Stihl RE 140 K, RE 160 K Repair Manual

RE 140 K, 160 K

CONTENTS

1. Foreword 2

1.1 Note on RE 160 K 2

2. Safety regulations 2

3. Technical

specifications 3

3.1 Motor 3

3.2 Pump 3

3.3 Weights and

dimensions 3

3.4 Capacities 3

3.5 Tightening torques 4

4. Summary of

possible faults 5

4.1 High-pressure pump 5

4.2 Electric motor 7

5. Housing 8

5.1 Removing /

fitting the shroud 8

5.2 Removing /

installing the motor /

pump unit 8

5.3 Chassis 9

6. Safety control block 9

7.4 Removing / installing

pump housing and

pump piston 15

7.5 Disassembly /

assembly of

pump piston 15

7.6 Replacing

high-pressure cups

and oil seals 16

7.7 Replacing thrust

bearings 17

8. Electric motor 18

8.1 Removal 18

8.2 Installation 21

9. Electrical system 23

9.1 Circuit diagram 23

9.2 Removing / installing

electrical components 24

9.2.1 Switch housing 24

9.2.2 Switch 25

9.2.3 Power cable 25

9.2.4 Capacitor 26

9.2.5 Microswitch 27

10. Spray attachment 27

10.1 Spray gun 28

10.2 Spray lance,

spray head 28

6.1 Removing / installing

11. Oil change 30

the safety control block 9

6.2 Removing / installing

the control piston 10

6.3 Setting the pressure

12. Special tools and

service tools 31

control system 11

6.4 Injector 12

6.5 Non-return valve 12

12.1 Special tools 31

12.2 Service tools 31

6.6 Detergent metering

and non-return valve 13

7. High-pressure pump 14

7.1 Screen in intake port

(water inlet) 14

7.2 Removing / installing

delivery valves 14

7.3 Removing / installing

valve block and

intake valves 14

© 2000, Andreas Stihl AG & Co., Waiblingen

RE 140 K, 160 K 1

1. FOREWORD 2. Safety regulations1.1 Note on RE 160 K

This Repair Manual contains a

detailed description of the

fundamental repair work on STIHL

high-pressure cleaners of series

STIHL RE 140 K, 160 K.

A test bed with the necessary

water and power supplies should

be provided for the repair work.

The unit must be connected to the

pressurized water supply and the

fault described by the customer

reproduced, with the customer

demonstrating the fault if

necessary. The customer’s

attention must be drawn to the

User Manual if the machine is

operated incorrectly.

Faults may be due to several

causes. The "Summary of

possible faults" should therefore

be consulted see 4.

The illustrated spare parts lists

must also be used for all repair

work. These lists show the

installation position and order in

which the individual assemblies

should be assembled. Microfilms

are more up-to-date than printed

spare parts lists.

Please refer to the preceding

Repair Manual for the RE 160 K if

the procedures described and

illustrated in this Repair Manual do

not correspond with your machine.

High-pressure cleaners may only

be repaired by qualified

electricians (in accordance with

DIN VDE 0701 and accident

prevention regulations VBG 4 in

Germany) with due regard for

national safety regulations and the

provisions of the User Manual.

Note the "Technical Information"

bulletins! They contain

information on technical changes

implemented after publication

of this Repair Manual. The

Technical Information bulletins

also supplement the spare parts

list until a new edition is printed!

Repair Manuals and Technical

Information bulletins should

always be kept on hand wherever

repairs are carried out.

They must not be passed on to

third parties.

Only original STIHL spare parts

maybeused!

2 RE 140 K, 160 K

3. TECHNICAL SPECIFICATIONS

RE 140 K RE 160 K

3.1 Motor

Voltage: 230 V / 240 V *) 230 V / 240 V *)

Frequency: 50 Hz / 60 Hz *) 50 Hz / 60 Hz *)

Power output: 2.3 - 2.9 kW *) 2.2 - 3.3 kW *)

Fuse: 16A**) 16A**)

Protection class: I I

Type of protection: IP X5 IP X5

3.2 Pump

Max. working pressure: 140 bar 150 bar

Permissible excess pressure: 150 bar 160 bar

Flow rate: 500 l/h 500 - 550 l/h *)

Suctionlift: 0.5m 0.5m

Max. water feed temperature:

- Pressurized water supply: 50 °C 50 °C

- In suction operation: 40 °C 40 °C

3.3 Weights and dimensions

Length approx.: 370 mm 370 mm

Width approx.: 270 mm 270 mm

Height approx.: 860 mm 860 mm

Weight approx.: 20.0 kg 25.0 kg

3.4 Capacities

High-pressure pump: 100 ml 100 ml

Oil grade: SAE 15 W 40 SAE 15 W 40

*) Depends on country concerned

**) Australia / New Zealand: 10 A

**) GB / N. Ireland / Malaysia: 13 A

**)

RE 140 K, 160 K 3

3.5 Tightening torques

Tightening torque

Assembly Connecting element Thread size Nm Remarks

Safety control block Socket-head screw M5x30 7 1)

to valve block

Valve block to Socket-head screw M6x35 15 1)

pump housing

Pump housing to Socket-head screw M6x30 10 1)

drive housing

Drive housing to Socket-head screw M5x25 7 1) 2)

stator housing

Bearing cover and Hex bolt M6x25 7 1) 3)

drive housing to

stator housing

Screw plug, Hexagonal socket-head bolt R1/4" 7 3)

drive housing

Remarks

1) Thread must be clean and dry

2) RE 140 K only

3) RE 160 K only

4 RE 140 K, 160 K

4. SUMMARY OF POSSIBLE FAULTS

4.1 High-pressure pump

Problem Cause Remedy

Pump runs, but does not build Pressure control sleeve not Set required working pressure

up the specified pressure set correctly

Nozzle in spray head worn Replace nozzle

Air in system Vent system; briefly operate

machine without

high-pressure hose

Leak in high-pressure system Seal high-pressure system

Pressure fluctuates or drops Shortage of water Turn on water tap, keep within

maximum suction head

(max. 0.5 m)

Water feed hose too long or Use specified water

cross-section too small feed hose

Water filter clogged Clean water filter in pick-up

body and pump inlet

Pump draws air Check intake line for leaks and

replace if necessary

High-pressure cups worn Replace high-pressure cups

Pump does not run smoothly Water feed temperature is Reduce water feed temperature

too high (see technical specifications)

Intake line is damaged, Replace intake line

pump draws air

Intake / delivery valves of Clean or replace valves

high-pressure pump

soiled or worn

Safety control block cycles after Leak in high-pressure system so Seal, clean and grease the

switching off the spray gun that safety control block does not safety control block

(constant audible switching sound), switch over correctly and the

pump becomes hot bypass does not open completely

Oil contains water High-pressure cups worn Replace high-pressure cups

Oil leak Gaskets in high-pressure pump Replace gaskets

worn

RE 140 K, 160 K 5

Problem Cause Remedy

No supply of detergents Detergent tank is empty Fill detergent tank

Detergent metering valve Set required detergent quantity

is closed on metering valve

Pressure control sleeve Set pressure control sleeve

not set to "CHEM." to "CHEM."

High-pressure hose coupling Tighten screw coupling

is not screwed tight

Detergent intake hose clogged Clean

Injector clogged Clean

Gasket on high-pressure hose Replace or fit gasket

connection defective or missing

Weak, ragged, High-pressure nozzle in Clean high-pressure nozzle

unclean jet spray head is soiled or worn with nozzle-cleaning needle

or replace if necessary

6 RE 140 K, 160 K

4.2 Electric motor

Problem Cause Remedy

Motor hums but does not run Mains voltage too low Check electrical connection

when switched on

Spray gun closed Actuate spray gun

Pump stiff Turn motor by hand as described

(blocked or frozen) for "Starting up after prolonged

storage" (User Manual)

Extension lead with wrong Use correct cable cross-section

cross-section (see User Manual)

Motor does not start Connector has not been plugged Check plug, cable and switch

when switched on in correctly, break in power supply

Mains fuse has been tripped Refit mains fuse

Motor stops Overload protection (in winding) Check that supply voltage matches

tripped because motor specified machine voltage.

overheating or overloaded Switch off machine and allow

to cool for at least 3 minutes.

Spray head soiled Clean nozzle in spray head

Note: A correct power supply is essential if the machines are to operate faultlessly. The voltage drop in the

motor during operation must not be excessive, otherwise the motor will turn too slowly and take up too much

power. This causes the windings to heat up and the overload switch cuts out the machine after only a short

period of operation. Moreover, the machine cannot build up the rated power output and problems may arise

during the starting phase, i.e. between switching on the motor and reaching the nominal speed.

RE 140 K, 160 K 7

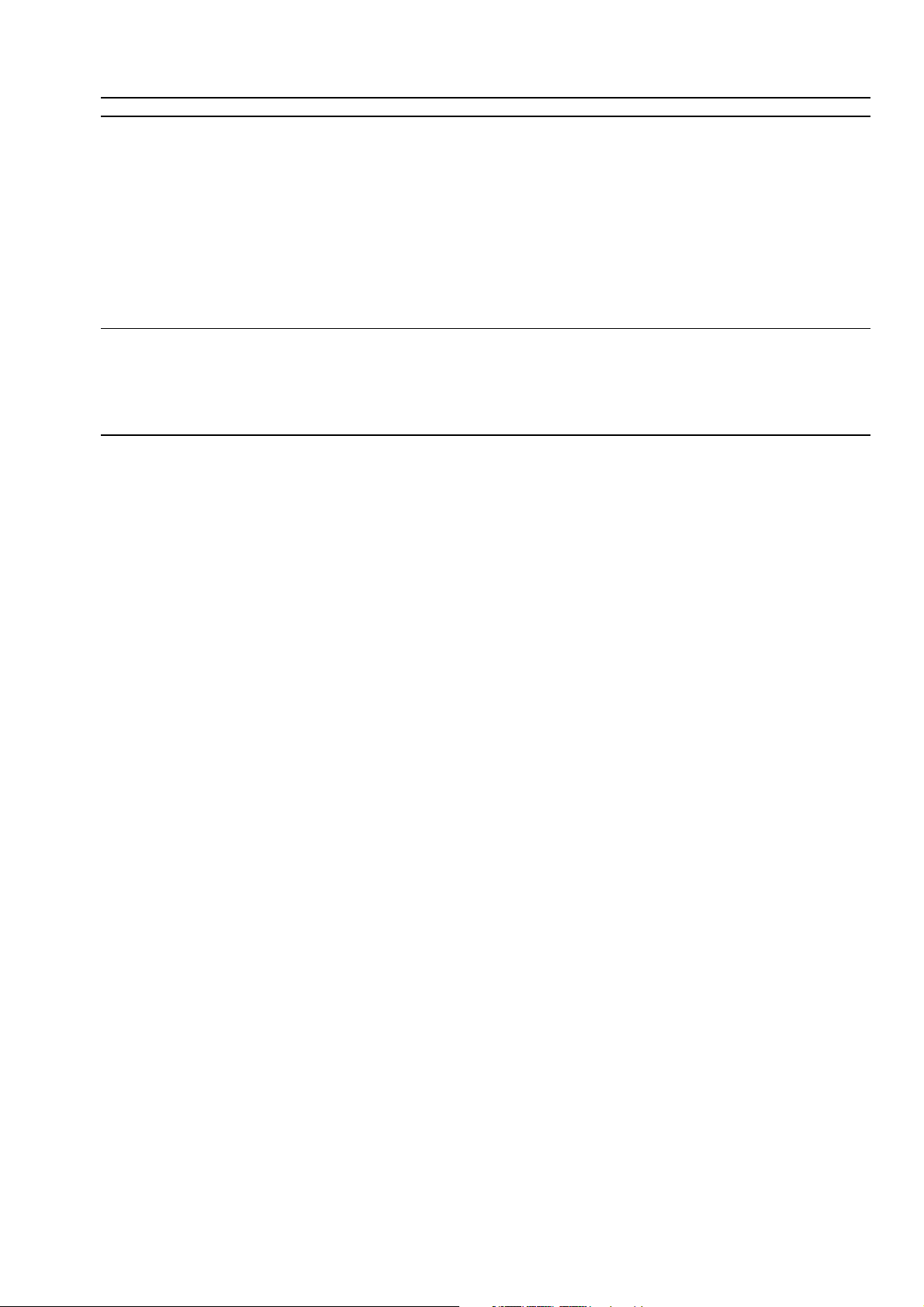

5. HOUSING

5.1 Removing / fitting the

5.2 Removing / installing motor / pump unit

1

•

Unscrew high-pressure hose (1).

•

Unscrew hose connector (2)

from water inlet.

2

621RA001 BL

•

Disconnect detergent intake

hose from metering valve.

- Remove shroud (see 5.1).

- Stand machine upright.

RE 140 K

621RA084 KN

RE 160 K

•

Undo fastening nuts on motor /

pump unit, steadying the bolts at

the same time if necessary.

Hold the machine steady and

ensure that washers are not lost.

- Lay machine in a horizontal

position.

621RA087 KN

•

Undo fastening screws (rear

screw not shown).

•

Remove shroud.

Ensure that spring nuts and

power cable are not lost.

Reassemble parts in reverse order.

621RA002 BL

•

Undo fastening screw on motor /

pump unit, steadying the

machine with the other hand at

thesametime.

•

Lift motor / pump unit out of

frame.

621RA085 KN

•

Lift motor / pump unit out of

frame. Ensure that rubber

buffers, screws and washers

are not lost.

All models

Reassemble parts in reverse order.

621RA086 KN

621RA005 BL

8 RE 140 K, 160 K

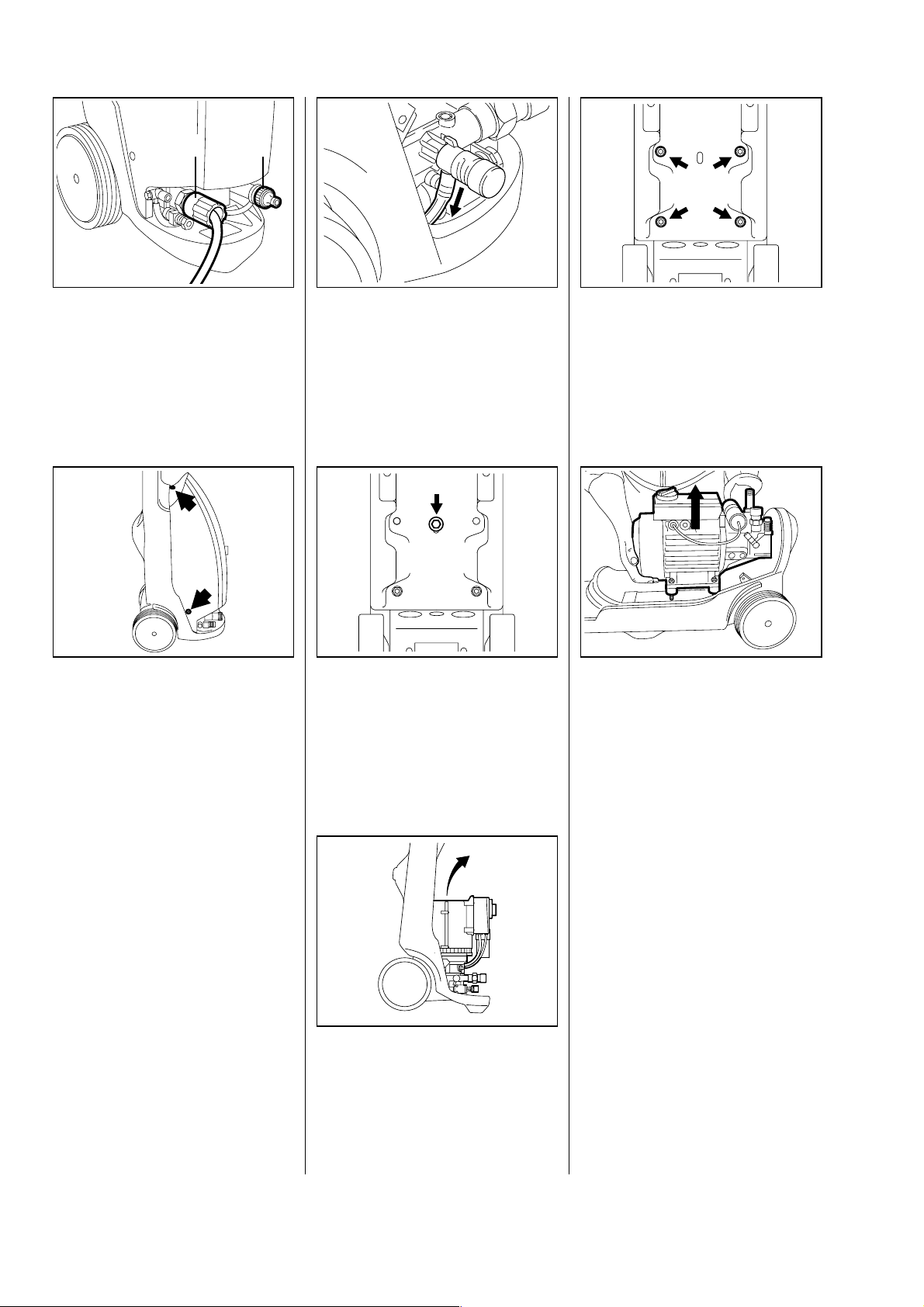

5.3 Chassis 6. SAFETY CONTROL BLOCK

6.1 Removing / installing thesafetycontrolblock

•

Remove handle:

•

Undo fastening screws with

size 5 hexagon socket wrench.

- Remove handle and replace if

necessary.

Important: The O-rings must

always be replaced when carrying

out repair work.

Before assembling the parts, all

moving parts, sealing rings and

screw threads must be thinly

coated with special grease

for high-pressure cleaners

0781 145 3516. Exceptions to

this rule are mentioned where

621RA007 BL

appropriate.

Note: The permissible working

pressure of the machine has been

set on the safety control block by

the manufacturer and must not be

changed. A lead seal is fitted to

the safety control block for this

reason.

The permissible working pressure

must be reset after all repairs and

a new lead seal fitted to the safety

control block.

- Remove shroud (see 5.1) and

motor / pump unit (see 5.2).

Note: The screw plug should only

be removed if leaking.

Remove retainer and shaft:

•

Undo fastening screws with

size 5 hexagon socket wrench.

- Remove retainer and shaft.

Proceed as described for the

high-pressure cleaners of series

STIHL RE 310 K, 340 K and 440 K

for changing wheels.

Replace faulty parts.

Reassemble parts in reverse order.

621RA008 BL

•

Undo fastening screws.

•

Carefully remove the safety

control block. Ensure that the

adjusting screw for the microswitch, O-rings and delivery

valves are not lost.

621RA009 BL

621RA010 BL

•

Replace O-rings.

RE 140 K, 160 K 9

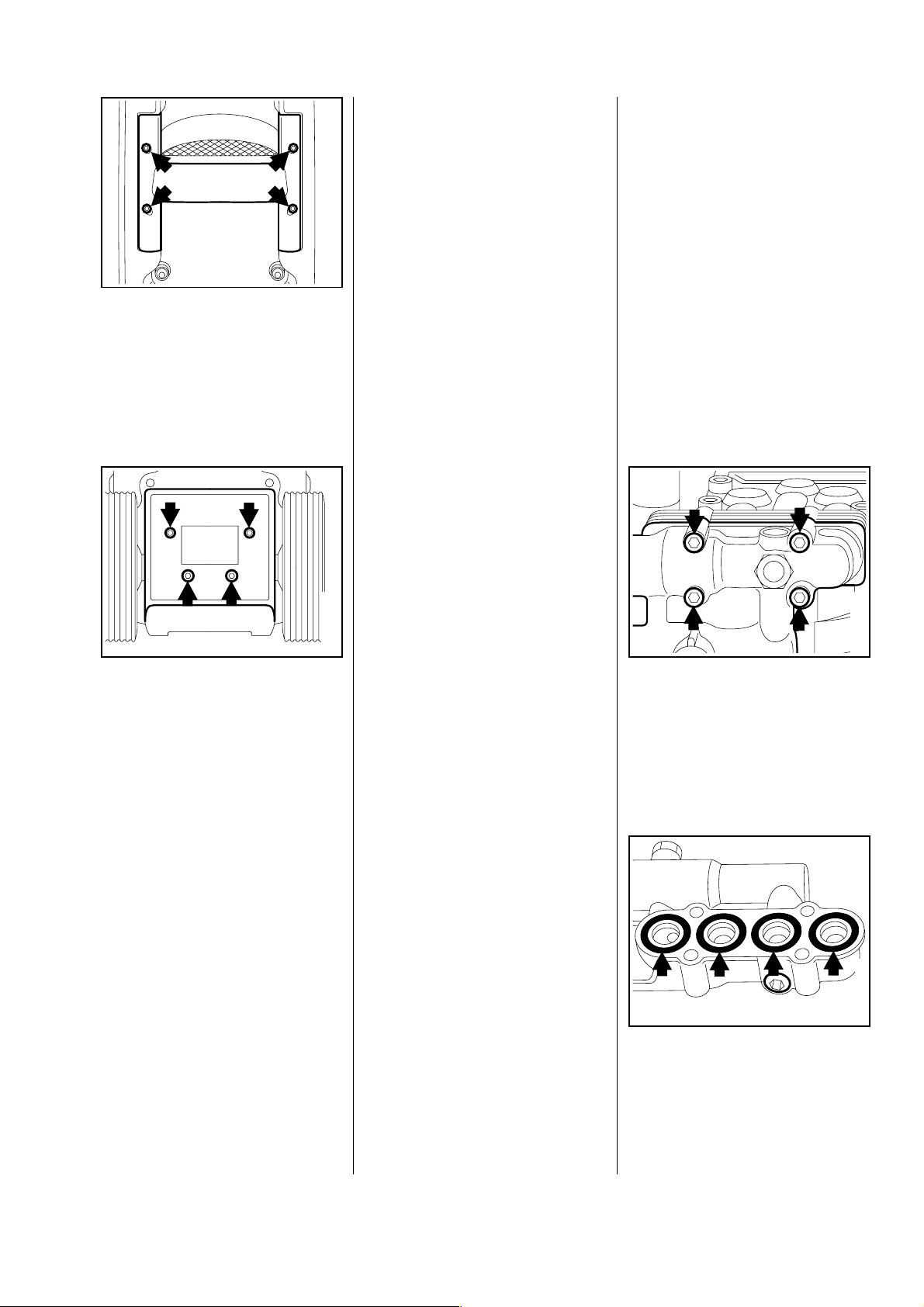

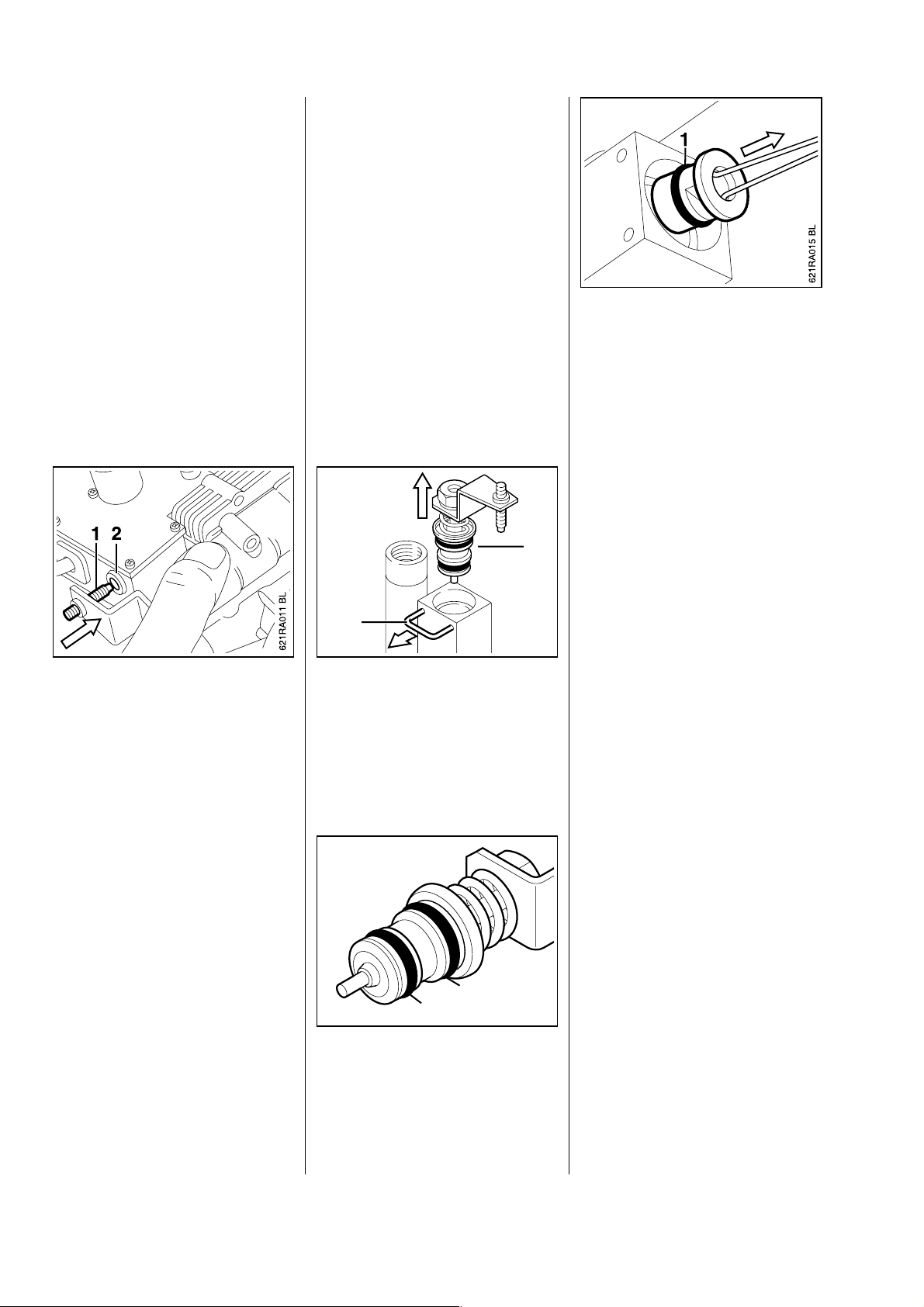

6.2 Removing / installing the control piston

To replace the safety control block

housing:

Remove

-controlpiston(see6.2),

- injector (see 6.4),

- non-return valve (see 6.5) and

- detergent metering valve

(see 6.6).

Reassemble parts in reverse order

and ensure that O-rings are fitted.

- Remove shroud (see 5.1).

•

Draw valve body out of

safety control block with hook

5910 890 2900. Remove ball

and valve-seat insert from safety

control block.

•

Replace O-ring (1) in valve body.

- Examine valve body, ball and

valve-seat insert; replace if necessary.

- Clean valve seat in safety control

2

block.

•

Carefully insert adjusting

screw (1) into opening (2) in

microswitch.

- Turn in fastening screws and

tighten down crosswise with a

torque of 7 Nm.

- Then set the working and cutout

pressure (see 6.3) and refit the

lead seal on the safety control

block.

1

•

Carefully prise off U-bar (1) with

a screwdriver if necessary and

pull it out.

•

Draw control piston (2) out of

safety control block housing.

2

1

Reassemble parts in reverse order.

Note: Thinly coat valve-seat

insert, valve body and O-ring with

621RA013 BL

special grease for high-pressure

cleaners 0781 145 3516 before

fitting them.

- Fit control piston and secure with

U-bar.

•

Then set pressure control

system (see 6.3).

621RA014 BL

•

O-rings (1, 2) on control piston

must always be replaced.

- Examine control piston for signs

of damage and replace

completely if necessary. Ensure

that correct control piston is fitted

(spare parts list).

10 RE 140 K, 160 K

Loading...

Loading...