Page 1

Model S100 / S400 / S500

OPERATORS MANUAL

Manual No. 513560

Page 2

Page 3

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

Page 4

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS .................................................................................................................................... 2

SECTION 1 - INTRODUCTION ......................................................................................................................... 4

1.1 Description ........................................................................................................................................ 4

1.2 Specifications .................................................................................................................................... 4

SECTION 2 - SHIPMENT ................................................................................................................................. 5

2.1 Shipment and Transit........................................................................................................ ................. 5

2.2 Installation ......................................................................................................................................... 5

SECTION 3 - OPERATION INSTRUCTIONS.................................................................................................... 6

3.1 Operator's Safety Precautions ........................................................................................................... 6

3.2 Lil’ Shaver and Blender Controls ........................................................................................................ 6

3.3 Cleaning and Sanitizing ..................................................................................................................... 7

SECTION 4 - ADJUSTMENTS.......................................................................................................................... 8

4.1 Dispense Rate................................................................................................................................... 8

4.2 Shaver Motor Reset ........................................................................................................................... 8

SECTION 5 - ELECTRICAL .............................................................................................................................. 9

SECTION 6 - MECHANICAL............................................................................................................................. 12

SECTION 7 - TROUBLESHOOTING ................................................................................................................ 16

SECTION 8 - DRAWINGS AND WIRING DIAGRAMS ..................................................................................... 18

Page 6

ILLUSTRATIONS

Fig.1 - Drain Hose Connection ......................................................................................................................5

Fig.2 - Operation Safety................................................................................................................................. 6

Fig.3 - Operation Control ...............................................................................................................................6

Fig.4 - Adjusting Screw & Overload ............................................................................................................ 8

Fig.5 - Electrical Access.................................................................................................................................9

Fig.6 - Switch Removal..................................................................................................................................9

Fig.7 - Time Delay Relay ...............................................................................................................................10

Fig.8 - Drink Selector Switch.........................................................................................................................10

Fig.9 - Potentiometer .....................................................................................................................................10

Fig.10 - Safety Switch ...................................................................................................................................... 11

Fig.11 - Contactors ...........................................................................................................................................11

Fig.12 - Time Delay Relay ...............................................................................................................................11

Fig.13 - Shaver Blade Replacement...............................................................................................................12

Fig.14 - Shaver Blade ......................................................................................................................................12

Fig.15 - Blender Motor .....................................................................................................................................13

Fig.16 - Shaver Drive Motor............................................................................................................................. 14

Fig.17- Drive Bearings Assembly ...................................................................................................................14

Page 7

SECTION 1

INTRODUCTION

1.1 DESCRIPTION

The LIL' SHAVER® is a heavy-duty ice shaver and frozen

drink blending machine. This machine can be used to

make perfect frozen cocktails, fruit juices, slush drinks,

frozen coffee drinks, non-alcoholic drinks and more. The

instructions in this manual should be followed closely for

trouble-free operation.

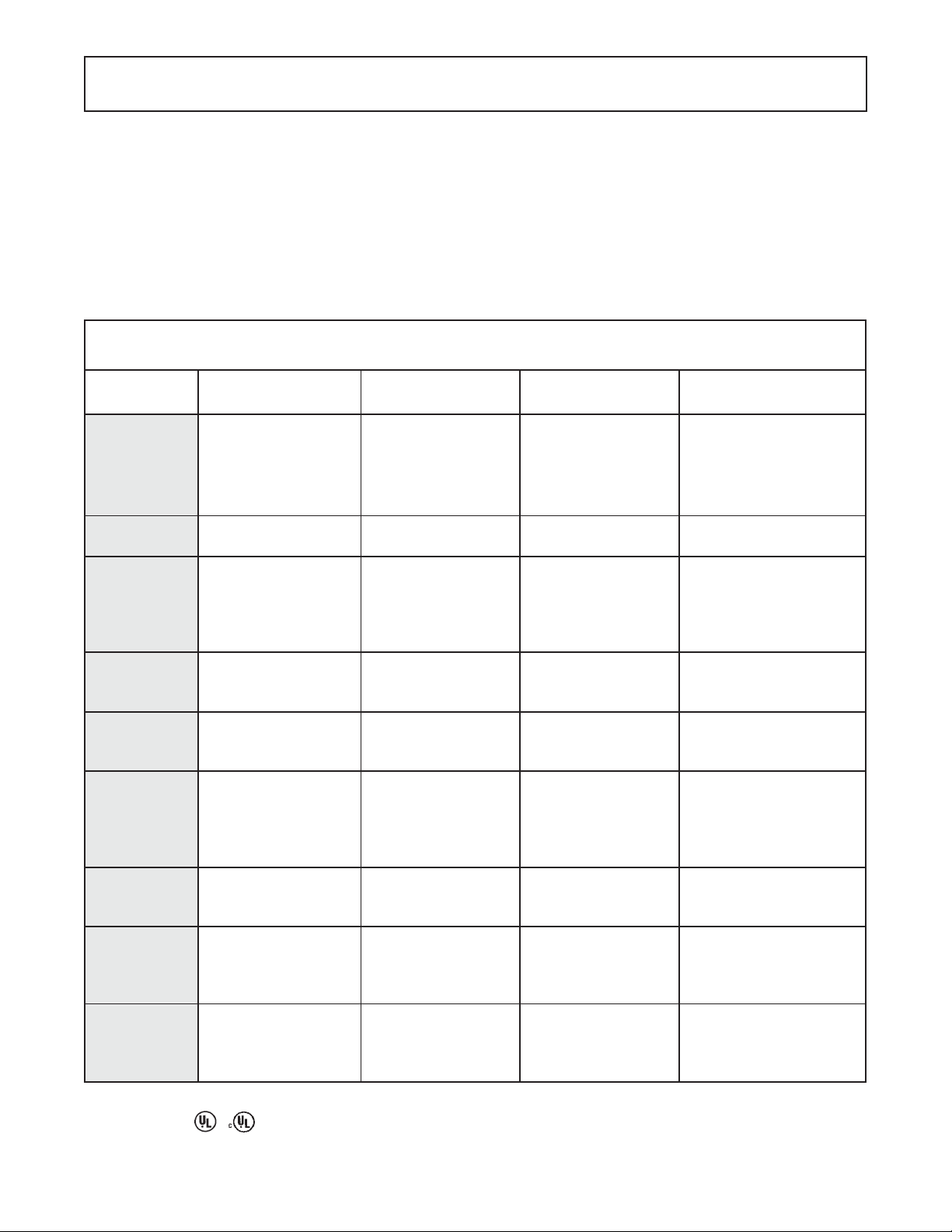

1.2 SPECIFICATIONS

001S004S005S015S/505S

SNOITACIFICEPS

SNOISNEMID

htdiW

htpeD

thgieH

THGIEW )gk23(.sbl17)gk23(.sbl17)gk23(.sbl17)gk23(.sbl17

LACIRTCELE ,stlov511,esahP1

REVAHS

ROTOM

REDNELB

ROTOM

REPPOH

YTICAPAC

)mc6.82("3.11

)mc66("62

)mc66("62

drocpmA51.zh06

gninnur21;detcennoc

spma

tratsroticapac,pH52.tratsroticapac,pH52.tratsroticapac,pH52.tratsroticapac,pH52.

deeps2,pH34.

)MPR00041&00081(

snollag5.xorppA

.sbl32(ecidebuc

)001(.xorppa=)gk01

sknird.zo21

uc

)mc6.82("3.11

)mc3.05("12

)mc66("62

,stlov511,esahP1

drocpmA51.zh06

1;detcennoc

spma

gninnur2

deeps2,pH34.

)MPR00041&00081(

snollag5.xorppA

.sbl32(ecideb

)001(.xorppa=)gk01

sknird.zo21

)mc6.82("3.11

)mc3.05("12

)mc66("62

,stlov511,esahP1

drocpmA51.zh06

gninnur21;detcennoc

spma

deeps2,pH34.

)MPR00041&00081(

snollag5.xorppA

.sbl32(ecidebuc

)001(.xorppa=)gk01

sknird.zo21

)mc6.82("3.11

)mc3.05("12

)mc66("62

)mc08-"5.13thgieH015S(

.zh06,stlov511,esahP1

ocpmA51

llag5.xorppA

;detcennocdr

spmagninnur21

deeps2,pH34.

)MPR00041&00081(

ecidebucsno

.xorppa=)gk01.sbl32(

sknird.zo21)001(

).lag01.xorppa015S(

REDNELB

YTICAPAC

)egnardim(

REDNELB

*EMITNUR

)egnardim(

U/L approved

.lag2/1,.zo46

)retil2(

EMITEVAHS

.ces7.5-knirD1

.ces1.9-knirD2

.ces0.31-knirD3

irD3

.lag2/1,.zo46

)retil2(

.ces7.5-knirD1

.ces1.9-knirD2

.ces0.31-kn

1

.lag2/1,.zo46

)retil2(

.ces7.5-knirD1

.ces1.9-knirD2

.ces0.31-knirD3

*.ces6.5-knirD1

.ces0.9-knirD2

.ces1.31-knirD3

* Not all models

.lag2/1,.zo46

)retil2(

.ces8-knirD1

.ces11-knirD2

.ces41-knirD3

*.ces01-knirD1

.ces51-knirD2

.ces0

2-knirD3

Page 8

2

Page 9

SECTION 2

SHIPMENT

2.1 SHIPMENT AND TRANSIT

The LIL' SHAVER® has been completely assembled,

operated and inspected at the factory. Upon arrival at the

final destination, the ice shaver must be checked for any

damage that may have occurred during transit. THE

CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN

TRANSIT,WHETHER VISIBLE OR CONCEALED. Do not

pay the freight bill until you have checked the equipment.

Have the carrier note any visible damage on freight bill. If

concealed damage and/or shortages are found later, advise the carrier inspector within ten days and request

inspection. You must make claim for damages and/or

shortages in shipment with the carrier. STOELTING, INC.,

CANNOT MAKE ANY CLAIMS AGAINST THE CARRIER.

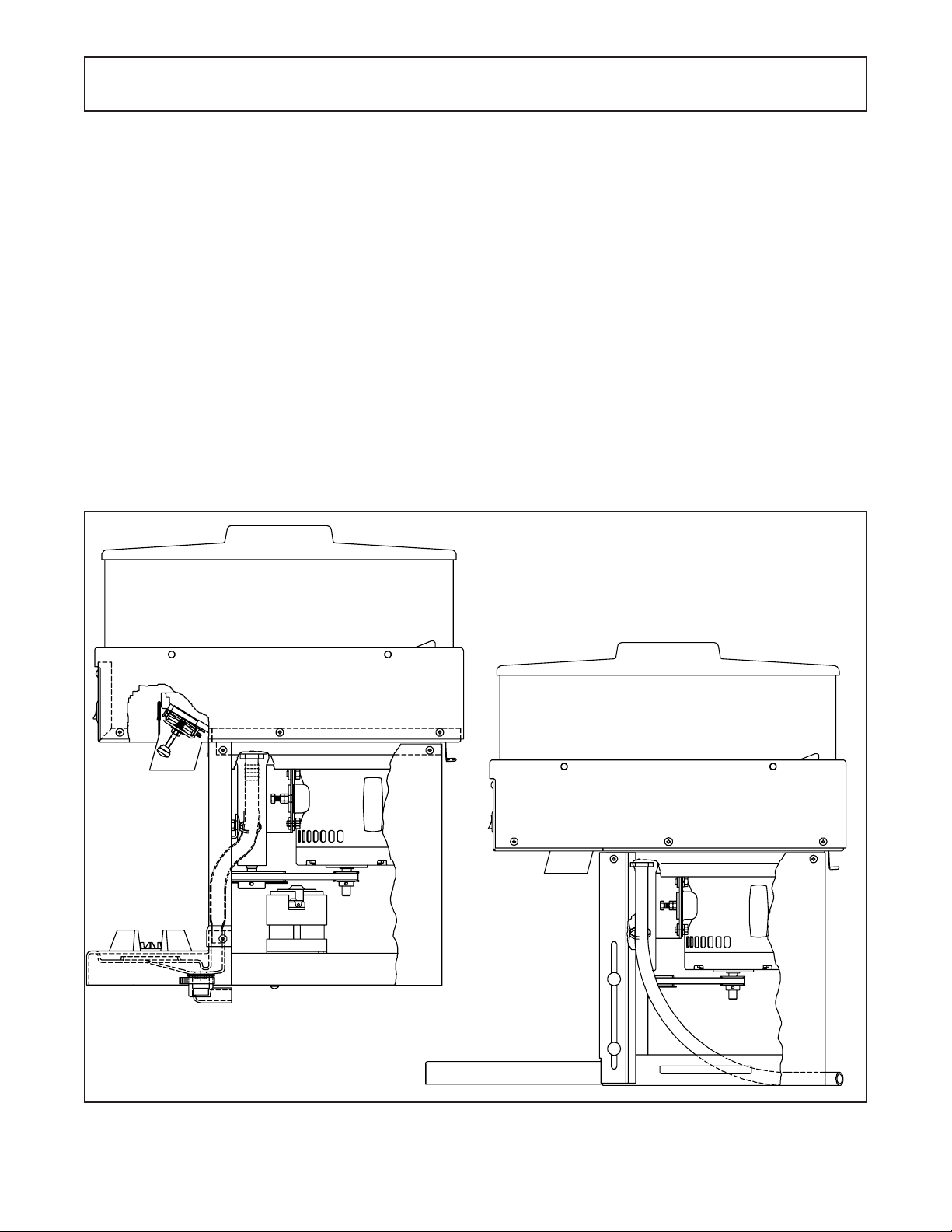

2.2 INSTALLATION

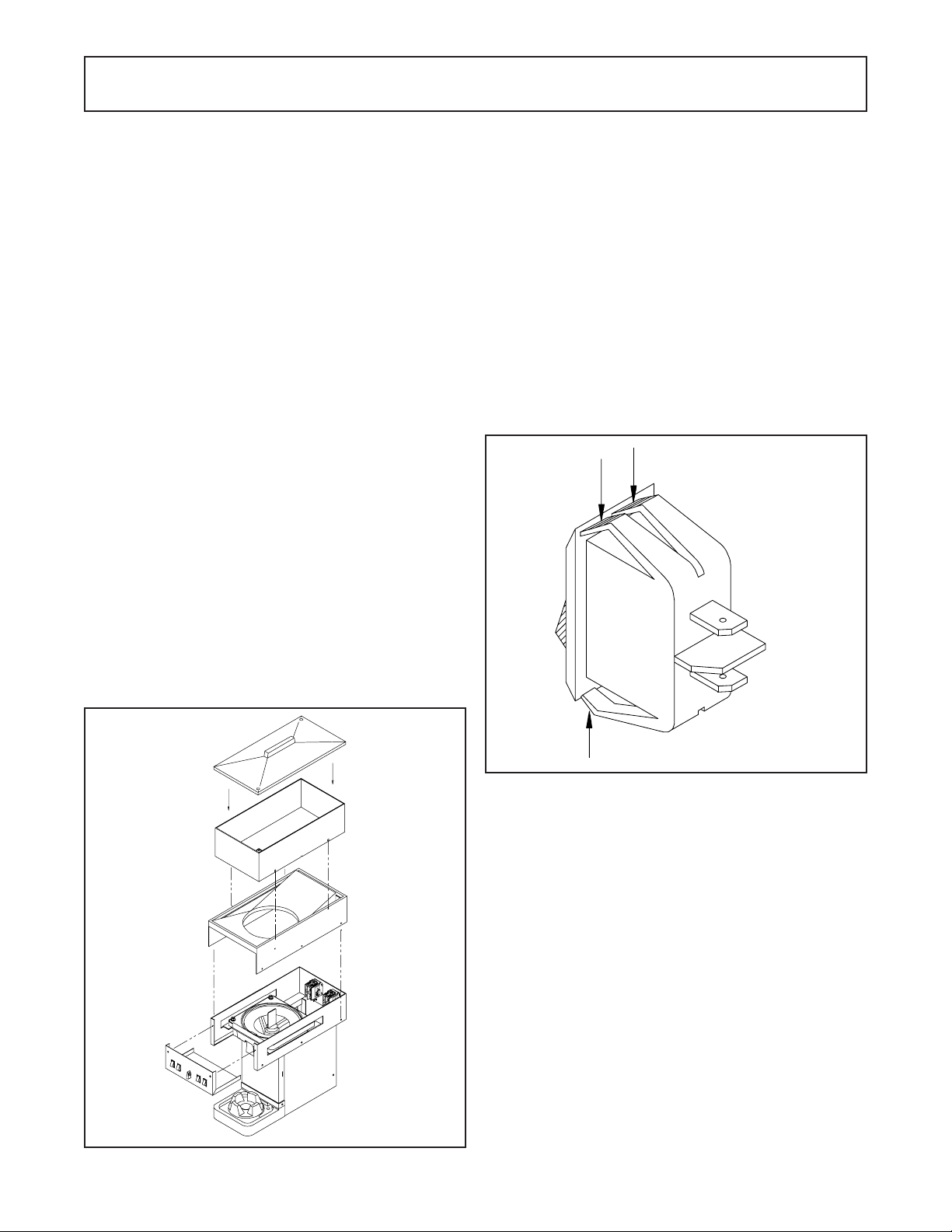

A. Unbox the Lil’ Shaver

B. Place on a level, solid surface.

C. Adjust the rubber feet until the shaver is level and

resting solidly on all four feet. (Feet can be placed in

alternate locations to match various counter depths).

D. Connect the separate drain hose to the drain, and direct

the hose to a sink, floor drain or container. Liquid must

not cover the hose end or the unit will not drain properly.

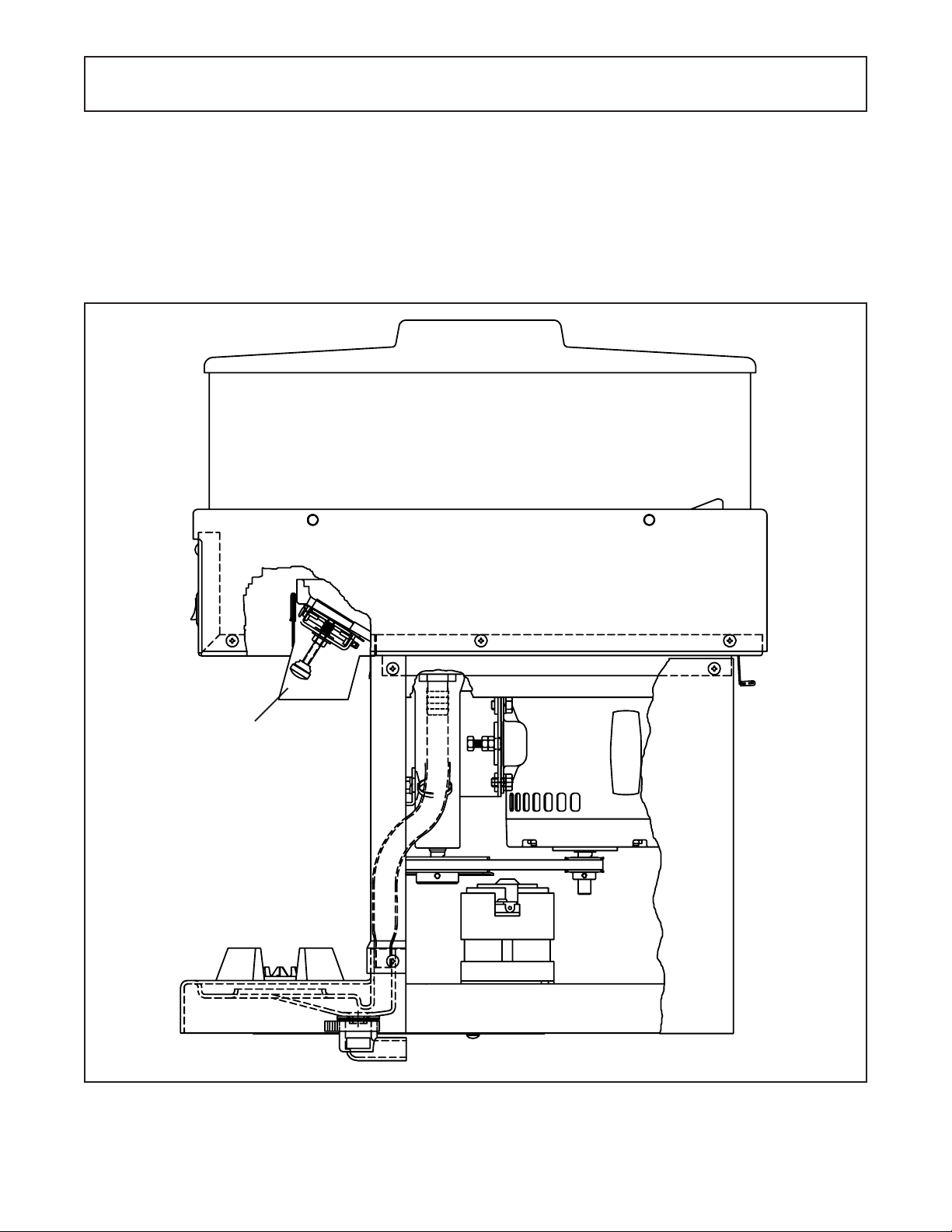

(Figure 1)

E. Plug the 115 volt 15 amp cord plug into a dedicated

circuit. We do not recommend using an extension cord,

but if it is necessary to use one, it must be a number 12

gauge or heavier wire with a ground.

WARNING

DO NOT USE A GROUNDED ADAPTER PLUG OR

ALTER THE ELECTRICAL CORD IN ANY WAY.

FAILURE TO HEED THE WARNING COULD

CAUSE DAMAGE TO THE MACHINE OR PERSONAL INJURY.

Late

Early

Figure 1

Drain Hose Connection

S500 Shown

3

Page 10

4

Page 11

SECTION 3

OPERATOR INSTRUCTIONS

3.1 OPERATORS SAFTEY PRECAUTIONS

Safe operation is no accident; observe these rules:

A. Know the equipment. Read and understand the operat-

ing instructions.

B. Notice all warning labels on the equipment.

C. Wear proper clothing. Avoid loose-fitting garments, and

remove watches, rings or jewelry which could cause a

serious accident.

D. Maintain a clean work area. Avoid accidents by clean

ing up the area and keeping it clean.

E. Stay alert at all times. Know which switch, push button

or control you are about to use, and what effect it is

going to have.

F. Disconnect electrical cord for maintenance. Never at-

tempt to repair or perform maintenance on the unit until

the main electrical power has been disconnected.

G. Do not operate under unsafe operating conditions.

Never operate the machine if unusual or excessive

vibration occurs.

H. Do not operate the unit without the hopper cover and

hopper in place and intact. (Figure 2)

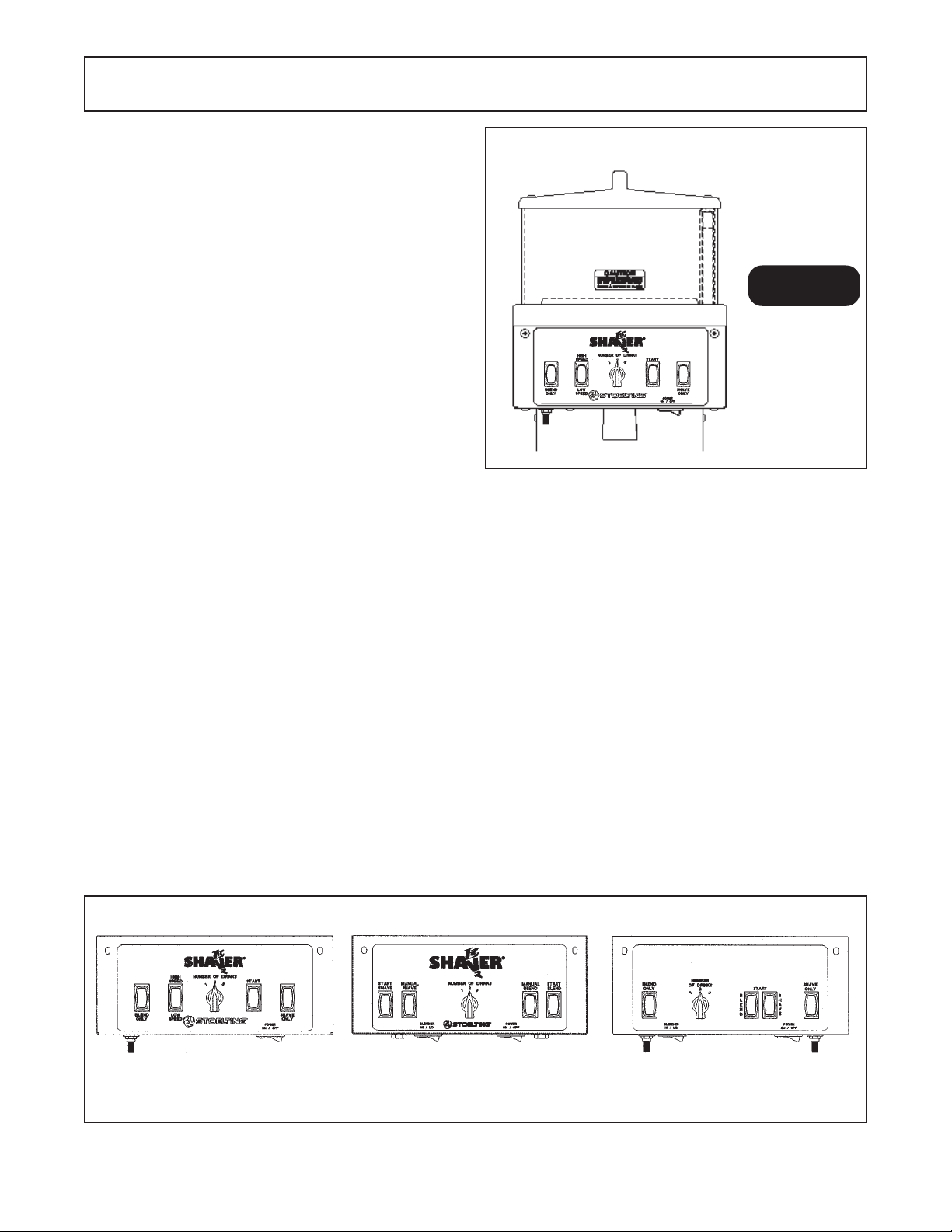

3.2 LIL’ SHAVER AND BLENDER CONTROLS

Before operating it is required the operator know the

function of each operation control. Refer to Figure 3 for

location of the operating controls on the machine.

Hopper Cover

ÌË

Hopper

Ë

CAUTION

HAZARDOUS ROTATING

PARTS. DO NOT OPERATE

Å

WITHOUT COVER OR HOPPER

IN PLACE.

Figure 2

Operation Safety

S100/S500 Shown

B. Blend Time Adjuster. To increase blend time (fine ice)

turn adjuster clockwise. To decrease blend time turn

adjuster counter-clockwise.

NOTE

Use a small screwdriver to adjust.

C. Blend Start Switch. When activated, the start switch

will blend the drink for the pre-set time.

A. The POWER ON/OFF switch. When the POWER ON/

OFF switch is placed in the OFF position, the machine

will not run. When the switch is placed in the ON

position the shaver and blender can be operated by

activating the appropriate switch.

S100/S500 S502+

S505/S510

Figure 3

Operation Controls

NOTE

Blender will not start until 2.2 seconds after the

shave switch has been activated. (Models 505/510)

5

Page 12

D. BLEND ONLY Switch when activated, the blender drive

will run until the switch is released.

E. HIGH SPEED/LOW SPEED Switch (models S100/

S500 only). When in the LOW SPEED position, the

blender drive operates at the lower speed when the

BLEND ONLY switch is activated. When in the HIGH

SPEED position, the blender drive will operate at the

higher speed when the BLEND ONLY switch is activated.

F. NUMBER OF DRINKS ROTARY Switch (models S100/

S500 series only).The NUMBER OF DRINKS switch

operates a timer. When the desired number of drinks

has been selected and the START switch activated, the

machine will shave enough ice for that number of drinks,

then stop.

WARNING

USE CAUTION WHEN ACCESSING THE ICE

SHAVING AREA. THE ICE SHAVING BLADE IS

EXTREMELY SHARP. CONTACT WITH THIS

BLADE COULD CAUSE INJURY .

B. Spray ice hopper and shaving area with an approved

cleaner/sanitizer.

C. Wash hopper cover in warm soapy water, rinse, then

sanitize and let dry.

CAUTION

DO NOT PUT ANY P ARTS THROUGH THE DISHWASHER. THESE PARTS ARE NOT DISHWASHER SAFE AND DAMAGE WILL OCCUR.

G. SHAVE TIME ADJUSTER to increase shave time

(more ice) turn adjuster clockwise. To decrease shave

time turn adjuster counter-clockwise.

NOTE

USE A SMALL SCREWDRIVER TO ADJUST .

H. Shave START Switch (models S100/S500 series only).

When activated, the START switch will shave ice for the

number of drinks selected, then stop.

I. SHAVE ONLY Switch. When the SHAVE ONLY switch

is activated, the machine will shave ice as long as the

switch is depressed. When released, it will stop.

3.3 Cleaning and Sanitizing

It is important to keep your LIL' SHAVER® clean and

sanitary. To properly clean and sanitize, follow the instructions below.

A. Remove ice from hopper by pressing the SHAVE ONLY

switch and dispensing into a container.

D. Disassemble blender following the steps outlined be

low.

1.Remove cover center knob (if used) by turning counter-

clockwise.

2.Remove blade assembly from bowl by turning counter-

clockwise viewed from driven end.

WARNING

NEVER GRASP THE BLADE ASSEMBL Y BY THE

CUTTING BLADES. THE BLADES ARE EXTREMEL Y SHARP AND COULD CAUSE INJUR Y

IF HANDLED IN A CARELESS MANNER.

3.Remove rubber gasket.

4.Clean all parts in warm soapy water, rinse, then

sanitize and let air dry.

5.Assemble all parts in reverse order.

6

Page 13

SECTION 4

ADJUSTMENTS

4.1 Dispense Rate

The rate of ice shaving can be adjusted by raising or

lowering the shaving blade. The adjusting screw is accessed from just behind the POWER ON/OFF switch.

Counter clockwise rotation of the adjusting knob gives a

faster dispense rate (more ice shaved in the same time.)

Make small (1/8 turn) changes in the adjusting screw until

the desired rate is achieved. (Figure 4)

4.2 Shaver Motor Reset

The machine’s shaver motor is equipped with an overload

devise to protect the motor and shaver. Manually reset this

protector by pulling the reset lever down. (Figure 4)

Ê

Adjusting Knob

Figure 4

Adjusting Screw and Overload

S500 Shown

Overload

Å

Reset

7

Page 14

8

Page 15

SECTION 5

ELECTRICAL

The control circuit consists of a combination of switches,

potentiometers, and time delay relays. The electrical controls along with an adjustable ice shaving blade allow the

operator to not only adjust the amount of ice shaved but

also the ice shaving size.

To gain access to the electrical controls perform the following procedures:

W ARNING

DISCONNECT SHAVER FROM THE SOURCE OF

ELECTRICAL SUPPL Y BEFORE SER VICING .

1. To access the front electrical box remove the six retaining screws, then pull down and out.

If additional room is desired to service the front electrical

box or if access to the contactors is required perform the

following procedures:

1. Remove the hopper cover. Figure 5.

2. Remove the four hand screws and lift the hopper up

and off.

3. Remove the seven screws holding the ice inlet chute,

then lift straight up.

4. T o provide access to the contactors remove the two

hex head nuts holding the contactor cover and lift off.

5. To access the time delay relays and the general

purpose relay, remove the lower sheet met al. Then

remove the two philips head screws and remove

electrical box cover. (Models 505/510 only .)

The components are now completely accessible and any

testing or service can be done.

IMPORTANT NOTE

When replacing electrical components identify wires

before removing or place the wires from the existing

component onto the replacement component one

at a time to avoid errors.

To replace electrical components perform the following

procedures:

Power on/off switch

1. Identify and remove the wires from the switch.

2. Squeeze the four retaining tabs together and push the

switch through the hole. Figure 6.

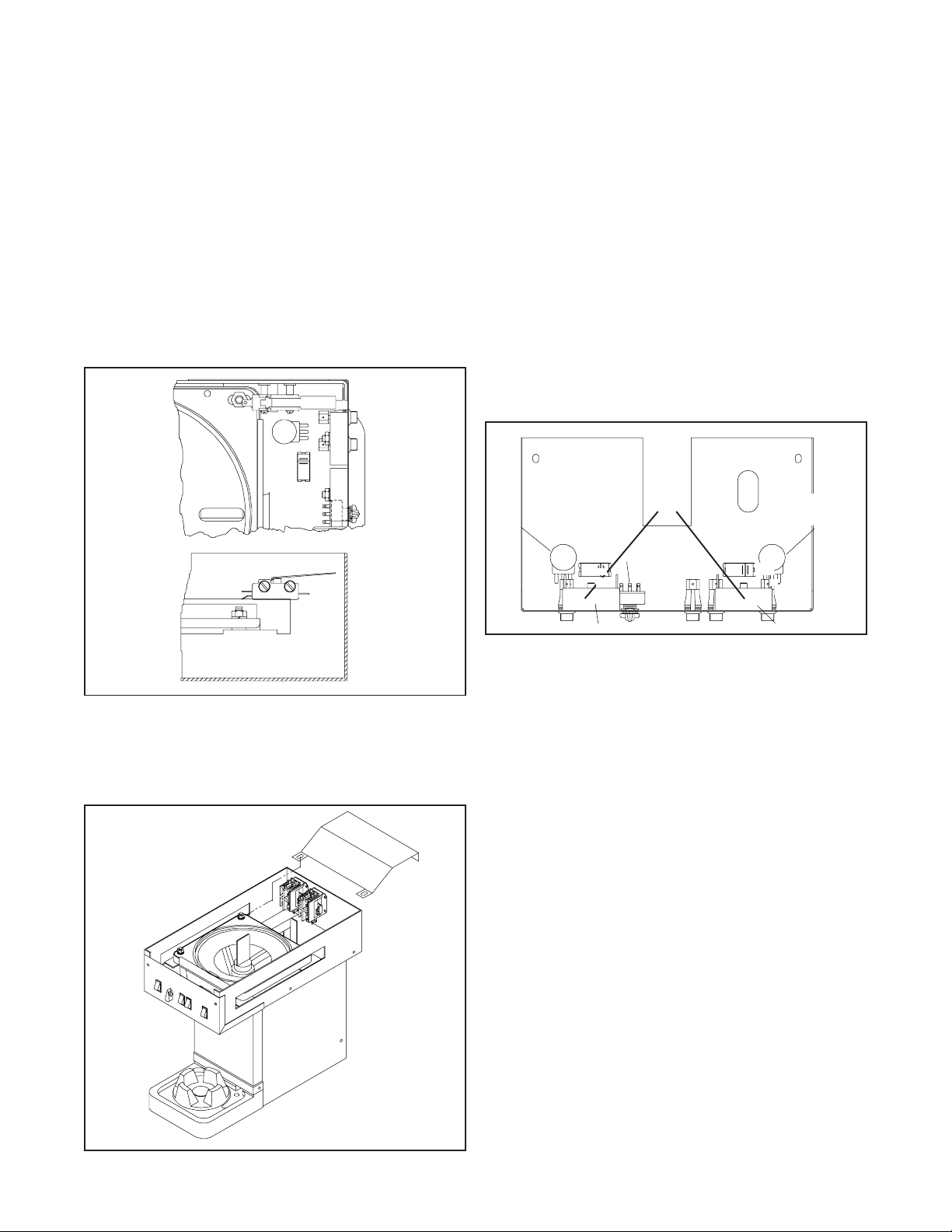

Fig. 5 - Electrical Access

Fig. 6 - Switch Removal

3. Push the replacement switch through the hole with the

red half of the rocker to the right side.

4. Reconnect the wires.

Blender High/Low Switch

1. Identify and remove the wires from the switch.

2. Squeeze the four retaining tabs together and push the

switch through the hole.

3. Push the replacement switch through the hole with the

red half of the rocker to the right side.

4. Reconnect the wires.

Blend Only Switch

1. Identify and remove the wires from the switch.

2. Squeeze the four retaining tabs together and push the

switch through the hole.

3. Push the replacement switch through the hole with the

protruding part of the rocker to the bottom.

4. Reconnect the wires.

9

Page 16

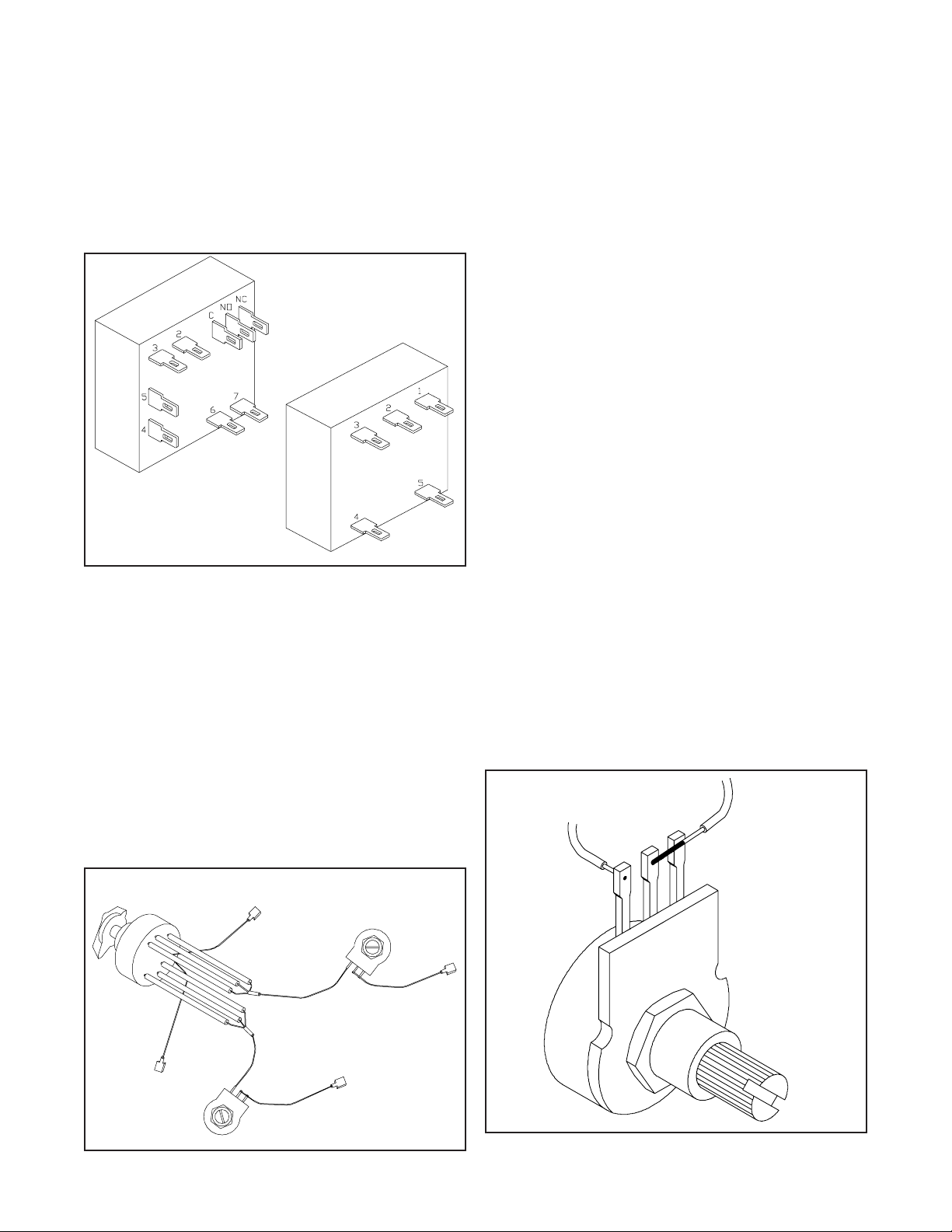

Drink Selector Switch

The selector switch is sold as an assembly that includes

the two potentiometers.

1. Remove the wire connecting the blender timer potentiometer to the time delay relay (Fig.7).

NOTE

On Models S505/S510 the time delay relays are

located in the rear of the shaver. Remove the lower

back sheet metal and electrical box cover to access.

Relay #1

Å

Relay #2

Æ

Blend Start Switch

1. Identify and remove the wires from the switch.

2. Squeeze the four retaining tabs together and push the

switch through the hole.

3. Push the replacement switch through the hole with the

protruding part of the rocker to the bottom.

4. Reconnect the wires.

Shave Start Switch

1. Identify and remove the wires from the switch.

2. Squeeze the four retaining tabs together and push the

switch through the hole.

3. Push the replacement switch through the hole with the

protruding part of the rocker to the bottom.

4. Reconnect the wires.

Shave Only Switch

1. Identify and remove the wires from the switch.

2. Squeeze the four retaining tabs together and push the

switch through the hole.

3. Push the replacement switch through the hole with the

protruding part of the rocker to the bottom.

4. Reconnect the wires.

Blend Potentiometer

1. Unsolder and remove the two wires.

Fig. 7 - Time Delay Relay

2. Remove the wire connecting the shave timer potentiometer to the time delay relay.

3. Remove the wire connecting the selector switch to the

blender time delay relay.

4. Remove the wire connecting the selector switch to the

shave time delay relay.

5. To remove the rotary selector switch knob loosen the

small set screw located at the bottom of the knob and

pull the knob off.

6. Remove the retaining nuts from the selector switch and

the two potentiometers (Fig.8). Then remove the complete assembly.

7. To install the replacement switch assembly reverse

steps 1 through 6.

Rotary Switch

Ë

Potentiometer

Ë

NOTE

Two legs of the potentiometer are jumpered, the replacement must be connected the same way.

2. Remove the retaining nut and remove the potentiometer. Take note where the shakeproof washer is

located.

3. Install the replacement potentiometer and shakeproof

washer, then install and tighten the retaining nut.

4. Reattach wires and solder.

Shave Potentiometer

1. Unsolder and remove the two wires.

Potentiometer

Fig. 8 - Drink Selector Switch

Æ

Fig. 9 - Potentiometer

10

Page 17

NOTE

Two legs of the potentiometer are jumpered, the replacement must be connected the same way

(Fig.9).

2. Remove the retaining nut and remove the potentiometer. Take note where the shakeproof washer is

located.

3. Install the replacement potentiometer and shakeproof

washer, then install and tighten the retaining nut.

4. Reattach wires and solder.

Safety Switch

1. Remove the three wires from the switch.

2. Remove the two retaining screws and spacers (Fig.10).

3. Install replacement switch using the spacers between

the switch and frame. Tighten screws.

3. Install replacement contactor with L1 & L2 terminals

up.

4. Install the star washers and hex nuts, then tighten

securely.

5. Reconnect the wires.

Shaver Contactor

1. Identify and remove the wires from the contactor.

2. Remove the two hex head nuts and star washers, then

lift out contactor.

3. Install replacement contactor with L1 & L2 terminals

up.

4. Install the star washers and hex nuts, then tighten

securely.

5. Reconnect the wires.

Blender Time Delay Relay

1. Identify and remove the wires from the delay relay.

2. Remove the hex head nut and star washer, then slide

off from weld stud (Fig.12).

Relay

Fig. 10 - Safety Switch

Blender Contactor

1. Identify and remove the wires from the contactor.

2. Remove the two hex head nuts and star washers, then

lift out contactor (Fig. 11).

Fig. 11 - Contactors

Fig. 12 - Time Delay Relay

3. Install the replacement part in the same position.

4. Install star washer and hex nut, then tighten.

5. Reconnect the wires.

Shaver Time Delay Relay

1. Identify and remove the wires from the time delay relay.

2. Remove the hex head nut and star washer, then slide

off from weld stud.

3. Install the replacement part in the same position.

4. Install star washer and hex nut, then tighten.

5. Reconnect the wires.

Blender Start Time Delay Relay (Some Models)

1. Remove the varistor.

2. Identify and remove the wires from the time delay relay.

3. Remove the hex head nut and start washers, then slide

off from weld stud.

4. Install replacement part in the same position.

5. Install star washer and hex nut, then tighten.

6. Reconnect the wires.

General Purpose Relay

1. Identify and remove wires from the relay.

2. Remove the two retaining screws and star washers.

3. Install the replacement part in the same position and

secure with the screws and star washers.

4. Reconnect the wires.

11

Page 18

12

Page 19

SECTION 6

MECHANICAL

W ARNING

WHEN WORKING ON MECHANICAL DEVICES

THAT ARE DESIGNED TO CUT, GRIND, OR

SHAVE, EXTREME CAUTION MUST BE EXERCISED. TAKE PROPER PRECAUTIONS WHEN

WORKING IN AREAS WHERE CUTTING BLADES

CAN BE CONT ACTED. FAILURE T O HEED THIS

WARNING COULD RESUL T IN INJUR Y .

Shaver Blade Replacement

1. Remove the six retaining screws from the electrical

box, then pull down and out.

2. Remove the protective strip (some models) and pull the

drip pan cover straight out (Fig.13).

ÈÈ

È

ÈÈ

Fig. 13 - Shaver Blade Replacement

3. Remove the ice discharge chute by removing the two

screws.

W ARNING

THE SHAVER BLADE IS EXTREMELY SHARP.

TAKE THE PROPER PRECAUTIONS TO AVOID

INJURY.

4. Remove the two screws holding the blade to the

bracket. (Fig. 14)

Bowl

Ì

Ê

Ê

6. Fasten the replacement blade to the bracket with the

two screws and tighten securely.

7. Install the ice discharge chute and secure with the two

screws.

8. Install the drip pan cover and protective strip.

9. Install the electrical box and secure with the six

screws.

Blender Drive Clutch Replacement

1. To remove the clutch hold the shaft with a straight

bladed screwdriver and turn the clutch clockwise (left

hand thread).

2. To install, thread the replacement clutch onto the shaft

counter-clockwise. Then hold the shaft with a straight

bladed screwdriver and tighten.

NOTE

Some early models did not have the screwdriver slot

in the shaft. Access from the bottom and hold the

pulley to remove the clutch.

Major Component Replacements

For major component replacements, you must first remove

the necessary sheet metal and plastic panels. Then

remove the four screws and star washers holding the

slotted cover at the bottom of the unit.

Bearing Replacement

When replacing bearings and seals a few simple rules

must be followed to secure longevity of the replacement

parts.

1. Make certain you have all the parts and tooling to

complete the job.

2. Maintain a clean work area.

3. Follow all instructions furnished with parts and/or tooling.

4. Make certain all set screws are loosened or removed

and remove all snap rings before pressing out parts.

5. Use proper tooling when pressing out parts to avoid

damage.

6. Thoroughly clean all parts to be reused.

7. When pressing in bearings or shafts, use tooling that

contacts the bearing race offering the greatest resistance.

Screws

Fig. 14 - Shaver Blade

5. Properly dispose of the used blade.

Blender Drive Bearing Replacement

1. Remove the blender drive clutch by holding the shaft

with a straight bladed screwdriver and turning the clutch

counter-clockwise (left hand thread).

2. Loosen the four retaining nuts holding the blender drive

motor mounting plate and slide toward the front to

loosen the belt.

3. Remove the drive belt.

4. Remove the blender drive pulley by loosening the two

set screws and pulling straight off.

13

Page 20

NOTE

For disassembly see parts breakdown on Pg.20.

4. Loosen the shaver drive motor adjustment screw and

remove the belt.

5. Remove the wave washer and flat washer.

6. Remove the flat head countersunk screws and remove

the bearing assembly.

7. Remove the shaft and flat washer from the bearing

assembly (slip fit). If stuck use a small arbor press.

8. To remove the bearings use an inside bearing puller. An

alternate method is to place the bearing retainer with

the small end down inside a 1-1/4" socket or a short

piece of pipe on a solid surface. Then using a small drift

punch and hammer go through the top bearing to the

lower bearing and tap the inner race moving the punch

after each tap in a circular motion. The second bearing

can be pushed out with a small arbor press.

9. Inspect the bearing retainer for any damage, if damaged

replace.

10.Use a small arbor press to push in the replacement bearings, use a tool that fully contacts the outer

race to avoid damaging the replacement bearing.

NOTE

Many bearings are destroyed during assembly because of improper assembly methods and tooling.

Pressure exerted on the race offering little or no resistance to push on a race of offering a much greater

resistance can cause cracks in the balls or race

and ultimate failure.

11.Reverse steps 1 through 7 to reassemble and replace

sheet metal and plastic panels.

Blend Motor Replacement

1. Cut the three wire ties.

NOTE:

Mark the location of the pulley’s before removing. When

re-installing pulleys make certain one of the set screws is

centered on the flat of the shaft if applicable.

5. Remove the pulley from the shaver motor by loosening

the two set screws and sliding the pulley off.

6. Loosen the two set screws on the impeller drive pulley.

7. Remove the four hex head screws from the blender drive

mounting plate, and move to the side. You can now

remove the impeller drive pulley and lift out the blender

drive assembly.

8. Loosen the two set screws on the blender motor pulley,

then turn counter-clockwise to remove. (Left hand

thread)

9. Remove the two ground wires by removing the hex head

nut and star washer.

10.Remove the four retaining screws and star washers to

separate the motor from the mounting plate.

11.To reassembly reverse steps 3 through 10, then reconnect the necessary wires securely.

12.Protect brush retainers with electrical tape.

Shave Motor Replacement

1. Cut the tie strap holding the black and white wires

leading from the drive motor to the terminal block and

contactor.

2. Loosen the belt tension adjustment screws by first

loosening the jam nuts then turning the adjustment

screw counter-clockwise (Fig.16).

NOTE

Identify wires before removing.

2. Cut the wires necessary for motor removal as close to

the connector as possible.

3. Loosen the four hex head screws and move the blender

motor forward then remove the belt (Fig.15).

Fig. 16 - Shaver Drive Motor

3. Remove the drive belt.

4. Remove the cap screws holding the drive motor to the

mounting bracket. Lower the motor down and out the

back.

5. Remove the electrical cover from the motor and disconnect the necessary wires.

Fig. 15 - Blender Motor

14

Page 21

NOTE

All motor wires are identified with letters and numbers.

Make a note of which wires go where.

6. Loosen the two set screws and remove the pulley.

7. Remove the two screws and remove the reset lever

assembly.

8. To reassemble reverse steps 1 through 7.

Shaver Bearing Replacement

1. To remove the front electrical box, remove the six

retaining screws and pull down and out.

2. Remove the agitator and impellor. Refer to Pg.19.

3. Remove the shaver drive motor. Refer to Pg.13.

4. Remove the two cap screws and lock washers holding

the drive bearing assembly to the frame (Fig.17).

5. Remove the two screws and spacers from the safety

switch and move the safety switch to the side.

6. Remove the four hex head nuts and the lock washers

from the bowl.

7. Remove the contactor cover.

NOTE

Cover the ice blade with a couple layer of duct tape

to avoid injury when removing the bowl from the shaver

frame.

8. Lift the bowl and drive bearing assembly up and out.

9. Remove the drive pulley by loosening the two set

screws and sliding off.

10.Remove the four cap screws and lock washers holding

the drive motor bracket to the drive bearing assembly

and remove the bracket.

1 1.Remove the four cap screws and lock washers holding

the drive bearing assembly to the bowl and separate.

12.Remove the snap ring from the shaft, then use an

arbor press to press the shaft out through the top.

NOTE

Use proper tooling when pressing out bearings to

avoid damage to the castings.

Fig. 17 - Drive Bearing Assembly

13.Press out the lower bearing, then the top bearing and

seal.

NOTE

When replacing bearings you must replace seals to

protect the bearings.

15

Page 22

16

Page 23

SECTION 7

TROUBLESHOOTING

melborP esuaC noitcerroC

.snurgnihtoN.nideggulptoN.gulpkcehC

esufrodeppirTrekaerB

.ecalperroteseR

.nwolb

wsytefaS.revocreppohkcehC

.detavitcatonhcti

.hctiwsffo/noytluaF.hctiwsecalpeR

-nrutt'nseodrellepmI

.snurrednelb

htrotoM

.deppirt

daolrevolamre

.daolrevo

rellepmimorfgnissimyeK

.yekecalpeR

teser&loocotrotomwollA

.tfahs

.demmajrellepmI.n

oitcurtsborofrellepmikcehC

.nekorbroffotleBfiecalper,tlebkcehC

.yrassecen

.nekorbroffosyelluPfiecalper,sye

llupkcehC

.yrassecen

.gnisolctonrotcatnoC.tiucrictolipkcehC

.deziesgniraeB.sgniraebecalpeR

.rotomytluaF.roto

,nurt'nseodrednelB

.snrutrellepmi

.daolrevo

lamrehtnotuorotomrednelB

mecalpeR

rofsetunim02ot51tiaW

daolrevo

.teserot

.nekorbroffotleBfiecalper,tlebkcehC

.yrassecen

.deziessgniraeB.sgniraebecalpeR

.nekorbroffosyelluPf

iecalper,syellupkcehC

.yrassecen

.gnisolctonrotcatnoC.tiucrictolipkcehC

17

Page 24

melborP esuaC noitcerroC

t'nseodtubsnrutrellepmI

.reppohniecioN.ecihtiwlliF

.eciesnepsid

.reppohnidegdirbecI.ecipukaerB

cecIeciraelcneht,revahsgulpnU

.dekcolbetuh

.etuhc

fotuoedalbgnivahS

.edalbgnivahstsujdaeR

.tnemtsujda

.enifootgnivahsecI.

.esraocootgnivahsecI.hgihoottesedalbgnivahS.noitisoprewol

.potstonlliwrevahsecIrohctiwsrotcelesytluaF

.gniriwgnitcennoc

woloottesedalbgnivahS.noitisoprehgihaotedalbteS

aotedalbteS

,hctiwsdnagniriwkcehC

.yrassecenfiecalper

.remitytluaF.remitecalpeR

.retemoitnetopytluaF.retemoitnetopecalpeR

18

Page 25

S100

S500/502+

SECTION 8

DRAWINGS

19

Page 26

2021222324

Page 27

Page 28

Page 29

Page 30

NOTE:

Left hand thread, turn

clockwise to loosen while

holding clutch

Page 31

2526272829

Page 32

Page 33

Page 34

Page 35

Page 36

NOTE

Location of contactors may vary .

30

Page 37

S100

S500/S502+

5/8" Mid-Span

31

Page 38

32

Page 39

S505/S510

33

Page 40

34

Page 41

S200

35

Page 42

36

Page 43

S300

37

Page 44

38

Page 45

S500

39

Page 46

40

Page 47

LS500

Some Models

41

Page 48

42

Page 49

S502

43

Page 50

44

Page 51

S505/S510

NOTE

See Page 46

45

Page 52

46

Page 53

S505/S510

47

Page 54

48

Loading...

Loading...