Plug

324141 Decal - Caution Rotating Blades

324208 Decal - Refrig. Leak Check

324242 Decal - T emp. Adjustment

324566 Decal - Wired According to

324676 Decal - Switches

324677 Decal - Stowaway

324686 Decal - Danger Starts Automatic

324689 Decal - Seal Assy.

342006 Drier - Main

342020 Drier - Cap. Tube

368140 Condenser Filter

208401 Brush 1" x 3" x 10"

230624 Start Capacitor - Comp.

231 1 05 Cap. Tube

232002 Retaining Cap. - Spigot Body

264061 Jaw Type Clamp - Drain T ube

282022-SV Compressor - T ecumseh (w/caps)

284081 Condenser

29501 1 Contactor

296179 Liquid Level Control

296658 Temperature Control

146353 Bearing - Brg. Housing Assy.

146449 Bearing - Drive Motor

152227 V-Belt

162051 Fan Blade - 6" (rear)

162052 Fan Blade - 5" (front)

162067 Fan Blade - Condenser

162156 Scraper Blade

32

Page 41

3334353637383940414243

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Loading...

Loading...