Page 1

• Quick-Freeze Technology™ minimizes size

of ice crystals to ensure smoother, creamier

product.

• Hold cycle keeps barrels at a safe temperature

during off-cycle periods.

• IntelliTec control with lighted display provides

simple two button operation.

• Easy to clean design facilitates sanitary operation

and ensures product is always fresh.

• Refrigerated hopper with independent

temperature control maintains safe storage

temperatures in any environment.

• Delrin®food grade plastic blades provide quiet

operation and superior durability.

• Highest production model (per barrel) without

sacrificing the quality of product.

• Continuous feed system provides high-speed

production with low overrun.

• Service panel provides easy access to

temperature controls.

• Standard, divided and separated, dipper well

helps prevent cross contamination between

flavors for food allergy concerns.

• Optional dual temperature control switch allows

for production of various types of frozen treats,

such as Italian ice, sorbet, and frozen custard.

• Optional hopper rinse faucet.

CC202

CONTINUOUS FLOW

FROZEN CUSTARD MACHINE

Page 2

,

Hopper Condensing

Distributed by:

502 Highway 67 Kiel, WI 53042-1600

920-894-2293 800-558-5807

Fax: 920-894-7029

E-mail: foodservice@stoelting.com

www.stoeltingfoodservice.com

Continuous research leads to ongoing product improvements; therefore, these specifications are subject to change without notice,

and should not be used for installation guidelines..

STMF-201-10/10

ISO 9001:2008 Registered

CC202A Air Cooled Remote CC202A Water Cooled

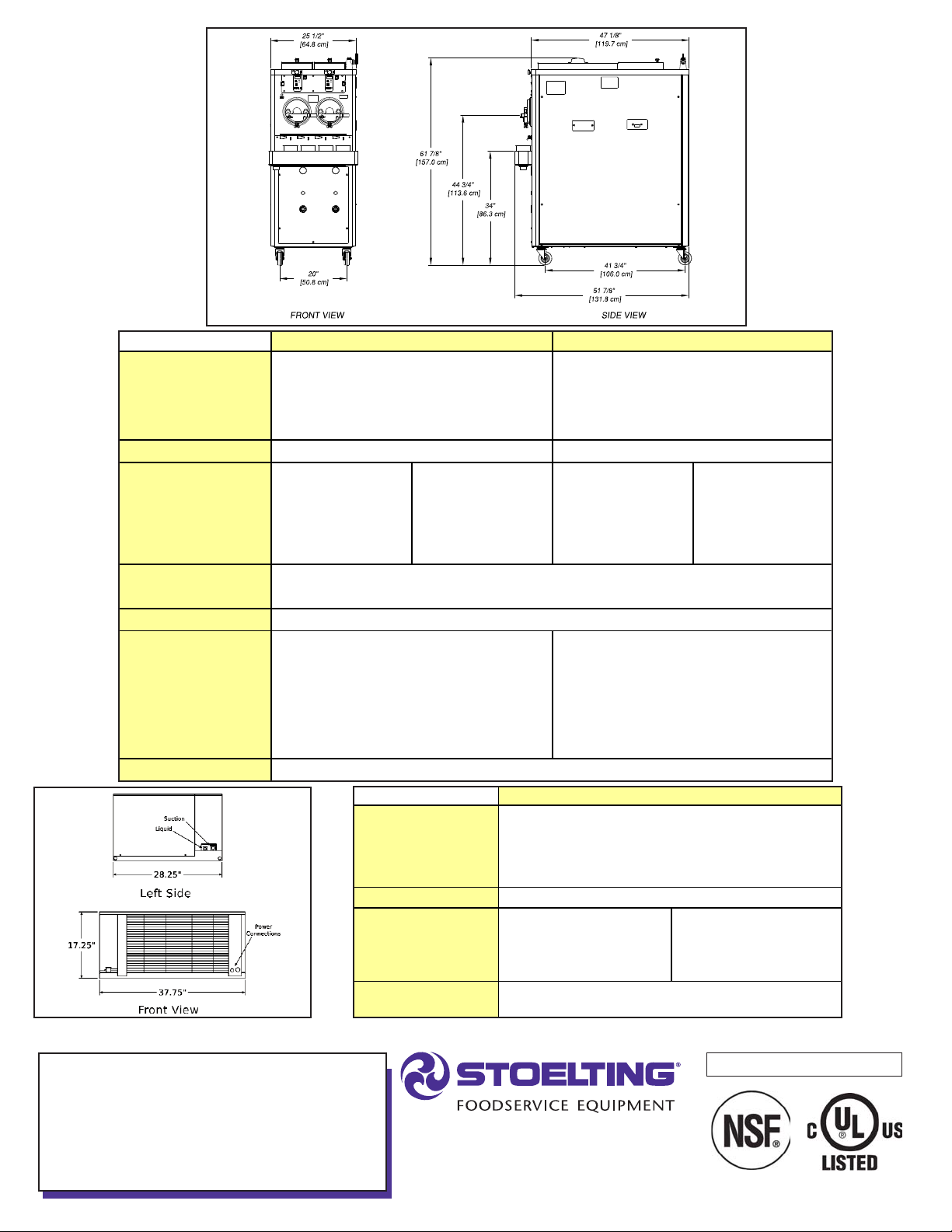

Dimensions

width

height

depth

Weight

Electrical

circuit ampacity

(per barrel)

overcurrent protection

device (per barrel)

Unit

Drive Motor

Cooling

Hopper Volume

Machine with crate Machine with crate

25-1/2'' (64,8 cm) 44-1/2'' (113,0 cm) 25-1/2'' (64,8 cm) 44-1/2'' (113,0 cm)

61-7/8'' (157,2 cm) 67'' (170,2 cm) 61-7/8'' (157,2 cm) 67'' (170,2 cm)

47-1/8'' (119,7 cm) 60'' (152,4 cm) 47-1/8'' (119,7 cm) 60'' (152,4 cm)

632 lbs (286,6 kg) 707 lbs (320,6 kg) 930 lbs (421,8 kg) 1005 lbs (455,8 kg)

1 Phase, 208-240 VAC,

60Hz

12A minimum 9A minimum 29A minimum 19A minimum

25A maximum 15A maximum 50A maximum 30A maximum

3 Phase, 208-240 VAC,

60Hz

1 Phase, 208-240 VAC,

60Hz

3 Phase, 208-240 VAC

60Hz

1 Phase, 115 VAC, 60Hz

NEMA5-15P power cord provided

Two - 2 hp

Water cooled units are self contained and

Air cooled units require a remote

condensing unit (with compressor) and 24

lbs of R-404A per barrel up to a 50' line set.

Add 1 lb of refrigerant for every 10' increase

to the line set. Line set max 100'.

require a Standard Hose Adapter water

fitting and a 5/8" OD drain fitting for each

barrel. They are charged with R-404A.

Maximum water pressure of 130 psi

Minimum water flow rate of 3 GPM

Ideal EWT of 60°-80°F

Two - 8.8 gallon (33,32 liters)

Remote Condensing Unit (1 per barrel)

Dimensions

width

height

depth

Weight

Electrical

circuit ampacity

overcurrent protection

device

1 Phase, 208-230 VAC, 60Hz 3 Phase, 208-230 VAC, 60Hz

20A minimum 15A minimum

25A maximum 20A maximum

Refrigerated Line

Sizes

Condenser

37-3/4'' (95,9 cm)

17-1/4'' (43,7 cm)

28-1/4'' (71,7 cm)

222 lbs (100,7 kg)

Liquid Line - 3/8"

Suction Line - 7/8"

Loading...

Loading...