Page 1

SC1 18 - Stowaway Slush/Cocktail

OWNER’S MANUAL

Manual No. 513556 Jan., 2001 Rev. 0

Page 2

Page 3

Need Part s or Service?

We stock the parts you need.

Our Technicians are factory

trained and are certified in the

Stoelting Technicare program.

CALL

Distributor: _________________________

Phone No.: _________________________

(fill in or affix label)

Model No.: _______________________

Serial No.: _______________________

Purchase Date: ____________________

Start-Up Date:____________________

Page 4

Page 5

OWNER'S MANUAL

FOR MODEL SC118

STOELTING COUNTER MODEL FREEZER

This manual provides basic information about the freezer. Instructions and suggestions are given covering its

operation and care.

The illustrations and specifications are not binding in detail. We reserve the right to make changes to the freezer

without notice, and without incurring any obligation to modify or provide new parts for freezers built prior to date

of change.

DO NOT ATTEMPT to operate the freezer until instructions and safety precautions in this manual are read

completely and are thoroughly understood. If problems develop or questions arise in connection with installation,

operation or servicing of the freezer, contact the company at the following location:

STOELTING, LLC Tele: 920-894-2293

502 Hwy 67

Kiel, WI 53042-1600 Fax: 920-894-7029

Page 6

Page 7

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1. Introduction................................................................................................................. 1

2. Installation Instruction

2.1 Safety Precautions ................................................................................................. 3

2.2 Shipment and Transit.............................................................................................. 3

2.3 Freezer Installation ................................................................................................. 3

2.4 Installing Permanent Wiring .................................................................................... 4

3. Initial Set-Up and Operation

3.1 Operator's Safety Precautions................................................................................ 5

3.2 Operating Controls and Indicators........................................................................... 5

3.3 Disassembly of Freezer Parts ................................................................................ 5

3.4 Cleaning the Freezer Parts..................................................................................... 7

3.5 Sanitize Freezer and Freezer Parts ........................................................................ 7

3.6 Assembly of Freezer .............................................................................................. 7

3.7 Sanitizing ............................................................................................................... 7

3.8 Initial Freeze Down and Operation.......................................................................... 8

3.9 Consistency Adjustment ......................................................................................... 8

4. Maintenance

4.1 Bulb Replacement .................................................................................................. 9

5. Sequence of Operations

5.1 Lights .....................................................................................................................11

5.2 Swithces ................................................................................................................ 11

5.3 Safety Circuit.......................................................................................................... 11

6. Troubleshooting......................................................................................................... 13

Page 8

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

1 Model SC118.........................................................................................................1

2 Specifications ........................................................................................................2

3 Leveling Unit ..........................................................................................................3

4 Power Cord ............................................................................................................4

5 Controls .................................................................................................................5

6 Disassembling Freezer ..........................................................................................5

7 Front Door and Auger Assembly ............................................................................6

8 Rear Seal Assembly..............................................................................................6

9 Consistency Control Knob .....................................................................................8

10 Bulb Replacement .................................................................................................9

Page 9

SECTION 1

INTRODUCTION

The Stowaway is a countertop profit machine. This compact unit fits onto any crowded bar, yet its high

capacity means it will turn out more than seven gallons every hour. And the Stowaway is as versatile

as it is fast, dispensing frozen, pre-mixed or ready-to-serve blends all with the same smooth

consistency.

Figure 1. Model SC118

Stowaway Features

[ Easy plug-in installation.

[ Lighted, moving product and front-mounted flavor label attract attention and merchandise

product.

[ Large 5.5 quart freezing cylinder serves cups, glasses or pitchers.

[ Mix-low warning light notifies when to refill.

[ Night-mode thermostat allows you to schedule cleaning frequency.

[ Front air intake requires less counter space.

[ Belt-drive system means quiet, dependable operation.

[ Torque control ensures consistent quality product.

1

Page 10

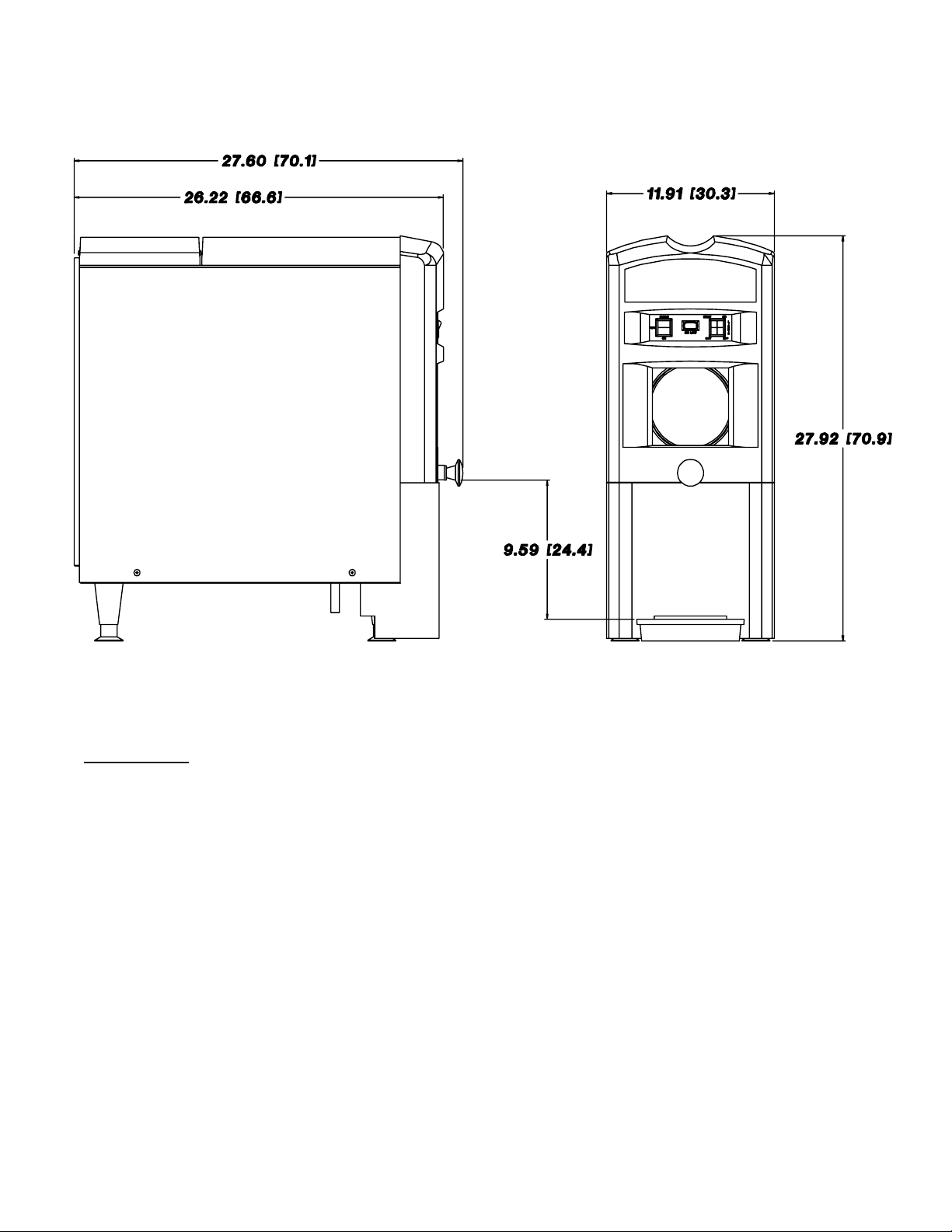

Specifications

12 running amps 1 15/60/1

15-amp fuse

2.5 gallon (9.5 liter) hopper capacity

5.5 quart (5.2 liter) barrel capacity

1/3 horsepower drive motor

UL & C-UL approved, and NSF approved

Figure 2. Specifications

2

Page 11

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the freezer. The labels

have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the freezer. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, INC.

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

Figure 3. Leveling Unit

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and inspected

at the factory. Upon arrival at the final destination, the

complete freezer must be checked for any damage which

may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLE OR CONCEALED. Do not pay the freight bill until

the freezer has been checked for damage. Have the carrier

note any visible damage on the freight bill. If concealed

damage and/or shortage is found later, advise the carrier

within 10 days and request inspection. The customer must

place claim for damages and/or shortages in shipment

with the carrier. Stoelting, Inc. cannot make any claims

against the carrier.

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

WARNING

DO NOT USE SPIGOT SPOUT AS A HANDLE TO

LIFT OR MOVE THE FREEZER.

A. Uncrate the freezer.

B. The freezer must be placed in a solid level position. To

level adjust bottom portion of leg.

C. Place all switches in the OFF position.

3

Page 12

Figure 4. Power Cord

D. Connect the power cord. The plug is designed for 115

volt/15 amp duty. The unit must be connected to a

properly grounded receptacle. The electrical cord furnished as part of the freezer has a three prong grounding type plug. The use of an extension cord is not

recommended. If one must be used, use one with a

size 12 gauge or heavier with a ground wire. Do not use

an adaptor to get around grounding requirements.

CAUTION

DO NOT AL TER OR DEFORM PLUG IN ANY WA Y!

E. Install the drip tray, cover and other miscellaneous

parts on the freezer.

2.4 INSTALLING PERMANENT WIRING

If permanent wiring is required by local codes, the following

procedure must be performed.

W ARNING

DISCONNECT FREEZER FROM THE SOURCE OF

ELECTRICAL SUPPL Y BEFORE SER VICING .

A. Remove the necessary panels to gain access to the

power cord connection.

B. Disconnect the black and white wires from the terminal

block (L1 and common). Disconnect the green ground

wire from the grounding screw.

C. Remove the strain relief connector from the bottom of

the freezer base.Remove the power cord.

D. Install permanent wiring according to local code.

E. Connect black wire to L1 on the terminal block. Con-

nect the white wire to the common on the terminal

block. Connect the green or yellow and green striped

ground wire to the grounding screw.

F. Replace all panels.

4

Page 13

SECTION 3

INITIAL SETUP AND OPERATION

3.1 OPERATOR'S SAFETY PRECAUTIONS

SAFE OPERA TION IS NO ACCIDENT; Observe these

rules:

A. Know the freezer. Read and understand the

Operating Instructions.

B. Notice all warning labels on the freezer.

C. Wear proper clothing. Avoid loose fitting garments,

and remove watches, rings or jewelry which could

cause a serious accident.

D. Maintain a clean work area. Avoid accidents by

cleaning up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push

button or control you are about to use and what

effect it is going to have.

Figure 5. Controls

F. Disconnect electrical cord for maintenance.

Never attempt to repair or perform maintenance on

the freezer until the main electrical power has been

disconnected.

G. Do not operate under unsafe operating condi

tions. Never operate the freezer if unusual or excessive noise or vibration occurs.

3.2 OPERATING CONTROLS AND INDICATORS

Before operating the freezer, it is required that the

operator know the function of each operating control.

Refer to Figure 8 for the location of the operating

controls on the freezer.

A. Clean OFF ON Switch

The clean off on switch is a three position switch. In

the clean position only the drive and condenser fan

will run. In the ON position the drive and condenser

fan and compressor will run until the proper consistency is reached, then the compressor will stop and

the drive and condenser fan will continue to run.

B. Mix Low Light

The mix low light will illuminate when the liquid level

in the hopper is less than 2".

C. Standby Serve Switch

The standby switch is a two position switch. In the

standby position mix temperature will be maintained

between 32° and 40°F . In the serve position the

product temperature in the barrel will be determined

by product consistency .

D. Lights Off On Switch

The lights Off On Switch is a two position switch.

When the switch is in the ON position the lights will

illuminate, when the switch is in the off position the

lights will be OFF.

E. High Pressure Cut Out Switch

The high pressure cut out switch is located under the

right side frame about halfway back. Push up to reset.

Figure 6. Disassembling Freezer

3.3. DISASSEMBLY OF FREEZER PARTS

CAUTION

PLACE THE CLEAN OFF ON SWITCH IN THE OFF

POSITION BEFORE DISASSEMBLING FOR

CLEANING OR SERVICING.

Inspection for worn or broken parts should be made at

every disassembly of the freezer for cleaning or other

purposes. All worn or broken parts should be replaced to

ensure safety to both the operator and the customer and

to maintain good freezer performance and a quality product. Frequency of cleaning must comply with the local

health regulations.

5

Page 14

Figure 7. Front Door and Auger Assembly

T o disassemble the freezer , refer to the following steps:

A. Remove the front door by removing the upper and lower

plastic shrouds then turn off the knobs, and pull the

front door off the studs.

B. Remove the spigot body from the spout by pulling the

horse shoe clip up and out. Then pull the spigot body

out of the spout. Disassemble by turning off the black

plastic knob and removing all loose pieces.

C. Pull the agitator assembly out of the freezer barrel.

D. Keep the rear of the agitator assembly tipped up once

it is clear of the freezer barrel to avoid dropping rear

seal.

E. Remove the front agitator support bearing and the two

agitator blades.

F. Remove the rear seal assembly and disassemble.

G. Wipe socket lubricant from the drive end (rear) of the

agitator with a cloth or paper towel.

H. Remove all "O" Rings.

WARNING

DO NOT USE ANY TYPE OF SHARP OBJECT TO

REMOVE THE "O" RINGS.

Figure 8. Rear Seal Assembly

6

Page 15

3.4 CLEANING THE FREEZER PARTS

Place all loose parts in a pan or container and take to the

wash sink for cleaning. To clean freezer parts refer to the

following steps:

C. Lubricate the drive end of the agitator (rear) shaft with

a small amout of white socket lubricant. A small

container of socket lubrication is shipped with the

freezer.

A. Place all parts in warm mild detergent water and clean

with brushes provided. Rinse all parts with clean hot

water.

CAUTION

DO NOT DAMAGE PARTS BY DROPPING OR

ROUGH HANDLING.

B. Wash the freezer barrel and spout with warm detergent

water and brushes provided.

C. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild alkaline

cleaner is recommended. Use a soft cloth or sponge to

apply the cleaner.

D. Remove the drip tray and insert. Clean with a soap

solution. Rinse with clean hot water.

3.5 SANITIZE FREEZER AND FREEZER PARTS

A. Use a sanitizer mixed according to manufacturer's

instructions to provide a 100 parts per million strength

solution. Mix sanitizer in quantities of no less than 2

gallons (7.5 liters) of 120°F water. Allow the sanitizer to

contact the surfaces to be sanitized for 5 minutes. Any

sanitizer must be used only in accordance with the

manufacturer's instructions.

D. Install the two plastic agitator blades onto the agitator.

Install front agitator bearing.

E. Push the auger into the freezer barrel and rotate slowly

until the agitator engages the drive.

F. Assemble and install the spigot body with "O" Rings

into the spout. Push straight in until the spigot is in

place. Then install the horse shoe clip.

G. Install door "O" Ring.

H. Install the front door on the freezer.

I. Install the knobs on the freezer studs and tighten.

CAUTION

FINGER TIGHTEN THE KNOBS EVENL Y . DO NOT

OVER-TIGHTEN KNOBS.

Look for the poper seal between the freezer barrel door, "O"

Ring, and front door.

3.7 SANITIZING

Sanitizing must be done after the freezer is clean and just

before filling with mix. Sanitizing the night before is not

effective. However, you should always clean the freezer

and parts after using it.

B. Place all parts in the sanitizing solution, then remove

and let air dry.

3.6 ASSEMBLY OF FREEZER

To assemble the freezer parts, refer to the following steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubricants used on food processing equipment be certified for this use. Use lubricants only in accordance

with the manufacturer's instructions.

A. Assemble all "O" Rings onto parts dry, without lubrica

tion. Then apply a thin film of sanitary lubrication to

exposed surfaces of the "O" Rings. Apply a thin film of

sanitary lubricant on the fron tof the agitator shaft.

B. Assembly the rear seal assembly onto the agitator. Be

sure the "O" Rings and gaskets are in place before

installing the rear seal.

WARNING

THE UNITED ST ATES DEPARTMENT OF AGRICUL TURE AND FOOD AND DRUG ADMINISTRATION REQUIRE THAT ALL CLEANING AND SANITIZING SOLUTIONS USED WITH FOOD PROCESSING EQUIPMENT BE CERTIFIED FOR THIS

USE. USE "STERA-SHEEN" OR EQUIVALENT.

When sanitizing the freezer, refer to local sanitary regulations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations. Mix sanitizer

according to manufacturer's instructions to provide a 100

parts per million strength solution. Mix sanitizer in quantities of no less than 2 gallons (7.5 liters) of 120°F water.

Allow sanitizer to contact the surfaces to be sanitized for

5 minutes. Any sanitizer must be used only in accordance

with the manufacturer's instructions.

NOTE

Stoelting, Inc. has found that STERA-SHEEN

GREEN LABEL SANITIZER AND CLEANER does

an effective job of properly sanitizing and cleaning a

soft serve freezer. We therefore include a sample

with each new freezer. For further information read

the directions on the packet. Other products may

be as effective.

7

Page 16

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MA Y CAUSE CORROSION OF ST AINLESS STEEL P ARTS.

In general, sanitizing may be conducted as follows:

A. Prepare 2 gallons (7.5 liters) of sanitizing solution

following manufacturer's instructions.

B. Pour sanitizer into hopper.

C. Place the CLEAN OFF ON switch in the CLEAN

position. Check for leaks around the front door seal.

D. After five mintues, open spigot to drain sanitizing

solution. When solution has drained, place the CLEAN

OFF ON switch in the OFF position. Allow the freezer

barrel to drain completely.

3.8 INITIAL FREEZE DOWN AND OPERATION

This section covers the recommended operating procedures to be followed for the safe operation of the freezer.

A. Sanitize just prior to use.

B. Place the CLEAN OFF ON switch in the OFF position.

C. Fill the hopper with mix.

D. Place the CLEAN OFF ON switch in the ON position.

The product will be ready to serve in about 20-30

minutes.

3.9 CONSISTENCY ADJUSTMENT

The consistency adjustment knob is located next to the

right front leg. Turn clockwise for a thicker product and

counterclockwise for a thinner product. Allow 15-30 minutes for the product to change consistency.

Figure 9. Consistency Control Knob

8

Page 17

SECTION 4

BULB REPLACEMENT

4.1 LIGHT BULB REPLACEMENT

1. Remove the upper plastic shroud.

2. Remove the four retaining screws from the electrical

panel and tip forward.

3. Grasp faulty bulb and pull out.

4. Push in replacement bulb until it snaps into place.

5. Replace the electrical panel and secure with the four

retaining screws.

6. Replace the plastic shroud.

Figure 10. Light Bulb

9

Page 18

10

Page 19

SECTION 5

SEQUENCE OF OPERATIONS

5.1 LIGHTS

On/Off light switch is independent of all other switches.

When on, the light transformer is operational and the lights

illuminate.

5.2 SWITCHES

On/Off/Clean Mode

Switch Switch

Position Position Sequence of Operations

Clean Serve -Drive Motor and Condenser Fan Motor start and run together,

or No time limit exists.

Standby -Power Transformer, torque switch, compressor, liquid level

control, and mix low light are non-operational.

On Serve -Drive Motor and Condenser Fan start and run together

continuously.

-Power Transformer is on.

-Liquid level control and mix low light are operational.

-With liquid mix or loose slush in the freezing cylinder, the torque

switch is closed. The delay-on-make timer starts the compressor

after a 10-30 second delay.

-When the slush reaches consistency, the torque switch opens

and the compressor immediately shuts off. The drive motor and

condenser fan motor continue to run.

On Standby -Power transformer, liquid level control and mix low light are

operational only when the temperature control is closed.

-Drive motor, condenser fan motor, and compressor cycle on and

off with the temperature control (compressor start delays 10-30

seconds).

NOTE

If the temperature control is set too cold, control will default to the torque switch to prevent freeeze-up.

5.3 SAFETY SWITCH

Door Switch - If the front door is removed, the freezer will not function.

Motor Internal Thermostat - If the motor overheats, the freezer will not function.

Warning - The motor internal thermostat automatically resets as the motor cools. The freezer will automatically

restart. Disconnect freezer from power source for servicing.

High Pressure Cutout Switch - If the compressor discharge pressure exceeds 470 PSIG, the freezer will not

function.

11

Page 20

12

Page 21

SECTION 6

TROUBLESHOOTING

PROBLEM: CAU SE CORRECTION

High Pressure Cutout Sw itch T ripped.

Drive motor overload trips. (Freez er

shuts down when running)

Dirty condenser. Clean condenser

Improper Brix readi ng. Refill with product that has Brix reading between 11

and 13.

Product dispenses incorrectly.

Product is too thin.

Agitator Does Not Rotate

Toggle Switch in Standby

No Ice Crystals on Initial Freeze Down

Spigot Leaking or Stuck.

No mix in product cylinder or low m i x in hopper. Keep product cylinder and hopper full.

Scraper bl ade missing f r om agit ator. Repl ac e scraper blad e.

Freez er is bein g overd rawn . Sl ow dow n rat e of draw .

Ambient t emperature is about 100°F (37.7°C) . Move or d irec t hot air away from fr eezer.

Freez er is bein g overd rawn . Sl ow d own t he rat e of dr aw.

Condenser is dirty. Clean condenser.

Dri ve motor over l oad t ri p ped off . Tur n f reez er of f for 5 m i n utes, al l ow au t om at i c r eset .

Agi t ator st uc k or f rozen . Check for locked or bent fingers. Thaw product in

No power to drive motor. Chec k w i r e har n ess and swit c h es i n dr i ve c i r c u it an d

Drive motor is defective. Check and repl ace i f nec essar y.

Toggle switch in OFF or CLEAN position. Place toggle sw itch in ON posi t ion.

Blown fuse in building or no input power to

freezer.

Mix too rich. Take "Brix" reading. Fill wit h properly mixed product.

Rest ric ted air fl ow t o freezer . Ai r en t ers l ow er f ron t and d i sc h arg es out t h e t op bac k ,

Consistency set for too thin a product. Set consistency to a thicker product.

Spigot "O" rings defective or missing. Drain mix to below spigot level. Remove spigot, clean,

freezer if frozen.

repai r or r epl ace.

Check for blown fuse or input power to freezer.

mak e cert ain bot h areas are clear.

repl ace "O" rin gs as need ed, lu bricate and inst all.

Dried m ix in spigot assem bl y . Drain mix to below spigot level. Remove spigot retainer

and spigot. Disassemble and clean with hot water and

brush. Lubricate, re-assemble and install. Fill with liquid

mix.

13

Page 22

1415161718192021222324

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

WARRANTY

MIX TRANSFER PUMPS / COCKTAIL / SLUSH

1. Scope:

Stoelting LLC warrants to the first user (the “Buyer”) that the evaporator assembly and compressor (if applicable)

of Stoelting mix transfer pump, cocktail and slush equipment will be free from defects in materials and workmanship under normal use and proper maintenance appearing within five (5) years (two (2) years for “Mirage” equipment), and that all other components of such equipment manufactured by Stoelting will be free from defects in

material and workmanship under normal use and proper maintenance appearing within twelve (12) months after

the date that such equipment is originally installed.

2. Disclaimer of Other Warranties:

THIS WARRANTY IS EXCLUSIVE; AND STOELTING HEREBY DISCLAIMS ANY IM-

PLIED WARRANTY OF MERCHANT ABILITY OR FITNESS FOR P AR TICULAR PURPOSE.

3.

Remedies:

Stoelting’s sole obligations, and Buyer’s sole remedies, for any breach of this warranty shall be the repair or (at

Stoelting’s option) replacement of the affected component at Stoelting’s plant in Kiel, Wisconsin, or (again, at

Stoelting’s option) refund of the purchase price of the affected equipment, and, during the first ninety (90) days of

the warranty period, deinstallation/reinstallation of the affected component from/into the equipment. Those obligations/remedies are subject to the conditions that Buyer (a) signs and returns to Stoelting, upon installation, the

Warranty Registration Card for the affected equipment, (b) gives Stoelting prompt written notice of any claimed

breach of warranty within the applicable warranty period, and (c) delivers the affected equipment to Stoelting or its

designated service location, in its original packaging/crating, also within that period. Buyer shall bear the cost and

risk of shipping to and from Stoelting’s plant or designated service location.

4. Extensions:

The warranty period for deinstallation/reinstallation of the affected component from/into the equipment is extended

to twelve (12) months on the following models: SO218, SO318, SO328. The warranty period for the drive motor

to be free of defects in materials and workmanship extended to five (5) years on the following models: SO218,

SO318, SO328.

5. Exclusions and Limitations:

This warranty does not extend to parts, sometimes called “wear parts”, which are generally expected to deteriorate

and to require replacement as equipment is used, including as examples but not intended to be limited to o-rings,

hoses, seals and drive belts. All such parts are sold

AS IS.

Further, Stoelting shall not be responsible to provide any remedy under this warranty with respect to any component that fails by reason of negligence, abnormal use, misuse or abuse, use with parts or equipment not manufactured or supplied by Stoelting, or damage in transit.

THE REMEDIES SET FORTH IN THIS WARRANTY SHALL BE THE SOLE LIABILITY

STOELTING AND THE EXCLUSIVE REMEDY OF BUYER WITH RESPECT TO EQUIPMENT SUPPLIED BY STOELTING; AND IN NO EVENT SHALL STOELTING BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER FOR BREACH

OF WARRANTY OR OTHER CONTRACT BREACH, NEGLIGENCE OR OTHER TORT,

OR ON ANY STRICT LIABILITY THEORY.

File: Policy Manual/Warrantyslush1

Loading...

Loading...