Page 1

513856

C111

Owner’s Manual

Page 2

C111

ENGLISH

C111-37

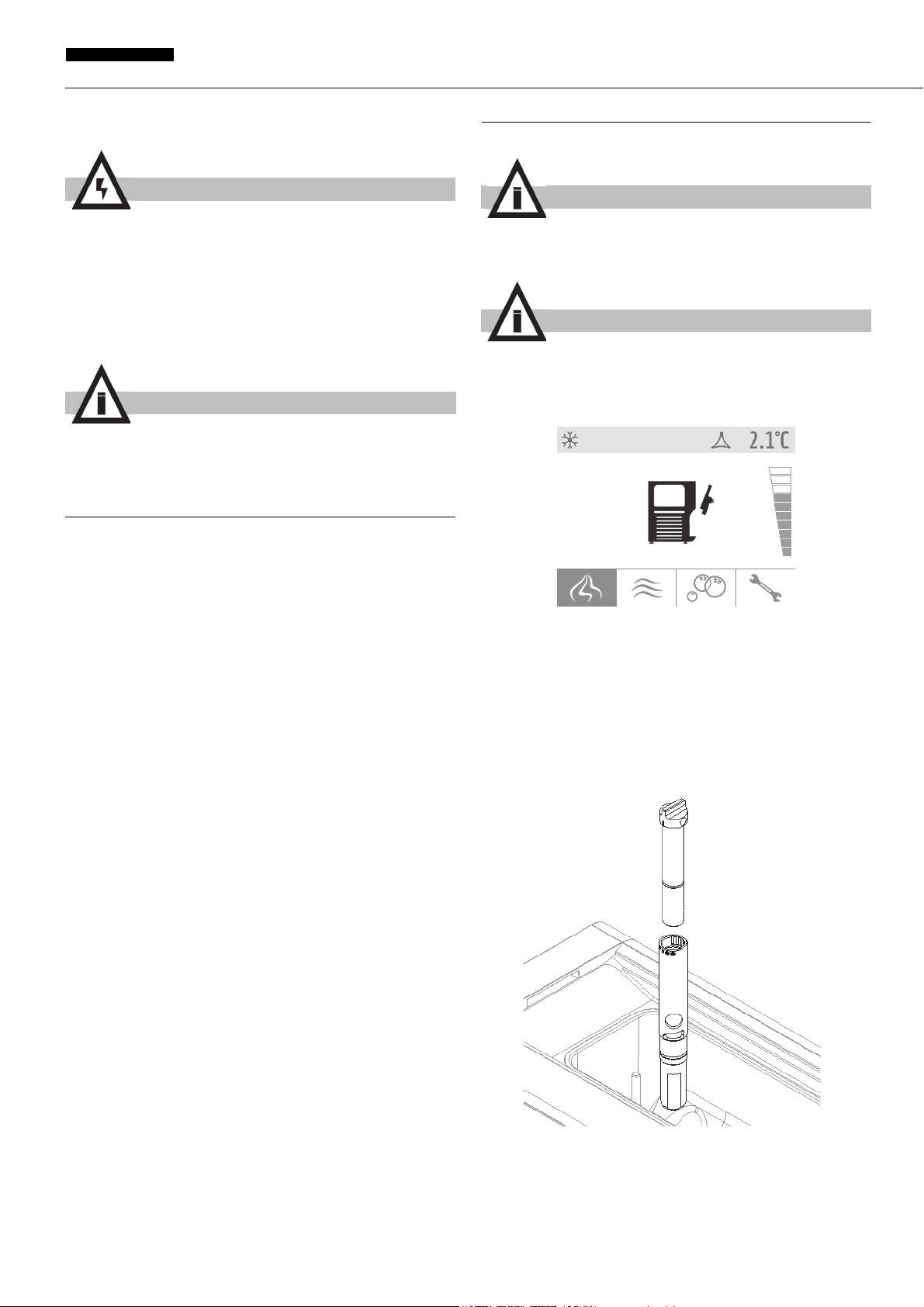

1 SAFETY PRECAUTIONS

1 Before connecting the machine to the power source, check

that the voltage shown on the rating plate matches your

electricity supply. Connect the machine to a single-phase

supply through a grounded outlet as required by current

regulations.

2 Do not use extension cables to connect the machine.

3 To avoid any risks, if the power cable is damaged, it must

be replaced by the manufacturer, by an authorized technician

or by a similarly qualified person.

4 The machine is not suitable for outdoor use.

5 The machine must be installed in the upright position.

6 Before cleaning, always disconnect the machine by

removing the plug from the outlet.

7 Always disconnect the machine before removing any of the

panels for cleaning or maintenance work.

8 This machine must not be used by persons unless they

have been trained regarding the safe use of the machine and

understand the risks involved.

9 Only persons who know and have practical experience of

the machine are permitted access to the inner components of

the machine, especially when dealing with issues regarding

safety and hygiene.

10 This machine is intended exclusively for domestic and

similar use.

11 For the machine to operate correctly, ambient temperature

must be between +41° and +89°F.

12 Use the machine to cool the indicated liquids only.

13 Do not introduce dangerous or toxic liquids to the machine.

2 TECHNICAL CHARACTERISTICS

Hopper capacity, approx gal 1

Freezing Cylinder capacity,

approx

Dimensions:

width in 10.2

depth in 22.4

height in 28.7

Net weight, approx. lbs 106

Gross weight, approx. lbs 121

Hermetic compressor

Air-cooled condenser

Overload protector

Noise level less than 70 dB (A)

gal 0.5

IMPORTANT

Electrical characteristics: read the data on the data plate

of the machine; this data plate is located in the lower part

of the front panel, behind the drip tray. The serial numbers of the machine (preceded by the symbol #) is indicated on the frame, at the rear of the machine, behind the

condenser cover panel. Always refer to the data shown

on the plate.

The manufacturer reserves the right to amend this manual without notice.

3 INTRODUCTION

Read this instruction booklet carefully in order to familiarize

yourself with all aspects of the machine.

As with all mechanical products, this machine also requires

cleaning and care. In addition, its correct operation may be compromised by possible errors made by the operator during the

disassembly and cleaning operations. For this reason, it is important that the disassembly, cleaning, sanitizing and reassembly procedures - being everyday tasks - are familiar, without any

room for error on the part of the machine user.

The warranty for the C111 is as follows: Five years on major

components including: freezing cylinder, hopper, compressor

and, drive motor; One year on non-wear parts and labor

.

Every machine includes White Glove

Service. One call does it all – customer

service, technical service, parts or

warranty information, installation,

startup, sales, on-site service dispatch

and much more. Available 24 hours a

day, seven days a week year-round.

Contact White Glove Service at 800319-9549

2

Page 3

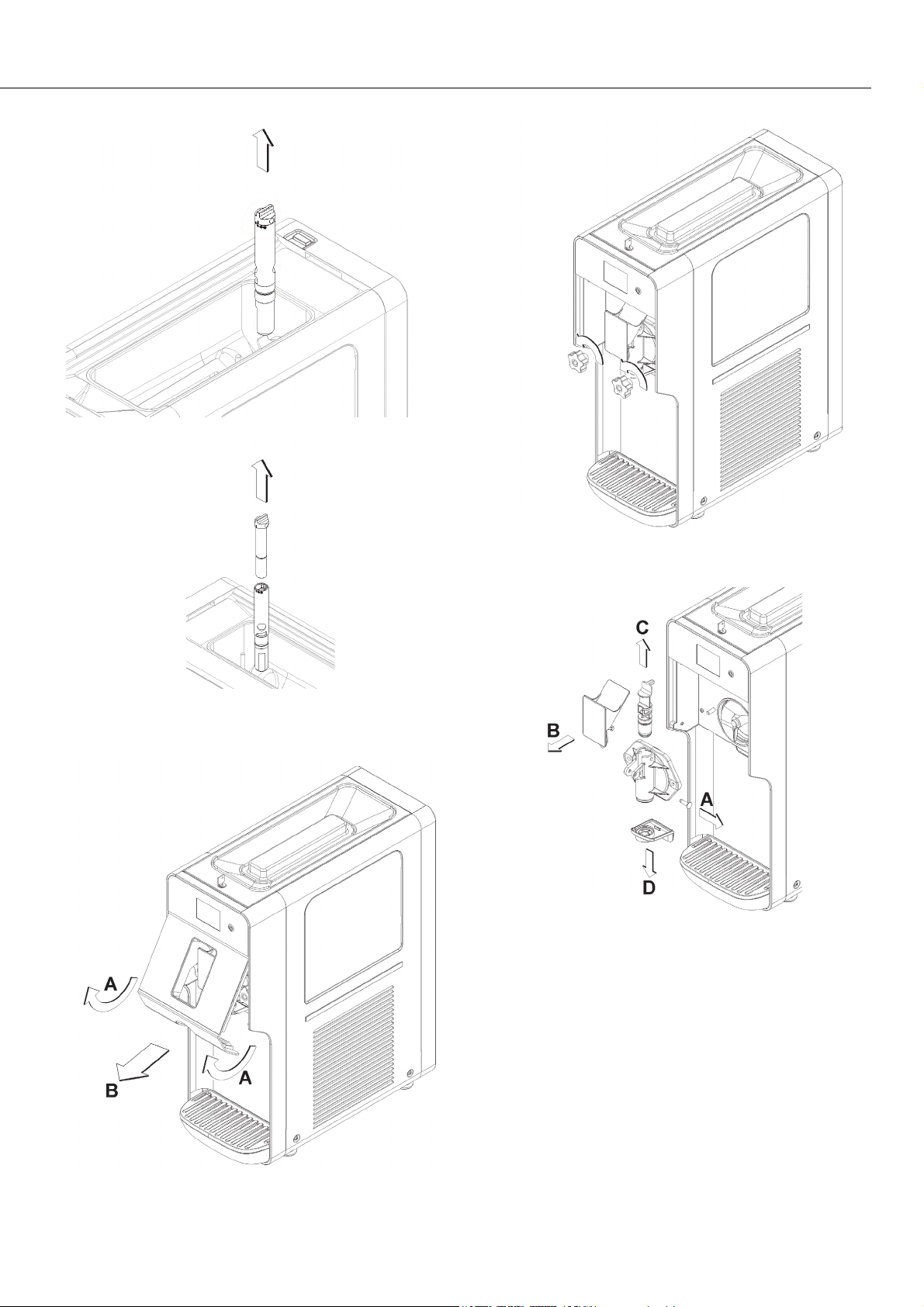

4 UNPACK THE MACHINE

1 Take the machine out of its packaging, which we

recommend you keep for future requirements.

2 Make sure that the machine has not been damaged during

transportation. If this is the case, immediately make a claim

with your carrier.

NOTICE: Do not lay the machine on its side or back.

6 OPERATING PROCEDURES

IMPORTANT

Before use, clean and sanitize the machine according to

the instructions provided in 6. 4 CLEANING.

NOTICE: Do not lift the machine by the tank, auger, or

handles. Only lift by grasping the bottom of the machine.

NOTICE: The machine must sit in the upright position for 24

hours before turning it on. This will allow the oil in the

compressor to settle into place following shipping.

3 Place the machine onto a counter designed to withstand its

weight, including when full.

4 Leave a clearance of at least 6” around the whole machine

to avoid obstructing the cooling air flow.

5 Check the stability of the device, adjusting the height of the

legs if necessary. If the dispenser is provided with taller legs

(approximately 4”), these must replace the original ones.

ATTENTION

Make sure the machine is properly grounded, otherwise

you may cause electric shocks to persons or damage to

the machine.

6 The machine does not leave the factory washed and

sanitized. Before use, it must be disassembled, washed and

sanitized, following the instructions in 6. 4 CLEANING.

IMPORTANT

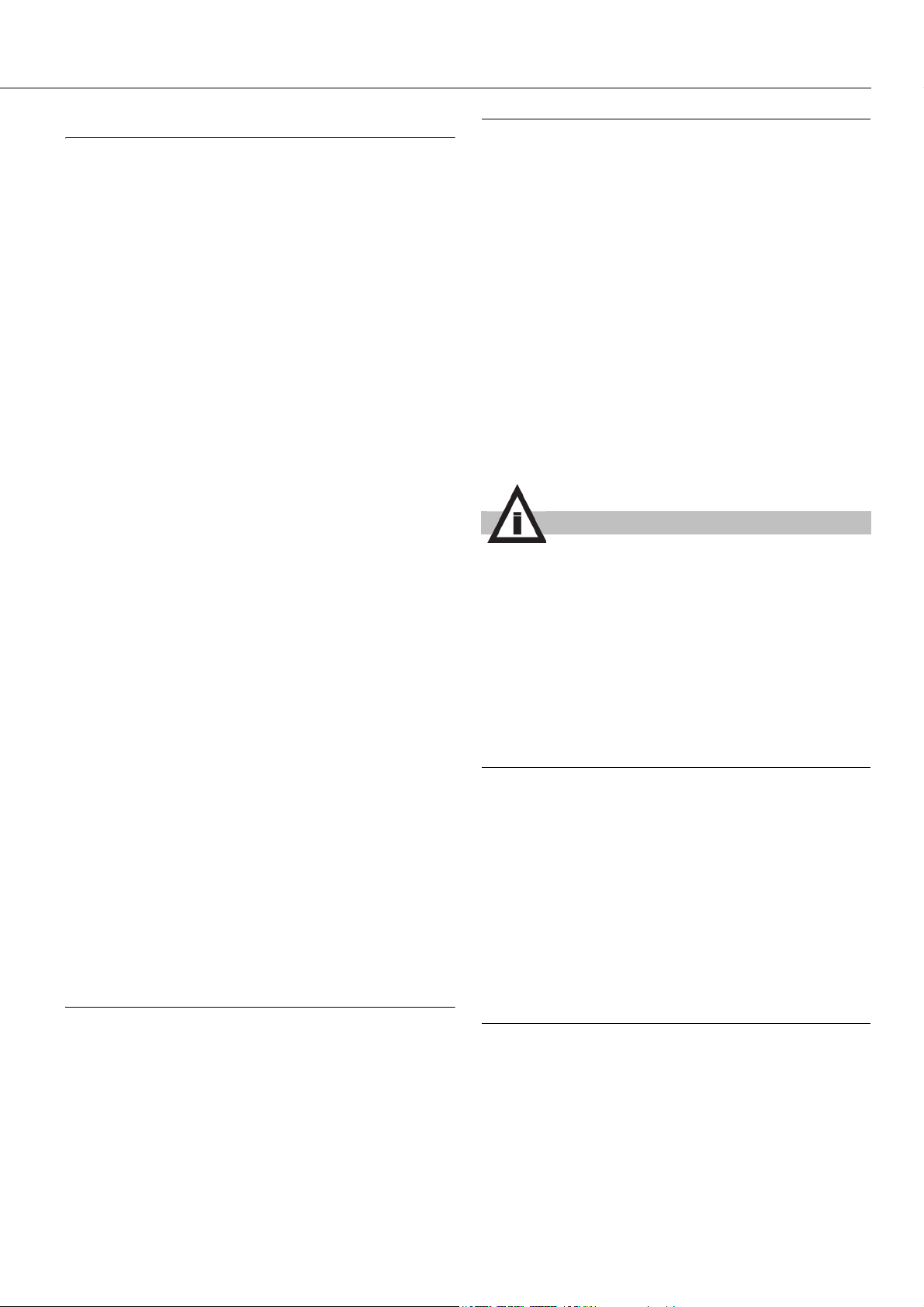

If the spigot assembly has not been installed, the

machine cannot operate and the display shows the

spigot assembly open icon (see figure 1).

figure 1

This machine is equipped with a hopper designed to keep the

mix refrigerated and a freezing cylinder for the production of the

soft serve.

Every time soft serve is dispensed, the same quantity of soft

serve mix feeds into the freezing cylinder from the hopper.

In order to obtain softer and lighter soft Serve, make sure that

the carburetor is installed correctly. (see figure 2)

IMPORTANT

Position the machine in such a way that the power supply cable is easily accessible.

5 TO OPERATE SAFELY

1 Do not use the machine before reading this instruction

manual first.

2 Do not use the machine unless it is properly grounded.

3 Do not operate the machine if the panels are not in place

and secured with screws.

4 Do not insert your fingers in panel louvers or spigot outlet.

5 Do not remove parts or panels for cleaning or maintenance

without first making sure the machine is disconnected from the

electricity supply.

6 The cover must remain closed at all times.

figure 2

For best results, the following steps must be performed in the order specified:

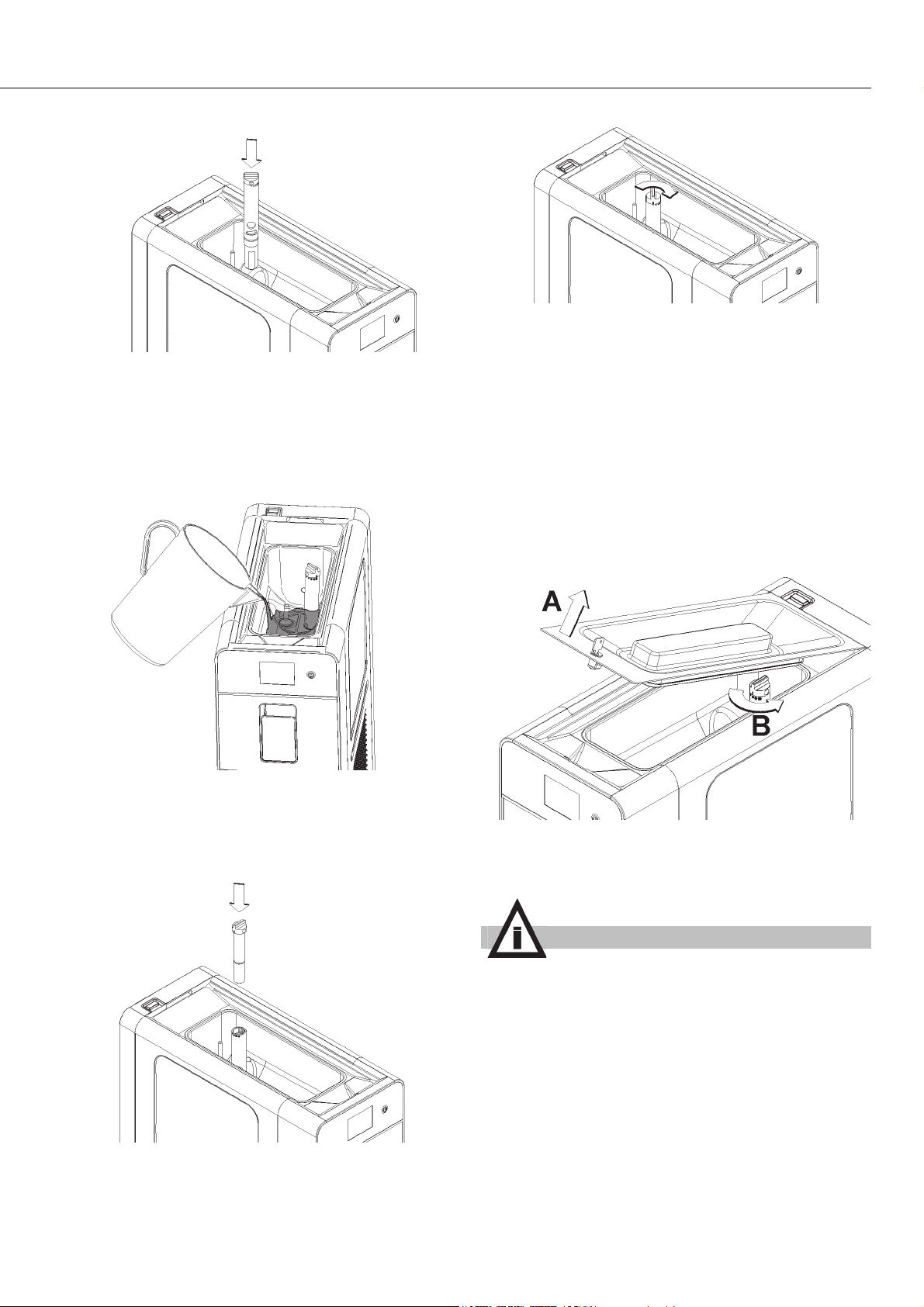

1 Insert the lower part of the carburetor into the mix inlet tube

3

Page 4

C111

ENGLISH

in the hopper, making sure it is fully seated. (see figure 3)

figure 3

2 Pour mix into the hopper and wait for the freezing cylinder

to fill. The cylinder is filled when no more air bubbles exit the

holes in the carburetor. (see figure 4)

6 When the product is ready, remove the hopper cover and

turn the upper part of the carburetor counterclockwise to allow

the mix to enter the freezing cylinder.(see figure 7)

The quantity of air in the soft serve can be adjusted, keeping in

mind that, starting from the closing position:

complete rotation

counterclockwise

minimum rotation counterclockwise

: fully open, lower quantity of air

in the soft serve (low overrun)

: only open slightly, greater quan-

tity of air in the soft serve (high

overrun)

figure 4

3 Insert the upper part of the carburetor into the lower one.

(see figure 5)

figure 5

4 Turn the carburetor fully clockwise to stop the mix entering

the cylinder. (see figure 6)

figure 7

7 After making adjustments, install the hopper cover.

IMPORTANT

Use the machine with foodstuff only. Not intended for

household use.

8 Dispense the soft serve using the spigot handle.

9 If the carburetor adjustments do not make the desired

consistency, the mix can be modified as follows:

Soft serve too soft : increase the amount of liquid (water or

milk) from 5 % to 10 % of the total volume.

Soft serve too hard : decrease the amount of liquid (water or

milk) from 5 % to 10 % of the total volume.

10 The machine must operate continuously: the cooling

system stops automatically when the product is ready to be

dispensed. The auger speed decreases and only increases

when dispensing. The cooling system and auger operate at

default time intervals in order to restore the proper consistency

to the product.

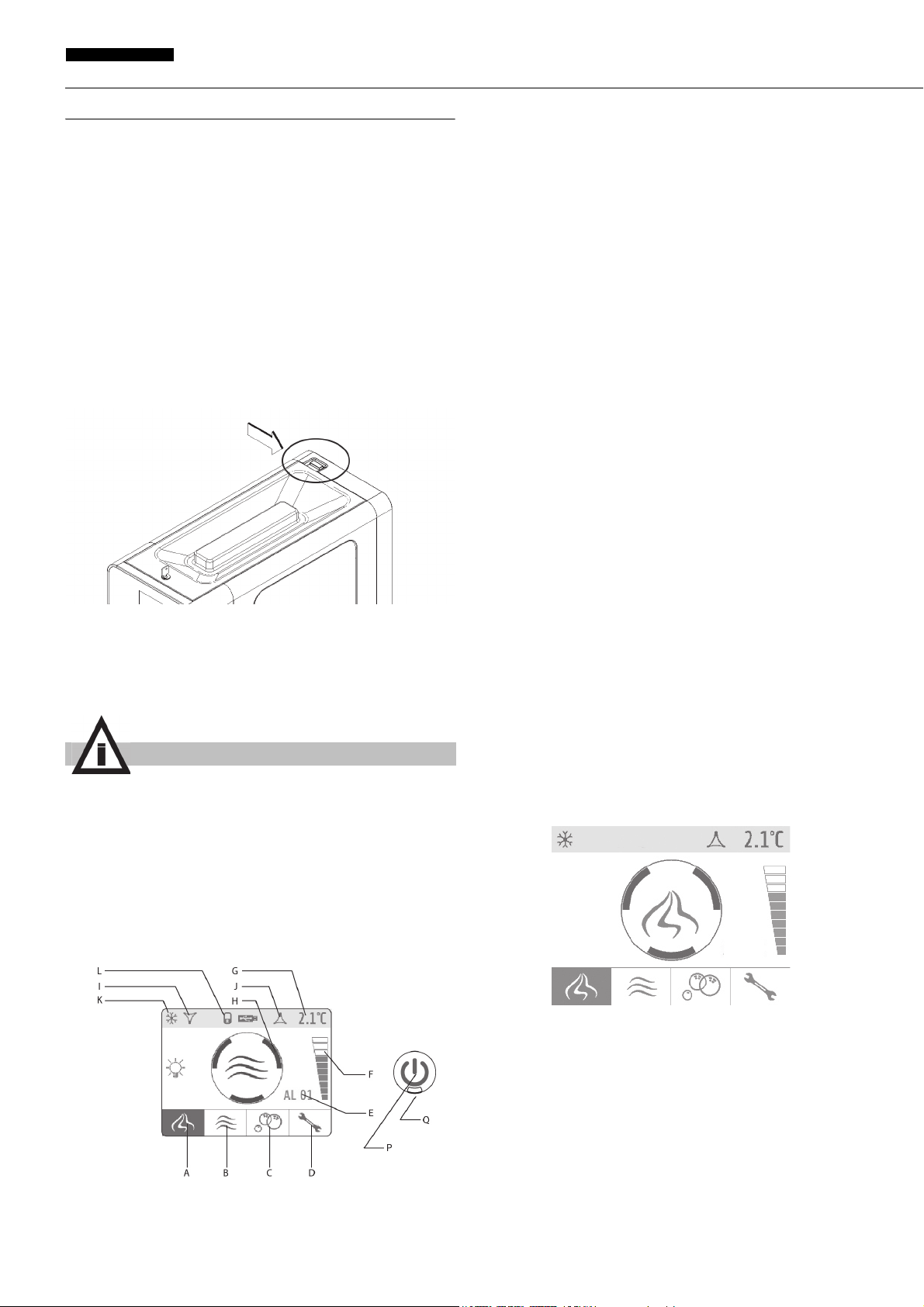

6. 1 DESCRIPTION OF CONTROLS

The machine has a main power switch, an on/off button and a

touch display. The following operating modes are available:

5 Install the hopper cover, turn the main power switch on, and

start preparing soft serve. (See 6. 1 DESCRIPTION OF

CONTROLS)

figure 6

SOFT SERVE PRODUCTION: in this operating mode, the machine prepares soft serve.

NIGHT MODE: in this operating mode, the machine keeps the

liquid mix at a suitable temperature to preserve it. This function

is useful at night to keep the quality of the mix intact and limit

electricity consumption.

WASHING: in this operating mode, cooling is disabled. This

function is used during washing and sanitizing to prevent the

solution used from being cooled and freezing.

4

Page 5

MAIN SWITCH

The main power switch is located on the top of the machine at

the back.

H Status icon. Indicates the machine status (soft serve, night

mode, washing, alarm) and the soft serve preparation status when the soft serve mode is enabled:

red icon: soft serve not ready

yellow icon: soft serve almost ready

green icon: soft serve ready

I Hopper cooling icon. Indicates that the hopper cooling is in

operation.

J Freezing cylinder cooling icon. Indicates that the freezing

cylinder cooling is in operation.

K Compressor icon. Indicates the compressor is in opera-

tion.

L Display shut-down icon. Indicates that the touch display

has shut down and no controls can be accessed.

Its function is as follows:

Position 0 : machine is off

Position I : machine enabled for operation but in Standby

mode. Only indicator light Q is on.

IMPORTANT

If you turn the machine off and back on at the main power

switch, it will restart in the same operating mode it was in

when it was switched off.

ON/OFF BUTTON

The ON/OFF button P is located to the right of the touch display.

If indicator light Q comes on, the machine is switched on and in

standby mode, ready for operation. Hold down the ON/OFF button for one second to turn the machine on and off.

TOUCH DISPLAY

FOR MACHINE OPERATION

Turn the main power switch to position I. Red indicator light Q

comes on.

Hold down button P until the machine starts up again.

Select the desired function using icons A, B, c or D.

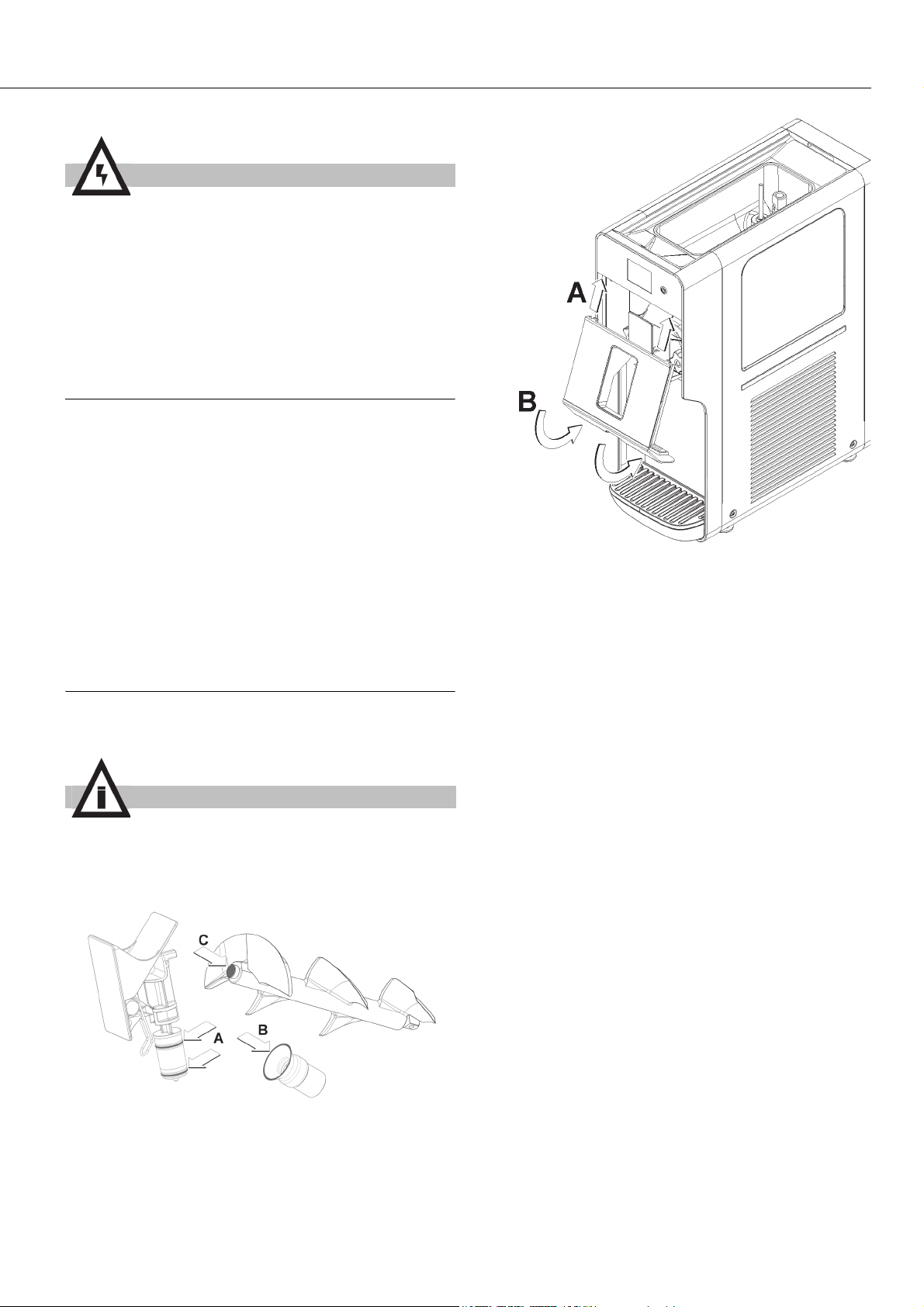

SOFT SERVE MODE

In this operating mode, the machine produces soft serve and the

mix in the hopper is kept at a suitable temperature to preserve

it. The soft serve preparation status is indicated on the display

by the central icon and by the color of the arrows.(see figure 9)

figure 9

When the soft serve is ready, the auger slows down, the cooling

system stops and the machine switches to serve mode. At default intervals (factory set to every 10 minutes), the auger increases speed and the cooling system runs to restore the proper

soft serve consistency.

When the spigot is opened, the auger speed increases and the

cooling system runs.

In order to produce soft serve, the hopper must contain a suitable quantity of mix. If the mix level gets low, the central icon displays low product.(see figure 10)

figure 8

The following icons appear on the display:

A SOFT serve PRODUCTION icon; when pressed, the

SOFT serve function is enabled.

B NIGHT MODE icon; when pressed, the NIGHT MODE

function is enabled

C WASHING icon; when pressed, the WASHING function is

enabled.

D PARAMETERS icon; when pressed, adjustments can be

made to the operating PARAMETERS.

E Alarm code. Indicates an alarm and displays the relevant

code.

F Consistency bar. Indicates the set consistency level.

G Mix temperature. Indicates the mix temperature in the hop-

per.

figure 10

Consistency adjustment

The consistency of the soft serve can be adjusted on a scale of

1 to 10. To adjust, touch the graduated bar on the right-hand

side of the touch display. The following controls are available:

A Exit icon: Exits without making any changes.

B Decrease icon: Decreases the consistency value.

C Increase icon: Increases the consistency value.

D Confirm icon: Confirms the value set.

5

Page 6

C111

ENGLISH

(see figure 11)

figure 11

NIGHT MODE

In this operating mode, the mix in both the hopper and in the

freezing cylinder is kept at a food safe temperature (factory set

to 36°F) to preserve it. The display indicates the night mode

icon. (see figure 12)

play. Press this icon to show the explanatory text relating to the

alarm. (see figure 14)

figure 14

MAINTENANCE ALARM (AL14)

After every 1500 hours of operation it is necessary to replace the

auger seal. After replacing the seal, the AL14 alarm must be reset.

To reset the alarm 14 is necessary:

- press parameters icon

- type user password (0000)

- press on hourglass icon

- press RESET button

- type user password (0000)

- press exit button

figure 12

When the mix has reached the set temperature, the auger slows

down, the cooling system stops, and the machine switches to

standby mode. At default intervals (factory set to every 10 minutes), the auger increases speed and the cooling system starts

to retain the proper temperature.

IMPORTANT

The product temperature during night mode is factory set

to 36°F.

WASHING MODE

In this operating mode, the cooling system does not operate and

the auger turns at a speed suitable for washing the machine.

The display indicates the Washing icon. (see figure 13)

figure 13

ALARMS

The machine is fitted with a self-diagnosis system. In the event

of a breakdown, the user is notified by the alarm icon on the dis-

6. 2 OPERATION HELPFUL HINTS

The machine parameters are factory set to guarantee optimum

operation. To prevent any risks of malfunctioning, the parameters must only be changed by the manufacturer, technical support, or other similarly qualified persons.

6. 3 SUGGESTIONS

1 All machines of this kind emit heat. Should the heat

generated be excessive, make sure that no heat sources are

located near the machine and, specifically, near the louvered

panels. Also make sure the air flow is not obstructed by the

walls, boxes or other items. Leave a clearance of at least 6” all

around the machine. Also make sure the filter situated behind

the rear panel is clean.

2 This machine is only intended for use with confectionery

products.

6. 4 CLEANING

1 Cleaning and washing the machine are vital to guarantee

perfect preservation of product flavor and maximum efficiency

of your machine. The procedures described below must be

considered of a general nature and may vary due to local

health and safety regulations.

2 Before disassembling for washing, the machine must be

emptied. Proceed as follows:

1 on the keypad, select the WASHING operating mode

2 if necessary, wait for the mix to liquify

3 place a bucket under the spigot and empty all the contents

of the hopper and freezing cylinder

4 remove the hopper cover.

If the cover is fitted with a safety lock, turn the key counterclockwise. (see figure 15)

6

Page 7

5 fill the hopper with water and allow the machine to operate

in WASHING mode for a few minutes. Then empty the wa-

ter out of the machine.

6 press and hold the ON/OFF button to turn off the machine

7 turn off the main power switch

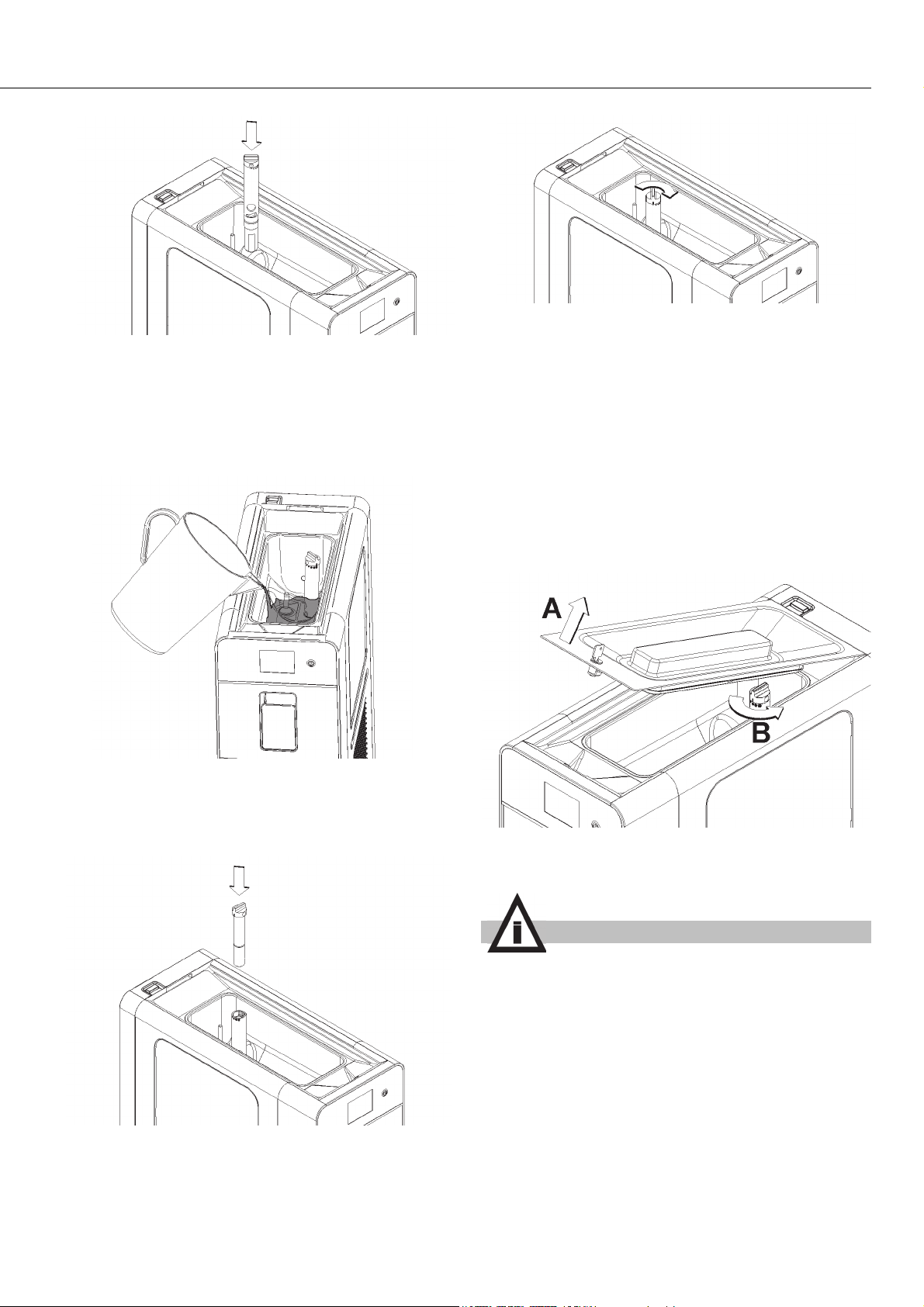

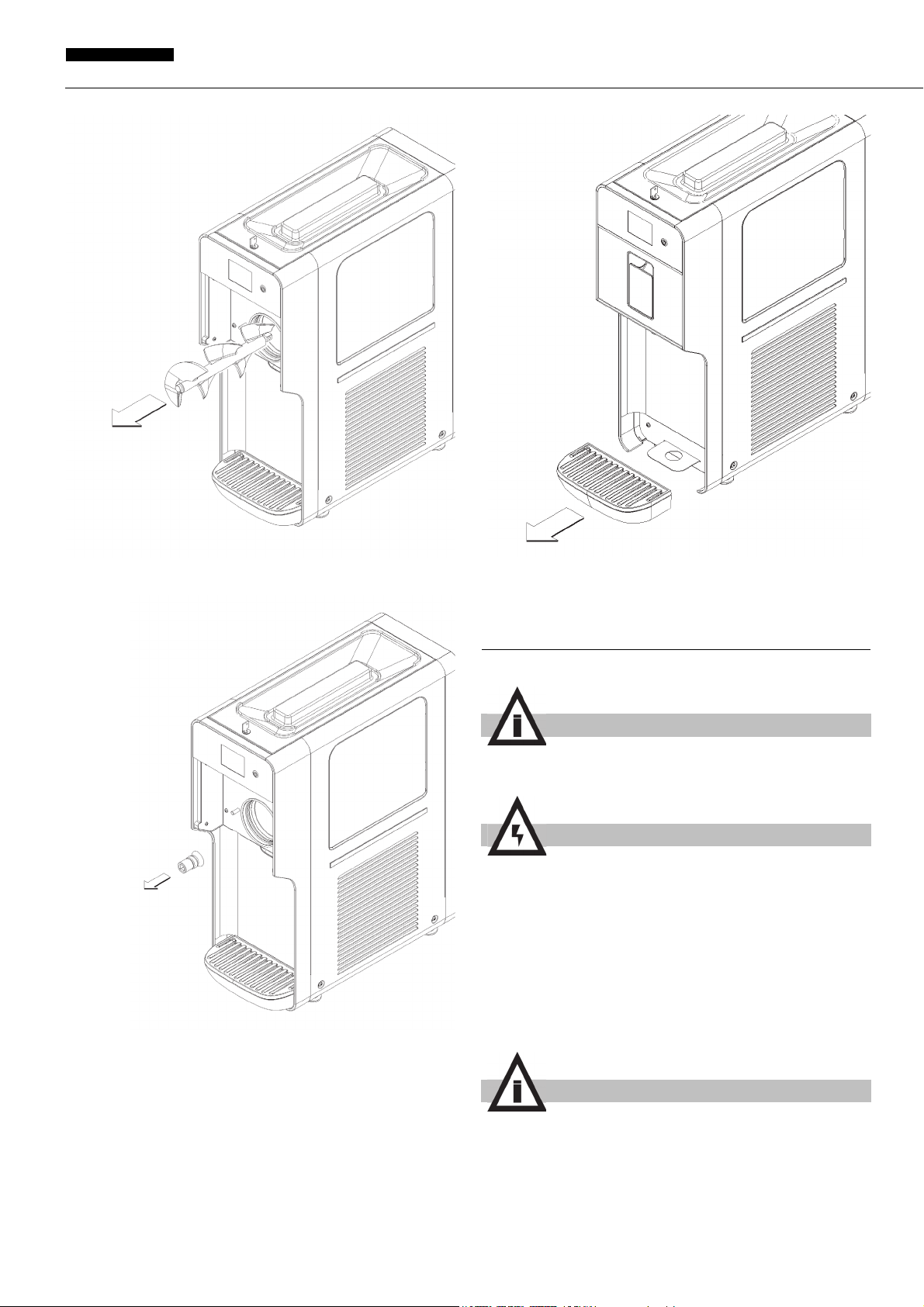

6. 4. 1 DISASSEMBLY

ATTENTION

Before disassembling any component, always unplug

the machine from the main power source.

part and disassemble it. (see figure 18) and (see figure 19).

1 Remove the hopper cover. (see figure 16)

If the cover is fitted with a safety lock, turn the key

counterclockwise. (see figure 15)

figure 15

figure 18

figure 19

4 Remove the front panel. (see figure 20)

figure 16

2 If present, remove the auger in the hopper. (see figure 17)

figure 17

3 Remove the carburetor, both the upper part that the lower

figure 20

5 Unscrew both knobs from the spigot assembly. (see figure

7

Page 8

C111

ENGLISH

21)

figure 21

6 Remove the spigot assembly and disassemble it, following

the sequence specified. (see figure 22)

9 Remove the drip tray. (see figure 25)

figure 25

6. 4. 2 WASHING

IMPORTANT

If the power supply cable is damaged, it must be replaced

by the manufacturer or an authorized service provider to

avoid all risk.

figure 22

7 Remove the auger. (see figure 23)

figure 23

8 Remove the auger coupling and seal. (see figure 24)

ATTENTION

Before any cleaning operation, always disconnect the

dispenser from the power source.

1 Fill a bucket with approximately one gallon of 90-110 °F

water) and 1 oz of mild detergent (Stera-Sheen green label),

following the manufacturer’s instructions. A solution that is too

concentrated may damage the parts to be washed, whereas

one that is too diluted may not clean properly. Do not use any

abrasive detergents.

IMPORTANT

In order to avoid damaging the machine, only use detergents that are compatible with plastic components.

2 In order to avoid damaging the machine, only use

detergents that are compatible with plastic components.

ATTENTION

When cleaning the machine, do not use excessive

amounts of water around the electrical components. This

could cause electric shocks or damage to the machine.

figure 24

3 Wash the freezing cylinder, the hopper, and the mix inlet

tube using the brush supplied with the unit.

4 Rinse all washed parts under running water.

6. 4. 3 SANITIZING

Sanitizing must be done immediately before starting up the

dispenser. Do not allow the dispenser to remain idle for a long

time after sanitation.

8

Page 9

1 Before starting the procedures described below, wash your

hands with antibacterial soap.

2 Prepare 2 gallons of Stera-Sheen sanitizing solution

according to the manufacturer's instructions.

3 Immerse all parts to be sanitized in the solution for the time

indicated by the product manufacturer.

4 Allow the sanitized parts to air dry on a clean surface.

5 Dry the external parts of the dispenser without using

abrasive cloths.

6. 4. 4 ASSEMBLY

5 Reassemble the front panel. (see figure 26)

NOTE: Total Blend sanitary lubricant, or equivalent must be

used when lubrication of parts is specified. Total Blend can

be used to lubricate parts and also as a spline lubricant. Do

not use more than one packet of Total Blend per freezing

cylinder.

NOTE: The United States Department of Agriculture and the

Food and Drug Administration require that lubricants used

on food processing equipment be certified for this use. Use

lubricants only in accordance with the manufacturer’s

instructions.

1 Install the drip tray.

IMPORTANT

Lubricate the spigot piston, the auger seal and the front

of the auger in the points indicated in figure using only

Total Blend or other food grade sanitary lubricant.

2 Install the auger coupling onto the auger and insert it into

the freezing cylinder. Rotate the auger so that the coupling

engages the drive shaft.

3 Assemble the spigot assembly by first inserting the spigot

piston into the front door. Then install the handle onto the door

and secure it with the pin. Refer to Figure 20.

4 Place the front door assembly onto the studs and secure

with the knobs, tightening them carefully.

figure 26

6 Assemble the hopper auger taking care to insert the ends in

the grooves in the hopper.(see figure 27)

figure 27

6. 4. 5 IN-PLACE SANITIZATION

The sanitizing of the assembled machine prior to operation

should be performed in addition to the sanitizing of the disassembled machine described herein above, and never instead of

it.

1 Prepare 2 gallons of sanitizing solution according to the

manufacturer's instructions (Stera-Sheen green label).

2 Pour the solution into the hopper.

3 Using a suitable brush, wipe the solution onto all the parts

above the level of the solution including the underside of the

hopper cover.

4 Install the cover and operate the machine for approximately

5 minutes.

5 Drain the sanitizing solution from the bowls through the

spigots and then dispose of it.

6 Place a container under the spigot and rinse the machine

with mix to flush out any remaining sanitizing solution.

7 MAINTENANCE

1 Every day: check the machine and make sure there are no

leaks from the spigot assembly seal. If you notice a leak, first

check that the components have been assembled correctly,

then make sure the seal is not worn or damaged, in which case

replace it with an original spare part from the manufacturer.

9

Page 10

C111

ENGLISH

(see figure 28)

figure 28

2 Every week: make sure the auger seal is not worn or

damaged. If it is, replace with an original spare part from the

manufacturer. (see figure 29)

figure 29

3 Every week: check for auger seal leaks by examining the

drain tray (see figure 30). In case of a leak, make sure the

auger seal is properly installed and not worn or damaged. If it

is, replace with an original spare part from the manufacturer

(see figure 29).

31)

figure 31

ATTENTION

Be careful with the condenser fins as they are sharp.

5 In case of strange noise or failure, disconnect the machine

from the power source and call for service.

figure 30

4 Every Month: eliminate any dust that has built up on the

condenser filter situated at the back of the machine. (see figure

10

Page 11

11

Page 12

C111

ENGLISH

12

Page 13

1 INSTRUCCIONES DE SEGURIDAD

ELÉCTRICA

3 CARACTERISTICAS TECNICAS

1 Antes de conectar la alimentación eléctrica del distribuidor,

verifique que la tensión de red sea la correcta, indicada en la

placa. Conecte el distribuidor a una red monofásica, utilizando

un enchufe con toma de tierra, en cumplimiento de las normas

vigentes. Si la desconexión del aparato de la red eléctrica se

realiza mediante un interruptor unipolar, este debe garantizar

una distancia de apertura de los contactos que permita la

desconexión completa, en las condiciones previstas para la

categoría de sobretensión III.

2 No utilice alargaderas para conectar el aparato a la

alimentación eléctrica.

3 En caso de deterioro del cable de alimentación, este debe

ser sustituido por el fabricante, por el servicio de asistencia

técnica o por una persona con cualificación similar, para

prevenir cualquier riesgo.

4 El aparato no es apto para ser utilizado ambientes

exteriores.

5 El aparato se debe instalar en posición vertical.

6 Antes de cualquier operación de limpieza, desconecte

siempre la alimentación eléctrica del distribuidor, extrayendo la

clavija de la toma.

7 No quite los paneles para realizar operaciones de limpieza

o mantenimiento, hasta verificar que el distribuidor está

desconectado de la alimentación eléctrica.

C111-37

Capacidad aproximada del contenedor l 4

Capacidad aproximada del evaporador l 2

Dimensiones:

ancho cm 26

largo cm 57

alto cm 72

Peso neto, aproximado kg 50

Peso bruto, aproximado kg 55

Motocompresor hermético

Condensador a ventilación forzada

Guardamotor

Nivel de ruido inferior a 70dB (A)

IMPORTANTE

Características eléctricas: lea los datos presentes en la

placa de cada distribuidor, situada en la parte inferior del

panel frontal, detrás del cajón colector de gotas. Los

números de serie de los aparatos (precedidos por el

símbolo #) están indicados en el bastidor, en la parte

posterior del aparato, detrás del panel de cobertura del

condensador. Los datos de referencia de la máquina son

los indicados en la placa.

8 No utilice chorros de agua para la limpieza.

9 Este aparato no puede ser utilizado por niños.

10 Evite que los niños jueguen con el aparato.

11 Este aparato no puede ser utilizado por personas con

capacidades físicas, sensoriales o mentales reducidas, o sin

experiencia y conocimientos, a menos que hayan recibido

asistencia y capacitación para el uso seguro del aparato y

comprendan los peligros que este implica.

12 El acceso al interior del distribuidor está reservado a

personas con conocimiento y experiencia con el aparato,

especialmente si se trata de operaciones relacionadas con la

seguridad y la higiene.

2 INSTRUCCIONES DE SEGURIDAD

HIGIÉNICA

1 Este aparato está destinado al uso doméstico o similar.

2 Para su correcto funcionamiento, la temperatura ambiente

debe estar comprendida entre +5 y +32 °C.

3 Utilice el aparato exclusivamente para enfriar los líquidos

indicados.

4 No introduzca sustancias o líquidos peligrosos o tóxicos en

el aparato.

El fabricante se reserva el derecho a modificar el presente

manual sin preaviso.

4 INTRODUCCION

Lea atentamente este manual de instrucciones para conocer

todas las características del distribuidor.

Como todos los productos mecánicos, también este distribuidor

requiere limpieza y cuidado. Además, su correcto

funcionamiento puede verse afectado por eventuales errores

cometidos por el operador durante las fases de desmontaje y

limpieza. Por este motivo, es importante que los procedimientos

de desmontaje, lavado, esterilización y montaje, que son

operaciones diarias, sean conocidos por quienes utilizan el

distribuidor, sin posibilidad de error.

5 INSTALACIÓN

1 Extraiga el distribuidor de su embalaje (que se recomienda

conservar para su eventual uso en el futuro).

2 Verifique que el distribuidor no haya sufrido daños durante

el transporte. Si así fuera, realice inmediatamente la

reclamación correspondiente al transportista.

3 Apoye el distribuidor sobre una superficie capaz de

soportar su peso, incluso con carga completa.

4 Deje un espacio libre de al menos 15 cm alrededor del

distribuidor, para no obstaculizar el flujo de aire de

enfriamiento.

5 Verifique la estabilidad del aparato, regulando —si es

necesario— la altura de los pies. Si el suministro incluye una

serie de pies altos (aproximadamente 100 mm), es necesario

13

Page 14

C111

ESPAÑOL

utilizarlos para sustituir los pies originales.

ATTENCION

Verifique que el aparato esté correctamente conectado a

tierra; en caso contrario, se podrían producir descargas

eléctricas a las personas o daños en el distribuidor.

6 El distribuidor no sale lavado y esterilizado de la fábrica.

Por este motivo, antes del uso, debe ser desarmado, lavado y

esterilizado, siguiendo las indicaciones contenidas en las

presentes instrucciones (capítulo 7.4 LIMPIEZA).

IMPORTANTE

Coloque el aparato de tal forma que la clavija del cable

de alimentación sea fácilmente accesible.

6 PARA UN FUNCIONAMIENTO SEGURO Y

CORRECTO

1 No use el distribuidor hasta haber leído el presente manual

de instrucciones.

2 No use el distribuidor si no está correctamente conectadoSi

el grupo grifo no está instalado, el aparato no puede funcionar

y en la pantalla se visualiza el ícono que representa el grupo

grifo abierto (véase la figura 1).a tierra.

3 No ponga en funcionamiento el distribuidor si los paneles

no están en su sitio y bloqueados con tornillos.

4 No introduzca los dedos u objetos en las ranuras de los

paneles ni en la abertura del grifo.

5 No quite partes o paneles para realizar operaciones de

limpieza o mantenimiento, hasta verificar que el distribuidor

está desconectado de la alimentación eléctrica.

6 La tapa debe permanecer siempre cerrada.

7 INSTRUCCIONES DE USO

IMPORTANTE

Antes del uso, lave y esterilice el distribuidor, siguiendo

las indicaciones contenidas en las presentes instrucciones (capítulo 7.4.2 LAVADO).

IMPORTANTE

Si el grupo grifo no está instalado, el aparato no puede

funcionar y en la pantalla se visualiza el ícono que representa el grupo grifo abierto (ver figura 1).

figura 1

Este aparato está dotado de una cuba superior, destinada a

mantener refrigerado el producto base para la producción de

helado, y un cilindro inferior para la producción de helado

propiamente dicha.

Cada vez que se distribuye una porción de helado, la misma

cantidad de preparado pasa por gravedad de la cuba superior

al cilindro inferior.

Para obtener un helado más suave y ligero, es necesario que,

junto con el producto base, también entre una cierta cantidad de

aire en el cilindro. A tal fin, la máquina está dotada de un tubo

de mezcla separado en dos partes. (ver figura 2)

figura 2

Para obtener los mejores resultados, es necesario realizar las

siguientes operaciones, en el orden indicado:

1 Introduzca la parte inferior del tubo de mezcla en el orificio

de conexión entre la cuba y el cilindro, orientándolo de tal

14

Page 15

forma que entre completamente en su alojamiento. (ver figura

3)

figura 3

2 Vierta el preparado en la cuba superior y espere hasta que

se llene el cilindro. Esta situación se verifica cuando ya no

salen burbujas por los orificios presentes en el tubo de mezcla.

(ver figura 4)

cilindro. (ver figura 6)

figura 6

5 Cierre la tapa superior, encienda la máquina y comience la

producción de helado (véase 7.1 DESCRIPCIÓN DE LOS

MANDOS).

6 Cuando el helado está listo, abra la tapa y gire la parte

superior del tubo de mezcla en sentido levógiro para permitir la

entrada del preparado en el cilindro inferior.

Es posible regular la cantidad de aire presente en el helado,

teniendo en cuenta que, à partir de la position de fermeture:

Rotación completa en

sentido levógiro

Rotación completa en

sentido levógiro

: máxima apertura, menor canti-

dad de aire en el helado.

: mínima apertura, mayor canti-

dad de aire en el helado.

figura 4

3 Introduzca la parte superior del tubo de mezcla dentro de la

parte inferior. (ver figura 5)

figura 5

4 Gire completamente la parte superior del tubo de mezcla en

sentido dextrógiro para cerrar la entrada del preparado al

figura 7

7 Cierre nuevamente la tapa superior.

IMPORTANTE

Utilice el distribuidor solamente con productos alimentarios.

8 La entrega de palanca de acción helado.

9 En el caso en el que el ajuste de la densidad disponible no

es suficiente para lograr el resultado deseado, la mezcla puede

ser corregida como sigue:

Helado demasiado suave: aumentar la dosis de líquido, agua o

leche, a un valor entre 5 y 10% del volumen total.

Helado demasiado compacto: disminuir la dosis de líquido,

agua o leche, a un valor entre 5 y 10% del volumen total.

10 El distribuidor debe funcionar en forma continua: el sistema

de enfriamiento se detiene automáticamente cuando el

producto está listo para su distribución. El dispositivo de

mezcla disminuye su velocidad y la aumenta solo en el

momento de la distribución. A intervalos preestablecidos, el

sistema de enfriamiento se reactiva y el dispositivo de mezcla

aumenta su velocidad para restablecer la correcta densidad del

producto.

15

Page 16

C111

ESPAÑOL

7. 1 DESCRIPCIÓN DE LOS MANDOS

El distribuidor está dotado de un interruptor general, un botón

de encendido y una pantalla táctil. Están disponibles los

siguientes modos de funcionamiento:

PRODUCCIÓN DE HELADO. En este modo de

funcionamiento, el distribuidor produce helado.

CONSERVACIÓN. En este modo de funcionamiento, el

distribuidor mantiene el preparado líquido a una temperatura

idónea para su conservación. Esta función es útil durante las

horas nocturnas, para mantener inalterada la calidad del

preparado y reducir el consumo de energía eléctrica.

LAVADO. En este modo de funcionamiento, el enfriamiento no

está habilitado. Esta función es útil durante el lavado y la

esterilización de la máquina, para evitar que la solución utilizada

se enfríe y se congele.

INTERRUPTOR GENERAL

El interruptor general esta posicionado en la parte de arriba del

distribuidor, en el lado posterior.

Su función es la siguiente:

Posición 0 : máxima apertura, menor cantidad de aire en el

helado.

Posición I : mínima apertura, mayor cantidad de aire en el

helado.

En la pantalla están presentes los siguientes íconos:

A Ícono PRODUCCIÓN HELADO: su presión activa la fun-

ción HELADO.

B Ícono CONSERVACIÓN: su presión activa la función

CONSERVACIÓN.

C Ícono LAVADO: su presión activa la función LAVADO.

D Ícono PARÁMETROS: su presión permite regular los

PARÁMETROS de funcionamiento.

E Código de alarma: indica la presencia de una alarma y el

código correspondiente.

F Barra de densidad: indica el nivel de densidad regulada.

G Temperatura del preparado: indica la temperatura del pro-

ducto base contenido en la cuba superior.

H Ícono ESTADO: indica el estado en que se encuentra el

distribuidor (helado, conservación, lavado o alarma) y,

cuando está activado el modo HELADO, el estado de pro-

ducción del helado.

Ícono rojo: helado no listo.

Ícono amarillo: helado casi listo.

Ícono verde: helado listo.

I Ícono ENFRIAMIENTO CUBA SUPERIOR: indica que el

enfriamiento de la cuba superior está en funcionamiento.

J Ícono ENFRIAMIENTO CILINDRO INFERIOR: indica que

el enfriamiento del cilindro inferior está en funcionamiento.

K Icono COMPRESOR: indica el funcionamiento del com-

presor de refrigeración.

L Icono COMPRESOR: indica el funcionamiento del com-

presor de refrigeración.

PARA UTILIZAR EL DISTRIBUIDOR

Ponga el interruptor general en posición I. Se enciende el piloto

rojo Q.

Mantenga pulsado el botón P hasta que se encienda el

distribuidor.

Seleccione la función deseada con los íconos A, B, C o D.

IMPORTANTE

Apagando y reencendiendo el distribuidor con el interruptor general, el aparato se reenciende en el mismo

modo de funcionamiento en el que se encontraba al ser

apagado.

BOTÓN DE ENCENDIDO

El botón de encendido P está situado a la derecha de la pantalla

táctil. El encendido del piloto Q indica que el distribuidor está

encendido y se encuentra en modo stand-by, listo para el

funcionamiento. Manteniendo pulsado el botón P durante un

segundo, es posible encender y apagar el distribuidor.

PANTALLA TÁCTIL

figura 8

MODO HELADO

En este modo de funcionamiento, la máquina produce helado y

el preparado en la cuba superior se mantiene a una temperatura

idónea para su conservación. El estado de producción de

helado es indicado en la pantalla por el ícono central y por el

color de las flechas. (ver figura 9)

figura 9

Cuando el helado está listo, el sistema de mezcla decelera, el

sistema de enfriamiento se apaga y el aparato se pone en fase

de espera de distribución. A intervalos preestablecidos (por

defecto, 10 minutos), el sistema de mezcla acelera y el sistema

de refrigeración se enciende para restablecer la correcta

densidad del helado.

Cuando se abre el grifo de distribución, el sistema de mezcla

acelera y el sistema de refrigeración se enciende.

Para producir helado, es necesario que en la cuba superior

haya una adecuada cantidad de preparado. En caso contrario,

el sistema de enfriamiento no se enciende y en la pantalla se

16

Page 17

visualiza el ícono de falta de producto.

figura 10

Regulación de la densidad

Es posible regular la densidad del helado en una escala de 1 a

10. Para realizar esta regulación, es necesario tocar la barra

graduada situada en el lado derecho de la pantalla y acceder al

modo DENSIDAD. Están disponibles los siguientes mandos:

A Ícono SALIDA: para salir del modo de funcionamiento sin

realizar modificaciones.

B Ícono DISMINUCIÓN: para reducir el valor regulado.

C Ícono AUMENTO: para aumentar el valor regulado.

D Ícono CONFIRMACIÓN: para confirmar el valor regulado.

(ver figura 11)

restablecer la temperatura correcta.

IMPORTANTE

La temperatura de conservación del producto está regulada de fábrica a 2 °C.

MODO LAVADO

En este modo de funcionamiento, el sistema de enfriamiento no

funciona y el sistema de mezcla gira a una velocidad idónea

para el lavado de la máquina. En la pantalla se visualiza el ícono

LAVADO. (ver figura 13)

figura 13

ALARMAS

La máquina está dotada de un sistema de autodiagnóstico. Si

se verifica una disfunción, esta es indicada por la visualización

en la pantalla del ícono de alarma. Pulsando este último, es

posible visualizar el texto explicativo correspondiente a la

alarma en curso. (ver figura 14)

figura 11

MODO CONSERVACIÓN

En este modo de funcionamiento, el preparado —tanto en la

cuba superior como en el cilindro inferior— se mantiene a una

temperatura idónea para su conservación. En la pantalla se

visualiza el ícono CONSERVACIÓN. (ver figura 12)

figura 12

Una vez que el preparado alcanza la temperatura regulada, el

sistema de mezcla decelera, el sistema de enfriamiento se

apaga y el aparato se pone en fase de espera. A intervalos

preestablecidos (por defecto, 10 minutos), el sistema de mezcla

acelera y el sistema de refrigeración se enciende para

figura 14

ALARMA DE MANTENIMIENTO (AL 14)

Cada 1500 horas de funcionamiento es necesario reemplazar el

sello colocado en el terminal de limpiaparabrisas. Se lleva a

cabo dicha sustitución es necesario proceder a la AL14 de alarma de reinicio.

Para restablecer la alarma 14 es necesario:

- icono de parámetros de la prensa

- tipo de contraseña de usuario (0000)

- pulse sobre el icono de reloj de arena

- pulse el botón RESET

- tipo de contraseña de usuario (0000)

- botón de salida de prensa

7. 2 PARÁMETROS DE FUNCIONAMIENTO

Los parámetros del aparato son preestablecidos en la fábrica

para garantizar un correcto funcionamiento. Para evitar

17

Page 18

C111

ESPAÑOL

disfunciones, su modificación solo puede ser realizada por el

fabricante, por su servicio de asistencia técnica o por personas

con cualificación similar.

7. 3 SUGERENCIAS

1 Todos los distribuidores de este tipo liberan calor. Sin

embargo, si la emisión de calor parece excesiva, verifique que

no haya ninguna fuente de calor cerca del distribuidor y, en

particular, cerca de las rejillas. Verifique también que el flujo de

aire no sea obstaculizado por la cercanía de paredes, cajas,

etc. Deje al menos 15 cm de espacio libre alrededor del

distribuidor. Por último, verifique que el filtro situado debajo del

panel posterior esté limpio.

2 Este aparato está diseñado para funcionar exclusivamente

con alimentos dulces.

ATTENCION

El uso del aparato está reservado a personas con seguridad, higiene, conocimiento y práctica suficientes para el

uso correcto del aparato.

7. 4 LIMPIEZA

15)

figura 15

figura 16

1 El lavado y la limpieza son esenciales para garantizar la

perfecta conservación del sabor del producto y la máxima

eficiencia del distribuidor. Los procedimientos descritos a

continuación se deben considerar de carácter general y

pueden variar en función de la reglamentación sanitaria

vigente.

2 Antes de desmontarlo para su lavado, es necesario vaciar

completamente el distribuidor. Proceda en la forma siguiente:

1 Utilizando el teclado, seleccione el modo de funcionamien-

to LAVADO.

2 Si es necesario, espere hasta que el producto se vuelva

líquido.

3 Coloque un recipiente debajo del grifo y vacíe todo el con-

tenido de la cuba superior y del cilindro.

4 Quite la tapa.

Si la tapa tiene cerradura, gire la llave en sentido levógiro.

(ver figura 15)

5 Llene la cuba superior con agua y deje funcionar el distri-

buidor en modo LAVADO durante algunos minutos. A con-

tinuación, vacíe completamente el distribuidor.

6 Llene la cuba superior con agua y deje funcionar el distri-

buidor en modo LAVADO durante algunos minutos. A con-

tinuación, vacíe completamente el distribuidor.

7 Accione el interruptor general.

7. 4. 1 DESMONTAJE

2 Si está presente, retire el mezclador cuenca alta. (ver figura

17)

figura 17

3 Retire el tubo de mezcla, tanto en la parte superior que en

la parte inferior.

4 Quite el tube de mezcla y desmontalo (ver figura 18) y (ver

Antes de proceder al desmontaje de cualquier componente, desconecte siempre la alimentación eléctrica del

aparato, extrayendo la clavija de la toma.

1 Quite la tapa superior. (ver figura 16) Si la tapa tiene

cerradura, gire la llave en sentido levógiro y quítela. (ver figura

ATTENCION

18

Page 19

figura 19).

figura 21)

figura 21

7 Desmonte el grupo grifo siguiendo la secuencia indicada.

(ver figura 22)

figura 18

figura 19

5 Quite el panel frontal. (ver figura 20)

figura 20

6 Desenrosque ambos pomos de fijación del grupo grifo. (ver

figura 22

8 Quite el raspador. (ver figura 23)

figura 23

19

Page 20

C111

ESPAÑOL

9 Quite la junta. (ver figura 24)

figura 24

10 Extraiga el cajón colector de gotas de su alojamiento. (ver

figura 25)

7. 4. 2 LAVADO

IMPORTANTE

No lave ningún componente de la máquina en el lavavajillas.

ATTENCION

Antes de cualquier operación de limpieza, desconecte

siempre la alimentación eléctrica del distribuidor,

extrayendo la clavija de la toma o apagando el interruptor exterior de pared.

1 Prepare en una cubeta aproximadamente cuatro litros de

agua caliente (45-60 °C) y 15 gr (1 oz) de detergente

específico, proveedores (stera sheen green label); una

solución demasiado concentrada puede dañar los

componentes a lavar, mientras que una solución demasiado

diluida puede no ser suficiente para garantizar una limpieza

adecuada. No use detergentes abrasivos.

IMPORTANTE

figura 25

La temperatura de conservación del producto está regulada de fábrica a 2 °C.

2 Use un cepillo adecuado y lave cuidadosamente con

solución detergente todas las partes en contacto con el

producto.

ATTENCION

Durante el lavado del distribuidor, no use una excesiva

cantidad de agua cerca de los componentes eléctricos;

en caso contrario, se podrían producir descargas

eléctricas a las personas o daños en el distribuidor.

3 Lave el cilindro evaporador, la cuba superior y el orificio

usando el cepillo en dotacion.

4 Enjuague todas las partes lavadas con agua corriente.

7. 4. 3 ESTERILIZACIÓN DEL DISTRIBUIDOR

DESARMADO

La esterilización se debe realizar inmediatamente antes de

poner el distribuidor en funcionamiento; evite que este

permanezca inactivo durante mucho tiempo después de la

esterilización.

1 Antes de comenzar los procedimientos que se describen a

continuación, lávese las manos con jabón antibacteriano.

2 Prepare en una cubeta aproximadamente ocho litros de

agua caliente (45-60 °C) y 30 gr (2 ozs) de solución

proveedores (stera sheen green label).

3 Sumerja en la solución todas las partes a esterilizar durante

el tiempo indicado por el fabricante del producto o, por lo

meno, por 5 minutos.

4 Deje secar las partes esterilizadas al aire, sobre una

superficie limpia.

5 Seque las partes externas del distribuidor sin usar paños

abrasivos.

20

Page 21

7. 4. 4 MONTAJE

1 Coloque el cajón colector de gotas en su alojamiento.

IMPORTANTE

Lubrique el pistón del grifo, el enganche del raspador y

la parte delantera del raspador en los puntos indicados

en la figura, utilizando exclusivamente la grasa suministrada con la máquina u otra grasa para uso alimentario.

extremos en las ranuras en la cuenca alta.(ver figura 27)

figura 27

7. 4. 5 ESTERILIZACIÓN DEL DISTRIBUIDOR

ARMADO

2 Vuelva a colocar la junta y el raspador siguiendo la

secuencia inversa a la de desmontaje.

3 Coloque el grupo grifo siguiendo la secuencia inversa con

respecto a la ilustrada en la figura 19, e introdúzcalo en su

alojamiento.

4 Enrosque ambos pomos, apretándolos con cuidado.

5 Coloque el panel frontal. (ver figura 26)

figura 26

6 Montar el mezclador juntos teniendo cuidado de insertar los

La esterilización del aparato armado, antes de su puesta en

funcionamiento, se debe realizar además de la

esterilización del aparato desarmado descrita en el punto

anterior, y no como alternativa a la misma.

1 Prepare en una cubeta aproximadamente cuatro litros de

de agua y 15 gr (1 oz) de solución proveedores (stera sheen

green label).

2 Vierta la solución en el recipiente.

3 Usando un cepillo adecuado, frote la solución sobre todas

las partes por encima del nivel de la solución.

4 Coloque la tapa y haga funcionar el distribuidor para agitar

la solución durante aproximadamente 5 minutos.

5 Extraiga la solución esterilizante a través del grifo y

elimínela.

6 Enjuague con agua corriente para eliminar todos los

residuos de solución esterilizante del fondo de los recipientes.

7 No realice otras operaciones de enjuague.

8 MANTENIMIENTO

1 Una vez por día: controle el distribuidor y verifique que no

haya pérdidas de producto a través de la junta del grupo grifo.

Si se detectan pérdidas, verifique en primer lugar que los

componentes estén colocados correctamente; a continuación,

verifique que la junta no sea defectuosa y no esté desgastada;

de ser así, sustitúyala con un repuesto original del fabricante.

(ver figura 28)

figura 28

2 Una vez por semana: verifique que la junta del raspador

no esté desgastada. de ser así, sustitúyala con un repuesto

21

Page 22

C111

ESPAÑOL

original del fabricante. (ver figura 29)

figura 29

3 Una vez por semana: verifique la presencia de eventuales

pérdidas, extrayendo la bandeja (ver figura 30). Si hay verifique

que la junta del raspador no esté desgastada. de ser así,

sustitúyala con un repuesto original del fabricante (ver figura

29).

se encienda improvisamente.

7 Después de cualquier operación de reparación, vuelva a

colocar todos los componentes (tapas, tornillos, etc.) en su

posición original.

figura 30

4 Una vez por mes: elimine el polvo acumulado en el filtro

del condensador, situado en la parte posterior de la máquina.

(ver figura 31)

figura 31

ATTENCION

Preste atención a las aletas del condensador, ya que son

cortantes.

5 En caso de ruido anómalo, desconecte la máquina y

contacte con el servicio de asistencia.

6 En caso de avería, desconecte la máquina para evitar que

22

Page 23

1 CONSIGNE DE SÉCURITÉ EN MATIÈRE

C111-37

ÉLECTRIQUE

1 Avant d'effectuer le branchement électrique du distributeur,

vérifier que la tension secteur est bien celle qui figure sur la

plaquette signalétique. Brancher le distributeur sur un réseau

monophasé en utilisant une prise munie d'un système de mise

à la terre conforme aux prescriptions des normes en vigueur.

En cas de déconnexion de l'appareil du réseau électrique par le

biais d'un interrupteur unipolaire, cet interrupteur doit garantir

une distance d'ouverture des contacts permettant la

déconnexion totale dans les conditions de la catégorie de

surtension III.

2 Ne pas utiliser de rallonges pour effectuer le branchement

électrique de l'appareil.

3 Si le câble d'alimentation est endommagé, il doit être

remplacé par le fabricant ou son service technique d'assistance

ou, quoi qu'il en soit, par une personne en possession de

compétences similaires, et ce, afin d'écarter tout risque.

4 L'appareil n'est pas conçu pour être utilisé à l'extérieur.

5 L'appareil doit être installé en position verticale.

6 Avant une quelconque intervention d'entretien, débrancher

systématiquement le distributeur en enlevant la fiche de la

prise.

7 Ne pas démonter les panneaux lors des opérations de

nettoyage ou d'entretien avant de s'être assuré que le

distributeur est bien débranché.

8 Ne pas utiliser de jet d'eau pour effectuer le nettoyage.

3 CARACTERISTIQUES TECHNIQUES

Capacité du bac, environ l 4

Capacité de l’évaporateur, environ l 2

Dimensions:

largeur cm 26

profondeur cm 57

hauteur cm 72

Poids net, environ kg 50

Poids brut, environ kg 55

Motocompresseur hermétique

Condenseur à ventilation mécanique

Protège-moteur

Niveau de bruit inférieur à 70 dB (A)

IMPORTANT

Caractéristiques électriques : lire les données figurant

sur la plaquette signalétique de chaque distributeur

située dans la partie inférieure du panneau de façade,

derrière le plateau récolte-gouttes. Les numéros de série

des appareils (précédés du symbole #) sont gravés sur le

châssis, à l’arrière de l’appareil, derrière le panneau de

protection du condensateur. Les données figurant sur la

plaquette signalétique sont les seules auxquelles il faut

toujours se référer.

9 Cet appareil ne peut pas être utilisé par des enfants.

10 Éviter que des enfants jouent avec l'appareil.

11 Cet appareil ne peut pas être utilisé par des personnes dont

les capacités physiques, sensorielles ou mentales sont

réduites ou qui ne disposent pas de l'expérience et des

connaissances suffisantes, sauf si celles-ci ont reçu

l'assistance nécessaire et suivi une formation pour utiliser

l'appareil en toute sécurité et qu'elles comprennent les dangers

inhérents à son emploi.

12 L'accès à la partie interne du distributeur est limité aux

personnes qui disposent des connaissances et de l'expérience

pratique nécessaires de l'appareil, notamment en matière de

sécurité et d'hygiène.

2 CONSIGNE DE SÉCURITÉ EN MATIÈRE

D'HYGIÈNE

1 Cet appareil est destiné à être utilisé dans le cadre

d'applications domestiques ou similaires.

2 Pour garantir son bon fonctionnement, la température

ambiante doit être comprise entre +5 et +32 °C.

3 Utiliser l'appareil exclusivement pour refroidir les liquides

indiqués.

4 Ne pas introduire de substances ni de liquides dangereux

ou toxiques à l'intérieur de l'appareil.

Le fabricant se réserve le droit de modifier ce manuel sans

préavis.

4 INTRODUCTION

Il convient de lire attentivement ce livret d’instructions afin de

bien maîtriser toutes les caractéristiques du produit.

Comme tous les produits mécaniques, ce distributeur nécessite

lui aussi un nettoyage et un entretien. En outre, son bon

fonctionnement peut être compromis par d'éventuelles erreurs

commises par l'opérateur durant les opérations de démontage

et de nettoyage. C'est la raison pour laquelle il est important que

les procédures de démontage, lavage, désinfection et

remontage, qui sont des opérations quotidiennes, soient

parfaitement assimilées, sans possibilité d’erreurs, par

l'utilisateur du distributeur.

5 INSTALLATION

1 Extraire le distributeur de l’emballage qu’il est conseillé de

conserver pour toute nécessité future.

2 Vérifier que le distributeur n'a pas subi de dégâts durant le

transport. Si tel est le cas, faire immédiatement une

réclamation auprès du transporteur.

3 Poser le distributeur sur un support en mesure de soutenir

son poids, même entièrement chargé.

4 Prévoir un espace de 15 cm au moins tout autour du

distributeur pour ne pas obstruer le flux d’air de

refroidissement.

5 Vérifier la stabilité de l’appareil en réglant, le cas échéant,

la hauteur des pieds. Si le distributeur est livré avec un jeu de

23

Page 24

C111

FRANCAIS

pieds en hauteur (100 mm environ), celui-ci devra alors

remplacer le jeu d’origine.

ATTENTION

Veiller à ce que l’appareil soit correctement mis à la

terre; dans le cas contraire, il se peut que les personnes

subissent des chocs électriques ou que le distributeur

soit endommagé.

6 Le distributeur n’a été ni lavé, ni désinfecté en usine. Avant

toute utilisation, il convient donc de le démonter, de le laver et

de le désinfecter en suivant les indications décrites au chapitre

7.4 NETTOYAGE de ce livret.

IMPORTANT

Placer l’appareil de manière à ce que la prise du câble

d'alimentation soit aisément accessible.

6 POUR GARANTIR LE BON

FONCTIONNEMENT EN TOUTE SECURITE

1 Ne pas utiliser le distributeur avant d’avoir lu ce livret

d’instructions.

2 Ne pas utiliser le distributeur s’il n'a pas été correctement

mis à la terre.

3 Ne pas mettre le distributeur en marche tant que les

panneaux ne sont pas en place et assujettis par des vis.

4 Ne pas introduire les doigts ou des objets dans les fentes

des panneaux ni dans l'ouverture du robinet.

5 Ne pas enlever les composants ni les panneaux lors des

opérations de nettoyage ou d'entretien avant de s’être assuré

que le distributeur est bien débranché.

6 Le couvercle doit toujours rester fermé.

7 MODE D’EMPLOI

IMPORTANT

Avant toute utilisation, laver et désinfecter le distributeur

en suivant les indications décrites au chapitre 7.4.2

LAVAGE de ce livret.

IMPORTANT

Si le groupe du robinet n’a pas été installé, l’appareil ne

peut pas fonctionner et l’icône représentant le groupe du

robinet ouvert s’affiche sur l’écran.(voir )

figure 1

Cet appareil est équipé d’un bac supérieur destiné à maintenir

la réfrigération de la base de préparation de glace et d’un

cylindre inférieur qui permet de produire la glace.

Chaque fois qu’une portion de glace est distribuée, une quantité

égale de préparation passe par gravité du bac supérieur dans le

cylindre inférieur.

Pour obtenir une glace plus aérée et légère, il faut faire en sorte

qu’une certaine quantité d’air entre dans le cylindre en même

temps que la base. C’est la raison pour laquelle l’appareil est

équipé d’un tube de mélange spécial constitué de deux parties.

(voir figure 2)

figure 2

Afin d’obtenir les meilleurs résultats, il faut exécuter les

opérations suivantes dans l’ordre indiqué :

1 insérer la partie inférieure du tube de mélange dans le trou

de raccordement spécial situé entre le bac et le cylindre en

veillant à l’orienter de manière à l’introduire entièrement dans

24

Page 25

son siège. (voir figure 3)

figure 3

2 Verser la préparation dans le bac supérieur et attendre que

le cylindre se remplisse. Le remplissage est terminé lorsqu’il

n’y a plus de bulles d’air qui s’échappent par les trous pratiqués

sur le tube de mélange. (voir figure 4)

dans le cylindre. (voir figure 6)

figure 6

5 Fermer le couvercle supérieur, mettre la machine en

marche et activer la préparation de la glace. (Voir 7.1

DESCRIPTION DES COMMANDES)

6 Quand la glace est prête, ouvrir le couvercle et tourner la

partie supérieure du tube de mélange dans le sens anti-horaire

pour que la préparation puisse entrer dans le cylindre inférieur.

(voir figure 7) :

Il est possible de régler la quantité d’air présente dans la glace

d’après les informations suivantes, à partir de la position de

fermeture :

rotation complète dans

le sens anti-horaire

rotation minimale dans le

sens anti-horaire

: ouverture maximale, faible

quantité d’air dans la glace

: ouverture maximale, faible

quantité d’air dans la glace

figure 4

3 Insérer la partie supérieure du tube de mélange à l’intérieur

de la partie inférieure. (voir figure 5)

figure 5

4 Tourner la partie supérieure du tube de mélange à fond

dans le sens horaire pour fermer l’entrée de la préparation

figure 7

7 Refermer le couvercle supérieur.

IMPORTANT

Utiliser le distributeur uniquement avec des produits alimentaires.

8 Débiter la glace en utilisant le lévier du robinet.

9 Au cas où la portée de régulation de la densité ne soit pas

suffisante pour obtenir le résultat désiré, le mélange peut etre

modifié comme suit:

Glace trop souple : augmenter la quantité de liquide, eau ou

lait, d’une valeur entre 5% et 10% du volume total.

Glace trop compacte : réduire la quantité de liquid, eau ou lait,

d’une valeur entre 5% et 10% du volume totale.

10 Le distributeur doit fonctionner sans interruption : Le

système de refroidissement s’arrête automatiquement quand le

produit est prêt à être distribué. La vitesse du dispositif de

mélange diminue et n’augmente qu’au moment de la

distribution. À des intervalles de temps préréglés, le système

de refroidissement se réenclenche et la vitesse du dispositif de

mélange augmente pour rétablir la densité correcte du produit.

25

Page 26

C111

FRANCAIS

7. 1 DESCRIPTION DES COMMANDES

Le distributeur est équipé d’un interrupteur général, d’une

touche de mise en marche et d’un écran tactile. Les modes de

fonctionnement suivants sont disponibles :

PRODUCTION DE GLACE : dans ce mode, le distributeur

prépare la glace.

CONSERVATION : dans ce mode, le distributeur maintient la

préparation liquide à une température adaptée à sa

conservation. Cette fonction est utile durant les heures

nocturnes afin de maintenir la qualité de la préparation inaltérée

et de réduire la consommation d’énergie électrique.

LAVAGE : Dans ce mode, le refroidissement n’est pas habilité.

Cette fonction est utile durant le lavage et la désinfection de la

machine afin d’éviter que la solution utilisée ne refroidisse et

gèle.

INTERRUPTEUR GÉNÉRAL

L'interrupteur general est positionné au dessus du distributeur,

dans la partie postérieure.

Sa fonction est la suivante :

Position 0 : le distributeur est éteint.

Position I : le distributeur est habilité à fonctionner, mais

il est en mode Veille. Seul le voyant Q est allumé.

IMPORTANT

Lorsque l’utilisateur éteint puis rallume le distributeur à

partir de l’interrupteur général, celui-ci se remet en marche dans le même mode de fonctionnement que celui

dans lequel il se trouvait au moment où il a été éteint.

Les icônes suivantes s’affichent sur l’écran :

A Icône PRODUCTION GLACE : permet d’activer la fonc-

tion GLACE si elle est enfoncée.

B Icône CONSERVATION : permet de passer à la fonction

CONSERVATION si elle est enfoncée.

C Icône LAVAGE : permet de passer à la fonction LAVAGE

si elle est enfoncée.

D Icône PARAMÈTRES : permet de régler les PARA-

MÈTRES de fonctionnement si elle est enfoncée.

E Code d’alarme. Indique la présence d’une alarme et le

code correspondant.

F Barre de densité. Indique le niveau de densité paramétré.

G Température de la préparation. Indique la température de

la base contenue dans le bac supérieur.

H

Icône d’état. Indique l’état dans lequel se trouve le

distributeur (glace, conservation, lavage, alarme) et,

lorsque le mode Glace est activé, l’état de préparation de

la glace :

icône de couleur rouge : la glace n’est pas prête

icône de couleur jaune : la glace est presque prête

icône de couleur verte : la glace est prête

I Icône de refroidissement du bac supérieur. Indique que le

refroidissement du bac supérieur est en marche.

J Icône de refroidissement du cylindre inférieur. Indique que

le refroidissement du cylindre inférieur est en marche.

K Icône du compresseur. Indique le fonctionnement du com-

presseur du réfrigérateur.

L Icône du compresseur. Indique le fonctionnement du com-

presseur du réfrigérateur.

POUR LE FONCTIONNEMENT DU DISTRIBUTEUR

Amener l’interrupteur général en position I. Le voyant rouge Q

est allumé.

Maintenir la touche P enfoncée jusqu’à ce que le distributeur se

mette en route.

Sélectionner à l’aide des icônes A, B, c ou D la fonction désirée.

MODE GLACE

Dans ce mode, la machine produit de la glace et la préparation

dans le bac supérieur est maintenue à sa température de

conservation idéale. L’état de préparation de la glace est

indiqué sur l’afficheur par l’icône centrale et par la couleur de la

flèche. (voir figure 9)

TOUCHE DE MISE EN MARCHE

La touche de mise en marche P est située à droite de l’écran

tactile. L’allumage du témoin Q indique que le distributeur est

allumé et qu’il est en veille, prêt à fonctionner. Il suffit de

maintenir la touche P enfoncée pendant une seconde pour

allumer et éteindre le distributeur.

ÉCRAN TACTILE

figure 8

figure 9

Quand la glace est prête, le système de mélange ralentit, le

système de refroidissement s’arrête et l’appareil se met en

phase d’attente de distribution. À des intervalles préréglés

(réglage d’usine : 10 minutes), la vitesse du système de

mélange augmente et le système de réfrigérateur se déclenche

pour rétablir la densité correcte de la glace.

Lorsque l’utilisateur ouvre le robinet de mélange, la vitesse du

système de mélange augmente et le système de réfrigérateur

se déclenche.

Pour qu’il soit possible de produire de la glace, il faut qu’il y ait

une quantité de préparation appropriée dans le bac supérieur.

Dans le cas contraire, le système de refroidissement ne se

déclenche pas et l’icône d’absence de produit s’affiche sur

26

Page 27

l’écran. (voir figure 10)

figure 10

Réglage de la densité

Il est possible de régler la densité de la glace sur une échelle de

1 à 10. Pour faire ce réglage, il faut effleurer la barre graduée

placée du côté droit de l’écran et entrer en mode Densité. Les

commandes suivantes sont disponibles :

A Icône de sortie : permet de quitter le mode sans apporter

de modifications.

B Icône de diminution : permet de diminuer la valeur réglée.

C Icône d’augmentation : permet d’augmenter la valeur ré-

glée.

D Icône de confirmation : permet de confirmer la valeur ré-

glée.

(voir figure 11)

déclenche pour rétablir la température correcte.

IMPORTANT

La température de conservation du produit est réglée en

usine sur 2 °C.

MODE LAVAGE

Dans ce mode, le système de refroidissement n’est pas en

marche et le système de mélange tourne à une vitesse

appropriée au lavage de la machine. L’icône de lavage s’affiche

sur l’écran. (voir figure 13)

figure 13

ALARMES

La machine est équipée d’un système de diagnostic

automatique. En cas de dysfonctionnement, la défaillance est

indiquée par l’affichage de l’icône d’alarme sur l’écran. Il suffit

d’appuyer sur celle-ci pour afficher le texte explicatif de l’alarme

en cours. (voir figure 14)

figure 11

MODE CONSERVATION

Dans ce mode, la préparation dans le bac supérieur et dans le

cylindre inférieur est maintenue à sa température de

conservation idéale. L’icône de conservation s’affiche sur

l’écran. (voir figure 12)

figure 12

Quand la préparation a atteint la température préréglée, le

système de mélange ralentit, le système de refroidissement

s’arrête et l’appareil se met en phase d’attente. À des intervalles

préréglés (réglage d’usine : 10 minutes), la vitesse du système

de mélange augmente et le système de réfrigérateur se

figure 14

ENTRETIEN ALARM (AL 14)

Toutes les 1500 heures de fonctionnement est nécessaire de

remplacer le joint d'étanchéité placé dans le terminal d'essuieglace. Réaliser un tel remplacement est nécessaire de procéder

à l'AL14 d'alarme de réinitialisation.

Pour réinitialiser l'alarme 14 est nécessaire:

- paramètres de presse icon

- type mot de passe utilisateur (0000)

- appuyez sur l'icône de sablier

- appuyez sur le bouton RESET

- type mot de passe utilisateur (0000)

- appuyez sur le bouton de sortie

7. 2 PARAMÈTRES DE FONCTIONNEMENT

Les paramètres de l’appareil sont préréglés en usine pour

garantir son fonctionnement optimal. Leur modification ne peut

être effectuée que par le fabricant, son service d’assistance ou,

dans tous les cas, par des personnes qui disposent d’une

qualification similaire pour éviter tout risque de

27

Page 28

C111

FRANCAIS

dysfonctionnement.

7. 3 SUGGESTIONS

1 Tous les distributeurs de cette catégorie doivent dégager

de la chaleur. Si toutefois la chaleur produite semble

excessive, contrôler l’absence de sources de chaleur à

proximité du distributeur, notamment au voisinage des

panneaux munis de grilles. S'assurer par ailleurs que le flux

d'air n’est pas obstrué par la présence de cloisons, de boîtes

ou autres aux alentours du distributeur. Prévoir un espace de

15 cm au moins autour du distributeur. Pour finir, vérifier que le

filtre situé en dessous du panneau arrière n'est pas encrassé.

2 Cet appareil est destiné à être utilisé exclusivement avec

des confiseries alimentaires.

ATTENTION

L'utilisation de l’appareil est limitée aux personnes qui

connaissent les consignes de sécurité/hygiène et savent

l’utiliser correctement.

7. 4 NETTOYAGE

1 Le nettoyage et le lavage du produit sont fondamentaux

pour garantir la parfaite conservation du produit et de son goût

ainsi que le rendement élevé du distributeur. Les procédures

décrites ci-après présentent un caractère général et sont

susceptibles de varier en fonction des règlements sanitaires en

vigueur.

2 Le produit doit être vidé avant de démonter le distributeur

pour le laver. Procéder comme suit :

1 sélectionner sur le clavier le mode de fonctionnement LA-

VAGE.

2 le cas échéant, attendre que le produit devienne liquide.

3 placer un récipient sous le robinet et vider l’ensemble du

contenu du bac supérieur et du cylindre.

4 enlever le couvercle.

Si le couvercle est équipé d’une serrure de sûreté pour sa

fermeture, tourner la clé dans le sens anti-horaire. (voir fi-

gure 15)

5 remplir le bac supérieur d’eau et laisser le distributeur mar-

cher en mode LAVAGE pendant quelques minutes. Vider

ensuite l’ensemble du distributeur.

6 remplir le bac supérieur d’eau et laisser le distributeur mar-

cher en mode LAVAGE pendant quelques minutes. Vider

ensuite l’ensemble du distributeur.

7 éteindre l’interrupteur général.

(voir figure 15)

figure 15

figure 16

2 Se il est présent, retirez le mélangeur de bassin supérieur.

(voir figure 17)

figure 17

3 Retirez le tube de mélange, à la fois la partie supérieure

que la partie inférieure.

4 Enlever le tube de mélange et le démonter (voir figure 18)

7. 4. 1 DÉMONTAGE

Avant de procéder au démontage des composants, couper systématiquement le courant qui alimente l’appareil

en débranchant la fiche de la prise.

1 Enlever le couvercle supérieur. (voir figure 16)

Si le couvercle est équipé d’une serrure de sûreté pour sa

fermeture, tourner la clé dans le sens anti-horaire et l’enlever.

ATTENTION

28

Page 29

et (voir figure 19).

robinet. (voir figure 21)

figure 18

figure 21

7 Enlever le groupe du robinet et le démonter en respectant

la séquence indiquée. (voir figure 22)

figure 19

5 Enlever le panneau de façade. (voir figure 20)

figure 22

figure 20

6 Dévisser les deux poignées de fixation du groupe du

29

Page 30

C111

FRANCAIS

8 Enlever le racleur. (voir figure 23)

figure 25)

figure 23

9 Enlever le joint avec sa garniture. (voir figure 24)

figure 24

10 Enlever le plateau récolte-gouttes de son logement. (voir

figure 25

7. 4. 2 LAVAGE

IMPORTANT

Ne pas laver les composants de la machine dans le lavevaisselle.

ATTENTION

Avant toute intervention de nettoyage, débrancher

systématiquement le distributeur en enlevant la fiche de

la prise ou en éteignant l'interrupteur mural extérieur.

1 Préparer environ quatre litres d'eau chaude (45-60 °C) et

15 gr (1 oz) de détergent spécifique équipé (stera sheen green

label); une solution trop concentrée peut en effet occasionner

des dommages aux pièces à laver, alors qu'une solution trop

diluée peut ne pas nettoyer suffisamment. Ne pas utiliser de

détergents abrasifs.

IMPORTANT

Afin de prévenir toute détérioration du distributeur, utiliser uniquement des détergents compatibles avec les

pièces en plastique.

2 Utiliser une brosse adaptée et laver soigneusement avec la

solution détergente toutes les pièces en contact avec la

30

Page 31

boisson.

ATTENTION

Pendant le lavage du distributeur, ne pas utiliser de trop

grandes quantités d’eau à proximité des composants

électriques ; dans le cas contraire, des chocs électriques

peuvent se produire ou le distributeur peut être endommagé.

3 Laver le cylindre d’évaporation, le bac supérieur et le trou

de connection à l’aide de la brosse en dotation.

4 Rincer toutes les pièces lavées à l'eau du robinet.

7. 4. 3 DÉSINFECTION DU DISTRIBUTEUR

DÉMONTÉ

La désinfection doit être effectuée tout de suite avant de

mettre le distributeur en marche ; éviter qu’il ne reste trop

longtemps inactif après la désinfection.

1 Avant de commencer les procédures décrites ci-après, se

laver les mains avec un savon antibactérien.

2 Verser environ huit litres d'eau chaude (45-60 °C) et 30 gr

(2 ozs) de désinfectant équipé (stera sheen green label);

3 Faire tremper toutes les pièces à désinfecter dans la

solution pendant la durée indiquée par le fabricant du produit

ou pour 5 minutes au moins.

4 Poser les pièces désinfectées sur une surface propre et

laisser sécher à l'air.

5 Sécher les parties extérieures du distributeur sans utiliser

de chiffons abrasifs.

5 Remonter le panneau de façade. (voir figure 26)

figure 26

6 Monter le mélangeur ensemble prenant soin d'insérer les

extrémités dans les rainures dans le bassin supérieur.(voir

7. 4. 4 REMONTAGE

1 Introduire le plateau récolte-gouttes dans son logement.

IMPORTANT

Lubrifier le piston du robinet, le raccord du racleur et la

partie avant du racleur aux points indiqués dans la

figure. Utiliser uniquement la graisse fournie avec la

machine ou une autre graisse prévue pour un usage alimentaire.

2 Remonter le joint et le racleur en suivant la séquence

inverse au démontage.

3 Remonter le groupe du robinet en suivant la séquence

inverse à celle illustrée sur la Figure 19 et le remettre dans son

siège.

4 Revisser les deux poignées en les resserrant

précautionneusement.

31

Page 32

C111

FRANCAIS

figure 27)

d'origine fournie par le fabricant. (voir figure 28)

figure 28

2 Toutes les semaines : vérifier l'usure de la garniture du

joint du racleur. Si elle est usée, la remplacer par une pièce de

rechange d’origine du fabricant. (voir figure 29)

figure 27

7. 4. 5 DÉSINFECTION DU DISTRIBUTEUR

DÉMONTÉ

La désinfection de l’appareil monté, avant sa mise en

service, doit être effectuée en plus de la désinfection de

l'appareil démonté décrite au point précédent, et jamais à la

place de celle-ci.

1 Verser environ quatre litres d'eau et 15 gr (1 oz)

désinfectant équipé (stera sheen green label);

2 Verser la solution dans le bac.

3 À l’aide d’une brosse appropriée, étaler la solution sur

toutes les pièces au-dessus du niveau de la solution.

4 Monter le couvercle et mettre le distributeur en marche de

façon à agiter la solution pendant 5 minutes environ.

5 Vider la solution désinfectante du bac en ouvrant le robinet

et l’éliminer.

6 Rincer à l’eau fraîche de façon à éliminer d'éventuels

résidus de solution désinfectante qui auraient pu se déposer

sur le fond des bacs.

7 Ne pas rincer ultérieurement.

figure 29

3 Toutes les semaines : vérifier la présence de fuites

éventuelles en enlevant le bac spécial (voir figure 30). Dans le

cas vérifier Il est correctement installé et l'usure du joint du

racleur. Si il est usé, le remplacer par une pièce de rechange

d’origine du fabricant. (voir figure 29)

8 ENTRETIEN

1 Tous les jours : inspecter le distributeur et s'assurer que

les garnitures du groupe du robinet ne fuient pas et ne laissent

pas le produit s'échapper. En présence de fuites, commencer

par vérifier que les composants sont correctement montés, puis

s'assurer que la garniture n’est ni défectueuse, ni usée ; dans

le cas contraire, la remplacer par une pièce de rechange

figure 30

4 Tous les mois : ôter la poussière qui s’est accumulée sur

le filtre du condensateur situé à l’arrière de la machine.(voir

32

Page 33

figure 31)

figure 31

ATTENTION

Prendre garde au tranchant des ailettes du condensateur.

5 En cas de bruit anormal, débrancher la machine et

contacter le service d’assistance.

6 En cas de panne, débrancher la machine étant donné

qu’elle risque de redémarrer à l’improviste.

7 Après toute intervention de réparation, remettre chaque

composant, comme les vis et les couvercles, dans sa position

d’origine.

33

Page 34

DOMESTIC WARRANTY

y

play

(5)

p

(Including Mexico)

1. Scope:

Stoelting, A Vollrath Company (“Stoelting”) warrants to the first user (the “Buyer”) that the Stoelting-branded freezer

equipment (the “Equipment”) will be free from defects in materials and workmanship under normal use and proper

maintenance for the period listed below in the Warranty Period section. All warra nty periods begin on the date of original

install or one (1) year from the shipping date, whichever occurs first. This warranty is subject to all conditions,

exceptions, and limitations contained herein.

2. Disclaimer of Other Warranties:

THIS WARRANTY IS EXCLUSIVE; AND STOELTING HEREBY DISCLAIMS ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

3. Remedies: