Page 1

White LED driver for mid-size LCD display backlight

Features

■ Boost DC-DC converter

■ Drives up to 40 LEDs (4 strings of 10) with a

total current up to 120 mA

■ Input voltage range: 3.0 V to 21 V

■ Output current control

■ 1.4 MHz fixed frequency PWM control

■ PWM input for output current dimming with

frequency range 25 kHz - 50 kHz

■ 2 A integrated switch

■ Overvoltage protection

■ Chip overtemperature detection and protection

■ Less than 1 µA standby current

■ Soft-start function

■ Package DFN8 (3 x 3) 0.65 mm pitch

STLD41

Datasheet − production data

DFN8 (3 x 3 mm)

signal connected to the EN pin. The LEDs can be

dimmed by applying a PWM signal to the PWM

pin.

Applications

■ Mini PCs

■ PMP & PND

■ Printers

■ Game consoles

Description

The STLD41 is a boost converter that operates

from 3.0 V to 21 V and can provide an output

voltage as high as 38 V. It can drive up to 40 white

LEDs connected in 4 strings of 10 LEDs in series.

The total output current capability is 120 mA at an

output voltage of 38 V. Regulation is performed by

the internal error amplifier which works with the

feedback voltage from the sensing resistor. The

device can be turned ON/OFF by way of the logic

Table 1. Device summary

Order code Package Packaging

STLD41PUR DFN8 (3 x 3 mm) 3000 parts per reel

June 2012 Doc ID 022283 Rev 5 1/19

This is information on a product in full production.

www.st.com

19

Page 2

Contents STLD41

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Typical application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.1 PWM input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Selection of external components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.1 CIN selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.2 C

7.3 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.4 R

7.5 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OUT

value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SENSE

8 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/19 Doc ID 022283 Rev 5

Page 3

STLD41 Block diagram

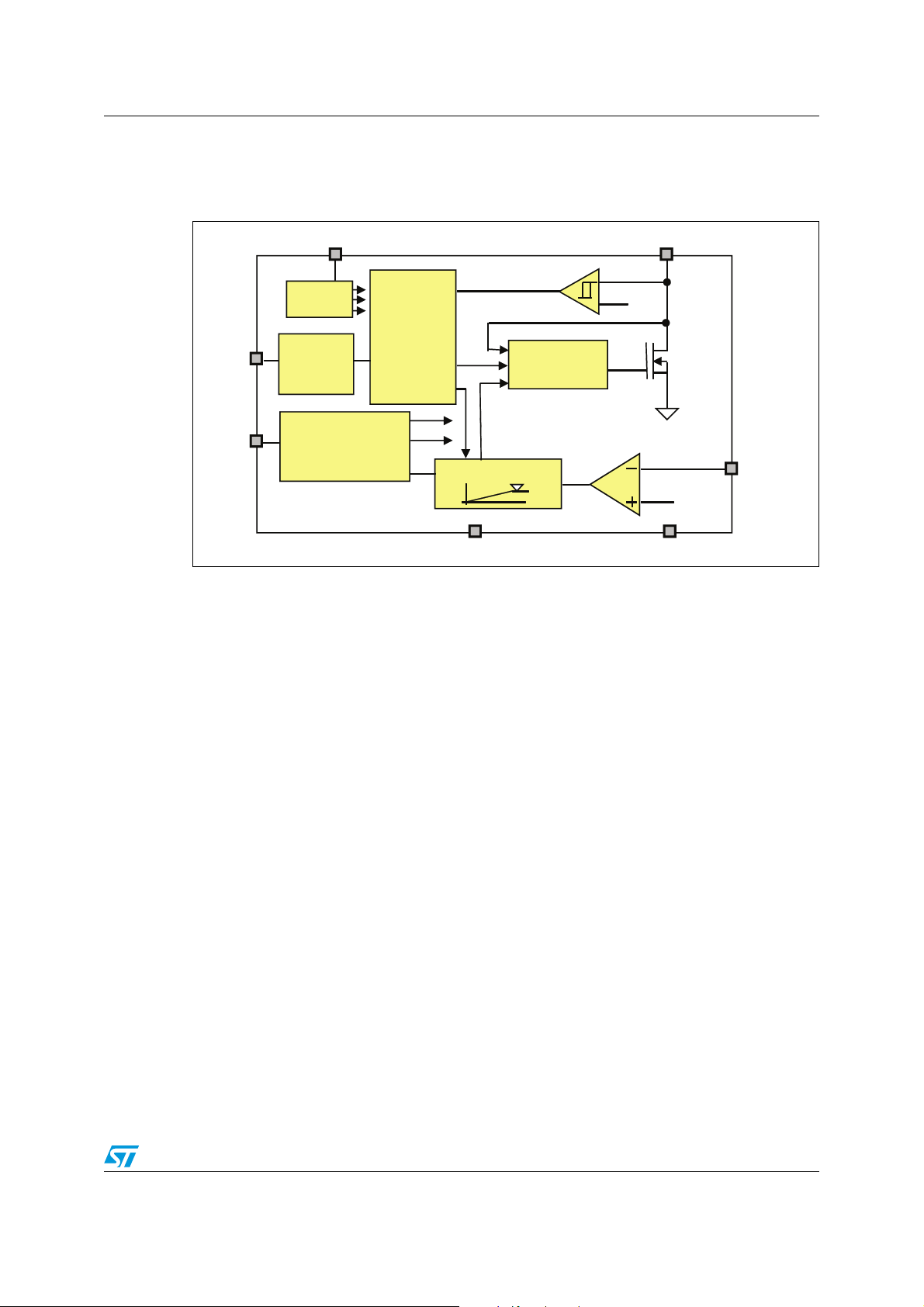

1 Block diagram

Figure 1. STLD41 block diagram

VIN

VLX

BIAS

20 V / 5 V

CONV

REFERENCE

PWM-V

CONV.

LOGIC

REF1

REF2

OVP

SOFT-START

PGND

STEP-UP

CONTROL

REF2

REF1

GND

FB

AM07829v1

Doc ID 022283 Rev 5 3/19

Page 4

Pin configuration STLD41

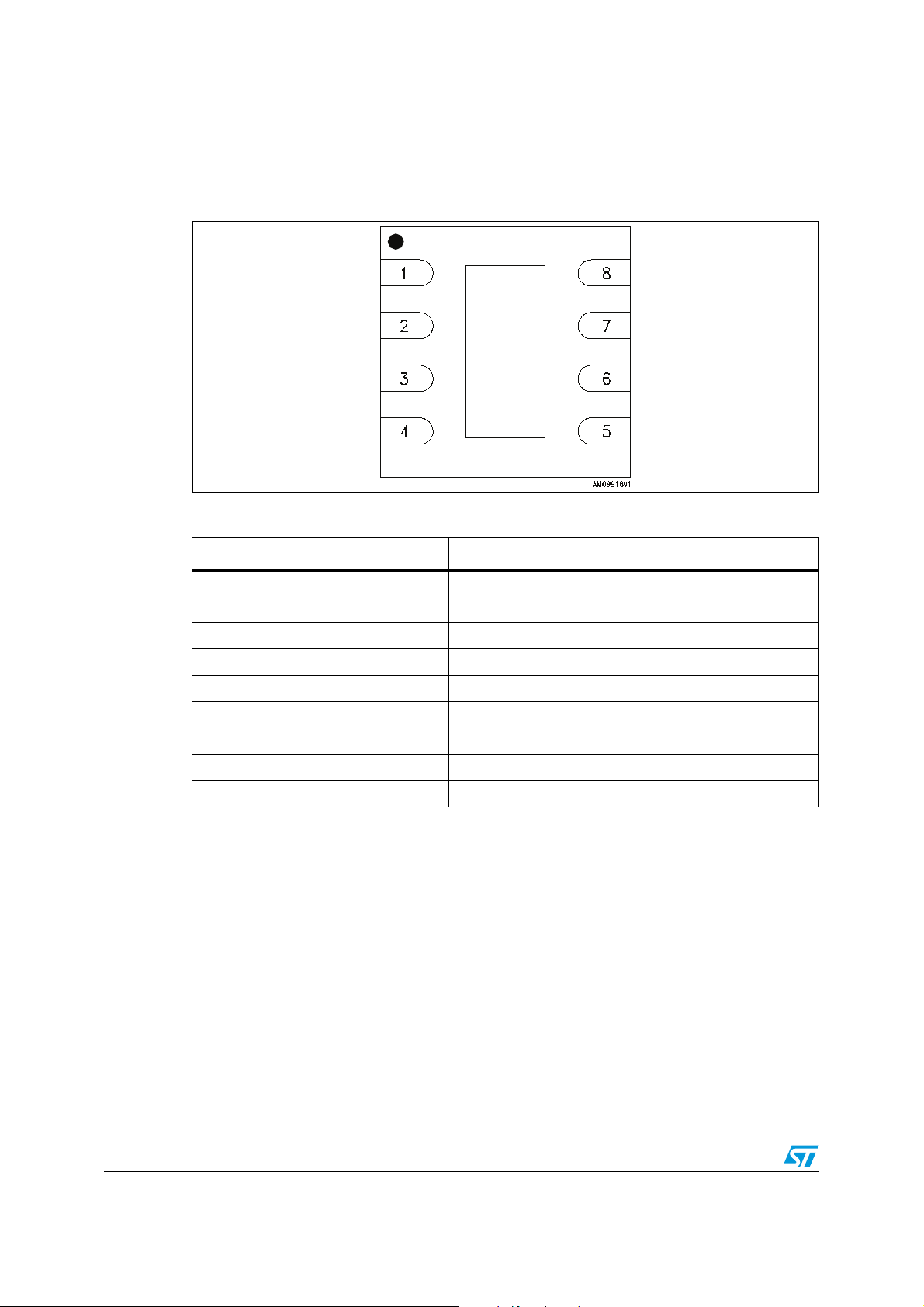

2 Pin configuration

Figure 2. Pin connections (top view)

Table 2 .

Exposed pad PGND Power ground

Pin description

Pin n° Symbol Description

1 GND Ground

2 FB Feedback connection

3 GND Analog ground

4 PGND Power ground

5 VLX Inductor connection

6 EN Enable input

7 VIN Supply voltage

8 PWM_IN PWM input for the output current dimming

4/19 Doc ID 022283 Rev 5

Page 5

STLD41 Maximum ratings

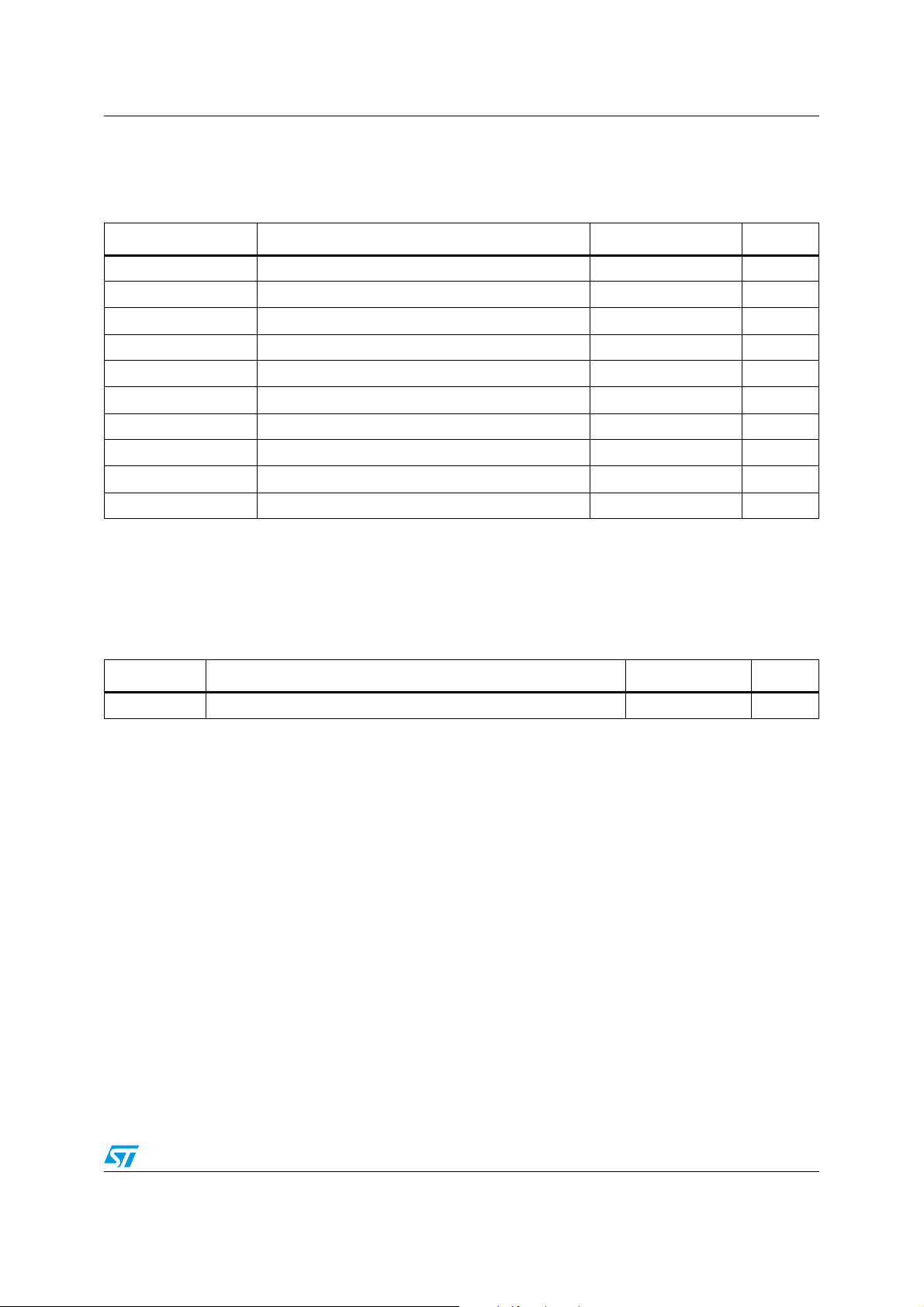

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

VIN Signal supply voltage - 0.3 to 23 V

VLX Inductor connection - 0.3 to 40 V

FB Feedback connection - 0.3 to 2 V

EN Logic pin - 0.3 to 21 V

PWM_IN PWM input - 0.3 to 6 V

ESD Human body model ± 2kV

P

TOT

T

OP

T

J

T

STG

1. Power dissipation is dependent on the PCB. PCB design recommendations are included in

Continuous power dissipation (at TA = 70 °C)

Operating ambient temperature range - 40 to 85 °C

Junction temperature - 40 to 150 °C

Storage temperature range - 65 to 150 °C

(1)

TBD mW

Section 7.5: PCB layout

.

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these conditions is not implied.

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

Thermal resistance junction-ambient 46 °C/W

Doc ID 022283 Rev 5 5/19

Page 6

Typical application circuit STLD41

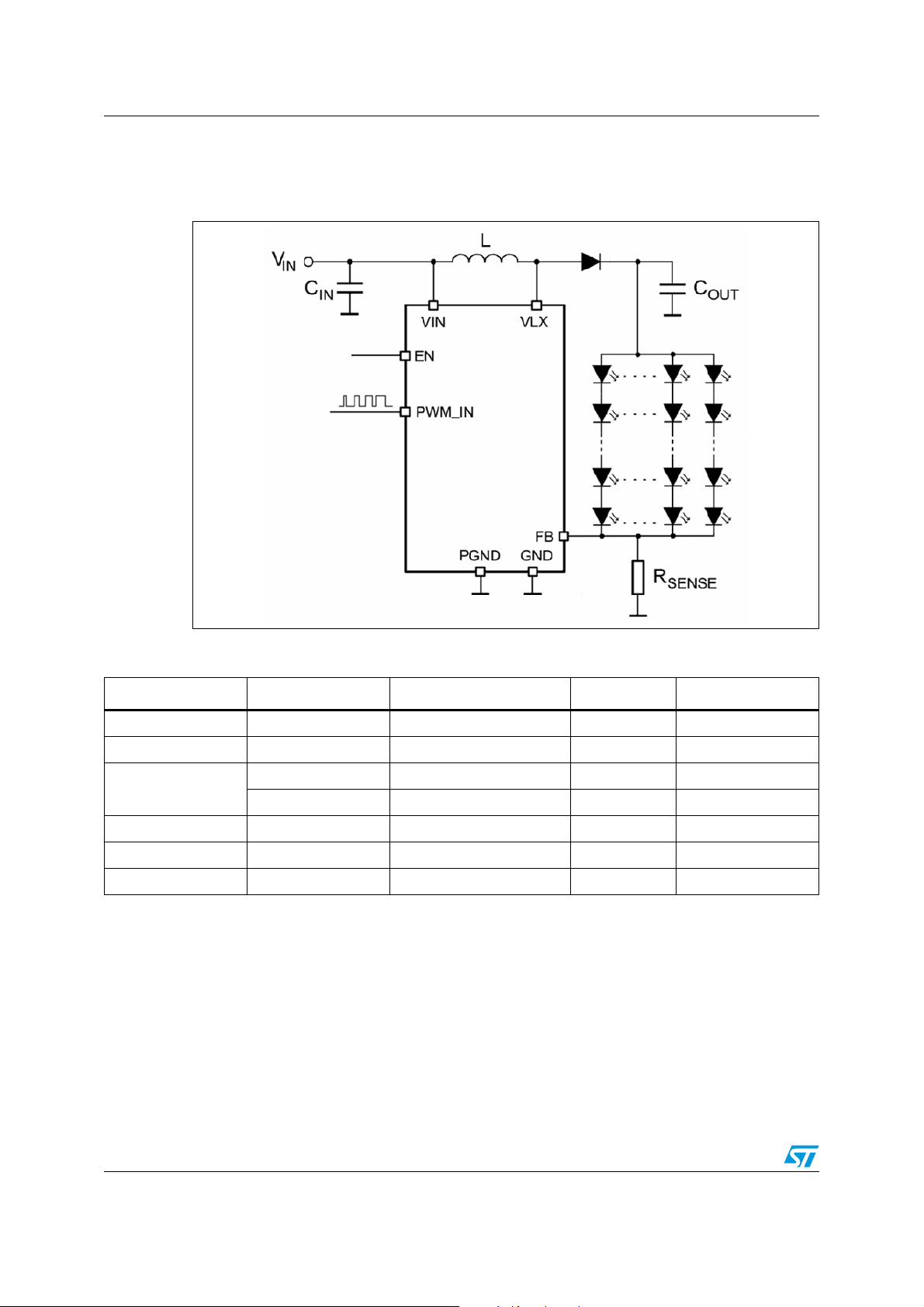

4 Typical application circuit

Figure 3. Application circuit schematic

Table 5. List of external components

Component Manufacturer Part number Value Size

C

IN

C

OUT

L

R

SENSE

Schottky diode STMicroelectronics STPS1L40M 1 A / 40 V 3.75 x 1 x 1.9 mm

LED OSRAM LWL283-Q1R2-3K8L-1-Z 20 mA / 3.1 V 0603

Murata GRM32ER71H106K 10 µF / 50 V 3.2 x 2.5 x 2.5 mm

Murata GRM31CR61H225KA88L 2.2 µF / 50 V 3.2 x 1.6 x 1.6 mm

Murata LQH6PPN470M43 47 µH / 1.25 A 6 x 6 x 4.3 mm

Coilcraft LPS6235-473MLB 47 µH / 1.2 A 6 x 6 x 3.5 mm

Tyco Electronics 1.3 Ω 0603 size

Note: The above listed components refer to a typical application with a maximum performance

setting. Operation of the STLD41 is not limited to the choice of these external components.

6/19 Doc ID 022283 Rev 5

Page 7

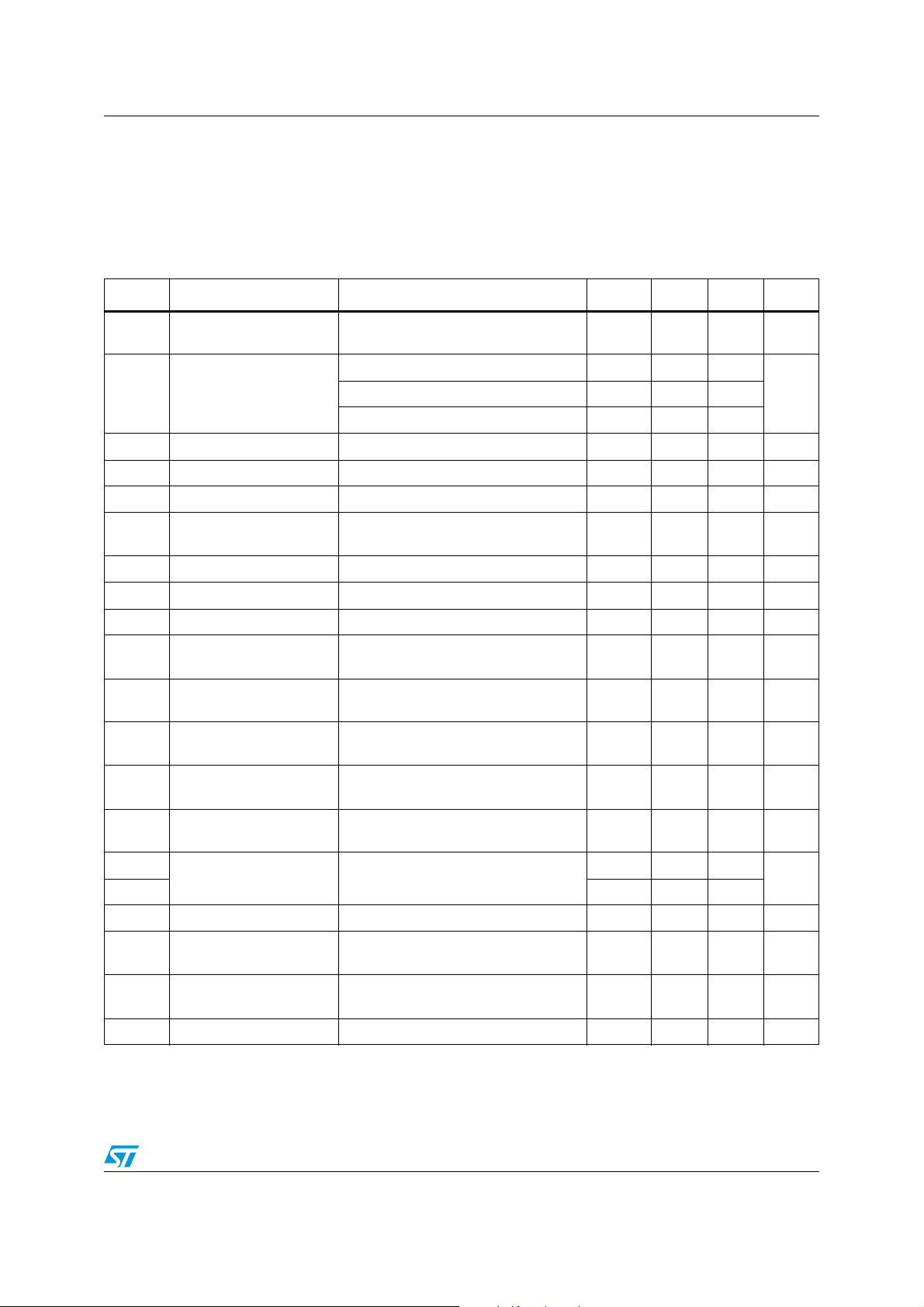

STLD41 Electrical characteristics

5 Electrical characteristics

C

= 10 µF, C

IN

Values are at 25 °C, unless otherwise specified.

Table 6. Electrical characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

= 2.2 µF, L = 47 µH / 1.25 A, R

OUT

= 1.3 Ω, TA = 25 °C, V

SENSE

= 5.5 V typ.

IN

V

V

I

PEAK

ΔI

V

V

FBMIN

OVP

Input operating supply

IN

voltage

Output current

I

O

adjustment range

Regulated voltage range V

OUT

Inductor peak current VIN = 3 V, V

Output current variation V

O

Quiescent current in

I

Q

Standby mode

Feedback voltage I

FB

= 3.0 V to 5.0 V; V

V

IN

= 5.0 V to 7.0 V; V

IN

V

= 7.0 V to 18 V; V

IN

= 3.0 V to 21 V 1.15*V

IN

= 38 V 2 A

OUT

= 3 V, I

IN

EN = LOW, V

= 120 mA, PWM_IN=HIGH 144 160 176 mV

LED

= 120 mA -10 10 %

LED

= 5.5 V 1 µA

IN

= 38 V 40

OUT

= 38 V 78

OUT

= 38 V 120

OUT

3.0 21 V

IN

Min. feedback voltage PWM_IN = 30 kHz, duty cycle = 10% 35 mV

f

Frequency V

s

Efficiency of the chip itself

ν

(1)

Efficiency of the whole

ν

application

(2)

Output overvoltage

protection

= 3.0 V 1.4 MHz

IN

V

= 7 to 21 V, IO = 120 mA,

IN

= 10 x V

V

O

V

= 3 to 21 V, IO = 78 mA 79 %

IN

V

= 21 V, No load 40 V

IN

FLED_max+VRSENSE

= 38 V

87 %

mAV

38 V

OTP

OT

V

I

ENHIGH

T

f

PWM

V

1. Calculated as (V

2. Calculated as (V

Overtemperature

protection

Overtemperature

HYST

hysteresis

V

IL

Low and high level input

logic signal on EN pin

IH

Enable input current V

LED current rise time I

ON

= 0 to I

PWM dimming signal

frequency

PWM signal level V

PWM

= max

LED

OUT*ILED

LED*ILED

LED

)/(VIN*IIN), guaranteed by design

)/(VIN*IIN), guaranteed by design

= 21 V 140 °C

V

IN

= 21 V 20 °C

V

IN

00.4

V

= 3.0 V to 21 V

IN

= 3.0 V to 21 V, V

IN

V

= 10 V 1 ms

IN

= 3.0 V to 21 V 25 50 kHz

V

IN

= 3.0 V to 21 V 1.4 5.5 V

IN

= 21 V 10 µA

EN

1.4 V

I

Doc ID 022283 Rev 5 7/19

V

Page 8

Introduction STLD41

6 Introduction

The STLD41 is a boost converter, dedicated to power and control the current of white LEDs

in an LCD backlight. The device operates at a typical constant switching frequency of 1.4

MHz. It steps an input voltage ranging from 3.0 V to 21 V up to 40 V. The output current is

dimmable by the PWM signal applied to the PWM pin.

6.1 PWM input

The light intensity can be dimmed by a signal applied to the PWM input. It is recommended

to use a signal whose frequency is between 25 kHz to 50 kHz. The maximum amplitude of

the signal is limited to 5.5 V. The minimum level of the signal must be at least 1.4 V. The

dimming range is from 20% to 100% of the current set by the R

SENSE

.

8/19 Doc ID 022283 Rev 5

Page 9

STLD41 Selection of external components

()

7 Selection of external components

7.1 CIN selection

It is recommended to use 10 µF as the input capacitor to achieve good stability of the device

and low noise on the V

track.

IN

7.2 C

selection

OUT

It is recommended to use 2.2 µF as the optimal value of output capacitor to achieve the best

compromise between output voltage ripple and load transient response. The output ripple

can be checked using the equation for step-up architecture:

Equation 1

V

−

PKPK

7.3 Inductor selection

A thin shielded inductor with a low DC series winding resistance is recommended for this

application. To achieve good efficiency in step-up mode, it is recommended to use an

inductor with a DC series resistance R

resistance of the LED [Ω, Ω, 1].

For nominal operation, the peak inductor current can be calculated using this formula:

Equation 2

=

DCL

−∗

2

OUTOUT

= RD / 10 [Ω, Ω, 1], where RD is the dynamic

100*VVI

)MIN(INOUT)MAX(OUT

[]

∗∗

fVC

Hz,F,V,A;V

2

∗−

VVV

ININOUT

V

OUT

∗

2

V

IN

I

PEAK

I

OUT

=

()

+

n

∗∗∗

VfL2

OUT

where:

I

= Peak inductor current

PEAK

I

= Current sourced at the V

OUT

OUT

pin

n = Efficiency of the STLD41

V

= Output voltage at the V

OUT

V

= Input voltage at the VBAT-pin

IN

OUT

pin

L = Inductance value of the inductor

f = Switching frequency

For optimal performance of the STLD41 device, is recommended to use an inductor value of

47 µH or higher with low serial resistance and relevant saturation current calculated from the

equation above.

Doc ID 022283 Rev 5 9/19

Page 10

Selection of external components STLD41

7.4 R

R

SENSE

SENSE

value

= V

REF1

If using a typical setting of I

must be rated for a power dissipation of 1.3 x 0.12² W = 0.02 W.

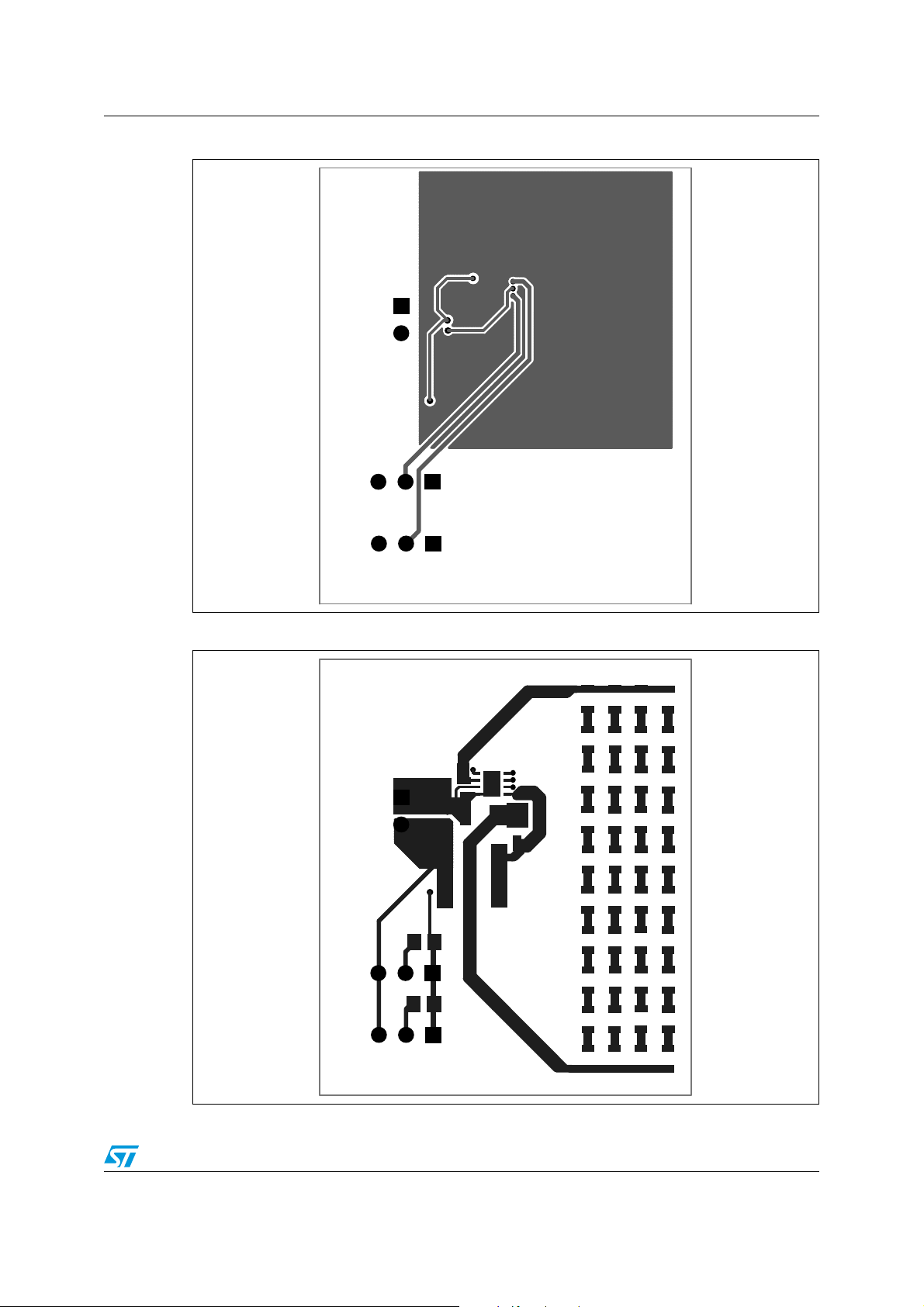

7.5 PCB layout

Because the STLD41 is a powerful switched device, the PCB must be designed in line with

rules for designing switched supplies. It is recommended to use a two-layer PCB. The power

wirings must be as short as possible and wide. Place all external components close to the

STLD41 device. High-energy switched loops should be as small as possible to reduce EMI.

Most LEDs need cooling, which can be attained utilizing a defined copper area on the PCB.

Use the reference guide for each LED to design the heatsink. Place the R

close as possible to pin 2 and ground of the system. The ground of the system is

represented by the size of the area created by the connections GND-PGDN-GND

GND

PCB must be focused on the minimum area of the application ground; the smaller the

ground area of the DC-DC converter

issues. It is recommended to place the copper plate connected through the vias to the

exposed pad to the bottom layer to create the heatsink of the device.

. When a change of PCB layer is needed, use sufficient vias. During routing, the

COUT

/ I

LED

= 120 mA, V

LED

= 160 mV, and R

REF1

(a)

, the better the stability and there will be fewer noise

= 1.3 Ω, the resistor

SENSE

SENSE

resistor as

-

CIN

a. The application ground area is represented by the area which is created by the ground pins of the CIN, C

and ground of the DEVICE and GND connection of the load.

10/19 Doc ID 022283 Rev 5

OUT

,

Page 11

STLD41 Selection of external components

Figure 4. Top layer

Figure 5. Bottom layer

Doc ID 022283 Rev 5 11/19

Page 12

Selection of external components STLD41

Figure 6. Top overlay

12/19 Doc ID 022283 Rev 5

Page 13

STLD41 Typical performance characteristics

8 Typical performance characteristics

Figure 7. Eff. vs. VIN, 6 x 6 LEDs, V

= 24 V Figure 8. Eff. vs. VIN, 5 x 7 LEDs, V

OUT

100

95

90

85

80

75

Eff [%]

70

65

60

55

I

I

I

OUT

OUT

OUT

=120m

=81mA

=66mA

I

I

OUT

OUT

=51mA

=35mA

I

=25mA

OUT

I

=15mA

OUT

50

5678 9 10111213 14 15 16 17 18 19 20 21 22

V

[V]

IN

Figure 9. Eff. vs. VIN, matrix 4 x 9 LEDs,

V

= 33 V

I

OUT

I

OUT

I

OUT

OUT

=120mA

=81mA

=66mA

I

I

OUT

OUT

=51mA

=35mA

V

IN

I

=25mA

OUT

I

=15mA

OUT

[V]

100

95

90

85

80

75

Eff [%]

70

65

60

55

50

5678 9 10111213 14 15 16 17 18 19 20 21 22

100

95

90

85

80

75

Eff [%]

70

65

60

55

50

Figure 10. Application eff. vs. V

I

=120mA

OUT

I

=81mA

OUT

I

=66mA

OUT

5678 910111213 14 15 16 17 18 19 20 21 22

I

I

OUT

OUT

=51mA

=35mA

V

I

=25mA

OUT

I

=15mA

OUT

[V]

IN

, matrix 4 x

IN

10 LEDs

I

=120mA

OUT

I

=78mA

OUT

95

90

85

80

75

Eff [%]

70

65

60

55

50

2 3 456 78 910111213 14 15 16 17 18 19 20 21 22

I

=25mA

OUT

IIN@120mA

[V]

V

IN

IIN@78mA

IIN@25mA

OUT

= 27 V

1200

1000

800

600

400

200

0

[mA]

IN

I

Figure 11. Output current regulation at 4 x 10

140

130

120

110

100

90

80

[mA]

70

OUT

I

60

50

40

30

20

10

LEDs

120mA / Rsens e=1R3

100mA / Rsens e=1R6

50mA / Rsens e=3R3

20mA / Rsens e=8R2

2 3 45678 910111213 14 15 16 17 18 19 20 21 22

V

[V]

IN

Doc ID 022283 Rev 5 13/19

Figure 12. VFB vs. PWM 25 kHz, V

I

OUTset

180

170

160

150

140

130

120

110

100

[mV]

90

FB

80

V

70

60

50

40

30

20

10

0102030405060708090100

= 120 mA

DC [%]

= 5.5 V,

IN

Page 14

Package mechanical data STLD41

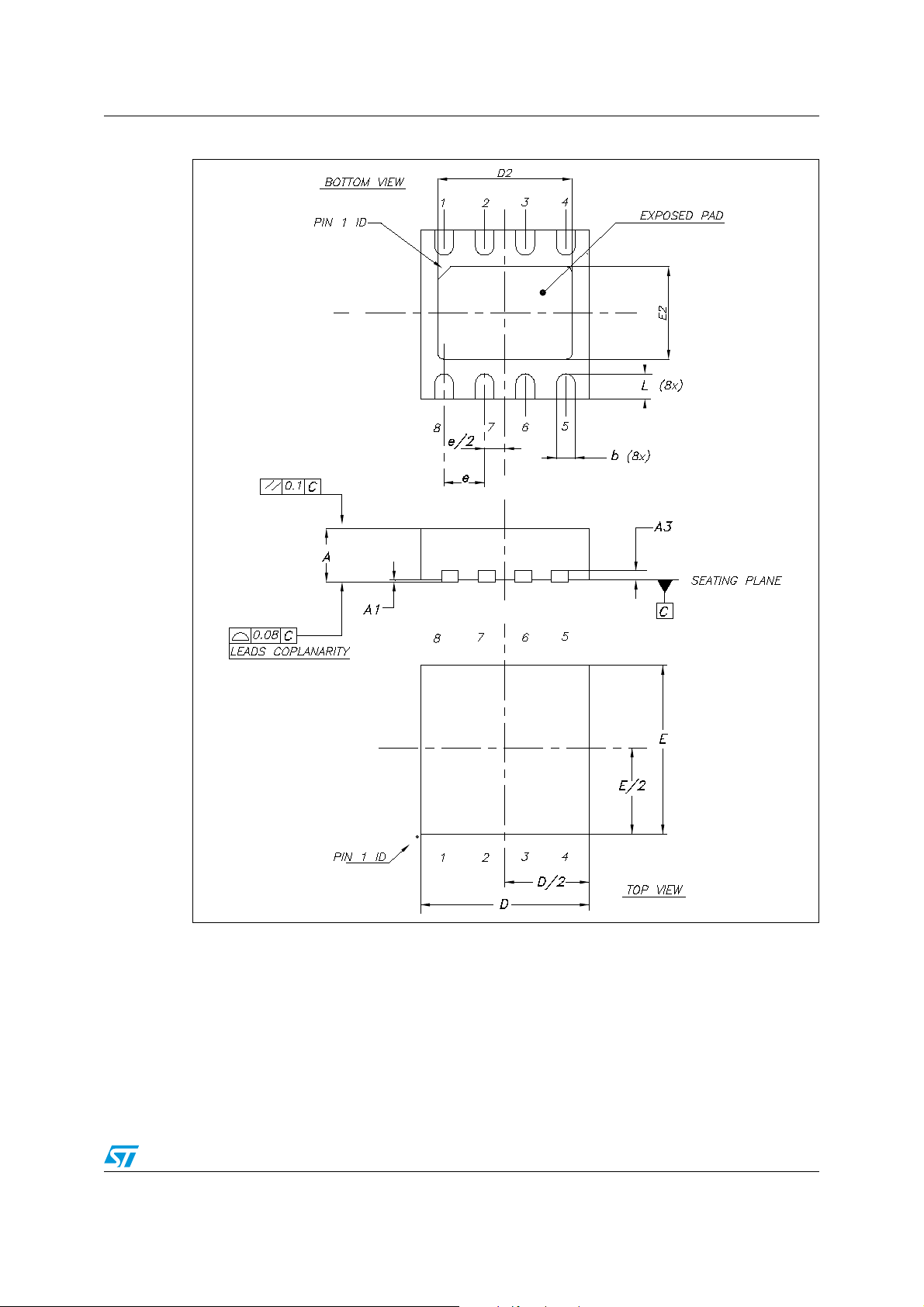

9 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

specifications, grade definitions and product status are available at:

ECOPACK

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

www.st.com

.

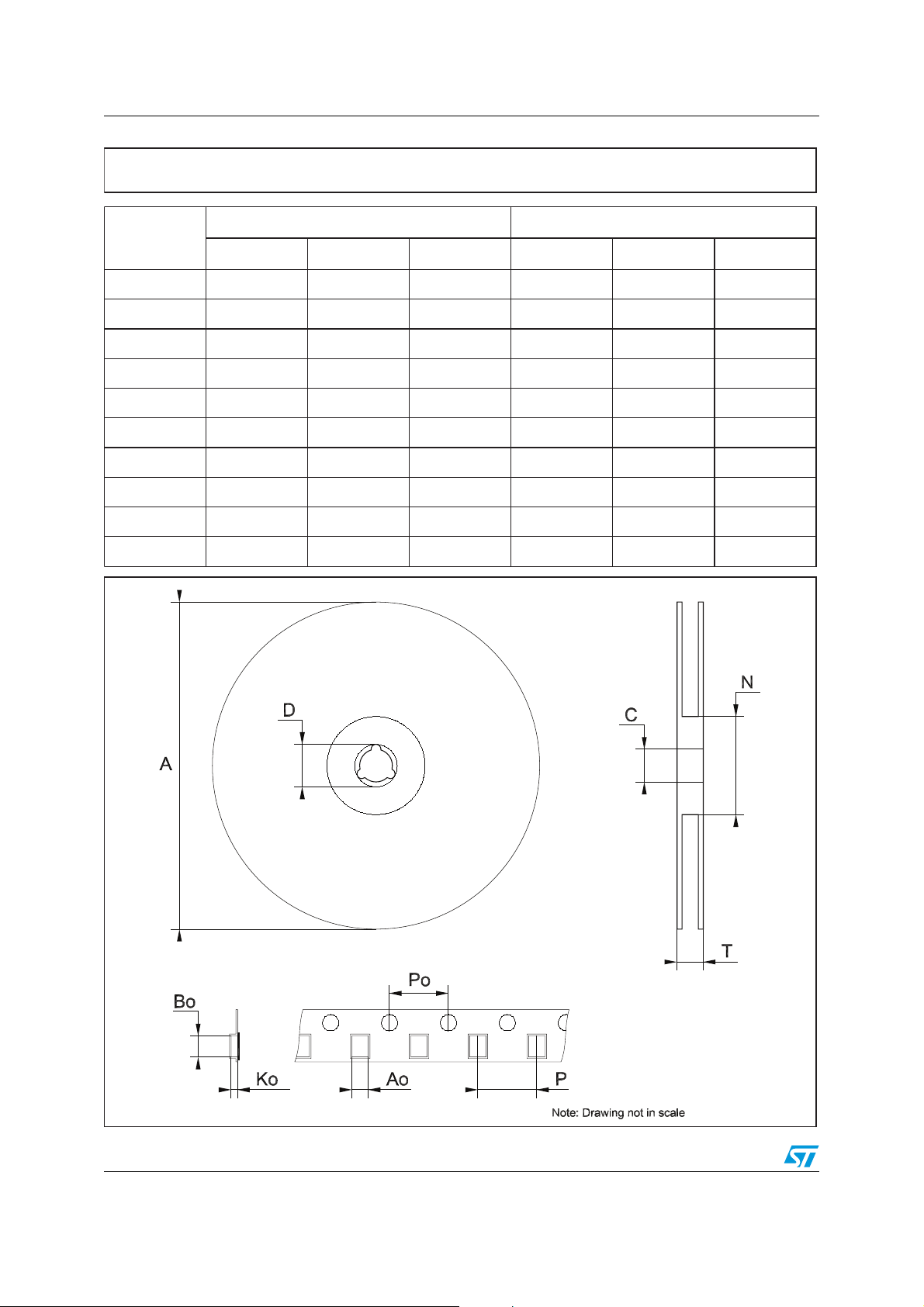

Table 7. DFN8 (3 x 3 mm) mechanical data

mm.

Dim.

Min. Typ. Max.

A 0.80 0.90 1.00

A1 0.00 0.02 0.05

b 0.25 0.30 0.35

D3.00

D2 2.234 2.384 2.484

E3.00

E2 1.496 1.646 1.746

e0.65

L 0.30 0.40 0.50

14/19 Doc ID 022283 Rev 5

Page 15

STLD41 Package mechanical data

Figure 13. Package dimension DFN8 (3 x 3 mm)

8057023/B

Doc ID 022283 Rev 5 15/19

Page 16

Package mechanical data STLD41

Tape & reel QFNxx/DFNxx (3x3) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A180 7.087

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N60 2.362

T 14.4 0.567

Ao 3.3 0.130

Bo 3.3 0.130

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

16/19 Doc ID 022283 Rev 5

Page 17

STLD41 Package mechanical data

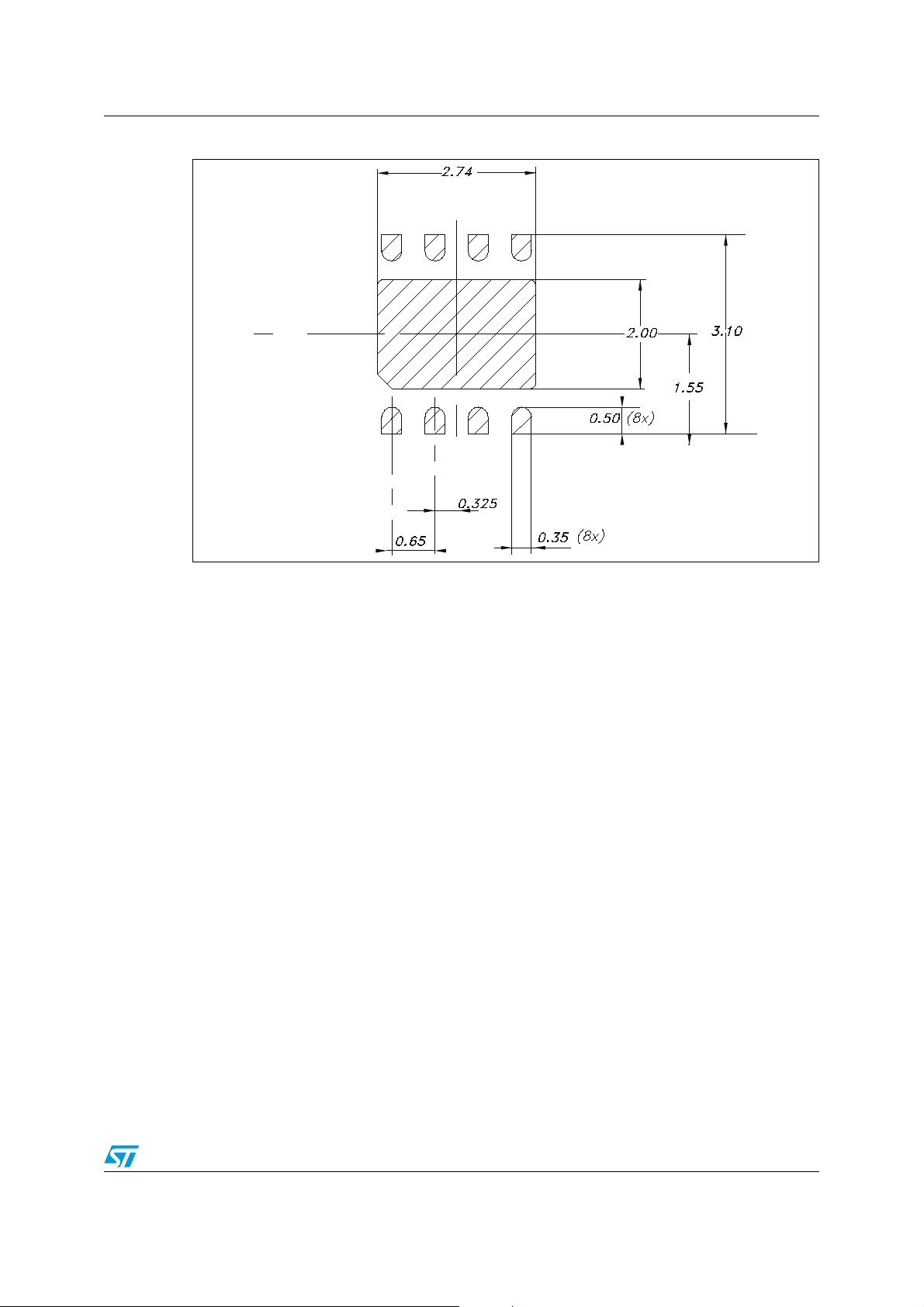

Figure 14. DFN8 (3 x 3) footprint recommended data (mm.)

Doc ID 022283 Rev 5 17/19

Page 18

Revision history STLD41

10 Revision history

Table 8. Document revision history

Date Revision Changes

28-Sep-2011 1 Initial release.

16-Nov-2011 2 Change value 1.8 MHz ==> 1.4 MHz

15-Mar-2012 3 Modified: 1.3 x 0.122 W ==> 1.3 x 0.12²

23-May-2012 4 Document status promoted from preliminary data to production data.

27-Jun-2012 5 Added: new L component Coilcraft

: Features on page 1

W

Section 7.4 on page 10

Table 5 on page 6

.

.

.

18/19 Doc ID 022283 Rev 5

Page 19

STLD41

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022283 Rev 5 19/19

Page 20

Loading...

Loading...